Page 1

Document No: ICM-IOM

Date: 0515

PHANTOM (PH10 and PH12) COMMERCIAL AND INDUSTRIAL

SERIES

Installation, Operation and Maintenance Manual

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or

maintain the product described. Protect yourself and others by observing all safety information. Failure to comply

with these instructions could result in personal injury and/or property damage. Retain these instructions for future

reference.

OVERVIEW

Mars Air Curtains

are designed to

cover door

openings,

providing both

temperature

control/environme

ntal separation

and flying insect

control, when the

building’s doors

are opened.

Typical

installation

heights are: Phantom 10 Series (Environmental up to

10’, Flying Insect Control up to 8’), and Phantom 12

Series (Environmental up to 12’, Flying Insect Control

up to 10’). The units are typically suspended from the

ceiling and hidden inside the false roof. They can also

be wall mounted using special brackets. The units are

ETL Listed, Canada and US, for either an inside or

outside mount. Heated units must be mounted on the

inside or the protected side of the opening. The motors

used in the Phantom 10 and Phantom 12 series are 1/2

HP and 1 HP respectively.

The Phantom Series come standard with an air intake

screen(s).

GENERAL SAFETY INFORMATION

Use this product only in the manner intended by the

manufacturer. If you have any questions, contact the

manufacturer. Only qualified personnel should install

this product. Installing personnel should have a clear

understanding

of these

instructions

and should be

aware of

general safety

precautions.

Improper

installation

can result in

electric shock,

possible injury

due to coming

in contact with

moving parts,

as well as other potential hazards.

WARNING

To reduce the risk of fire, electric shock or injury to

persons, observe the following.

A. Always disconnect, lock and tag power source before

installing or servicing product.

B. Installation work or electrical wiring must be done by

qualified person(s) in accordance with all applicable

codes and standards, including fire-rated construction.

C. The combustion airflow needed for safe operation of

fuel burning equipment in the area may be affected by

the product’s operation. Follow the heating equipment

manufacturer’s guideline and safety standards, such

as those published by the National Fire Protection

Agency (NFPA), the American Society of Heating,

Refrigeration and Air Conditioning Engineers

(ASHRAE) and local code authorities.

D. When cutting or drilling into a wall or ceiling, be careful

not to damage electrical wiring and other hidden

utilities.

Page 2

WARNING

Precaution should be taken in explosive atmospheres.

WARNING

When servicing the product, motor may be hot enough

to cause pain or injury. Allow motor to cool before

servicing.

RECEIVING AND INSPECTION

Upon receiving the product, check to make sure all

items are accounted for by referencing the Bill of Lading

to ensure all items were received. Inspect each carton

for shipping damage before accepting delivery. Notify

the freight carrier if any damage is noticed. The carrier

will make notification on the delivery receipt

acknowledging any damage to the product. All damage

should be noted on all copies of the Bill of Lading which

is countersigned by the delivering carrier. A Carrier

Inspection Report should be filled out by the carrier

upon arrival and a report given to the Traffic

Department. If damaged upon arrival, file a claim

immediately with the carrier. Any physical damage to

the unit after acceptance is not the responsibility of

Mars Air Systems.

UNPACKING

Verify that all parts, components and accessories, and

the correct quantities of each have been received. If

any items are missing, report shortages to Mars Air

Systems directly to arrange for obtaining the missing

items. Again, verify quantities received against those

on the Bill of Lading only, as multiple shipments may be

involved.

INSTALLATION

Typical Mounting – Wall or Ceiling Mounted

Horizontally Above the Door Opening

1. Gently remove all packaging materials, hardware and

all other accessories from interior of unit prior to

operating. Severe unit damage will occur if these items

are not removed prior to operation.

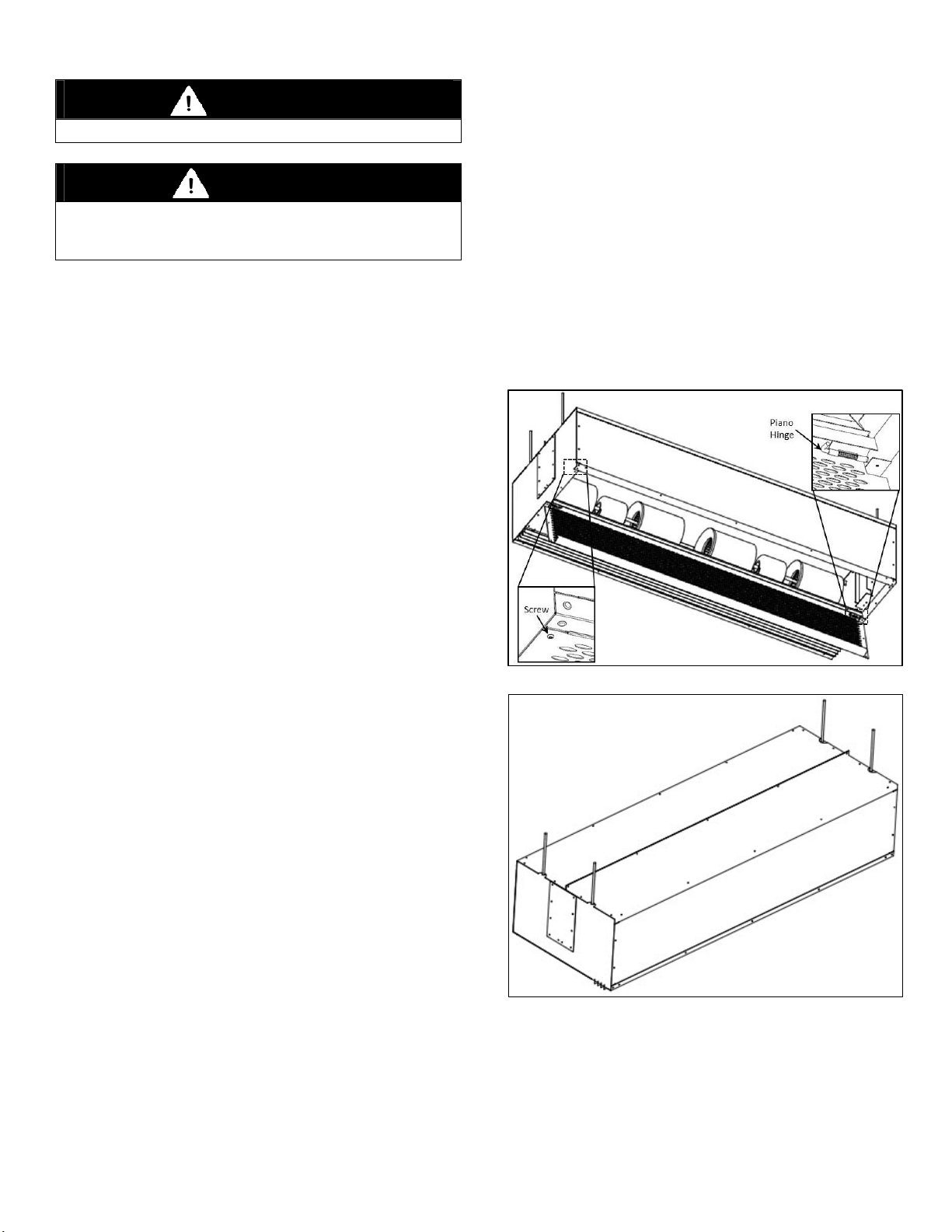

2. The intake screen can be opened by removing the two

screws on the bottom of the unit. The screen can be

removed from the unit by pulling the spring loaded

piano hinges. (FIG. 1)

3. All Phantom series have the Motor Fan Assembly

(MFA) shipped internally mounted.

4. All units are equipped with (4) 3/8’’ threaded inserts on

top for overhead installation (FIG. 2)

5. Determine the exact mounting locations to suspend

the unit above the ceiling so that the unit is centered

and parallel with the door opening. Use (4) threaded

rods to suspend the enclosure to the ceiling.

Note: When installed in the ceiling above the door, the

air curtain must be moved 3/8” away from the wall for

every 1" above the door height.

6. If applicable, extended wall mounting brackets are

available for attaching the unit to a wall.

7. If applicable, for tandem installation (units longer than

72”) of products mounted side by side, allow no more

than 6” between the two units. Note that (4) sets of

threaded rods are used to suspend each unit to the

ceiling or center mounting brackets are to be used for

joining and top mounting tandem units.

8. Mount the product such that the discharge is flush with

the ceiling.

9. All wires must be connected internal of the unit and

some knockouts are provided. However, it may be

necessary to create your own knockout, as required.

10. The unit must be wired per NEC and local codes.

FIG. 1

FIG. 2

Electrical Field Wiring

1. For electric models, reference the Heated Products

Supplement.

2. The unit and any optional accessories must be wired

with the proper voltage to the junction box per the

wiring diagram. (FIG. 3, unheated products only)

Page 3

3. All 3 phase motors are bi-directional, which means

they can rotate in either direction. Follow directional

arrows on the blower wheel housings for proper

rotation. If the motor is rotating incorrectly, switch two

of the 3 phase power or motor leads and the motor will

rotate the opposite direction. Make sure all motors are

turning in the same and proper direction. (FIG. 3)

FIG. 3

WARNING

The following items must all be completed by a qualified

installer and checked off when completed

A. Re-check that the product has been installed

properly and is level and secure.

B. Check all terminal screws are tight and field wiring is

connected in accordance to National Electrical Code

and wired per the enclosed wiring diagram. For

electric heated models, ensure that the coils are

secured and not touching each other on any metal

surface.

C. Verify proper voltage prior to powering the product.

(See product label for reference).

D. Check all field wired components “if supplied” are

wired correctly.

E. Check that the inlet air supply and the discharge air

supply are free of obstructions.

F. Check that all air filter(s) and/or air intake grille(s) are

in place and installed properly, as originally shipped.

G. Verify voltage to the product once more and turn

power on.

H. Regardless of whether the product is mounted on the

inside or outside of the door opening, set the air

directional vanes in the discharge nozzle slightly

outward to approximately 10-15° towards the outside,

or the wind load. (FIG. 4).

For accessory installation, reference Accessory

NOTE

Installation Supplement.

For heated products, reference Heated Products

Supplement.

START-UP

This product has been assembled and tested at the

factory prior to shipping. The following procedures

should be performed to assure its performance. Before

continuing with the start-up, it is important to recognize

the safety controls furnished with the unit.

WARNING

Prevent hazard of electrical shock. More than one

disconnect switch may be required to de-energize this

product.

FIG. 4

I. For products with control panels, turn the HOA

(Hand-On-Auto) selector switch to “On” position and

open the door to energize the product. For products

without a control panel or an On/Off switch, open the

door to energize the product.

J. If heated products are installed, reference Heated

Products Supplement.

K. For three phase units, verify direction of rotation of

blower wheels (note direction arrows on the blower

wheel housing). Correct if needed by changing

polarity of three phase power.

Page 4

L. VERY IMPORTANT Using a clamp meter, measure

the amperage to each motor and ensure that they do

not exceed the amperage listed on the product label.

M. If applicable, adjust the air intake grille(s) such that

the output air stream reaches the floor. For

temperature control and environmental separation

applications, the air stream should reach the floor

with sufficient strength to create an air seal around

the door opening without creating turbulent mixing of

the inside and outside air. If applicable, adjust the air

intake grille(s) such that the output air stream

reaches the floor. For flying insect control

applications, the air stream should reach the floor

with maximum strength. If after proper installation

and adjustment, the product appears to be producing

too little or too much air for the application, contact

the manufacturer.

MAINTENANCE

To reduce the risk of fire, electrical shock or injury to

persons, observe the following:

A. Maintenance is to be performed only by qualified

personnel who are familiar with local codes and

regulations and are experienced with this type of

product.

B. Before servicing or cleaning the product switch power

off at service panel and lock service panel to prevent

power from being switched “ON” accidentally.

Routine maintenance is required to keep this product

operating at its peak performance and efficiency. Over

time, the housing, air intake grille, air intake filter,

blower wheels and motor(s) will accumulate a build up

of dust, debris and other residue. It is imperative to

keep these components clean. Failure to do so will not

only lower operational efficiency and performance, but

also reduce the useful life of the product. The time

between cleanings depends on the application, location

and daily hours of use. On average, under normal use

conditions, the product should require a thorough

cleaning once every six (6) months.

To clean the product, perform the following:

1. Verify the product has been disconnected from the

power source.

2. Use a damp cloth and either a warm mild soapy water

solution or bio-degradable degreaser, to wipe down

the exterior components of the housing.

3. To access the interior of the product, remove the air

intake grille(s) and/or air intake filter(s). This is

accomplished by removing the screws on the face of

the air intake grille(s)/filter(s) and releasing the grille by

pulling on the spring hinge.

4. Thoroughly clean the air intake grille(s) and clean or

replace the intake filter(s).

WARNING

5. Thoroughly wipe down the motor, blower wheels and

blower wheel housings. Be careful not to spray the

motor with a water hose.

6. The motor(s) require no additional lubrication. They

are permanently lubricated and feature double sealed

ball bearings.

7. To re-install the product, reverse the procedures

above.

8. Reconnect the power source to the product.

9. If you have any questions regarding the maintenance

of the product, contact the manufacturer.

DISCLAIMER

Mars reserves the right to change specifications and

product design without notice. Such revisions do not

entitle the buyer to corresponding changes,

improvements, additions or replacements for previously

purchased equipment.

Page 5

TROUBLESHOOTING

PROBLEM CAUSE SOLUTION

NO AIR BLOWING

OUT OF DISCHARGE

NOZZLE

- Circuit breaker is tripped - Reset circuit breaker

- Blown fuses on power supply - Replace fuses

- Motor overload is open or tripped

- Failed switch - Replace or repair limit switch

MOTOR IS RUNNING

BUT FANS ARE NOT

SPINNING

- Loose set screws on wheel hubs - Tighten set screws on motor shaft flats

- Fan spinning inside fan housing - Tighten fan on shaft or replace fan

- Broken fan hub - Replace fan wheels

ELECTRICAL

CONTROLS NOT

WORKING WHEN

DOOR IS OPEN

- Door limit switch is not operating - Repair or replace door limit switch

UNIT WILL NOT TURN

OFF

LOW AIR FLOW

- Obstruction on intake or discharge - Remove obstruction or move air curtain

- Power leads out of polarity

- Fan rubbing against housing - Free fan from housing

- Blower wheels clogged with dirt - Clean and remove dirt from blower wheels

EXCESSIVE AIR

VELOCITY AT DOOR

OPENING

- Air temperature too cold - Add auxiliary heat to overcome wind chill

AIR NOT HITTING

THE FLOOR

- Obstruction in the direction of air flow

- Negative building pressure

UNEVEN AIR - Shaft rotating inside fan - Replace fan or tighten fan on shaft

- One motor not functioning - Replace or repair motor

EXCESSIVE NOISE

AND OR VIBRATION

- Loose set screws on wheel hubs - Tighten set screws on motor shaft flats

- Fan spinning inside fan housing - Tighten fan on shaft or replace fan

- Broken fan hub - Replace fan wheels

- Bearing end caps worn - Replace Bearing end caps

- Damaged blower wheel - Replace Blower Wheel

- Bearing end caps worn - Replace Bearing end caps

- Balancing clips missing - Replace Blower Wheel

- No power being supplied to the unit

from the electrical power source

- Motor contactor / relay defective

(if applicable)

- Loose or broken coupling (belt drive) - Replace or tighten coupling

- Switch is in off position - Turn unit's switch to the on position

- Door limit switch is permanently

closed or energized

- Discharge air vanes out of

adjustment

- Blower motor rotating below normal

speed

- Nozzle out of adjustment and not

angled far out enough (BD only)

- Air stream pushing air outside of the

building

- Low air velocity

- Loose or broken coupling (belt drive) - Replace or tighten coupling

- Confirm power source / check if in on position

- Allow the motor to cool down; motor has auto reset

internal overload; if unit is panel equipped, press

reset button on overload inside panel, or replace

motor overload if overload remains tripped

- Check voltage to coil; check contacts to see if they

are pulling in

- Position the door switch in a manner that turns off the

unit when the door closes, and turns on the unit when

the door opens. Only light pressure required.

- Adjust vanes to proper position

(Refer to Start-Up Section in this manual)

- Switch power leads to correct polarity

(3 phase models only)

- Apply proper voltage per unit requirement

(see unit label) / Adjust adjustable motor speed knob

(if applicable)

- Adjust nozzle angle to outside

- Adjust discharge angle back into building

- Adjust vanes to proper position or check installation

height (Refer to Start-Up Section in this manual)

- Remove obstruction or move air curtain

(Move out 3/8" for every 1" up from the door)

- Provide a make-up air system to relieve negative

building pressure

Page 6

WARRANTY

Mars’ warranty coverage, period, extent and

limitations apply to the product only. It does not

apply to labor. Mars warrants that Mars product 1)

Is free from defects in materials and workmanship

and 2) Conforms to Mars’ published specifications.

The warranty period for Mars product except heated

and custom models, is a five (5) year period

commencing on its date of shipment. The date on

customer’s invoice is the date of shipment, unless

Mars or your reseller informs otherwise. For heated

and custom models, the warranty period is an

eighteen (18) month period commencing the date of

shipment. Mars will provide free replacement of any

part that fails as a result of a defect in material or

manufacturer’s workmanship. Changes in

operational specification parameters that are

different from those provided on the original

purchase order are not covered. Mars product is

inspected and tested before packaging and is

shipped in working condition. The warranty for

Mars product only covers free-of-charge

replacement of failed parts. The warranty does not

cover labor and transportation expenses that may

be required to provide and to install replacement

parts. Because in many instances, it is impossible

to determine the cause of failure, customer may be

responsible for transportation charges associated

with replacement of failed part. Mars does not

warrant uninterrupted or error-free operation of

Mars product. Under no circumstance is Mars liable

for any of the following: 1) Third-party claims

against you for damages; or 2) Special, incidental,

or indirect damages or for any economic

consequential damages (including lost profits and

savings), even if Mars, its suppliers, or its reseller is

informed of their possibility. The warranty does not

cover repair or exchange of Mars product resulting

from misuse, accident, modification, unsuitable

physical or operating environment, improper

maintenance and installation by customer, or failure

caused by a product for which Mars is not

responsible. The warranty does not cover damages

caused by mishandling during transportation. The

warranty is voided by removal or alteration of Mars

product or parts identification labels, by improper

installation of product, and resulting non-compliance

to federal, state and local codes and regulations.

Additionally, Mars reserves the right to void the

warranty for non-payment of invoice.

CONTACT FACTORY FOR COMPLETE PARTS

LIST FOR ALL MODELS.

KEEP THIS MANUAL FOR YOUR RECORDS.

Model Number: _____________________________

Serial Number: _____________________________

Date Purchased: ____________________________

Dealer Purchased From:______________________

14716 S. Broadway St., Gardena, CA 90248

(310) 532–1555 ● (800) 421-1266

Fax: (310) 324-3030

Please go to our website at www.marsair.com for a

downloadable version of this document.

Loading...

Loading...