Marshalltown FS13 Owner's Manual

" FLOORING SHEAR

Part# FS13 | EDI# 28847

104 S. 8th Ave. | Marshalltown, IA

Phone 800-888-0127 / 641-753-0127 | Fax 800-477-6341 / 641-753-6341

www.MARSHALLTOWN.com

WS1980

INTRODUCTION

Congratulations on your purchase of a MARSHALLTOWN Flooring Shear. Proudly made in the USA,

MARSHALLTOWN flooring shears are heavy duty and manufactured with the highest grade materials.

MARSHALLTOWN shears are designed with the flooring professional in mind to ensure accuracy and reliability.

Other features of your MARSHALLTOWN flooring shear include:

• Easy, quiet one-cut action

• Ability to cut inside and produce no dust

• Cut material up to 13" (330mm) wide and 1" (25.4mm) thick

• Built in ruler for accurate cuts

• Moveable fence for 90° and 45° cuts

This owner’s manual provides the information needed to operate and maintain this MARSHALLTOWN flooring

shear. Carefully read and follow all safety and operating instructions in this manual. Ensure every operator of this

flooring shear reads this manual before operating the unit. The replacement of any part on this flooring shear by

other than the manufacturer’s authorized replacement part may adversely affect the performance, durability or

safety of the product.

Be sure safety precautions are observed. Read and follow all safety and operating instructions in this

operator’s manual. The manufacturer reserves the right to make changes on or add improvements to its

product at any time without prior notice or obligation. The manufacturer reserves the right to decide, upon its

sole discretion and at any time, to discontinue this product.

This manual covers the MARSHALLTOWN 13" Flooring Shear. For technical questions or repair parts, please call

MARSHALLTOWN customer service at 1-800-888-0127 or visit www.MARSHALLTOWN.com.

2 of 12

104 S. 8th Ave. Marshalltown, IA Phone 800-8 88-0127 / 6 41-753-012 7 • Fax 800-47 7-6341 / 6 41-753-6341 www.MARSHALLTOWN.com WS1980

DANGER!

WARNING!

WARNING!

WARNING!

TABLE OF CONTENTS

Safety Precautions ......................................................................................................................................................................3

Safety Decals ...............................................................................................................................................................................4

Warranty ........................................................................................................................................................................................4

Assembly ..................................................................................................................................................................................5-6

Product Operation ......................................................................................................................................................................7

Cutting Guide ...............................................................................................................................................................................8

Parts Breakdown ....................................................................................................................................................................8-9

Maintenance ..............................................................................................................................................................................10

Trouble Shooting........................................................................................................................................................................ 11

SAFETY PRECAUTIONS

• DANGER or

WARNING safety signs are located near specific hazards.

• General precautions are listed on CAUTION safety signs.

• This notation appears before warnings in the text. It means that the step that follows must be carried out to

avoid the possibility of personal injury or death. These warnings are intended to help the technician avoid any

potential hazards encountered in the normal service procedures. We strongly recommend that the reader

takes advantage of the information provided to prevent personal injury or injury to others.

THE FOLLOWING PRECAUTIONS ARE SUGGESTED TO HELP PREVENT ACCIDENTS. A CAREFUL OPERATOR

IS THE BEST OPERATOR. MOST ACCIDENTS CAN BE AVOIDED BY OBSERVING CERTAIN PRECAUTIONS.

READ AND TAKE THE FOLLOWING PRECAUTIONS BEFORE OPERATING THIS EQUIPMENT TO HELP

PREVENT ACCIDENTS. EQUIPMENT SHOULD BE OPERATED ONLY BY THOSE WHO ARE RESPONSIBLE AND

INSTRUCTED TO DO SO.

CALIFORNIA PROPOSITION 65 WARNING: This product can expose you to chemicals known to the

State of California to cause cancer, birth defects, or other reproductive harm.

• Read all operating and maintenance instructions before operating or servicing the flooring shear.

• A flooring shear is only as safe as its operator. Give complete and undivided attention to the operation of the

flooring shear.

• Know how to stop the flooring shear instantly.

NEVER operate the flooring shear if any shear components have been removed.

• Keep inexperienced and unauthorized people away from the flooring shear at all times.

• Keep the flooring shear in good operational condition. Loose or damaged parts are dangerous.

• Avoid loose clothing that could get caught in moving parts.

Keep hands and feet away from moving parts.

• Keep all warning, caution and safety instruction labels in good condition. Replace missing, damaged or illegible labels.

• Clear the work area around the shear to prevent tripping or falling onto the shear.

• Operate on level ground to prevent the flooring shear from flipping over.

•

DO NOT OPERATE this flooring shear under the influence of alcohol or while taking medication that impairs your reactions.

• Use only factory authorized parts for replacement.

• Wear safety glasses when operating the flooring shear.

• Always use caution when replacing the shear blade.

• Only operate the shear with the approved materials. If extreme force is required to cut a material, it may result in personal

injury and/or damage to the flooring shear.

• Wear proper protective clothing while operating flooring shear, including eye, ear, and clothing.

• Handle all solvents and cleaning agents with care and follow manufacturer’s instructions on safety and disposal.

104 S. 8th Ave. Marshalltown, IA Phone 800-8 88-0127 / 6 41-753-012 7 • Fax 800-47 7-6341 / 6 41-753-6341 www.MARSHALLTOWN.comWS1980

3 of 12

SAFETY DECALS

If your safety decals are damaged, they can be replaced by contacting Customer Service.

WS2020

WS2021

WARRANTY

This product is warranted to the original purchaser only, to be free of defects in material and workmanship

under normal use, for one year from purchase date. MARSHALLTOWN shall without charge for parts and labor,

repair or replace such parts which are found to be defective. All transportation charges for replacement parts

must be borne by the purchaser.

For warranty service, the product must be delivered, with proof of purchase date, to MARSHALLTOWN.

Contact MARSHALLTOWN Customer Service to determine the best method of delivering the product that is

under warranty. The delivery of the product must be made no later than 30 days after the expiration of the

warranty period.

All implied warranties, including those of merchantability and fitness for a particular purpose, are limited to one

year from date of purchase by the original retail customer and to the extent permitted by law any and all implied

warranties are excluded and disclaimed after the expiration of such period.

Some states do not allow limitations on how long an implied warranty lasts, or the exclusion or limitations of

incidental or consequential damages, so the above limitations or exclusions may not apply to you. This warranty

gives you specific legal rights, and you may also have other rights, which vary from state to state.

Exclusion from this warranty:

1. All consequential damages, including pickup and delivery of the unit, communication, mileage charges and/

or rental of a replacement unit during repairs are not covered under this warranty, or are any loss of income

and/or other loss resulting from the failure of the product to function due to a warranty defect.

2. This warranty will not apply when the product becomes inoperative due to misuse, normal wear, neglect,

improper maintenance, accident or freight damage; has not been operated and maintained in accordance

with the instructions furnished in the Operator’s Manual; or has been altered or modified without approval

from the factory Service Department.

3. No parts or products are to be returned to the factory without prior written approval from the factory.

4 of 12

104 S. 8th Ave. Marshalltown, IA Phone 800-8 88-0127 / 6 41-753-012 7 • Fax 800-47 7-6341 / 6 41-753-6341 www.MARSHALLTOWN.com WS1980

1. Lay out all of the parts.

Tools for Assembly:

• #2 Phillips Screwdriver

• #3 Phillips Screwdriver

• " Hex Wrench (included)

A B C D E

ASSEMB LY

A. Table Assembly

B. Shear Assembly

C. Handle Base

D. Bed Fence

E. Handle Extension

F

H

J

L

2. Lay out all hardware.

G

I

K

F. #3 Phillips Flat Head Screw, "–20 X 2 " (4x)

G. #2 Phillips Flat Head Screw, 10-24 X " (4x)

H. " Hex Drive Flat Head Screw, "–18 X 1 " (2x)

I. Wing Nut, "–20 (2x)

J. Honing Stone (1x)

K. Cam Locking Pin (1x)

L. End Cap (1x)

104 S. 8th Ave. Marshalltown, IA Phone 800-8 88-0127 / 6 41-753-012 7 • Fax 800-47 7-6341 / 6 41-753-6341 www.MARSHALLTOWN.comWS1980

5 of 12

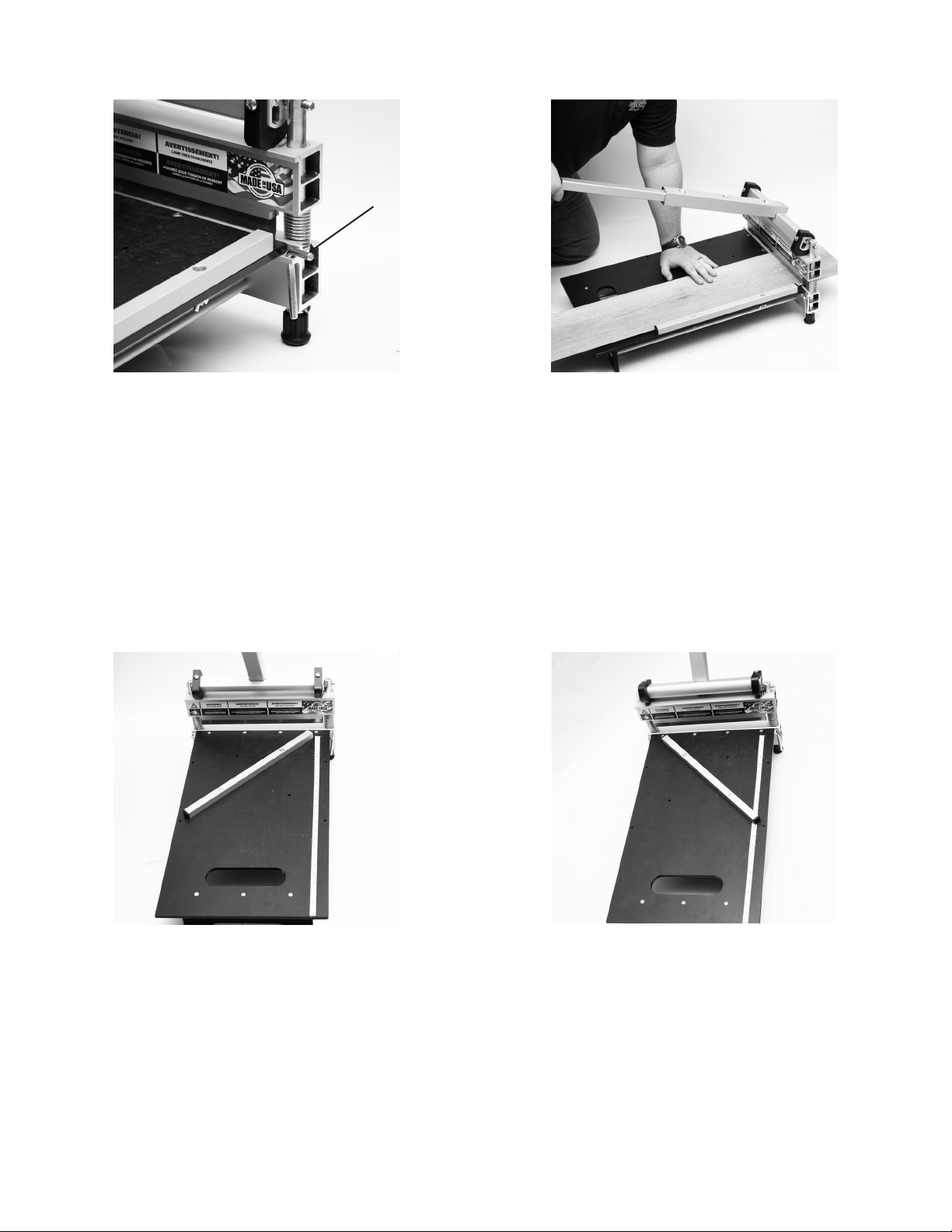

3. Attach Table Assembly (A) and Shear Assembly

(B) using hardware set G.

4. Attach the bed brace extrusion from the Table

Assembly (A) to the Shear Assembly (B) using

hardware set F.

5. Attach Handle Base (C) to Shear Assembly (B) using

one screw from hardware set H. Press the Handle

Base (C) down and insert Cam Locking Pin (K).

7. Press in the spring button and insert Handle

Extension (E) into Handle Base (C).

6 of 12

104 S. 8th Ave. Marshalltown, IA Phone 800-8 88-0127 / 6 41-753-012 7 • Fax 800-47 7-6341 / 6 41-753-6341 www.MARSHALLTOWN.com WS1980

6. Remove Handle Base (C), insert End Cap (L) bevel

side down into Handle Base (C) and reattach to

Shear Assembly (B) using hardware set H.

8. Place the Bed Fence (D) in two holes on the right

side of Table Assembly (A) and attach using

hardware set I.

PRODUCT OPERATION

1. Press down handle and carefully remove the

Cam Locking Pin. Insert Cam Locking Pin into its

storage hole to prevent losing the pin. Carefully

raise and release the handle.

2. Place material to be cut on the table and slide past

the blade to the desired length. Press flooring

against the Bed Fence and hold firmly in place to

ensure a clean and accurate cut. Press handle

down until the blade touches the material and then

firmly press down on the handle until the material

is cut.

DEGREE CUTS

1. Loosen wing nuts and remove the Bed Fence. Insert the fence into either of the angled holes for the desired

cut and tighten wing nuts.

DOUBLE CUTTING

Some materials may require the double cutting method to obtain a clean cut. For these materials, make your

first cut " longer than your mark. Then, make a second cut on your mark. This method will help produce

cleaner cuts on some materials.

104 S. 8th Ave. Marshalltown, IA Phone 800-8 88-0127 / 6 41-753-012 7 • Fax 800-47 7-6341 / 6 41-753-6341 www.MARSHALLTOWN.comWS1980

7 of 12

CUTTING GUIDE

The MARSHALLTOWN Flooring Shear is designed to cut a variety of materials. Some of the most common

materials are laminate flooring, engineered hardwood, luxury vinyl tile, luxury vinyl plank, vinyl composite tile,

fiber cement board siding, and more.

Note: DO NOT attempt to cut any solid wood, high pressure laminate, or engineered hardwood with a

Janka Hardness Rating higher than 1300.

Note: Even the approved materials may vary greatly in density and hardness. If extreme force is required to cut

a material stop immediately, as it could lead to damage to your shear or injury. Attempting to cut unapproved

materials will void the warranty.

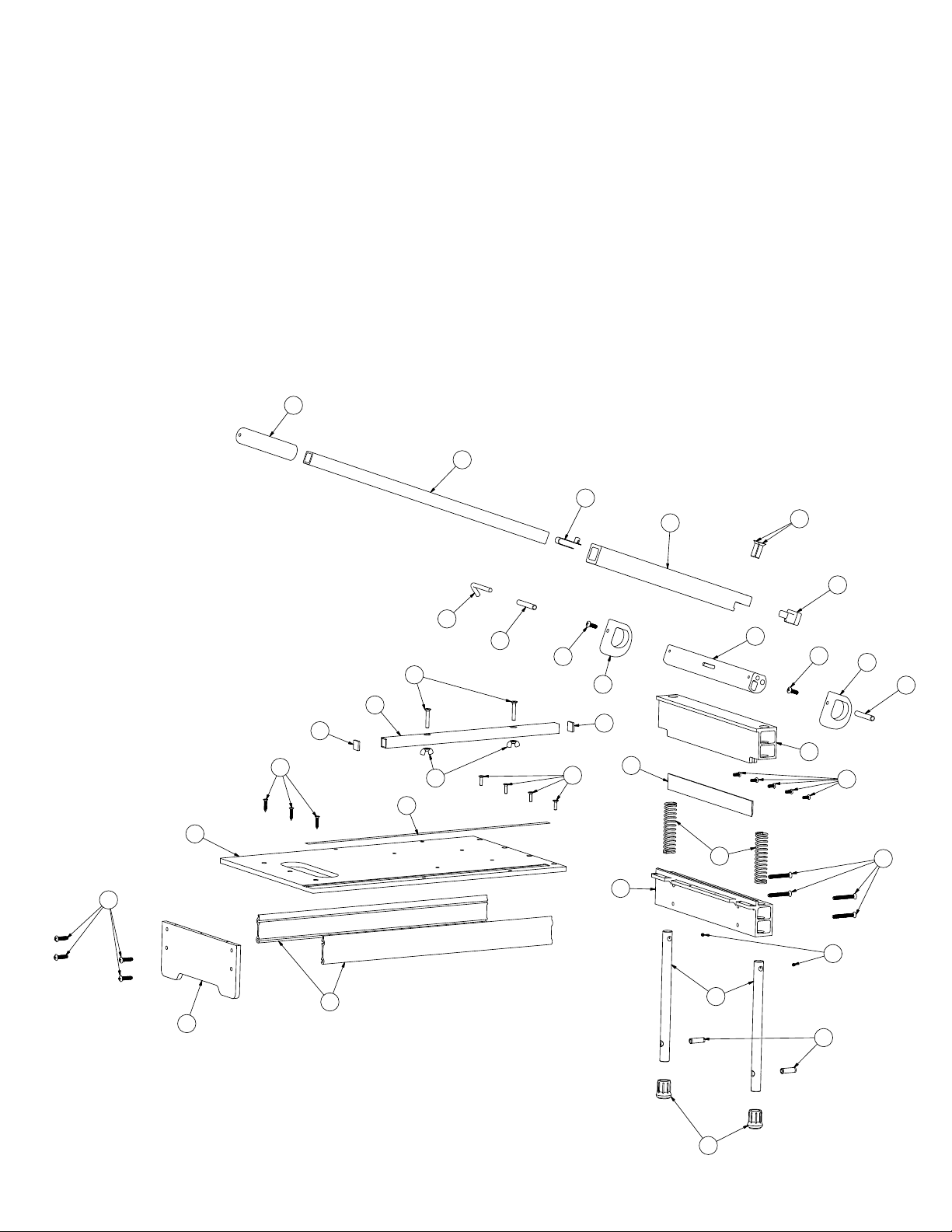

PARTS BREAKDOWN

30

29

28

1

4

32

12

20

14

2

31

7

24

27

23

22

25

3

26

15

7

5

8

16

19

14

18

10

17

15

20

13

6

11

21

8 of 12

9

104 S. 8th Ave. Marshalltown, IA Phone 800-8 88-0127 / 6 41-753-012 7 • Fax 800-47 7-6341 / 6 41-753-6341 www.MARSHALLTOWN.com WS1980

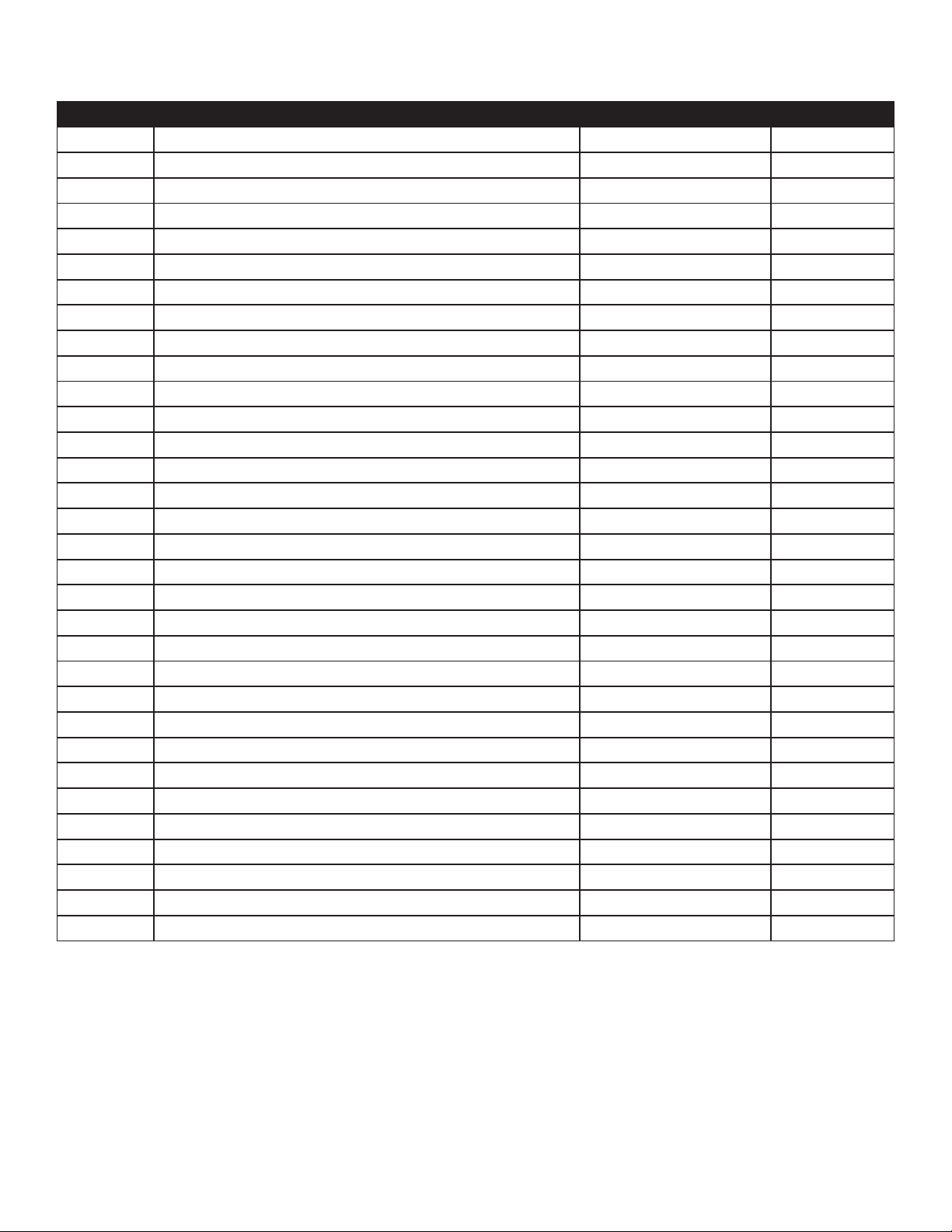

PARTS BREAKDOWN

REF # DESCRIPTION PART# Quantity

1 HANDLE BASE R4529 1

2 #3 PHILLIPS FLAT HEAD SCREW, 1/4"-20 X 1 1/2" WR1386 2

3 WING NUT, 1/4"-20 WR1382 2

4 3/16" HEX DRIVE FLAT HEAD SCREW, 5/16”–18 X 1 1/4" WR1383 2

5 #2 PHILLIPS FLAT HEAD SCREW, 10-24 X 3/4" WR1384 4

6 #3 PHILLIPS FLAT HEAD SCREW, 1/4"-20 X 2 1/2" WR1385 4

7 PLASTIC CAP WL710 2

8 BLADE WX2417 1

9 SLIP-ON FOOT, 3/4" WK219 2

10 COMPRESSION SPRING WX2424 2

11 SET SCREW, 10-24 X 3/16" WR1377 2

12 CAM LOCKING PIN WU904 1

13 #2 PHILLIPS PAN HEAD SCREW, 1/4"-20 X 1/2" WR1158 5

14 #3 PHILLIPS PAN HEAD SCREW, 1/4"-20 X 3/4" WR1378 2

15 EXCENTRIC CAM WX2425 2

16 ANVIL BEAM R4525 1

17 GUIDE ROD WU903 2

18 BLADE BEAM R4526 1

19 CAM BAR R4527 1

20 CAM PIN WU905 2

21 SPRING PIN, 3/8" DIA X 1 1/4" LONG WR1379 2

22 BED BRACE EXTRUSION WC921 2

23 #3 PHILLIPS PAN HEAD SCREW, 1/4"-20 X 1" WR1380 4

24 #2 PHILLIPS FLAT HEAD SCREW, #10 X 1" LONG WR1381 3

25 LEG R4531 1

26 ADHESIVE RULE WX2426 1

27 BED WL708 1

28 SPRING BUTTON WT173 1

29 EXTENSION HANDLE R4528 1

30 SOFT GRIP WT507 1

31 BED FENCE R3944 1

32 END CAP WL741 1

104 S. 8th Ave. Marshalltown, IA Phone 800-8 88-0127 / 6 41-753-012 7 • Fax 800-47 7-6341 / 6 41-753-6341 www.MARSHALLTOWN.comWS1980

9 of 12

MAINTENANCE

Honing the Blade

Push the handle down until the blade 1/8” (3mm)

above the tabletop. Place the provided Honing Stone

(J) against the flat side of the blade. Slide the honing

stone from one end of the blade to the other 3-4

times. This will remove any burrs from your blade and

should be done every 100 cuts. Use caution when

honing the blade. The blade is sharp and can easily

cause injury. Cut resistant gloves are recommended

when honing the blade.

Replacing the Blade

Use cut-resistant gloves when replacing the blade.

Cover the cutting edge with a blade guard or other

suitable covering. Place the shear upside down on

a workbench with the jaws in the open position,

creating a gap to allow blade removal. To remove the

blade use a #2 Phillips screwdriver and loosen the

5 retaining screws one full turn counterclockwise.

Do not remove the screws. When the last screw is

loosened, the blade will slip out of the retaining slot.

Cover the cutting edge of the new blade with a blade

guard or other suitable covering. Slide the new blade

into the slot with the beveled edge facing the screws.

Center the blade in the slot and make sure the blade

is fully inserted. Hand-tighten the center screw.

Hand-tighten the remaining screws to complete the

installation.

Beveled edge

on blade facing

retaining screws

Gap

Retaining screws

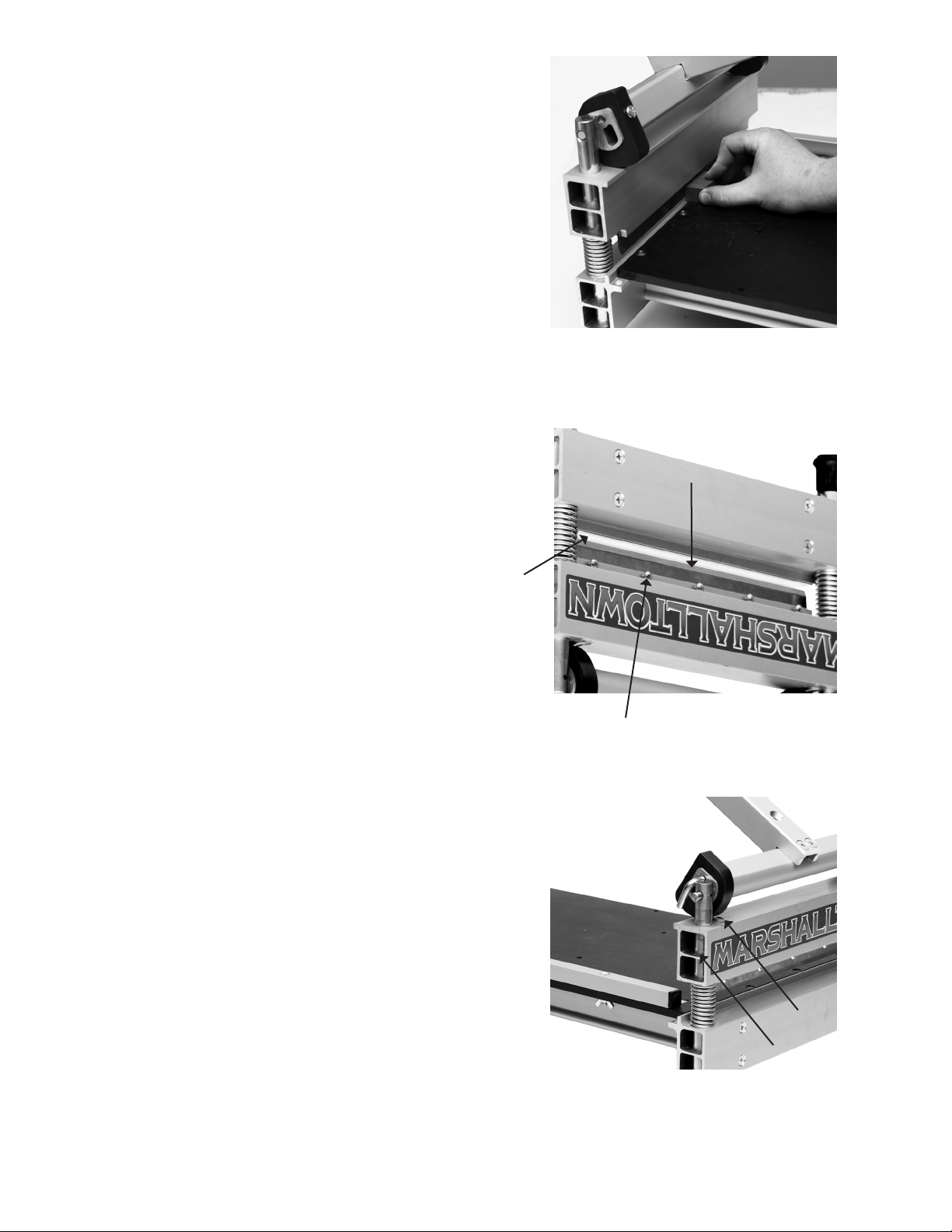

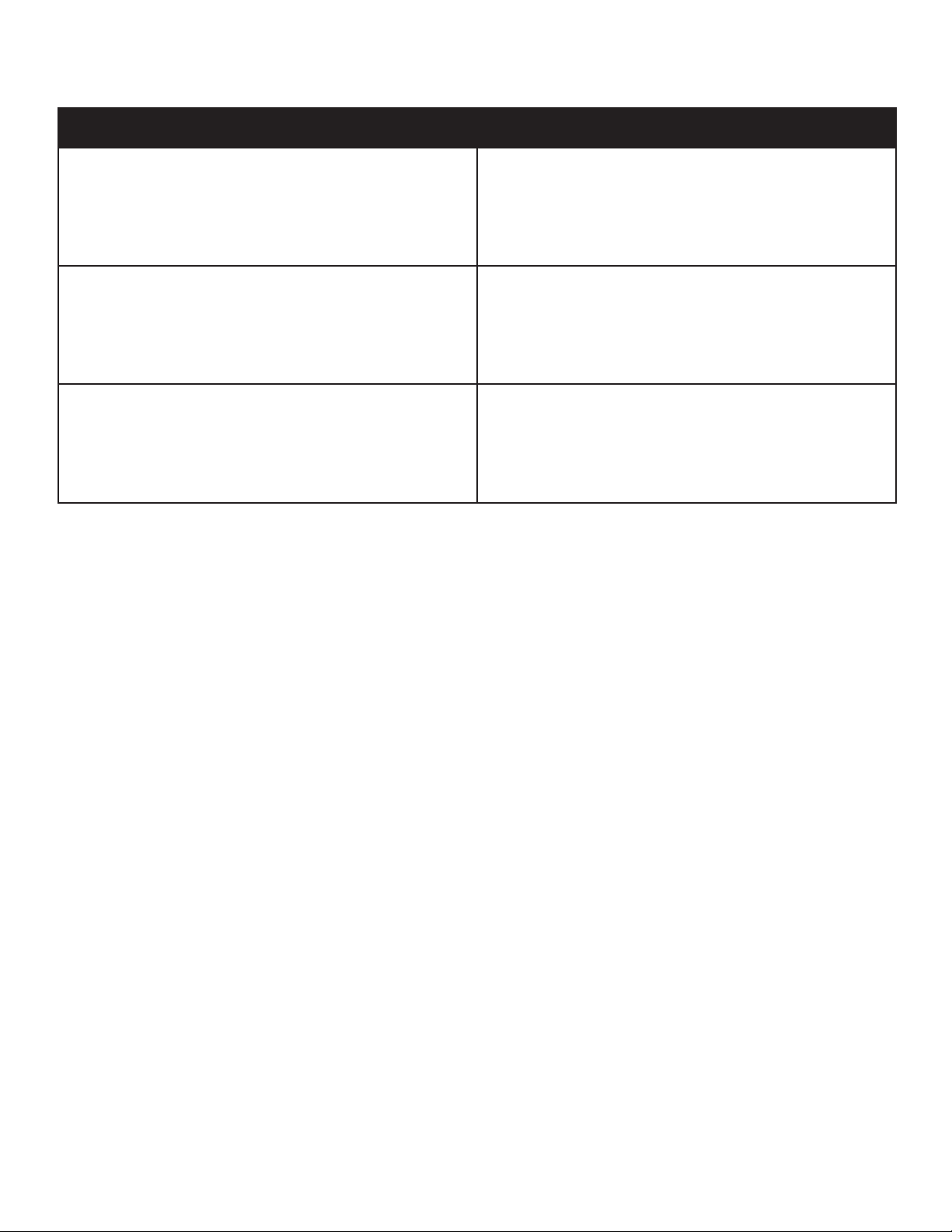

Lubrication

After every 100 cuts, it is recommended that the

shear be lubricated. Use a light oil and grease (wheel

bearing grease) and apply according to the image

below. Lubricating the shear will extend the life of the

shear and result in easier cutting.

10 of 12

104 S. 8th Ave. Marshalltown, IA Phone 800-8 88-0127 / 6 41-753-012 7 • Fax 800-47 7-6341 / 6 41-753-6341 www.MARSHALLTOWN.com WS1980

Grease

Oil

TROUBLESHOOTING

ISSUE RESOLUTION

Shear won’t cut desired material

Shear is leaving a jagged edge on flooring

Shear requires more force to cut than normal

Review cutting guide in manual to confirm it is a

confirmed material. Contact MARSHALLTOWN

customer service. Do not attempt to use

extreme force to cut the material.

Use honing stone to carefully touch up the blade

as described in the manual. Use double cutting

method as described in the manual if necessary.

Use honing stone to carefully touch up the

blade as described in the manual. Follow the

maintenance section of the manual to oil and

grease the shear.

104 S. 8th Ave. Marshalltown, IA Phone 800-8 88-0127 / 6 41-753-012 7 • Fax 800-47 7-6341 / 6 41-753-6341 www.MARSHALLTOWN.comWS1980

11 of 12

Loading...

Loading...