Page 1

WS570

R10-15-12

OPERATIONS MANUAL

AND PARTS BOOK

EDI-13261 PART# SW100H

Marshalltown, IA

Phone 800-888-0127 / 641-753-0127

Fax 800-477-6341 / 641-753-6341

www.marshalltown.com

1 of 16

Page 2

TABLE OF CONTENTS

Safety Precaution...............................................2

Common Components ...........................................3

Assembly Instructions .........................................4-6

Machine Adjustments............................................7

Parts Breakdown .............................................8-9

Wet Screeding ................................................10

Form to Form Screeding ........................................11

Technical Data/Capacities .......................................12

Maintenance Schedule..........................................12

How to Operate ............................................13-14

Warranty.....................................................15

This machine was built with user safety in mind, however, it can present hazards if improperly operated and serviced. Follow

operating instructions carefully and use good judgement when operating!

If you have questions about operating or servicing this equipment, please contact your Marshalltown distributor or Marshalltown

Company at 800-888-0127 or 641-753-0127

.

SAFETY PRECAUTION

ALWAYS

• Always stop engine between loads of concrete

• Always screed while walking backwards

• Always clearly mark and be aware of all grade pins,

form stakes or other trip hazards

• Always follow all safety warnings and labels of the

engine manufacturer

• Always read and understand the owners manual of

the engine manufacturer

• Always wear approved hearing, eye and breathing protection

• Always use form oil to coat blade or other parts susceptible

to concrete build up (avoiding electrical connections) before

each use

• Always properly secure screed before transporting

• Always follow recommended maintenance schedules

• Always make sure all connections and fasteners are tight

before every use

• Always always make sure engine is in "OFF" position when

servicing or not in use

• Always use in a well ventilated area

• Always keep Shockwave™ and engine manual handy

on the job site

• Always replace parts as they become damaged or worn

2 of 16

104 S. 8th Ave. Marshalltown, IA Phone 800-888-0127 / 641-753-0127 • Fax 800-477-6341 / 641-753-6341 www.

NEVER

• Never operate screed without all parts and safety

covers correctly attached

• Never allow children to operate

• Never operate under the influence of drugs or alcohol

• Never use screed for anything other than its

intended purpose

• Never set eccentric weights to where excessive vibration

occurs at low RPM (weights too far open)

• Never set eccentric weights to where it takes excessive

RPM to make weights vibrate (weights too far closed)

• Never allow engine to run unattended or idle on

top of wet concrete

• Never place concrete higher than the leading

“curl edge” of the blade

• Never fill gas tank while engine is running

• Never start engine near spilt fuel

• Never fill gas tank, operate, or service screed

near open flame

• Never use parts or blades from other manufacturers

• Never service a hot engine

• Never operate without proper training

• Never spray water or other liquid on a hot engine

marshalltown

.com

R10-15-12

WS570

Page 3

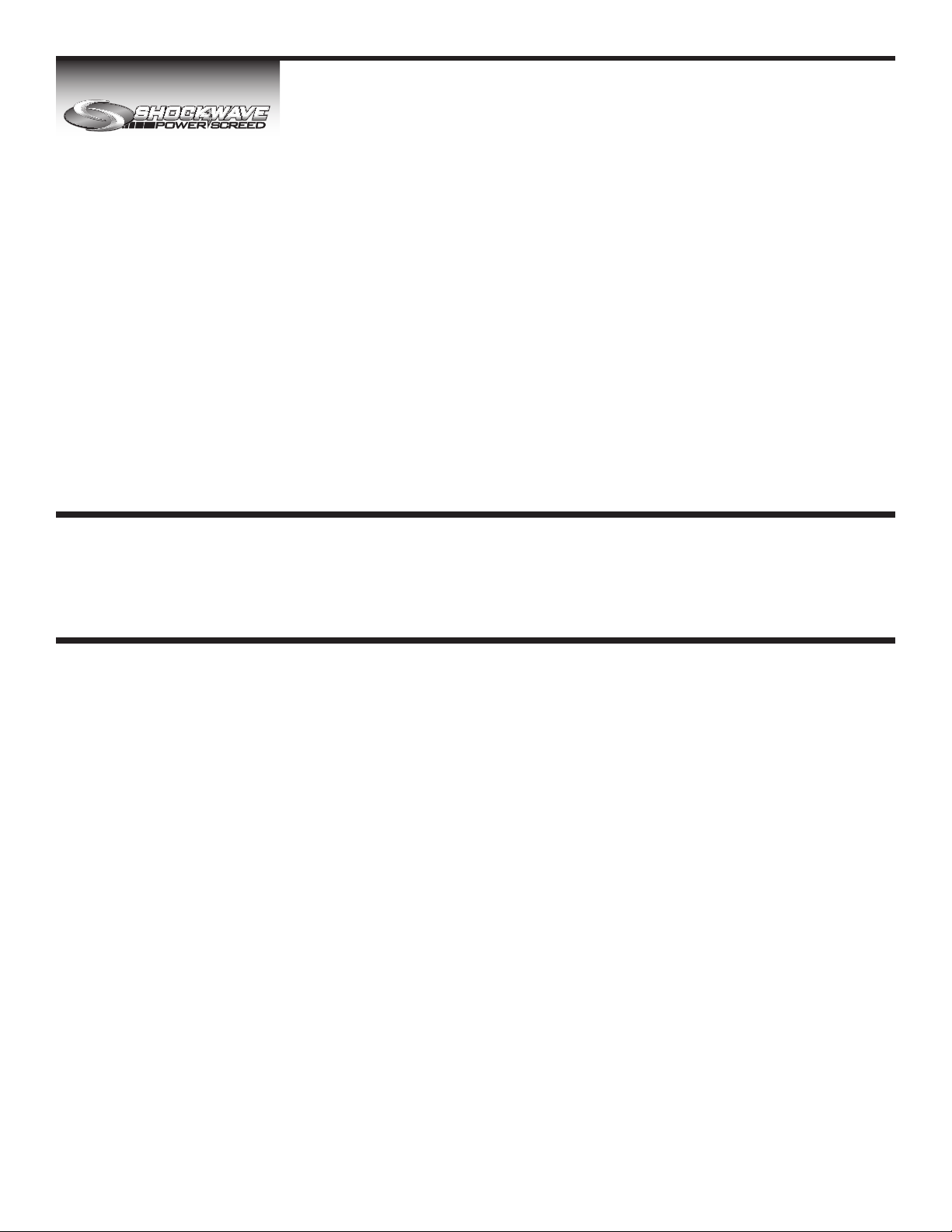

COMMON COMPONENTS

The Premier Line

1.

Start/Stop Switch

2.

Engine

3.

Recoil Starter

4.

Oil Cap

5.

Gas Cap

6.

Throttle Lever

7.

Handle Bar Mounting Blocks

8.

Handle Bars

9.

Adjustable Hand Grips

10.

Kickstand

11.

Drive Shaft

12.

Vibration Dampeners

13.

Blade

14.

Eccentric Weight Cover

15.

Frame

16.

Lifting Bar

17.

Tachometer/Hour Meter

18.

Board Mounting Plate

19.

Throttle Cable

20.

Air Filter

6

19

20

9

16

8

3

5

4

2

10

1

17

15

18

7

12

13

14

11

12

WS570

R10-15-12

104 S. 8th Ave. Marshalltown, IA Phone 800-888-0127 / 641-753-0127 • Fax 800-477-6341 / 641-753-6341 www.

marshalltown

.com

3 of 16

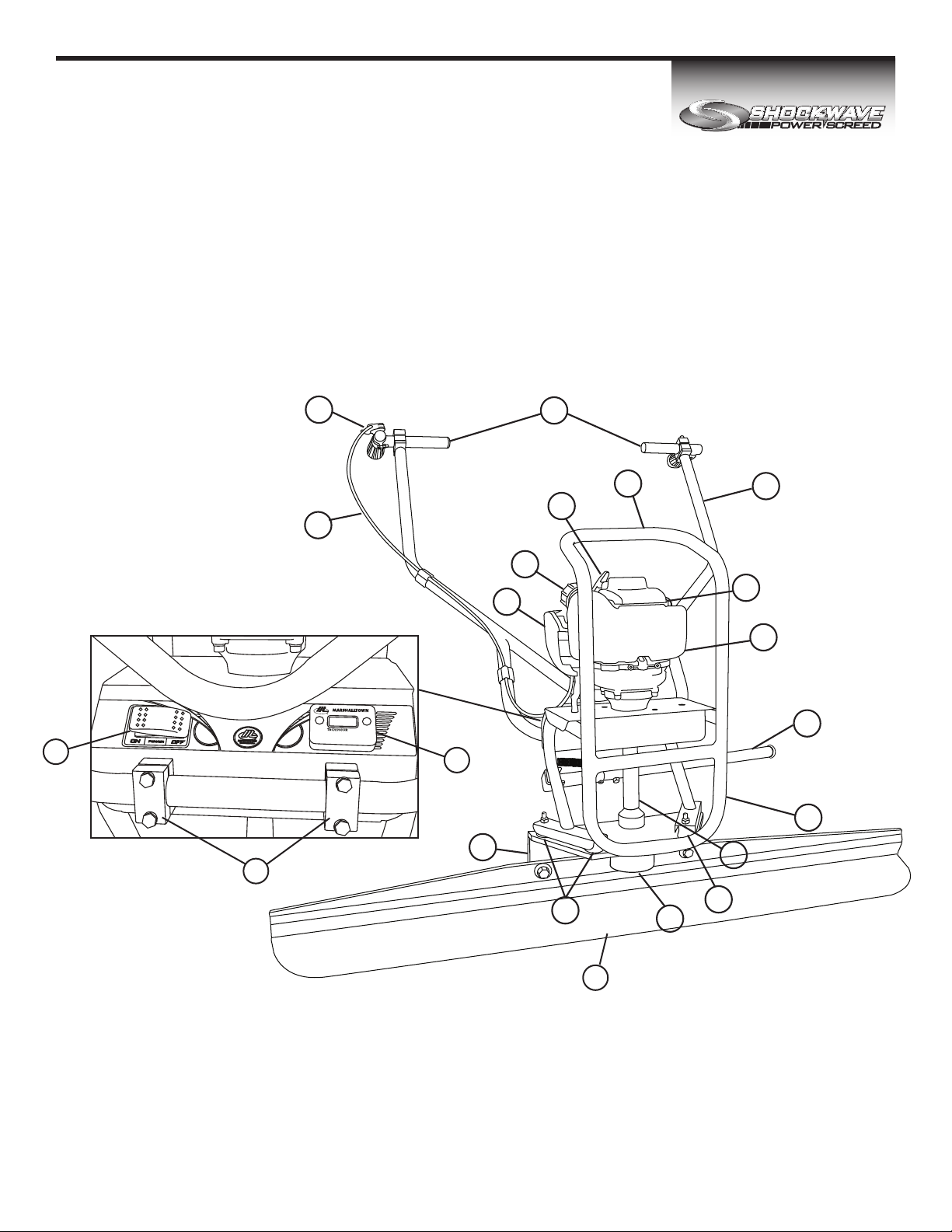

Page 4

ASSEMBLY INSTRUCTIONS

Your Shockwave™ Screed power unit ships in two boxes, one containing the

handle bars and the other containing the power unit. Assembly is easy,

following these steps:

INSTALLING HANDLE BARS AND KICKSTAND:

Step 1 –

handle mounting blocks

Remove the 4 hex screws (A) that hold down the two

.

Step 2 – Slide kickstand arm onto kickstand end and fasten

with nut & bolt (B) as shown

Step 3 – Place handle bars into mounting blocks, making sure

handle bars are centered evenly across the mounting blocks.

A

B

Step 4 – Making sure all mounting block and frame holes are

aligned, insert hex screws and tighten with 7/16" wrench or

socket.

4 of 16

104 S. 8th Ave. Marshalltown, IA Phone 800-888-0127 / 641-753-0127 • Fax 800-477-6341 / 641-753-6341 www.

marshalltown

.com

WS570

R10-15-12

Page 5

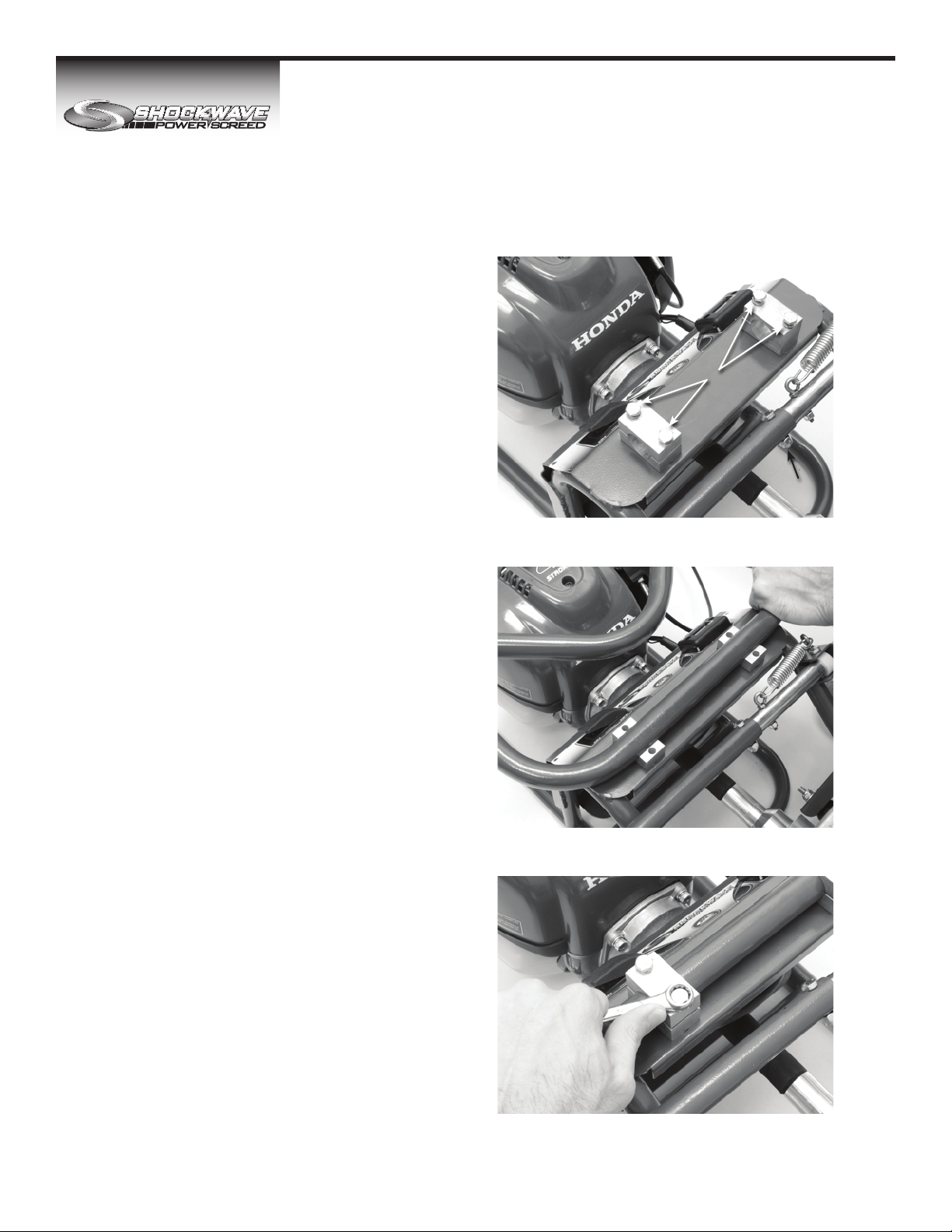

ASSEMBLY INSTRUCTIONS

INSTALLING THROTTLE CABLE:

Step 1 – Remove carburetor cover by pressing clips.

B

A

Step 2 – The throttle has a rotating silver peg (A) with a slot

on one side of it. One end of the throttle cable has a metal

barrel (B) that fits into this slot. Insert barrel into the slot so

when the throttle cable is pulled, it will pull the throttle open

(toward the base plate of the screed).

Step 3 – Fasten the throttle cable as shown. Make sure

there is a nut on each side of plastic fitting. Made sure the

cable does not work itself out of the plastic fitting

while tightening.

WS570

R10-15-12

104 S. 8th Ave. Marshalltown, IA Phone 800-888-0127 / 641-753-0127 • Fax 800-477-6341 / 641-753-6341 www.

Step 4 – Attach the throttle lever to the “T” grip handle,

as shown above.

marshalltown

.com

5 of 16

Page 6

ASSEMBLY INSTRUCTIONS

Step 5 – Thread the exposed metal end of the throttle cable

into the throttle lever. The lever will need to be “opened” to

expose the hole it fits into. Back out the set screw to allow

the cable to pass through.

Step 7 – Secure throttle cable using clips,

as shown above.

Step 6 - Once cable is through throttle lever, return the

lever to the “idle” position shown above. Using pliers, pull

all extra slack out of the cable, making sure you are not

actually opening the throttle at the carburetor. Once all

slack is removed, tighten locking screw.

Note – the plastic housing of the throttle cable will fit up into

the throttle cable housing.

ATTACHING BLADE

Attach blade as shown,

making sure that blade

is positioned on the

“front side” of the base

extrusion.

Make sure bolts

!

are tight before

each use.

6 of 16

104 S. 8th Ave. Marshalltown, IA Phone 800-888-0127 / 641-753-0127 • Fax 800-477-6341 / 641-753-6341 www.

marshalltown

.com

WS570

R10-15-12

Page 7

MACHINE ADJUSTMENTS

HANDLES

Your Shockwave™ screed has handles that can be

adjusted for a customized fit.

ADJUSTABLE

The height of the handle can be adjusted right

below the motor

The grips can also be moved to accommodate wider

and narrower grips, as well as flipped to the inside of the

machine for an even narrower grip.

CAUTION

Always make sure engine is stopped with switch in "OFF"

position before making adjustments.

ECCENTRIC WEIGHTS

The factory weight setting will provide sufficient

board vibration for most

jobs. For jobs where low

slump or dry concrete is

being poured, the weight

can easily be adjusted to

allow for more vibration at

lower RPM.

Using a slotted screwdriver remove the

eccentric cover. Using a

7/16" socket, loosen the

eccentric weight tightening

bolt (A). You will need

to wedge a screwdriver

against the weight to keep

it from turning while

loosening bolt.

!!

ADJUSTABLE

The pitch of the grips can be adjusted 360˚ vertically

WS570

R10-15-12

104 S. 8th Ave. Marshalltown, IA Phone 800-888-0127 / 641-753-0127 • Fax 800-477-6341 / 641-753-6341 www.

INCREASE

Increase vibration, increase the gap between the weights

by spreading them apart.

Decrease vibration, decrease the gap between the

weights. If imbalance is increased then use less engine

RPM. Note: Always check and retighten the eccentric

weights every 10 hours of use.

marshalltown

DECREASE

.com

7 of 16

Page 8

16

46

44

45

1

5

4

33

19

39

7

8

29

9

11

30

35

32

27

31

12

34

28

23

43

26

48

2

15

21

10

13

14

33

25

37

38

42

40

49

DET. QTY. DESCRIPTION

1 1 GX35 HONDA MOTOR

2 8 HANDLEBAR CLAMP

3 1 HANDLEBAR ASSEMBLY

4 1 BASE EXTRUSION

5 1 TACHOMETER

6 1 KILL SWITCH

7 4 VIBRATION ISOLATOR

8 1 ECCENTRIC WEIGHT #1

9 1 ECCENTRIC WEIGHT #2

10 1 ECCENTRIC SHAFT

11 1 ECCENTRIC WEIGHT BUSHING

12 1 WEIGHT ADJUSTMENT CAP

13 1 LOWER BEARING HOUSING

14 1 COUPLING DRIVE SHAFT

15 1 CLUTCH

16 1 FLEX SHAFT

17 1 HANDLEBARS, L-GRIP

18 1 HANDLEBARS, T-GRIP

19 2 BLADE ATTACHMENT NUT

20 1 BLADE

21 1 KICKSTAND END

22 1 KICKSTAND ARM

23 2 KICKSTAND EYEBOLT

24 1 KICKSTAND END CAP

25 1 SPRING

26 1 FRAME

27 1 ECCENTRIC COVER

28 1 ECCENTRIC COVER CAP

29 3 DRIVETRAIN BASE MOUNTING SCREW

30 1 ECCENTRIC WEIGHT JAM NUT

31 1 ECCENTRIC TIGHTENING CAP BOLT

32 2 BLADE ATTACHMENT BOLT

33 4 ECCENTRIC COVER MOUNTING SCREW

34 4 ECCENTRIC CAP SCREW

35 8 VIBRATION ISOLATOR NUT

36 4 WELD NUT FOR HANDLEBAR CLAMPS

37 2 TACHOMETER MOUNTING SCREW

38 2 TACHOMETER MOUNTING NUT

39 4 VIBRATION ISOLATOR NUT

40 2 BLADE ATTACHMENT LOCK WASHER

41 8 HANDLEBAR CLAMP BOLT

42 2 KICKSTAND NUT

43 2 KICKSTAND BOLT

44 1 REPLACEMENT DRIVESHAFT CORE (NOT PICTURED)

45 1 THROTTLE LEVER ( FRICTION STYLE)

46 4 ENGINE MOUNTING BOLTS

47 2 HANDLEBAR GRIPS

48 1 THROTTLE CABLE

49 1 KILL SWITCH WIRING

8 of 16

104 S. 8th Ave. Marshalltown, IA Phone 800-888-0127 / 641-753-0127 • Fax 800-477-6341 / 641-753-6341 www.

PARTS BREAKDOWN

REPLACEMENT PARTS INDEX

EDI PART# DESCRIPTION DETAILS INCLUDED

13308 13308 HANDLES WITH GRIPS 17, 18, 47

13309 13309 GRIPS 47

13310 ENG-HONDA HONDA ENGINE 1, 46

13312 13312 THROTTLE LEVER 45

13313 13313 THROTTLE CABLE 48

13314 13314 HANDLEBARS 3

13315 13315 HANDLEBAR CLAMPS W/HARDWARE 2, 41

13316 13316 HANDLEBAR CLAMP HARDWARE ONLY 41

13317 13317 ON/OFF SWITCH W/WIRES 6, 49

13318 13318 ON/OFF SWITCH WIRES 49

13319 13319 TACHOMETER 5, 37, 38

13320 13320 ECCENTRIC COVER W/HARDWARE 27, 28, 33, 34

13321 13321 KICKSTAND 21, 22, 23, 24, 25, 42, 43

13322 13322 KICKSTAND HARDWARE 23, 25, 42, 43

13323 13323 DRIVE TRAIN 10, 13, 14, 16, 29, 44

13324 13324 CLUTCH 15, 46

13325 13325 VIBRATION DAMPENING KIT 7, 35, 39

13330 13330 ECCENTRIC WEIGHTS & HARDWARE 8, 9, 11, 12, 30, 31

13331 13331 ECCENTRIC WEIGHT HARDWARE ONLY 11, 12, 30, 31

13332 13332 MACHINE BASE 4

13333 13333 BLADE LOCKING HARDWARE 19, 32, 40

13334 13334 DRIVE SHAFT 44

13335 13335 DRIVE SHAFT HOUSING 10, 13, 14, 16

12951 12951 FRAME ONLY 26

12952 12952 ECCENTRIC COVER HARDWARE ONLY 33, 34

marshalltown

.com

WS570

R10-15-12

Page 9

PARTS BREAKDOWN

1

45

2

44

46

48

26

33

16

15

14

13

10

23

38

43

21

42

37

5

49

36

25

18

17

3

47

6

2

22

24

2

41

17

47

20

BLADE SIZE CHART

EDI Part # SIZE-FT. SIZE-M

13336 SWSBLADE4 4 1.2

13281 SWSBLADE6 6 1.8

13283 SWSBLADE8 8 2.4

13284 SWSBLADE10 10 3.0

13287 SWSBLADE12 12 3.7

13290 SWSBLADE14 14 4.3

13291 SWSBLADE16 16 4.9

12950 SWSBLADE16P2 16 (2 sets of mounting holes) 4.9

WS570

R10-15-12

104 S. 8th Ave. Marshalltown, IA Phone 800-888-0127 / 641-753-0127 • Fax 800-477-6341 / 641-753-6341 www.

A

marshalltown

.com

9 of 16

Page 10

HOW TO WET SCREED

SETTING ELEVATION OF SLAB

• Use grade pins (A) to set height of slab

in the middle of the pour.

• Chalk line or expansion joint sets

elevation around walls.

• Form boards set elevation where

there are no walls.

MAKING WET PADS

1. Using hand float, make wet pads around all grade

pins (A).

Note: Make sure all wet pad distances

are shorter than the length of board

being used.

2. Use board to stretch from wet pad to wet pad forming rows (B).

3. Once rows are formed, run screed board off of the

two rows leveling the previously untouched concrete (C) in between.

NOTE: Height of concrete in area (C)

must be slightly higher than wet

pad rows (B) prior to striking off.

1

Blade Length

12-18 inches

2

12-18 in.

Once floated, wet pads (B) and concrete (C) will all be the

same height

10 of 16

104 S. 8th Ave. Marshalltown, IA Phone 800-888-0127 / 641-753-0127 • Fax 800-477-6341 / 641-753-6341 www.

3

marshalltown

.com

WS570

R10-15-12

Page 11

HOW TO SCREED FORM TO FORM

Length of board should overlap form boards on both

sides of the pour

WIDTH OF SCREED BOARD

Keep bottom of blade as flat as possible while striking

off of forms

To ensure the longest possible board life, use the

lowest possible vibration setting in relationship to the

slump of concrete being used.

BOARD KEPT FLAT

Excess Concrete

WIDTH OF FORM

Keep bottom of blade as flat as possible while

striking off of forms

ELEVATED

TRAILING EDGE

Excess Concrete

An elevated trailing edge may provide an area

for concrete to build up resulting in a slab

elevation that is too high

WS570

R10-15-12

104 S. 8th Ave. Marshalltown, IA Phone 800-888-0127 / 641-753-0127 • Fax 800-477-6341 / 641-753-6341 www.

ELEVATED

LEADING EDGE

Excess Concrete

An elevated leading edge can trap rocks

between the blade and forms resulting in a

slab elevation that is too high

marshalltown

.com

11 of 16

Page 12

TECHNICAL DATA/CAPACITIES

Model Number SW100H

Drive System Flexible Shaft

Weight 33.5 lbs. (15.2 kg)

Blade Lengths

Blade Weight 1.85 Lb./ft. 2.75(kg/m)

Engine Type 4-stroke, overhead cam, single cylinder

Engine Make Honda

Engine Model GX35

Engine Horsepower 1.6 hp (1.2kW) @ 7,000 rpm

Engine Displacement 2.18 cu-in (35.8cm

Spark Plug

Spark Plug Gap

Engine Speed - idle 3,100 ± 200 rpm

Oil Type - Engine SAE 10W-30 (refer to engine manual)

Oil Capacity - Engine 0.11 qt (3.5 oz., 0.10 L)

Fuel Type Pump octane rating 86 or higher (refer to engine manual)

Fuel Tank Capacity 0.166 US gal (0.63 L)

4, 6, 8, 10, 12, 14, 16'

1.2, 1.8, 2.4, 3, 3.7, 4.3, 4.9M

3

)

CM5H (NGK)

CMR5H (NGK)

0.60 - 0.70mm

(0.024 - 0.028 in)

CAUTION

Your Shockwave ships with a

pre-measured bottle of oil (3.5 oz).

Do not at anytime have more than 3.5 oz. of

oil in the engine. Too much oil will foul out

the spark plug resulting in an engine that is

hard to start and keep running.

!!

MAINTENANCE

The Shockwave's tachometer is a great way to keep track of

maintenance schedules and track service life.

Check and retighten eccentric weights Every 10 hours or every month

Check oil level Before each use

Change engine oil First month or 10 hrs. - 6 mo. or 50 hrs after

Check fuel level Before each use

Inspect air filter Before each use

Replace air filter Every 25 hours or every 3 months

Spark plug - check and adjust Every 100 hours or 1 year

Spark plug - replace Every 300 hours or 2 years

Cooling fins Every 50 hours

Electronic Connections Before each use

Check Nuts and bolts Before each use

Replace nuts and bolts As necessary

12 of 16

104 S. 8th Ave. Marshalltown, IA Phone 800-888-0127 / 641-753-0127 • Fax 800-477-6341 / 641-753-6341 www.

marshalltown

.com

WS570

R10-15-12

Page 13

HOW TO OPERATE

FUEL AND OIL

Make sure gas tank has plenty of 86 octane or

higher gasoline. Your 4 stroke Honda engine uses

straight gasoline, NEVER USE A GAS/OIL MIX.

Empty entire bottle of provided Honda engine oil

into crank case. 3.5 oz. is the maximum oil

capacity. Always lay screed down on roll cage as

shown when filling gas and oil or checking oil.

NEVER OVERFILL.

STARTING

1. On a cold engine, move choke lever to CLOSED

position. To restart a warm engine leave choke in

OPEN position

2. Press priming bulb repeatedly until fuel can be

seen in the clear-plastic fuel-return tube

3. Press On/Off Switch to the On Position.

1

CLOSED

OPEN

2

4. Pull the starter grip lightly until you feel resistance,

then pull briskly. Repeat until engine starts.

5. If the choke lever was moved to the CLOSED

position to start the engine, gradually move it to

the OPEN position as the engine warms up.

RESTARTING A WARM ENGINE

1. Leave the choke lever in the OPEN position.

2. If there is no fuel in the clear-plastic fuel-return

tube, press priming bulb repeatedly

until fuel can be seen in the tube.

3. Press On/Off Switch to the On Position

4. Pull the starter grip lightly until you feel resistance,

then pull briskly. Repeat until engine starts.

3

4

WS570

R10-15-12

104 S. 8th Ave. Marshalltown, IA Phone 800-888-0127 / 641-753-0127 • Fax 800-477-6341 / 641-753-6341 www.

marshalltown

.com

13 of 16

Page 14

OPERATING ON WET CONCRETE

Once the engine is warm

and running by itself with

the choke OPEN you can

begin screeding concrete.

For specific instructions on

Wet Screeding and Form to

Form screeding please see

pages 10 and 11.

1. Begin by placing concrete within your forms slightly higher

than the forms themselves.

2. Place screed on top of concrete and start engine.

3. Increase engine RMP until the clutch engages causing

the screed to vibrate.

4. Walking backwards, begin screeding concrete (see page 10

for Wet Screeding or Page 11 for Form to Form screeding).

5. Your throttle lever does not require constant contact, but

you can adjust RMP and vibration to accommodate wet or

dry concrete. Dry or low slump concrete may require

more vibration to level and screed

6. Continue moving backwards while keeping concrete placed

in front of the blade. The roll back feature of the blade will

keep help keep concrete from sliding over the blade.

Concrete placed too high may slide over the board! This

could make the screed too hard to pull and result in a slab

that is out of level.

DO NOT OVER VIBRATE CONCRETE!

!

The following are signs of too much vibration:

• Excessive concrete splatter

• Blade sinking below wet pads

• Ripple or “wake marks” following the blade

• Concrete easily sliding underneath form boards causing dips

along the form edge

Always remember, the less vibration the better. Use only

enough vibration to be able to comfortably pull screed backwards, leaving a smooth, level surface.

14 of 16

104 S. 8th Ave. Marshalltown, IA Phone 800-888-0127 / 641-753-0127 • Fax 800-477-6341 / 641-753-6341 www.

marshalltown

.com

WS570

R10-15-12

Page 15

PRODUCT WARRANTY

ONE YEAR LIMITED WARRANTY

Marshalltown Company (the Company) warrants, that for a period of twelve (12) months from the date of purchase, it will replace or repair, free of charge, for the

original retail purchaser only, any part or parts, manufactured by the Company, found upon examination by the Company or its assigned representatives, to be defective

in material or workmanship or both. All transportation charges for parts submitted for replacement or repair under this warranty must be borne by the original retail

purchaser. This is the exclusive remedy under this warranty.

Failure by the original retail purchaser to install, maintain and operate said equipment in accordance with good industry practices, or failure to comply with the specific

recommendations of the Company set forth in the owner’s manual, shall render this warranty null and void. The Company shall not be liable for any repairs, replacements,

or adjustments to the equipment or any costs for labor performed by the purchaser without the Company’s prior written approval. The effects of corrosion, erosion and

normal wear and tear are specifically excluded from this warranty.

THE COMPANY MAKES NO OTHER WARRANTY OR REPRESENTATION OF ANY KIND WHATSOEVER, EXPRESSED OR IMPLIED, EXCEPT THAT OF TITLE.

ALL IMPLIED WARRANTIES, INCLUDING ANY WARRANTY OF MERCHANTABILITY AND FITNESS FOR PARTICULAR PURPOSE ARE HEREBY DISCLAIMED.

LIABILITY FOR CONSEQUENTIAL AND INCIDENTAL DAMAGES UNDER ANY AND ALL WARRANTIES, OTHER CONTRACTS, NEGLIGENCE, OR OTHER TORTS IS

EXCLUDED TO THE EXTENT EXCLUSION IS PERMITTED BY LAW.

Notwithstanding the above, any legal claim against the Company shall be barred if legal action thereon is not commenced within twenty–four (24) months from the date of

purchase or delivery, whichever occurs last. This warranty constitutes the entire agreement between the Company and the original retail purchaser and no representative

or agent is authorized to alter the terms of same without expressed written consent of the Company.

GARANTIE LIMITÉE D’UN AN

La Société Marshalltown Company (la Société) garantit que, pendant une période de douze (12) mois à partir de la date d’achat, elle remplacera ou réparera,

gratuitement, pour l’acheteur d’origine uniquement, n’importe quelle pièce, fabriquée par la Société, jugée défectueuse par la Société ou les représentants désignés,

tant au niveau des matériaux qu’à celui de la fabrication. Tous les frais de transport pour les pièces à échanger ou à réparer dans le cadre de cette garantie doivent être

assurés par l’acheteur d’origine. Cela constitue le seul recours dans le cadre de cette garantie.

Par l’acheteur d’origine d’installer, d’entretenir et de faire fonctionner ledit matériel conformément aux recommandations normales pour ce type de matériel ou toute des

recommandations spécifiques de la Société définies dans le manuel de l’opérateur d’entretien, se solderont par l’annulation de cette garantie. La Société ne pourra pas

être tenue responsable des réparations, remplacements, ou réglages du matériel ou des coûts de main d’oeuvre de l’acheteur sans le consentement préalable par écrit

de la Société. Les effets de la corrosion, de l’érosion et de l’usure normale sont spécifiquement exclus de cette garantie.

LA SOCIÉTÉ NE FOURNIT AUCUNE AUTRE GARANTIE OU REPRÉSENTATION QUELLE QU’ELLE SOIT, EXPLICITE OU IMPLICITE, SAUF POUR LE TTTRE.

TOUTES LES GARANTIES IMPLICITES, Y COMPRIS TOUTE GARANTIE DE COMMERCIABILITÉ ET D’APTITUDE À UNE UTILISATION SPÉCIFIQUE SONT

PAR CONSÉQUENT REFUSÉES. LA RESPONSABILITÉ QUANT AUX DOMMAGES INDIRECTS OU FORTUITS COUVERTS PAR TOUTES LES GARANTIES,

LES AUTRES CONTRATS DE GARANTIE, LA NÉGLIGENCE OU AUTRES ACTES PRÉJUDICIABLES EST EXCLUE CONFORMÉMENT AUX DISPOSITIONS

D’EXCLUSION PERMISES PAR LA LOI.

Sauf pour les termes définis ci–dessus, tout recours légal contre la Société sera exclus si l’action en justice n’est pas entamée l’échéance la plus longue étant retenue

dans les vingt–quatre (24) mois à partir de la date d’achat ou de livraison. Cette garantie constitue la totalité de l’accord entre la Société et l’acheteur d’origine, et aucun

représentant ou agent n’est autorisé à modifier les termes sans le consentement écrit dela Société.

GARANTIA LIMITADA POR UN AÑO

Marshalltown Company (la Empresa) garantiza que durante un período de doce (12) meses a partir de la fecha de compra reemplazará o reparará, sin cargo, para el

comprador minorista original, cualquier pieza o piezas fabricadas por la Empresa que, al ser estudiados por la Empresa o los representivas asignados de la Empresa,

tengan defectos en el material o mano de obra o ambos. Todos los costos de transporte para las piezas enviadas para reparación o reemplazo bajo esta garantía deben

ser pagados por el comprador minorista original. Este es el único recurso posible bajo esta garantía.

Si el comprador minorista original no instala, mantiene u opera dicho equipo de acuerdo con las prácticas industriales correspondientes, o no cumple con las

recomendaciones específicas de la Empresa presentadas en el manual del propietario, entonces la garantía será anulada y no válida. La Empresa no será responsable

de cualquier reparación, reemplazo o ajuste al equipo o cualquier costo de mano de obra realizados por el comprador sin la aprobación previa por escrito de la Empresa.

Los efectos de la corrosión, erosión y desgaste normal están específicamente excluidas por esta garantía.

LA EMPRESA NO HACE NINGUNA OTRA GARANTIA NI REPRESENTACION DE NINGUN TIPO, EXPRESA O IMPLICITA, SALVO LA ANTERIOR. TODAS LAS

GARANTIAS IMPLICITAS, INCLUYENDO LA GARANTIA DE COMERCIABILIDAD Y APTITUD PARA UN PROPOSITO PARTICULAR ESTAN EXCLUIDAS POR

ESTE MEDIO. LA RESPONSABILIDAD POR DAÑOS EMERGENTES O INCIDENTALES BAJO CUALQUIERA Y TODAS LAS GARANTIAS, OTROS CONTRATOS,

NEGLIGENCIA U OTROS PERJUICIOS QUEDA EXCLUIDO EN LA MEDIDA QUE LO PERMITA LA LEY.

No obstante lo anterior, cualquier demanda legal contra la Empresa será impedida si dicha acción legal no se inicia dentro de los veinticuatro (24) meses a partir de la

fecha de compra o entrega, lo que ocurra último. Esta garantía constituye todo el acuerdo entre la Empresa y el comprador minorista original y ningún representante o

agente está autorizado para alterar los términos del mismo sin el consentimiento expreso por escrito de la Empresa.

WS570

R10-15-12

104 S. 8th Ave. Marshalltown, IA Phone 800-888-0127 / 641-753-0127 • Fax 800-477-6341 / 641-753-6341 www.

marshalltown

.com

15 of 16

Page 16

Marshalltown, IA

Phone 800-888-0127 / 641-753-0127

Fax 800-477-6341 / 641-753-6341

www.marshalltown.com

WS570

Loading...

Loading...