Page 1

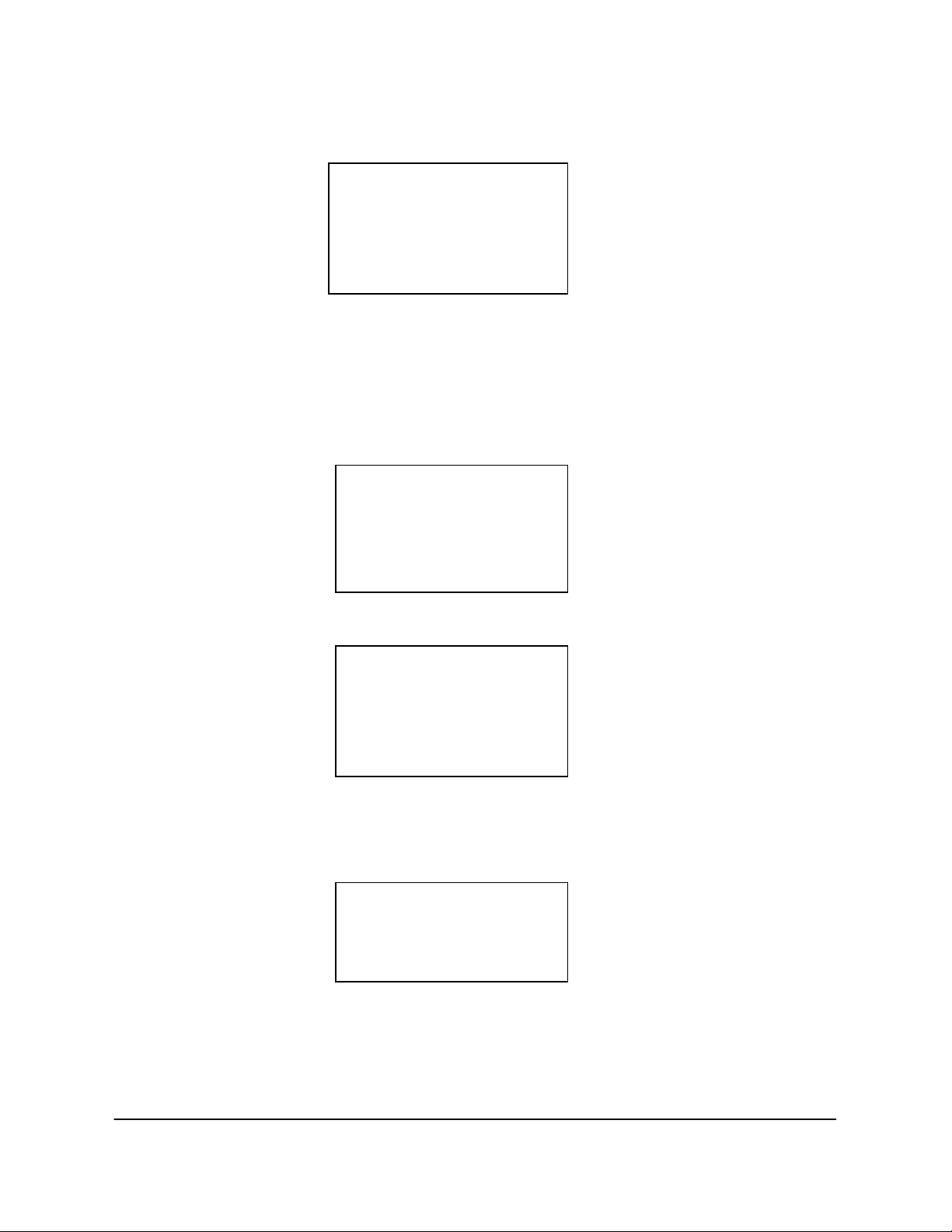

MODEL 230/235

Temperature Calibrator

User’s Guide

Page 2

Temperature Calibrator

Model 230

ON

OFF

BAT

CK

CE

ZERO

V

mV

mA

7

4

1

.

8

9

TC

RTD

In

Put

5

6

Ramp

Ω

Out

Put

2

3

Auto

-

0

Ent

Opt

Set

Up

INPUT

V/TC mA 2W 4W

3W

OUTPUT

Ω/RTD V/TC

ECJ

Beta Model 230 Calibrator

See back cover for Model 235

Page 3

Table of Contents

Introductions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

General Description . . . . . . . . . . . . . . . . . . . . . . . . . 1

Battery Charging . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Power On Sequence . . . . . . . . . . . . . . . . . . . . . . . . . 3

Input/Output Selection . . . . . . . . . . . . . . . . . . . . . . . 5

Menu Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Battery Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

INC/DEC Key Functions . . . . . . . . . . . . . . . . . . . . . . . . 7

CE/ZERO Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Auto Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Option Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Ramp Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

% Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

SYS Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Using Calibration System . . . . . . . . . . . . . . . . . . . . . . 14

Using Calibration System (manual). . . . . . . . . . . . . . . . . 16

Operator Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

External Temperature Compensation Module . . . . . . . . . . .31

Input Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Volts/Millivolts . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Milliamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

TC (Thermocouples). . . . . . . . . . . . . . . . . . . . . . . . . 33

RTD/Ω . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Pressure Module . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Trip Detect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Min-Max Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Input Reading in Percent of Scale . . . . . . . . . . . . . . . . . 43

230/235 i

Page 4

Output Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Volts/Millivolts . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Milliamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Thermocouple Simulation. . . . . . . . . . . . . . . . . . . . . . 46

Ramp Function . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Auto Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

mA/V Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Ohm/RTD Module (Optional) . . . . . . . . . . . . . . . . . . . 57

Loop Power Supply (Optional) . . . . . . . . . . . . . . . . . . . 57

Application Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

mV to Current Converters . . . . . . . . . . . . . . . . . . . . . 59

Thermocouple 2-Wire Transmitter . . . . . . . . . . . . . . . . 60

RTD to Current 2-Wire Transmitter . . . . . . . . . . . . . . . . 62

3-Wire Platinum RTDs . . . . . . . . . . . . . . . . . . . . . . . 63

Using Ramp and Trip Detect . . . . . . . . . . . . . . . . . . . . 64

mA/V Module . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Pressure Module . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Loop Powered Differential Pressure . . . . . . . . . . . . . . . . 69

Using Loop Power Supply (LPS) . . . . . . . . . . . . . . . . . . 70

Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

mA/V Module Error Messages . . . . . . . . . . . . . . . . . . 73

Service Information . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Return for Calibration/Repair . . . . . . . . . . . . . . . . . . . 74

Fuse Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Fuse Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . 77

mA/V Module Service Information . . . . . . . . . . . . . . . . . 79

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

ii 230/235

Page 5

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Input Specifications . . . . . . . . . . . . . . . . . . . . . . . . 82

Output Specifications . . . . . . . . . . . . . . . . . . . . . . . 85

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

mA/V Module Specifications . . . . . . . . . . . . . . . . . . . . 89

Pressure Module Specifications . . . . . . . . . . . . . . . . . . 90

Loop Power Supply Specifications . . . . . . . . . . . . . . . . . 91

230/235 iii

Page 6

Introduction

General Description

The Model 230/235 Temperature Calibrators are compact, versatile,

functionally styled calibrators. These units are menu driven so

technicians can immediately begin using them to their fullest

capabilities without extensive training.

The Model 230/235 consists of four functional areas:

At the top is an alphanumeric liquid crystal display (LCD) for

simultaneous indication of input and output readings and operator

prompting. The Model 230 uses a 2 line display while the Model 235

uses a 4 line display.

The center section is a tactile membrane keyboard for operator entry.

The lower section contains recessed input/output jacks for connecting

the supplied test leads to the device being calibrated.

There is a feature connector located at the lower end of the

instrument, below the terminals, which is used to connect external

modules to the calibrator to expand the calibrator’s capability. This

connector is also used to calibrate the Model 230/235 calibrator and as

the RS-232 interface to the Calibration System Database.

Introduction 230/235 1

Page 7

Battery Charging

Note: Before using the Model 230/235 calibrator for the first time,

it is necessary to charge the batteries for a minimum of 14 to

16 hours.

CALIBRATOR CHARGER

INPUT: 120VAC 60 HZ

OUTPUT: 5.8VDC 200 mA

For use only with

Beta Calibrators

Units are shipped with the internal batteries in an uncharged state.

The calibrator battery charger is a wall plug-in type (see below) which

connects to a jack on the right-hand side of the instrument. Battery

operation time is 7-8 hours, typically.

2 230/235 Introduction

Page 8

Operation

CAUTION: The operation of the calibrator may be impaired if a two way radio is keyed near the unit.

BETA Calibrator

Last cal 080593

The Model 230/235 Temperature Calibrators are user friendly and

menu driven. A first time user can normally start operating the unit

with little or no instruction. The following instructions are intended to

provide a detailed understanding of the unit.

Power On Sequence

The calibrator is turned on or off by pressing the ON/OFF key. Each

time it is turned on, a series of internal tests and calibrations are

performed. The start up tests provide pass/fail tests of certain internal

circuitry. If the tests determine the unit has an internal failure, a

message is displayed and the unit may or may not allow further

operation. A list of error messages can be found on page 71.

The start up calibrations provide for dynamic recalibration of the

internal calibrator support circuitry by applying the primary reference

voltages to points in the circuitry and recording the readings as

references for further measurements. The start up auto calibration

does not in any way affect the primary calibration done at the factory

or at a field metrology lab.

During the time the start up tests and calibrations are being performed,

certain informational displays are presented to show the status of the

calibrator. The first message displayed will be:

Operation 230/235 3

Page 9

This indicates the date in MMDDYY format of the last factory

property of

YOUR NAME HERE

Auto Calibration

in progress

Select Select

Input Output

Select Select

Input Output

Apr 26 12:21:18

calibration. The example indicates the Model 230/235 was calibrated

on August 5, 1993.

The next display will be:

This shows the name of the owner of the calibrator. The above display

shows the default setting as the calibrator is shipped. The name can be

changed by selecting “owner” from the setup menu. See page 25 for

details on how to change the owner’s name.

The next display will be:

This display will remain until the internal tests and calibrations are

finished, followed by the main prompt display:

On the Model 235 calibrator four line display, the time and date are

displayed.

This display indicates the calibrator is operating properly and is ready to

accept input or output function selections.

Operation 230/235 4

Page 10

Input/Output Selection

The Model 230/235 calibrator has a single set of function keys for

controlling both input measurements and output simulation. The input

measurement section of the calibrator is completely isolated from the

output simulation section.

To select input or output functions the INPUT and OUTPUT keys are

used. The calibrator is in output mode following power on.

Pressing the INPUT key places the calibrator in input mode, and

pressing any function key will cause the input to begin measurements

using that function.

Pressing the OUTPUT key places the calibrator in the output mode, and

pressing any function key will cause the output to request the value to

be simulated.

The current mode of the calibrator is indicated by the position of the

blinking cursor. When the calibrator is in input mode, the cursor is on

the leftmost column. When the calibrator is in output mode the cursor

is on the rightmost column.

The calibrator stays in the last mode selected until the mode is changed

by pressing the alternate key. For example, if you press INPUT and then

V, the calibrator will begin measuring volts. If you then press MV, the

input will begin measuring millivolts. If you then press OUTPUT

followed by V, the output function will respond by requesting the value

for the voltage.

Changing the input and output mode in no way affects the functions in

operation at the time. Input and output functions operate

simultaneously and without interaction. Input or output mode simply

indicates whether subsequent keystrokes will be applied to the input or

output function.

Operation 230/235 5

Page 11

Menu Selection

The Model 230/235 calibrator has several functions that require

additional information once the function has been selected. The

additional information is entered by picking from a menu or list of

items. For example, when selecting the Thermocouple function, you

must pick the type of thermocouple and the temperature scale.

A detailed description of the menu is provided with each function that

has menu choices. The following general information will provide an

understanding of the operation of the menus.

The menus are composed of a title (the top line) and a list of choices

(the bottom line). The title will indicate which parameter you are

entering.

On the bottom line, one of the choices will be blinking. This indicates

the active choice and the one that will be used if you press ENT. To

select a different choice, use the INC and DEC keys. The INC key moves

the choice to the right and the DEC key moves the choice to the left. If

there are more choices than will fit on one line, the additional choices

will scroll into view as you move the selection past the rightmost

choice. When the desired choice is blinking, press ENT. If you find

yourself in a function menu by mistake, pressing CE will cancel the

menu and return the calibrator to the previous or idle state as

appropriate.

Battery Check

The BAT CK key may be pressed at any time to display the current

battery voltage for approximately 1 second before the normal display

returns. The current input and output function are not disturbed by

making a battery check measurement.

The battery voltage should be between 5.3 and 4.6 volts. When the

Operation 230/235 6

Page 12

voltage falls below 4.65 volts, a warning message is displayed is

displayed approximately every minute. When the voltage falls below

4.5 volts for 1 minute, the calibrator will turn itself off to prevent

damage to the batteries due to possible cell reversal.

INC/DEC key functions

The INC and DEC keys are represented on the keyboard by up and down

arrow symbols respectively. They are multifunction in nature. Their

use is explained in detail in each section of the manual where they are

used. The following is intended to give an overall understanding of

their use.

With menus:

When a menu is displayed, the INC and DEC keys act as “cursor”

keys to move the highlight to the selection that you wish to make.

In general, the INC key moves the selection to the right or forward,

the DEC key moves the selection to the left or backward. Once you

have selected the correct item, press ENT.

With Input functions:

When the calibrator is displaying an input reading and is in the input

mode, i.e., the INPUT key was last pressed, the INC key causes the

maximum and minimum values to be displayed. See the description

of Min-Max mode for a full description.

With Output functions:

When the calibrator is outputting a variable and is in the output

mode, i.e., the OUTPUT key was last pressed, the INC and DEC keys

cause the output to change in one of the following manners. If

ramp is active, the INC or DEC key will start the ramp in the positive

or negative direction. If CalPts are enabled, the INC or DEC key will

select the next or previous calibration point from the user defined

list. If CalPts are not enabled, the output is increased or decreased

by the user defined percent of selected scale.

Operation 230/235 7

Page 13

CE/ZERO Key

When the calibrator is in the output mode and you press any of the

numeric keys (0-9), the keystrokes will be displayed until you press ENT

and the value is accepted by the output function. If you make a keying

error, the CE key is used to clear the erroneous entry and allow the

correct value to be re-entered. If you press CE a second time before

entering any numeric data, the keypad display mode is canceled and

the calibrator returns to displaying the actual output simulation value.

When the calibrator is in the input mode the CE/ZERO key acts as a zero

adjustment. This is used mostly on functions such as 2-wire ohms and

when using the external pressure module, but can be used on any Input

function. When the key is pressed, the most recent reading is retained

as the “zero point” and all subsequent readings have the zero point

subtracted from them prior to being displayed.

When the calibrator is displaying a menu, the CE/ZERO key acts as a

CANCEL key to terminate the menu and return to the previous function

or the idle state.

Auto Key

The AUTO key is used in conjunction with the calibration points or

Ramp functions to automatically repeat the function. The time

interval between the automatic repeats is determined by Setup option

“Pause.” The time can range from 5 to 10,000 seconds. The Model 235

uses the AUTO key with the “System” function.

The operation of the AUTO key is covered in detail with the Calibration

Points and Ramp functions.

Operation 230/235 8

Page 14

Option Key

Pressure Module

PSIG 30

Serial No. 2045

LastCal 080593

The OPT key is used to activate the external module that is attached to

the feature connector of the Model 230/235 calibrator. When the OPT

key is pressed for the first time after the calibrator is powered on, the

calibrator reads the configuration and calibration data from the

attached module. If no valid module is attached, or if the attached

module is not supported by the software revision of the calibrator, an

error message will appear. A list of error messages and their meanings

can be found on page 71.

The first time the OPT key is pressed, a series of messages are displayed

listing the configuration of the module.

A typical display is:

The top line shows the module type and the second line gives the

range. The above example is for the 30 PSIG Pressure Module. The

second display is:

The top line shows the serial number of the module and the second line

shows the date of the last calibration. The displays will remain for

approximately 1 second each, and then the appropriate display for the

attached module will appear.

When the OPT key is pressed a subsequent time(s), the calibrator

checks the ID and serial number of the attached module. If these

match the previous values, the module is activated immediately,

bypassing the title and serial number displays.

The OPT key can be pressed when the calibrator is in input or output

mode, depending on the function of the attached external module.

Operation 230/235 9

Page 15

If the module is not capable of operating in the mode requested, an

MCC #2 TT-101 34688-A1-B

SEQ=01 READY

error message will be displayed.

The operation of the Pressure Module can be found on page 36, that of

the mA/V Module can be found on page 54.

Ramp Key

The RAMP key is used to activate the ramp function which is covered in

the Output Functions section starting at page 54.

% Key (Model 235 Only)

The % Key allows easy access to the % Error Function. If the % ERR

Function has been set up using the SETUP menus (see page 19), press

the % Key to alternate between the Engineering Unit display and the %

ERR display.

SYS Key (Model 235 Only)

The SYS Key allows the Model 235 Calibrator to be used with a

Calibration System Database. Refer to the Calibration System Database

Instruction Manual for system information. Operation of the calibrator

is covered in this manual.

To enter the System mode of operation, press the SYS Key. The display

will show the tag number of an instrument previously loaded into its

memory on the top two lines of the display. Additionally, its sequence

in the group previously loaded from 01 to 28, and whether or not it has

been calibrated, is also indicated.

Operation 230/235 10

Page 16

If no tags have been entered, the display will indicate:

- - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - SEQ=01 EMPTY

MCC#2 TT-10134688-A1-B

REVIEW TEST

CLEAR ALL DATA

MA mVOLTS

+4.000 +10.000

AUTO TO START

CE TO ABORT

If calibration is complete, the display will indicate “Pass” or “Fail”

instead of “Ready”.

Pressing the INC/DEC key will allow the user to scroll through the tag

list. To directly view the desired tag, type its two digit sequence number

on the numeric keypad. Press SYS to exit the system mode; to

continue, press ENT when the desired instrument tag is displayed.

The selected tag will be displayed on the top two lines. The third line

gives the user the option to review the test points for the selected

instrument or proceed to the test. Pressing the INC/DEC key to cause

the desired menu to flash, then pressing ENT will advance the calibrator

to the next step.

Pressing CE will put the calibrator back to the beginning of the

sequence in all cases.

If “TEST” is selected and the ENT key is pressed, the calibrator will

automatically select the proper input and output mode for the

instrument tag selected and provide the proper output for the first

calibration point. Additionally, the operator will be prompted to press

AUTO to start the test or press CE to abort.

Operation 230/235 11

Page 17

If “Review” was selected, the test points would be displayed.

INPUT OUTPUT

+4.000 +10.000

+6.000 +20.000

+8.000 +30.000

MA mVOLTS

+4.000 +10.000

TESTING CALPT 01

AS FOUND

TEST COMPLETE

UNIT FAILED

REVIEW ADJUST

RETEST DONE

Press the INC/DEC keys to scroll through additional points. Press ENT or

CE to return to the previous menu.

Clear All Data allows “As Found” and “As Left” data previously stored to

be cleared. This option is only allowed if enabled by the Calibration

System. If this option is not enabled, the display will not have Clear All

Data as an option beneath the REVIEW and TEST options.

If AUTO was pressed to start the “As Found” test, the display will

indicate:

Once the test is completed, the display will indicate “Test Complete” on

the top line, whether the unit passed or failed on the second line and,

give the operator four choices on lines three and four - Review, Adjust,

Retest, Done. Selecting “Review” allows the operator to review the test

data, selecting “Retest” allows the test to be run again, selecting

“Done” takes the calibrator to the final sequence, selecting “Adjust”

allows the operator to adjust the instrument under test.

Selecting “Adjust” allows the operator to perform a normal calibration

procedure on the instrument under test. Pressing the INC/DEC key will

Operation 230/235 12

Page 18

step the calibrator output through the calibration points.

MA mVOLTS

+4.000 +10.000

ADJUST UNIT

AUTO WHEN DONE

MA mVOLTS

+4.000 +10.000

AUTO TO START

CE TO ABORT

MA mVOLTS

+4.000 +10.000

TESTING CALPT 01

AS LEFT

TEST COMPLETE

UNIT PASSED

REVIEW DONE

Once the desired results are achieved, press AUTO as indicated on the

calibrator display.

When “AUTO” is pressed, the calibrator again sets itself at the first cal

point and prompts the operator to press AUTO again to start the “As

Left” calibration procedure.

Pressing CE will take the calibrator back to the Test Complete menu.

If AUTO is pressed, the calibrator proceeds with the “As Left”

calibration.

When the test is finished, the calibrator will display “Test Complete,

Unit Passed or Failed”, and give the operator the option to “Review”

data or select “Done”.

Operation 230/235 13

Page 19

If “Done” is selected, the calibrator will prompt “Test Finished” and the

TEST FINISHED

ENTER TECH ID#

???????

UNIT FINAL STATUS

NO ACTION ADJUSTED

REPLACED

Invalid test

Config detected.

No Pressure

operator will be prompted to enter his/her ID number.

The operator will press ENT and then be prompted to indicate “Unit

Final Status” and choose from “Adjusted”, “Replaced”, or “No Action”.

Select the desired menu and press ENT.

At this time, the calibrator returns to the beginning mode and a new

tag number can be selected for the next calibration.

The calibrator records the time and date that Unit Final Status is

entered. Additionally, the number of calibration cycles required to

achieve a “Unit Passed” indication is also recorded.

Pressure Calibrations using

Calibration System

If the instrument being calibrated has pressure as either an input or

output, a Pressure Module with the appropriate range should be

attached to the calibrator before starting the test. If a Pressure Module

is not attached, an error message will be displayed.

Press any key to return to the Instrument Select Menu.

Operation 230/235 14

Page 20

Note: It is the responsibility of the user to ensure that the Pressure

Module being used is the proper range for the calibration

being performed.

mA PSI

+ 4.000 +0.0000

Apply +1.0000

Press ENT Low

If the instrument being calibrated has a pressure output, no special

action is required during the automatic test. The pressure will be

monitored as the input function on the calibrator and will be recorded

automatically at each calibration point.

If the instrument being calibrated has a pressure input, the pressure

will have to be generated manually by the user. The pressure will be

monitored as the output function on the calibrator and will be recorded

after the user has set the pressure to within the prescribed limits and

then pressed the ENT key.

The following shows the main screen while performing a pressure

calibration requiring an externally generated pressure.

Line two gives the actual pressure being measured. Line three is

the target pressure for this cal point. Line four indicates that the

pressure is too low (or too high if display shows “HIGH” or within

tolerance if display reads “READY”.

When LOW or HIGH is being displayed, the applied pressure is not

within the tolerance specified in the Calibration Database and the

calibrator will not accept it. You may press CE to cancel the calibration

attempt if you are not able to generate the requested pressure.

Operation 230/235 15

Page 21

When READY is being displayed, the applied pressure is within

Man_GPM mV

+10.000

Testing Calpt 01

As Found

Man_GPM mV

??????? +10.000

Enter Input Value

tolerance. You should wait until the actual pressure readings stabilize

and then press the ENT key. The calibrator will then store the readings

and step to the next calibration point.

Manual Calibration using

Calibration System

If the instrument being calibrated requires an input that cannot be

generated by the calibrator or if the output of the instrument cannot be

read by the calibrator, then the Calibration Database will indicate that

the instrument has a Manual input or output.

If the output of the instrument cannot be read by the calibrator, the

calibrator will be configured for Manual input. An example would be a

digital recorder with a mV input and a chart display as an output. The

calibrator will set its output to the required value, pause for the

number of seconds specified in the Calibration Database, and then

prompt the user to enter the indicated value in the engineering units

requested.

The display above is shown while the calibrator is setting its output and

waiting for the instrument to stabilize.

The display shown above is the calibrator prompting the user to enter

the value shown on the instrument’s digital indicator.

The three characters following Man_ (GPM, in this example) are the

engineering units expected as configured in the Calibration Database.

Operation 230/235 16

Page 22

If the input to the instrument cannot be generated by the calibrator,

mA Man_GPM

+4.000 5000

Set Ext Output

Press Ent

mA Man_GPM

+4.000 10000

Set Ext Output

Enter Value

the calibrator will be configured for Manual output. An example might

be a magnetic flow meter that requires a manufacturer specific device

to simulate a flow into its input.

There is an additional feature associated with Manual outputs. The

Calibration Database can be configured to require that the user

generate the exact value specified, or that the user generate

approximately the values specified and then enter the exact value that

was set.

If the calibration procedure specifies exact values, the calibrator will

prompt the user to set the external calibration device to the desired

value and press ENT when ready. The calibrator will then store its input

reading and step to the next calibration point.

The display shown above is instructing the user to set the external

calibration device to simulate a flow of 5,000 gallons per minute and

then press ENT.

If calibration procedure specifies approximate values, the calibrator will

prompt the user to set the external calibration device to the desired

value and then enter the exact value that was set. The calibrator will

then store its input reading and step to the next calibration point.

The display above is instructing the user to set the external calibration

device to simulate a flow of approximately 10,000 gallons per minute.

If you are able to set exactly 10,000 GPM, then you enter 10000 on the

Operation 230/235 17

Page 23

numeric keypad and then press ENT. If the closest you could get to the

desired value was 9,950 GPM, you would enter this value and press

ENT.

It is possible for an instrument to be configured for both Manual input

and Manual output. An example might be a glass thermometer that is

to be calibrated in a temperature bath. In this case the calibrator will

first prompt for the user to set the external output and then prompt

the user to enter the external input.

Operation 230/235 18

Page 24

Operator Setup

1-LCD Vu 2-BatSav

3-IncDec 4-CJunct

1-Owner 2-Pause

3-MfgTst 4-Save

1-InpRdg 2-Damp

3-% err

1-LCD Vu 2-BatSav

3-IncDec 4-CJunct

5-Owner 6-Pause

7-SerItf 8-Save

1-% err 2-Damp

3-InpRdg

The SETUP key activates the operator setup mode. This allows the

operator to preset several convenience features to customize the

calibrator for a particular user or application. The SETUP can be

activated any time except when the calibrator is displaying a menu.

When the SETUP key is pressed, a screen is displayed on the Model 230

showing the first 4 options available.

If the INC or DEC keys are pressed, additional groups of setup options

are displayed.

The Model 235 displays 8 setup options on each screen.

If INC or DEC keys are pressed, additional groups of setup options are

displayed.

To select one of the options, press the number key corresponding to

the option you desire (you need not press ENT). To exit from setup

mode, press SETUP a second time. The individual options are described

below.

Operation 230/235 19

Page 25

LCD Vu (Adjust LCD viewing angle)

Viewing Angle

sn 1355 uc 0300

Battery Save

Disable Enable

Note: All calibrators are shipped from the factory with battery save

enabled.

The LCD viewing angle or contrast may be adjusted electronically for

optimum viewing under various conditions. There are 8 levels to the

contrast adjustment. Press the INC or DEC key to select the adjustment

that is optimum for your conditions.

The second line of the viewing angle screen displays additional useful

information. The left side displays the serial number of the unit and

should agree with the serial number label on the case. The right side

displays the revision level of the internal software (microcode).

BatSav (Battery save)

The battery save feature will turn the calibrator off if there is no

keyboard activity for 10 minutes. This prevents running the batteries

down if the unit is accidentally turned on, or if the unit is left

unattended. Battery save should be enabled unless you have a specific

application where the calibrator needs to run attended for greater than

10 minutes.

Select either Disable or Enable using the INC/DEC keys and press the

ENT key.

IncDec (Program functions of the INC/DEC keys)

When the calibrator is in the output mode and a valid output function is

active, pressing INC or DEC key will cause the output to change by a

predetermined amount. This amount can be either a percentage of the

Operation 230/235 20

Page 26

current scale or a user defined calibration point from a predefined list

IncDec Key Funct

CalPts Percent

enter Cal Pts

CE when done

cal point #1

% of scale .00

of calibration points. This feature allows the user to program the

INC/DEC keys to function in one of two modes: user defined calibration

points, or percent of scale. Press the 3 key to program or setup the

INC/DEC key functions. The first menu allows you to select Cal Points

or Percent. The display will prompt with following:

To setup for the cal points function, highlight CalPts and press ENT. To

setup for the Percent function, highlight Percent and press ENT.

Calibration Points

The Calibration Points function allows storage of up to 10 calibration

values. The values are stored as a percent of a user defined scale. First

enter the percentage values, then enter the scale.

The next screen will be an information screen to remind you to enter as

many calibration points as needed (max 10). Press CE when all of the

cal points have been entered.

Press ENT to begin entering new calibration points. Points are entered

as a percent of scale in the range of 0.00% to 150.00%. Press CE when

all of the cal points have been entered.

Enter the new values for each calibration point up to a total of 10

points. If you press ENT without entering a value, the previous value,

as shown, is retained. If you make a keying error, you may press CE to

clear the entry and allow re-entry. When you have entered your final

calibration point press the CE key before entering the next value. After

Operation 230/235 21

Page 27

the last calibration point is entered, the next screen will be:

Zero point

value ???????

Full scale point

value ???????

Enter the value in engineering units for the function you will be using

that represents the zero value for the calibration points function.

After entering the zero point, the next screen will be:

Enter the value in engineering units for the function you will be using

that represents the full scale value for the calibration points function.

After entering the full scale point, you will return to the overall Setup

menu.

Calibration points examples

Example #1: Programming a 5 point calibration for a thermocouple

transmitter ranged for 100 to 600 degrees. The calibration points

entered would be:

cal point #1 0 (%)

cal point #2 25 (%)

cal point #3 50 (%)

cal point #4 75 (%)

cal point #5 100 (%)

zero point 100 (degrees)

full scale point 600 (degrees)

Operation 230/235 22

Page 28

Example #2: Programming a 3 point calibration for a 0-10mV input to a

recorder. The calibration points entered would be:

cal point #1 0 (%)

cal point #2 50 (%)

cal point #3 100 (%)

zero point 0 (mvolts)

full scale point 10 (mvolts)

Utilizing Calibration Points

Once calibration points have been enabled in the Setup Menu, they are

activated by simply pressing the INC or DEC key after selecting the

appropriate output function. The INC key steps forward through the

calibration points list, and the DEC key steps backwards. If you attempt

to step beyond the limits, the list will wrap around from the last to first

when incrementing, or the first to last when decrementing. To

automatically step through the selected calibration points, press the

AUTO Key. The steps will continue until the AUTO Key is pressed again.

Percent of Scale

The percent of scale function allows the user to specify a fixed

percentage that the output will change each time the INC or DEC key is

pressed.

Since the temperature scales have various ranges that would be

difficult to remember, the temperature functions are setup to change

by a fixed number of degrees. The range of values for percent are .01%

to 100.00%; the range of values for temperature are .1 degree to

1000.0 degrees.

The top line of the display lists the functions affected by the

increase/decrease value. The second line shows whether the value is a

percent of full scale or degrees. The current value is also shown.

Operation 230/235 23

Page 29

The first prompt will be for the functions that require a percent of

V, mV, Ohms

percent 10.00

RTD, TC

degrees 100.0

Cold junct. Comp

auto manual

Enter Ref Temp.

In °F + 32.0

scale.

Enter a new value or just press ENT to retain the current value. The

second prompt will be for the functions that require a degree value.

Enter a new value or just press ENT to retain the current value.

CJunct (thermocouple cold/reference junction compensation)

The Model 230/235 calibrator performs automatic cold junction

compensation for both input and output thermocouples. The

automatic cold junction compensation can be disabled if necessary and

a fixed compensation temperature can be entered.

The menu allows you to select either manual or automatic

compensation.

If you select manual and press ENT, you will be prompted to enter the

manual compensation temperature in degrees Fahrenheit.

If you enter 32°F, the calibrator will convert temperature to millivolt

values directly from the standard thermocouple tables. If you select

Auto and press ENT, the Model 230/235 calibrator will use either the

standard internal cold junction compensation, or the optional external

reference junction.

Operation 230/235 24

Page 30

The internal temperature compensation is performed by a

Note: This module must be used to obtain specified accuracy.

Martel P/N 910200-001

Ref junc sensor

rdg °F + 72.0

semiconductor temperature sensor located next to the thermocouple

output terminals.

The external temperature compensation is performed in a special

external module that connects to the Model 230/235 calibrator’s ECJ

jack on the front panel.

If automatic compensation is selected, the calibrator will display the

current reference junction temperature reading.

Press any key to continue.

The calibrator will automatically use the external module if it is plugged

into the ECJ jack; otherwise, the internal compensation will be used.

The choice between internal or external is largely determined by

environment. The internal sensor is slower to respond to changes in

the ambient temperature. The external sensor, being outside of the

calibrator case, can respond to ambient changes more quickly. Also,

the external sensor can be extended to allow it to be placed in close

proximity to the device being calibrated and to allow connection to

short or inaccessible thermocouple leads.

Owner (Enter owner’s name)

The Model 230/235 calibrator contains a security feature that allows

the owner to enter a name or other identifying number into the

calibrator’s non-volatile memory. The owner’s name cannot be

changed unless the operator knows the unit’s access code. The access

code is unique to each calibrator and is printed on the individual

calibration sheet that is shipped with each calibrator.

Operation 230/235 25

Page 31

When a new calibrator is received, the owner should enter the

desired owner name and file the access code in a safe place for

future reference. DO NOT keep the access code with the calibrator.

_YOUR_NAME_HERE_

_NEW_OWNER_NAME_

ENT+OK CE+cancel

When the owner setup is selected, the operator is prompted to enter

the access code. Enter the access code from the calibration sheet and

press ENT. If the incorrect code is entered, an error message is

displayed and the calibrator returns to the setup menu. If the correct

code is entered, the next display will be the current owner on the top

line with the leftmost character blinking.

The name of the owner can be any alphanumeric combination of up to

16 characters. Different characters are selected by pressing the INC or

DEC keys to scroll forward or backward through the alphabet. The

space character is represented by the underscore in this mode. If held

down, the INC and DEC keys will auto repeat to allow fast advancing

through the alphabet. Once the correct character is displayed in the

current position, press ENT to advance to the next character position.

You may back up to a previous position by pressing the CE key. After

you have entered the last character and pressed ENT, you will be

prompted to press ENT if everything is OK, or press CE to cancel the

change.

Press ENT if you are satisfied with the entry, or CE to cancel. If you

press CE, the owner’s name will not be changed. If you press ENT, a

momentary wait message will appear while the new information is

written into the non-volatile memory.

Operation 230/235 26

seconds btwn cal

points 10

Page 32

Serial Intf Mode

BetaCal SYS

Pause (Set pause time for auto CalPts and Ramp)

The AUTO key will cause the Calibration Points or Ramp program to

repeat continuously without intervention. This setup option allows you

to specify how long the calibrator will pause between Calibration Points

or Ramps when the AUTO key is pressed.

Enter the dwell time in seconds to pause between each cal point or at

the end of each ramp cycle, and press ENT.

SerItf (Serial Interface) (Model 235 Only)

This enables the feature port on the bottom of the Model 235 to be

configured to calibrate the calibrator using the BetaCal Software or for

connection to the Calibration System.

Select BetaCal when calibrating the calibrator with BetaCal software.

For normal calibrator operation, select SYS. The selection of BetaCal or

SYS can be saved with the Save feature (see the following page).

MfgTst (Enable manufacturing test routines)

(Model 230 Only)

This option enables several test routines used in the manufacturing,

test, and calibration of the calibrator. These routines are not intended

for use in the field. A special factory access code is required to activate

these routines.

Operation 230/235 27

Page 33

enter zero %

value ???????

enter 100 %

value ???????

Save (Save setup values in non-volatile RAM)

This function allows the setup parameters that have been entered to be

saved in non-volatile RAM. If the Setup mode is exited without saving

(by pressing the SETUP key a second time), the setup parameters

remain temporary in nature and will only be retained until the

instrument is powered off.

The SAVE option will allow the setup parameters to be retained, even

with power off, until they are changed by the operator.

InpRdg (Input Readings displayed as percent of scale)

This option allows you to configure the active input function to display

in percent of scale, rather than the standard engineering units. The

calibrator will prompt for the value of zero percent.

Enter the value in engineering units that represents the 0% value. Next

the calibrator will prompt for the value for 100 percent.

Enter the value in engineering units that represents the 100% value.

The input function will now be configured to display in percent of scale

rather than engineering units. The input functions will return to

displaying in engineering when the next input function is selected.

Damp (Dampen input readings)

This feature allows noisy input signals to be electronically dampened

for easier reading. When the feature is enabled, a running average is

displayed, rather than the instantaneous value.

Operation 230/235 28

Page 34

Input Dampening

Disable Enable

% error % scale

+0.00% +0.00%

% error % scale

+0.00% +100.00%

Select either Enable or Disable using the INC/DEC keys and press the

ENT key.

% Error Display

This option allows the user to configure the active input and output

function so the calibrator can internally compare them and display the

% error. For example, assume a 300°F to 1200°F calibrator output and

4-20mA calibrator input. If 300°F is being generated, 0% of scale will be

indicated on the right side of the display and if 4 mA is being received,

0% error will be displayed on the left.

Again assume, for the same signals, a 1200°F calibrator output and a 20

mA input.

This feature is particularly handy when using the pressure modules

because exact pressure need not be achieved or held. Even if the

pressure input is changing, the display will indicate any error between

input and output. For example, assume the calibration of a 0-1500 PSI

P/I transmitter. The configuration would be:

Input Zero = 4

Input F.S. = 20

Output Zero = 0

Output F.S. = 1500

Operation 230/135 29

Page 35

% error % scale

-0.10% +98.58%

% error

Disable Enable

Enter input Zero

EngUnits ???????

Enter input F.S.

EngUnits ???????

Enter output Zero

EngUnits ???????

Enter output F.S.

EngUnits ???????

If a pressure of 1478.7 PSI (98.85% of scale) is applied, the transmitter

would be expected to output 98.58% of range or 19.773mA. If the

transmitter were outputting only 19.757 (which is a -.1% error), the

display would indicate:

It is then a simple matter to adjust the transmitter span to achieve a 0%

error reading.

The calibration technique is to adjust zero for zero % error and adjust

span for zero % error. Repeat as required.

To configure the % ERR display, first select the desired input and output

engineering units (V, mV, mA, or Pressure). Then select the % err

option from the Setup menu, and the 130 will display the prompt:

Then both the 230 and 235 will prompt:

Exit the Setup menu.

The 230 will display the input in % ERR and the output in % Scale on exit

from the setup menu.

The 235 will now display in the previously selected Engineering Units.

Operation 230/235 30

Page 36

To display the 235 input and output in % ERR and % Scale units, press

the % Key. Subsequent presses of the % key, will toggle the 235

between engineering unit and % ERR/% Scale unit displays.

Once the calibrator is turned off, all % Error setup are lost.

External Temperature Compensation Module

The External Temperature Compensation Module allows the calibrator

to perform thermocouple calibration using copper wire and to operate

under harsh temperature variations.

Under normal circumstances, the calibrator should be connected to the

instrument under test using the same type wire as the thermocouple

being simulated. This allows differences in temperature between the

calibrator and instrument to be compensated automatically.

If the proper thermocouple wire is not available when making a

calibration, the External Temperature Compensation Module may be

extended from the calibrator using the Lead Extension Kit, and

connected to the instrument with very short copper leads. The Module

should then be positioned as close as possible to the instrument’s

terminals, and allowed to stabilize to the instrument’s terminal

temperature.

When making thermocouple calibrations in extreme temperature

conditions, the External Temperature Compensation Module must be

used to provide optimum performance. The internal sensor response

time may lag that of the module’s response time.

The External Temperature Compensation Module can be attached to

either the input or output TC jacks. The sensor plug attaches to the ECJ

jack on the calibrator face. The calibrator will automatically switch to

the External Module as soon as the sensor plug is attached.

Operation 230/235 31

Page 37

Input Functions

Input functions are selected by pressing any of the function keys while

the calibrator is in input mode. Functions available on the Model

230/235 are Volts, Millivolts, Milliamps, Ohms, RTDs, and

Thermocouples. Input mode is selected by pressing the INPUT key. The

calibrator remains in input mode until the OUTPUT key is pressed. The

cursor position on the display provides an indication of input or output

mode. When the calibrator is in the input mode, the cursor is displayed

in the leftmost column.

Input measurements are displayed on the left-hand side of the display.

The engineering units are displayed on the top line, and the actual

measurement value is displayed on the second line.

Volts/Millivolts

To measure Volts or Millivolts, press the V/mV (235) key when the

calibrator is in the input mode. Pressing the V/mV key will cause the

235 to toggle between the two ranges. The 230 has separate V/mV

keys.

The Model 230/235 calibrator will begin making voltage measurements

or millivolt measurements. Press the V/mV key to alternate between

the two measurements. The calibrator will autorange between the 3

internal voltage ranges. The ranges available for millivolts are identical

to the voltage ranges. The only difference between volts and millivolts

is the format of the display.

Milliamps

To measure Milliamps, press the mA key when the calibrator is in the

input mode. The calibrator will begin making current measurements

and displaying Milliamps.

Input Functions 230/235 32

Page 38

TC (Thermocouples)

Input TC type

JKTERSBNCGD

Select Temp Std

1948 1968

Input TC type

JKTERSBNCGDLtMP

Select Temp Std

Temperature Scale

°C°F

The Model 230 calibrator supports 11 thermocouple curves,

JKTERSBNCGD.

The Model 235 calibrator supports 15 thermocouple curves,

JKTERSBNCGDLtMP. The additional curves on the Model 235 are:

L = J Thermocouple (Din Curve)

t = T Thermocouple (Din Curve)

M = Ni-Ni Moly

P = Platinel

Both calibrators can read out in either degrees Celsius or Fahrenheit.

To measure a thermocouple output, press the TC key when the

calibrator is in the input mode. The calibrator will display a prompting

menu asking for the type of thermocouple.

Model 230 Display:

Model 230 (Optional):

Model 235 Display:

Select the type of thermocouple you will be using and press ENT. The

calibrator will then prompt for the temperature unit to use.

Select the proper temperature unit and press ENT. The calibrator will

Input Functions 230/235 33

Page 39

begin making thermocouple measurements and display the readings on

Int J °F

+ 212.0

the left-hand side of the display.

The top line of the display contains information about the

measurements.

The first three characters indicate the type of reference junction

compensation in effect.

Int = automatic compensation using the INTERNAL sensor.

Ext = automatic compensation using the EXTERNAL sensor.

Man = manual compensation.

Next is the single character thermocouple designation followed by the

temperature scale selected.

OBSERVE THERMOCOUPLE POLARITY. The negative lead of the

thermocouple connects to the V/TC black (negative) terminal of the

calibrator.

The ranges, resolutions, and accuracy of the various thermocouples can

be found on page 83.

RTD/OHMS

The 230/235 calibrator supports two 100 ohm Platinum RTD curves, the

European/DIN 43760 α=.00385 and the American α=.003916 curve, 120

Ohm Nickel Minco and 10 Ohm copper SAMA RC21-4-1966 with read

out in degrees Celsius or Fahrenheit. Measurements may be made in 2-

wire, 3-wire, or 4-wire mode and readings displayed in degrees Celsius

or Fahrenheit.

To measure Ohms:

Press the RTD/Ω key when the calibrator is in the input mode. (Note:

on the 230, press the Ω key).

Input Functions 230/235 34

Page 40

The 235 display will prompt:

Resistance Function

RTD OHMS

Termination type

2W 3W 4W

Resistance Function

RTD OHMS

Input RTD type

p385 p392 Cu10 Ni

Temperature Scale

°C°F

Select OHMS using the INC/DEC keys and press ENT.

The Model 230/235 calibrator will display a prompting menu asking for

the type of connection: 2-wire, 3-wire, or 4-wire.

Select the type connection you will be using and press ENT. For actual

calibration the more accurate 3-wire or 4-wire method should be used.

Two wire connections are normally used for go/no-go measurements

and trouble shooting.

To make an RTD measurement:

Press the RTD/Ω key while the calibrator is in the input mode. (Note:

on the 230, press the RTD key).

The 235 display will prompt:

Select RTD using the INC/DEC keys and press ENT.

The Model 230/235 calibrator will display a prompting menu asking for

the RTD curve to use: 385 or 392 or Ni or Cu10.

Select the desired RTD and press ENT. The calibrator will then prompt

for the temperature scale to use.

Select the proper temperature scale and press ENT. Next, the

Input Functions 230/235 35

Page 41

calibrator will prompt for the type of connection: 2-wire, 3-wire, or 4-

The pressure module should only be connected while the calibrator

is off.

Termination type

2W 3W 4W

RTD 4w°F

+ 212.0

wire.

Select the type of connection you will be using and press ENT. For

actual calibration, the more accurate 3-wire or 4-wire method should

be used. The calibrator will begin making RTD measurements and

display the readings on the left-hand side of the display.

The top line of the display contains information about the

measurements being made. The first three characters indicate that

RTD is selected.

Next is the termination method selected and then the temperature

scale.

Pressure Module (Optional)

The Pressure Module allows a Model 230/235 calibrator to make the

precise pressure measurements required for calibrating field pressure

instruments. The Pressure Module is a measurement only device. The

source of pressure must be supplied externally, usually by a hand

pump.

Electrical Connections

The Module attaches to the calibrator’s feature connector, located at

the bottom of the unit. The connector is keyed to prevent improper

installation.

Pressure Connections

The Pressure Module has a female 1/8 inch pipe thread for making the

pressure connection. The fitting is 316 stainless steel. A suitable

Input Functions 230/235 36

Page 42

thread lubricant should be used when making the connection to

Pressure Module

PSIG 30

Serial No. 2045

LastCal 080593

prevent seizing or galling.

Media Compatibility

The Pressure Module is designed to provide optimum accuracy as a

secondary calibration device. It is not designed to be a general purpose

test gauge to be attached to live processes. The low pressure ranges

(0-100 PSIG) are compatible with non-corrosive gases. For long service

with good stability and accuracy, clean, dry instrument air or nitrogen

should be used. The high pressure ranges (300-5000 PSIG) are

compatible with non-corrosive liquids and gases. The best liquid to use

is distilled water.

Operation

The Pressure Module is activated by pressing the OPT key just as you

would with any of the other function keys, such as volts or milliamps.

When the OPT key is pressed for the first after the calibrator is

powered on, the calibrator reads the configuration and calibration data

from the Pressure Module. The first time the OPT key is pressed, a

series of messages is displayed listing the configuration of the Pressure

Module.

The first display is:

The top line shows that a Pressure Module is attached and the second

line gives the range. The above example is for a 30 PSIG Pressure

Module. The second display is:

The top line shows the serial number of the module and the second line

shows the date of the last calibration. The displays will remain for

approximately 1 second each, and then the pressure units menu will

Input Functions 230/135 37

Page 43

appear.

Engineering Unit

PSI “H2O “Hg Kpa

This menu allows the selection of engineering units for pressure

display. The choices are displayed 4 at a time. Scrolling past the first or

last displayed selection provides additional choices.

The engineering units available are: PSI, inH₂O, inHg, Kpa, cmH₂O,

mmHg, mbar, Bar. The selection between absolute and gauge is made

automatically based on the type of module attached.

When any of the water column scales are selected from the main

engineering units menu, a second menu will be displayed that allows

the operator to select the conversion temperature desired. 20°C is the

Instrument Society of America (ISA) standard, 60°F is used by the

American Gas Association (AGA) and 4°C is used in scientific research.

Software versions prior to 03.35 use the 4°C conversion temperature.

The factors used by the Pressure Module to convert from PSI to other

engineering units are listed below.

2.036 “Hg @0°C

51.715 mmHg @0°C

6.8948 KPascals

68.948 milliBars

0.068948 Bars

27.681 “H2O @4°C

27.707 “H2O @60°F

27.730 “H2O @20°C

70.310 cmH2O @4°C

70.376 cmH2O @60°F

70.433 cmH2O @20°C

When the OPT key is pressed a subsequent time(s), the calibrator

checks the ID and serial number of the attached module. If these

match the previous values, the module is activated immediately,

bypassing the title and serial number displays.

Input Functions 230/235 38

Page 44

The Pressure Module is capable of operating as an input or output

If pressure measurements are not being made, the calibrator should

be turned off and the pressure module disconnected.

Note: To zero the reading, press the CE/Zero Key while the

calibrator is in input mode.

function, even though it is a measurement only device. This allows

simultaneous measurement of pressure and milliamps if desired.

To operate the Pressure Module as an input function, press the OPT key

while the calibrator is in the input mode. This will permit any allowable

output function to be active simultaneously with pressure

measurements.

To operate the Pressure Module as an output function, press the OPT

key while the calibrator is in the output mode. This will allow pressure

readings to be displayed on the output side, and milliamps to be

displayed on the input side. In this mode, the calibrator is actually

alternating readings between pressure and milliamps. This may cause a

barely perceptible slowing of response time of the readings. If the

simultaneously display of pressure and milliamps readings are not

required, the Pressure Module should be operated as an input function

for quickest response times.

To reactivate pressure readings simply press the OPT Key after first

selecting INPUT or OUTPUT mode as desired.

Zeroing a gauge pressure module

When a pressure module with a gauge pressure sensor is first activated,

it will typically display a non-zero pressure reading.

This is true even if the pressure is being displayed on the output side of

the calibrator.

There may be a slight drift of the zero reading during the first few

minutes of operation after power is first applied to the Pressure

Module. The user should recheck the zero by venting any pressure and

Input Functions 230/235 39

Page 45

Enter actual val

???????

observing the reading. If a shift has occurred, a new zero is obtained by

pressing the CE/Zero Key while in input mode. Note that you must zero

the pressure reading any time a new engineering unit is selected.

Zeroing an absolute pressure module

When a Pressure Module with an absolute sensor is used, the zero or

offset procedure is modified to allow the user to enter the local

barometric pressure as the zero. When the CE/Zero key is pressed, a

prompting screen is displayed.

Enter the local barometric pressure in the engineering units that are

selected, and press ENT. The absolute pressure readings are then

compensated by using the entered value as the reference pressure.

There may be a slight drift of the zero reading during the first few

minutes of operation after power is first applied to the Pressure

Module. The user should recheck the zero by venting any pressure and

observing the reading. If the reading does not match the local

barometric pressure, a new zero is obtained by pressing the CE/Zero

key while in input mode, and entering the barometric pressure. Note

that you must enter the barometric zero any time a new engineering

unit is selected. The barometric reference standard used should be

.02% FS accuracy.

Disconnected Pressure Module

If the Pressure Module is disconnected while pressure readings are

being made, the display will show invalid for the pressure reading.

After a few seconds, the calibrator will determine that the Pressure

Module has been disconnected or malfunctioned and the following

display will be seen:

Input Functions 230/235 40

Page 46

no external

module present

The pressure adapter module receives power and commands from

the calibrator’s output section and the pressure readings are made

through the calibrator’s input section. As a result the calibrator loses

its input to output isolation any time the pressure module is plugged

into the feature connector. This is not a problem as far as pressure

measurements are concerned. However, if you are operating the

calibrator in a mode that requires input-output isolation, such as

calibrating an E to E or I to E transmitter that is loop powered from

an external 24V power supply, you MUST UNPLUG the pressure

module. To be safe, you should disconnect the module anytime you

are making simultaneous input-output electrical measurements.

Safety

Good safety practices should always be followed when using high

pressures. Although liquids are considered non-compressible, dissolved

gases and trapped gases can exist in the system and can store

significant energy when compressed under high pressure. Always use

good quality fittings that are rated for the pressures being used.

Always wear safety glasses or goggles.

The ranges and resolution of the various pressure modules can be

found on page 90.

Trip Detect

The trip detect feature is used in conjunction with the Ramp Function.

Trip detect is a feature to aid in calibrating trip point alarms under

simulated operating conditions. The ramp output of the calibrator

simulates the changing process as an input to the alarm circuit.

The contact output of the alarm circuit connects back to the voltage

input of the calibrator.

Input Functions 230/235 41

Page 47

The trip detect feature can utilize either the volts or 2-wire ohms input

terminals. If the alarm circuit has powered contacts, the volts input

should be used. If the alarm circuit has dry or non-powered contacts,

the ohms 2-wire input should be used. If the voltage input is used, the

maximum input voltage is 30 volts; however, the calibrator can only

detect changes in the 0-10 volt range. This is normally not a problem,

since the powered contacts typically switch between 0 volts and 24

volts.

A change of more than 1 volt or 100 ohms on the input is considered a

change of state of the alarm circuit.

Trip detect is enabled when the Ramp Function is initiated. The final

prompt when initiating the ramp is to enable or disable the trip detect

function. If you enable the trip detect function, the final prompt will be

to select ohms or volts and the input function will monitor for a

significant change in its input measurement. When a change is

detected, the output ramp is stopped and the current value is

displayed.

The ramp is controlled by the INC/DEC keys. The first press of the INC

or DEC key will cause the ramp output to assume the full scale or zero

value, respectively. The second press of the key will cause the ramp to

start and the input function to start monitoring for a change of state.

When the change of state is detected, the ramp is stopped. Pressing

the INC or DEC key again will restart the cycle.

To test the dead band of an alarm, first initiate a positive going ramp

using the INC key and record the trip point. Next initiate a negative

going ramp using the DEC key and record the trip point again. The

difference in the two recorded trip point values represents the dead

band of the alarm.

While the ramp is running and before the trip occurs, the input display

shows:

Input Functions 230/235 42

Page 48

Armed

xxxxxx

Tripped

xxxxxx

After the trip occurs, the input display shows:

To restart the ramp and reset the trip condition, press either the INC or

DEC key once to reset the ramp to the starting or ending value and

reset the tripped indication. Press the INC or DEC key a second time to

start the ramp. Be sure to reset the external trip circuit if necessary

before starting the ramp.

Min-Max Mode

The calibrator continuously stores the minimum and maximum values

of the input readings. The min-max function allows these values to be

displayed at any time.

To use the function, select the input variable to be displayed and press

the INC key to display the minimum and maximum values recorded.

The minimum and maximum values will be displayed until any key is

pressed. Pressing any key will reset the min and max values to the

most recent reading and the calibrator will return to displaying real

time values. The minimum and maximum values are reset each time an

input function is selected or re-selected.

Input Reading in Percent of Scale

This feature allows the input measurements to be displayed as a

percent of scale rather than in engineering units. This allows error

calculations in percent to be quickly calculated.

The feature is accessed through the Setup option InpRdg, and is

normally utilized with output Calibration Points which are also

programmed in percent of scale.

Input Functions 230/235 43

Page 49

An example would be the testing of a thermocouple transmitter. The

output CalPts would be setup for 0-25-50-75-100 percent and the zero

and full scale points entered. Next the input mA function would be

selected. Press SETUP and select the menu for InpRdg. Enter 4 as the

zero point and 20 as the full scale point.

Step through the CalPts using the INC key and observe the input

readings. The transmitter’s error in percent of scale will be the

observed reading minus the CalPts value. For example, if on the third

calibration point (50%) the input reads 50.15, the error is 0.15% of scale

(50.15-50.00).

Input Functions 230/235 44

Page 50

Output Functions

VOLTS

??????

Output functions are selected by pressing any of the function keys

while the calibrator is in output mode. Output functions available on

the Model 230/235 are Volts, Millivolts, Ohms, RTDs, and

Thermocouples. Output mode is selected by pressing the OUTPUT key.

The calibrator remains in output mode until the INPUT key is pressed.

The cursor position on the display provides an indication of input or

output mode. When the calibrator is in output mode, the cursor is

displayed in the rightmost column.

Output measurements are displayed on the right-hand side of the

display, with engineering units displayed on the top line and simulated

value on the bottom. The output value displayed is the actual value at

the output terminals, not simply the setpoint value.

Volts/Millivolts

To output Volts or Millivolts, press the V/mV key when the calibrator is

in the Output mode. Pressing the V/mV key will cause the display to

alternate between volts and millivolts. (Note: the 230 has separate V

and mV keys. Press V for Volts and mV for Millivolts).

The calibrator will prompt for the value desired. The calibrator will

automatically select the proper range for the value entered. See page

85 for a description of the ranges and resolutions.

Enter the desired voltage and press ENT. If an improper or out of range

value is entered, the calibrator will display an error message. Error

messages and their meanings are displayed on page 71. If the value is

within the operating limits, the calibrator will set the output to the

requested value. The output display will show the actual output

Output Functions 230/235 45

Page 51

achieved at all times. The internal microprocessor will automatically

Output TC type

JKTERSBNCGD

Select Temp Std

1948 1968

Output TC type

JKTERSBNCGDLtMP

Select Temp Std

1948 1968 1990

correct for any drift due to temperature or battery change.

Millivolts

The millivolts output function is identical to the volt function except

that the value is entered and displayed in millivolts.

TC (Thermocouples)

The Model 230 calibrator supports 11 thermocouple curves,

JKTERSBNCGD.

The Model 235 calibrator supports 15 thermocouple curves,

JKTERSBNCGDLtMP. The additional curves on the Model 235 are:

L = J Thermocouple (Din Curve)

t = T Thermocouple (Din Curve)

M = Ni-Ni Moly

P = Platinel

Both calibrators can read out in either degrees Celsius or Fahrenheit.

To simulate a thermocouple output, press the TC key when the

calibrator is in the output mode. The calibrator will display a prompting

menu asking for the type of thermocouple.

Model 230 Display:

Model 230 (Optional):

Model 235 Display:

Output Functions 230/235 46

Page 52

Select the type of thermocouple you will be using and press ENT. The

Temperature Scale

°C°F

Int J °F

+ 212.0

Temp

calibrator will prompt for the temperature unit to use.

Select the proper temperature unit and press ENT. The calibrator will

prompt for the desired output temperature in degrees.

Enter the desired temperature within the range of the selected

thermocouple and press ENT. If an incorrect or out of range value is

entered, the calibrator will display an error message and prompt again

for a value. Once a valid temperature is entered the calibrator will set

the output to the desired temperature. The display will reflect the

actual temperature being simulated at the terminals as the calibrator

adjusts its output to compensate for errors and drifts.

When the display indicates the selected temperature, the output is

properly set to simulate the requested thermocouple.

The top line of the display contains information about the simulation

being made.

The first three characters indicate the type of reference junction

compensation in effect.

Int = automatic compensation using the INTERNAL sensor.

Ext = automatic compensation using the EXTERNAL sensor.

Man = manual compensation.

Next is the single character thermocouple designation followed by the

temperature scale selected.

Output Functions 230/235 47

Page 53

OBSERVE THERMOCOUPLE POLARITY. THE RED V/TC TERMINAL OF THE

CALIBRATOR IS THE POSITIVE TERMINAL.

The calibrator should be connected to the device under test using the

same type wire as the thermocouple being simulated. This will cause

any difference in temperature between the calibrator’s reference

terminals and the terminals of the unit under test to be compensated

for automatically.

The ranges, resolutions, and accuracy of the various thermocouples can

be found on page 86.

Output functions 230/235 48

Page 54

RTD/Ω Simulation

Resistance Function

RTD OHMS

Input RTD type

p385 p392 Cu10 Ni

Temperature Scale

°C°F

Temp

??????

The calibrator output supports two 100 ohm Platinum RTD curves, the

European/DIN 43760 α=.00385 and the American α=.003916 curve, 120

Ohm Nickel Minco and 10 Ohm copper SAMA RC21-4-1966 with read

out in degrees Celsius or Fahrenheit.

To simulate an RTD:

Press the RTD/Ω key while the calibrator is in the output mode. (Note:

on the 230, press the RTD key).

The 235 display will prompt:

Select the RTD function using the INC/DEC keys and press ENT.

The Model 230/235 calibrator will display a prompting menu asking for

the RTD curve to use: 385 or 392 or Ni or Cu10.

Select the desired RTD and press ENT. The calibrator will then prompt

for the temperature scale to use.

Select the proper temperature scale and press ENT. The calibrator will

prompt for the desired temperature.

Enter the desired temperature within range of the RTD selected and

press ENT. If an incorrect or out of range value is entered, the

calibrator will display an error message and prompt for a value. Once a

valid temperature is entered, the calibrator will set the output to the

Output Functions 230/235 49

Page 55

desired simulated temperature. The display readout will reflect the

RTD °F

+ 212.0

actual temperature being simulated at the terminals as the calibrator

adjusts its output to compensate for errors and drift. When the display

indicates the selected temperature, the output is properly set to

simulate the requested RTD.

The RTD simulation requires that the unit under test supply a nominal

.1 to 2 milliamp test current. Pulsing excitation requires a minimum 60

mSecond pulse width, at 1 Hertz minimum, with no overshoot or

ringing. If the calibrator detects that the current is absent or out of

range, it will display OPEN or OVRANGE as appropriate. The polarity of

the current is significant and is the same as the voltage terminals, i.e.,

red is positive. If the test current is of the incorrect polarity, the

calibrator will display REVERSED. Simply reverse the leads at the

calibrator or the devise under test.

The top line of the display contains information about the

measurements being made. The first three characters indicate that

RTD is selected. Next is the temperature scale.

Output Functions 230/235 50

Page 56

To simulate ohms:

Resistance Function

RTD OHMS

OHMS

??????

The Model 230/235 calibrator can simulate Ohms directly. This may be

useful if the RTD does not conform to a standard curve or if the actual

resistance in Ohms is needed.

To select the Ohms output function, press the RTD/Ω key while the

calibrator is in the output mode. (On the 230 press the Ω key).

The 235 display will prompt:

Select the Ohms function using the INC/DEC keys and press ENT.