INSTALLATION & OPERATING MANUAL

Deck Ovens: MB42, MB60, MB236, MB260, MB866, SD236, SD248, SD260, SD448, SD660, SD1048,

SD1060, SD866, SD10866, WF42, WF60

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND LIQUIDS IN THE

VICINITY OF THIS OR ANY APPLIANCE.

FOR YOUR SAFETY

POST INSTRUCTIONS TO BE FOLLOWED IN THE EVENT THE USER SMELLS GAS IN A

PROMINENT LOCATION. THIS INFORMATION SHALL BE OBTAINED BY CONSULTING YOUR

LOCAL GAS SUPPLIER.

WARNING

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY, OR DEATH. READ THE INSTALLATION,

OPERATING, AND MAINTENANCE INSTRUCTIONS BEFORE INSTALLING OR SERVICING

THIS EQUIPMENT.

ELECTRICAL GROUNDING INSTRUCTIONS

THIS APPLIANCE, WHEN INSTALLED, MUST BE ELECTRICALLY GROUNDED IN ACCORDANCE WITH LOCAL CODES,

OR IN THE ABSENCE OF LOCAL CODES, WITH THE NATIONAL ELECTRICAL CODE, ANSI/NFPA 70, OR THE CANADIAN

ELECTRICAL CODE, CSA C22.2 AS APPLICABLE.

THIS APPLIANCE IS EQUIPPED WITH A THREE PRONG (GROUNDING) PLUG FOR YOUR PROTECTION AGAINST SHOCK

HAZARD AND SHOULD BE PLUGGED DIRECTLY INTO A PROPERLY GROUNDED THREE-PRONG RECEPTACLE. DO

NOT CUT OR REMOVE THE GROUNDING PRONG FROM THIS PLUG.

KEEP THE OVEN AREA FREE AND CLEAR FROM COMBUSTIBLE AND NONCOMBUSTIBLE CONSTRUCTION. DO NOT

OBSTRUCT THE FLOW OF COMBUSTION AND VENTILATION AIR.

THIS OVEN HAS ZERO CLEARANCE ON BOTH SIDES BUT A 3” - 4” SPACE MUST BE LEFT AT THE REAR TO ALLOW

ADEQUATE CLEARANCE FOR AIR OPENINGS INTO THE COMBUSTION CHAMBER INSURING PROPER CIRCULATION

OF AIR INTO THE BURNER SYSTEM.

AN ELECTRICAL DIAGRAM IS LOCATED ON THE INSIDE OF THE CONTROL DOOR ON ALL MB SERIES OVENS.

Marsal & Sons, Inc. 175 East Homan Ave., Lindenhurst, NY 11757

THIS MANUAL MUST BE RETAINED FOR FUTURE REFERENCE.

INSTALLATION & OPERATING MANUAL

I.

INSTALLATION MANUAL

SERVICE ACCESS 1

ELECTRICAL CONNECTION 1

GAS CONNECTION 1

GAS AND ELECTRICAL SPECIFICATIONS 2

DELIVERY 3

OVEN LOCATION 3

ADJUSTMENTS ASSOCIATED WITH INITIAL INSTALLATION 3

ASSEMBLY INSTRUCTIONS 4

TABLE OF CONTENTS

VENTILATION - CANOPY METHOD 5

VENTILATION - DIRECT CONNECTION METHOD 5

VENTILATION PROBLEMS 7

INSTALLATION OF BAKING CHAMBER BRICKS 7

CURING THE OVEN DECK 10

II.

OPERATING MANUAL

STARTING THE OVEN 11

OVEN CONTROL 11

MAINTENANCE 12

CLEANING THE OVEN 12

WF Operation 13

INSTALLATION MANUAL

Installation must conform with local codes, or in the absence of local codes, with the National

Fuel Gas Code, ANSI Z223.1, Natural Gas Installation Codes, CAN/CGA-B149.1, or the Propane

Installation Code, CAN/CGA-B149.2, as applicable.

1.

The appliance and its individual shuto valve must be disconnected from the gas supply

piping system at test pressures in excess of ½ psig (3.45kPa).

2.

The appliance must be isolated from the gas supply piping system by closing its individual

manual shut-o valve during any pressure testing of the supply system at test pressures

in excess of ½ psig (3.45kPa).

SERVICE ACCESS

All service can be done through the Control Door opening and the Burner Door opening. An

access panel is located on the left side of the oven for more access to the controls. If this is

blocked o all service can be done from the front of the oven.

1

ELECTRICAL CONNECTION

A 15 AMP service must be provided for each oven. For 115 Volt usage, a cord and plug is

provided but connection to the electrical service must comply with local codes; or in the

absence of local codes, with the National Electrical Code, ANSI/NFPA No. 70 (or latest edition)

GAS CONNECTION

A ¾” NPT inlet is located at the rear of the oven. Undersized gas supply lines will restrict gas

supply and aect oven performance. If other appliances are supplied by the same supply

line the supply line must be sized to carry the combined volume without causing more than

½” pressure drop at the manifold of each appliance on the line at full rate. When installing a

stacked oven with one line, the line should be 1” to the tee and the 3/4” into each oven

NOTE: During installation, there will be air in the line. The air must be bled o before ignition

can be established.

GAS PIPING

A properly sized gas supply system is essential for maximum oven performance. Piping should

be sized to provide a supply of gas sucient to meet the maximum demand of all appliances

on the line without loss of pressure at the equipment.

Additional Gas Connection Instructions

GAS HOSE RESTRAINT

If the oven is mounted on casters, a commercial exible connector with a minimum of 3/4” (1.9

cm) inside diamter must be used along with a quick connect device.

The restraint, supplied with the Flexible Hose Kit, must be used to limit the movement of the

unit so that no strain is placed upon the exible connector. With the restraint fully stretched

the connector should be easy to install and quick connect.

1.

Mount the supplied bracket to the hold located on the rear or base frame on the same

side as the gas supply.

The connector must comply with the Standard Connectors for Movable Gas Appliances, ANSI

Z21.59 or Connectors For Moveable Gas Appliances CAN/CHA-6.16 and a quick disconnect

device that complies with the Standard for Quick Disconnect Devices for Use With Gas Fuel,

ANSI Z.41 or Quick Disconnect For Use With Gas Fuel CAN 1-6.9. Adequate means must be

provided to limit the movement of the appliance without depending on the connection and

the quick disconnect device or its associated piping. Adequate means must be provided to

limit the movement of the appliance qithout depending on the connection and the quick

disconnect device or its associated piping.

2

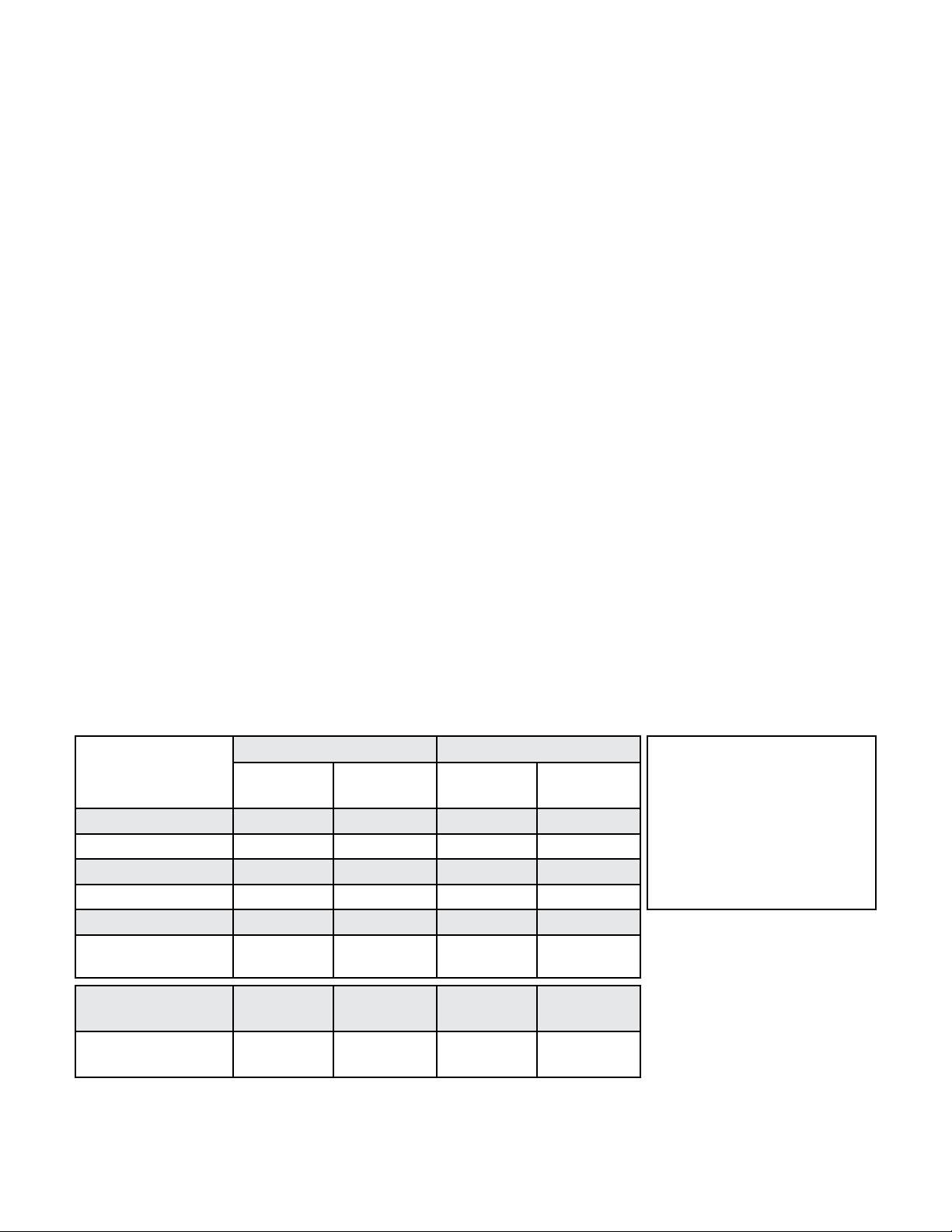

GAS AND ELECTRICAL SPECIFICATIONS

Input Rate Manifold Pressure Electrical Requirements

Models

MB42, SD448, SD1048

MB60, SD660, SD1060

SD236

SD248

SD260

MB866, SD866,

SD10866

WF42

WF60

NATURAL

GAS

95,000 90,000 4.5 IN. WC 11 IN. WC Volts 120VAC

115,000 115,000 4.5 IN. WC 11 IN. WC Frequency 60Hz

50,000 50,000 4.5 IN. WC 11 IN. WC 0.9 AMPS Phase 1

65,000 65,000 4.5 IN. WC 11 IN. WC

80,000 80,000 4.5 IN. WC 11 IN. WC

115,000 115,000 4.5 IN. WC 11 IN. WC

135,000 135,000

155,000 155,000

PROPANE

GAS

NATURAL

GAS

4.5 main

3.5 side

4.5 main

3.5 side

PROPANE

GAS

11 main

10 side

11 main

10 side

(MB Models Only)

DELIVERY

Marsal & Sons, Inc. cannot assume responsibility for loss or damage suered in transit. The

carrier assumed full responsibility for delivery in good order when the shipment was accepted.

We are, however, prepared to assist you if ling a claim is necessary.

OVEN LOCATION

The oven should be installed in a location in which the facilities for ventilation permit satisfactor y

combustion of gas and proper venting. The oven should be located so as not to interfere with

proper circulation of air within the conned space. In buildings where normal inltration does

not provide the necessary air, outside air should be introduced.

It is essential that an adequate air supply to the oven be maintained to provide a sucient

ow of combustion and ventilation air.

•

Place the oven in an area that is free of drafts.

•

Do not place the oven on a curb base or seal to a wall. This will restrict the ow of air and

3

prevent proper ventilation. Pilot outages or yellow, oating ames on the main burners

are indicative of a lack of secondary air.

Before making any utility connections to this oven, check the rating plate to be sure the oven

specications are compatible with the gas and electrical services supplied for the oven. The

rating plate is located on the inside of the control door.

ADJUSTMENTS ASSOCIATED WITH INITIAL INSTALLATION

Each oven, and its component parts, have been thoroughly tested and inspected prior to

shipment. However, it is often necessary to further test or adjust the oven as part of a normal

and proper installation. These adjustments are the responsibility of the installer, or dealer.

Since these adjustements are not considered defects in material or workmanship, they are not

convered by the Original Equipment Warranty. They include, but are not limited to:

•

calibration of the thermostat

•

adjustment of the doors

•

burner adjustments

•

leveling

•

testing of gas pressure

•

tightening of fasteners

No installation should be considered complete without proper inspection, and if necessary,

adjustment by qualied installation or service personnel.

Loading...

Loading...