Mars Air LPN Installation Manual

Document No: LP-IOM

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or

with these instructions could result in personal injury and/or property damage. Retain these instructions for future

To reduce the risk of fire, electric shock or injury to

WARNING

Precaution should be taken in explosive atmospheres.

Date: 0810

LOW PROFILE (LPV) VARIABLE SPEED AND LOW PROFILE (LPN)

NSF COMMERCIAL SERIES

Installation, Operation and Maintenance Manual

maintai n the product described. Protect yourself and others by observing all safety information. Failure to c ompl y

reference.

OVERVIEW

Mars Air Curtains

are designed to

cover door

openings, providing

both temperature

control/environment

al separation and

flying i nsect control ,

when the building’s

doors are opened.

Typical installation

heights are: LoPro

Series; LPV

(Variable Speed) models (Environmental up to 8’), LPN

(NSF for Customer Entrances) models (Flying Insect

coming in contact with moving parts, as well as other

potential hazards.

Control up to 7’) and LPN-F (NSF for Counter Top/Pass

Through Windows) models (Flying Insect Control up to

4’ from Counter Top) All NSF Certified Models (ETL)

WARNING

should be mounted at the Flying Insect Control heights

referenced above. The units are typically wall mounted

horizontally above the door opening. They can also be

suspended from the ceiling. The units are ETL Listed,

Canada and US, for either an inside or outside mount

and ETL Sanitation Certified. Heated units must be

mounted on the inside or the protected side of the

opening. The motors used in all LoPro Series are

1/6HP.

The LoPro Series come standard with a stamped air

intake screen(s). The LPV models can be configured

with an aluminum mesh filter(s) as an option. The LPN

models 25”, 28” and 30” and all LPN-F models come

standard with an aluminum mesh air intake filter(s) in

conjunction with the punched air intake screen(s).

GENERAL SAFETY INFORMATION

persons, observe the following.

A. Always disconnect, lock and tag power source before

installing or servicing product.

B. Installation work or electrical wiring must be done by

qualified person(s) in accordance with all applicable

codes and standards, including fire-rated construction.

C. The combustion airflow needed for safe operation of

fuel burning equipment in the area may be affected by

the product’s operation. Follow the heating equipment

manufacturer’s guideline and safety standards, such

as those published by the National Fire Protection

Agency (NFPA), the American Society of Heating,

Refrigeration and Air Conditioning Engineers

(ASHRAE) and local code authorities.

D. When cutting or drilling into a wall or ceiling, be careful

not to damage electrical wiring and other hidden

utilities.

Use this product only in the manner intended by the

manufacturer. If you have any questions, contact the

manufacturer. Only qualified personnel should install

this product.

personnel should

have a clear

understanding of

these instructions

and should be

aware of general

precautions.

installation can

result in electric

shock, possible

injury due to

Installing

safety

Improper

WARNING

When servicing the product, motor may be hot enough

to cause pain or injury. Allow motor to cool before

servicing.

RECEIVING AND INSPECTION

Upon receiving the product, check to make sure all

items are accounted for by referencing the Bill of Lading

to ensure all items were received. Inspect each carton

for shipping damage before accepting delivery. Notify

the freight carrier if any damage is noticed. The carrier

will make notification on the delivery receipt

acknowledging any damage to the product. All damage

should be noted on all copies of the Bill of Lading which

is countersigned by the delivering carrier. A Carrier

Inspection Report should be filled out by the carrier

upon arrival and a report given to the Traffic

Department. If damaged upon arrival, file a claim

immediately with the carrier. Any physical damage to

the unit after acceptance is not the responsibility of

Mars Air Systems.

UNPACKING

Verify that all parts, components and accessories, and

the correct quantities of each have been received. If

any items are missing, report shortages to Mars Air

Systems directly to arrange for obtaining the missing

items. Again, verify quantities received against those

on the Bill of Lading only, a s mul ti ple s hipm ent s may b e

involved.

INSTALLATION

Typical Mounting – Wall or Ceiling Mounted

Horizontally Above the Do or Opening

1. Remove the air intake gr ille(s) and/or air intake f ilter(s)

from the product and set aside. Gently remove all

packaging materials, hardware and all other

accessories from interior of unit prior to operating.

Severe unit damage will occur if these items are not

removed prior to operation.

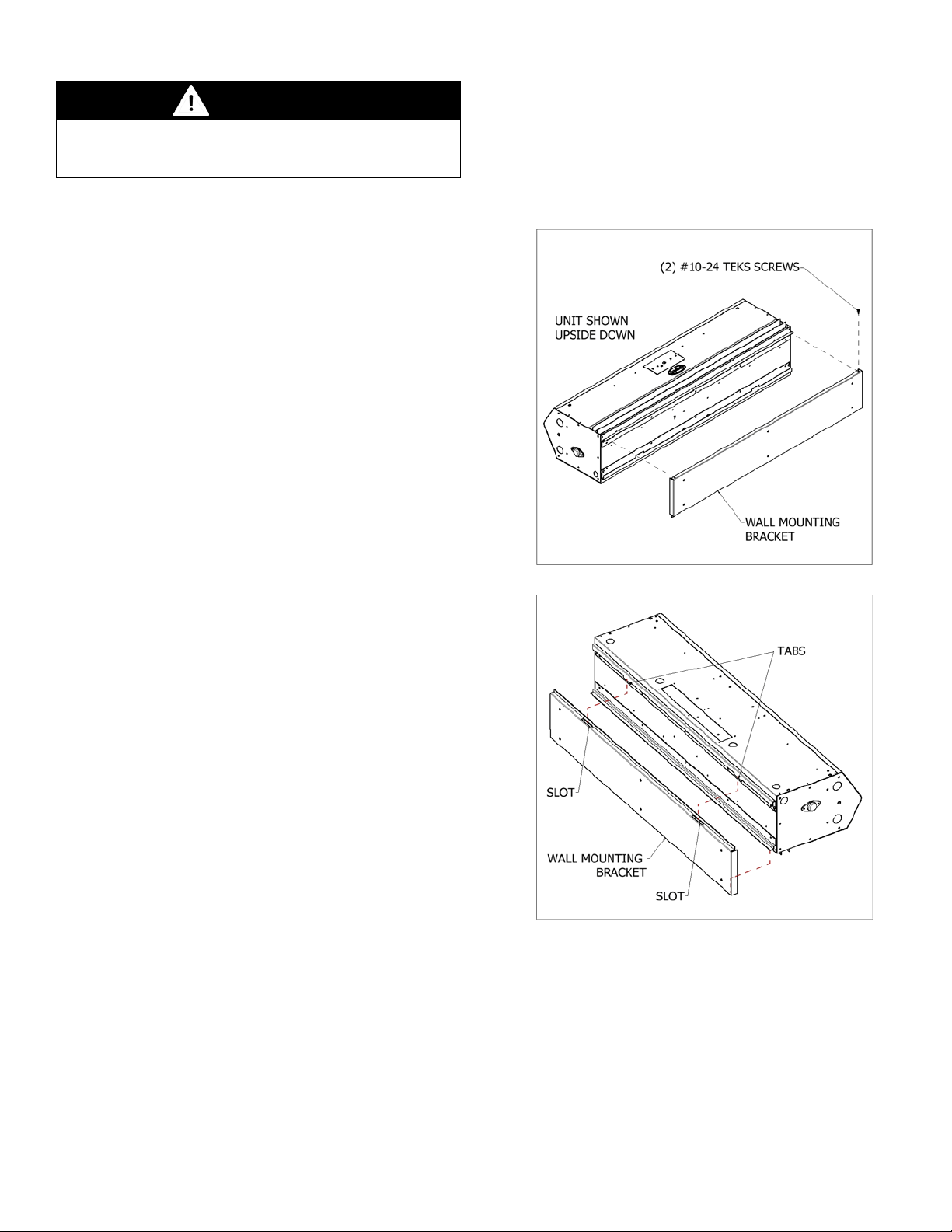

2. Lay unit on its top with directional vanes pointing up

and remove the Tek Screws from the wall mounting

plate, just behind the discharge nozzle, and remove

the mounting plate f rom the unit. (FIG. 1) Measur e the

mounting plate and center it over the opening. The air

curtain shall be equal to or greater than the width of

the opening.

3. Install the mounting plate(s) above the opening.

Multiple pre-punched 7/16” mounting holes are

provided for your convenience. These holes must be

utilized to secure t he product to the wa ll. All hardwar e

is field provided by others.

4. Align the tabs on the rear of the unit with the slots

provided on the wall mounting plate (FIG. 2). The

bottom flange on the unit m ust also drop in the bottom

channel

Screws to secure the unit in place.

Note: If the holes provid ed on the bottom of the unit and

the bottom of the wall m ounting plate do not align, rem ove

the unit and re-insta ll. The holes on the bottom channel of

the wall mounted plate must be on the bottom.

FIG. 1

FIG. 2

5. Mount the product such that the disc harge is 1” above

the opening and all obstacles. (FIG. 3)

Note: If the product is installed higher than the

recommended 1” above the opening, then it must be

moved 3/8” away from the wall for every 1” that it is

moved up. Any void betwe en the wall and the product

must be sealed, by others, to optimize performance.

6. Use four (4) threaded rods f or overhead installation or

four (4) threaded bolts for wall installation. All

hardware is field provided by others. (FIG. 3)

of the wall mounting plate. Replace the Tek

Loading...

Loading...