Page 1

OPERATIONS MANUAL

AND PARTS BOOK

36E55 - 36" 5.5HP

36PE9 - 36" 9HP EDGER

46E9NH - 46" 9HP

46E11 - 46" 11HP

Marshalltown, IA

Phone 800-888-0127 / 641-753-0127

Fax 800-477-6341 / 641-753-6341

www.marshalltown.com

Page 2

LIMITED WARRANTY

Marshalltown Company warrants its products to be free of defects in material or workmanship for the following periods:

A. All New Machines and Parts 6 Months

B. All New Gear Boxes 2 Years

Warranty period begins on first day of use by End User. This first day of use is established by a completed warranty card or a Bill of

Sale to the end user. All warranty is based on the following limited warranty terms and conditions.

1. Marshalltown Company’s obligation and liability under this warranty is limited to repairing or replacing parts if, after

Marshalltown’s inspection, it is determined to be a defect in material or workmanship. Marshalltown Company reserves the choice to

repair or replace.

2. If Marshalltown Company chooses to replace the part, it will be at no cost to the customer and will be made available to

the Distributor/Dealer from whom the customer purchased the product.

3. Replacement or repair parts, installed in the product, are warranted only for the remainder of warranty period of the product as

though they were the original parts.

4. Marshalltown Company’s warranty applies only to the products that are manufactured by Marshalltown Company and does not cover

component parts such as engines and clutches. Marshalltown Company DOES NOT warranty clutches. Engine warranty claims

should be made directly to an authorized factory service center for the particular engine make.

5. Marshalltown Company’s warranty does not cover the normal maintenance of products or its components (such as engine tune-ups

and oil changes). The warranty also does not cover normal wear and tear items (such as belts and consumables).

6. Marshalltown Company’s warranty will be void if it is determined that the defect resulted from operator abuse, failure to perform

normal maintenance on the product, modification to product, alterations or repairs made to the product without the written approval

of Marshalltown Company. Marshalltown Company specifically excludes from warranty any damage to any trowels resulting from

an impact to the rotors. Marshalltown Company also excludes from warranty any failure of clutches on any engine driven piece of

equipment.

7. If a new gearbox has a factory defect within the first year of use, Marshalltown Company will either repair the gearbox or replace it

with a new gearbox. If a new gearbox has a factory defect in the second year of use, Marshalltown Company will either repair it or

replace it with a factory reconditioned gearbox. Impact damage is NOT covered under the gear box warranty.

8. Marshalltown Company will pay shop labor repair on warranty at the Marshalltown Company Shop Labor Rate in existence on the

date of the warranty claim. A Marshalltown Company Labor Chart will determine the time allowed to complete a repair and will govern the shop labor hours that will be allowed.

9. Marshalltown Company will pay freight on warranty replacement parts at Worldwide standard ground rates. No warranty replacement parts will be shipped air freight at the expense of Marshalltown Company. Marshalltown Company only pays outbound freight

charges when sending warranty replacement parts to the customer VIA ground service. Marshalltown Company does not pay any

inbound freight, however, if Marshalltown Company determines this to be warranty defect only then will Marshalltown Company

reimburse the customer for inbound freight at standard ground rates.

10. Marshalltown Company’s warranty policy WILL NOT COVER the following; taxes, shop supplies, environmental surcharges, air

freight, travel time, loss of rental revenue, or any other charges whatsoever or any liabilities for direct, incidental, or consequential

damage or delay.

11. Marshalltown Company makes no other warranty, expressed or implied. This limited warranty is in lieu of the warranty of

merchantability and fitness. There are no other warranties that extend beyond the description on this document.

12. No Marshalltown Company employee or representative is authorized to change this warranty in anyway or grant any other warranty

unless such change is made in writing and signed by an officer of Marshalltown Company.

Page 3

1A

OPERATIONS

THE INFORMATION CONTAINED IN THIS MANUAL WAS BASED ON MACHINES IN PRODUCTION AT THE TIME OF

PUBLICATION. MARSHALLTOWN COMPANY RESERVES THE RIGHT TO CHANGE ANY PORTION OF THIS MANUAL

WITHOUT NOTICE.

Information Contained in this Manual:

This manual provides information and procedures to safely operate and maintain the Marshalltown Company’s

CYCLONE™ Power Trowels.

For your own safety and protection from personal injury, carefully read, understand and observe the safety instructions

described in this manual.

Always operate and maintain this machine in accordance with the instructions described in this manual. A well maintained

piece of equipment will provide many years of trouble free operation.

This manual is divided into the sections listed below:

1A

OPERATIONS

2A

ASSEMBLY

3A

PARTS

Ordering Parts

This manual contains an illustrated parts list for help in ordering replacement parts for your machine . Follow the instructions listed

below when ordering parts to ensure prompt and accurate delivery.

1. On all orders for service parts include the SERIAL NUMBER and MODEL NUMBER of

machine. Shipment will be delayed if this information is not included.

2. Include correct description and part number from parts section.

3. State exact shipping instructions including preferred routing and complete destination address.

4. DO NOT return parts to Marshalltown Company without first receiving written authorization from Marshalltown Company.

All authorized returns must be shipped prepaid.

Keep this manual or a copy of it with the machine. If you lose this manual or need an additional copy, please contact

your Marshalltown distributor or Marshalltown Company at 800-888-0127 or 641-753-0127.

Marshalltown Company

104 S 8th Ave

Marshalltown, IA 50158 U.S.A

© 2009 Marshalltown Company

All Rights Reserved Contents Subject to Change Without Prior Notice

1A-1

Page 4

1A

OPERATIONS

IMPORTANT REMINDER

Fill out your Marshalltown Company warranty card and place it in the mail within 24 hours of delivery.

Complete other warranty requirements as specified by the engine manufacturer in their instructions attached to the engine.

Your engine is not manufactured by Marshalltown Company, and therefore is not covered under our warranty.

Your engine manufacturer should be contacted if you wish to purchase a parts manual or a repair manual for your engine.

Refer to the enclosed owners manual on the engine for complete Operation & Maintenance

instructions.

Your Distributor

Your distributor has trained mechanics and access to original replacement parts. Always contact the distributor who sold you

this machine for repairs and replacement parts.

Place distributor information here for future reference.

DISTRIBUTOR NAME:___________________PHONE NUMBER:_____________________________

ADDRESS:_________________________________________________________________________

CITY:_________________________________STATE:__________________ZIP:_________________

SALESMAN:________________________________________________________________________

ADDITIONAL INFORMATION:__________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

1A-2

Page 5

1A

Marshalltown Cyclone™ Power Trowels

Table of Contents

1.1 Safety Notes ................................................ 1A-4

1.2 Laws Pertaining to Spark Arrestors .............................. 1A-4

1.3 Operating Safety .............................................1A-4

1.4 Service Safety ............................................... 1A-5

1.5 Technical Data .............................................. 1A-6

1.6 Dimensions ................................................. 1A-7

1.7 Description ................................................. 1A-8

1.8 Before Starting ..............................................1A-8

1.9 Starting .................................................... 1A-8

1.10 Steering .................................................... 1A-9

1.11 Pitch Adjustment ............................................. 1A-9

1.12 Periodic Maintenance Schedule ................................. 1A-10

1.13 Trowel Gear Box ............................................. 1A-10

1.14 Drive Belts .................................................. 1A-11

1.15 Compensation for Bent Trowel Arms ............................. 1A-11

1.16 Lift Lever Adjustment ......................................... 1A-12

1.17 Mounting a Float Disc .........................................1A-12

Operating Information

OPERATIONS

This machine was built with user safety in mind, however, it can present hazards if improperly operated and serviced. Follow

operating instructions carefully!

If you have questions about operating or servicing this equipment, please contact your Marshalltown distributor or Marshalltown

Company at 800-888-0127 or 641-753-0127

.

1A-3

Page 6

1A

OPERATIONS

This manual contains NOTES, CAUTIONS, and WARNINGS which must be followed to reduce the possibility of improper

service, damage to the equipment, or personal injury. Read and follow all NOTES, CAUTIONS and WARNINGS included

in instructions.

1.1 Safety Notes

NOTE: Contains additional information important to a procedure

CAUTION: Provides information important to prevent errors which could damage machine

or components

WARNING: Warns of conditions or practices which could lead to personal injury or death

1.2 Laws Pertaining to Spark Arresters

Notice: Some states require that in certain locations spark arresters be used on internal combus-

tion engines. A spark arrester is a device designed to prevent the discharge of sparks or

flames from the engine exhaust. It is often required when operating equipment on forest

ed land to reduce the risk of forest fires. Consult the engine distributor or local authorities

and make sure that you comply with regulations regarding spark arresters.

1.3 Operating Safety

SAFETY PRECAUTION

Familiarity and proper training are required for the safe operation of this equipment! Equipment operated improperly or by

untrained personnel can be dangerous! Read the operating instructions contained in both this manual and the engine manual

and familiarize yourself with the location and proper use of all the controls.

1. Read operating and safety instructions before using the Cyclone™ Power Trowel and operate the

machine in accordance with the manufacturer’s instructions.

2. Inspect your Cyclone™ Power Trowel for damage or tampering that can sometimes occur during

shipping. If damage is found, file a claim with your carrier immediately. Mark freight bill of landing as

damaged shipment.

3. Do not operate your Cyclone™ Power Trowel if any guards have been removed or if the “Safety

Switch” is not operational.

5. Only trained personnel should be allowed to operate your Cyclone™ Power Trowel.

6. No foreign objects such as buckets, tools, or materials should ever be attached or allowed to ride

on the trowel during operations.

7. Do not attempt to fill fuel tank or oil sump while engine is running. Allow engine to cool 5 minutes

before refueling.

8. Never attempt to operate the trowel on steeply inclined surfaces.

9. Do not use over-the-counter hardware to replace manufacturer’s hardware.

10. HEALTH HAZARD: When operating machines with gas engines in confined areas, the fumes MUST be ventilated!

11. Always wear safety goggles and gloves when operating the Cyclone™ Power Trowel.

1A-4

Page 7

1.4 Service Safety

1A

OPERATIONS

Poorly maintained equipment can become a safety hazard! In order for the equipment to operate safely and properly over a

long period of time, periodic maintenance and occasional repairs are necessary.

Warning

DO NOT attempt to clean or service machine while it is running. Rotating parts can cause servere injury.

DO NOT crank a flooded engine with the spark plug removed on gasoline-powered engines.

Fuel trapped in the cylinder will squirt out of the spark plug hole.

DO NOT test for spark on gasoline-powered engines if engine is flooded or the smell of gasoline

is present. A stray spark could ignite fumes.

DO NOT use gasoline or other types of fuels or flammable solvents to clean parts, especially in

enclosed areas. Fumes from fuels and solvents can become explosive.

ALWAYS operate machine with all safety devices and guards in place and in working order.

ALWAYS keep area around muffler free of debris such as leaves, paper, cartons, etc.

A hot muffler could ignite them, starting a fire.

ALWAYS replace worn or damaged components with spare parts designed and recommended

by Marshalltown Company.

ALWAYS disconnect spark plug on machines equipped with gasoline engines before servicing to

avoid accidental start up.

1A-5

Page 8

1A

OPERATIONS

1.5 Technical Data

Honda Engines

Engine Make and Model Honda 5.5 GX160 Honda 9.0 GX270 Honda 11.0 GX340

Rated Power - hp (kw) 5.5 (2.9) 9.0 (6.0) 11.0 (8.2)

Piston Displacement - cu. in (cc) 9.9 (162) 16.5 (270) 21 (344)

Spark Plug BPR6ES (NGK) BPR6ES (NGK) BPR6ES (NGK)

Electrode Gap - in. (mm) .029 (.75) .029 (.75) .029 (.75)

Operating Speed - RPM 3800 3800 3800

Fuel Capacity - gal. (L) .95 (2.5) 1.4 (5.3) 1.6 (6.0)

Fuel Consumption - lb/hph (g/kwh) .50 (310) .51 (313) .51 (313)

Running Time - Hours 1.9 3.13 3.33

Centrifugal Clutch Mech Ramp Mech Ramp Mech Ramp

Low Oil Shutdown Alert Yes Yes Yes

Engine Oil Capacity - US qt. (L) .63 (.6) 1.16 (1.1) 1.16 (1.1)

Engine Lubrication - Oil Grade SAE 10W30 SAE 10W30 SAE 10W30

Operating Weight - lbs. (kg) 31 (12) 55 (25) 68 (31)

1A-6

Page 9

1A

OPERATIONS

TROWEL 36" 36" EDGER 46” 9HP 46" 11HP

Length - in. (mm) 72 (1828) 80 (2032 78 (1981) 78 (1981)

Width - in. (mm) 38 (965) 36.5 (927) 48 (1219) 48 (1219)

Operating Weight - lbs (kg) 230 (104) 226 (102) 238 (108) 238 (108)

Troweling Width - in. (mm) 36 (914) 36.5 (927) 46 (1168) 46 (1168)

Rotor Speed - RPM 118 118 118 118

Pitch Range - Degrees 0 - 20 0 - 20 0 - 20 0 - 20

Gear Box Standard Standard Standard Standard

Safety Switch - handle mount Yes Yes Yes Yes

Gear Box Lub. - 25 oz.

1.6 Dimensions

Special Formula

Part# M048299

Special Formula

Part# M048299

Special Formula

Part# M048299

Special Formula

Part# M048299

36 36"

914mm

36 38"

965mm

46 48"

1219mm

CAUTION

!

DO NOT mix different types of gear oil.

DO NOT overfill the gearbox with gear oil.

Damage to the gearbox may occur if gear oils

aremixed, or if the gearbox is overfilled.

46 39"

991mm

36 72"

1828mm

46 78"

1981mm

1A-7

Page 10

1A

OPERATIONS

The Cyclone™ Power Trowel is a modern high production machine. Finishing rate will vary depending on operator

skill and job conditions. The trowel has four finishing blades. The standard duty gearbox is designed to provide exceptional

performance low maintenance and trouble free use under the worst conditions. All Cyclone™ Power Trowels are

equipped with a safety shutdown switch and a low oil shutdown alert for added job safety and engine protection. Operating

time between fuel refills is approximately 2-1/2 to 3 hours with rotor speeds between 80 and 120 rpm. Cyclone™ Power

Trowels are the most technically advanced trowels on the market today. With proper maintenance and use your trowel will

provide you with exceptional service.

Throttle Lever

1.7 Description

Choke Lever

Fuel ON/OFF

Crank Wheel Pull Handle

1.8 Before Starting

Before starting trowel check the following:

*Oil level in engine

*Oil level in trowel gear box

*Fuel level

*Condition of air filter

*Condition of trowel arms and blades

Engine ON/OFF

1.9 Starting

Before starting the operator must know the

location of all the controls.

Move the choke lever to the closed position

to start a cold engine. The choke may not be

needed if the engine is warm or the air temperature is hot. In this case keep the choke

lever open. Pull crank wheel pull handle

until engine starts.

1A-8

Page 11

1.10 Steering

Push down on the handle to move the

rotor assembly to the right.

Pull up on the handle assembly to move

the rotor assembly to the left.

1A

OPERATIONS

1.11 Pitch Adjustment

When changing or setting the pitch of the machine be sure that the machine is at a complete stop. On machines equipped

with standard pitch, turn the pitch control knob clockwise to increase the pitch and turn it counter-clockwise to decrease the

pitch.

1A-9

Page 12

1A

OPERATIONS

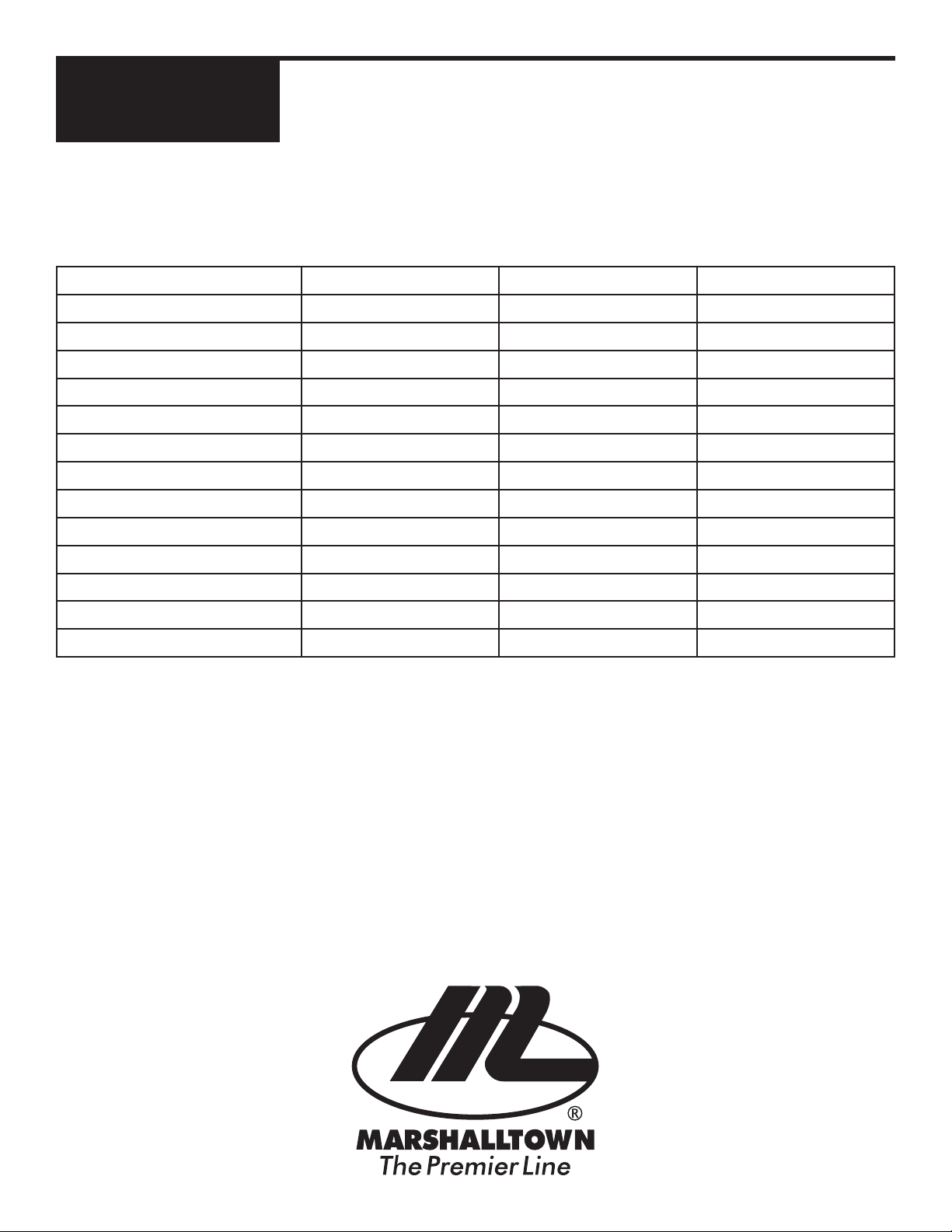

The chart below lists basic engine maintenance. Refer to engine manufacturer’s Operation Manual for additional information

on engine maintenance. A copy of the engine Operator’s Manual was supplied with the machine when it was shipped.

DAILY EVERY 50 EVERY 100 EVERY 300

HOURS HOURS HOURS

GREASE TROWEL ARMS X

CHECK OIL LEVEL IN GEARBOX X

CHECK FUEL FILTER X

INSPECT AIR FILTERS - REPLACE AS NEEDED X

CHECK AND TIGHTEN EXTERNAL HARDWARE X

CHECK AND ADJUST DRIVE BELTS X

CHANGE ENGINE OIL X

REPLACE FUEL FILTER X

REPLACE SPARK PLUG X

1.12 Periodic Maintenance Schedule

1.13 Trowel Gearbox

Check gearbox sight glass for correct oil level daily(every 8 hours). Add oil if oil level is below the bottom third of sight glass.

The gearbox oil level should only be checked when the gearbox is in the level position. To add oil, tilt trowel back and remove

sight glass. Add oil through sight glass opening. Replace sight glass and check oil level. Do NOT fill past the 3/4 full point.

Use only special blend Marshalltown gear oil part# M048299.

1A-10

Page 13

1A

1.14 Drive Belts

D

A

B

C

OPERATIONS

E

D

Figure 1

To Replace Belts:

1. Remove belt guard (A) by removing the four belt guard mounting bolts (B). See figure 1.

2. Rotate the pulley (C) while pulling the bottom of the belt (D) out. See figure 2.

3. After the belt (D) has cleared the pulley, remove it from the clutch (E). See figure 3.

4. Repeat steps 1 through 3 in reverse order to install the new belt.

NOTE: When replacing the belt be sure that the pulley and the clutch are in perfect alignment. If the belt is allowed to lean

to the left or the right it will cause the clutch to engage prematurely on start-up.

Figure 2

Figure 3

1.15 Compensating for Bent Trowel Arms

1. Loosen nut (B) slightly.

2. Adjust bolt (A) until trowel blade is level.

3. Tighten nut.

(See figure 4)

A

B

Figure 4

1A-11

Page 14

1A

1.16 Lift Lever Adjustment

OPERATIONS

Damage to, or replacement of, a trowel arm can change the adjustment of the lift lever. This can unbalance the trowel arms and cause

the trowel to wobble during operation. To operate smoothly, the lift

lever on all arms must be adjusted equally. All arms should be adjusted at the same time to ensure that the trowel is balanced correctly.

Adjust trowel arms using optional adjusting tool as described below.

1. Block up pressure plate using wooden blocks (b).

and have blades without contact.

2. Loosen hex head screws (a) on spider which

secures trowel arm in place (do not remove screws).

3. Remove trowel arms from spider with lift levers in

place.

4. Remove blade from trowel arms.

5. Clean all flats on trowel arm before placing it in the

adjusting tool (c) to make sure it lies flat. Clean thor oughly using a wire brush and scraper.

6. The adjusting tool comes with three different size

spacers. Use the shortest spacer (d) when adjusting

a Cyclone™ Power Trowels.

7. Insert trowel arm into adjusting tool as shown.

8. Tighten socket head bolts (e) down on the trowel

arm to hold it in place.

9. Move adjusting tool arm (f) over carriage bolts (g)on

lift levers shown.

10. Loosen the jam nut (h) and adjust the carriage bolt

so that the top of the bolt is just touching and mak ing contact with the bottom of the adjusting tool.

11. Tighten jam nut to secure adjustment in place.

12. Attach blades to arms and trowel arms to spider

plate. Tighten hex head screws to secure arm in

spider.

1.17 Mounting Floating Disc

Certain applications may require the use of a floating disc. To

mount disc(a), lift trowel off the ground (engine off) and position

disc against blades. Turn disc either to the right or the left to

engage clip angles (b) as shown. Remember the right hand trowel

blades turn counterclockwise the left-hand blades turn clockwise.

1A-12

A

B

Page 15

2A

ASSEMBLY INSTRUCTIONS

ASSEMBLY

STEP 1: Un-pack the handle assembly(A) and the

lower unit from their boxes. Check to make sure no

damage was done during shipment. Mount the handle

assembly(A) to the gearbox(B) on the lower unit using 4

3/8" nylock nuts(C) that are supplied in a package on the

lower unit.

C

STEP 2: With the handle mounted to the lower unit, attach

the pitch control cable(A) through the yoke arm(B) using

the remaining 3/8" nylock nut(C). Tighten the nylock nut

to where there is approximately a 1/4" of the threads are

showing.

STEP 3: Attach the kill wire(A) that is coming from the

handle assembly to the engine using the wire splicer(B)

that is supplied on the lower unit.

Step 1

Step 2

A

B

C

A

B

STEP 4: Make sure that the throttle lever on the handle

assembly is pushed all the way forward. Remove the

breather cap and the breather from the engine. Unscrew

the cable adjustment clasp(A). Next, make sure that

the throttle lever(B) on the engine is pushed all the way

forward. Insert the wire coming out of the cable into the

hole(C) shown on the diagram. With everything in place,

put the cable adjustment clasp(A) back on and tighten

down snug.

2A-1

A

B

Step 3

C

B

A

Step 4

Page 16

3A

PARTS

LOWER END ASSEMBLY

3A-1

Page 17

LOWER END ASSEMBLY (cont’d)

3A

PARTS

ILL. PART # DESCRIPTION QTY.

1 . . . . . . . M037619 ..... RING, 36" .............1

. . . . . . . . M037626 ..... RING, 46" .............1

2........ M221480 ..... LIFTING HOOK.........1

3........ M018961 ..... ENGINE, 5.5 HO........1

. . . . . . . . M018735 ..... ENGINE, 9 HO .........1

. . . . . . . . M018967 ..... ENGINE, 11 HO ........1

4........ KEY SUPPLIED WITH ENGINE.........1

5........ M016604 ..... CLUTCH, 3/4" ..........1

. . . . . . . . M015701 ..... CLUTCH, 1" ...........1

6........ M010083 ..... FLAT WASHER ........1

7........ M010090 ..... LOCK WASHER ........1

8........ M022553 ..... BOLT.................1

9........ M010100 ..... NUT..................4

10....... M010090 ..... LOCK WASHER ........4

11....... M010082 ..... FLAT WASHER ........4

12....... M018012 ..... STUD ................4

13....... M010039 ..... BOLT.................4

14....... M037648 ..... RUBBER BUSHING .....4

15....... M037660 ..... MTR MNT RH 9 HP .....1

. . . . . . . . M037665 ..... MTR MNT RH 11 HP ....1

. . . . . . . . M037656 ..... MTR MNT RH 5.5 HP....1

16....... M037675 ..... FLAT WASHER ........4

17....... M010464 ..... NUT..................4

18....... M015711 ..... SCREW...............4

19....... M010273 ..... KEY, 3/16 X 2 ..........1

20....... M015707 ..... PULLEY ..............1

20a . . . . . M012784 ..... PULLEY (used on 040973

. . . . . . . . . . . . . . . . . . . . & 040974) ............1

21....... M015202 ..... GEARBOX ............1

. . . . . . . . M040969 ..... SFC GEARBOX ........1

22....... M020977 ..... GUARD BRACKET ......1

23....... M037661 ..... MTR MNT LH 9&11 HP . .1

. . . . . . . . M037659 ..... MTR MNT LH 5.5 HP ....1

24....... M015987 ..... SMALL GUARD ........1

. . . . . . . . M015703 ..... LARGE GUARD ........1

25....... M012753 ..... STAR WASHER ........4

26....... M010002 ..... BOLT.................20

27....... M010019 ..... BOLT.................2

28....... M010090 ..... LOCK WASHER ........2

29....... M015677 ..... E-CLIP ...............2

30....... M015678 ..... YOKE ARM PIN ........1

31....... M015683 ..... BOLT.................4

32....... M015682 ..... STAR WASHER ........4

33....... M016920 ..... TROWEL ARM CLIP ....4

34....... M015816 ..... 4-BOSS...............1

35....... M015684 ..... NUT..................8

36....... M012990 ..... BOLT.................4

37....... M015686 ..... BOLT.................4

ILL. PART # DESCRIPTION QTY.

38........M010022......BOLT ................. 4

39........M010024......BOLT ................. 4

40........M010090......LOCK WASHER ........ 8

41........M015688......INSERT ...............4

42........M015818......36" TROWEL ARM ...... 4

. . . . . . . . .M024794......46" TROWEL ARM ......4

43 . . . . . . .M6093........BLADE, 36" ............4

. . . . . . . . .M6095........BLADE, 46" ............4

43a . . . . . .M3745........EDGER BLADE, 36" ..... 4

44........M017264......YOKE ARM ............ 1

45........M015821......PRESSURE CAP .......1

46........M015822......THRUST BEARING...... 1

47........M015824......PRESSURE PLATE .....1

48........M015696......KEY, 1/4 X 1-1/4 ........ 1

49 . . . . . . .M015893......36" SPIDER ASSEMBLY..1

. . . . . . . . .M024812......46" SPIDER ASSEMBLY.. 1

50........M015690......WASHER.............. 1

51........M015691......BOLT ................. 1

52........M041325......BELT, 36" .............1

. . . . . . . . .M041324......BELT, 46" ............. 1

. . . . . . . . .M032701......BELT, (LOW SPEED) 5HP 1

52a . . . . . .M041353......11/13 LO SPEED ....... 1

53 . . . . . . .M036665......SPACER .............. 1

. . . . . . . . .M039407......SPACER .............. 1

54........M033032......LIFT LEVER ...........4

. . . . . . . . .M033034......LIFT LEVER ...........4

55........M039203......UPPER RING (36") ...... 1

56........M037265......WHEEL HOUSING ...... 4

57........M037422......RETAINING SPACER .... 4

58........M037269......PIN................... 4

59........M037267......BEARING .............8

60........M039204......LOWER RING (36")...... 1

61........M039211......URETHANE BELT(36”)111 1

62........M012974......5/16-24 X 3/4 BOLT ..... 4

63........M010090......LOCK WASHER ........ 2

64........M010082......FLAT WASHER ......... 2

65........M015693......PLUG................. 1

66........M015694......PLUG................. 4

. . . . . . . . .M015694......PLUG -- (46) ........... 12

67........M041681......COVER, LH (436) ....... 2

..........M042072......COVER, BC (430) .......1

. . . . . . . . .M042073L.....COVER, LH (430) ....... 1

68........M042073R ....COVER, RH (430) .......2

. . . . . . . . .M041683......COVER, RH (436) ....... 2

69........M040860......BRACKET ............. 4

70........M020542......NUT, 1/4" STOVER ......16

71........M015805......STAB. RING (46") ....... 1

3A-2

Page 18

3A

PARTS

FINE PITCH

HANDLE ASSEMBLY

ILL. PART # DESCRIPTION QTY.

1..........M037668....... GRIP....................2

2..........M015724....... HNDL ASSY FINE PITCH LG 1

. . . . . . . . . .M015725....... HNDL ASSY FINE PITCH ST 1

. . . . . . . . . .M028012....... HNDL ASSY POS PITCH LG. 1

. . . . . . . . . .M034449....... HNDL ASSY POS PITCH ST . 1

. . . . . . . . . .M020498....... HNDL ST WELD’T F/PT..... 1

. . . . . . . . . .M020499....... HNDL LG WELD’T F/PT..... 1

3..........M015739....... KNOB. ADJ. HANDLE ...... 1

4..........M015740....... PIN, SPIRAL 3/16 X 1-3/4 ... 1

5..........M015741....... SCREW, SHAFT ..........1

6..........M015743....... BUSHING ................1

7..........M015746....... BUSHING, SLIDE..........1

8..........M018409....... SWITCH, SAFETY ASSY....1

9..........M015736....... LEVER, THROTTLE........1

10.........M015410....... SET SCREW 1/4-20 X 3/8 ...1

11.........M013370....... SCREW, 10-32 X 3/8 ....... 2

12.........M015769....... BAR, CARRY .............1

13.........M011238....... NUT, NYLOCK 1/2-13 ...... 2

14.........M015754....... PIN, 3/8 X 1-3/8 ........... 1

15.........M015753....... PULLEY CABLE ........... 1

16.........M015752....... BLOCK, CABLE SUPPORT ..1

17.........M034714....... BRKT, MTG. F/ SHT HNDL ..1

. . . . . . . . . .M034201....... BRKT, MTG. F/ LNG HNDL ..1

18.........M010075....... FSTN, 1/2-13 X 3 GR. 5..... 2

19.........M015735....... THROTTLE CABLE ASSY ...1

ILL. PART # DESCRIPTION QTY.

21.........M016691....... CABLE, FINE SHORT ...... 1

. . . . . . . . . .M015748....... CABLE, FINE LONG .......1

21A .......M027952....... CABLE LEVER PITCH ASSY 1

21B. ......M028013....... CABLE 44.25 POSTIVE

. . . . . . . . . . . . . . . . . . . . . . . . PITCH SHORT HANDLE ....1

22.........M015742....... BEARING ................1

23.........M034441....... INSULATION F/ HANDLE ...1

24.........M034440....... COVER, F/ HANDLE BAR ... 1

25.........M010004....... FSTN, 1/4-20 X 1-1/4 .......4

26.........M034279....... BLOCK, ADJ HANDLE ...... 1

27.........M034282....... HANDLE, ADJUSTABLE .... 1

28.........M034283....... HNDL FINE PITCH ADJ (LG) 1

. . . . . . . . . .M034284....... HNDL FINE PITCH ADJ (SH) 1

. . . . . . . . . .M034450....... HNDL POS PITCH ADJ (LG) . 1

. . . . . . . . . .M034451....... HNDL POS PITCH ADJ (SH) . 1

29.........M010089....... FSTN, 1/4 LW.............4

30.........M015744....... WASHER ................ 1

31.........M015747....... ROLL PIN ................1

32.........M015745....... RING, RETAINING ......... 1

33.........M034285....... EXT. F/ LONG HANDLE .... 1

. . . . . . . . . .M034286....... EXT. F/ SHORT HANDLE ... 1

3A-3

Page 19

PITCH CONTROL ASSEMBLY

POSITIVE PITCH

3A

PARTS

From this view the Chain (11) go around the

Sprocket (9) in a clockwise motion to operate

correctly.

ILL. PART # DESCRIPTION QTY.

1............ M019427..... KNOB, BURLOP PLASTIC 1-7/8 ............ 1

2............ M036448..... HANDLE, POSITIVE PITCH................ 1

3............ M010002..... BOLT, 1/4-20 x 3/4 ....................... 3

4............ M010081..... FLAT WASHER, 1/4 ...................... 3

5............ M027963..... COVER, WELD!T LEVER PITCH ........... 1

6............ M027958..... CLUTCH, POS PITCH ASSY............... 1

7............ M018510..... GREASE FITTING, 1/4-28 x 45˚ ............ 1

8............ M032346..... NUT, 3/8 FLEX LOCK PLAIN............... 1

9............ M027946..... SPROCKET, LEVER PITCH ...............1

10........... M015813..... KEY, 3/16 x 1 ........................... 1

11........... M028033..... CHAIN, #35 R/V ......................... 13.25 in

12........... M028013..... CABLE, POS PITCH CONTROL (SHORT) . . . . 1

. . . . . . . . . . . . M027952..... CABLE, POS PITCH CONTROL (LONG) ..... 1

13........... M010019..... BOLT, 5/16-18 x 3/4 GR. 5 ................ 2

14........... M024630..... BUSHING, FLANGE...................... 1

15........... M027948..... BUSHING, SUPPORT BRACKET ........... 1

16........... M027961..... BRKT, LEVER PITCH CLUTCH............. 1

17........... M010100..... NUT, HEX 5/16-18 . . . . . . . . . . . . . . . . . . . . . . . 2

18........... M010090..... LOCKWASHER, 5/16 ..................... 4

19........... M010018..... BOLT, 5/16-18 x 1/2 GR. 5 ................ 2

20........... M010081..... FSTN, 1/4 LW........................... 3

21........... M028035..... LINK, MASTER (BOTH ENDS) ............. 2

3A-4

Page 20

3A

PARTS

GEARBOX ASSEMBLY

3A-5

Page 21

GEARBOX ASSEMBLY (cont’d)

3A

PARTS

ILL. PART # DESCRIPTION QTY.

1...............M015205 .........SCREW, 5/16-18 x 1.................................8

2...............M015209 .........VALVE, 1/8 NPT-27 RELIEF...........................1

3...............M015208 .........COVER, GEARBOX MACHINED .......................1

4...............M032772 .........SHIM, (.002) .......................................AS REQ.

. . . . . . . . . . . . . . . M020018 .........SHIM, (.003) .......................................AS REQ.

. . . . . . . . . . . . . . . M015210 .........SHIM, (.005) .......................................AS REQ.

5...............M015212 .........SCREW, 3/8-16 x 1 (LH)..............................1

6...............M015213 .........WASHER, PRESSURE...............................1

7...............M022073 .........BEARING, TAPERED ROLLER ........................1

. . . . . . . . . . . . . . . M022074 .........BEARING RACE ....................................1

8...............M015216 .........GEAR, BRONZE (RH) ...............................1

9...............M015217 .........BEARING, RADIAL BALL .............................1

10..............M015219 .........SHAFT, MAIN MACH. FINISHED .......................1

11..............M015696 .........KEY, 1/4 x 1-1/4 HARDENED..........................1

12..............M015660 .........O-RING, GEARBOX END CAPS .......................1

13..............M015222 .........SHIM, (.005) .......................................AS REQ.

. . . . . . . . . . . . . . . M015186 .........SHIM, (.003) .......................................AS REQ.

14..............M017314 .........BOLT, 1/4-20 x 5/8 ..................................4

15..............M015221 .........CAP, GEARBOX END (4-HOLE) .......................1

16..............M010498 .........PLUG, 3/8 NPT BI SQUARE HD PIPE...................1

17..............M015672 .........SIGHTGLASS, 3/4-14 NPT ............................1

18..............M015673 .........O-RING ...........................................1

19..............M015204 .........GEARBOX, MACHINE FINISHED ......................1

20..............M015671 .........SEAL, OIL CR# 13650 ...............................1

21..............M012953 .........PLUG, 3/4 NPT BI SQUARE HD PIPE...................1

22..............M015662 .........NUT, JAM LH 5/8-18.................................1

23..............M015663 .........BEARING, ANGULAR CONTACT ......................1

24..............M022025 .........SPACER, FIBER GEARBOX COUNTERS................1

25..............M026740 .........SHAFT, INPUT RH GEARBOX.........................1

26..............M015668 .........BEARING, TAPERED ROLLER ........................1

. . . . . . . . . . . . . . . M015669 .........BEARING RACE ....................................1

27..............M015660 .........O-RING, GEARBOX ENDCAPS ........................1

28..............M015222 .........SHIM, (.005) .......................................AS REQ.

. . . . . . . . . . . . . . . M015186 .........SHIM, (.003) .......................................AS REQ.

29..............M015223 .........FLANGE, GEARBOX (4-HOLE) ........................1

30..............M017314 .........BOLT, 1/4-20 x 5/8 ..................................4

31..............M015670 .........SEAL, OIL SEAL CR# 7443 ...........................1

Note: Items 4, 13, and 28 from above are sold only in a kit. SHIM SET - M029457 This kit consist of (2) M015210,

(2) M015222, (2) M020018, and (2) M022186.

3A-6

Page 22

3A

PARTS

KILL SWITCH ASSEMBLY

ILL. PART # DESCRIPTION QTY.

1...............M013370 .........SCREW, 10-32 x 3/8 SLOTTED ........................2

2...............M018512 .........CONDUIT, RD PVC 1/4” SMOOTH .....................6.6 ft.

3...............M018624 .........SCREW, SLT 8-32 x 1 ...............................1

4...............M018267 .........CLIP, CONTACT PT SAFETY SWITCH ..................1

5...............M018407 .........BLOCK, CONTACT F/ PT SAFETY SWITCH .............1

6...............M018324 .........HOUSING, SAFETY SWITCH MF ......................1

7...............M018264 .........INSULATOR, RUBBER SAFETY SWITCH ...............1

8...............M013704 .........LOCK WASHER, EXT STAR 8-32 ......................2

9...............M018406 .........NUT BRASS, HEX 8-32 ..............................2

10..............M034072 .........KNOB, SAFETY SWITCH F/ WALKER ..................1

11..............M034316 .........LEVER, SAFETY SWITCH F/ PT .......................1

12..............M018326 .........COVER, SAFETY SWITCH ...........................1

13..............M018623 .........SCREW, BRASS 8-32 x 3/8 ...........................1

14..............M018404 .........SCREW, SLT BRASS 8-32 x 1.........................1

15..............M013270 .........WIRE, RED 14 GA. ELECT. ...........................7.1 ft.

3A-7

Page 23

LOW SPEED KITS

SPEED KITS

3A

PARTS

3

3

5 HP

1

2

4

5

ILL. PART # DESCRIPTION QTY.

1...............M027242 .........BELT GUARD (9 & 11 HP) ...........................1

. . . . . . . . . . . . . . . M032696 .........BELT GUARD (5.5 HP)...............................1

2...............M029102 .........PULLEY, BK90 .....................................1

3...............M041353 .........V-BELT, #6937 (9 & 11 HP) ...........................1

. . . . . . . . . . . . . . . M032701 .........V-BELT, B32 (5.5 HP)................................1

4...............M012387 .........H-BUSHING, 3/4" BORE..............................1

5.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . BOLT (COMES W/ H-BUSHING) .......................2

6...............M032697 .........BRKT, BELT GUARD (5.5HP) .........................1

. . . . . . . . . . . . . . . M032693 .........BRKT, BELT GUARD (9 & 11HP).......................1

6

8 & 11 HP

1

2

4

5

6

KIT ............M027239 .........EPOXY KIT FOR 9 & 11 HP STD.......................1

KIT ............M032702 .........EPOXY KIT FOR 5.5 HP .............................1

. . . . . . . . . . . . . . . M042676 .........EPOXY KIT FOR 11/13 SD ...........................1

HIGH SPEED KIT

ILL. PART # DESCRIPTION QTY.

1........M041325 ....V-BELT #6929 ........1

2........M012784 ....PULLEY, BK45H ......1

3........M012387 ....H-BUSHING 3/4" .....1

4........BOLT (COMES WITH H BUSHING) ...2

KIT .....M022942 ....HIGH SPEED.........1

3A-8

Page 24

3A

PARTS

OPTIONAL ACCESSORIES

PAN36-4C

PAN36-4CE

PAN46-4C

SPIDER PULLER

M035688

ALIGNMENT JIG

10 POUND WEIGHT

M010640

ROLLING TRANSPORT SYSTEM

M040349

M016863

3A-9

Loading...

Loading...