Page 1

MP-4V Heavy Duty Riveter / 39048

Alcoa Fastening Systems

1925 N MacArthur Dr

Suite 200

Tracy, CA 95376

This newly designed heavy-duty air/hydraulic riveter is

ergonomically designed with the professional in mind. The light

weight 3.7 lbs. well balanced MP-4V includes a Vacuum system

and is designed to maximize a 1” stroke and 3,420 lbs. of pulling

force with a 3 jaw setup that gets the job done. The air supply can

be connected directly or you can use the supplied swivel air

connector with the attached hose for operator convenience. Each

tool is supplied with nosepieces to set 5/32”- 1/4” rivets in all

alloys. A 1/4" monobolt nosepiece is included in addition to

adjustment service wrenches, hydraulic fluid, fluid applicator,

spare jaws and an air off/on valve. The adjustable Vacuum

System control knob located on the side of the tool allows you to

control the force of the air needed to hold the rivet in place or you

may operate with the vacuum system turned off.

Recommended air pressure is 70-95 PSI.

Page 2

1. Connect air supply then switch ON/OFF valve

to ON position

2. To turn on and adjust vacuum system rotate silver

knob on side of tool and turn it clockwise until

desired amount of vacuum is obtained to hold rivet

in place and eject spent mandrel into the collection

cup. If you don't want to use the vacuum system

rotate the silver knob counter-clockwise to shut it

off. The tool will still function but must be tilted

backwards to allow spent mandrel to fail into

collection cup.

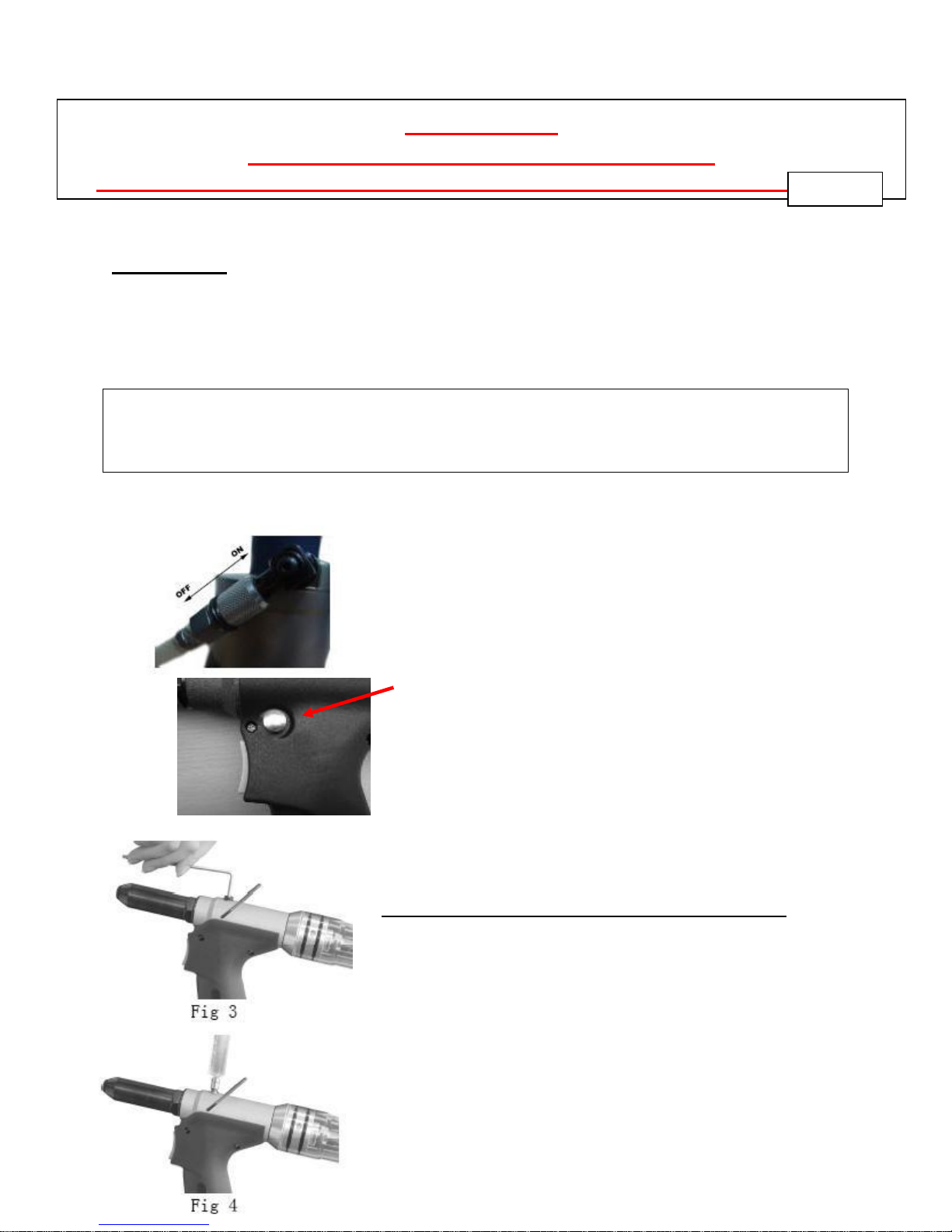

ADDITION OF HYDRAULIC FLUID

1. Disconnect air supply to tool and switch ON/OFF valve to

OFF position.

2. Remove seal screw and seal (see Fig. 3)

3. Screw the priming pump of filled oil into the bleed screw

hole. Actuate the priming pump by pressing down and

releasing several times until resistance is felt. (Fig. 4)

4. Remove the priming pump and the excessive oil will flow

out. Wipe away and clean out the excessive oil and replace

the seal and screw.

WARNING:

ALWAYS WEAR SAFETY GLASSES

WHEN OPERATING AND PERFORMING MAINTENANCE ON TOOL

LA-534

AIR FEED

Use only compressed air. Check airline for damage from humidity &

contaminants. In order to protect the tool from premature wear, we

recommend the use of a filter, lubricator & regulator. Air connection

size ¼” NPT.

WARNING:

Do not use air supply greater than recommended or tool

may be damaged or burst.

Page 3

WARNING:

ALWAYS WEAR SAFETY GLASSES

WHEN OPERATING AND PERFORMING MAINTENANCE ON TOOL

CHANGING NOSEPIECES

1. After selecting the correct size nosepiece for the rivet being used

Connect tool to air supply and pull trigger and hold trigger button.

2. Using wrench (supplied), unscrew nosepiece from frame head &

replace with proper size nosepiece. Tighten down with wrench. DO

NOT OVERTIGHTEN. Release trigger.

Your tool is now ready to work. Insert rivet mandrel into nosepiece. Insert

rivet into predrilled hole in application and pull trigger button and hold until

rivet sets then release the trigger. A second pull may be required.

CLEANING & CHANGING OF JAWS

With use, the jaws of the tool may become dirty or worn. This will cause

slipping of the rivet mandrel & and improper setting of the rivet. To clean

the jaws follow this procedure.

1. Disconnect air supply.

2. Use a suitable wrench, unscrew frame head and remove.

3. Using a pair of wrenches, disassemble front jaw case from rear jaw case.

DO NOT MOVE rear jaw case as this will affect tool operation.

4. To clean jaws, use a stiff dry wire brush.

5. If excessive wear is apparent, replace with new jaws.

6. Reassemble the jaw case assembly.

Page 4

Part Number

AFS Part No.

Description

1

M95300

5/32" Nosepiece

1

M95301

3/16" Nosepiece

1

M95302

1/4" Nosepiece (Standard)

1

M95303

1/4" Nosepiece(Monobolt)

2

M95304

O-Ring (meas.9x1)

3

M95305

Nosepiece casing

4

M95306

O-Ring (meas.22x2)

5

M95307

Jaw housing

6

M95308

Jaws (3pcs)

7

M95309

Pusher 8 M95310

Washer 9 M95311

Jaw pusher spring

10

M95312

Lock ring

11

M95313

Housing

12

M95314

Polyurethane ring (meas. 16x2)

13

M95315

Set nut

14

M95316

Polyurethane ring (meas. 14.3x2)

Page 5

Part Number

AFS Part No.

Description

15

M95317

O-Ring (meas. 13x16x1.5)

16

M95318

Vacuum sleeve

17

M95319

Seal plastic housing

18

M95320

Sealing ring (meas.2 5x13.5x3.5)

19

M95321

Head assembly

20

M95322

Lip Seal (meas.14x11x6.3)

21

M95323

O-Ring 48

22

M95324

O-Ring (meas. 26.7x3 26x1.78)

23

M95325

Lip Seal (22x30x6)

24

M95326

Axis

25

M95327

Buffer

26

M95328

O-Ring (meas.35x1.5)

27

M95329

EL(meas. 8x14x5)

28

M95330

End cap

29

M95331

Plastic ring (3 3x21x1.8)

30

M95332

Stem collector adaptor

31

M95333

O-Ring (meas.24x2)

32

M95334

O-Ring (meas.47x1.5)

33

M95335

Stem collector outer

34

M95336

Stem Collector body

35

M95337

Retaining nut

36

M95338

Silencer

37

M95339

Stem collector end cap

38

M95340

Silence

39

M95341

Silencer cap

40

M95342

Handle (left)

41

M95343

Handle (right)

42

M95344

Trigger

43

M95345

Trigger valve

44

M95346

On/Off base

45

M95347

O-Ring (meas.6x1)

46

M95348

Air interface

47

M95349

Tie ring

48

M95350

Air tube

49

M95351

Regulatable button

50

M95352

Retaining screw (meas.3x3)

51

M95353

Vacuum valve

52

M95354

O-Ring (meas. 4x6x1)

53

M95355

Tapping screw (meas.3x10)

Page 6

IF further maintenance is beyond the scope of this direction sheet and the tool fails to

function properly, contact the factory or return it to the factory for service. Contact our Tool

Repair Center at 317-704-8874 for further information.

LIMITED TOOL WARRANTY

Alcoa Fastening Systems - Marson division warrants that this tool will be free from defects

in material and workmanship under normal service and for ninety (90) days from the date

of purchase. This warranty applies to the purchaser of the tool for original use only. All

other warranties, whether expressed or implied, including any warranties of merchantability

or fitness for purpose are hereby excluded.

Should this tool fail during this ninety (90) day period, and no unauthorized repairs have

been made, return the tool freight prepaid to the factory for free of charge replacement of

any part or parts found by Alcoa Fastening System - Marson division to be defective due to

faulty material or workmanship. This represents the sole obligation of Alcoa Fastening

Systems - Marson under this warranty. In no event shall Alcoa Fastening Systems - Marson

division be liable for any consequential or special damages arising from the purchase or use

of this tool. You may have other rights which vary from state to state.

Loading...

Loading...