Page 1

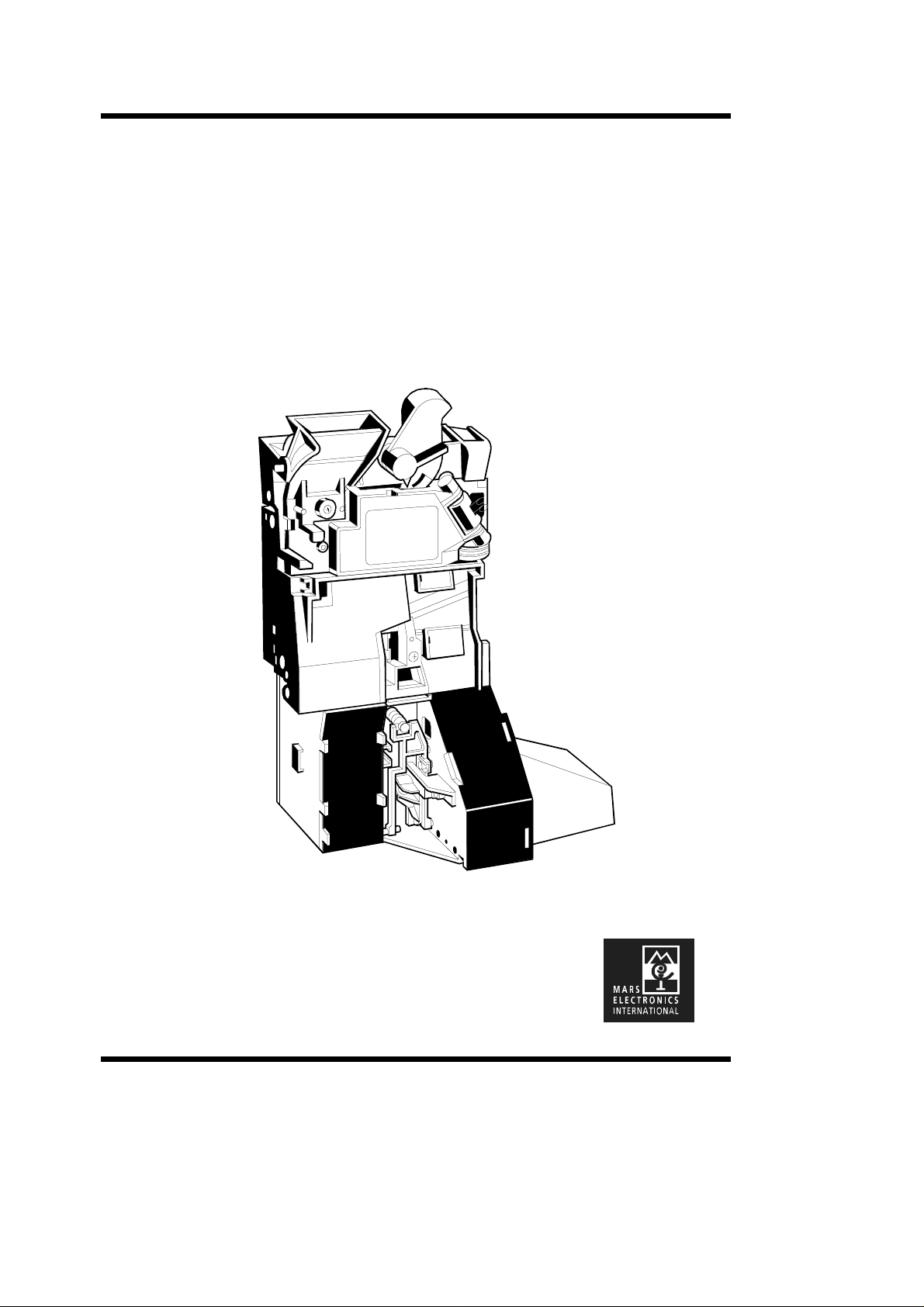

CASHFLOW® 126 and CASHFLOW® 129

4-WAY and 8-WAY SELECTORS

USER GUIDE

25859 G3 705707044

Page 2

Published by :

CashFlow® 126 and CashFlow® 129 selectors User Guide

Mars Electronics International

Eskdale Road

Winnersh Triangle

Wokingham, Berkshire, RG41 5AQ

United Kingdom.

Internet: http://www.meiglobal.com

For further information on editions in other languages please write to the Technical

Communications Manager at the above address.

CashFlow® 126 and CashFlow® 129 selectors User Guide

© , Mars, Inc., 1998. All rights reserved

Except as permitted under the relevant local legislation, no part of this publication may be

copied, transmitted, transcribed, or distributed in any form or by any means, or stored in a

database or retrieval system, or translated in any language (natural or computer), without

the prior written permission of Mars Electronics International.

Mars®, CashFlow® and the Mars Electronics International device are registered

trademarks.

Mars Electronics International reserves the right to change the product or the product

specifications at any time. While every effort has been made to ensure that the

information in this publication is accurate, Mars Electronics International disclaims any

liability for any direct or indirect losses (howsoever caused) arising out of use or reliance

on this information.

This document does not necessarily imply product availability.

Part number 705707044

This edition ( January 1998 ) Printed in the United Kingdom.

ii ©, Mars, Inc., 1998

Page 3

CashFlow® 126 and CashFlow® 129 selectors User Guide

CONTENTS

Safety Summary 1

Product Identification 3

Installation 6

Acceptance & Routing 10

Product Features 11

Configuration 12

Maintenance 21

Product Support 22

Appendix 25

©, Mars, Inc., 1998 iii

Page 4

CashFlow® 126 and CashFlow® 129 selectors User Guide

iv ©, Mars, Inc., 1998

Page 5

CashFlow® 126 and CashFlow® 129 selectors User Guide

SAFETY

Warning

Before cleaning, servicing, removing or replacing CashFlow® units, ALWAYS SWITCH

OFF or ISOLATE the ELECTRICITY SUPPLY to the host machine.

Caution

This guide is recommended for use by personnel trained to carry out electrical installation.

Maximum Operating Voltage

Do not apply more than the voltage specified on the unit, and within the following;

Full Operating Voltage range:

+12V DC nominal +3V, -2V.

Supply Voltage Ripple:

Within Vmin to Vmax up to 100Hz, <250mV pk - pk for Frequency>100Hz

Current consumption:

Quiescent current: 35mA Max

Max current: 2.5A Max (4 solenoids active, CashFlow® 129)

Dangerous Environments

Do not operate the unit in the presence of flammable gasses or fumes, or after the entry of

fluid into the machine.

Disposal of Product

If necessary, always dispose of defective units according to local regulations.

Conformance to International Standards

When installed and operated according to the instructions provided for the particular unit,

CashFlow® products meet the applicable international and national safety standards for

any country in which they are used.

SAFETY

All electrical connections to the product must be rated according to the requirements for

“Accessible SELV” circuits as defined in EN60335-1. The product is therefore suitable for

use in a class 2 (non-earthed or non-grounded) appliance.

Overcurrent protection is not included in the product and should be provided as part of the

host machine. The recommended fuse value at the rated supply of 12V is:

3A Slow blow (to EN60127)

Other protection methods may be used providing their overcurrent characteristics remain

within the overall operating characteristics of the above fuse.

©, Mars, Inc., 1998 1

Page 6

CashFlow® 126 and CashFlow® 129 selectors User Guide

DOCUMENT GUIDE

This document is for field engineers using the CashFlow® 126 and

CashFlow® 129 products produced by Mars Electronics International (MEI).

As an aid to using this document a series of symbols are used in the text and

have the following meanings:

+ This indicates that a useful tip or word of advice is shown here.

q Where this symbol is shown it indicates that a specific action is called for

to ensure a successful installation or setup of the product.

v A note regarding the function to be carried out will appear beside this

symbol.

2 ©, Mars, Inc., 1998

Page 7

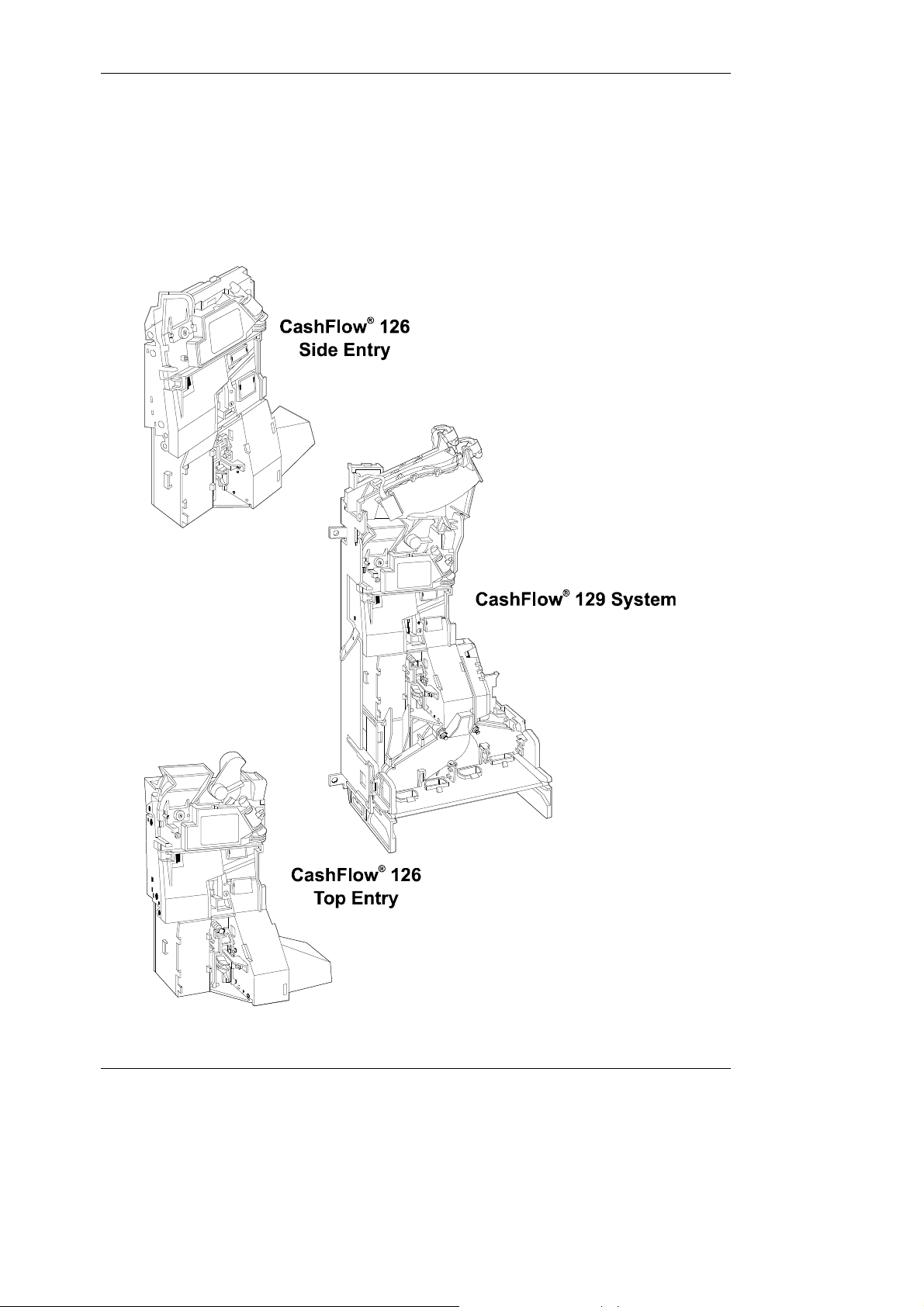

CashFlow® 126 and CashFlow® 129 selectors User Guide

PRODUCT IDENTIFICATION

Mars Electronics International (MEI) has manufactured coin mechanisms compatible with

gaming and amusment machines for a number of years. Over this time the functionality of

the range has been enhanced to match your needs and still maintain mechanical

compatibility. The product detailed in this book is the CashFlow series. Use the following

pages to check you have the right product for your application.

©, Mars, Inc., 1998 3

Page 8

CashFlow® 126 and CashFlow® 129 selectors User Guide

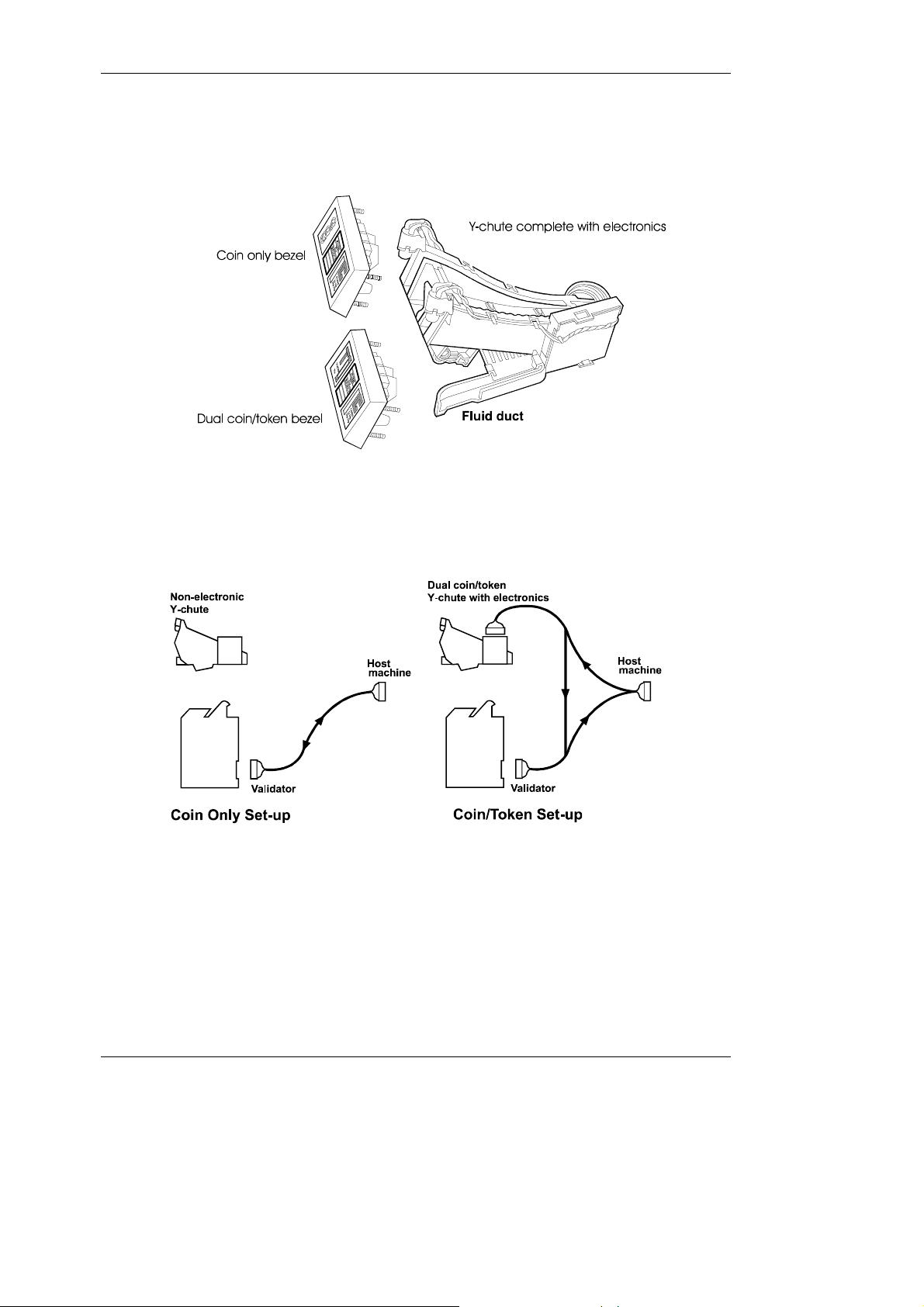

The entry bezel and the Y-chute options can be used with either the CashFlow® 126

system or CashFlow® 129 system. The CashFlow® 126 can be supplied for fitting into a

short channel, so long as the machine has suitable mounting points for the bezel and

Y-chute.

The Y-chute is available in two versions, the one shown above which includes electronics

with back illumination of the dual coin/token bezel, and a version which has no

electronics. This version is suitable for coin only applications.

In a coin only application the interface loom from the machine goes directly to the

validator. The use of the dual coin/token application, however, requires a different loom,

which connects as shown above.

4 ©, Mars, Inc., 1998

Page 9

CashFlow® 126 and CashFlow® 129 selectors User Guide

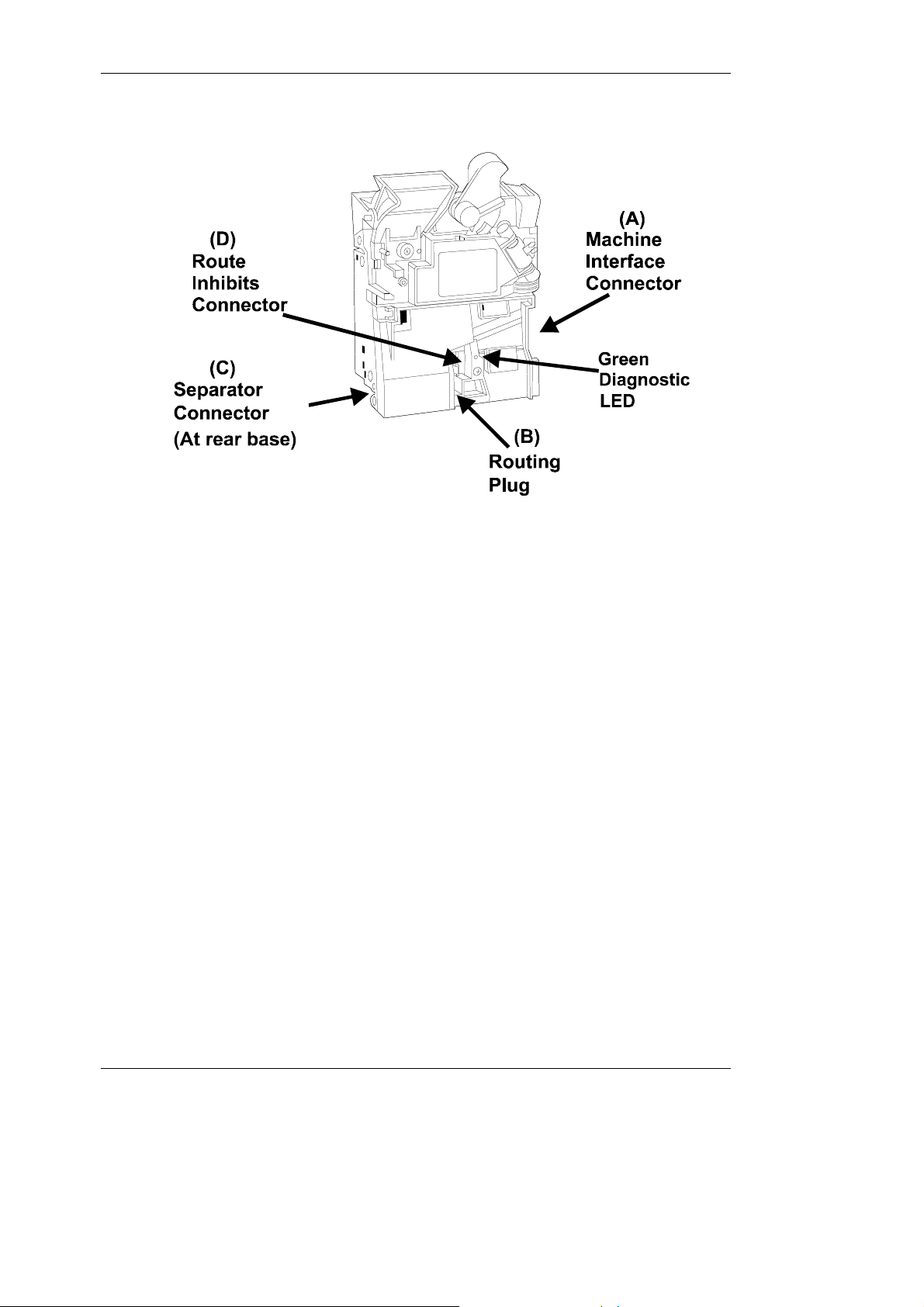

The electrical connections and interfaces to each variant of CashFlow® 126 and

CashFlow® 129 are identical, and are found in the same locations.

(A) Machine Interface - This provides power to the validator and carries the coin inhibit

signals from the machine and coin outputs to the machine.

(B) Routing Plug - This comprises a series of links fitted to a route plug housing and is

used to set up the primary coin exits and any specific overflow exits.

(C) Separator Connector - The separator interface connection must be made before

physically attaching the validator and separator together. The separator will direct

accepted coins/tokens to defined exits.

(D) Route Inhibits -This connector is used to signal that a particular exit has reached

“full” status. Subsequent coins will be diverted to their defined overflow exits.

©, Mars, Inc., 1998 5

Page 10

CashFlow® 126 and CashFlow® 129 selectors User Guide

INSTALLATION

Installing or removing the CashFlow®® product from your machine can be done by

following these simple instructions.

+ When installing the CashFlow®® 126 Front Entry product it will be fitted to an MEI Front Plate and

the following instructions will always apply.

+ The mounting channel for the CashFlow®® 126 top entry product is supplied by the machine

manufacturer, and therefore some variations may exist from machine to machine, however in

principle these instructions still apply.

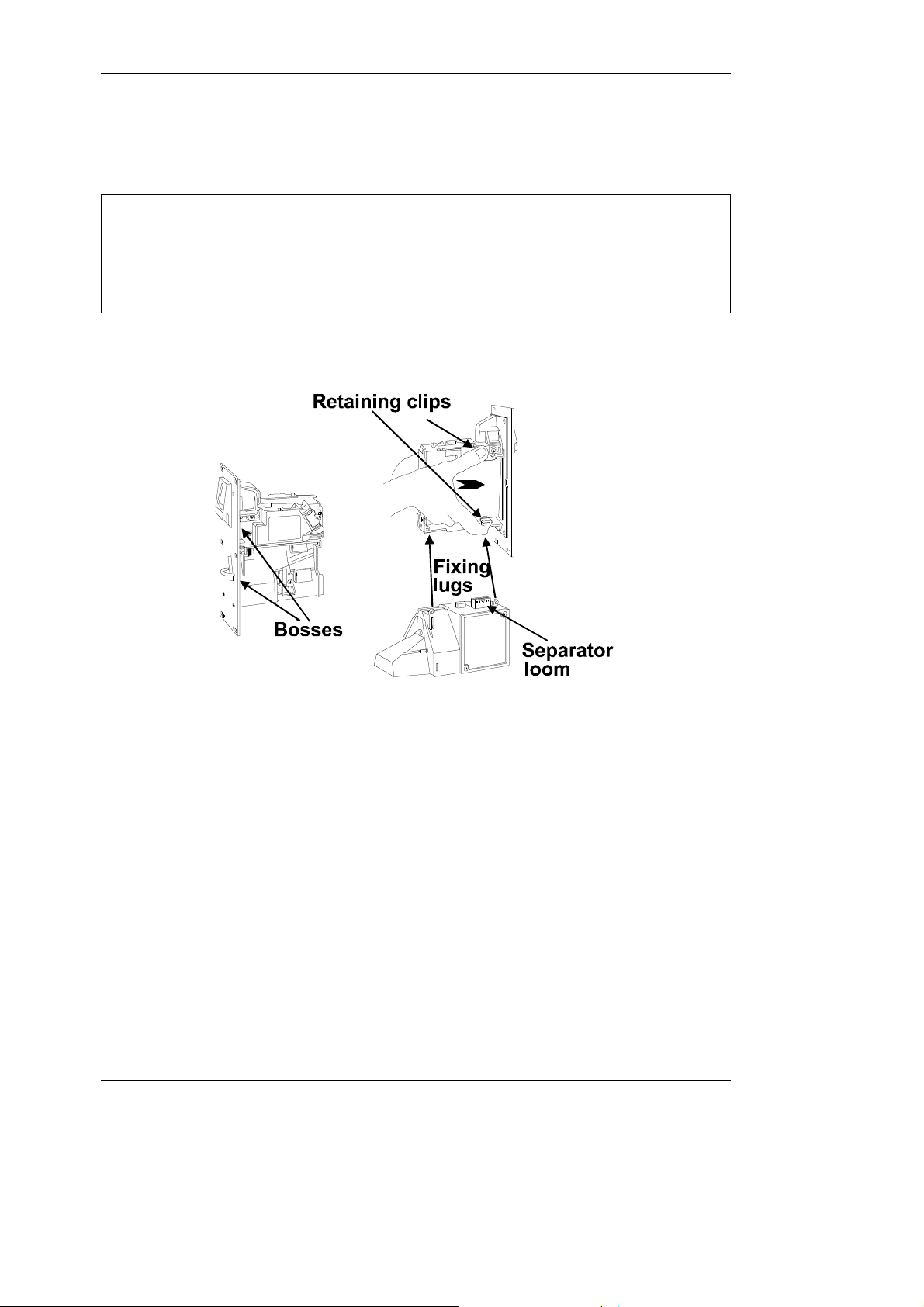

CF126 Front Entry Installation

q Connect the separator loom to the connector at the base of the validator and locate

the rectangular boss on the top of the separator into the base of the validator.

q Firmly screw the separator fixing lugs onto the rear of the validator.

q Having ensured that the front plate has a firm location onto the front of the

machine, insert the side of the validator onto the two round bosses at the rear of

the front plate and push firmly together until the two retaining clips are fully

engaged.

6 ©, Mars, Inc., 1998

Page 11

CF 126 Top Entry Installation

CashFlow® 126 and CashFlow® 129 selectors User Guide

+ When mounted into a short channel the product must be fully assembled and ready for use,

with only the machine interface loom to be connected.

q The mounting points indicated must be firmly seated into the channel and a

gap of between 2-3 mm left between the reject lever and the reject arm from

the machine. This small gap will ensure that the validator lid is able to fully

close when the reject button on the machine has been pressed and released.

The two Y-chutes already referred to can both be used with the short channel

version, but care must be taken to ensure that the gap mentioned above is

maintained between the Y-chute reject arm link and the reject lever of the coin

mechanism.

©, Mars, Inc., 1998 7

Page 12

CashFlow® 126 and CashFlow® 129 selectors User Guide

CashFlow® 129 System Installation

The system consists of a channel, Y-chute, CashFlow® 129 validator, 8-way separator,

manifold and tube collar plate.

This is supplied as a complete system, but should you need to replace any part of it do so

only in a set sequence, starting from near the top.

+ The Y-chute can, of course, be removed first, but it is not necessary to do so just to access the

other modules.

Removal of Validator and Separator

q Ensure that power is turned off, not only to the validator, but also to the Y-chute if

live.

q Dis-connect machine interface loom, and the route inhibit connector.

q Dis-engage the release catch and lift the validator and separator upwards out of

the mounting points. Pull the validator and separator forwards clear of channel.

8 ©, Mars, Inc., 1998

Page 13

Removal of Manifold and Collar Plate

CashFlow® 126 and CashFlow® 129 selectors User Guide

q The manifold is supported in position by four lugs which slot into the side plates of

the channel. It is retained there by two catches, as is the collar plate at the bottom.

Bottom section of CashFlow®® 129 system

Removal of Y-chute

q Always dis-connect the electrical connection first, if used, before removal of the

Y-chute.

q Pinch together the bottom ends of the Y-chute and lift upwards and to the right

from the channel.

Top section of CashFlow® 129 system

©, Mars, Inc., 1998 9

Page 14

CashFlow® 126 and CashFlow® 129 selectors User Guide

ACCEPTANCE AND ROUTING

When the product is successfully mounted you will need to confirm that it is set up

correctly to accept good coins/tokens and direct them to where you want them to go.

First things first

q Press and release the reject button on the machine. Confirm that the lid on the

front of the validator closes fully when the reject button is released. If it does not

close fully the validator cannot function properly.

q Test that power is on by checking that the green LED on the front of the validator is

illuminated, it will flash off once when the reject lever is pressed.

Testing for Acceptance

q Insert into the machine a selection of all the coins/tokens shown on the validator

label. Acceptance of each one will be indicated by the LED flashing off once, and if

the coin/token is outside of the programmed window it will flash off twice. If the

LED flashes three time this indicates that the coin/token has been rejected by the

validator 4th sensor. Should the LED flash off four times this indicates either a

hardware or software inhibit is being applied.

Coin Routing

q Confirm that all coins and tokens are being routed to the required exits. If they are

not refer to the Trouble Shooting section. Settings may have been made on the

machine for hopper or tube limit switches, and these must be taken into account.

q If further help is required then consult the Operators Handbook for the product or

contact either your distributor or local MEI office.

10 ©, Mars, Inc., 1998

Page 15

CashFlow® 126 and CashFlow® 129 selectors User Guide

PRODUCT FEATURES

The CashFlow® 126 and CashFlow® 129 products have the flexibility to change certain

settings such as varying the coin-set that it handles, or new routing for some of the

coins/tokens.

These changes can be carried out using the rotary data switch and the configuration

switch which are fitted uniquely to the CashFlow® 126 and CashFlow® 129 products. The

following pages show how, with the use of these switches, coins/tokens can be inhibited

or enabled, either a new individual token or a group of tokens selected and the machine

output mode changed.

In addition to these two switches there is a green diagnostic LED which signifies if any

changes you make have been successfully actioned or not.

Changes can also be made to the coin routing with the use of

a routing plug.

The routing plug is available in two forms, either ready-made

for specific applications, or do-it-yourself kits, consisting of

loose plugs and either wire links with crimps at each end or

links incorporating a sleeved IN4148 diode with crimps at each end. The diode version is

required to give protection from shorting where two separate coins are required to got to

the same exit. An illustration of how these can be assembled is shown on the next page.

Both versions are available from your distributor, who can assist you with assembly

details.

A summary follows of the way in which you can use the above features. For greater detail

of how to use all of these features you are advised to contact either your distributor or MEI

office for technical assistance.

©, Mars, Inc., 1998 11

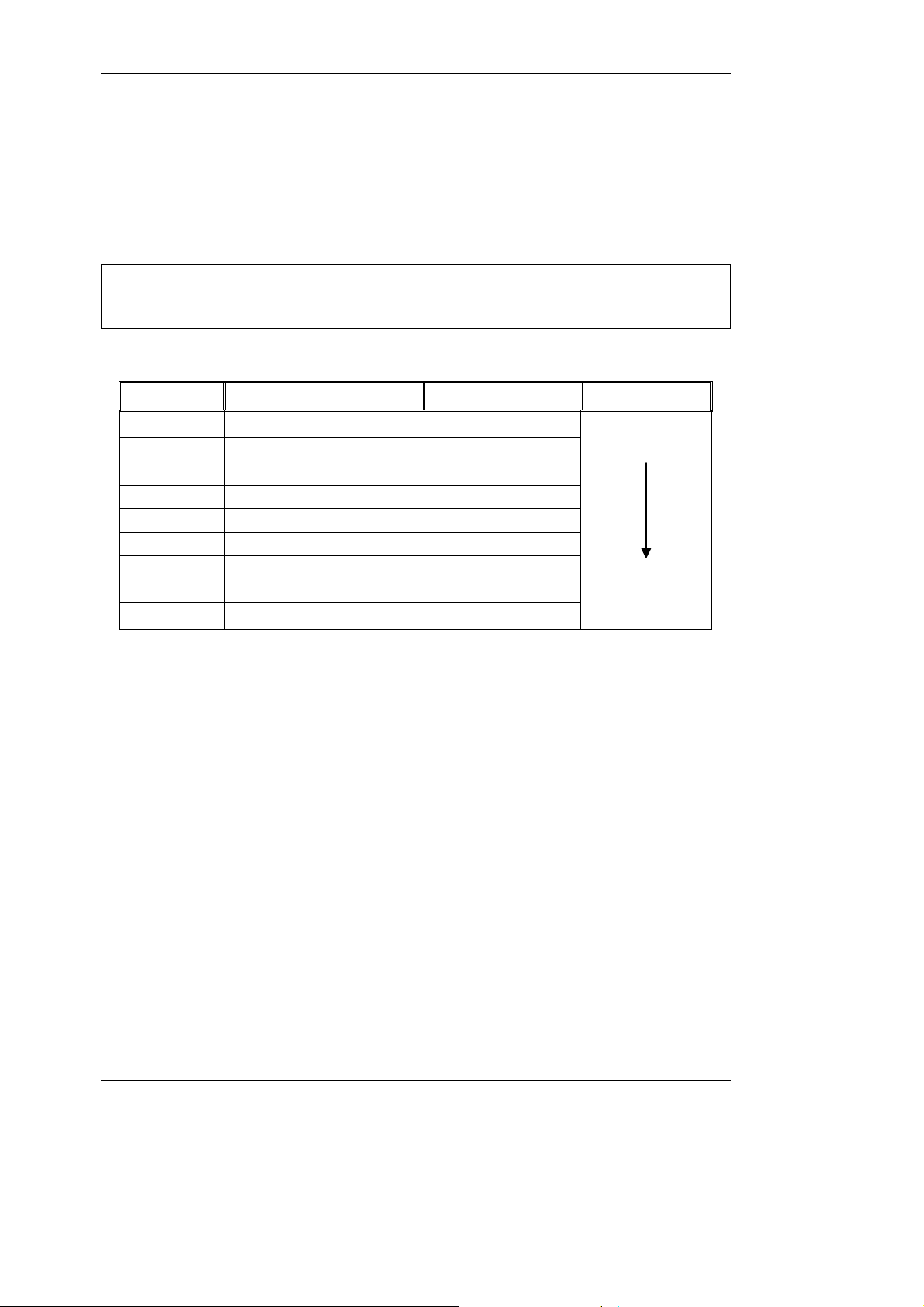

Page 16

Inhibit 6

17IA Coin Inhibit

-

17

0V Supply

12I0V Supply

11

12

Accept Output 3

7OD Coin Output

6

7

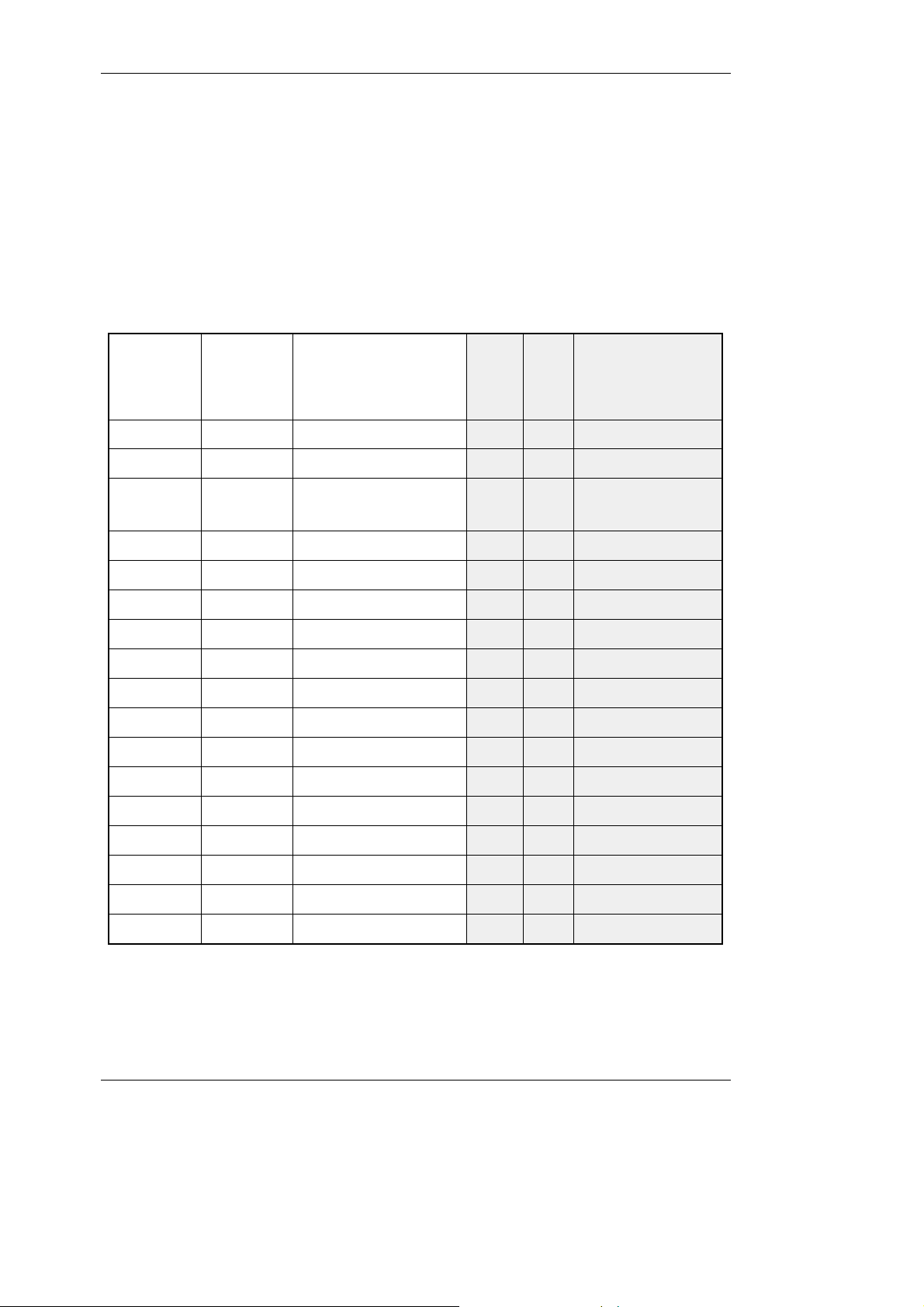

CashFlow® 126 and CashFlow® 129 selectors User Guide

CONFIGURATION

Validator Interface Connector

The interface to the validator from the machine is exactly the same as those which apply

to the MS/ME series validators, with the exception of pin 8 of the 17-way connector

Connector 1 can accept either 15 pin or 17 pin interface connectors.

17

Way

Connector

15

Way

Connector

23

Function

Mars Compatible

Definitions

Common

Input

or

Outpu

t

PIN

No.

Function

BACTA Standard

Definition

Ident signal1OA Coin Output-1

Accept Output 52OB Coin Output12

Accept Output

3ICoin Output

Common

Accept Output 14OF Coin Output34

Polarising Key5-Polarising Key 145

Accept Output 26OE Coin Output56

Select Line8IOutput Mode Input78

Accept Output 49OC Coin Output89

Inhibit 410IC Coin Inhibit910

+12V Supply11I+12V Supply1011

12 ©, Mars, Inc., 1998

Inhibit 313ID Coin Inhibit1213

Inhibit 214IE Coin Inhibit1314

Inhibit 115IF Coin Inhibit1415

Inhibit 516IB Coin Inhibit1516

Page 17

CashFlow® 126 and CashFlow® 129 selectors User Guide

Coin A

1516Coin B

Exit C

56Exit C

Coin E

1920Coin F

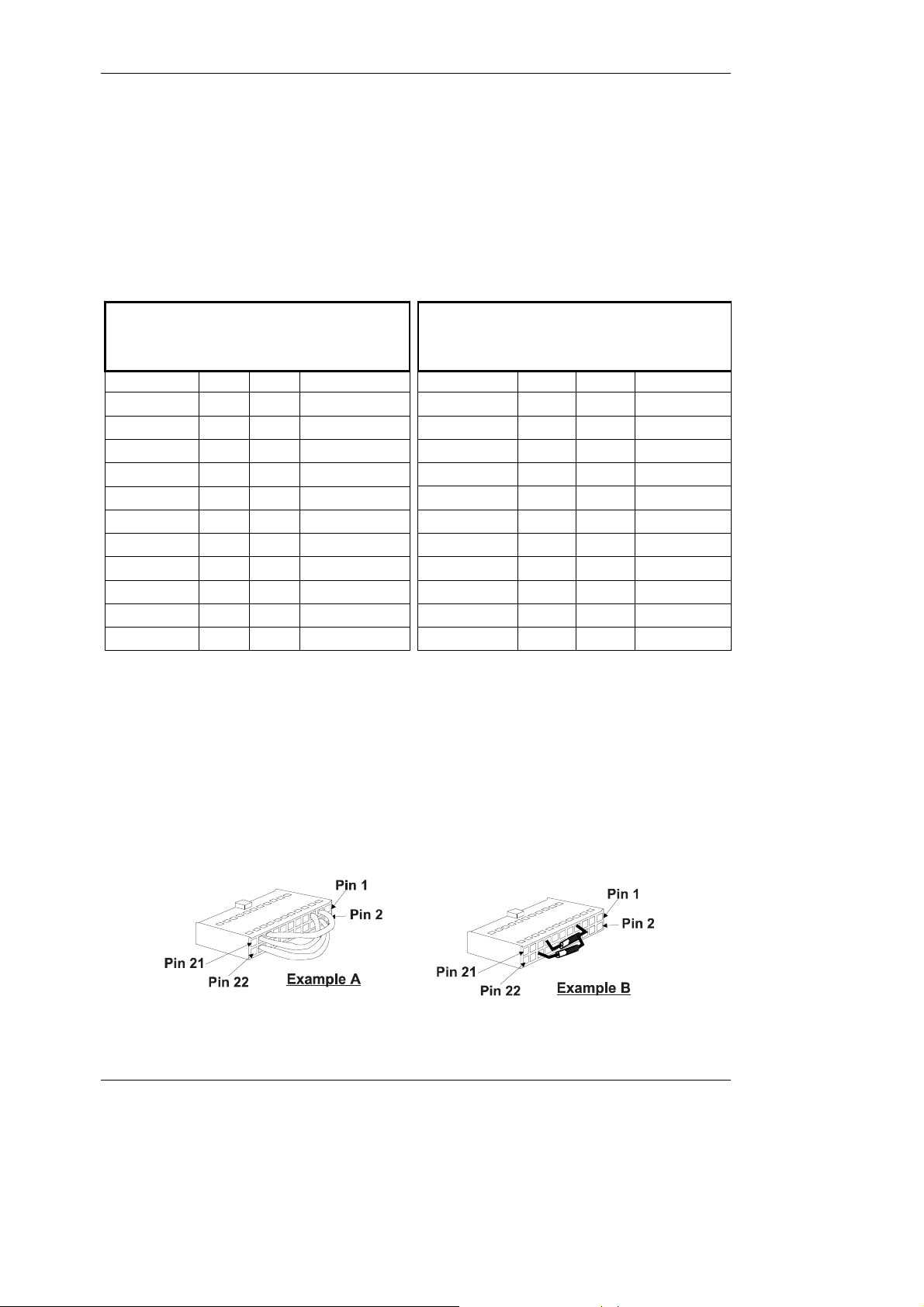

Assembling a 22-Way Routing Plug

While the links are readily inserted into the routing plug by hand without specialist tools,

care is needed to ensure that they are fitted the correct way round, particularly with the

doide version, so that the barb in the pin engages with the recess in the plug. Having

inserted a link give it a gentle tug to ensure that it has engaged with the recess.

126 Routing Plug

Pin outs and Functions

FUNCTIONPINPINFUNCTION

Coin G2122Coin H

129 Routing Plug

Pinouts and Functions

FUNCTIONPINPINFUNCTION

Coin G2122Coin H

Coin E1920Coin F

Coin C1718Coin D

Coin C1718Coin D

Coin A1516Coin B

(Exit ‘d’)1314(Exit ‘d’)

(Exit ‘c’)1112(Exit ‘c’)

(Exit ‘a’)910(Exit ‘a’)

(Exit ‘b’)78(Exit ‘b’)

Route 11314Route 1

Route 21112Route 2

Route 3910Route 3

Route 478Route 4

Route 556Route 5

Exit D34Exit D

Exit B12Exit B

Route 634Route 6

Route 712Route 7

To assemble routing plugs which will route specified UK coins to the required exits

see the examples shown.

In example A Coin C (10P) is being directed to Exit D, Coin E (50P old) to Coin Exit C and

Coin F to Exit D.

Example B shows Coin B (Token) going to Exit B and Coin E (50p old) to Exit ‘b’.

©, Mars, Inc., 1998 13

Page 18

Coin and token values as shown on the coin set label are expressed in the following text

Shaded exits are Manifold only

CashFlow® 126 and CashFlow® 129 selectors User Guide

as channels. The relative positions of these channels and coins/tokens are shown on the

table below.

Seperator Exits

129

Separator Outline

EXIT POSITIONS

Viewed from above

Manifold Outline

Position

Coin Channel/

Label Position

Channel/Coin

Value

Token 100

Token 211

5p22

10p33

20p44

50p old Tight55

50p old66

50p New77

£188

£199

£2 Tight10A

£211B

-12C

-13D

-14E

-15F

126

8

7

6

6

7

5

Reject

2

8

4

3

3

2

1

N.B. Clear exits are Separator only

1

14 ©, Mars, Inc., 1998

5

D

4

(d)

A

(a)

C

(c)

B

(b)

Page 19

(c)Divert route 2

2

CashFlow® 126 and CashFlow® 129 selectors User Guide

Route Inhibit Connector

The function of the route Inhibit Connector is to signal when specific exits, external to the

product, are in a “Full” condition. Signals from the machine ensure that, while the “Full”

condition continues, further coins/tokens directed to that exit will be re-routed to an

alternative exit. The instruction as to which alternative exits can be used will normally

come from the routing plug.

+ In order to inhibit a particular route, 0V must be applied to its respective pin.

+ An alternative route must always be of a lower priority

126129PIN

(d)Divert route 11

(a)Divert route 33

(b)Divert route 44

CDivert route 55

DDivert route 66

BDivert route 77

Not definedNot defined8

0v0v9

Priority

Highest

Lowest

©, Mars, Inc., 1998 15

Page 20

CashFlow® 126 and CashFlow® 129 selectors User Guide

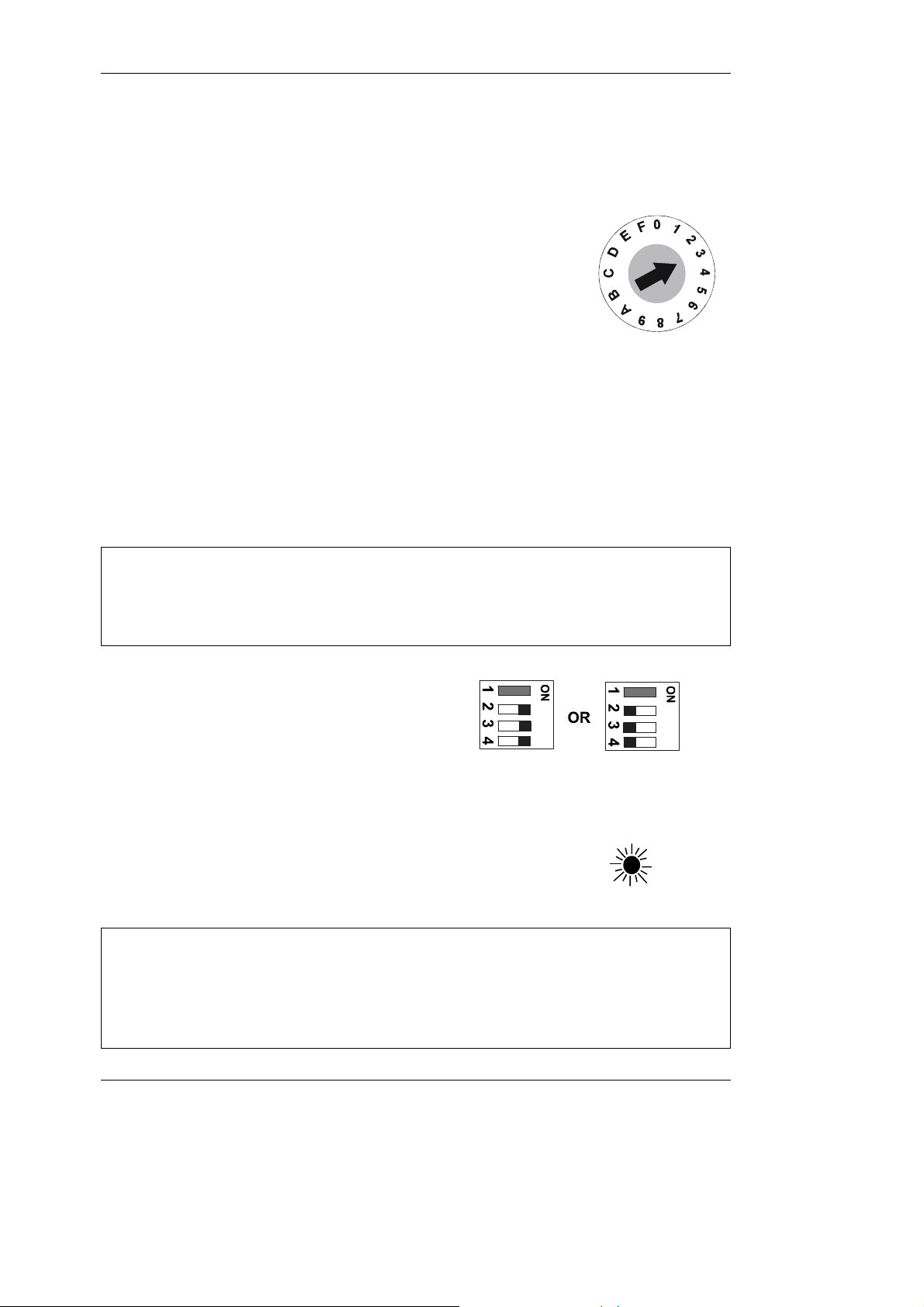

Using the Rotary Data Switch and Configuration

Switches

Rotary Data Switch

The rotary data switch is used in conjunction with the

configuration switches. By pointing the arrow in the middle of

the switch, using a fine screwdriver, data can be entered into

the product. In Normal Operation mode the position of the arrow

is not critical to correct operation.

Configuration Teach Switches

These switches can be set to a series of positions which enable the product configuration

to be changed.

When teach modes are to be entered first SWITCH POWER OFF to

the unit, or an un-intended action could be set.

The example given here, with both the rotary data switch and the

configuration switch settings, is to enable channel 3 in the coin set.

+ Wherever in the examples that follow the switch is shown as hatched grey (usually switch 1) it

indicates that it does not matter if the switch is in the ON or OFF position. Switch 1 only features

in the settings for Alarm Enable when it must be in the ON position. When it is in the OFF

position the Alarm function is NOT active.

q After making any changes the

configuration switches 2, 3, and 4

MUST always return to either of the

Normal Operation positions shown

here.

Diagnostic LED

q The LED will illuminate to indicate that the product is

powered up, and in addition will give various sequences of

flashes to confirm the acceptance or rejection status of

coins/tokens.

+ Flash Sequence:Constantly ON Validator Power On

1 Flash Coin accepted / Reject lever pressed

2 Flashes Coin not recognised and rejected

3 Flashes Coin rejected by validator 4th sensor.

4 Flashes Coin recognised but not accepted due to inhibit setting

16 ©, Mars, Inc., 1998

Page 21

CashFlow® 126 and CashFlow® 129 selectors User Guide

END

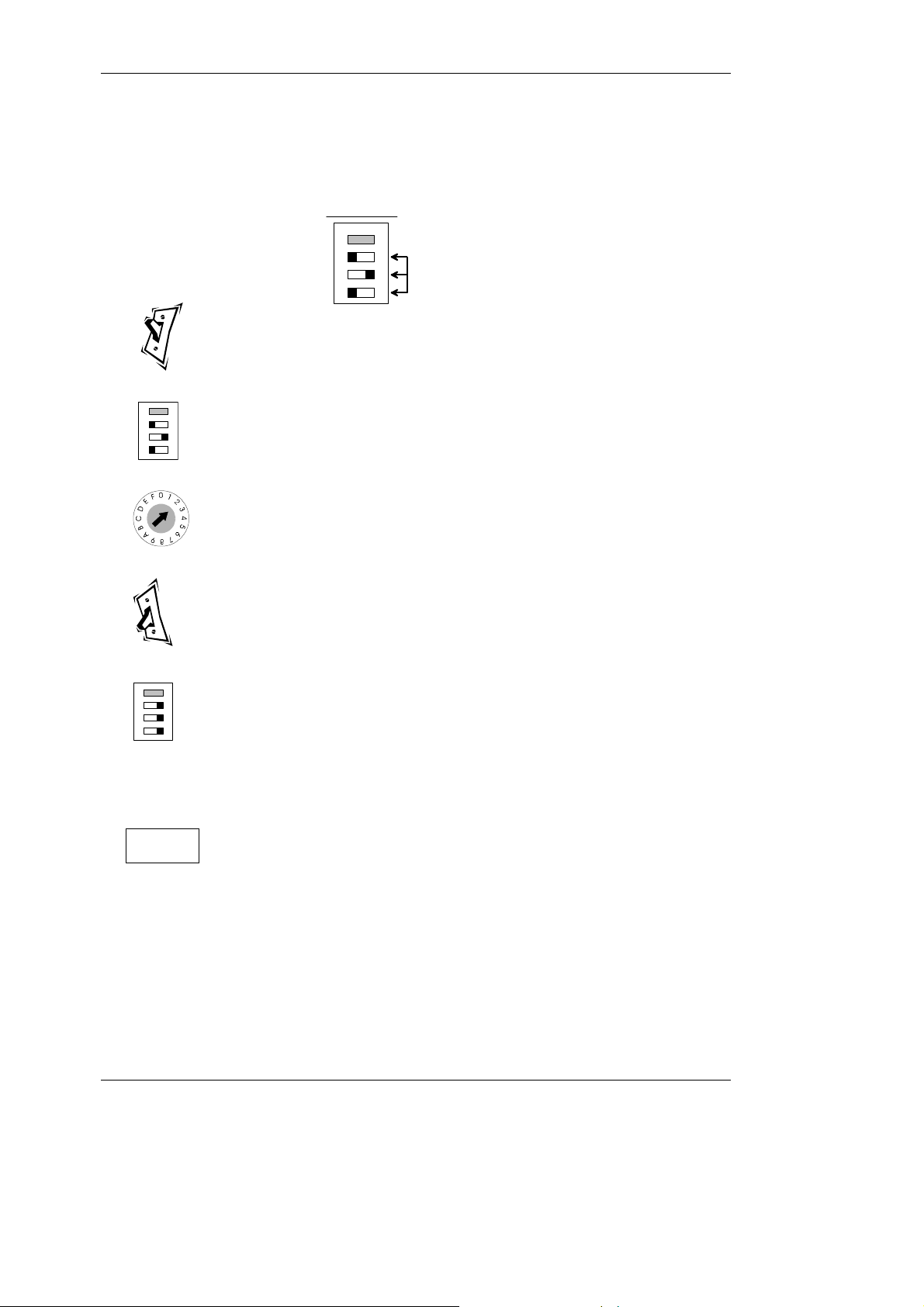

Product Configuration - Inhibiting coins or tokens

Example:- To inhibit channel 2 (the 5p coin) on your validator follow

these simple steps.

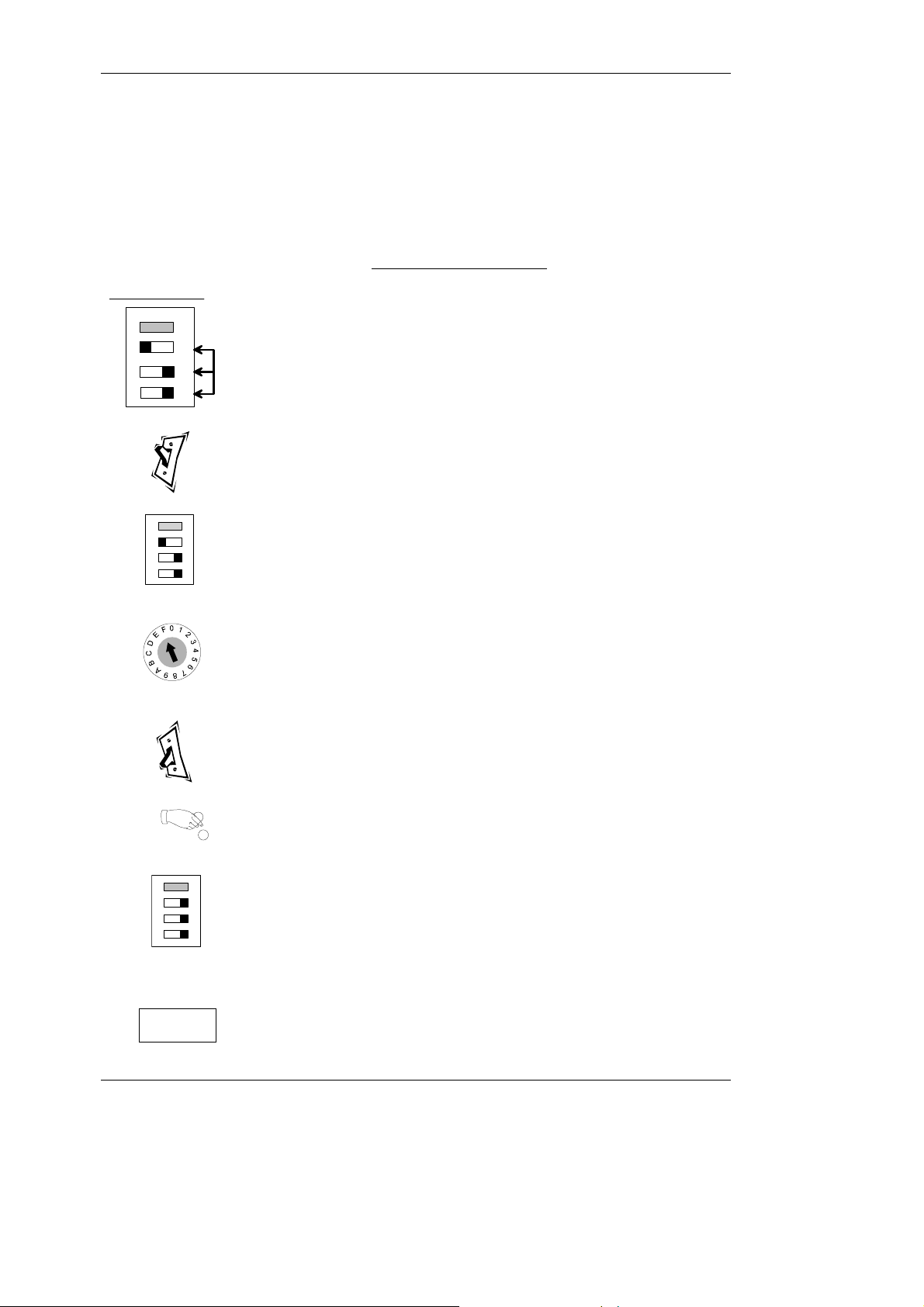

Channel Inhibit

ON

1 2 3 4

Set switches 2, 3 and 4

as shown here.

1. Switch Validator Power OFF.

ON

1

2 3 4

2. Set 4 Way Switches to Inhibit Teach.

3. Set Rotary Switch Dial to the appropriate channel.

(Channel No.2 for the 5p In this instance).

4. Switch Validator Power ON (LED will flash).

ON

1

5. Set switches 2, 3 & 4 to ON.

2 3 4

(LED will stop flashing and stay on).

The Rotary Switch settings can be left unchanged.

6. The chosen coin is now inhibited and the product

is ready for normal operation. For each additional

channel to be inhibited repeat process from 1 above.

©, Mars, Inc., 1998 17

Page 22

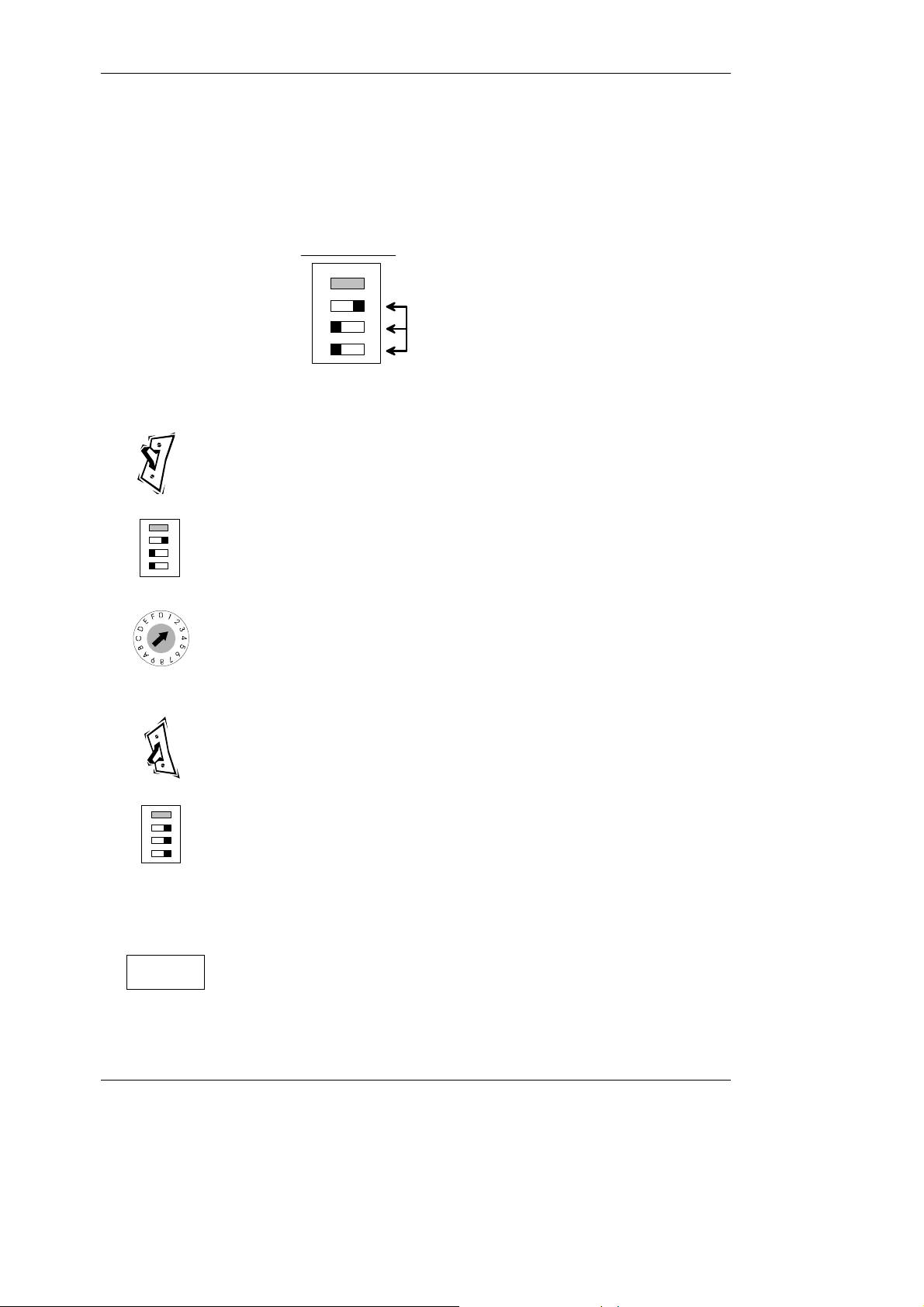

CashFlow® 126 and CashFlow® 129 selectors User Guide

Product Configuration - Enabling coins or tokens

Example:- To enable channel 2 (the 5p coin in this instance) on your

validator follow these simple steps.

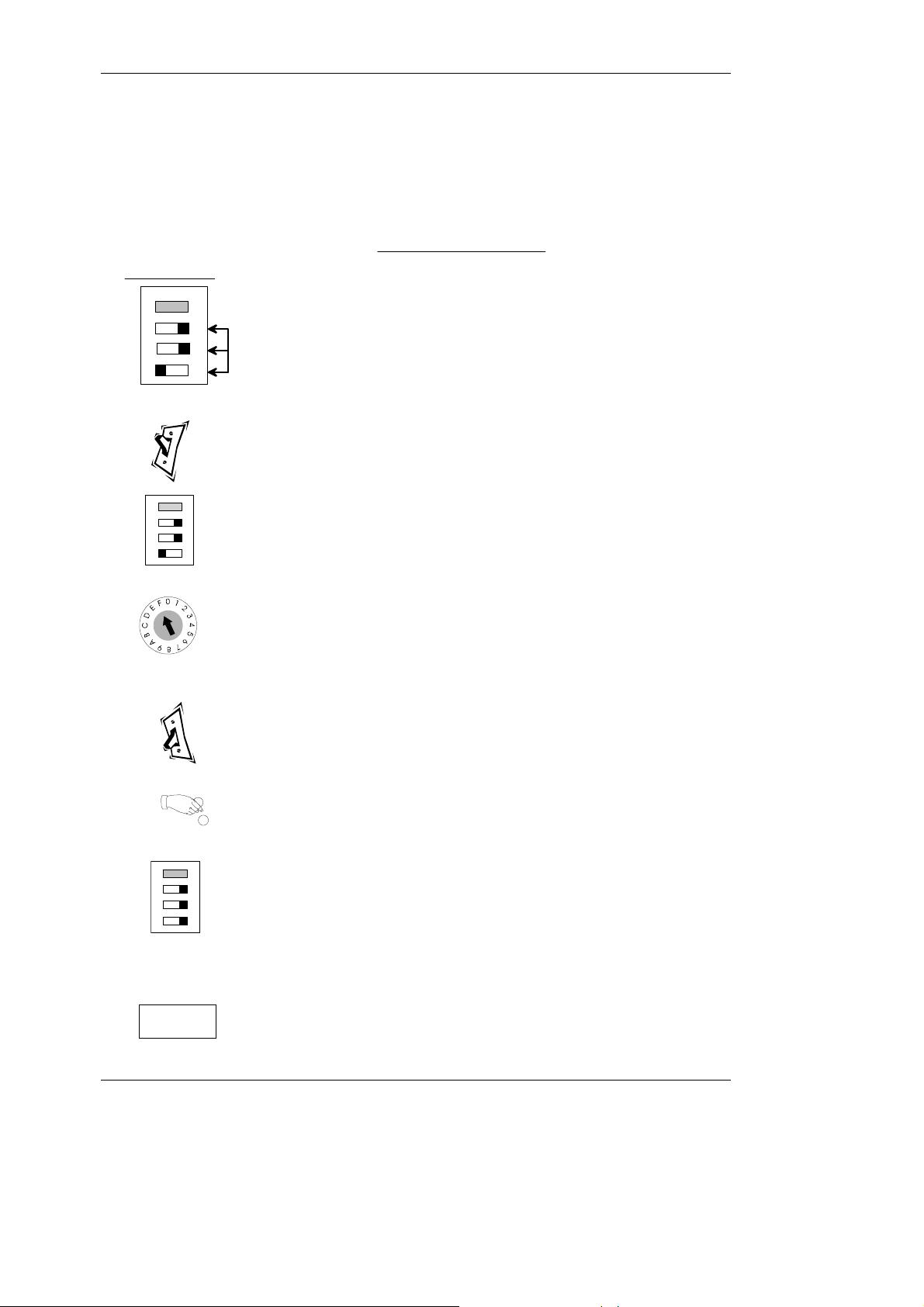

Channel Enable

1 2 3 4

1. Switch Validator Power OFF.

ON

Set switches 2, 3 and 4

as shown here.

ON

1

2 3 4

2. Set 4 Way switches to Enable Teach.

3. Set Rotary Switch Dial to the appropriate channel.

(Channel No.2 for the 5p In this instance)

4. Switch Validator Power ON (LED will flash).

ON

1

2 3 4

5. Set switches 2, 3 & 4 to ON.

(LED will stop flashing and stay on).

The Rotary Switch settings can be left unchanged.

6 The chosen coin is now enabled and the product is

END

ready for normal operation. For each additional

channel to be inhibited repeat process from 1 above.

18 ©, Mars, Inc., 1998

Page 23

CashFlow® 126 and CashFlow® 129 selectors User Guide

Product Configuration - teaching a new token,

channel 0

Example:- To Teach a Token (with standard window limits) into channel

0 follow these simple steps.

LED Flash Codes for Tokens:

Channel Enable

1 2 3 4

ON

Set switches 2, 3 and 4

as shown here.

2 flashes = No activity detected (for last 30 seconds)

3 flashes = Insufficient Tokens (10 min.)

4 flashes = Invalid Rotary Switch (setting E or F)

5 flashes = Token thickness outside allowable limits

6 flashes = Token diameter outside allowable limits

7 or 8 flashes = Token material outside allowable limits

1. Switch Validator Power OFF.

ON

1 2 3 4

2. Set 4 Way switches to Token Teach.

3. Set Rotary Switch Dial to position F (standard

window limits).

(Position E will teach tight token window limits)

4. Switch Validator Power ON (LED will Flash).

+5. Drop between 10 and 20 Tokens.

ON

6. Return switches to Normal Operation. (LED

1

2 3 4

should stop flashing and stay on to indicate a

successful change). If the LED continues to

flash this indicates a failure to teach the token.

If needed repeat the process from step 1.

7. Token successfully taught & programmed

END

into Channel 0.

©, Mars, Inc., 1998 19

Page 24

CashFlow® 126 and CashFlow® 129 selectors User Guide

7 or 8 flashes = Token material outside allowable limits

Product Configuration - teaching a new token,

channel 1

Example:- To Teach a Token (with standard window limits) into channel

1 follow these simple steps.

LED Flash Codes for Tokens:

Channel Enable

1 2 3 4

ON

Set switches 2, 3 and 4

as shown here.

2 flashes = No activity detected (for last 30 seconds)

3 flashes = Insufficient Tokens (10 min.)

4 flashes = Invalid Rotary Switch (setting E or F)

5 flashes = Token thickness outside allowable limits

6 flashes = Token diameter outside allowable limits

1. Switch Validator Power OFF.

ON

1 2 3 4

2. Set 4 Way switches to Token Teach.

3. Set Rotary Switch Dial to position F ((standard

window limits). ).

(Position E will teach narrow slug windows)

4. Switch Validator Power ON (LED will Flash).

5. Drop between 10 and 20 Tokens.

6. Return switches to Normal Operation. (LED

ON

1

2 3 4

should stop flashing and stay on to indicate a

successful change). If the LED continues to

flash this indicates a failure to teach the token.

If needed repeat the process from step 1.

7. Token successfully taught & programmed

END

into Channel 1.

20 ©, Mars, Inc., 1998

Page 25

CashFlow® 126 and CashFlow® 129 selectors User Guide

Product Configuration -

Selecting a pre-programmed token group to be used

in channel 0

14 token groups are already programmed into the product. This feature

allows a defined token group to be accepted.

v NOTE: Each token group selected is automatically copied to channel 0.

Refer to the Appendix at the end of the book for further details of token

groupings.

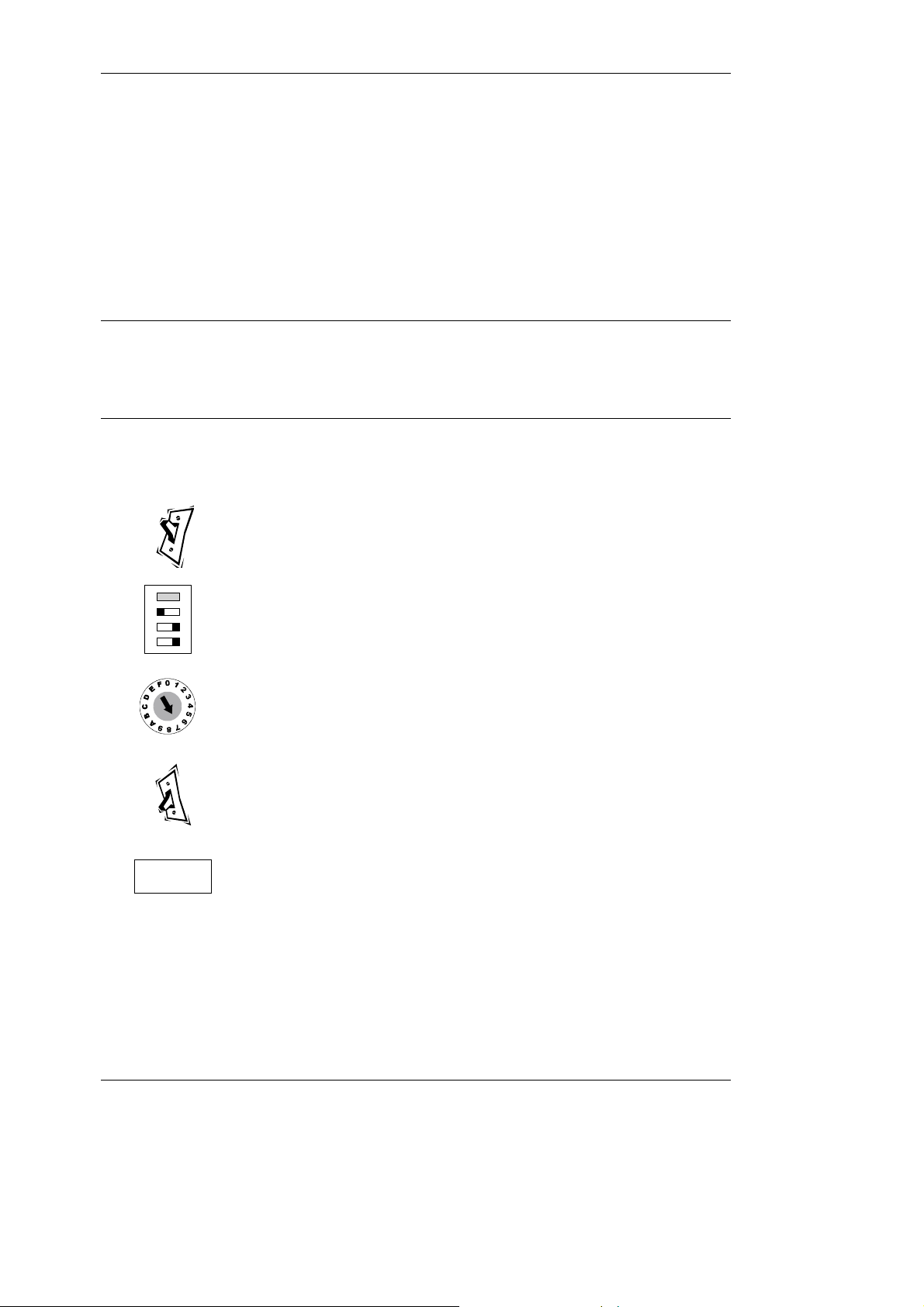

Example:- To select Token Group 7 on your validator follow these

simple steps.

1. Switch Validator Power OFF.

ON

1 2 3 4

2. Set 4 Way Switches to Select Token Group.

3. Set Rotary Switch Dial to the appropriate

Channel. (Token group 7 in this example).

4. Switch Validator Power ON (LED will flash).

5. Return Switches to Normal Operation

END

(LED stops flashing and stays on to indicate

successful change. Token Group 7 successfully

selected and programmed into Channel 0.

©, Mars, Inc., 1998 21

Page 26

CashFlow® 126 and CashFlow® 129 selectors User Guide

Product Configuration -

Selecting a pre-programmed token group to be used

in channel 1

14 token groups are already programmed into the product. This feature

allows a defined token group to be accepted.

v NOTE: Each token group selected is automatically copied to channel 1.

Refer to the Appendix at the end of the book for further details of token

groupings.

Example:- To select Token Group 7 on your validator follow these

simple steps.

1. Switch Validator Power OFF.

ON

1 2 3 4

2. Set 4 Way Switches to Select Token Group.

3. Setting Rotary Switch Dial to position 7 selects

MHG token group

4. Switch Validator Power ON (LED will flash).

5. Return Switches to Normal Operation

END

(LED stops flashing and stays on to indicate

successful change. Token Group 7 successfully

selected and programmed into Channel 1.

22 ©, Mars, Inc., 1998

Page 27

CashFlow® 126 and CashFlow® 129 selectors User Guide

Position D = Fixed Parallel mode

Position F = Automatic mode

END

Product Configuration Changing the machine output mode

To change the coin output interface to Fixed Binary Coded Output

(BCO) use these simple steps. For BCO mode set the rotary data switch

to position C , to D for Fixed Parallel mode and F for Automatic

mode.

v NOTE: The product will normally be supplied in Automatic mode. This

will automatically configure to most machines through the Mode Select

feature. Some gaming machines have pre-BACTA standard Binary code

software and in this case the coin mechanism should be set to fixed

Parallel mode.

Example:- To set mode to Binary Coded Output

1 2 3 4

ON

Set switches 2, 3 and 4

as shown here.

Position C = Fixed B.C.O. mode.

1. Switch Validator Power OFF.

ON

1 2 3 4

2. Set 4 Way switches to Output Mode Teach.

3. Set Rotary Switch Dial to appropriate position.

(Position C in this example).

4. Switch Validator Power ON (LED will Flash).

ON

1

5. Set switches 2, 3 & 4 to ON. (LED will stop

2 3 4

flashing and stay on).

Leave the Rotary Switch settings as they are.

6. Product is now ready for use with the chosen

machine interface.

©, Mars, Inc., 1998 23

Page 28

CashFlow® 126 and CashFlow® 129 selectors User Guide

MAINTENANCE

+ The practical maintenance that can be carried out is limited to cleaning the areas of the

validator that the coins travel through, and the replacement of the coin entry liner if it becomes

worn. All other servicing is carried out through your distributor.

The cleaning should be carried out on a regular basis of at least once a month, but, if you

have to visit the validator outside of that routine, it is worth while doing it then as well.

The shaded areas shown below, plus the back of the reject cover, are those to be cared

for.

The coin entry liner is accessed by unscrewing the coin entry moulding at the top of the

validator. The coin entry liner can then be eased off with the aid of a fine screwdriver, and

a replacement slid into place.

q Cleaning and maintenance must only be carried out by suitably trained personnel.

q Cleaning must only be carried out after power has been removed from the product.

q Never use a cleaner containing solvents, scrapers or abrasive materials.

q Never apply water or cleansers directly onto the product. Always apply them to a

clean cloth first, and not too liberally, so that the cloth used is only moist.

APPENDIX

24 ©, Mars, Inc., 1998

Page 29

0

Reserved

16FN-Plate

Steel

15EN-Plate

Steel

14DN-P

Brass &

13CBrass &

N-Plate

Brass

3

12BDefault (Brass-Wide)

333

3

11AOversized Token

108Paymaster

87MHG

76Stretton

Leisure

64LMS

333

43Ralin

& Thomas

333

32BFS

21Rank Leisure

1ECBA

ME token group

Token Grouping Compatibility

CashFlow® 126 and CashFlow® 129 selectors User Guide

Product Revision

The revision level of the 126/129 product can be confirmed from a label on the left side of

the product. There are two levels of digits and bar-code markings on the label, and the

fifth and sixth digits on the lower numbers indicate the product level.

For example; if the label read 1773G322580 the revision level would be G3.

Do not use the label on the right side of the product for reference of the revision level.

ME Token

groups

LINK settings

(links inserted = 3)

333

3

33

33

33

3

333

33

3

Token Type or

Operator

Oversized

CF126/129

token group

Rotary switch

position

©, Mars, Inc., 1998 25

Page 30

CashFlow® 126 and CashFlow® 129 selectors User Guide

PRODUCT SUPPORT

In addition to the MEI offices around the world an international network of Distributors and

Approved Service Centres can offer you technical support and other services as well.

These services include repairs, re-programming of your CashFlow® products with new

coinsets, replacing damaged modules, and the supply of a range of spare parts.

In the U.K. these can be obtained from the following:

BRENT LEISURE SPARES LTD.

Unit 5, Acton Vale Industrial Estate

The Vale, Acton

London W3 7QE

Contact: Steve Ansell

Telephone: 0181 - 324 - 6000

EUROCOIN LTD

Fortune House

Moxon Street

Barnet

Herts

Contact: Ray Moore

Telephone: 0181 - 449 - 0077

MICRO ELECTRONIC SERVICES (M.E.S.)

7 Aircraft Esplanade

Farnborough

Hampshire GU14 6TG

Contact: Mike Clokie

Telephone: 01252 375302

(Service Centre only)

©, Mars, Inc., 1998 26

Page 31

Helping you deliver

YOUR MEI REPRESENTATIVE

Loading...

Loading...