55208033-08

TECHNICAL MANUAL

DX CASSETTE 600E/M, 600E & 600L

Heronhill - for all your Marstair requirements

Tel: 01823 665660

www.heronhill.co.uk

Fax: 018123 665807

2/25

55208033-08

INDEX

CONTENTS

PAGE

General. 2

Unit part numbers, dimensions & weights. 3

Features, optional accessories & system matches 4

Performance data. 5

Airflows & discharge velocities. 6

Sound power & sound pressure levels. 6

Branch duct (spigot) data. 7

Electrical data: Loads & fuses 8-9

Installation.

10

Contents & dimensions. 10

Removal of chassis & mounting. 11

Pipework & restrictor sizes. 12

Remote controllers. 13-14

Fan speed selection & interconnecting wiring diagrams. 15-17

Reinstalling chassis & fascia. 18

Condensate drain piping. 19

User maintenace. 21

Fault finding. 22-23

Component identification. 24-25

GENERAL

1. TEV Ltd recommend that personnel working on this equipment be skilled and fully conversant with

the appropriate Air Conditioning, Refrigeration and Electrical practices and have sound knowledge

of current Industrial Safe Working practices.

2. These units consist of 600E/M cassettes using remote wired controllers, 600 L cassettes using

infrared controllers and 600 E cassettes using infrared controllers.

3. These units contain live electrical components, moving parts and refrigerant under pressure.

Always site out of reach of children and protect from vandalism.

4. The data plate only gives information for the 600 unit.

5. Refer to the outdoor unit manual / installation instructions for evacuating and adding refrigerant.

Heronhill - for all your Marstair requirements

Tel: 01823 665660

www.heronhill.co.uk

Fax: 018123 665807

3/25

55208033-08

PART NUMBERS

Fascia

55222000 (all models)

Fitted with 0.5m lift pump

Fitted with 5m condensate pump

600E/M model 20 40 60

20 40 60

Part number

55222001 55222002 55222003

55222004 55222005 55222006

600L model 20L 40L 60L

20L 40L 60L

part number

55222007 55222008 55222009

55222022 55222023 55222024

600E model 20E 40E 60E

20E 40E 60E

Part number

55222013 55222014 55222015

55222016 55222017 55222018

NOTE: The fascia is shipped separate from the chassis and they are ordered on separate part numbers.

DIMENSIONS AND WEIGHTS

UNPACKED (with fascia fiitted).

600

Model

20 40 60

Height mm

335 335 335

Width mm

675 675 675

Depth mm

675 675 675

Weight kg

21 23 25

PACKED

600 Chassis

600 Fascia

Model

20 40 60

20 / 40 / 60

Height mm

360 360 360 100

Width mm

810 810 810 760

Depth mm

610 610 610 760

Weight kg

22 24 26 4

Heronhill - for all your Marstair requirements

Tel: 01823 665660

www.heronhill.co.uk

Fax: 018123 665807

4/25

55208033-08

FEATURES AND OPTIONAL ACCESSORIES

STANDARD

600E/M 600L 600E

De-ice thermostat/sensor STD STD STD

3 fan speed combinations STD STD STD

Remote infrared control --- STD STD

Remote hard wired control STD --- STD

0.5m lift pump STD STD STD

5m condensate pump STD STD STD

Programmable timer --- STD STD

Long life cleanable filter STD STD STD

Remote temperature sensor STD --- ---

OPTIONS

NOTE: These kits are easier to fit before installation, some may also be factory fitted.

SYSTEM MATCHES

Air Conditioning Systems

Heat Pump Systems

600 (ALL)

MCU+ or DCU+

600L / 600E MHPUL / MHPUE / DHPUE

20 15 20 15

20 20 40 30

20 30 60 50

40 30

40 40

40 50

60 40

60 50

60 60

NOTE: Table above is for 600 units matched with Marstair outdoor units.

Heronhill - for all your Marstair requirements

Tel: 01823 665660

www.heronhill.co.uk

Fax: 018123 665807

5/25

55208033-08

PERFORMANCE DATA (kW)

NOTE THAT THERE ARE 3 SPEED RANGES OF LOW, MEDIUM AND HIGH

Range 3 = highest for maxium duties

Range 2 = medium for normal operations

Range 1 = lowest for minimum noise levels

UK CONDITIONS

ROOM 21°C/15°C

AMBIENT 27°C/19°C

EUROVENT

(NEMA)

ROOM

27°C/19°C

AMB 35°C/24°C

TROPICAL

ROOM

29°C/19°C

AMB 46°C/24°C

RANGE 3

LOW MEDIUM HIGH HIGH HIGH

RANGE 2

LOW MEDIUM HIGH

RANGE 1 LOW MEDIUM HIGH

600

(ALL)

MCU+

or

DCU+

TOT SHR SENS TOT SHR SENS TOT SHR SENS TOT SHR SENS TOT SHR SENS TOT SHR SENS TOT SHR SENS

20 15 1.77 0.75 1.33 1.82 0.80 1.46 1.87 0.85 1.59 1.91 0.92 1.75 1.94 1.00 1.94 2.13 1.00 2.13 2.05 1.00 2.05

20 20 2.28 0.69 1.58 2.35 0.72 1.70 2.40 0.76 1.83 2.45 0.81 1.99 2.50 0.88 2.19 2.65 0.93 2.47 2.28 1.00 2.28

20 30 N/A* 2.63 0.70 1.84 2.71 0.73 1.97 2.78 0.77 2.14 2.85 0.83 2.35 3.03 0.86 2.61 2.37 1.00 2.37

40 30 3.13 0.67 2.09 3.29 0.68 2.25 3.40 0.71 2.41 3.52 0.74 2.61 3.60 0.79 2.84 3.86 0.81 3.14 3.06 1.00 3.06

40 40 3.50 0.66 2.30 3.69 0.67 2.47 3.84 0.69 2.63 3.98 0.71 2.83 4.09 0.75 3.06 4.27 0.77 3.30 3.84 0.93 3.57

40 50 N/A* 4.59 0.66 3.01 4.83 0.67 3.22 5.05 0.69 3.47 5.27 0.72 3.78 5.66 0.72 4.08 4.73 0.89 4.20

60 40 3.60 0.66 2.39 3.79 0.68 2.58 3.92 0.70 2.76 4.06 0.73 2.98 4.18 0.78 3.25 4.33 0.81 3.52 3.87 0.99 3.84

60 50 4.35 0.65 2.82 4.66 0.66 3.06 4.89 0.67 3.26 5.14 0.68 3.51 5.35 0.71 3.81 5.72 0.72 4.09 4.80 0.88 4.20

60 60 N/A* 4.97 0.65 3.24 5.24 0.66 3.45 5.51 0.67 3.71 5.78 0.70 4.02 6.26 0.69 4.32 5.18 0.84 4.36

* Cannot be used on low speed

Rated at BS2852: Part 1: 1982: UK condition C; NEMA condition A; Tropical condition B

HEAT PUMP

a. Cooling (MAX speed outdoor unit fan)

UK CONDITIONS

ROOM 21°C/15°C

AMBIENT 27°C/19°C

EUROVENT (NEMA)

ROOM 27°C/19°C

AMBIENT 35°C/24°C

RANGE 3

LOW MEDIUM HIGH HIGH

RANGE 2

LOW MEDIUM HIGH

RANGE 1 LOW MEDIUM HIGH

600 (ALL)

MHPUL

MHPUE

DHPUE

TOT SHR SENS TOT SHR SENS TOT SHR SENS TOT SHR SENS TOTAL SHR SENS TOTAL SHR SENS

20 15 1.77 0.75 1.33 1.82 0.80 1.46 1.870.85 1.59 1.91 0.92 1.75 1.94 1.00 1.94 2.23 1.00 2.23

40 30 3.13 0.67 2.09 3.29 0.68 2.25 3.400.71 2.41 3.52 0.74 2.61 3.60 0.79 2.84 3.86 0.81 3.14

60 50 4.35 0.65 2.82 4.66 0.66 3.06 4.890.67 3.26 5.14 0.68 3.51 5.35 0.71 3.81 5.72 0.72 4.09

b. Heating (Room 20°C/12°C, outdoor unit fan at MAX speed)

HEATING OUTPUT AT 7°C AMBIENT

(EUROVENT)

HEATING OUTPUT AT -1°C AMBIENT

RANGE 3 LOW MEDIUM HIGH LOW MEDIUM HIGH

RANGE 2 MEDIUM HIGH MEDIUM HIGH

RANGE 1 HIGH HIGH

600 (ALL)

MHPUL

MHPUE

DHPUE

kW COP kW COP kW COP kW COP kW COP kW COP

20 15 2.06 2.50 2.07 2.52 2.13 2.60 1.58 2.10 1.68 2.20 1.72 2.23

40 30 2.92 2.70 2.98 2.75 3.46 3.23 2.30 2.30 2.40 2.40 2.60 2.60

60 50 5.48 2.48 5.68 2.58 5.71 2.89 4.42 2.31 4.64 2.31 4.75 2.59

Heronhill - for all your Marstair requirements

Tel: 01823 665660

www.heronhill.co.uk

Fax: 018123 665807

6/25

55208033-08

AIRFLOWS

RANGE 3

LOW SPEED MEDIUM SPEED HIGH SPEED

RANGE 2

LOW SPEED MEDIUM SPEED HIGH SPEED

RANGE 1 LOW SPEED MEDIUM SPEED HIGH SPEED

600 (ALL) m3/s m3/s m3/s m3/s m3/s

20 0.12 0.146 0.173 0.209 0.256

40 0.12 0.146 0.173 0.209 0.256

60 0.12 0.146 0.173 0.209 0.256

DISCHARGE VELOCITIES

SOUND POWER and SOUND PRESSURE

speed 1 = lowest, speed 5 = highest

SOUND POWER LEVELS

Frequency Hz

SOUND PRESSURE LEVELS

600 (ALL) SPEED 125 250 500 1K 2K 4K dBA

dBA NC

1 56.3 48.3 45.5 39.0 36.6 35.8 47 26 18

2 58.8 51.9 50.2 44.9 41.4 37.5 52 31 23

3 61.6 57.8 55.6 53.8 48.5 44.4 58 37 31

4 62.9 60.1 57.6 56.3 51.3 46.8 61 40 34

20

5 67.0 65.6 62.9 61.3 57.6 53.0 66 45 39

1 55.7 49.7 46.4 39.2 37.2 35.7 48 27 19

2 57.5 53.6 50.9 45.1 42.3 39.8 52 31 24

3 61.9 59.0 56.2 54.2 48.9 44.2 59 38 32

4 63.1 62.0 58.3 56.6 51.6 46.7 61 40 34

40

5 68.0 67.3 63.5 61.9 57.5 52.8 67 46 40

1 55.5 51.1 47.8 41.8 41.1 40.0 50 29 22

2 58.8 54.8 52.0 47.5 46.2 42.3 54 33 26

3 62.1 59.2 56.4 53.6 49.9 43.2 59 38 31

4 64.1 61.2 58.5 55.6 51.7 45.4 60 39 33

60

5 69.4 66.5 63.1 60.6 56.5 51.6 66 45 39

Sound Power Levels were obtained in conformance with BS 4196: Part 5: 1981. Values are shown in dB with a standard reference of 1 pW.

Sound Pressure Levels are dB relative to 2 x 10

-5

N/m2 and are calculated from results measured in anechoic conditions. Values relate to a

position of 3m away from the centre line of the unit, 1m down.

Heronhill - for all your Marstair requirements

Tel: 01823 665660

www.heronhill.co.uk

Fax: 018123 665807

7/25

55208033-08

BRANCH DUCT

The graphs below show the amount of conditioned air passed by a single branch duct.

FAN SPEED RANGE 1 FOR MINIMUM NOISE LEVELS

As shown on the graphs above, branch duct airflow can be be increased by blanking off the fascia side to

which the branch duct has been connected.

FAN SPEED RANGE 2 FOR NORMAL NOISE LEVELS

FAN SPEED RANGE 3 FOR MAXIMUM NOISE LEVELS

Heronhill - for all your Marstair requirements

Tel: 01823 665660

www.heronhill.co.uk

Fax: 018123 665807

8/25

55208033-08

ELECTRICAL DATA

Cooling data rated at EUROVENT (NEMA) conditions 27°C / 19.4°C indoor; 35°/24°C ambient.

Heating data rated at 20°C/12°C indoor; 7°C/6°C ambient

With MCU+

1 Ph 230V 50Hz 3 Ph 400V 50Hz

MODEL

COMBINATION

INPUT

FULL LOAD

AMPS

SYSTEM

MAX.

STARTING

CURRENT

INPUT

FULL LOAD

AMPS

SYSTEM

MAX.

STARTING

CURRENT

Cooling Heating Cooling Heating Cooling Heating Cooling Heating

600 (ALL) MCU+ kW kW AMPS AMPS AMPS kW kW A/PH A/PH* A/PH

20 15 1.2 2.0 6.4 8.3 23 -- -- -- -- -20 20 1.4 2.0 7.4 8.3 28 -- -- -- -- -20 30 1.7 2.0 8.6 8.3 37 1.7 2.0 4.1 8.3 19

40 30 1.7 2.0 8.6 8.3 37 1.7 2.0 4.1 8.3 19

40 40 2.2 2.0 10.7 8.3 51 2.1 2.0 5.3 8.3 23

40 50 2.1 2.0 9.4 8.3 59 2.0 2.0 4.7 8.3 27

60 40 2.2 2.0 10.7 8.3 51 2.1 2.0 5.3 8.3 23

60 50 2.1 2.0 9.4 8.3 59 2.0 2.0 4.7 8.3 27

60 60 2.5 2.0 10.5 8.3 63 2.4 2.0 4.7 8.3 33

With DCU+

1 Ph 230V 50Hz 3 Ph 400V 50Hz

MODEL

COMBINATION

INPUT

FULL LOAD

AMPS

SYSTEM

MAX.

STARTING

CURRENT

INPUT

FULL LOAD

AMPS

SYSTEM

MAX.

STARTING

CURRENT

Cooling Heating Cooling Heating

Cooling Heating Cooling Heating

600 (ALL) DCU+ kW kW AMPS AMPS AMPS kW kW A/PH A/PH* A/PH

20 15 1.4 2.0 6.6 8.3 25 -- -- -- -- --

20 20 1.5 2.0 7.4 8.3 29 -- -- -- -- --

20 30 1.8 2.0 9.0 8.3 37 1.9 2.0 4.1 8.3 19

40 30 1.9 2.0 9.0 8.3 37 1.9 2.0 4.1 8.3 19

40 40 2.4 2.0 11.3 8.3 51 2.4 2.0 5.2 8.3 24

40 50 3.0 2.0 11.8 8.3 52 2.5 2.0 5.0 8.3 23

60 40 2.4 2.0 11.3 8.3 51 2.4 2.0 5.2 8.3 24

60 50 3.0 2.0 11.8 8.3 52 2.5 2.0 5.0 8.3 23

60 60 3.2 2.0 15.1 8.3 61 3.2 2.0 6.4 8.3 26

With MHPUL/MHPUE

1 Ph 230V 50Hz 3 Ph 400V 50Hz

INPUT FULL LOAD AMPS INPUT FULL LOAD AMPS

MODEL

COMBINATION

STD.

MODEL

+ELECT

Heating

STD.

MODEL

+ELECT

Heating

SYSTEM

MAX.

STARTING

CURRENT

STD.

MODEL

+ELECT

Heating

STD.

MODEL

+ELECT

Heating

SYSTEM

MAX.

STARTING

CURRENT

600L / E MHPUL/E kW kW AMPS AMPS AMPS kW kW A/PH A/PH* A/PH

20 15 1.2 3.1 6.4 14.7 24 -- -- -- -- --

40 30 1.7 3.4 8.6 16.4 44 1.7 3.5 4.1 12.2 27

60 50 2.1 4.1 9.4 17.2 67 2.0 3.8 4.7 12.3 35

With DHPUE

1 Ph 230V 50Hz 3 Ph 400V 50Hz

INPUT FULL LOAD AMPS INPUT FULL LOAD AMPS

MODEL

COMBINATION

STD.

MODEL

+ELECT

Heating

STD.

MODEL

+ELECT

Heating

SYSTEM

MAX.

STARTING

CURRENT

STD.

MODEL

+ ELECT

Heating

STD.

MODEL

+ ELECT

Heating

SYSTEM

MAX.

STARTING

CURRENT

600E DHPUE kW kW AMP S AMPS AMPS kW kW A/PH A/PH* A/PH

20 15 1.4 3.3 4.9 12.9 24 -- -- -- -- --

40 30 1.8 3.7 8.9 16.9 45 1.8 3.7 4.1 12.1 27

60 50 2.5 4.4 11.8 19.8 59 2.5 4.3 5.4 13.2 32

Heronhill - for all your Marstair requirements

Tel: 01823 665660

www.heronhill.co.uk

Fax: 018123 665807

9/25

55208033-08

ELECTRICAL LOADS [ 230V 50Hz 1Ph (A) OR 400V 50Hz 3PhN (A/Ph)]

600 (ALL)

20 40 60

FAN MOTOR

0.5 0.5 0.5

LIFT PUMP (10 watts)

9mA 9mA 9mA

CONDENSATE PUMP (27.6 watts)

12.5mA 12.5mA 12.5mA

ELECTRIC HEATER (1kW) 4.2 4.2 4.2

ELECTRIC HEATER (2Kw) 8.3 8.3 8.3

FUSES

The system and its supply/interconnecting wiring must be protected by fuses, preferably High Rupture

Current (HRC) motor rated types (to BS EN60269) or miniature circuit breakers to (BS EN60898) or local

codes having similar time lag characteristics, that allow starting of the compressor yet still afford close

overcurrent protection under running conditions. The ratings below are for HRC motor rated fuses.

S= Standard units (no heaters) H= Electric heaters fitted

FUSES FOR ALL-ELECTRONIC SYSTEMS HAVING SEPARATE SUPPLIES

Provided that both indoor and outdoor units are electronic (ie. 600E matched with MHPUE or DHPUE) and

control cables between them are data cables, the units may be independently supplied and fused .

600

20E 40E 60E

1Ph Cool Only

5 5 5

1Ph with Electric Heating

10 10 10

FUSES FOR SYSTEMS WITH 1 PH

230V OUTDOOR UNITS (A)

600

20 40 60

MCU+

S H1 H2 S H1 H2 S H1 H2

15 16 16 16

20 16 16 16

30 16 16 16 16 16 16

40 20 20 20 20 20 20

50 16 16 16 16 16 16

60 20 20 20

DCU+ S H1 H2 S H1 H2 S H1 H2

15 16 16 16

20 16 16 16

30 16 16 16 16 16 16

40 20 20 20 20 20 20

50 25 25 25 25 25 25

60 25 25 25

MHPUE (L) S H1 H2 S H1 H2 S H1 H2

15 16 16 16

30 16 20 20

50 16 25 25

DHPUE S H1 H2 S H1 H2 S H1 H2

15 16 16 16

30 16 25 25

50 20 32 32

FUSES FOR SYSTEMS WITH 3PH

400V OUTDOOR UNITS (A/Ph)

600

20 40 60

MCU+

S H1 H2 S H1 H2 S H1 H2

30 10 10 10 10 10 10

40 10 10 10 10 10 10

50 10 10 10 10 10 10

60 10 10 10

DCU+ S H1 H2 S H1 H2 S H1 H2

30 10 10 10 10 10 10

40 10 10 10 10 10 10

50 10 10 10 10 10 10

60 16 16 16

MHPUE S H1 H2 S H1 H2 S H1 H2

30 10 16 16

50 10 16 16

DHPUE S H1 H2 S H1 H2 S H1 H2

30 10 16 16

50 10 20 20

MHPUL S H1 H2 S H1 H2 S H1 H2

30 10 16 16

50 10 16 16

Heronhill - for all your Marstair requirements

Tel: 01823 665660

www.heronhill.co.uk

Fax: 018123 665807

10/25

55208033-08

30

306

≥

580 x 580

610

300

675 x 675

187.5 187.5

INSTALLATION

CONTENTS

DIMENSIONS

Heronhill - for all your Marstair requirements

Tel: 01823 665660

www.heronhill.co.uk

Fax: 018123 665807

11/25

55208033-08

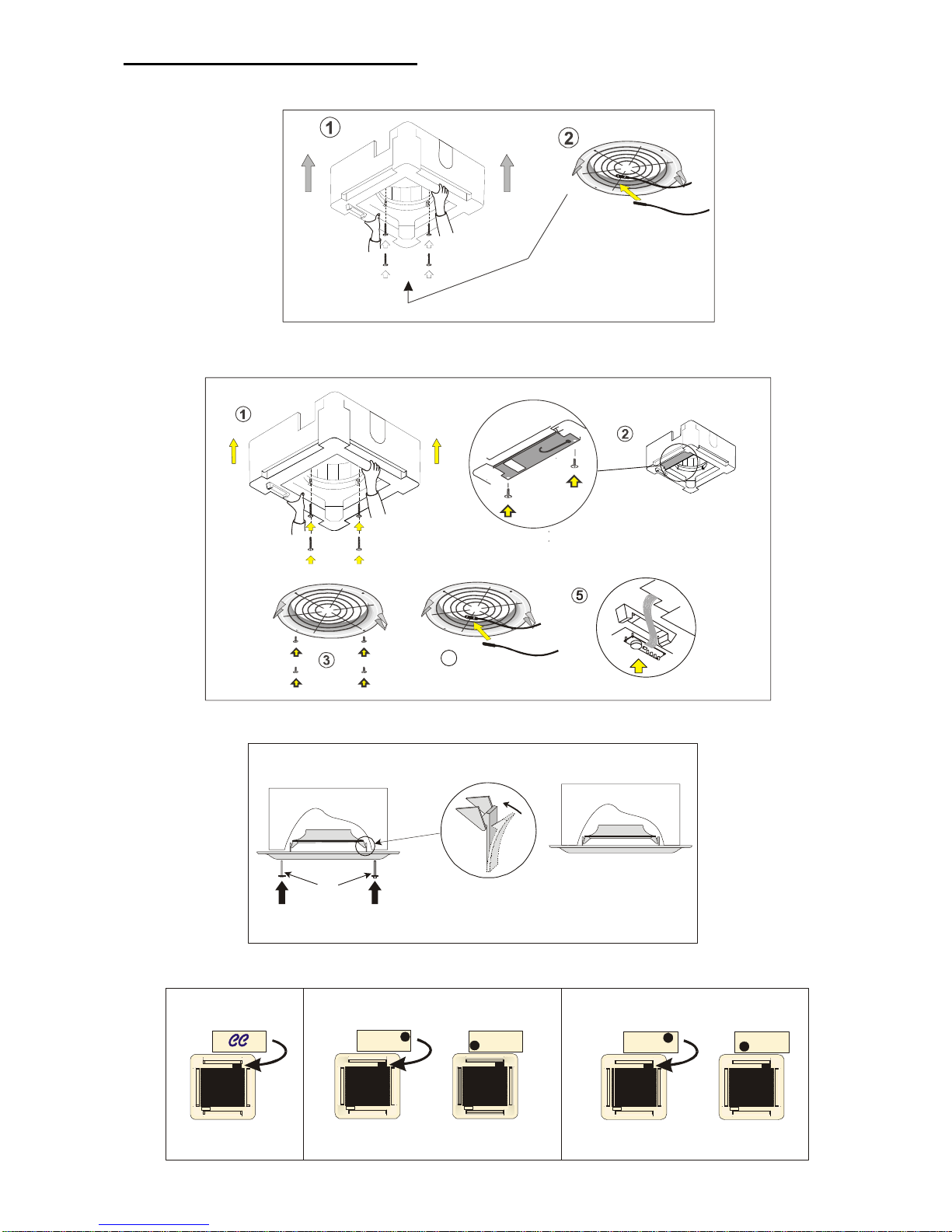

REMOVAL OF CHASSIS

600L & 600E

600E/M

MOUNTING

Heronhill - for all your Marstair requirements

Tel: 01823 665660

www.heronhill.co.uk

Fax: 018123 665807

12/25

55208033-08

PIPEWORK

HEATPUMP CONDITIONS

= NO RESTRICTOR CHANGE

NEEDED

Heat pump cooling conditions

MHPUE

IMAGE

600

COOLING

RESTRICTOR

FITTED

UK

CONDITIONS

NEMA

CONDITIONS

Heating

restrictor

fitted into the

expansion

assembly

15 20 033

035

30 40 040

039

50 60 052 051 051 041

Heat pump cooling conditions

DHPUE

IMAGE

600

COOLING

RESTRICTOR

FITTED

UK

CONDITIONS

NEMA

CONDITIONS

15 20 032

027

30 40 039

037

50 60 049

041

Heronhill - for all your Marstair requirements

Tel: 01823 665660

www.heronhill.co.uk

Fax: 018123 665807

13/25

55208033-08

REMOTE CONTROLLER

ON

Fan control is

temperature

dependent in

all operating

modes

Changeover

between

normal

operation and

energy saving

mode

Changeover

activated

when contact

of switch is

closed (NO)

Frost

protection

disabled

1K in heating

mode, 0.5K in

cooling mode

2K

OFF

Fan control in

normal

operation is

temperature

independent

Changeover

between

normal

operation and

standby

Changeover

activated when

contact of

switch is

opened (NC)

Frost

protection

enabled

4K in heating

mode, 2K in

cooling mode

5K

Function

Fan control

Operating

mode

changeover via

external switch

Action of

switch for

externally

operated mode

changeover

Standby

Switching

differential

Dead zone in

normal

operation

Switch 1 2 3 4 5 6

█ =Factory setting

Heronhill - for all your Marstair requirements

Tel: 01823 665660

www.heronhill.co.uk

Fax: 018123 665807

14/25

55208033-08

Heronhill - for all your Marstair requirements

Tel: 01823 665660

www.heronhill.co.uk

Fax: 018123 665807

15/25

55208033-08

600

600

POWER - TO SUIT SUPPLY FUSE

INTERNAL

SIGNAL - 230 V (0.75 - 2.5 mm²)

SIGNAL - 230 V ( - 2.5 mm²)

0.5

C

PENLPE N L

PE N L

C

3

PENL1 L2 L3

L / L1

3 PE N L

C

PE N L

FUSED SUPPLY (230V 1Ph 50Hz)

FUSED SUPPLY (400V 3Ph 50Hz)

N 7 53 4

L Q2Q3 Q1Y11 Y21NMB1

OPTIONAL REMOTE RETURN AIR SENSOR

(97200212)

97200212

6 N 72 53 4

30

25

20

15

10

L Q2Q3 Q1Y11 Y21NMB1

6

1Ph MCU+ / DCU+ 3Ph MCU+ / DCU+

30

25

20

15

10

LOW

MEDIUM

HIGH

Factory

Settings

FAN SPEED SELECTION

INTERCONNECTING WIRING

Heronhill - for all your Marstair requirements

Tel: 01823 665660

www.heronhill.co.uk

Fax: 018123 665807

16/25

55208033-08

230 V 50 Hz

<10 V DATA

+

0.75mm² MAX

230 V 50 Ø

<10 V DATA

MHPUE / DHPUE

OR INDEPENDENT FUSED SUPPLY

PE

PENNL1 L1

1Ø MHPUE / DHPUE

PCBA

DATA

OK

PENL1

1Ø DCU+ / MCU+

600E

600E

600E

600E

L1NPE

3 PE N L1

C PE N

DATA

21

FUSED SUPPLY (230V 1Ø 50Hz) FUSED SUPPLY (230V 1Ø 50Hz)

3Ø DCU+/ MCU+

PENL1 L2 L33 PE N L2L2L1

L1

C

PE N

FUSED SUPPLY (400V 3Ø 50Hz)

L2

DATA

21

OR INDEPENDENT FUSED SUPPLY

L1

3Ø MHPUE / DHPUE

PENL1L1 L3PE N

PCBA

DATA

OK

FUSED SUPPLY (400V 3Ø 50Hz)

L2 L2

L1

55200301 EMC TERMINATION GLAND

BMS

BMS +

ALARM

NETWORK

x 3

x 1 x 1

x 2

x 2

x 1

x 1

53800402

<10 V

DATA

Heronhill - for all your Marstair requirements

Tel: 01823 665660

www.heronhill.co.uk

Fax: 018123 665807

17/25

55208033-08

NOTE: Refer to page 9 for fuse ratings.

230 V 50 Hz

<10 V DATA

+

0.75mm² MAX

230 V 50 Ø

<10 V DATA

MHPUE / DCUE / DHPUE

PENL1

1 MCU+ / DCUE

ø

PE N L1

PE N L

3

FUSED SUPPLY (230V 1Ø 50Hz)

600L

600L

600L

600L

600L

600L

600L

600L

3 MCU+ / DCUE

ø

PENL1 L2 L33 PE N L2 L1

L

PE N

FUSED SUPPLY (400V 3Ø 50Hz)

3 MHPUL

ø

OK

PENL1 L2 L3PE N L2 L1

L

PE N

SS

S S

1 3

7

FUSED SUPPLY (400V 3Ø 50Hz)

PE PENNL1 L1

1 MHPUL

ø

OK

NPE

SS

S S

1

1

1

3

C

C

7

RV

RV

FUSED SUPPLY (230V 1Ø 50Hz)

L

C

RV

C

RV

Heronhill - for all your Marstair requirements

Tel: 01823 665660

www.heronhill.co.uk

Fax: 018123 665807

18/25

55208033-08

x 4

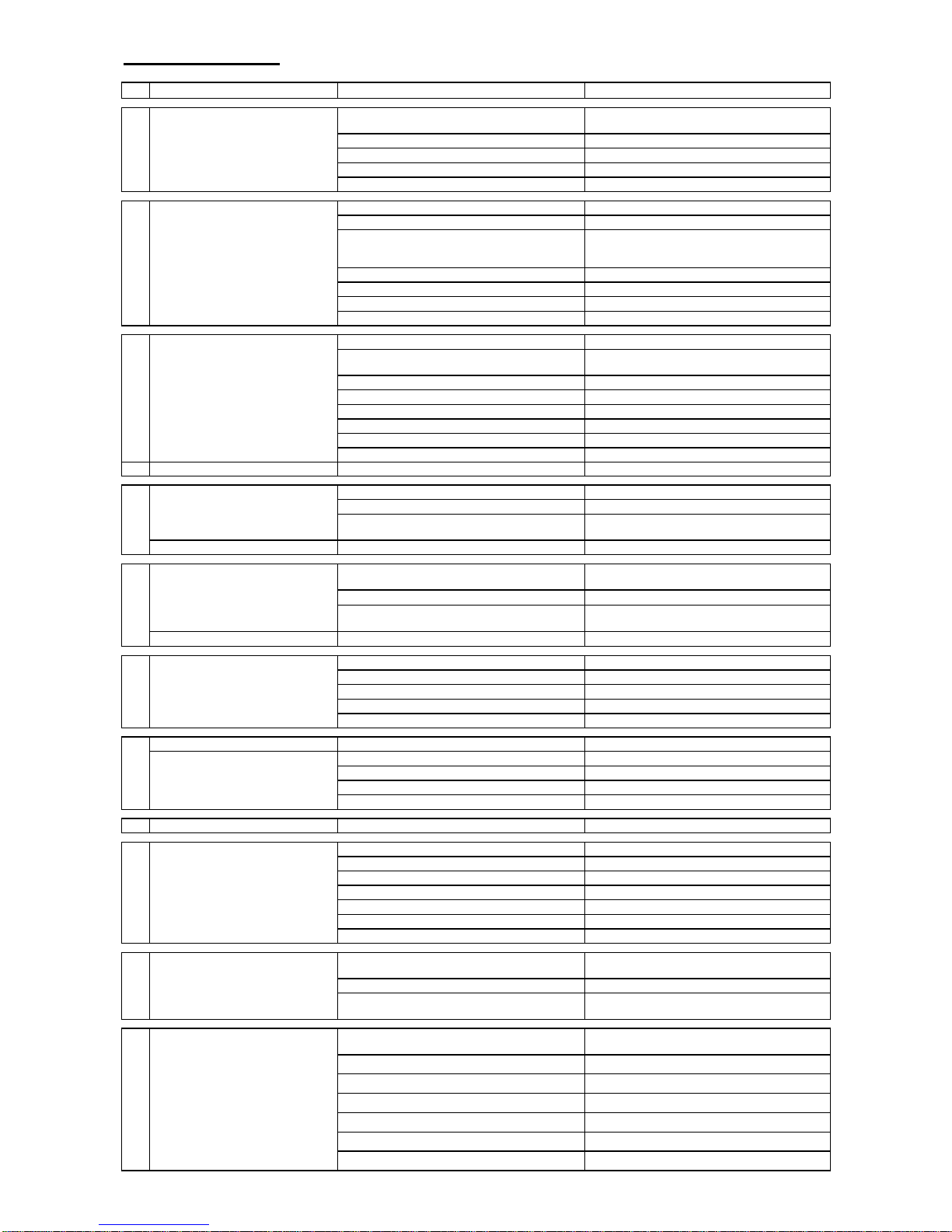

FITTING THE FASCIA

600 L & 600 E

4

600E/M

DI4F

D

I4F

☺

☺

CFD

C

FD

☺

600E/M 600 E600 L

REINSTALLING THE CHASSIS

Heronhill - for all your Marstair requirements

Tel: 01823 665660

www.heronhill.co.uk

Fax: 018123 665807

19/25

55208033-08

CONDENSATE DRAIN PIPING

Heronhill - for all your Marstair requirements

Tel: 01823 665660

www.heronhill.co.uk

Fax: 018123 665807

20/25

55208033-08

(Cold)

USER MAINTENANCE

ISOLATE THE UNIT ELECTRICALLY BEFORE COMMENCING ANY WORK

We recommend that in order to maintain maximum efficiency of this unit, it’s important that the filter behind

the return air grille is cleaned regularly.

THE UNIT SHOULD ALWAYS BE USED WITH A FILTER. FAILURE TO DO SO WILL CAUSE A

DECLINE IN UNIT PERFORMANCE AND MAY RESULT IN MALFUNCTION.

It is recommended that in order to prolong life and maintain performance of the unit, it is regulary serviced by

a TEV installer / dealer.

Heronhill - for all your Marstair requirements

Tel: 01823 665660

www.heronhill.co.uk

Fax: 018123 665807

21/25

55208033-08

FAULT FINDING

CONDITION POSSIBLE CAUSE ACTION

A Indoor fan motor will not run No electric supply at socket or switched fuse box

Check fuse rating and replace if necessary. Check

for loose electrical connections

Unit wiring fault Check wiring and connections

Fan motor capacitor defective Replace if faulty

Fan motor defective Replace if faulty

Internal fuse blown Clear fault and replace fuse

B Inadequate cooling or heating Dirty evaporator fins/filter Clean if blocked

Evaporator motor not running As in section A

Refrigerant shortage or excess

Check for leaks. Repair, evacuate and recharge or

check for high head pressure and recover refrigerant

if necessary

Faulty or incorrectly set thermostat Replace if faulty

Dirty condenser Clean if necessary

Faulty compressor Replace

LP cutout circuit open (if LP fitted) Check as refrigerant shortage or excess

C Compressor and outdoor fan motor LP cutout circuit open (if LP fitted) Check as above

will not run No electric supply at socket or switch fuse box

Check fuse rating and replace if necessary. Check

for loose electrical connection.

Unit wiring fault Check wiring and connections

Capacitor, thermostat, relay or overload defective Replace if faulty

Compressor failure Replace if faulty

Controls not set properly Check and rectify

Off cycle delay operating If applicable, wait 3 minutes

High condensate level detected See G

Compressor runs, outdoor fan doesn't Pressure at sensor <200psig Normal: or short of gas

D System runs for long periods and will Unit underrated for conditioned area Check heat load against capacity

not cycle Thermostat not operating correctly Check wiring, position of phial and operation

Refrigerant shortage

Check for leaks. Recover, repair, evacuate and

recharge

Indoor coil dry or partly sweating Dirty condenser Clean fins if necessary

E Indoor coil frosting Refrigerant shortage

Check for leaks. Recover, repair, evacuate and

recharge

Dirty evaporator fins/filter Clean if blocked

Running in cool ambient without a head pressure

controller

Fit head pressure controller

If room temperature is also low Thermostat set too low or cooling permanently Reset or replace

F Noisy unit Fan fouling cowl (outdoor unit) Realign fan

Worn motor bearing Replace motor

Casing or piping vibration Check cause and rectify

Loose parts or mounting Find and tighten

Bent fan blade Replace fan

G Water leaking from unit Blocked drain or filter Clear obstruction

Units with lift pump or condensate pump No supply to pump or loose connection Secure the supply

Pumping slowly Check drain pipes; if clear, replace pump

Pump windings shorted Replace pump

Fouled sensor (5m condensate pump only) Clean sensor

H Pump always runs Faulty sensor or pcb Replace sensor or pcb

I No heating Controls not set for heating Reset

Unit wiring fault Check wiring and connections

Dirty evaporator fins/filter Clean

Faulty thermostat Check for signal; replace if faulty

Faulty heater element Replace

Faulty heater cutout Replace, (check for short circuiting)

Reversing valve jammed A light tap may free it; preferably replace

J

Overload tripped on three phase

units

High voltage supply Max rated voltage 254v -- check supply

Compressor failure Replace

Fuses blown

Replace fuses and investigate reason for fuses

blowing

K Outdoor unit does not operate No mains supply

Check fuse rating and replace. Check for loose

electrical connections

Supply below 187V Check supply

Isolator switched off Turn isolator on

Internal fuse blown Check fuse and replace

Data wires disconnected Reconnect data wires

No command signal Check indoor unit

Off cycle delay operating Wait in cooling for 3 minutes

Heronhill - for all your Marstair requirements

Tel: 01823 665660

www.heronhill.co.uk

Fax: 018123 665807

22/25

55208033-08

SPECIFIC FAULT DIAGNOSIS FOR L UNITS

CONDITION POSSIBLE CAUSE ACTION

Check for alarms

i LEDs flashing - see table below

ii

If NO external connections are made to alarm terminal 5, the presence of an alarm condition can be tested for by checking for mains voltage at

terminal 5; full mains voltage = Alarm; less than mains voltage = Clear.

The outdoor unit can be caused to operate for test purposes by temporarily linking live directly to terminal 3

(up to 20 seconds delay)

L Outdoor unit runs continually at high Charge link still fitted Remove charge link

speed MHPUL in heating Normal

Minimum speed adjustment set too high Reset minimum speed

If all external devices test O.K. the outdoor unit pcb must be replaced

M No LED's lit or flashing Unit commanded to be OFF Transmit 'ON'

No mains supply or internal fuse blown. (Fuse F2

on internal control board blown during configuring)

Check electrical supply and fuses

Fan motor plug disconnected Reconnect fan motor plug

Motor internal thermal protector operated Check motor and rectify

Cables to fascia not connected Reconnect

Circuit board fault Check circuit board and replace

High water level Check pump circuit (if fitted)

N All LED's lit, one flashing Temperature sensor problem See table below

Resistor problem (non MHPUL) Check resistor connected

Outdoor sensor problem (MHPUL)

Replace outdoor unit sensor/check

interconnecting wiring

P

Indoor unit continues after stop/off

Overrun of 30 seconds in heating Normal

Q

Unit will not respond to infrared commands.

Battery discharged Replace battery

Handset corrupted Reset

R

Unit does not switch on/off at

intended times

Power cut has occurred

Send any command from the handset to

synchronise the timer

S

Unit not running in intended

mode/temperature

Power has been shut off for three or more days,

unit is exercising default programme

Use handset retransmit button

T

Fan does not run at the intended

speed

Heat Pumps Only

Fan runs at low speed until indoor coil is warm,

then changes to intended speed

U Short cycles between cool and heat System oversized for room Use cool or heat programmes NOT 'Auto'

V

First operation, room is overcooled

or overheated by 2°C

Set point temperature reverts to normal after

deadband is reached or 20 minutes of

operation

Normal

W Handset will not transmit Heating commands Incorrectly configured - see page 23

Any commands Battery flat

X Compressor runs on Automatic minimum run time of 1.5 minutes Normal

HANDSET

If the handset fails to respond to button operations, disconnect and then reconnect the battery.

The previous programme state is retained in the memory for a few seconds provided none of the user buttons are pressed.

LED STATUS AND ALARM INDICATIONS

Cool Dry Fan Heat DIAGNOSTICS

D I 4 F

Green Red Red Amber

OFF OFF OFF OFF

No power, manual OFF, timed OFF, condensate

high level, fault in condensate control

ON OFF ON OFF Cooling mode selected

ON OFF ON BLINKS AUTO - predominantly cooling

OFF OFF ON ON Heating mode selected

BLINKS OFF ON ON AUTO - predominantly heating

OFF OFF ON OFF Fan mode selected

OFF ON ON OFF Dry mode selected

OFF OFF OFF BLINKS Outdoor unit defrosting

Diagnostics

OFF OFF BLINKS x 4 OFF Room sensor missing

OFF OFF BLINKS x 4 OFF Indoor coil sensor missing

OFF BLINKS BLINKS x 4 OFF Heat pump only, outdoor coil sensor missing

BLINKS OFF BLINKS x 1 OFF Compressor overload

Heronhill - for all your Marstair requirements

Tel: 01823 665660

www.heronhill.co.uk

Fax: 018123 665807

23/25

55208033-08

SPECIFIC FAULT DIAGNOSIS FOR E UNITS

A fully electronic system comprising 600 E with MHPUE or DCUE communicates between the units by digital codes. Signals are transmitted every 10

seconds, therefore a delay of up to 10 seconds could occur before the system responds to a command. Similarly if the communication link is broken, the

outdoor unit will shut down within 15 seconds. To reset: Switch the mains off to both indoor and outdoor units to reset the microprocessor; the current

programme is retained in the indoor pcb memory.

Check for alarms i.e.

i Audible alarm or LEDs flashing - see table below

ii

If NO external connections are made to alarm terminal 5, the presence of an alarm condition can be checked for by testing continuity between L and

5; Alarm = 220ohms, Clear = open circuit. WARNING: All parts of the circuit are at high voltage, if any external connections are made to terminal 5,

the continuity meter will be damaged

The outdoor unit can be forced to operate for test purposes by temporarily linking live directly to terminal 3

(up to 20 seconds delay)

L Outdoor unit runs Charge link JP6 still fitted Remove JP6 charge link

continually at high speed MHPUE in heating Normal

Minimum speed adjustment set too high Reset minimum speed

If all external devices appear O.K. the pcb may need to be replaced

M No LED's lit or flashing No mains supply or internal fuse blown Check electrical supply and fuses

Fan motor plug disconnected Reconnect fan motor plug

Motor internal thermal protector operated Check motor and rectify

Ribbon cable to fascia not connected Reconnect

Receiver pcb fault Check circuit board and replace

N

Regular audible pulsed signal -

all LED's lit

Indoor temperature sensor problem

Disconnect data link to identify which unit, if fault

clears it is outdoor unit

Outdoor sensor problem Replace outdoor unit sensor

O

Indoor unit continues after stop/off

command

Overrun of 30 seconds in heating NORMAL

P

Unit will not respond to infrared

commands.

No audible answer signal

Handset not plugged into wall bracket (if

appropriate). Fault in connections between wall

bracket and indoor unit

Plug in correctly and check connections

Battery discharged Replace battery

Operating in charge mode Remove charge link from outdoor unit

Q

Unit answers infrared commands

with double audible signal

Communications not yet established. Wait 2 minutes

from power up

If electric heater is known to be fitted, double signal

indicates open circuit element or thermal protector

Demanded mode not available

Double signal in response to on/off command

indicates under time control

R

Sounder beeps and LED(s) flash 0.5s

ON, 0.5s OFF

Warning of alarm status See table below

S

All LED's lit and continuous audible

signal

Microprocessor fault Replace indoor unit pcb assembly

T Short cycles between cool and heat System oversized for room

Use cool or heat programmes NOT 'Auto' and set to

lower speed

HANDSET

If the handset fails to respond to button operations, disconnect and then reconnect the battery.

The previous programme state is retained in the memory.

LED STATUS AND ALARM INDICATIONS

Status display LED

Flash Rate

ON/OFF

(seconds)

Sounder Condition Status

Red Amber Green

C

ON OFF In Operation Normal

C F

ON OFF Heating Demand Normal

C

D

ON OFF Cooling Demand Normal

C

0.5 / 5.0 OFF Standby Normal

C

0.5 / 15 OFF Clock Controlled Standby Normal

C

2 x 0.5 / 15 OFF Setback Normal

C

0.5 / 0.5 OFF Filter Clean Advisable Normal

Alarm indications

F

0.5 / 0.5 BEEPS Network Warning Call Engineer

D 0.5 / 0.5 BEEPS High Condensate Level Call Engineer

C F

0.5 / 0.5 BEEPS Low Pressure Warning Call Engineer

C

D

0.5 / 0.5 BEEPS High Pressure Warning Call Engineer

C F D

0.5 / 0.5 BEEPS

Contactor Overload

Operated

Call Engineer

F D

0.5 / 0.5 BEEPS Outdoor Fan Fail Call Engineer

C F D

ON BEEPS Sensor Fault Call Engineer

Heronhill - for all your Marstair requirements

Tel: 01823 665660

www.heronhill.co.uk

Fax: 018123 665807

24/25

55208033-08

COMPONENT IDENTIFICATION

CHASSIS ASSEMBLY

1 Top panel

2 Suspension bracket

3 Capacitor

4 Fan motor

5 5m condensate pump

6

5m condensate pump PCB

and filter

7 Heat exchanger

8 Coil blanking panel

9 Electric box cover

10 External electrics box

11 Chassis

12 Fresh air cover

13 Fan

14 Coil bracket

15 Heater bracket/clip

16 Fan cowl

17 Fan guard

18 Heater element

19 Heater cut out

20 Thermal fuse

21 Internal electrics cover

22 PCBA

23 Receiver board

24 Threaded bung

25 Pipe panel

26 Lift pump

27 Float switch

28 Lift pump PCB bracket

29 Lift pump condensate PCBA

30 Motor mounts

Heronhill - for all your Marstair requirements

Tel: 01823 665660

www.heronhill.co.uk

Fax: 018123 665807

25/25

55208033-08

TEV LTD, ARMYTAGE ROAD, BRIGHOUSE, WEST YORKSHIRE, HD6 1QF. + 44 (0) 1484 405600 +44 (0) 1484 405620

sales@marstair.com www.marstair.com

TEL: FAX:

EMAIL: WEB:

FASCIA ASSEMBLY

1

LED lens/cover

8

Vane bearing

2

Fascia

9

Vane connector

3

Grille

10

Vane motor

4

Filter

11

Double yoke

5

Badge

12

Spider

6

Air deflector vane

13

Actuator arm

7

Vane end cap

Heronhill - for all your Marstair requirements

Tel: 01823 665660

www.heronhill.co.uk

Fax: 018123 665807

Loading...

Loading...