Page 1

IC Radio Standards Specification: RSS-247

Certification Exhibit

FCC ID: SJS-400099WH

IC: 5379A-400099WH

FCC Rule Part: 15.247

ACS Project Number: 16-0481

Manufacturer: MARS Company

Model: 400099WH

Manual

5015 B.U. Bowman Drive Buford, GA 30518 USA Voice: 770-831-8048 Fax: 770-831-8598

Page 2

MARS SmartTransmitter MK-I/II

MARS SmartTransmitter VHP

FlowBridge FlowCast

Installation and Programming Guide

Page 3

Revision 1.E (CM)

January 2017

MARS Company

A Division of OW Investors, LLC

sales@marswater.com

800.782.5268

Page 4

Table of Contents

Table of Contents

1

Introduction

3

Connecting to a Meter

4

Wiring Configurations

5

Programming Configurations - Overview

7

MK-I/II Programming Configurations - Step-by-Step Guide

8

MK-I/II Programming Configurations - Parameters Explained

9

MK-I/II Programming Configurations – Meter Type Settings

10

VHP Programming Configurations - Step-by-Step Guide

12

VHP Programming Configurations - Parameters Explained

14

VHP Programming Configurations – Meter Type Settings

15

Troubleshooting

17

Contact Us

19

Information to the User (FCC Information)

21

Page 1 of 21

Page 5

Page 2 of 21

Page 6

Introduction

Page 3 of 21

Welcome to the exciting world of MARS Automated Meter Reading (AMR) Solutions. In the following

pages we will learn how to connect and program a MARS SmartTransmitter MK-I/II, a MARS

SmartTransmitter VHP (Very High Power), a FlowBridge FlowCast, and to perform occasional

troubleshooting.

There are a few points to remember while reading through the manual that can potentially help avoid

some common mistakes, and also give suggestions to help streamline the process of installing MARS

AMR.

• There are various materials that may be needed for each task, which are presented in

the beginning of each section. It is recommended that you have these nearby.

• Notes are listed in italics next to or underneath the section they are referring to. They

will list suggestions or offer advice on the adjacent topic.

• Sections in BOLD letters must be followed exactly, otherwise device operation will be

adversely affected or the manufacturer’s warranty will be voided.

• Underlined items are references to other sections of this manual.

As always, feel free to refer to the Contact Us section of the manual to call or email MARS if you have

any questions or if you would like additional information.

Page 7

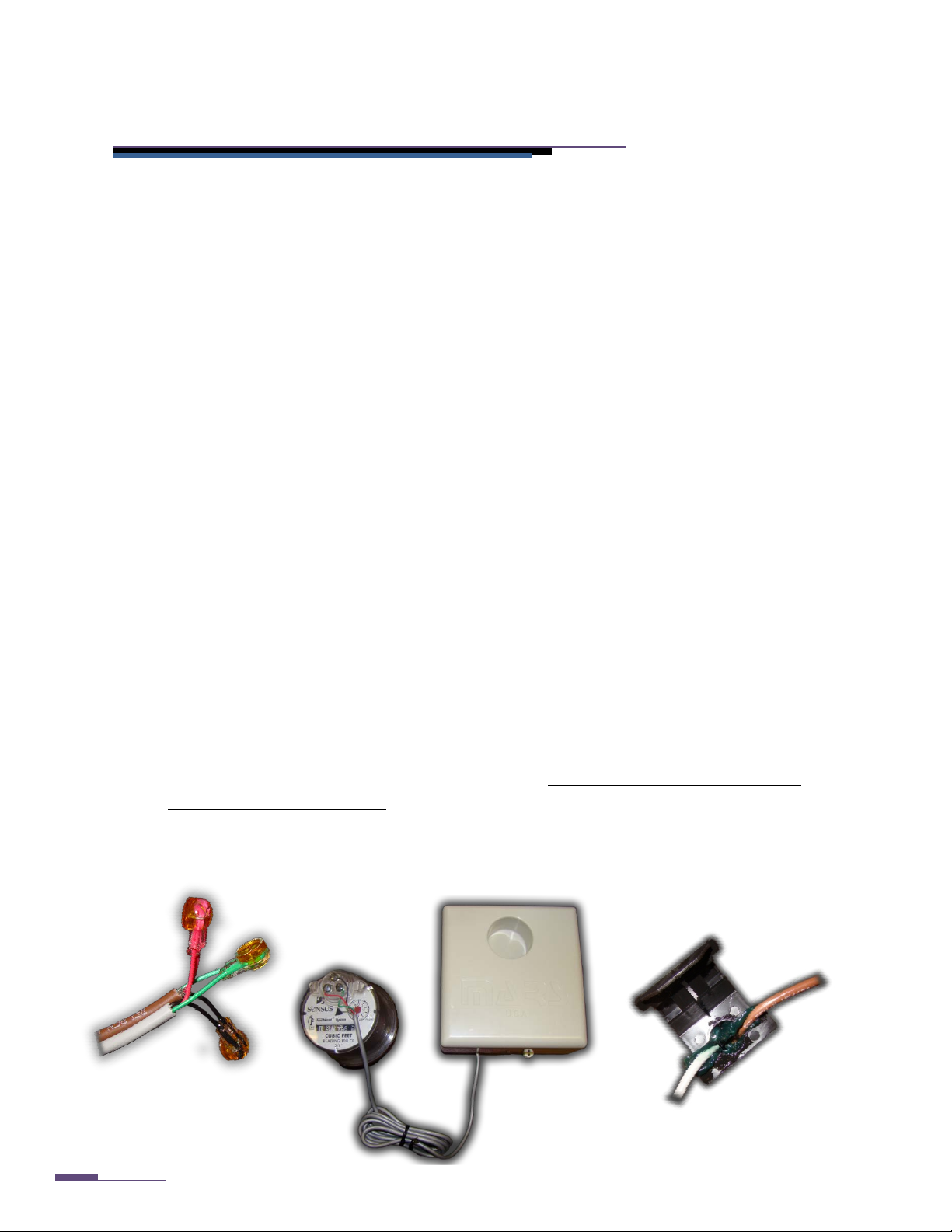

Connecting to a Meter

Page 4 of 21

Materials Needed

• MARS SmartTransmitter/FlowBridge FlowCast

• Meter with AMR output

• Gel Caps with Gel Cap Tool (optional)

• Wire Strippers (optional)

• Screwdriver (optional)

• Mounting Equipment (optional)

Depending on the installation environment, whether it is inside of a meter pit or on a wall, the materials

needed may differ slightly as a pit mounted SmartTransmitter/FlowBridge FlowCast installation may

require a pit mount bracket or AMR-ready pit lid. This is installation specific, and will vary between

installations.

For a meter with screw terminals available for AMR output, wire strippers and a screwdriver

will be required. Use the wire strippers to ensure there is enough bare wire to make reliable

contact with the screw terminals. Then use the screwdriver to attach each wire to its respective

terminal, as outlined in MARS SmartTransmitter/FlowBridge FlowCast Wiring Configurations.

For a meter with a pre-wired lead, wire strippers will be needed to remove the outer jacket on

the lead and Gel Caps are recommended by MARS to attach the SmartTransmitter/FlowBridge

FlowCast to the meter. First, remove the outer jacket on the pre-wired lead. When removing

the outer jacket, do not strip the inner 2 or 3 wires. These should not be stripped as this will

case unreliable performance. Once the outer jacket is removed, use the Gel Caps and Gel Cap

Tool to connect the 2 or 3 wire leads to their respective wire on the MARS

SmartTransmitter/FlowBridge FlowCast, as outlined in MARS SmartTransmitter/FlowBridge

FlowCast Wiring Configurations.

Once these connections are made and the installation environment is appropriately prepared with any

additional equipment, the MARS SmartTransmitter/FlowBridge FlowCast is ready to be programmed.

Page 8

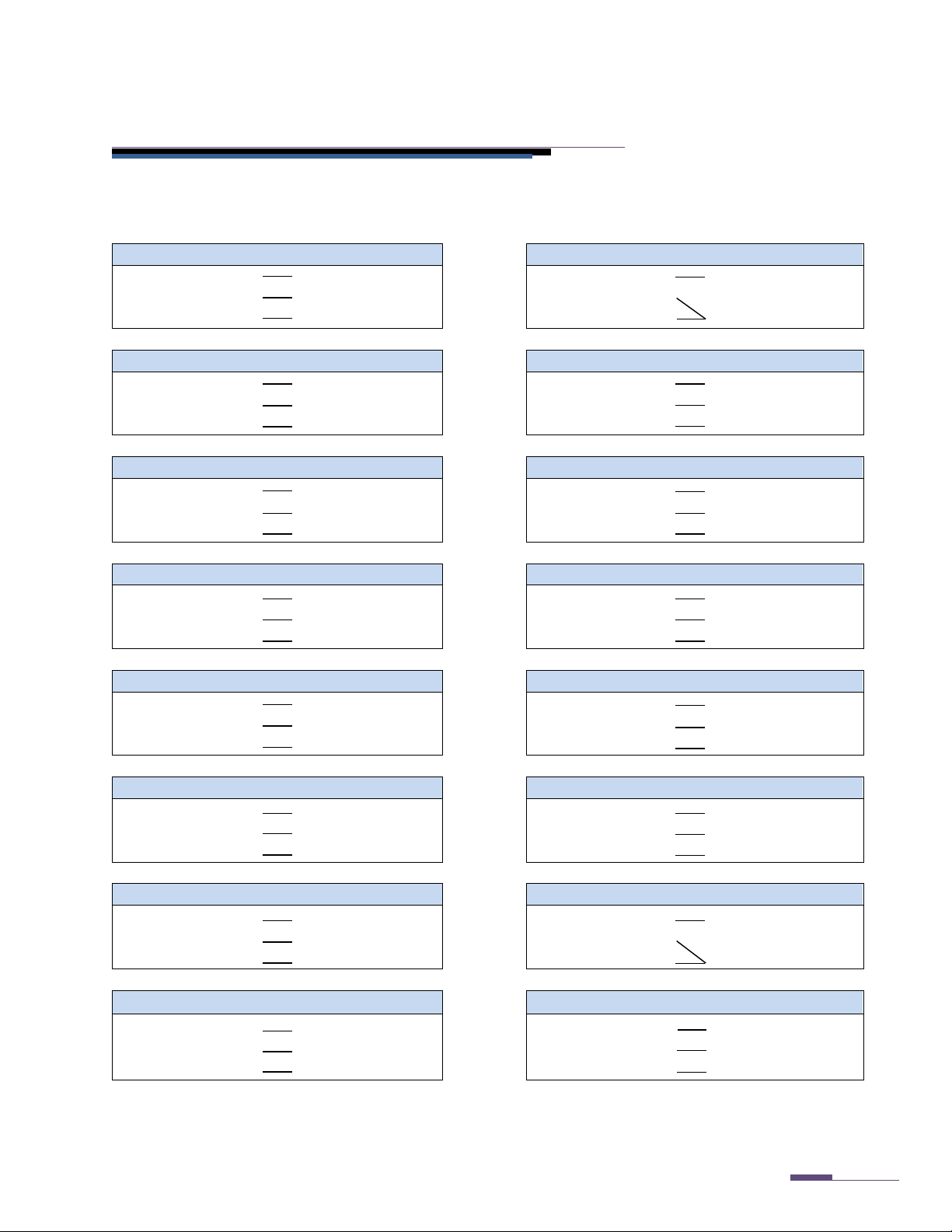

Wiring Configurations

MARS Encoder

Master Meter / 2-Wire Pulse/Generator Meter

Radio Green

Meter Green

Radio Green

Meter Red

Radio Red

Meter Red Radio Red

(3-wire Gel Cap)

Radio Black

Meter Black

Radio Black

Meter Black

Sensus Encoder

Hersey Encoder

Radio Green

Meter Green

Radio Green

Meter Green

Radio Red

Meter Red Radio Red

Meter Red

Radio Black

Meter Black

Radio Black

Meter Black

Neptune AutoRead

Neptune ProRead

Radio Green

Meter Red

Radio Green

Meter Red

Radio Red

Meter Black Radio Red

Meter Black

Radio Black

Meter Green

Radio Black

Meter Green

Elster AMCO Absolute Encoder (InVISION)

Neptune ARB V

Radio Green

Meter Red

Radio Green

Meter Red

Radio Red

Meter Green Radio Red

Meter Black

Radio Black

Meter Black

Radio Black

Meter Green

AMCO / ABB / Kent Scancoder

Elster AMCO Digital Register (pulse)

Radio Green

Meter Red

Radio Green

Meter Black

Radio Red

Meter Green Radio Red

Meter Green

Radio Black

Meter Black

Radio Black

Meter Red

Severn Trent – First Generation

Severn Trent – Second Generation

Radio Green

Meter Terminal 3

Radio Green

Meter Green

Radio Red

Meter Terminal 1

Radio Red

Meter Red

Radio Black

Meter Terminal 5

Radio Black

Meter Black

Badger ADE

Badger RTR

Radio Green

Meter Green

Radio Green

Meter Red

Radio Red

Meter Red Radio Red

(3-wire Gel Cap)

Radio Black

Meter Black

Radio Black

Meter Black

3+ -Wire Pulse/Generator Meter

Elster AMCO V-100 PSMT

Radio Green

Meter Signal Wire

Radio Green

Meter Red

Radio Red

Meter Tamper Wire

Radio Red

Meter Yellow

Radio Black

Meter Commons

Radio Black

Meter Black & Blue

Page 5 of 21

The diagrams below show the connections that must be made for each different type of meter. These

must be made correctly for the system to function normally. Unless directed otherwise by MARS or

MARS authorized personnel, follow these wiring instructions.

Page 9

Pit Mount MK – II / VHP

Wall Mount MK - II / VHP

MK - I SmartTransmitter

Page 6 of 21

Inductive Coil Locations

FlowBridge FlowCast /

SmartTransmitter

MK-IV

SmartTransmitter

Center SmartReader nozzle on these points.

Page 10

Programming Configurations - Overview

Page 7 of 21

The MARS SmartTransmitter and the FlowBridge FlowCast are programmed via an inductive coil and the

parameters are set using the MARS SmartReader handheld device. The software that is involved is very

different between the traditional MK-I or II and the VHP MARS SmartTransmitter. If you are unsure if

the proper software is installed, please refer to the Contact Us section of this manual and call MARS to

confirm.

The FlowBridge FlowCast can be programmed to be compatible with either the MK-I/II instructions or

VHP instructions outlined in this manual. As this is set by MARS during manufacture, please refer to

MARS to determine which configuration steps must be followed.

Before programming a MARS SmartTransmitter or FlowBridge FlowCast, be sure the SmartReader is fully

charged. The center of the black nozzle on the SmartReader must be centered over the locations

(shown on the left) when a function is being processed, and the center of the black nozzle of the

SmartReader MUST be flush with the SmartTransmitter/FlowBridge FlowCast housing. The

SmartReader can NOT be moved or pulled away from the SmartTransmitter/FlowBridge FlowCast

until the function in process is complete. When the function is complete, the light on the rear of the

SmartReader will stop flashing and the device will emit either an escalating tone (low to high) with a

solid green LED for a successful command, or a low, flat tone with a solid red LED for a failed command.

To program the MARS SmartTransmitter/FlowBridge FlowCast, follow the appropriate instructions in

this manual. There are many functions that are not manufacturer specific, all of which will be outlined.

Manufacturer specific information will be listed in a simplified format in this section as well.

Page 11

Programming Configurations - Step-by-Step Guide

Page 8 of 21

MK – I/II ONLY

1. Power on the SmartReader by either pushing the red power button or pulling the trigger.

2. On the “Main Menu”, press the down-arrow key twice to highlight “MARS RADIO SET-UP”.

Press the Enter key or pull the trigger.

3. At the password prompt, type in 2764 and press the Enter key or pull the trigger.

4. Press the F1 key on the SmartReader and hold the nozzle of the SmartReader against the

SmartTransmitter as outlined in this section’s Overview. Press the Enter key or pull the trigger.

This will pull the current settings from the SmartTransmitter.

Note: You may need to repeat Step 4 once or twice to get a reading. Many factors can

either cause interference, and if you move the nozzle off of the radio before the operation is

completed the SmartReader may not correctly communicate with the SmartTransmitter.

5. Once the configuration is pulled from the SmartTransmitter, they can now be edited. To edit

each parameter, use the up-arrow and down-arrow keys to highlight each field and press the

Enter key. Choose the parameter to be set using the up-arrow and down-arrow keys and press

the Enter key. You will notice that the “Current:” option at the top of the screen (for most

parameters) will change to the option that was selected. Press the Exit key once to return to the

“MARS RADIO SET-UP” screen. You may program all parameters at one time. Proceed to Step 6

when all relevant parameters are set. On the next page is an explanation of each parameter,

and the available choices.

6. Once each parameter is programmed to your specification, press the F6 key on the SmartReader

and hold the nozzle of the SmartReader against the SmartTransmitter as outlined in this

section’s Overview. Press the Enter key or pull the trigger. This will send each changed

command to the SmartTransmitter.

Note: Many factors can either cause interference, and if you move the nozzle off of the radio

before the operation is completed the SmartReader may not correctly communicate with the

SmartTransmitter.

7. After programming, confirm the changed settings are correct by repeating the F1 function

completed in Step 4. Remember, a successful read tone is the escalating tone, whereas the

unsuccessful tone is the low, flat tone.

8. When the correct settings are confirmed in the device, press the F2 key from the “MARS RADIO

SET-UP” menu. Hold the nozzle of the SmartReader against the SmartTransmitter as outlined in

this section’s Overview. Press the Enter key or pull the trigger. This will force an interrogation

of the register, and will check the connection. This is the last function that will need to be done

to program a SmartTransmitter.

Note: You may need to repeat Step 8 once or twice to get a reading. Many factors can

either cause interference, and if you move the nozzle off of the radio before the operation is

completed the SmartReader may not correctly communicate with the SmartTransmitter.

Page 12

Programming Configurations - Parameters Explained

Radio on?

Options are “ON” or “OFF”. “ON” setting will cause the device to transmit.

Enc Type

Select the meter manufacturer from this list. This enables the SmartTransmitter

Refer to the manufacturer-specific information in this section for more info.

TX rate

Sets the interval between transmissions. Default is “004sec”, or every 4 seconds.

Read Rate

ENCODER ONLY. Sets the interval between interrogations. Default is “240min”, or

every 4 hours. MARS recommends this be kept at this time; decreasing the interval

between interrogations WILL negatively impact battery life.

Time

Current time in 24-hour format. Example: 7:00PM = 19:00, NOT 07:00.

Day

Current day of the week.

Freq

NOT USER CHANGEABLE. Current transmit frequency.

Time Mode?

Options are “OFF”, “TIMED”, “MON-FRI” and “T & M-F”. This enables the

recommended setting.

Start Time

“Wake up” time for the Time Mode setting. See above.

End Time

“Sleep” time for the Time Mode setting. See above.

Radio ID:

PULSE / ARB-V ONLY. 10-digit ID for the SmartTransmitter to transmit. When

ID of the register.

Serial No:

NOT USER CHANGEABLE. Internal serial number.

Pulse Fact

PULSE / ARB-V ONLY. 8-Digit pulse multiplier for the internal odometer of the

and “Pulse Digits”=6.

Pulse Num

PULSE / ARB-V ONLY. Starting point for the internal odometer in pulse or ARB-V

and Pulse Digits align! Otherwise, you may experience undesired operation.

Pulse Digits

PULSE / ARB – V ONLY. Number of digits, or wheels, for the internal odometer to

be changed to suit the customers’ needs.

Page 9 of 21

MK – I/II ONLY

to “understand” what the meter is “saying” and correctly interpret the data.

SmartTransmitter to “sleep” at the designated intervals set below. When

enabled, this option will significantly extend the performance and usable life of

the SmartTransmitter.

• “OFF” will make the SmartTransmitter transmit 24/7.

• “TIMED” will make the radio “sleep” (stop transmitting) at the End Time and

“wake up” (start transmitting) at the Start Time.

• “MON-FRI” will make the radio “sleep” (stop transmitting) on Saturday and

Sunday and “wake up” (start transmitting) Monday through Friday.

• “T & M-F” combines both the “TIMED” and “MON-FRI”, so the

SmartTransmitter will only “wake up” (start transmitting) Monday through

Friday between the Start Time and End Time, and “sleep” (stop

transmitting) at night and on the weekends. This is the MARS

connected to an encoded register, the SmartTransmitter will ALWAYS assume the

SmartTransmitter. It is ALWAYS read left to right. This tells the SmartTransmitter

what each pulse means as far as advancing the internal odometer to match the

meter.

Example: Meter is configured for 1 pulse/gallon. The utility wants to bill in 100’s

of gallons with 6 digits. “Pulse Fact”=00000001, “Pulse Num”= current reading,

mode. Input the current reading for the register in this field. It is ALWAYS read

left to right.

Take care to note that the units when calculating the Pulse Factor, Pulse Number,

read and transmit. Normally this would be 6, but in pulse or ARB-V mode this can

Page 13

Programming Configurations - Meter Type Settings

Enc Type

Meter Connected to the MARS SmartTransmitter/FlowBridge FlowCast

SENSUS

Standard output protocol, MARS, Sensus, Invensys, encoders configured for Sensus

output, such as the Elster AMCO InVISION Absolute Encoder with the blue leak detector.

AMCO

Elster AMCO InVISION Absolute Encoder with white leak detector, ABB/Kent Scancoder

NEPTUNE P

Neptune ProRead, Schlumberger ProRead

STMS

Severn Trent SmartMeter (Example: SM700E)

HERSEY

Hersey encoder

BADGER

Badger ADE

NEPTUNE A

Neptune AutoRead

ARB V

Neptune ARB-V

PULSE

Standard 2 or 3+ wire pulse switches/registers, Elster AMCO Digital Register, Badger RTR,

PSMT

0 0 0 0 0 0 0

0

0 0 0 0 0 0 0

0

Page 10 of 21

MK-I/II ONLY

Encoder Type

The encoder type is dependent upon the configuration of the encoded register at the factory. The

options for the encoder type are listed below, along with the meters that fall into each specific category.

For the meter that is used, the parameter that it coincides with is the parameter that is input into the

“Enc Type” field.

Master Meter pulse, Performance Meters pulse, Severn Trent SM700P, Elster AMCO

As these are popular configuration choices, there are many other configurations that are possible with

the MARS SmartTransmitter/FlowBridge FlowCast. For further information, or to check meter

compatibility, please see the Contact Us section in this manual.

Radio ID, Pulse Factor, Pulse Digits, and Pulse Number

When calculating the pulse parameters for a pulse register or Neptune ARB-V, the following pieces of

information are required: the unique 10-digit ID number for the SmartTransmitter to broadcast,

amount of pulses per unit (usually printed on the face of the register), amount of digits (wheels from left

to right) to be broadcast for the reading system to collect and the current reading of the meter. The 10digit ID number, current reading (pulse number) and pulse digits (wheels) can be directly input into

these fields, leaving the pulse factor left.

To calculate the pulse factor, start with the 8-digit internal odometer like this…

…and mark off (from the LEFT) the pulse digits (wheels).

For the purpose of an explanation, we will assume 6 pulse digits.

Page 14

For the purpose of demonstration, let’s assume that the register is in gallons, and that we want to

0 0 0 0 0 1 0

0

0 0 0 0 0 1 0

0

Pulse Factor =

00000100

(number of pulses for a full sweep hand revolution)

Page 11 of 21

transmit the reading in 10’s of gallons, or one revolution of the sweep hand. The example register

completes one pulse for every revolution of the sweep hand (1 pulse / 10 gallons). This is what one

sweep would make the internal odometer look like:

As of this moment, we can safely input a pulse factor of 100, or as it would be in the setup software,

00000100.

To calculate this out, especially for registers that are not as straightforward as this, assume a register

advance of 1 on wheel number 6 (again in our example).

How many pulses did it take us to get to this point (a full revolution of the sweep hand)? This will be

variable a in the MARS Pulse Factor Formula.

Using this formula and “padding” zeros in front of the pulse factor to keep 8 digits, this is the pulse

factor to use when configuring these radios.

This pulse factor, which can now be put into the the “Pulse fact” field in the “MARS RADIO SET-UP”

software, will now allow the MARS SmartTransmitter/FlowBridge FlowCast to accurately count the

pulses off of the pulse-type meter.

(internal 8-digit odometer reading with leading zeros to fill all 8 digits)

a

Page 15

Programming Configurations - Step-by-Step Guide

Page 12 of 21

VHP ONLY

1. Power on the SmartReader either by pushing the red power button or pulling the trigger.

2. Confirm the time and date at the top of the screen are correct. This must be accurate, as the

SmartReader updates the time in the SmartTransmitter according to the time and date in the

SmartReader. If the time is incorrect, continue to Step 3. If it is correct, proceed to Step 4.

3. To reset the time and date in the SmartReader:

a. Press the down-arrow key 3 times to highlight “ADMIN”. Press the Enter key or pull the

trigger.

b. “SMART-READER SETUP” is automatically selected. Press the Enter key or pull the

trigger.

c. Press the down-arrow key 3 times to highlight “TIME & DATE”. Press the Enter key or

pull the trigger.

d. Key in the time and date in this format: YYYY-MM-DD HH:MM.

e. Press the Tab key 5 times until the Day of the Week list appears. Use the up and down-

arrow keys to select the Day of the Week.

f. Press the Enter key or pull the trigger when done. The time and day at the top of the

screen will be updated. Press the Exit key twice.

g. Press the up-arrow key twice to select “MARS RADIO SET-UP” and press the Enter key or

pull the trigger. Proceed to Step 5.

4. Press the down-arrow once to highlight “MARS RADIO SET-UP”. Press Enter key or pull the

trigger.

5. You now have the option to use either a user defined setting or a preset configuration. If these

configurations are preset, proceed to Step 5a. If these are not set, proceed to Step 6.

a. Use the arrow keys to highlight the configuration and press the Enter key or pull the

trigger.

b. Press the F4 key and follow any prompts. When this function is complete, the

SmartTransmitter is programmed.

c. Press the Exit key twice, up-arrow key once, and use the “TEST READING” function to

check the register. Programming is complete.

Note: You may need to repeat Step 5c once or twice to get a reading. Many factors can

either cause interference, and if you move the nozzle off of the radio before the operation is

completed the SmartReader may not correctly communicate with the SmartTransmitter.

6. To set Configuration 1-3, use the up and down-arrow keys to highlight the specific

Configuration. Press the Enter key.

7. Highlight the first option to change. Press the Enter key.

Page 16

8. Use the number pad to key 2764 at the password warning and press the Enter key.

Page 13 of 21

9. Use the up and down-arrow keys highlight each parameter to be changed. Press the Enter key

or pull the trigger. Refer to the section MARS SmartTransmitter/FlowBridge FlowCast

Programming Configurations – VHP Parameters Explained for an overview of the options

available.

10. Select the appropriate option from the list using the up and down-arrow keys. Press the Enter

key or pull the trigger. You will be returned to the Configuration screen each time.

11. Follow Steps 9 and 10 for each parameter to be changed. When done, press the Exit key twice.

12. Pull the trigger or press the Enter key twice to reenter the Configuration. This will allow you to

use the Configuration and disallow further changes unless the password is entered as in Step 8.

13. Use the arrow keys to highlight the configuration and press the Enter key or pull the trigger.

14. Press the F4 key and follow any prompts. When this function is complete, the SmartTransmitter

is programmed.

15. Press the Exit key twice, up-arrow key once, and use the “TEST READING” function to check the

register. If the meter is successfully read, programming is complete.

Note: You may need to repeat Step 14 once or twice to get a reading. Many factors can

either cause interference, and if you move the nozzle off of the radio before the operation is

completed the SmartReader may not correctly communicate with the SmartTransmitter.

Page 17

Programming Configurations - Parameters Explained

Radio

Options are “ON” or “OFF”. “ON” setting will cause the device to transmit.

Register

Select the meter manufacturer from this list. This enables the SmartTransmitter to

Refer to the VHP manufacturer-specific information in this section for more info.

TX rate

Sets the interval between transmissions. Default is “044sec”, or every 44 seconds.

Time

NOT USER CHANGEABLE. Current time in 24-hour format. Example: 7:00PM = 19:00,

NOT 07:00.

Day

NOT USER CHANGEABLE. Current day of the week.

Time Mode?

Options are “OFF”, “TIMED”, “MON-FRI” and “T & M-F”. This enables the

weekends. This is the MARS recommended setting.

Start Time

“Wake up” time for the Time Mode setting. See above.

End Time

“Sleep” time for the Time Mode setting. See above.

Radio ID:

PULSE / ARB-V ONLY. 10-digit ID for the SmartTransmitter to transmit. When

the register.

Serial No:

NOT USER CHANGEABLE. Internal serial number.

Pulse Fact

PULSE / ARB-V ONLY. 8-Digit pulse multiplier for the internal odometer of the

“Pulse Digits”=6.

Digits

PULSE / ARB – V ONLY. Number of digits, or wheels, for the internal odometer to read

changed to suit the customers’ needs.

Reading

PULSE / ARB-V ONLY. Starting point for the internal odometer in pulse or ARB-V

Pulse Digits align! Otherwise, you may experience undesired operation.

No-Flow

Options are “OFF” or “ON”. Sets the no-flow alarm. This will set a flag to alert the user

while reading the route if this condition exists.

Leak Lrg

Options are “OFF” or “ON”. Sets the large leak detection alarm. This will set a flag to

alert the user while reading the route if this condition exists.

Leak Sml

Options are “OFF” or “ON”. Sets the small leak detection alarm. This will set a flag to

alert the user while reading the route if this condition exists.

Wheel Num

This is the wheel for the alert flags to monitor, and is set as the digit of the odometer

.

Page 14 of 21

VHP ONLY

“understand” what the meter is “saying” and correctly interpret the data.

SmartTransmitter to “sleep” at the designated intervals set below. When enabled, this

option will significantly extend the performance and usable life of the

SmartTransmitter.

• “OFF” will make the SmartTransmitter transmit 24/7.

• “TIMED” will make the radio “sleep” (stop transmitting) at the End Time and

“wake up” (start transmitting) at the Start Time.

• “MON-FRI” will make the radio “sleep” (stop transmitting) on Saturday and

Sunday and “wake up” (start transmitting) Monday through Friday.

• “T & M-F” combines both the “TIMED” and “MON-FRI”, so the SmartTransmitter

will only “wake up” (start transmitting) Monday through Friday between the

Start Time and End Time, and “sleep” (stop transmitting) at night and on the

connected to an encoded register, the SmartTransmitter will ALWAYS assume the ID of

SmartTransmitter. It is ALWAYS read left to right. This tells the SmartTransmitter

what each pulse means as far as advancing the internal odometer to match the meter.

Example: Meter is configured for 1 pulse/gallon. The utility wants to bill in 100’s of

gallons with 6 digits. “Pulse Fact”=00000001, “Pulse Num”= current reading, and

and transmit. Normally this would be 6, but in pulse or ARB-V mode this can be

mode. Input the current reading for the register in this field. It is ALWAYS read left to

right.

Take care to note that the units when calculating the Pulse Factor, Pulse Number, and

from the left. For small leak detection, MARS recommends setting the wheel number

to the 10’s of gallons wheel to avoid any false alarms. Please refer to the pulse

parameter information in this section for more information on odometer wheels

Page 18

Programming Configurations – Meter Type Settings

Register

Meter Connected to the MARS SmartTransmitter/FlowBridge FlowCast

AMCO Enc

Elster AMCO InVISION Absolute Encoder with white leak detector, ABB/Kent Scancoder

AMCO Puls

Elster AMCO Digital Register, Elster AMCO PSMT

AMCO Gen

Elster AMCO Generator Pulse registers

Badgr Enc

Badger ADE

Badgr Puls

Badger RTR

Badgr Gen

Badger Generator Pulse registers

Hersey Enc

Hersey encoder

Mastr Puls

Master Meter Pulse register / switch

Nep Auto

Neptune AutoRead register

Nep ProRe

Neptune ProRead register

Nep ARB V

Neptune ARB-V

Perf Enc

Performance Meters encoder

Sens Enc

Standard output protocol, MARS, Sensus, Invensys, encoders configured for Sensus

output, such as the Elster AMCO InVISION Absolute Encoder with the blue leak detector.

STMS Enc

Severn Trent SmartMeter (Example: SM700E)

Other Puls

Standard 2 or 3+ wire pulse switches/registers, Performance Meters pulse, Severn Trent

SM700P

0 0 0 0 0 0 0

0

Page 15 of 21

VHP ONLY

Encoder Type

The encoder type is dependent upon the configuration of the encoded register at the factory. The

options for the encoder type are listed below, along with the meters that fall into each specific category.

For the meter that is used, the parameter that it coincides with is the parameter that is input into the

“Register” field.

As these are popular configuration choices, there are many other configurations that are possible with

the MARS SmartTransmitter/FlowBridge FlowCast. For further information, or to check meter

compatibility, please see the Contact Us section in this manual.

Radio ID, Pulse Factor, Pulse Digits, and Pulse Number

When calculating the pulse parameters for a pulse register or Neptune ARB-V, the following pieces of

information are required: the unique 10-digit ID number for the SmartTransmitter to broadcast,

amount of pulses per unit (usually printed on the face of the register), amount of digits (wheels from left

to right) to be broadcast for the reading system to collect and the current reading of the meter. The 10digit ID number, current reading (pulse number) and pulse digits (wheels) can be directly input into

these fields, leaving the pulse factor left.

To calculate the pulse factor, start with the 8-digit internal odometer like this…

Page 19

…and mark off (from the LEFT) the pulse digits (wheels).

0 0 0 0 0 0 0

0

0 0 0 0 0 1 0

0

0 0 0 0 0 1 0

0

Pulse Factor =

00000100

(number of pulses for a full sweep hand revolution)

Page 16 of 21

For the purpose of an explanation, we will assume 6 pulse digits.

For the purpose of demonstration, let’s assume that the register is in gallons, and that we want to

transmit the reading in 10’s of gallons, or one revolution of the sweep hand. The example register

completes one pulse for every revolution of the sweep hand (1 pulse / 10 gallons). This is what one

sweep would make the internal odometer look like:

As of this moment, we can safely input a pulse factor of 100, or as it would be in the setup software,

00000100.

To calculate this out, especially for registers that are not as straightforward as this, assume a register

advance of 1 on wheel number 6 (again in our example).

How many pulses did it take us to get to this point (a full revolution of the sweep hand)? This will be

variable a in the MARS Pulse Factor Formula.

Using this formula and “padding” zeros in front of the pulse factor to keep 8 digits, this is the pulse

factor to use when configuring these radios.

This pulse factor, which can now be put into the “Pulse fact” field in the “MARS RADIO SET-UP”

software, will now allow the MARS SmartTransmitter/FlowBridge FlowCast to accurately count the

pulses off of the pulse-type meter.

(internal 8-digit odometer reading with leading zeros to fill all 8 digits)

a

Page 20

Troubleshooting

Problem

Solution

Register is not interrogating.

• Check the meter for functionality with a touchpad.

See section labeled Contact Us.

SmartTransmitter is not

• Make sure you are holding the devices together as

See section labeled Contact Us.

SmartTransmitter is not

• Several reasons exist for this issue. The main reason

• See section labeled Contact Us.

SmartTransmitter is cracked.

See section labeled Contact Us.

Page 17 of 21

Attach a testing touchpad to the meter. There is a

“READ” function in the Main Menu of the SmartReader

that will allow the device to read any encoder.

• Make sure you are holding the devices together as

outlined in MARS SmartTransmitter/FlowBridge FlowCast

Programming Configurations – Overview.

• Check the settings in the SmartTransmitter using the F1

key.

• Check wiring to make sure the meter and

SmartTransmitter are connected correctly.

•

communicating with the

SmartReader.

transmitting outside of meter

pit / building.

outlined in MARS SmartTransmitter/FlowBridge FlowCast

Programming Configurations – Overview.

• Go to Main Menu → Radio Tools → Radio Info (scroll

down past the bottom of the Main Menu screen to find

Radio Tools). “X” should be a number VERY close to

908750000. If it is not near this number, go to the Main

Menu

→ Radio Tools → Set Rx Frequency (scroll down

past the bottom of the screen for this option). Press

Enter. Key in 908750000 on the number pad. Press

Enter. The receiver frequency will be updated.

• Make sure the nozzle is properly attached to the

SmartReader.

•

includes EM/RF Interference. A good overview is

available here:

http://en.wikipedia.org/wiki/RF_interference

• Check the battery voltage (MK-II and VHP pit/wall only).

If at any time you would like to speak with MARS concerning troubleshooting or issues you may be

experiencing in the field, please refer to the Contact Us page.

Page 21

Page 18 of 21

Page 22

Contact Us

Page 19 of 21

If you would like to contact MARS Company regarding any material contained in this book, or if you have

additional questions, please find our information below.

MARS Company

Ocala, FL USA

Toll Free: 800.782.5268

Telephone: 352.694.7195

Fax: 352.694.7397

Web: http://www.marswater.com/amr-support-request/

Email: sales@marswater.com

customerservice@marswater.com

Page 23

Page 20 of 21

Page 24

Information to the User

Page 21 of 21

Warning:

Changes or modifications to this device not expressly approved by

MARS Company could void the user’s authority to operate the equipment.

FCC Class B:

“NOTE: This equipment has been tested and found to comply with the limits for a

Class B digital device, pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference in a

residential installation. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications. However,

there is no guarantee that interference will not occur in a particular installation. If

this equipment does cause harmful interference to radio or television reception,

which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following

measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to

which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.”

RF Exposure:

This equipment complies with FCC radiation exposure limits set forth for an

uncontrolled environment. This equipment should be installed and operated with

minimum distance 20cm between the radiator and your body. This transmitter

must not be co-located or operating in conjunction with any other antenna or

transmitter.

Innovation, Science, and Economic Development (ISED) Canada:

This device complies with Industry Canada license-exempt RSS standard(s). Operation is subject to

the following two conditions: (1) this device may not cause interference, and (2) this device must

accept any interference, including interference that may cause undesired operation of the device.

Le présent appareil est conforme aux CNR d’Industrie Canada applicables aux appareils radio

exempts de licence. L’exploitation est autorisée aux deux conditions suivantes: (1) l’appareil ne doit

pas produire de brouillage, et (2) l’utilisateur de l’appareil doit accepter tout brouillage

radioélectrique subi, même si le brouillage est susceptible d’en compromettre le fonctionnement.

Cet équipement est conforme aux limites d’exposition aux radiations dans un environnement non

contrôlé. Cet équipement doit être installé et utilize à distance minimum de 20 cm entre le

radiateur et votre corps. Cet émetteur ne doit pas être co-localisées ou opérant en conjonction avec

tout autre antenne ou transmetteur.

Loading...

Loading...