Page 1

OWNER’S MANUAL

2424, 121224 AUTOBROIL™

THIS MANUAL APPLIES TO BROILERS WITH S/N 3284 FORWARD

MODEL: 2424 121224 AUTOBROIL™

TABLE OF CONTENTS

I. BROILER SETTINGS ..................................................................................................... .......................1

II. EQUIPMENT INSTALLATION ........................................................................................ .......................2

Pre-Installation.......................................................................................................... .......................2

Equipment Location .................................................................................................. .......................2

Electrical Information ................................................................................................ .......................2

III. OPERATING INSTRUCTIONS ....................................................................................... .......................3

Pre-Operation Check ................................................................................................ .......................3

Broiler Adjustment .................................................................................................... .......................3

Toaster Operating Instructions ................................................................................. ................... 3-4

Toaster Shut-Off Instructions.................................................................................... .......................4

Toaster Conveyor Speed.......................................................................................... .......................4

Operation of 6-Button Controller............................................................................... ................. 5-11

IV. SCHEDULED MAINTENANCE....................................................................................... .....................12

Daily Cleaning Procedures ....................................................................................... ............... 12-13

Monthly Cleaning Procedures................................................................................... .....................13

Quarterly Cleaning Procedures and Preventive Maintenance.................................. ............... 13-14

V. TROUBLE SHOOTING ................................................................................................... ............... 14-18

VI. ASSEMBLY & DISASSEMBLY INSTRUCTIONS ........................................................... ............... 18-19

VII. REPLACEMENT PARTS ................................................................................................ ............... 19-21

ILLUSTRATIONS

Overall Dimensions...................................................................................................……….. .......... Figure 1

Exploded View - Removable Parts ........................................................................... ....................... Figure 2

Exploded View - Internal Parts ................................................................................. ....................... Figure 3

Exploded View - Drive System ................................................................................. ....................... Figure 4

Drive System Detail .................................................................................................. ..................... Figure 4A

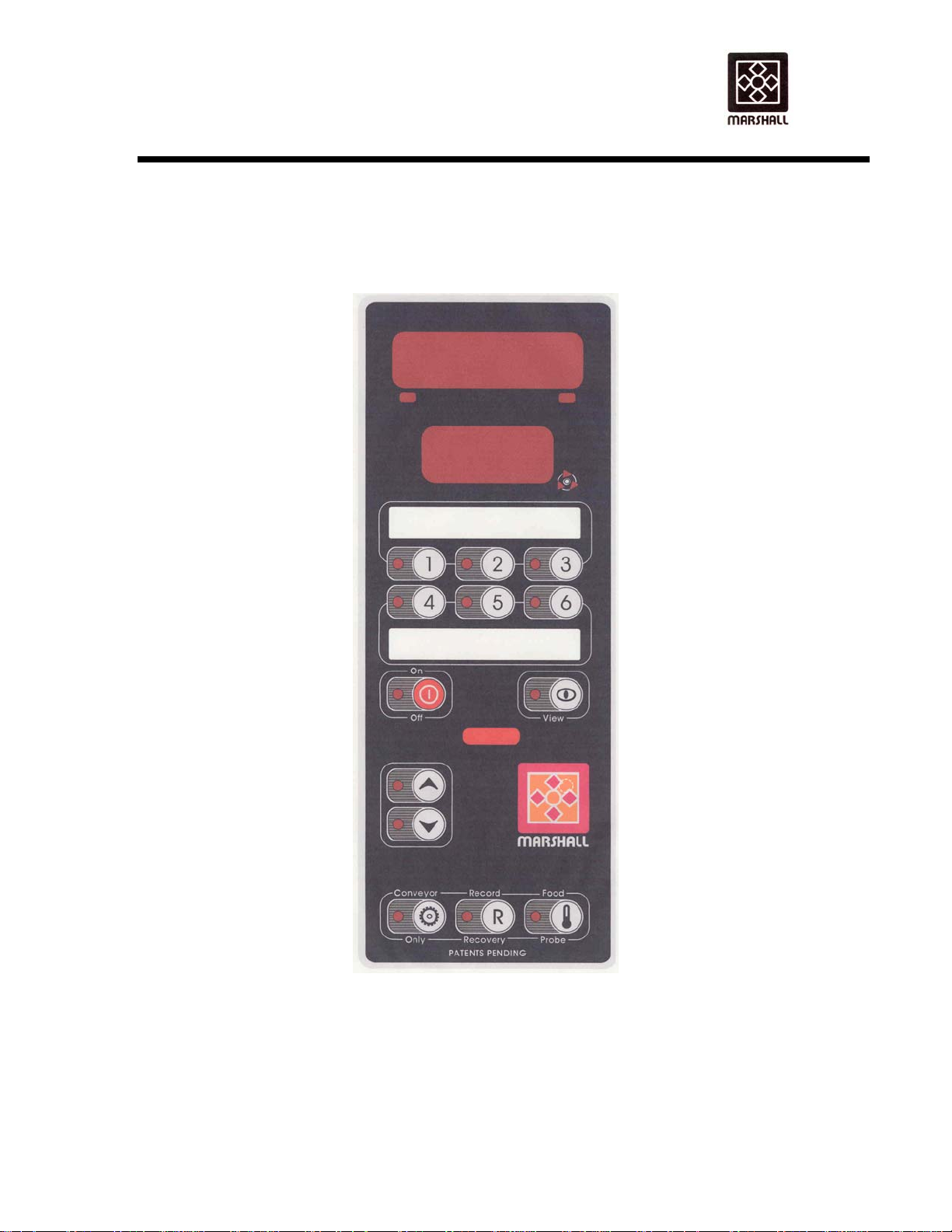

Control Panel With 6-Button Control......................................................................... ....................... Figure 5

Conveyor Axle Scraper............................................................................................. ....................... Figure 6

Spark Guard Installation…………………………………………………………………. ........................ Figure 7

Broiler Arm Extension 2424 ...................................................................................... ........................ Figure 8

Broiler Arm Extension 121224 .................................................................................. ........................ Figure 9

Broiler Idler Shaft Asby ............................................................................................. ...................... Figure 10

Toaster Platen Asby LH............................................................................................ ...................... Figure 11

Toaster Platen Asby RH ........................................................................................... ...................... Figure 12

Speed Control Circuit Board ..................................................................................... ...................... Figure 13

Fuse Location ........................................................................................................... ..................... Figure 14

Toaster Platen Heat Control ..................................................................................... ..................... Figure 15

Element Locations .................................................................................................... ..................... Figure 16

Wiring Schematic 121224……………………...(208V, 3PH, 60 AMP w/6-Button Control) Drawing #145703

Control Panel Quick Guide……………………………………………………...........................Drawing #145747

145861 Rv101105

Copyright© 2005 Marshall Air Systems, Inc.

All Rights Reserved.

1

Page 2

OWNER’S MANUAL

2424, 121224 AUTOBROIL™

145861 Rv101105

Copyright© 2005 Marshall Air Systems, Inc.

All Rights Reserved.

2

Page 3

OWNER’S MANUAL

2424, 121224 AUTOBROIL™

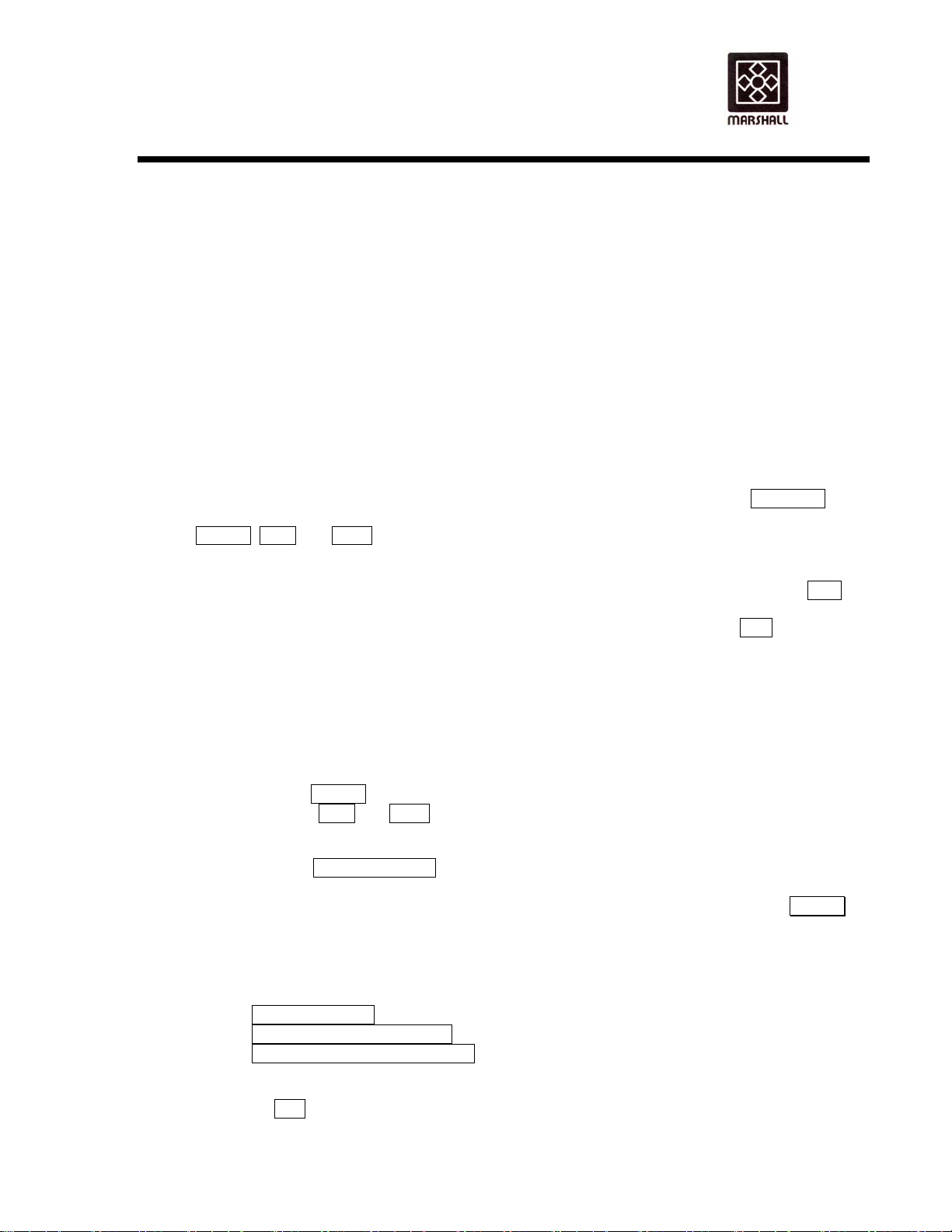

I. BROILER SETTINGS

MODEL NUMBER:____________________________________________________________

SERIAL NUMBER: ____________________________________________________________

ELECTRICAL SUPPLY: _________________________________________________________

SCHEMATIC NUMBER___________________ REV. _________

TOASTER PLATEN TEMPERATURE SETTING (425°F IS FACTORY SETTING)_______________

MENU SETTINGS: TEMPERATURE

RECIPE KEY SPEED TOP BOTTOM

1 ______________ _______ _______

2 ______________ _______ _______

3 ______________ _______ _______

4 ______________ _______ _______

5 ______________ _______ _______

6 ______________ _______ _______

START-UP TECHNICIAN: __________________________________________________________

START-UP DATE: ________________________________________________________________

COMMENTS: ____________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

AUTOBROIL™

MODEL: 2424 121224

145861 Issued111104

Copyright© 2004 Marshall Air Systems, Inc.

All Rights Reserved.

1

Page 4

OWNER’S MANUAL

2424, 121224 AUTOBROIL™

II. EQUIPMENT INSTALLATION

PRE-INSTALLATION

1. After uncrating the Autobroil™ unit, inspect for shipping damage. Check that the controller, switches, and

components are intact on the electrical cabinet front. Set the Autobroil™ in place and use the plastic bag

to protect it from the debris and trash of building construction. Check that sideskins have not been dented

or damaged by the carrier. If damaged, notify your freight carrier immediately to file a concealed damage

claim, following the instructions attached to the outside of the shipping crate. Your warranty will not cover

freight damage.

2. Because this unit is required to be power fan exhausted, it is necessary to provide adequate make up air

equal to the amount of air removed. In addition to this, any other exhausts, flues, or air removal systems

must be taken into consideration. Examples of this are heat removal fans or hot water heater flues.

EQUIPMENT LOCATION

1. Position Autobroil™ to properly align with exhaust hood. Check name plate for clearance requirements.

2. The hood/ventilator for the catering equipment should be located in accordance with the National Fire

Protection Association Standard #96, "Removal of Smoke and Grease-Laden Vapors from Commercial

Cooking Equipment" and any local applicable requirements.

3. For proper installation, the minimum clearance from combustible construction is 6" (152mm) from sides

and 6" (152mm) from back.

4. Adequate clearance should be maintained to allow easy access to loading and unloading areas of the

machine.

5. For servicing, unit must be moved 2' (610mm) clear from all construction.

ELECTRICAL INFORMATION

1. The Electrical Schematic is inside the electrical cabinet, and a copy is also included at the back of this

manual. Make certain the supply voltage and number of supply conductors agrees with the Electrical

Schematic. The load-carrying conductors should be sized according to the loads shown on the Electrical

Schematic per local codes and the National Electrical Code, ANSI/NFPA 70 -Latest Edition. If the broiler

is supplied with a cord, it will be type 4/4 or 6/4 SO 90 DEG C or higher, L1, L2, L3 and ground (See

electrical schematic for proper cord size). The cord will be approximately 9 feet long.

2. On a new electrical service - MAKE CERTAIN THAT VOLTAGE IS WITHIN 10% OF THE UNIT'S

RATED VOLTAGE. Appliance should be protected by a properly-sized circuit breaker furnished from the

main building circuit panel.

3. There is an Electrical Schematic located in the back of this Owner's Manual and also inside the

electrical cabinet of the machine.

145861 Issued111104

Copyright© 2004 Marshall Air Systems, Inc.

All Rights Reserved.

2

Page 5

OWNER’S MANUAL

2424, 121224 AUTOBROIL™

III. OPERATING INSTRUCTIONS

PRE-OPERATION CHECK (START-UP)

Before operating your Autobroil™, make a quick check of critical items as follows:

1. Check that no "binding" and resultant conveyor overloading is present. With the electrical

connections complete and with the electrical cabinet door secured shut, turn the broiler "ON" and run

the conveyors. Adjust the speed control for mid-point speed. The conveyor should move forward in

smooth unaltered motion. Shut down immediately if there is any evidence of "binding" or other

mechanical blockage.

2. Proper conveyor operation is when the amperage draw in the white or black motor lead from the

circuit board (Figure 4) to the motor cord measures .15 DC amps or less. To check amperage the

cabinet door will need to be open. THIS PROCEDURE SHOULD ONLY BE PERFORMED BY A

QUALIFIED ELECTRICIAN.

3. The Autobroil™ was tested at the factory before shipping so excessive amperage will indicate

conveyor binding caused by shipping damage. Remove the roller chain (Figure 4) driving the

conveyor in question and move the conveyor by hand. Loosen the sprockets (Figure 4) that drive the

various axles and reposition them by 1/32" (1mm) until the conveyor tightness is eliminated. Twentyfive inch pounds of torque is required to drive a properly set up conveyor.

4. After the conveyor checkout is complete, turn on the heat switch. All heater elements should glow

red. After the unit is up to temperature, these two elements will cycle. For trouble shooting problems,

see Section V. CAUTION: NEVER RUN HEAT WITHOUT CONVEYOR ON AS THIS CAN WARP

THE CHAIN.

5. Before first use, and after any special cleaning, it is necessary to "season" the BROILER

is done by bringing the broiler chain to operating temperature and applying liquid shortening from a

saturated cloth over the full width of the broiler chain while the chain makes five or six complete

revolutions.

6. Check to see that the three heat reflectors (Figure 3) are in place.

BROILER ADJUSTMENT

The Autobroil™ requires 30 minutes to reach stable temperature. After this time lapse, the conveyor speed

can be set to properly cook the product. The control will display “READY” when the broiler reaches cooking

temperature.

TOASTER OPERATING INSTRUCTIONS

1. The temperature control is located behind the right side lift-off cover. The control is factory-preset for

425ºF (218ºC).

2. Adjust the bun platen height over the conveyor so the platen touches the bun as it is moved under the

platen. To lower platen, turn the knob counter clockwise. To raise platen, turn the knob clockwise. This

produces a caramelized surface. If the platen is adjusted too low, the bun will be crushed.

chain. This

145861 Issued111104

Copyright© 2004 Marshall Air Systems, Inc.

All Rights Reserved.

3

Page 6

OWNER’S MANUAL

2424, 121224 AUTOBROIL™

TOASTER SHUT-OFF INSTRUCTIONS

1. The toaster section will continue to operate when the main heating (cooking) section of the broiler is on.

DURING A PROLONGED POWER FAILURE, NO ATTEMPT SHOULD BE MADE TO OPERATE THE

CATERING EQUIPMENT.

TOASTER CONVEYOR SPEED

1. The toaster conveyor is the lower conveyor on the broiler. This conveyor is linked to the main cooking

chamber broiler and does not have a separate speed control for the toasting section. For broilers without

computer controls, he toasting section is controlled by adjusting the toasting section temperature, using

the control located behind the right side lift-off cover.

145861 Issued111104

Copyright© 2004 Marshall Air Systems, Inc.

All Rights Reserved.

4

Page 7

OWNER’S MANUAL

2424, 121224 AUTOBROIL™

OPERATION OF 6-BUTTON CONTROLLER

1. USER INTERFACE

The following is the user interface layout. This control is located on the front of the broiler on the

right side.

The Control Panel illustration above shows a typical control interface layout. Also See Figure 5 for

Description of the Buttons. A Control Panel Quick Guide is located at the end of this manual.

145861 Issued111104

Copyright© 2004 Marshall Air Systems, Inc.

All Rights Reserved.

5

Page 8

OWNER’S MANUAL

2424, 121224 AUTOBROIL™

TIME AND DATE SETUP (USED ONLY ON BROILERS WITH FOOD PROBE OPTION)

When the controller is in Off mode, the system Time and Date can be adjusted by pressing the Off

Key for 10 seconds. The time is displayed on the 1

Down Keys, the hours are changed. Pressing the View Key moves the “focus” to the MM. Use the

Up/Down Keys to adjust. By pressing View Key again, HH:MM are replaced by DD/MM (or

MM/DD, depending on setting of temperature units) (1

to travel from one setting to another, and use the Up/Down Keys to modify. The View Key will

return to HH:MM. Pressing the Off Key again stores the new Time and Date, and returns to Off

mode.

ON/OFF KEYS

A normal press of this key turns on the controller. This causes the unit to start heating the

elements and running the motors at the slowest recipe speed found (overcooked food is safer

than undercooked food). This recipe is automatically selected (its corresponding LED lights up)

and the temperature set point is the one defined by this same recipe. At any time in On mode, the

user can change the selected recipe. When initially turned On, the unit will scroll PREHEAT on

the 1st line until the broiler comes up to temperature. After this time, unit will display either

READY, LOW, OR HIGH, depending on the current temperature readings.

A 3-second long press of the On/Off key turns off the unit. When the unit is turned Off, the Heater

Kill output is deactivated to disable power to heating elements. The 1st line will then blink HOT for

the Cool Down period (heating elements are off, but the conveyor motor is still running at the

fastest speed allowed by the unit). At that point, the unit will then simply display OFF, and all

outputs will be disabled.

RECIPE KEYS

Recipes are defined by a time and a temperature. The time basically sets the conveyor speed.

The top three (3) recipe buttons are for the left conveyor belt and the bottom three (3) buttons are

for the right conveyor belt.

When the unit is READY, a simple press of the recipe key will activate the selected recipe speed

and temperature (LOW and HIGH conditions may or may not be triggered).

When a specific recipe must be changed, keep its button pressed for 3 seconds, until the 1

parameter name SET COOK TIME scrolls on the 1

LED’s will also blink indicating that they can be used. Pressing either Up or Down the 1st time

simply makes the display switch to the parameter’s value (preceded by an arrow, as in ► 4.25, to

indicate a changeable value). Subsequent presses will then modify the parameter. If Up or Down

is not pressed in 5 seconds, the display resumes scrolling the parameter name.

Each recipe has 3 programmable parameters. To switch from one to the next, press the recipe

key. After the last parameter is programmed, the unit resumes normal operation.

- SET COOK TIME,

- SET TOP TERMPERATURE,

- SET BOTTOM TEMPERATURE.

By default, all recipes are set as follows:

Cook time: 5.00

st

line, and the HH is blinking. Using the Up and

st

line) and YY (2nd line). Use the View Key

st

st

line. The recipe as well as the Up/Down

145861 RV050405

Copyright© 2005 Marshall Air Systems, Inc.

All Rights Reserved.

6

Page 9

OWNER’S MANUAL

2424, 121224 AUTOBROIL™

Top temperature: 1325 ºF

Bottom temperature: 1250 ºF

VIEW KEY

The View key allows a user to view actual or programmed system parameters. Changes cannot

be made just by using this key.

In normal operation (On mode), pressing the View key will start scrolling the message BOTTOM

TEMPERATURE; also, the View and Up keys blink, indicating they can be used. If the broiler has

two conveyors, the down key also blinks. The 2nd line shows the current conveyor speed of the

illuminated recipe key. Pressing the Up key causes the 1st line to toggle between the message

and the actual temperature value. The down key will cycle to the recipe for the second conveyor.

A final press of the View key resumes normal operation.

When simply pressing the view key (not holding for 3 seconds), the 2nd line always shows the

current conveyor speed. If the unit is Off, or Hot, the conveyor speed is not shown.

A 3-second long press of the View key allows users to see the current recipe programs without

actually being able to change them. After this delay all 6 recipe LED’s blink, allowing the user to

select the wanted recipe. Once a recipe is selected, the procedure is the same for all recipes. The

1st parameter shows COOK TIME. By pressing the Up key, the user can view the value that is

currently programmed (but cannot change it). In 5 seconds the unit returns to the parameter

name. Pressing the Recipe key a 2nd time will bring up BOTTOM TEMPERATURE. Again, using

the Up key, the value can be seen. In 5 seconds, the unit returns to the parameter name.

Pressing the recipe key one last time returns the unit to normal operation.

CONVEYOR ONLY KEY

The Conveyor Only key is only accessible from the Off state. This key allows the conveyor to be

used without any heating. Press the Conveyor Only Key, then press the View Key. Press the Up

arrow to start the left conveyor moving. Do not run the conveyor faster than 230 on the display.

Press the Conveyor Only key to return to Off state. To start the other conveyor moving, press the

View button 2 times, then press the Up Arrow to the desired speed. This does not change the

programmed speed.

The parameter name SPEED is displayed on the 1

2nd line (expressed as a time). The flashing triangle indicates the speed can be changed using

the Up and Down keys. Exit this mode by pressing Conveyor Only a 2

selection is lost (i.e. the 1

st

speed used in READY mode is always the slowest recipe speed).

The display shows the theoretical motor shaft speed (divided by 100) on the top display, and the

real tachometer input (divided by 100) on the 2

st

line. The current speed is displayed on the

nd

time; however, the speed

nd

line. The theoretical value is simply derived

from the requested speed (in terms of time) and the programmed K value. The real value is

exactly that, the value coming in from the external tachometer. In an ideal world, the top and

bottom lines should read very close to the same value.

The next screen of data in the Conveyor Only mode is the real RPM coming in from the

tachometer input. By pressing the View key a 2

enough characters to display the information, as in the previous screen). A third and final press of

the View key returns to the standard Conveyor Only screen with SPEED on the 1

nd

time, this is displayed on the 1st line (which has

st

line.

7

145861 Issued111104

Copyright© 2004 Marshall Air Systems, Inc.

All Rights Reserved.

Page 10

OWNER’S MANUAL

2424, 121224 AUTOBROIL™

RECORD/RECOVERY KEY

A recovery time is the time required for the temperature to go from 200°F to 800°F. A log exists

for each heater (top and bottom). This is useful for service and HACCP purposes.

Do not press the Recovery Key while in the conveyor only mode. This key is available anytime

the broiler is in normal operation. When pressed, the controller will list a log of the last 3 recovery

times.

When the Recovery Key is pressed, the controller will successively display TOP 1, TOP2, TOP 3,

BOT 1, BOT 2, AND BOT 3 recovery times, “1” being the most recent ramp logged. To actually

see the logged time, press the Up key. After the last set is seen (BOT 3), the unit resumes

normal operation.

FOOD PROBE KEY – THE FOOD PROBE IS OPTIONAL AND MAY NOT BE INSTALLED ON

ALL BROILERS

This key is useable only when the unit is On (and the Food probe is enabled in the Low-level

programming). It is accessible in 2 modes: automatic or manual. In manual mode, it is up to the

user to press the Food Probe key to initiate a log, whereas, the automatic mode will remind the

user (up to 6 times a day) to take a sample. Even in automatic mode, the user still has the

capability to log extra samples manually as he/she wishes.

To do a manual log, the user must first make sure the temperature probe is correctly connected,

and then press the Food Probe Key.

Step #1

This step prepares the controller for logging.

Display: SELECT RECIPE TO LOG is scrolled and recipe LED blink.

Sound: None.

User Action: Select the Recipe corresponding to the sample that will be probed.

Step #2

This step starts the logging as such, and gives the user time to set up for the sampling.

Display: Shows INSERT PROBE. Actual temperature can be seen when Up key is

pressed. The Up key and Record LED blink.

Sound: None.

User Action: Insert the Food Probe into the sample according to local sanitary codes and normal

restaurant procedures.

Step #3

In this step (basically a continuation of Step #2), the temperature continues to be displayed for the

user. Nothing is being logged yet. The user must wait until a certain temperature is reached (that

depends on what is being sampled (chicken, beef, etc.), as well as specific restaurant

procedures).

Display: The 1

Record key LED also blinks.

Sound: No particular sound.

User Action: Keep Food Probe inserted. When temperature reaches a specific point (known to

st

line displays the temperature currently measured by the Food Probe. The

145861 Issued111104

Copyright© 2004 Marshall Air Systems, Inc.

All Rights Reserved.

8

Page 11

OWNER’S MANUAL

2424, 121224 AUTOBROIL™

the user), the user presses the Record button.

Step #4

When the Record button was pressed, 2 things happened: the “Start Temperature” was stored, and

the equalization timer was started. The controller now waits for the timer countdown to finish.

st

Display: The 1

However, there are no keys that function at this point.

Sound: A beep every 1 second until 5 seconds before end of timer. During last 5 seconds, beeps

accelerate to 2 beeps per second.

User Action: Keep Food Probe inserted.

Step #5

In this last step, the actual log is written to memory. The temperature now displayed is logged as the

“End temperature.”

Display: Last temperature read when timer reached zero is displayed until Food Probe Key is pressed

again. This exits Food Probe.

Sound: None.

User Action: Remove probe, and press any key to resume normal operation.

Data Logged

The following is logged each time a sample is taken (in Step #5):

Date/time stamp (MM/DD/YY if English (degree F), DD/MM/YY if Metric (degree C) as well as HH:MM)

Recipe number (that was selected by user)

Top element temperature

Bottom element temperature

Food “Start temperature” (when user pressed Record)

Food “End temperature” ( at the end of the equalization time)

NOTE: At the end of Step #5, the user can record another sample of same recipe by pressing Record

again instead of Food Probe, which clears display of previous samples. Display then shows probe’s

current temperature and Steps 3, 4, and 5 are repeated.

UP AND DOWN KEYS

line continues to display the temperature currently measured by the Food Probe.

These keys are used to adjust the various system parameters when required. Time is

incremented/decremented at 5-second intervals, and temperature at 5°F (2°C) intervals. These keys

have a typematic feature associated with them. Keeping them pressed for more than 2 seconds

causes the rate of change to accelerate to 25°F/10°C (temperature), or 20 seconds (time) every 500

msec.

2. DISPLAY

GENERAL

In general, all messages are scrolled on the 1st line (about 2 characters per second), and

times are displayed on the 2

nd

.

Some keys have a LED, which is used to indicate various situations.

• On/Off LED: full on when broiler is On, otherwise Off.

9

145861 Issued111104

Copyright© 2004 Marshall Air Systems, Inc.

All Rights Reserved.

Page 12

OWNER’S MANUAL

2424, 121224 AUTOBROIL™

• Up/Down LED’s: blink when Up/Down keys are expected.

• Recipe LED’s: on when a recipe is active, blinking when programming or viewing

recipes.

• Conveyor Only: blinking when feature is in use.

• Recovery: full on when feature is in use.

• Food Probe: off.

• View: full on when feature is in use.

• Conveyor: this is a group of 3 LED’s that simulate a rotating motion (about 2 changes per

second). This is active whenever the controller is receiving pulses from all installed

tachometers.

• Top and Bottom Heater LED’s: full on when the corresponding heaters are on, otherwise

off.

Also, whenever the arrow symbol (Z) is displayed with the data, this means that this is a

parameter being changed/adjusted.

TIME DISPLAY

All conveyor speeds are displayed on the 2nd line, and are limited to 9.59. All other times are

displayed as MM.SS, or HH:MM (in Low-level programming, this information is on the top line,

which has more characters available). For example, 9.59 is 9 minutes and 59 seconds, and 1:10

is 1 hour and 10 minutes.

3. SYSTEM STATES

There are several states of operation as follows:

POWER-UP STATE

When a power-up occurs, there is a lamp test, where all LED’s come on for 5 seconds (this

includes all LED’s in the two displays). Following the lamp test, the software number and revision

are displayed. These are useful for troubleshooting purposes when several versions exist in the

field. The first line shows the software number and the second line shows the revision in the

format 1.09. Following this, the unit falls automatically into Off mode.

OFF STATE

In this state, the heaters are disabled. Nothing is displayed, except for OFF on the 1

The conveyor motor(s) may be used (and the speed displayed on the 2

Only function is used. Also the View and Recovery keys may be used in the Off state.

ON STATE

This is the normal cooking state. Before displaying READY, the unit will go through the

PREHEAT mode. The pre-heat mode lasts until the pre-heat time expires.

In the On mode, 2 extra conditions may exist: LOW and HIGH . Both depend on the current set

point, and the current temperature. If the difference between the set point and the current

temperature exceeds the programmable thresholds, then either the LOW or HIGH messages are

displayed. This warns the user to wait until the READY condition comes back before putting

product onto the conveyor. These conditions are likely to occur when a recipe calls for different

temperatures.

st

line.

nd

line) if the Conveyor

145861 Issued111104

Copyright© 2004 Marshall Air Systems, Inc.

All Rights Reserved.

10

Page 13

OWNER’S MANUAL

2424, 121224 AUTOBROIL™

HOT STATE

This state is active after the unit is turned Off (or if an error occurs that causes the unit to shutdown). This state is basically a cool down step between the On and Off states. The conveyor

continues to roll at the fastest speed programmed, but the heaters are off. The display

continuously shows HOT until the Cool Down Time has elapsed, at which point OFF appears.

4. DIAGNOSTICS

This section describes the various diagnostics errors that are available.

HEATER TEMPERATURE PROBES

All probes are type-K probes. All temperature readings normally associated with a type-K probe

are considered valid by the controller. However, if the probes become disconnected or broken,

the controller will sound the buzzer

display. The defective probe number is displayed on the 2nd line: On the toaster (lower)

controller, there are two thermocouples connected:

• 1 is top heater temperature probe

• 2 is bottom heater temperature probe

On the broiler (upper) controller, there is only one thermocouple connected. Pressing any key shuts

the buzzer off, but will not remove the error message. The only way to remove the error message is

to resolve the probe and/or connection problem.

When these heater probe errors occur, there are 2 possible ways to react, depending on the

Probe Error parameter:

• If Probe Error Action is set to 0 (default), the unit goes into shutdown via the HOT state. After

the Cool Down delay, the error message becomes OFF - PROBE ERROR instead of HOT -

PROBE ERROR.

• If Probe Error Action is set to 1, then the unit continues operation, at full temperature. The

operator will most likely have to adjust the recipe times, but at least the unit can still operate.

EXTERNAL DC ERROR

The DC I/O connector has a +5VDC supply. This supply is internally protected against overcurrents. Should this occur, the unit will internally disconnect the supply and report HOT –

EXTERNAL DC ERROR. The unit goes into shutdown (through HOT mode) and the only way to

reset this is to resolve the problem (most likely a short). Since the buzzer is powered through the

same +5VDC supply as the DC I/O connectors, the buzzer does not sound when this error occurs.

After the Cool Down delay, the error message becomes OFF - EXTERNAL DC ERROR instead

of HOT - EXTERNAL DC ERROR.

5. EMERGENCY STOP SWITCH

An emergency stop switch is available on the front of the broiler as shown in Figure 1A. This toggle

switch is for immediately stopping the conveyors in case of a conveyor jam or other problem

requiring the broiler to shut down.

Do not use this switch for normal shut down at the end of the day. Use it if the conveyor jams or

you need to stop the broiler quickly. This switch stops the conveyors and turns off the heating

elements and turns off power to the control panels. When you turn the “Emergency Shut Off

Switch” back on, the control panels will cycle through an initialization, then display “Off.” From here

you can start as normal.

and scroll HOT - PROBE ERROR on the 1st line of the

145861 Issued111104

Copyright© 2004 Marshall Air Systems, Inc.

All Rights Reserved.

11

Page 14

OWNER’S MANUAL

2424, 121224 AUTOBROIL™

IV. SCHEDULED MAINTENANCE

DAILY CLEANING PROCEDURES

CAUTION: Do not touch the broiler section immediately after appliance shut-down. The temperature

inside enclosures is in excess of 500°F (260°C), which eliminates the need to clean any parts

inside the enclosures for sanitary purposes. Any grease that may build up on the exterior of

the enclosures should be cleaned off with a damp cloth and a minimum amount of detergent.

Disconnect the power supply to the appliance before cleaning or servicing.

CAUTION: Under no circumstances should oven cleaner be used on this appliance. IT WILL EAT

HOLES IN THE LOWER PLATEN (HOLDING AREA). CAUSTIC FUMES CAUSE

ELECTRICAL COMPONENT DAMAGE, AND WILL CAUSE MANY OTHER PROBLEMS IF

USED TO CLEAN THIS BROILER.

CAUTION: KEEP THE APPLIANCE AREA FREE AND CLEAR FROM COMBUSTIBLES.

1. Allow broiler burners and chain to operate for 30 minutes

grease on broiler components. Then turn the unit off and allow to cool. (This applies every time a

meat chain is turned off -- regardless of what time of day meat chain is shut down -- and regardless of

how few patties were broiled in the last 30 minutes, last hour, etc.) This will clean some parts of the

cooking chamber. Failure to perform this procedure daily will result in poor cooking times.

2. Remove all exterior panels except those which are attached with screws. Be careful not to touch any

hot internal broiler components.

* Grease Drain Channel

* Grease Pans

* Crumb Tray (Toaster Section)

Front and Rear Tunnel Guard

Heat Shield Assembly

Tunnel Filler

* Broiler Arm Cover and Heat Guard

* Broiler Grease Tray

Tube Bundle Asby (2)

Meat Stripper

* Grease Catch Pan and Insert

Toaster Bun Tray

* Toaster Arm Covers

* NOTE: these items may be removed during the 30 minute period.

after cooking last patty to burn off excess

Figure 3

Figure 2

Figure 2

Figure 2

Figure 2

Figure 2

Figure 2

Figure 2

Figure 2

Figure 3

Figure 2

Figure 2

Figure 2

145861 Issued111104

Copyright© 2004 Marshall Air Systems, Inc.

All Rights Reserved.

12

Page 15

OWNER’S MANUAL

2424, 121224 AUTOBROIL™

3. With the conveyor running and heat OFF, wire brush the broiler conveyor and, as it cools, wipe with

damp cloth.

4. Scrape deposits from the axles with the axle scraping tool, furnished with each machine as shown in

Figure 6. * THIS IS IMPORTANT TO PREVENT GREASE FIRES AT THE REAR OF THE

BROILER.

5. Remove grease and meat residue from any part of remaining broiler structure where visible. Use a

damp cloth with detergent and a putty knife for best results. * DO NOT SCRAPE THE LOWER

PLATEN (HOLDING AREA).

6. The tube bundles (2) (Figure 2) should be removed and wire brushed. Further cleaning is not

necessary; however, make sure carbon deposits are scraped from between the tubes with a tool such

as a screwdriver.

7. Additional cleaning should exhibit good housekeeping and entail a general wiping of all exterior

surfaces. DO NOT GET WATER ON THE ELECTRICAL CABINET OR THE HEATING ELEMENTS.

NEVER HOSE THE MACHINE.

8. After cleaning all removable parts as noted, allow to dry and reassemble.

MONTHLY CLEANING PROCEDURES

1. Remove the broiler conveyor chain from the machine and steam clean or soak in detergent solution.

The conveyor is removed by taking the conveyor apart at the cutlinks. When the conveyor is removed, check all heating elements and replace elements showing extreme corrosion. Check

bearings for excessive wear and order replacements where needed. (See Figure 5 for cutlink

illustration.) Make certain conveyors are reinstalled going in the correct direction. PLACING CHAIN

ON BACKWARDS WILL CAUSE SEVERE BINDING PROBLEMS.

2. Remove spark guard and wipe out. (Figure 2)

QUARTERLY CLEANING PROCEDURES & PREVENTIVE MAINTENANCE

1. If required, remove conveyor and soak in hot soapy water overnight. The chain is removed by lifting

axle up to produce slack and separating as described in Figure 5. When replacing chain, make

certain the conveyor is installed properly. PLACING CHAIN ON BACKWARD WILL CAUSE

SEVERE BINDING PROBLEMS. CLOSE

2. If required, spread conveyor links open with screwdriver or chain pliers (part#500033). Lift front axle

up to make slack in the conveyor belt, unhook conveyor chain and remove to gain access to lower

cooking chamber for cleaning side walls. Make reference to the orientation of the conveyor links and

the conveyor direction for reassembly. (Figure 5)

3. Lubricate the roller (drive) chain with a few drops of any grade motor or machine oil.

4. Remove and inspect all motor brushes and replace if less than 1/4" (6mm) is left.

5. CAUTION: DISCONNECT POWER BEFORE OPENING PANEL. Retighten the screw lugs on the

main power wires at the main terminal block or contactor inside the control box. Check that other

electrical connections are still tight. Check that fuse block wire connection screws are tight.

open links to match other links. (Figure 5)

145861 Issued110807

Copyright© 2007Marshall Air Systems, Inc.

All Rights Reserved.

13

Page 16

OWNER’S MANUAL

2424, 121224 AUTOBROIL™

INVENTORY THE SPARE PARTS KIT (IF APPLICABLE) AND ORDER MISSING PARTS AS NEEDED.

KEEP A COMPLETE SET OF PARTS ON HAND AT ALL TIMES.

TROUBLE SHOOTING

This section contains a list of possible problems with your Autobroil. By locating the problem in this section,

you may be able to make a quick repair. ALL ELECTRICAL TROUBLE SHOOTING INVOLVING ACCESS

INTO THE MOTORS OR ELECTRICAL ENCLOSURES MUST BE PERFORMED BY A QUALIFIED

ELECTRICIAN.

*

E) Check fuses to each element.

F) Check elements.

* B) Check 1.5 amp fuse on side of the control cabinet. SOLUTION: Replace if blown and

turn broiler off, and turn broiler on.

* E) Check switch to make sure power is flowing through it. SOLUTION: Replace switch.

* F) Connect motor control leads to an operating motor speed control board. SOLUTION: If motor

runs, replace motor control board. If motor still does not run, replace motor.

INSTRUCTIONS MARKED WITH ASTERISKS SHOULD BE PERFORMED BY

AUTHORIZED SERVICE PERSONNEL.

1. MACHINE HAS POWER BUT ELEMENTS ARE OUT.

POSSIBLE CAUSE

A) Check to make sure broiler on-off switch is in

coming out of switch (see Electrical Schematic).

B) Check that heat switch is in ON position.

C) Check that power is passing to and through the mercury relays.

D) Check wiring to individual elements.

2. CONVEYOR CHAIN WILL NOT MOVE.

POSSIBLE CAUSE

A) Check for object caught in conveyor, causing a jam. SOLUTION: Remove object.

* C) Check 10 amp fuse. SOLUTION: Replace if blown.

D) Check to see if motor shaft is moving. SOLUTION: Sprocket needs to be tightened.

"ON" position and that the correct voltage is

145861 Issued110807

Copyright© 2007Marshall Air Systems, Inc.

All Rights Reserved.

14

Page 17

OWNER’S MANUAL

2424, 121224 AUTOBROIL™

3. CONVEYOR RUNS BUT SPEED IS CONSTANT

POSSIBLE CAUSE

* A) There are four parts to the motor system. They are the motor, the circuit board, the rotary speed

control and the fuse mounted on the side of the control cabinet. The most likely problem would

be a blown fuse. SOLUTION: Using spare parts, replace one part at a time until the trouble

spot is identified.

4. REPEATED MECHANICAL BINDING.

POSSIBLE CAUSE

A) Check to see that chain is not on backward. SOLUTION: See proper chain installation on

Figure 5.

B) Inspect chain closely for bent or warped links that may be snagging and causing a binding

condition. Also check that the chain links are not climbing out of the sprockets as the conveyor

rotates. SOLUTION: Straighten or replace bad links. Season new links with cloth saturated with

shortening before broiler reaches full operating temperature.

C) Make sure the axle assembly is clean and free of grease and food residue to allow smooth

movement of the conveyor. SOLUTION: Clean axle. See Figure 5.

D) Check the axle assembly to make certain all set collars, bearings, etc. are properly positioned

and secure.

E) Disassemble conveyor axle assembly and check condition of bushings and bearings for

excessive wear. SOLUTION: Replace if worn or damaged.

F) Visually inspect the motor drive chain assembly for smooth rotation of chain. SOLUTION:

Make certain there are no binding or worn components.

G) Make sure conveyor is not catching on meat stripper. See Figure 3 SOLUTION: Straighten

bent stripper.

5. HEAT PLATEN TEMPERATURE CONTROL DOES NOT WORK (LOCATED BEHIND RIGHT

SIDE LIFT-OFF PANEL).

POSSIBLE CAUSE

* If control flashes "EEE" or "999", then inspect thermocouple for continuity. SOLUTION: Check to

be sure thermocouple leads are securely fastened to temperature controller. If so, then

replace thermocouple.

6. MEAT DOES NOT COOK COMPLETELY.

POSSIBLE CAUSE

A) Check to make sure tube bundle is clean.

B) Check to make sure the heat shield is installed (Figure 2).

145861 Issued110807

Copyright© 2007Marshall Air Systems, Inc.

All Rights Reserved.

15

Page 18

OWNER’S MANUAL

2424, 121224 AUTOBROIL™

C) Check to make sure all elements are working. If not, check fuses in the control cabinet that

protect the elements. Replace fuses and/or heating elements.

D) Check the speed of the conveyor.

E) Check refrigeration of meat. Holding temperature of meat may be lower than 0°F (-18°C).

F) Check for excessive exhaust by momentarily turning exhaust fan off.

G) Check setting on temperature controller.

7. CANNOT MAINTAIN CONSISTENT TEMPERATURE DURING COOKING.

POSSIBLE CAUSE

A) Check that tube bundles are being cleaned in accordance with Item 6 in Section IV.

B) Check store power supply for large voltage variation. A 5% swing in voltage will require more

than a 5% change in speed to counteract.

C) Meat of different temperatures is being used. (Frozen vs. partially thawed.)

D) Check for excessive exhaust by momentarily turning off exhaust fan.

E) Check to make sure the heat shield is installed (Figure 2).

F) Check to make sure all elements are working. If not, check fuses in the control cabinet that

protect the elements. Replace fuses and/or heating elements.

8. MEAT OVERCOOKED ON OUTSIDE AND UNDERCOOKED ON INSIDE.

POSSIBLE CAUSE

A) Check refrigeration of meat. Holding temperature of meat may be lower than 0°F (-18°C).

B) Check that tube bundles are being cleaned in accordance with Item 6 in Section IV.

9. MEAT NOT SLIDING INTO HAMBURGER CATCH AREA.

POSSIBLE CAUSE

A) Meat stripper (Figure 3) needs cleaning.

B) Meat stripper needs adjustment.

10. BUNS WILL NOT GET HOT ENOUGH.

POSSIBLE CAUSE

A) Check that toaster platens touch bun. SOLUTION: Lower platens by turning the knob

counterclockwise to correct height to compress buns properly for toasting.

145861 Rv081205

Copyright© 2005 Marshall Air Systems, Inc.

All Rights Reserved.

16

Page 19

OWNER’S MANUAL

2424, 121224 AUTOBROIL™

* B) Check toaster platen electrical power. SOLUTION: Check temperature control power output.

C) Check speed to make sure conveyor is not running too fast. SOLUTION: Speed should be

about 50 to 60 seconds.

* D) Check element connections to top of toaster platens. SOLUTION: Tighten

* E) Check the sensor to make sure it is inserted into side of platen. SOLUTION: Remove control

cabinet lid and push sensor into position.

11. BUNS WILL NOT FEED CORRECTLY.

POSSIBLE CAUSE

A) Check for buildup of black residue on teflon sheet caused by improper cleaning. SOLUTION:

See cleaning instructions under Daily Cleaning Procedure.

B) Teflon sheet is worn or damaged. SOLUTION: SHEET MUST BE REPLACED.

12.

TROUBLE SHOOTING GUIDE FOR 6-RECIPE BUTTON

CONTROLS

The following Error Messages are associated with the 6-Recipe Button controls:

ERROR MESSAGE PROBLEM SOLUTION

TACH ERROR or HOT – TACH ERROR or OFF – TACH ERROR

Note: On the lower display window, the number 1 or 2 or 12 will be shown 1 indicates a single conveyor

problem, or a left conveyor problem on a dual conveyor broiler. 2 indicates a right conveyor problem.

When a problem occurs, the first message displayed is TACH ERROR, which almost immediately will

cause the broiler to shut down and display HOT – TACH ERROR. After the cool down period, the broiler

will turn off and display OFF – TACH ERROR

Jammed Conveyor Remove Items Preventing Conveyor From

Moving

Failed Fuse Replace Fuse

Loose Wire or Connector Check wire connections

Loose Pick-up Tighten Pick-Up

Failed Pick-up Replace Pick-Up

Failed Speed Control Circuit Board Replace Circuit Board

Failed Motor Replace Motor

Failed Speed Module Replace Speed Module

HOT – PROBE ERROR or OFF – PROBE ERROR

Note: The number on the second line of the control display indicates the thermocouple number.

For electric broilers, 1 indicates the top heater thermocouple, and 2 indicates the bottom heater

thermocouple.

145861 Rv081205

Copyright© 2005 Marshall Air Systems, Inc.

All Rights Reserved.

17

Page 20

OWNER’S MANUAL

2424, 121224 AUTOBROIL™

For gas broilers, which have only one thermocouple, the display will indicate 2

When a problem occurs, the first message displayed is HOT - PROBE ERROR. After the cool down

period, the broiler will turn off and display OFF – PROBE ERROR.

Loose Thermocouple Fix wiring connection

Failed Thermocouple Replace Thermocouple

Depending on the 6-Recipe Button Control factory setting, some electric broilers will default to 100 percent

heater output to allow the broiler to continue to operate until the problem is fixed. In this case, the recipe

cook time should be temporarily adjusted to achieve the desired cooked product using the 100 percent

heat. A PROBE ERROR message will be displayed until the problem is fixed.

HOT – EXTERNAL DC ERROR or OFF – EXTERNAL DC ERROR

Check Wiring and Connectors For ShortRepair Wiring

Failed Pick-up Replace Pick-up

Failed Speed Control Circuit Board Replace Circuit Board

Failed Speed Module Replace Module

Failed Gas Module Replace Module

Failed 6-Recipe Button Control Replace 6-Recipe Button Control

FOOD PROBE ERROR

Food Probe Not Connected Plug in Food Probe

Failed Food Probe Replace Food Probe

CLEAR LOG Log File almost full Clear Food Probe Log File

LOG FULL Log File is full Clear Food Probe Log File

VI. ASSEMBLY & DISASSEMBLY INSTRUCTIONS

1. To Replace the Heating Elements:

A. Disconnect power to the broiler.

B. Remove the access cover on the element box on the top right side of the broiler.

C. Disconnect the wires to the element to be replaced.

D. Remove the screws attaching the access cover on the left side of the broiler.

E. Pull the element out of the broiler through the slot in the side of the broiler.

F. Insert a new element, being careful to position the element rods through the central support.

G. Reconnect wiring and install covers.

H. Connect power and test operation.

145861 Rv080105

Copyright© 2005 Marshall Air Systems, Inc.

All Rights Reserved.

18

Page 21

OWNER’S MANUAL

2424, 121224 AUTOBROIL™

2. When replacing the thermocouple which attaches to the hi/low temperature controller, make certain it

is inserted through side wall of machine into cooking chamber exactly one inch (1") (25mm).

3. To properly set the clearance between the meat stripper and the conveyor chain, the machine must

be HOT. Loosen the bolts holding the brackets to the sides of the unit and adjust their position until

the top edge of the stripper is within 1/16" (2mm) of the hot conveyor. See Figure 3.

WARNING: THIS APPLIANCE IS NOT CAPABLE OF BEING SAFELY PLACED INTO

OPERATION DURING A POWER FAILURE AND NO ATTEMPT TO

OPERATE IT SHOULD BE MADE.

VII. REPLACEMENT PARTS

When ordering parts, make sure to specify the machine model number, type of gas and serial number as

shown by the label attached to the right side cover.

PART #

124676 9.5" Conveyor Arm, LH 1 3, 8, 9

132579 9.5" Conveyor Arm, RH 1 3, 8, 9

132579 9.5" Conveyor Arm, RH 1 3

124677 Arm Bearing Bracket 2 3, 8, 9

128147 Arm Cover Asby, 9.5" Arms 1 2, 8

118040 Axle Drive 1 4

118731 Bearing Backup Plate 4 4, 4A

503104 Boxer Cooling Fan, 240V 1 Schematic

118402 Broiler Catch Pan Insert 1 2

134475 Bun Exit Tray Asby 1 2

134475 Bun Exit Tray Asby 1 2

130694 Charcoal Tray Cover 1 3

140158 Circuit Board, 230V Input 2 13,Schematic

141643 Circuit Board, 230V Input 2 Schematic

500211 Contactor 2 Schematic

145704 Control, 6-Button 1 Schematic

116088 Conveyor Idler Shaft 1 3

120030 Conveyor Idler Shaft 1 3, 8, 10

120029 Conveyor Support Pin 1 4

121696 Conveyor Wiper Asby, 24" 1 3

124654 Conveyor, 24" X 73.25" 1 2

135883 Conveyor, 24" X 73.25" LG 1 2

135883 Conveyor, 24" X 73.25" LG 1 2

118529 Crosstube, .5" OD x 24.563" 1 3

116084 Crosstube, .5" Dia. X 24.875" 2 3, 8

501864 Curvette Rocker Switch 1 Schematic

501864 Curvette Rocker Switch 1 Schematic

145727 Element w/ Thermocouple Clip 2 Schematic

503366 Element, 1350W 208V 11 3, Schematic

503366 Element, 1350W 208V 9 3, Schematic

503393 Element, 1441W 220V 11 3, Schematic

2424 AUTOBROIL

DESCRIPTION

QUANTITY

PER UNIT

FIGURE

145861 Rv080105

Copyright© 2005 Marshall Air Systems, Inc.

All Rights Reserved.

19

Page 22

OWNER’S MANUAL

2424, 121224 AUTOBROIL™

144139 Fan 2 Schematic

118401 Front Grease Tray 1 2

128364 Front Tunnel Guard 1 2

504052 Fuse, ABC 20 12 14,Schematic

504052 Fuse, ABC 20 12 Schematic

502739 Fuse, AGC - 10 2 Schematic

501139 Fuse, AGC .5 2 Schematic

500061 Fuse, AGC 1.5 AMP 2 14,Schematic

500061 Fuse, AGC 1.5 AMP 2 Schematic

504053 Fuse, MDL – 1/16 2 Schematic

500066 Fuseblock, 2 Pole 1 Schematic

500069 Fuseblock, 2 Pole 7 Schematic

500068 Fuseholder, Panel Mount, 15A 250V 2 Schematic

500068 Fuseholder, Panel Mount, 15A 250V 2 Schematic

124662 Grease Pan Asby 1 2

500732 Ground Lug 1 Schematic

500732 Ground Lug 1 Schematic

501835 Half Size Pan, 4" Deep 1 2

501835 Half Size Pan, 4" Deep 1 2

123879 Hamburger Catch Pan Asby 1 2

123832 Heat Guard, Loading Arm Cover 1 2, 8, 9

145749 Heat Shield 1 2

145749 Heat Shield, Tunnel Top 1 2

124578 Idler Bearing Asby, 1.250" OD x .500 ID 2 3, 8, 10

116090 Idler Bearing Asby, 1.626 Dia., 500 DEG F 2 3

124580 Idler Sprocket Asby 1 4

122551 Idler, 1.688" OD, .755" ID 2 3, 8, 10

501827 Knot with stud 2 4

501827 Knot with stud 2 4

130442 Meat Stripper Asby 121224 1 3

119531 Meat Stripper Hanger, LH 2 3

119530 Meat Stripper Hanger, RH 1 3

121625 Motor Idler Mount 1 4

117234 Motor Mounting Bracket 1 4

118426 Motor Sprocket Guard 1 4

118702 Rear Tunnel Guard Asby 1 2

118007 Side Panel Asby 2 2

118425 Spark Guard 1 2, 7

115813 Spring Tensioning Bracket 2 3, 8, 9

116087 Spring Tensioning Rod 2 3, 8, 9

101357 Teflon Bearing, .750" Shaft 4 4, 4A

118427 Thermocouple Mount-Platen 1 11

121658 Toaster Arm Cover LH 1 2

117248 Toaster Arm, RH 1 3

123844 Toaster Drive Shaft 1 4

118403 Toaster Pan 1 2

102153 Tube Bundle Asby, 12" 2 2

136519 Meat Stripper Asby 2424 1 3

121224 AUTOBROIL

145861 Rv010809

Copyright© 2009 Marshall Air Systems, Inc.

All Rights Reserved.

20

Page 23

OWNER’S MANUAL

2424, 121224 AUTOBROIL™

503287 Motor Brush Type 24Y2FETM-D4 4 N/A

503287 Motor Brush Type 24Y2FETM-D4 4 N/A

500940 Motor, 1/50 HP 1 4, Schematic

500940 Motor, 1/50 HP 2 4, Schematic

131398 Mount, Motor Pick-Up 2 4

145861 Owner's Manual 1 N/A

130694 Reflector Tray Cover 1 3

500035 Roller Chain 4.3 FT 4

500035 Roller Chain 4.3 FT 1

129746 Set Collar Asby, .505" Dia. 500117 2 4

129746 Set Collar Asby, .505" Dia. 500117 2 4

128489 Set Collar Asby, .755" Dia. 1 3, 4, 10

500518 Set Collar, .250" ID 2 3, 8, 9

500518 Set Collar, .250" ID 2 3

500118 Set Collar, 0.750" ID 1 4, 4A

500118 Set Collar, 0.750" ID 1 4

502809 Spring, 2.750" 2 3, 8, 9

502809 Spring, 2.750" 2 3

500040 Sprocket 3510 x ½ (Motor) 2 Schematic

143366 Sprocket 3512 x ½ for Idler 1 Schematic

134825 Sprocket 5010 x ¾ 4 4A

152705 Sprocket 5010 x 1 2 4A

124643 Sprocket, 3512 x .750" (Toaster) 1 4

502838 Sprocket, 3515 x .750" (Toaster) 1 4

502839 Sprocket, 3524 x .750" (Broiler) 1 4

129210 Sprocket, 3524 x .750" (Broiler) 1 4

108582 Teflon Sheets 12" x 35" 1 4

108582 Teflon Sheets 12" x 35" 2 4

131360

145738 Temperature Controller, Toaster Platen 1 Schematic

500932 Terminal Jumper 1 Schematic

503087 Terminal Strip 12 Pole 1 Schematic

502390 Thermocouple, Type K, 36” 2 Schematic

503416 Thermocouple, Type K, Toaster Platen 1 Schematic

127027 Toaster Arm Cover, RH 1 2

127028 Toaster Arm, LH 1 3

502916 Transformer, 115/230 24V Secondary 1 Schematic

502168 Transformer, 240V Primary, 12V Secondary 2 Schematic

502206 Transformer, 240V Primary, 12V Secondary 2 Schematic

130446 Tunnel Filler 1 2

130446 Tunnel Filler 1 2

128320 Washer, 1.000" OD x 0.765" ID 6 4A

Temperature Controller, DEG F°

1 Schematic

145861 Rv010809

Copyright© 2009 Marshall Air Systems, Inc.

All Rights Reserved.

21

Page 24

Page 25

Page 26

Page 27

Page 28

Page 29

Page 30

Page 31

Page 32

Page 33

Page 34

Page 35

Page 36

Page 37

Page 38

Page 39

Page 40

Page 41

Page 42

CONTROL PANEL QUICK GUIDE

AUTOBROIL™

Scrolls Messages and Temperatures

Displays Time in View Mode

1–3 Left Conveyor Recipes

4–6 Right Conveyor Recipes

recipe. Press and hold 3 seconds to

program speed and temperature.

1 pres

A 1-second press turns

broiler on

A 3-second press turns Infrared Port

broiler off

Use anytime flashing

to change a setting

up or down

Turns on conveyor

without heat

LEFT BELT

RIGHT BELT

Quick press of any Button activates that

Press View Button once to view the left

conveyor recipe setting. Press the View

Button followed by Down Button to

view the right conveyor recipe setting.

Optional – see Owners Manual

145747 RV021207

Copyright© 2004 Marshall Air Systems, Inc.

All Rights Reserved.

Press Recovery Button followed

by Up Button to view Broiler

Heat Up Time today, yesterday

and the day before.

Loading...

Loading...