Mars Air BD-26-144 Installation Manual

Document No: BD-IOM

Date: 1015

WINDGUARD BELT DRIVE (BD) INDUSTRIAL SERIES

Installation, Operation and Maintenance Manual

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or

maintain the product described. Protect yourself and others by observing all safety information. Failure to

comply with these instructions could result in personal injury and/or property damage. Retain these instructions

for future reference.

OVERVIEW

Mars Air Curtains are

designed to cover

door openings,

providing both

temperature

control/environmental

separation and flying

insect control when

the building’s doors

are opened. Typical

installation heights

are: BD-14 Series

(14’), BD-18 Series

(18’), BD-22 Series (22’), BD-26 Series (26’) and

BD-30 Series (30’). The units are typically

overhead mounted horizontally above the door

opening. They can also be vertically mounted

alongside the opening. Heated units must be

mounted on the inside or the protected side of the

opening. The motors used in the BD Series range

from 5 HP to 30 HP (see submittal for details).

All the BD Series come standard with an

expanded metal air intake grille(s). The BD Series

can be configured with Flat Bank or V-Bank

Sections, as options.

GENERAL SAFETY INFORMATION

Use this product only in the manner intended by

the manufacturer. If you have any questions,

contact the manufacturer. Only qualified

personnel should install this product. Installing

personnel should have a clear understanding of

these instructions and should be aware of

general safety precautions. Improper

installation can result in electric shock, possible

WARNING

To reduce the risk of fire, electric shock or injury to

persons, observe the following.

A. Always disconnect, lock and tag power source

before installing or servicing product.

B. Installation work or electrical wiring must be done by

qualified person(s) in accordance with all applicable

codes and standards, including fire-rated

construction.

C. The combustion airflow needed for safe operation of

fuel burning equipment in the area may be affected

by the product’s operation. Follow the heating

equipment manufacturer’s guideline and safety

standards, such as those published by the National

Fire Protection Agency (NFPA), the American

Society of Heating, Refrigeration and Air

Conditioning Engineers (ASHRAE) and local code

authorities.

D. When cutting or drilling into a wall or ceiling, be

careful not to damage electrical wiring and other

hidden utilities.

WARNING

Precaution should be taken in explosive atmospheres.

injury due to

coming in

contact with

moving parts,

as well as

other potential

hazards.

WARNING

When servicing the product, motor may be hot

enough to cause pain or injury. Allow motor to cool

before servicing.

RECEIVING AND INSPECTION

Upon receiving the product, check to make s ure all

items are accounted for by referencing the Bill of

Lading to ensure all items were received. Inspect

each carton for shipping damage before accepting

delivery. Notify the freight carrier if any damage is

noticed. The carrier will make notification on the

delivery receipt acknowledging any damage to the

product. All damage should be note d on all copies

of the Bill of Lading which is countersigned b y the

delivering carrier. A Carrier Inspection Report

should be filled out by the carrier upon arrival

and a report given to the Traffic Department. If

damaged upon arrival, file a claim immed iately with

the carrier. Any physical damage to the unit after

acceptance is not the responsibility of Mars Air

Systems.

UNPACKING

Verify that all parts, components and accessories,

and the correct quantities of each have been

received. If any items are missing, report

shortages to Mars Air Systems directly to arrange

for obtaining the missing items. Again, verify

quantities received against those on the Bill of

Lading only, as multiple shipments may be

involved.

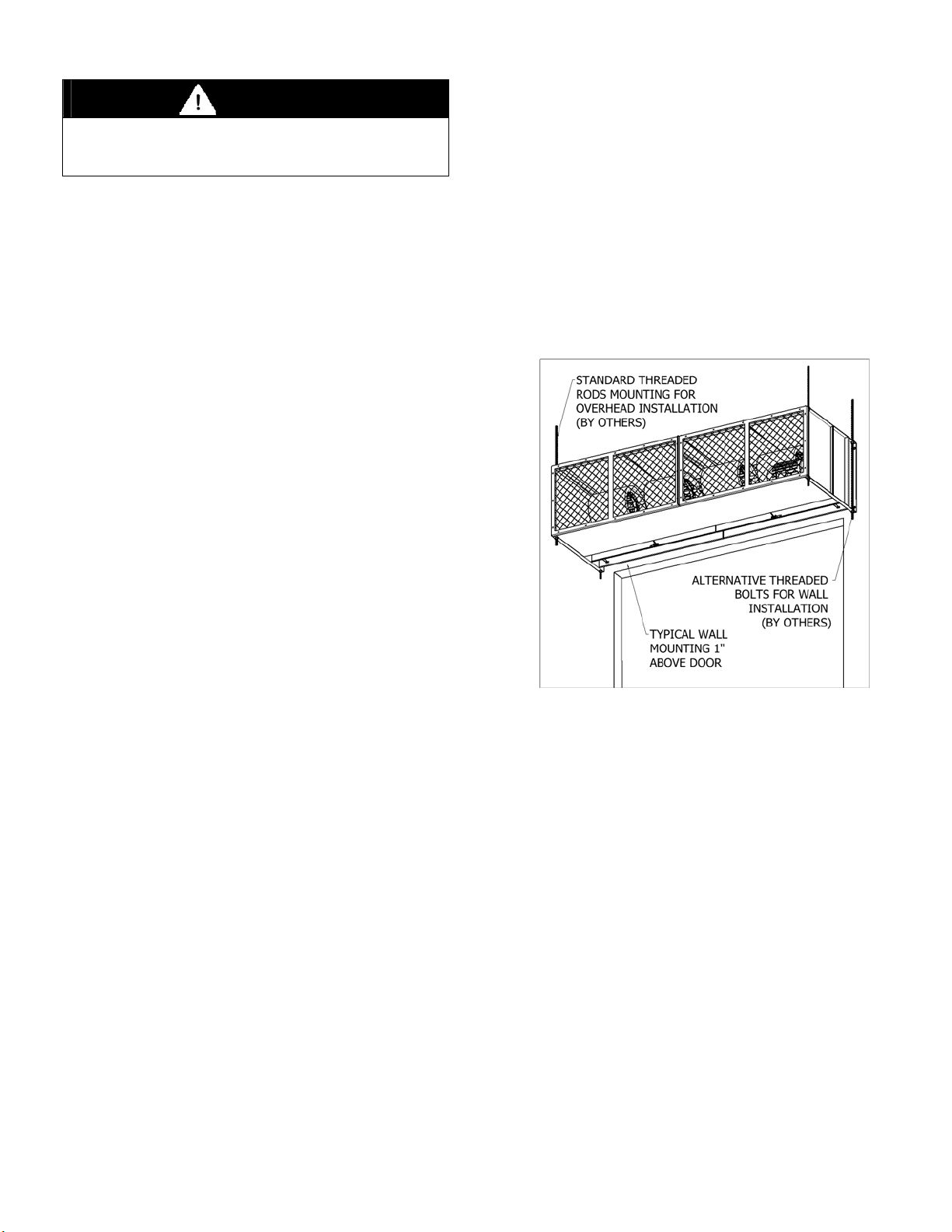

INSTALLATION

Typical Mounting – Wall or Ceiling Mounted

Horizontally Above the Door Opening

1. Overhead installation is recommended to

prevent the possibility of the unit falling if the

wall to which the unit is mounted is hit by a

truck or material handling device. If however,

wall or bracket mounting is preferre d, additional

holes may be drilled in the side panels of the

housing.

Note: Bracket/Support mounting is not

generally recommended for Air Curtains

equipped with steam or hot water coils.

Overhead installation using threaded rods with

independent suspension of coils is

recommended.

2. Center the unit over the opening. The air

curtain shall be equal to or greater than the

width of the opening.

3. Four pre-punched 1/2” mounting holes on the

top of the unit are provided for your

convenience. These holes must be utilized to

secure the product overhead. All hardware is

field provided by others.

4. Mount the product such that the discharge is 1”

above the opening and all obstacles . (FIG. 1)

Note: If the product is installed higher than the

recommended 1” above the opening, then it

must be moved 3/8” away from the wall for

every 1” that it is moved up. Any void between

the wall and the product must be sealed, by

others, to optimize performance.

FIG. 1

5. Use four (4) threaded rods for overhead

installation or four (4) threaded bolts for wall

installation. All hardware is field provided by

others. (FIG. 1)

6. If applicable, for tandem instal lation or products

mounted side by side, allow no more than 6”

between the two products. For overhead

installation using threaded rods, the products

may require a beam, by others, to span the full

distance of the mounting length. (Reference

Accessory Installation Supplement)

7. All wires must be connected to the external

junction box(s) of the unit.

8. The unit must be wired per NEC and local

codes.

Electrical Field Wiring

The unit and any optional accessories must be

wired with the proper voltage to the junction box

per the wiring diagram. (FIG. 2, unheated products

only)

Loading...

Loading...