Page 1

Bi-Flow Heat Pump Driers

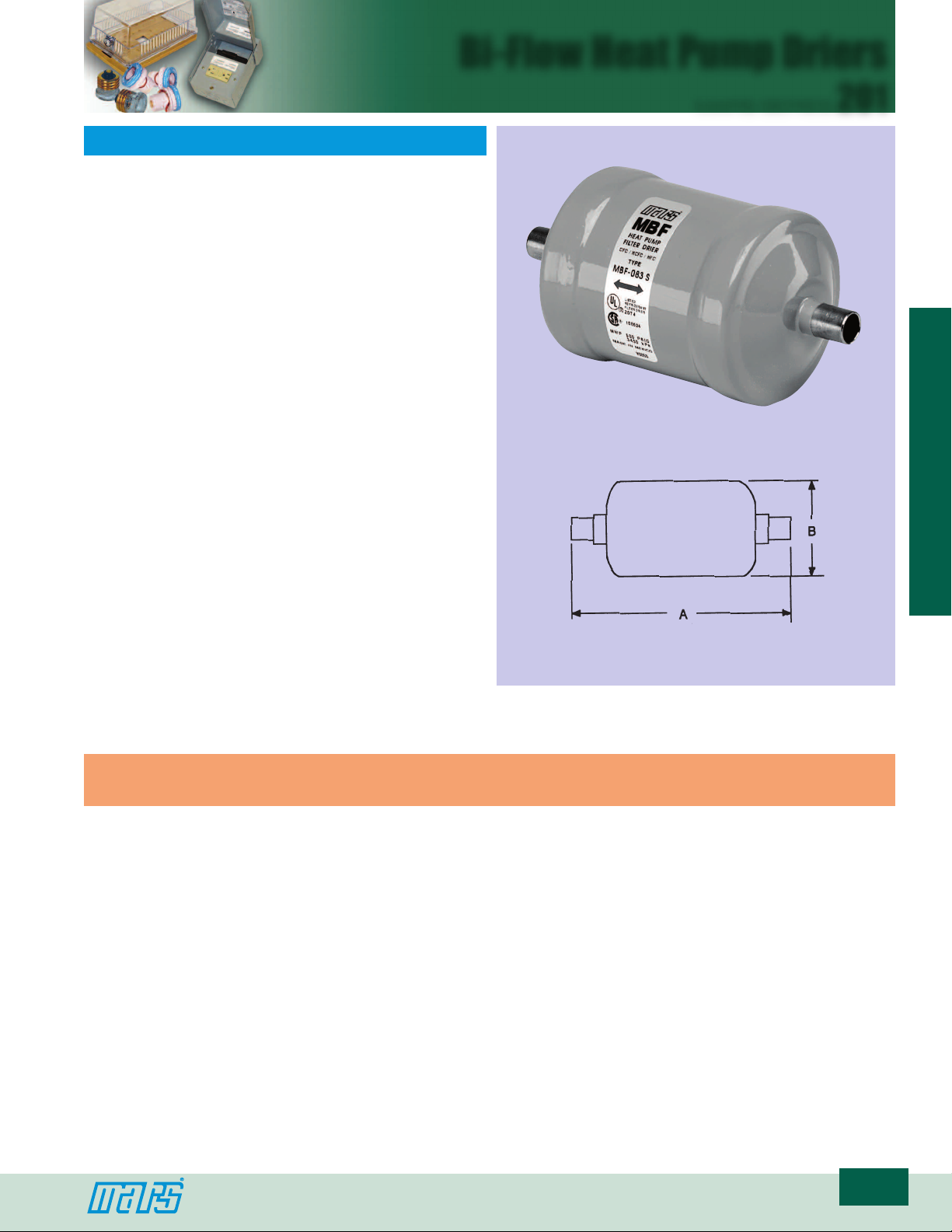

MARS Bi-Flow Heat Pump Driers

The MARS Bi-Flow Heat Pump Driers are designed to provide

complete protection to the heat pump or reverse cycle system.

he molded block core exposes maximum surface area for

T

efficient filtration and retention of solid contaminants. The internal

check valves prevent the release of collected contaminants when

the heat pump cycles from the heating to cooling modes.

The use of molecular sieve and activated alumina in the

desiccant core block provide the heat pump drier maximum

moisture and acid removal. The addition of charcoal to the

desiccant core allows for the removal of wax that may occur at

low evaporator temperatures, giving protection to your expansion

device.

Features & Benefits:

• For use on R134A, R12, R22, R500, R404A, R410A, R507

• For heat pump or reverse cycle applications

• High organic & inorganic acid removal

• Solid block desiccant core

• Proven, nylon internal check valves

• High moisture removal

• Nickel plated SAE flare and solid copper ODF fittings

• Corrosion resistant paint

• Maximum working pressure 600 PSIG

• Minimum burst pressure 2500PSIG

• UL & CSA listed

MARS SERIES 201

SERVICE & INSTALLATION

20176

MARS

NO.

20176

20178

20181

20182

20186

1

All ratings in accordance with ARI standard 710-04

2.9 lbs./min./ton for R-22

MODEL

NO.

MBF-083S 3/8 ODF 5.63 2.63 7.4 12

MBF-084S 1/2 ODF 5.66 2.63 9.4 12

MBF-163 3/8 SAE 6.97 3.09 6.7 12

MBF-163S 3/8 ODF 6.31 3.09 7.5 12

MBF-165S 5/8 ODF 6.63 3.09 12.4 12

The largest selection of motors, components and accessories for the HVAC/R Industry

CONNECTIONS

SIZE & TYPE

DIMENSIONS Flow Capacity1Tons @ 1 PSI

A B R-22/R410A

CASE

QTY.

SI-59

Loading...

Loading...