Page 1

CALIBRATORS

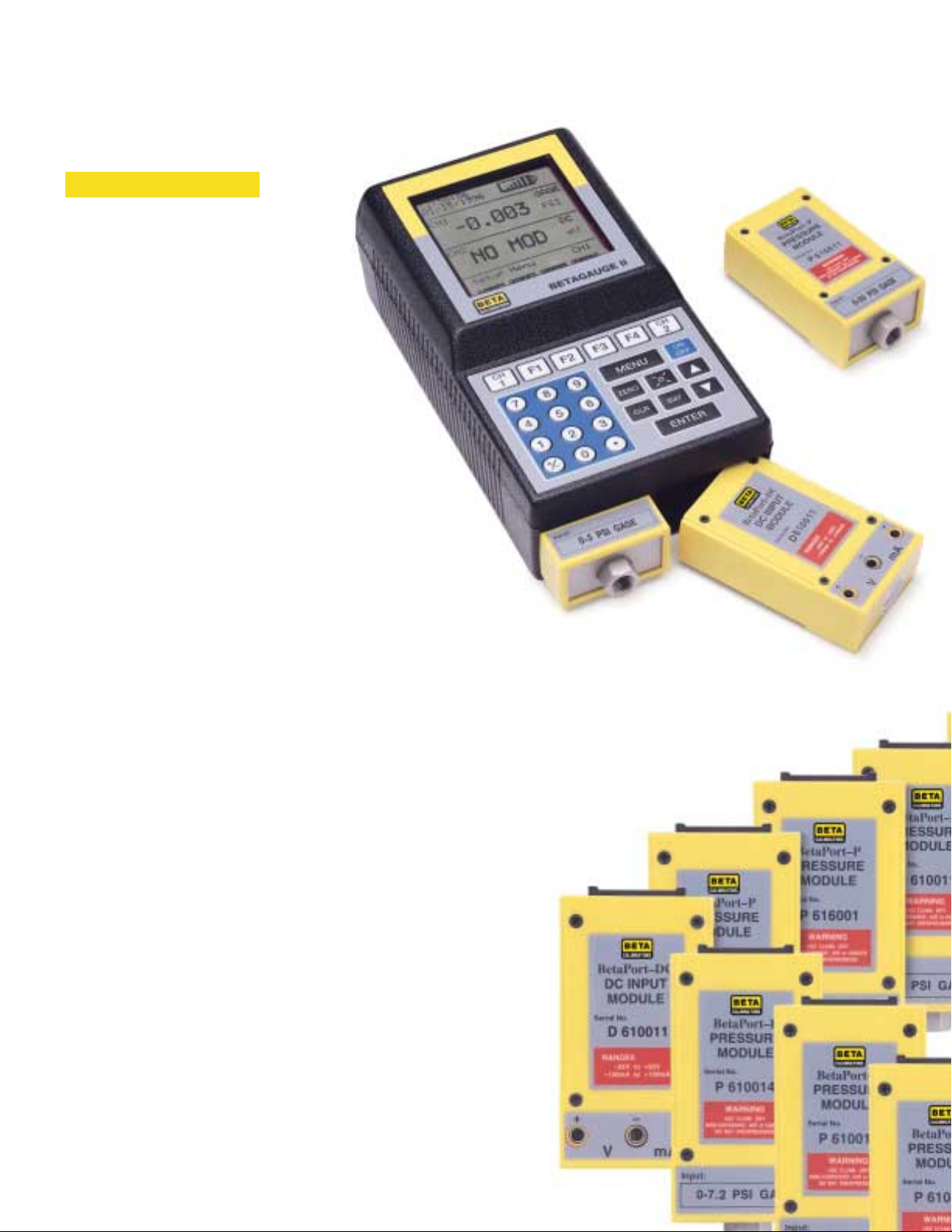

BetaGauge II

INTRINSICALLY

SAFE

MODEL

AVAILABLE

INTRINSICALLY

SAFE

MODEL

AVAILABLE

Page 2

BetaGauge II.

The new industry standard

in portable pressure

calibrators is

0.025% accuracy.

The process industries are quite

literally under pressure. There’s a lot

of pressure instrumentation out there

(one source estimates nearly 75% of

all field calibrations involve some type

of pressure variable). There’s a lot riding on this instrumentation — process

quality, plant safety, company profits.

And a lot of the instrumentation rides on

calibration accuracy.

That’s why we weren’t about to introduce just another pressure calibrator. We

wanted to develop a successor that would

significantly improve upon our own bestselling BetaGauge™. We wanted to meet

calibration requirements now and into the

next decade.

By any measure, we satisfied that design

criterion and then some. BetaGauge II™ is a

quantum leap over every other DPG on the

market. Over other pressure calibration

devices like dead weight testers. Even over

our own BetaGauge 320.

In terms of accuracy, the most critical

feature of any calibrator, BetaGauge II is

unmatched by any device in its price range.

For the majority of its available ranges, it has

a typical pressure accuracy of 0.025%

fullscale and an electrical accuracy of

±0.01%. That makes it four times more

precise than the instruments it is used to

calibrate, including 0.10% accuracy smart

pressure transmitters. Even so, BetaGauge II

is priced competitively with distant second

0.05% pressure calibrators. The closest

devices more accurate are far more expensive — lab instruments not intended for field

use, such as quartz gauges used to calibrate

other calibrators.

Yet remarkably, best-of-class accuracy is

but one of many reasons for specifying

BetaGauge II.

Page 3

A wide range of software

makes BetaGauge II

a full-featured documenting

calibrator.

By automating pressure calibrations via a

variety of popular software packages,

BetaGauge II users can create a centralized

database for reporting and analyzing instrument maintenance tasks. Automation saves

time and money, while resulting in better

performing instrumentation.

BetaGauge II, like other Beta Calibrators,

is compatible with most leading calibration

management software, including ASTEC

Cornerstone™, CAL Station™ and Base

Station™, Emerson Asset Management

System (AMS™), and Honeywell

Documint™.

In addition, Beta supplies the Field

Calibrator Interface Standard (FCINTF),

which provides communications with other

FCINTF compatible software.

EC92 Compliant

Page 4

The calibration data you

need. With urgency and

clarity.

The first thing you notice about BetaGauge II

is its “big screen” display. More specifically,

its 128 by 128 pixel, 63 by 63 mm LCD

display with on-demand backlighting, top

viewing angle, and per-channel display

fields. A simple-to-use membrane keypad

and a user-prompting program make

BetaGauge II especially easy to navigate.

In addition to psig, psia, and psid, readouts are keypad selectable in any of the

following engineering units for pressure:

Kp/cm

2

; Atmos; mBar; Bar; Kpa; mmHg;

InHg; InWc 4°C, 20°C, 60°F; cmWc 4°C,

20°C, 60°F; plus one user-defined unit.

Other valuable BetaGauge II features include

minimum/maximum measurement memory,

which automatically retains the lowest and

highest values in any procedures, and %

error display, which allows difficult pressure

calibrations to be done without the need to

maintain exact or steady test pressures.

Built for punishment.

Ready for anything.

BetaGauge II is a complete pressure

calibrator. Engineered to perform in any

industrial environment. Equipped with everything you need for maintaining your pressure

instruments to their manufacturers’ specs.

We developed BetaGauge II as

intrinsically safe for use in Class I, Groups A,

B, C, and D, and suitable for use in Class I

Division 2, Groups A, B, C, and D hazardous

areas. BetaGauge II is built and tested with

intrinsically safe circuits and as intrinsically

safe equipment. An intrinsically safe version

is available.

Other safeguards include rugged ABS

plastic cases, ESD protection on all pins,

and EMI shielding. For optimum mechanical

strength, external pressure connection is

made by a 1/8” FNPT 316SS connector

welded to a stainless steel metal plate.

BetaGauge II is supplied with the

following standard equipment:

• A multifunction, English-language,

two-channel pressure calibrator.

• A standard voltage/current input module.

• An external battery pack (NiCad,

rechargeable).

• One set of test leads.

• A standard trickle charger.

• An instruction manual.

• A vinyl carrying case.

• A 9 pin D shell to 9 pin D

shell serial cable.

Options for BetaGauge II include:

• A 9 to 25 pin D shell adaptor.

• Additional standard input modules

(23 pressure ranges to choose from).

• Vacuum and pressure pumps.

• Quick charge battery charger/conditioner.

• Wall mount fast charger.

• CSA Exia rated intrinsically safe battery

pack.

Page 5

PRESSURE

Gauge (PSIG) Sealed Gauge (PSIG) Vacuum (PSIG) Absolute (PSIA) Compound (PSIG) Differential (PSID)*

0-5 (0-350 mBar)††0-300 (0-20 Bar) 0 to -5 (0 to -350 mBar)††0-15 (0-1 Bar)†-15 to 15 (-1 to 1 Bar)†0-5 (0-350 mBar)

††

0-7.2 (0-500 mBar)**†0-1000 (0-70 Bar) 0 to -15 (0 to -1 Bar)

†

0-30 (0-2 Bar) -15 to 30 (-1 to 2 Bar) 0-30 (0-2 Bar)

0-10 (0-700 mBar)†0-1500 (0-100 Bar) 0-50 (0-3.5 Bar) 0-50 (0-3.5 Bar)

0-30 (0-2 Bar) 0-3000 (0-200 Bar) 0-100 (0-7 Bar)

0-50 (0-3.5 Bar) 0-5000 (0-340 Bar) 0-300 (0-20 Bar)

0-100 (0-7 Bar)

0-150 (0-10 Bar)

ELECTRICAL

Voltage:

> 1M ohms input impedance

Autoranging: 0 to ±249.99 mVdc

0 to ±2.4999 Vdc

0 to ±24.999 Vdc

Current:

5 ohms input impedance

Autoranging: 0 to ±24.999 mAdc

0 to ±149.99 mAdc

AVAILABLE RANGES

Dual-channel operation and 24

field changeable ranges

redefine calibrator versatility.

With pressure devices of varying types and

ranges scattered throughout a typical

process plant, dedicated calibrators can get

very costly, very quickly. BetaGauge II

addresses this problem simply and sensibly.

It is both a two-channel and multi-range

device. Changing ranges is as easy as plugging in new input modules, which can be

done even while the unit is powered up.

BetaGauge II automatically recognizes the

signals and assigns them to the proper

channel. That versatility makes it the ideal

answer for pressure calibration, even in

critical applications like gas pipelines and

other smart transmitter-equipped sites.

There are 24 standard BetaGauge II

pressure ranges available in fully interchangeable input modules:

• 12 gauge ranges (from 0-5 psig up to

0-5000 psig).

• Two vacuum ranges (from 0 to -5 psig up to

0 to -15 psig).

• Five absolute ranges (from 0-15 psia up to

0-300 psia).

• Two compound ranges (from -15 to 15 psig

up to -15 to 30 psig).

• Three differential ranges (from 0-5 psid up

to 0-50 psid).

The standard dc module provides five

electrical ranges:

• Three voltage ranges (from 0 to ±249.99

mV dc up to 0 to ±24.999 Vdc).

• Two current ranges (0 to ±24.999 mA dc

and 0 to ±149.99 mA ).

Special ranges and calibrations are available

upon request at additional cost.

This plug-in design simplifies maintenance,

too. The base unit needs no recalibration;

only the input modules do. That means you

never have to be out of service — you send

only the out-of-calibration modules back to

the shop, while still using BetaGauge II in

the field.

Other Pressure Units (keypad selectable): Kp/cm2; Atmos; mBar; Bar; Kpa; mmHg; InWc 4°C, 20°C,

60°F; plus one user-defined unit; choice of engineering unit may be restricted by available resolution.

All gauge and sealed gauge ranges have 316 S.S. wetted parts and are compatible with media suitable

for that material. Other ranges are non-isolated and are compatible with non-corrosive and non-conductive gases only.

Notes: 0-7.2PSI, 0-150 PSI, and 0-1500 PSI are extended ranges. (See specifications for accuracies.)

†

Thermal and Pressure Hysteresis: .0025 PSI (.1724 mBar)

††

Thermal and Pressure Hysteresis: .0030 PSI (.2068 mBar)

All other ranges: No Hysteresis

*Maximum static pressure, 200 psig (14 Bar)

**200 InWc

Page 6

Specifications

RANGES

See foldout page for table of pressure

ranges and listing of electrical ranges. Each

of the ranges is for a specific input module.

Additional modules can be provided as

options.

ACCURACY

Pressure

a. Gauge, Vacuum, Absolute, Compound,

and Differential Standard Ranges:

±0.025% FS (0°C to 50°C) for six months

b. Gauge Extended Ranges:

±0.035% FS (0°C to 50°C) for six months

c. Accuracy for ranges with thermal and

pressure hysteresis is:

± (Accuracy% FS + Hysteresis in PSI)

Electrical:

±0.01% FS + ±0.01% Rdg (15°C to 35°C)

for 12 months

ENVIRONMENTAL

Temperature:

-20°C to 50°C (operating)

-30°C to 50°C (storage with batteries)

-30°C to 70°C (storage without batteries)

Relative Humidity:

0 to 95% non-condensing

Effects:

a. Pressure: none over the operating

temperature

b. Electrical: ±0.002% Range/°C outside

15°C to 35°C

Overpressure

(without damage or calibration effects)

a. 0-15 psi* 400% of sensor range

b. 30-250 psi 300% of sensor range

c. 300-10,000 psi 150% of sensor range

*0-200 InWc is 300% of sensor range

OTHER

Alarm Trip Detect: Wet contact input, 48

Vdc max.

Damping Factor: Programmable 1.0 to 5

sec response time for all inputs (running

average)

Display: 128 X 128 pixel LCD with LED

backlight; two inputs simultaneously displayed with maximum of 5 digits resolution

Power Supply:

a. Rechargeable NiCad external battery

pack: 6 V, 1.0 Ah, 10 hours nominal

operation time at 25°C; extra battery

packs available; battery charger (trickle)

standard

b. Charging: 16 hours maximum; fast charge

battery optional, 90 min. charge time

Circuit Protection: Voltage and current

input protected for connection to 120 Vac

Pressure Connections: 1/8” FNPT 316SS

Electrical Connections: Standard banana

jack on 3/4” centers

Weight: < 1.5 kg with carrying case and

accessories (typical)

Size: 4.3” x 7.5” x 2.4” (110 mm x 190 mm x

60 mm)

Specifications subject to change without notice.

BetaGauge and BetaGauge II are trademarks of Beta

Calibrators Corporation. Other trademarks used in this

document are trademarks of their respective owners.

We make calibrators as if your

process depends on them.

We’re BETA Calibrators, a unit of Martel

Electronics Corporation. Together we are the

largest maker of instrument calibrators and

calibration systems in North America.

Our combination of high performance,

productivity and reliability have made ours

the calibrators of choice world-wide.

The BETA line includes calibrators that

address virtually every requirement:

• Multi-function calibrators that efficiently

combine measurement and simulation

capabilities for T/Cs, RTDs, frequency, DC

current and voltage and even pressure.

• Documenting calibrators like the

BetaFLEX

®

with HART™ and Honeywell

DE™ protocol for “smart” instrumentation.

• Reliable fixed sensor BetaGauge 320

pressure calibrators.

• Easy to use and value priced CALTool

®

single function calibrators for T/Cs,

RTDs, DC current and voltage,

frequency and pressure.

BETA documenting calibrators are

compatible with a wide variety of

software including Cornerstone CAL Station

and Base Station and others using industry

standard FCINTF interfaces.

BETA CALIBRATORS CORPORATION

A Martel Electronics Corporation Company

2309 Springlake Road

Farmers Branch, TX 75234 USA

1-800-537-2181 1-972-241-2200

Fax: 1-972-241-6752

e-mail: sales@betacalibrators.com

www.betacalibrators.com • www.martelcorp.com

©Beta Calibrators, 2003 03-82 Printed in U.S.A.

CALIBRATORS

Loading...

Loading...