Page 1

BETAGAUGE

311A-Ex/321A-Ex

Reference Manual

Page 2

BETAGauge 311A-Ex/321A-Ex

Reference Manual

1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.1 Contacting Martel / Beta . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.2 Standard Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.3 Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

2. Calibrator Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2.1 Calibrator Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.2 Using the Backlight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.3 Using the Zero Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.4 Other Menu Controlled Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

3. Measuring Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

3.1 Media Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

4. Measuring Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

5. Measuring Temperature with an RTD . . . . . . . . . . . . . . . . . . . . . . .16

6. Performing a Pressure Switch Test . . . . . . . . . . . . . . . . . . . . . . . . .17

7. Calibrating Transmitters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

7.1 Using the mA Input Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

7.2 Calibrating a Pressure-to-Current Transmitter . . . . . . . . . . . . . . . . . . . .19

7.3 Percent Error Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

8. Minimum and Maximum Storage Capability . . . . . . . . . . . . . . . . . . .22

9. Factory Setups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

10. Custody Transfer / Flow Calibration . . . . . . . . . . . . . . . . . . . . . . .24

11. Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

12. Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

13. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

13.1 Replacing Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

13.2 Cleaning the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

13.3 Service Center Calibration or Repair . . . . . . . . . . . . . . . . . . . . . . . . .28

Page 3

1. Introduction

The BETA 311A-Ex/321A-Ex is designed to be a simple to use yet very versatile pressure

calibrator. Its two internal pressure sensors combined with inputs for mA, switch contacts

and an RTD probe allow the 311A-Ex/321A-Ex to calibrate virtually any pressure device.

The BetaGauge 311A-Ex is a single sensor pressure calibrator; the BetaGauge 321A-Ex is

a dual sensor pressure calibrator. The 311A-Ex uses the P1 port for all pressure inputs.

The P2 port is only used on the model 321A-Ex. Therefore on the model 311A-Ex, all

menu choices involving pressure are limited to the P1 port only. All other model 311A-Ex

features and functions are the same as for the 321A-Ex.

1.1 Customer Service

Corporate Office:

www.martelcorp.com

e-mail: sales@martelcorp.com

Tel: (603) 434-1433 800-821-0023 Fax: (603) 434-1653

Martel Electronics

3 Corporate Park Dr.

Derry, NH 03038

1.2 Standard Equipment

Check to see if your calibrator is complete. It should include: BETA 311A-Ex/321A-Ex

Calibrator, instruction manual, Beta 321A-Ex/311A-Ex Concept Control Drawing (CCD),

test leads, carrying case, calibration certificate with data.

1.3 Safety information

Ex Hazardous Areas

An Ex-hazardous area as used in this manual refers to an area made hazardous by the

potential presence of flammable or explosive vapors. These areas are also referred to as

hazardous locations.

The Model 321A-Ex calibrator has been designed for use in Ex Hazardous Areas. These

are areas where potentially flammable or explosive vapors may occur. These areas are

referred to as hazardous (classified) locations in the United States, as Hazardous

Locations in Canada, as Potentially Explosive Atmospheres in Europe and as Explosive

Gas Atmospheres by most of the rest of the world. The Model 321A-Ex calibrator is

designed as intrinsically safe. This means that connecting the 321A-Ex calibrator to

equipment that is used within intrinsically safe circuits will not cause an ignition capable

arc as long as the entity parameters are suitably matched.

Warning

Check entity parameters before making any connections to this device.

1

Page 4

Symbols Used

The following table lists the International Electrical Symbols. Some or all of these symbols

may be used on the instrument or in this manual.

Symbol Description

AC (Alternating Current)

AC-DC

Battery

CE Complies with European Union Directives

DC

Double Insulated

Electric Shock

Fuse

PE Ground

Hot Surface (Burn Hazard)

Read the User’s Manual (Important Information)

Off

On

The following definitions apply to the terms “Warning” and “Caution”.

• “Warning” identifies conditions and actions that may pose hazards to the user.

• “Caution” identifies conditions and actions that may damage the instrument being used.

Use the calibrator only as specified in this manual, otherwise injury and damage to the

calibrator may occur.

2

Page 5

3

Warning

To avoid possible electric shock or personal injury:

• Do not apply more than the rated voltage. See specifications for supported ranges.

• Follow all equipment safety procedures.

• Never touch the probe to a voltage source when the test leads are plugged into the

current terminals.

• Do not use the calibrator if it is damaged. Before you use the calibrator, inspect the

case. Look for cracks or missing plastic. Pay particular attention to the insulation

surrounding the connectors.

• Select the proper function and range for your measurement.

• Make sure the battery cover is closed and latched before you operate the calibrator.

• Remove test leads from the calibrator before you open the battery door.

• Inspect the test leads for damaged insulation or exposed metal. Check test leads

continuity. Replace damaged test leads before you use the calibrator.

• When using the probes, keep your fingers away from the probe contacts. Keep your

fingers behind the finger guards on the probes.

• Connect the common test lead before you connect the live test lead. When you

disconnect test leads, disconnect the live test lead first.

• Do not use the calibrator if it operates abnormally. Protection may be impaired. When in

doubt, have the calibrator serviced.

• Only operate the calibrator in non-hazardous areas or classified areas for which this

device is certified to operate in.

• When measuring pressure, make sure the process pressure line is shut off and

depressurized before you connect it or disconnect it from the pressure module.

• Disconnect test leads before changing to another measure or source function.

• When servicing the calibrator, use only specified replacement parts.

• To avoid false readings, which could lead to possible electric shock or personal injury,

replace the battery as soon as the battery indicator appears.

Caution

To avoid possible damage to calibrator or to equipment under test:

• Use the proper jacks, function, and range for your measurement or sourcing application.

Page 6

2. Calibrator Interface

Figure 1 shows the location of the process measurement inputs, while table 1 describes

their use.

Figure 1

Pressure Measurement Inputs

Table 1 Process Measurement Inputs

No. Name Description

1, 2 Input Terminals These terminal are used to measure current and a contact

closure for switch test.

3 P1 Pressure Port This is the connection for the internal sensor P1

4 P2 Pressure Port This is the connection for the internal sensor P2

5 RTD Probe Connector This connector is where the RTD probe is plugged in.

4

Side View

Page 7

Figure 2 shows the location of the keys. Table 2 describes the function of each key.

Figure 2

Keypad

Table 2 Key Functions

No. Name Description

1 Function Keys These keys are used in various ways, primarily to config-

ure the calibrator

2 ON/OFF Key This key is used to turn the calibrator on and off

3 ZERO Key This key is used to zero pressure measurements

4 Backlight Key This key is used to turn the backlight on and off

Note: When the calibrator is turned on by pressing the ON/OFF key, it will go through a

short startup self-check routine. During that routine, the display shows the current

firmware revision level, auto shutdown status and the ranges of the 2 internal pressure

sensors. The calibrator requires a maximum of 5 minutes warm-up to rated accuracy.

Large changes in ambient temperature may require a longer warm-up period. See

section 2.3 for instructions on zeroing the pressure sensor displays. Pressure ranges

should be zeroed each time the calibrator is started.

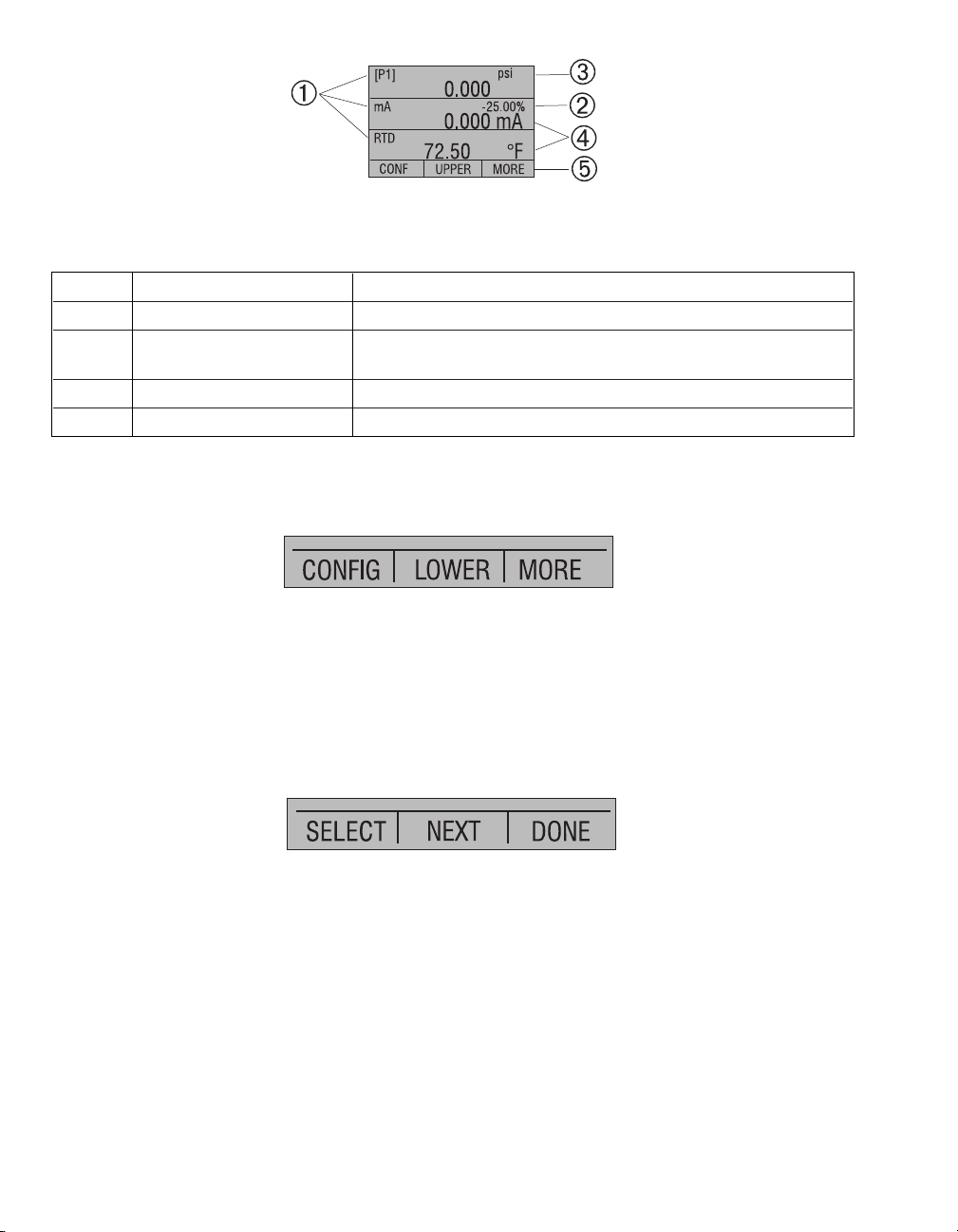

2.1 Calibrator Display

The Calibrator Display consists of two regions: The menu bar (located along the bottom

of the screen) is used to access a menu system. The main display (the rest) consists of

up to three process measurement sub-regions. These sub-regions will henceforth be

referred to as the UPPER, MIDDLE and LOWER displays. Figure 3 shows the location of

the different display fields while table 3 describes them.

5

Page 8

6

Figure 3

Display

Table 3 Display Functions

No. Name Description

1 Primary Parameters Indicates what is being measured.

2 Span Indicator Indicates the percent of the 4 to 20 mA span. (For mA

functions only)

3 Pressure Units Indicates one of 17 pressure units available for display.

4 Units Indicates the unit of measure for the display.

2.1.1 Main Menu Functionality

There are three options on the Main Menu, CONFIG, {current display} and MORE. The

Main Menu is home for the menu display.

2.1.1.1 Setting the Current Display

The current display is indicated by the center option on the Main Menu, pressing the F2

key will toggle the current display.

2.1.1.2 Setting Current Display Parameters

To set the parameters of the current display use the CONFIG option to get to the Display

Configuration Menu.

Here the SELECT option will toggle through the choices for each parameter. The first

parameter is MODE. Since current and switch test modes all use the same jacks, two of

these functions cannot be used concurrently. The ability to select certain functions is

limited based on what is already selected in another active display. The NEXT option is

used to change to the second parameter. Only RTD and Pressure modes have a second

parameter, RTDs can be read in Celsius or Fahrenheit and Pressures can be read in 11

engineering units.

With a single display the following modes are available:

P[1] = Pressure on left side sensor.

P[2] = Pressure on right side sensor.

P[1] ST = Switch Test with left side sensor.

Page 9

CURRENT DISPLAY

P[1] P[2] P[1] P[2] mA RTD

ST ST

P[1]

P[2]

P[1]ST X X X

P[2]ST X X X

mA X X

RTD

OTHER DISPLAYS

7

P[2] ST = Switch Test with right side sensor.

mA = Milliamps measure

RTD = RTD Temperature Measurement (if a probe is connected).

The following table shows which functions are available concurrently.

An X in a column indicates that the mode in the current display will not be available for

selection if the mode in that row is in use in any other active display.

Table 4 Mode Concurrency

Note: P2 is only available on the model 321A-Ex.

2.1.1.3 Accessing Other Menus

Use the MORE option on the Main Menu to access the other menu functions.

Page 10

8

Figure 4

Menu Map

Page 11

9

Page 12

10

2.2 Using the Backlight

The backlight is controlled by the dedicated backlight key. It toggles on and off when the

key is pressed; this is one of the few functions that cannot be controlled by the serial

interface. There are no user configuration settings for the backlight.

2.3 Using the Zero Function

When the ZERO KEY is pressed, the calibrator will zero the current display if a pressure

mode is selected, and the pressure is within the zero limit. The zero limits are within 5% of

the full scale range of the selected sensor. If the display indicates “OL,” the zero function

will not operate.”

2.3.1 Internal Sensor (non-absolute)

When a sensor or module is selected on the current display and the ZERO KEY is

pressed the calibrator subtracts the current reading from the output. The zero limits are

within 5% of the full scale range of the selected sensor. If the display indicates “OL,” the

zero function will not operate.

2.3.2 Absolute Internal Sensor

When an absolute module is selected on the current display and the ZERO KEY is

pressed, the calibrator prompts the user to either set or default the pressure reference.

If the set option is selected, the calibrator prompts the user to enter the barometric

reference pressure. This is done using the arrow keys (F2 and F3 keys). The sensor port

should be open (vented) to atmosphere while performing this procedure.

Alternately, if the DEFAULT option is selected, the user is asked to confirm the choice to

go to factory default or cancel the request.

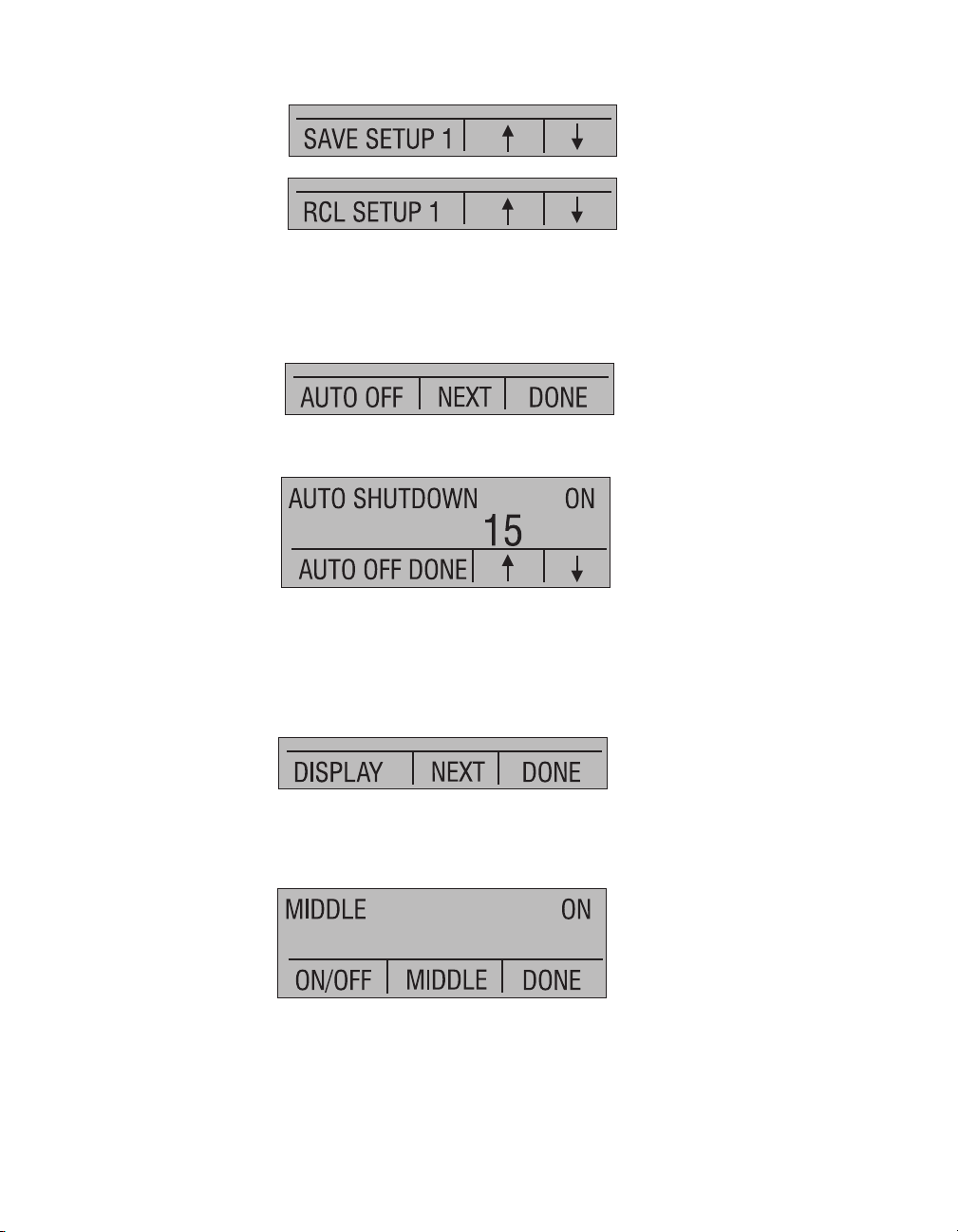

2.4 Other Menu Controlled Functions

There are eight ‘sub-main’ menus that can be accessed through the MORE option of the

Main Menu. A ‘sub-main’ menu contains three options. The first option is unique to the

Page 13

11

function. The second and third options of a ‘sub-main’ menu are always the same. The

NEXT option leads to the next ‘sub-main’ menu and the DONE option returns home . For

the last ‘sub-main’ menu the NEXT option wraps around to home. See Figure 4 for a

detailed mapping of the menu structure.

A note on naming convention:

If a ‘sub-main’ menu has subordinate menus, it will henceforth be referred to as

{function} Main Menu. E.g. the display contrast sub-main menu will be called the

Contrast Main Menu. If not it will be called the {function} menu.

2.4.1 Setting the Contrast

From the Contrast Main Menu choose the CONTRAST option to access the Contrast

Adjustment Menu.

Use the arrow keys to adjust the display contrast to the desired level and then use the

CONTRAST DONE option to return home.

2.4.2 Locking and Unlocking Configurations

Use the LOCK CFG or UNLOCK CFG option of the Configuration Lock Menu to lock or

unlock the display configuration.

When the LOCK CFG option is chosen the menu display returns home and the CONFIG

option on the Main Menu indicates that it is locked. Also all menus are locked out with

the exception of the Contrast Adjustment menus and the Configuration Lock Menu.

When the UNLOCK CFG option is chosen the configuration is unlocked and the menu

display continues to the next sub-main menu.

2.4.3 Saving and Recalling Setups

The calibrator will automatically save the current set-up for recall at power-up.

Additionally 5 set-ups can be accessed through the SETUPS menu. Select the SETUPS

option from the Setups Main Menu.

Choose SAVE to save a set-up , RECALL to recall the set-up, or DONE to do nothing and

return home.

If SAVE or RECALL is selected use the arrow keys to select the set-up location. Then use

the save option to store the current set-up into the selected location or the recall option to

Page 14

12

recall the set-up stored in the selected location. The display menu will automatically go

home.

2.4.4 Setting AutoShut-off Parameters

The calibrator can be set to automatically shut-off after a selected number of minutes; this

function can also be disabled. To set the auto shut off parameters select the AUTO OFF

option on the Auto Shut Off Main Menu.

Use the arrow keys to select the number of minutes before the calibrator turns off or

disable auto shut-off by scrolling all the way down.

Use the AUTO OFF DONE option to set the parameters and return home. The auto shut

off time is reset whenever a key is pressed.

2.4.5 Activating and Deactivating a Display

Use the DISPLAY option on the Display Selection Main Menu to access the Display

Activation Menu.

The {function} option can be used to select which display to act upon. The ON/OFF

option turns the selected display on or off. The selected display and current on/off state

are displayed in the lower display.

Use the DONE option to save the changes and return home. When a display is

deactivated its configuration is retained. When the display is activated its configuration is

checked against the configurations of the other currently active displays, if the

configurations are in conflict the recalled display’s configuration is modified to avoid the

conflict. If all three displays are deactivated the LOWER display will come on

automatically

Page 15

13

2.4.6 Low resolution function.

Due to the high accuracy of the 311A-Ex/321A-Ex the measured values are displayed with

many digits, this might be an disadvantage in some cases, therefore the 311A-Ex/321AEx has a low resolution function. The function takes away the last digit.

To turn the function on or off, proceed as follows:

1. With the calibrator turned on and operating press the F3 key to activate the MORE

menu option. Press the NEXT button until RESOLUTION appears in the left text field.

Now press the F1 key to enter the function.

2. The select ON or OFF to turn the low resolution function on or off.

3. Pressing DONE returns to main menu.

2.4.8 Setting the RTD probe type

Use the PROBE TYPE option of the RTD Probe Type main menu to access the RTD

Probe selection menu.

There are four probe types to select from P100-385, P100-392, P100-JIS and CUSTOM.

Use the SELECT option to select the desired probe type and the DONE option to store

the change and return home.

Note: The default probe type is PT100-385.

2.4.9 Damping

Damping can be turned ON or OFF using the Damping menu selection. When damping

is ON, the calibrator displays an running average reading of ten measurements. The

calibrator makes approximately 3 readings per second.

Page 16

14

3. Measuring Pressure

To measure pressure, connect the calibrator using an appropriate fitting. Choose a

pressure setting for the display being used. The calibrator is equipped with two internal

sensors. Be sure to choose the sensor based on working pressures and accuracy.

Warning

Pressure sensors may be damaged and/or personnel injury may occur due to improper

application of pressure. Please refer to the table of ranges and resolutions at the back of

this manual for information on overpressure and burst pressure ratings. Vacuum should

not be applied to any gauge pressure sensor. The calibrator display will indicate “OL”

when an inappropriate pressure is applied. If “OL” is observed on any pressure display,

the pressure should be reduced or vented immediately to prevent damage or possible

personnel injury. “OL” is displayed when the pressure exceeds 120% of the nominal range

of the sensor or when a vacuum in excess of 2 PSI is applied on gauge range sensors.

Figure 5

Use the (ZERO) key to zero the pressure sensor when vented to atmospheric pressure.

Important NOTE: To protect sensor integrity and prevent damage to the sensor, the

calibrator will display OL [overload] when the applied pressure exceeds 120% of the full

scale calibrated range of the sensor.

Important NOTE: To ensure accuracy of the calibrator it is critical to zero the calibrator

before a device is calibrated.

Page 17

15

3.1 Media Compatibility

The calibrator utilizes a media isolated sensor to prevent sensor contamination.

Whenever possible clean, dry air is the media of choice. If that is not always possible,

make sure that the media is compatible with Nickel Plated Brass and 316 Stainless Steel.

4. Measuring Current

Warning

Check entity parameters before making any connections to this device.

To measure current use the input terminals in the front of the calibrator. Select the mA

function on one of the displays. Current is measured in mA and percentage of range.

The range on the calibrator is set to 0% at 4 mA and 100% at 20 mA.

Note: The display will indicate “OL” when the measured current exceeds the nominal

range of current measurement (24 milliAmps).

For example:

If the current measured is displayed as 75% then the mA value is 16 mA.

Figure 6

5. Measuring Temperature with an RTD

To measure temperature using an RTD probe you must select the RTD function on one of

the displays. Make sure the proper probe type is selected. There are 4 probe types

supported, P100-385, P100-392, P100-JIS and CUSTOM. The standard probe has a 9”

insertion depth with a 3/16” diameter stainless steel sheath.

Note: The factory default type is PT100-385 so if the 311A-Ex/321A-Ex is being used with

the Martel Model LPT100A probe you do not have to set the probe type. Simply plug the

probe into the 311A-Ex/321A-Ex and configure the display to read temperature.

Note: The display will indicate “OL” when the measured temperature is outside the

nominal measurement range of the RTD function (below -40°C or above 150°C).

If a custom probe is being used, the entering of R0 and coefficients is handled through

the serial interface (see section 11).

Page 18

Figure 7

6. Performing a Pressure Switch Test

Warning

Check entity parameters before making any connections to this device.

Figure 8

16

Page 19

17

To perform a switch test, follow these steps:

1. Change the setup to Setup 4 (default switch test).

Setup 4: The upper display is set to [P1] ST, all other displays are off.

Important NOTE: The pressure Switch Test can be performed with the following

functions[P1] ST, [P2] ST.

2. Connect the calibrator to the switch using the pressure switch terminals. The polarity

of the terminals does not matter. Then connect the pump to the calibrator and the

pressure switch.

3. Make sure the vent on the pump is open. Zero the calibrator if necessary. Close the

vent after zeroing the calibrator.

4. The top of the display will read “CLOSE”.

5. Apply pressure with the pump slowly until the switch opens.

Important NOTE: In the switch test mode the display update rate is increased to help

capture changing pressure inputs. Even with this enhanced sample rate pressurizing the

device under test should be done slowly to ensure accurate readings.

6. Once the switch is open, “OPEN” will be displayed, bleed the pump slowly until the

pressure switch closes.

7. At the top of the display it will now read, “SW OPENED AT” and give you the

pressure that the switch opened at.

Page 20

8. Press the “NEXT” option to view when the switch closed, and the dead band.

9. Press the “NEW TEST” option to clear the data and perform another test.

10. Press the “DONE” option to end the test and return to the standard pressure setting.

Example: [P1] ST will return to [P1].

Important NOTE: The previous example uses a normally closed switch. The basic

procedure is still the same for a normally open switch, the display will just read “OPEN”

instead of “CLOSE”.

7. Calibrating Transmitters

Warning

Check entity parameters before making any connections to this device.

18

Page 21

7.1 Using the mA Input Function

The mA input function allows the user to read back the 4-20 mA output from the device

being calibrated. This can be done passively – where the device under test directly

generates 4-20 mA and can be read by the calibrator.

7.2 Calibrating a Pressure-to-Current Transmitter

To calibrate a pressure-to-current transmitter (P/I), perform the following steps:

1. Connect the calibrator and the pump to the transmitter.

2. Apply pressure with the pump.

3. Measure the current output of the transmitter.

4. Ensure the reading is correct. If not, adjust the transmitter as necessary.

Warning

Check entity parameters before making any connections to this device.

Figure 9.

19

Page 22

20

7.3 Percent Error Function

Warning

Check entity parameters before making any connections to this device.

The calibrator features a unique function which can calculate pressure vs. milliamp error

as a percentage of the 4 to 20 mA loop span. The percent error mode uses all 3 screens

and has a unique menu structure. It simultaneously displays pressure, mA and percent

error.

Figure 10.

Example:

Suppose a pressure transmitter under test is 30 psi (2 Bar) Full Scale and outputs a

corresponding 4 to 20 mA signal. The user can program in a 0 to 30 psi pressure span

into the calibrator and the calibrator will calculate and display the deviation or % Error

from the expected 4 to 20 mA output. This eliminates the need for manual calculations

and also helps if it becomes difficult to set an exact pressure with an external pump.

To use the %ERROR function proceed as follows:

1. With the calibrator turned on and operating press the F3 key to activate the MORE

menu option. Now press the F1 key to activate the %ERROR option.

2. Press the F1 key to select the CONFIG option.

3. The first option is setting the Port, use the select option to scroll through the port

choices, when finished select the NEXT option.

Page 23

21

4. Use SELECT to toggle through the UNIT options, and select NEXT to move on.

5. Use the ↑ and ↓ arrows to set the 100% point of the desired pressure range, select

DONE SET when finished.

6. Again, use the arrows to set 0% point and select DONE SET when finished and the

%ERROR mode will be ready to use.

Page 24

22

Note: The 0% and 100% point will be saved in non-volatile memory until they are

changed again by the user for the internal sensors, and external pressure modules.

When using an external module the 0% and 100% are set to low and full scale of the

module until the user changes it, or if it was previously saved.

8. Minimum and Maximum Storage Capability

The 300 Series Pressure Calibrators have a min/max feature for capturing the minimum

and maximum values of any displayed parameter.

The min/max function can be accessed by stepping through the menu options until

“min/max” is shown on the display above the F1 key. At this time, pressing the F1 key will

toggle the display through the min/max values that are stored in the min/max registers.

These readings are live so that the new min/max values will be recorded while in this mode.

To reset the min/max registers simply press the clear key. These registers are also cleared

at power-up or when the configuration is changed.

Page 25

23

9. Factory Setups

The Calibrator is loaded with five factory setups. These setups are shown below.

Setup 1: The upper display is set to [P1] mode and the middle is set to mA, lower is off.

Setup 2: The upper display is set to [P2] mode and the middle is set to mA, lower is off.

Setup 3: The upper display is set to [P1] mode and the middle is set to [P2], lower is off.

Page 26

Setup 4: The lower display is set to [P1] switch test, the other displays are off.

Setup 5: The upper display is set to [P1], the middle display is set to [P2] and the lower

display is set to RTD.

10. Custody Transfer / Flow Calibration

Warning

Check entity parameters before making any connections to this device.

The Model 311A-Ex/321A-Ex is ideal for flow computer calibration. Every manufacturer of

flow computers has a different calibration procedure, but most call for calibration of three

parameters: static pressure, differential pressure and temperature. To facilitate these

measurements recall setup #5 on the 311A-Ex/321A-Ex.

Note: The pressures in the UPPER, and MIDDLE displays can be changed to [P1],

[P2], and EXT.

1. Connect the calibrator to your static and differential pressures. ([P1], [P2]) Then

connect the RTD sensor to the calibrator.

2. Using the reading of your RTD, static, and differential pressures make sure the flow

computer has the correct reading. If not, adjust the flow computer as necessary.

24

Page 27

25

11. Specifications (18 °C to 28 °C unless otherwise noted.)

General

Instrument Setup Recall 5; last used on power-up

Environmental

Operating Temperature -10 °C to +45 °C

Storage Temperature -20 °C to +60 °C

Power Requirements 6.0 VDC

Battery Four (4) standard AA cells

Battery Life > 35 hours, typical usage

Physical

Dimensions 8.3” H x 3.9” W x 1.8” D (21.082 x 9.906 x 4.572 cm)

Weight 1 lb. 4 oz. (0.567 kg)

Product Compliance Markings Ex ia IIB T3 Gb (Ta=–10... +45°C)

KEMA 10 ATEX 0168X 0344

Ex ia IIB T3 Gb (Ta=–10... +45°C)

II 2 G IECEx CSA 10.0013X

Manufactured by Martel Electronics, Inc.,

3 Corporate Park Dr.

Derry, NH, USA

Entity Parameters MEASUREMENT JACKS:

Ui = 30 V; Ii = 80 mA; Pi = 750 mW; Ci = 0 μF; Li = 0 mH

Uo = 7,14 V; Io = 1,12 mA; Po = 2 mW; Co = 240 μF; Lo = 1 H

LEMO CONNECTOR: FOR USE WITH LTP100A RTD PROBE ONLY

EMI/RFI Conformance EN6136, Annex A

Connectors/Ports Pressure - two, 1/8” NPT

BetaPort-P pressure module adapter;

RTD probe

Included Accessories Soft case, batteries, manual, NIST-traceable certificate,

and test leads

Ranges

Available Pressure (select any two)

Gauge: 0.3 psi, 1 psi, 5 psi, 15, psi, 30, psi, 100 psi, 300 psi, 500 psi, 1000 psi, 3000 psi, 5000 psi,

10,000 psi

Absolute: 15 psi, 30 psi, 100 psi, 300 psi.

Compound: -15 to 15 psi, -15 to 30 psi. (see table of ranges and resolutions for more information)

mA 0 to 24.000 mA

RTD -40.0°C to 150.0°C

(-40.0°F to 302.0°F)

Engineering Units psi, bar, mbar, kPa, MPa, kgcm2, mmH

2

O @ 4°C, mmH2O @ 20°C,

cmH2O @ 4°C, cmH2O @ 20°C, inH2O @ 4°C, inH2O @ 20°C,

inH2O @ 60°F, mmHg @ 0°C, inHg @ 0°C

Page 28

26

Accuracy

Pressure

0.3 psi ±0.1% F.S.

1.0 psi ±0.05% F.S.

15 psi through 3000 psi ±0.025% F.S.

5 psi, 5000 psi, 10,000 psi ±0.035% F.S.

mA ±0.015% of rdg ±0.002mA

RTD (ohms) ±0.015% of rdg ±0.02 ohms; or ±0.1°C @ 0°C for Pt100

Temperature Effect

No effect on accuracy on all functions from 15°C to 35°C

Add ±0.002% F.S./°C for temps outside of 15°C to 35°C

Optional LPT100A Probe Meets PT-100 ALPHA 385 Class “A” Specifications

12. Warranty

Martel Electronics Corporation warrants all products against material defects and

workmanship for a period of twelve (12) months after the date of shipment. Problems or

defects that arise from misuse or abuse of the instrument are not covered. If any product

is to be returned, a “Return Material Authorization” form can be obtained from our website

www.martelcorp.com under customer service. You can also call 1-800-821-0023 to have a

form faxed. Martel will not be responsible for damage as a result of poor return

packaging. Out of warranty repairs and recalibration will be subject to specific charges.

Under no circumstances will Martel Electronics be liable for any device or circumstance

beyond the value of the product.

Page 29

13. Maintenance

13.1 Replacing Batteries

Replace batteries as soon as the battery indicator turns on to avoid false measurements.

If the batteries discharge too deeply the 311A-Ex/321A-Ex will automatically shut down to

avoid battery leakage.

Note: Use only AA size alkaline batteries.

Warning

Only change batteries in an area known to be non-hazardous.

Approved Batteries

Battery Manufacturer

(All Batteries Alkaline - A 1.5 V) Type

Duracell MN1500

Rayovac Max Plus 815

Eveready (Energizer) E91

Panasonic LR6XWA

27

Page 30

13.2 Cleaning the Unit

Warning

To avoid personal injury or damage to the calibrator, do not allow water into the case.

Caution

To avoid damaging the plastic lens and case, do not use solvents or abrasive cleansers.

Clean the calibrator with a soft cloth dampened with water or water and mild soap.

13.3 Service Center Calibration or Repair

Only qualified service personnel should perform calibration, repairs, or servicing not

covered in this manual. If the calibrator fails, check the batteries first, and replace them if

needed.

Verify that the calibrator is being operated as explained in this manual. If the calibrator is

faulty, call for an RMA number or go to www.martelcorp.com to download an RMA form

to return the unit. Be sure to pack the calibrator securely, using the original shipping

container if it is available.

28

Page 31

29

BETAGauge 311A-Ex/321A-Ex Ranges and Resolutions

Range (psi) 0.4 (10"H2O) 1 5 7 (200"H2O) 15 15 30 30 100 300 500 1000 1500 3000 5000 10000

Burst Pressure (psi) 3 10 15 30 300 90 300 90 1000 2000 2000 10000 10000 10000 10000 15000

Proof Pressure (psi) 1 3 10 15 60 30 60 60 200 600 1000 3000 3000 6000 10000 15000

Static Pressure (psi) 1 100 100 100 NA NA NA NA NA NA NA NA NA NA NA NA

Sensor Type non-isolated non-isolated non-isolated non-isolated isolated non-isolated isolated non-isolated isolated isolated isolated isolated isolated isolated isolated isolated

Range Type differential differential differential differential gauge compound gauge compound compound compound compound gauge gauge gauge gauge gauge

compound compound compound compound absolute absolute absolute absolute

psi 1 0.4000 1.0000 5.0000 7.0000 15.000 15.000 30.000 30.000 100.00 300.00 500.00 1000.0 1500.0 3000.0 5000.0 10000

bar 0.06894757 0.0276 0.0689 0.3447 0.4826 1.0342 1.0342 2.0684 2.0684 6.8948 20.684 34.474 68.948 103.42 206.84 344.74 689.48

mbar 68.94757 27.579 68.948 344.74 482.63 1034.2 1034.2 2068.4 2068.4 6894.8 20684 34474 68948 NA NA NA NA

kPa 6.894757 2.7579 6.8948 34.474 48.263 103.42 103.42 206.84 206.84 689.48 2068.4 3447.4 6894.8 10342 20684 34474 68948

MPa 0.006894757 0.0028 0.0069 0.0345 0.0483 0.1034 0.1034 0.2068 0.2068 0.6895 2.0684 3.4474 6.8948 10.342 20.684 34.474 68.948

kg/cm2 0.07030697 0.0281 0.0703 0.3515 0.4921 1.0546 1.0546 2.1092 2.1092 7.0307 21.092 35.153 70.307 105.46 210.92 351.53 703.07

cmH2O@4°C 70.3089 28.124 70.309 351.54 492.16 1054.6 1054.6 2109.3 2109.3 7030.9 21093 35154 70309 NA NA NA NA

cmH2O@20°C 70.4336 28.173 70.434 352.17 493.04 1056.5 1056.5 2113.0 2113.0 7043.4 21130 35217 70434 NA NA NA NA

mmH2O@4°C 703.089 281.24 703.09 3515.4 4921.6 10546 10546 21093 21093 70309 NA NA NA NA NA NA NA

mmH2O@20°C 704.336 281.73 704.34 3521.7 4930.4 10565 10565 21130 21130 70434 NA NA NA NA NA NA NA

inH2O@4°C 27.68067 11.072 27.681 138.40 193.76 415.21 415.21 830.42 830.42 2768.1 8304.2 13840 27681 41521 83042 NA NA

inH2O@20°C 27.72977 11.092 27.730 138.65 194.11 415.95 415.95 831.89 831.89 2773.0 8318.9 13865 27730 41595 83189 NA NA

inH2O@60°F 27.70759 11.083 27.708 138.54 193.95 415.61 415.61 831.23 831.23 2770.8 8312.3 13854 27708 41561 83123 NA NA

mmHg@0°C 51.71507 20.686 51.715 258.58 362.01 775.73 775.73 1551.5 1551.5 5171.5 15515 25858 51715 77573 NA NA NA

inHg@0°C 2.03603 0.8144 2.0360 10.180 14.252 30.540 30.540 61.081 61.081 203.60 610.81 1018.0 2036.0 3054.0 6108.1 10180 20360

ftH2O@60°F 2.308965833 0.9236 2.3090 11.545 16.163 34.634 34.634 69.269 69.269 230.90 692.69 1154.5 2309.0 3463.4 6926.9 11545 23090

Proof Pressure - maximum allowable pressure without a shift in calibration

Burst Pressure - sensor damaged or destroyed; some risk of personal injury

Static Pressure - Differential units only. Maximum allowed common mode pressure between both ports.

Page 32

www.martelcorp.com

e-mail: sales@martelcorp.com

Tel: (603) 434-1433 800-821-0023

Fax: (603) 434-1653

Martel Electronics

3 Corporate Park Dr.

Derry, NH 03038

0200051 Rev G 9/11

Loading...

Loading...