Page 1

Smart-pac

™

Transport Display

Service Manual

403596-036 Revision E

BATTERY

CHARGING

ICU-5

II

1X

150

AR1

0

60

PA2

0

RESP

ALARM

PAUSE

ALARMS OFF

MONITOR DISPLAY

9-JAN-92 14:36

*

70

E

137/ 73

C

G

( 95 )

A

R

34/ 14

1

( 22 )

P

A

120/ 80

( 94 )

40

23.4°C

39.4°C

TRIM KNOB

2

N

B

P

R

E

S

T1

T

M

T2

P

mmHg

+

HELP

-

TRENDS GRAPH

16:08

LEAD II

OFF

BP ZEROFREEZEALARM RESET

I

O

WRITER DISPLAY POWER

Page 2

NOTE

Due to continuing product innovation, specifications in

this manual are subject to change without notice.

Trademarks

Trademarked names appear throughout this document. Rather

than list the names and entities that own the trademarks or insert a

trademark symbol with each mention of the trademarked name, the

publisher states that it is using the names only for editorial

purposes and to the benefit of the trademark owner with no

intention of improperly using that trademark.

ACCUSKETCH, APEX, AQUA-KNOT, ARCHIVIST, AUTOSEQ, BABY

MAC, CASE, CD TELEMETRY, CENTRA, CHART GUARD, CINE 35,

CORO, COROMETRICS, CRG PLUS, DIGISTORE, Digital DATAQ, E

for M, EAGLE, Event-Link, HELLIGE, IMAGE STORE, LASER SXP ,

MAC, MAC-LAB, MACTRODE, MARQUETTE, MARQUETTE UNITY

NETWORK, MARS, MAX, MEI, MEI in the circle logo, MEMOPORT

C, MIDAS SYSTEM, MIDASNET, MINISTORE, MINNOWS, Monarch

8000, MULTI-LINK, MULTISCRIPTOR, MUSE, MUSE CV, Neo-Trak,

OnlineABG, OXYMONITOR, PRESSURE-SCRIBE, PRES-R-CUFF,

QMI, QS, Quantitative Medicine, Quantitative Sentinel, Qwik

Connect Spiral, RAMS, SAM, SEER, SOLAR, Spectra 400, SpectraTel, ST GUARD, TRAM, TRAM-NET, TRAM-RAC, TRAMSCOPE,

TRIM KNOB, UNITY NETWORK, UNITY twist logo, V ari-X, Vari-X

Cardiomatic, and VAS are trademarks of Marquette Medical

Systems, Inc. registered in the United States Patent and Trademark

Office.

12SL, 15SL, AccuVision, ADVANTAGE, BODYTRODE, CardioMail,

CardioServ, CardioSmart, CardioSpeak, CardioSys, CD

TELEMETRY®-LAN, CENTRALSCOPE, Corolation, Corometrics

Sensor Tip, CV Mail, CV-Web, DASH, EDIC, HI-RES, IMAGE

VAULT, INTELLIMOTION, INTER-LEAD, LIFEWATCH, MARQUETTE

MEDICAL SYSTEMS, MARQUETTE® RESPONDER, MENTOR,

MIDAS Com, MRT, MUSE CardioWindow, MUSEWord, O2SENSOR,

OMRS, Premium, RSVP, SIL VERTRACE, SMART-PAC,

SMARTLOOK, SOLARVIEW , Spectra-Overview, Trimline, UNITY,

and Universal are trademarks of Marquette Medical Systems, Inc.

T-2

SMART-PAC TRANSPORT DISPLAY

403596-036

Revision E

26 November 1997

Page 3

Table of Contents

Contents

Introduction ........................................................iii

Manual Information ..................................................................iv

Safety Information ................................................................... vii

Service Information ...................................................................xi

How to Reach Us...................................................................... xii

Abbreviations.......................................................................... xiii

General Information ........................................... 1-1

About the Smart-pac Transport Display .................................. 1-2

Caring for Your Smart-pac Battery Pack.................................. 1-5

Technical Specifications ......................................................... 1-7

Troubleshooting ................................................. 2-1

Considerations for Special Components .................................. 2-2

Replacing the LCD Display ..................................................... 2-4

Disassembly Procedure .......................................................... 2-5

Problems and Solutions........................................................ 2-11

Calibration ......................................................... 3-1

Display Processor PCB PN 800814 .......................................... 3-2

Display Processor PCB PN 85638............................................ 3-4

Battery Interface PCB PN 403861 ........................................... 3-9

Preventative Maintenance................................... 4-1

Maintenance Schedule ........................................................... 4-2

Inspection ............................................................................. 4-3

Cleaning ................................................................................ 4-4

Checkout Procedure ............................................................... 4-5

414189/900022 Smart-pac Transport Display ............................... 5-1

Parts List (PN 414189-001D) .................................................. 5-2

Exploded View (PN 414189-001D)........................................... 5-3

Parts List (PN 900022-100C)................................................... 5-4

Exploded View (PN 900022-100C) ........................................... 5-5

413780/404706 Tram Transport Display Assembly........................ 6-1

Parts List (PN 413780-001D/002E)......................................... 6-2

Exploded View (PN 413780-001D/002E) ................................. 6-3

Revisions to the Assemblies .................................................... 6-5

Parts List (PN 404706-100D) .................................................. 6-6

Exploded View (PN 404706-100D)........................................... 6-7

Revision E

SMART-PAC TRANSPORT DISPLAY

403596-036

i

Page 4

➔ Table of Contents

800814/85638 Display Processor PCB Assembly.......................... 7-1

85639 Switch PCB Assembly ......................................... 8-1

Contents

Parts List (PN 800814-001D) .................................................. 7-2

Parts List (PN 801446-001A)................................................... 7-4

Parts Location Diagram (PN 800814-001D)............................. 7-5

Parts Location Diagram (PN 801446-001A) ............................. 7-7

Schematic Diagram (SD800814-001B) ................................... 7-9

Schematic Diagram (SD 801446-001A) ................................. 7-16

Theory of Operation for PN800814 ........................................ 7-17

List of Inputs and Outputs ................................................... 7-22

Revisions to the Assemblies .................................................. 7-26

Parts List (PN 85638-006C) .................................................. 7-27

Parts Location Diagram (PN 85638-006C .............................. 7-30

Schematic Diagram (SD85638-006A) ................................... 7-32

Parts List (PN 85639-002B) .................................................... 8-2

Parts Location Diagram (PN 85639-002B)................................ 8-2

Schematic Diagram (PN 85639-002B) ..................................... 8-2

800138 Cartridge PCB Assembly ...................................... 9-1

Parts List (PN 800138-001D/002C)......................................... 9-2

Parts Location Diagram (PN 800138-001D/002C).................... 9-3

Schematic Diagram (SD800138-001B) .................................... 9-4

Revisions to the Assemblies .................................................... 9-5

402472 Battery Backpack Assembly .............................. 10-1

Parts List (PN 402472-001K)................................................. 10-2

Exploded View (PN 402472-001K) ......................................... 10-3

Interconnection Diagram (402472-001K)............................... 10-4

403191 Contact Plate Assembly .................................... 11-1

Parts List (PN 403191-001F)................................................. 11-2

Exploded View (PN 403191-001F) ......................................... 11-2

402708 Contact Plate PCB Assembly.............................. 12-1

Parts List (PN 402708-002D) ................................................ 12-2

Parts Location Diagram (PN 402708-002D) ........................... 12-2

Schematic Diagram (PN 402708-002D) ................................. 12-2

403861 Battery Interface PCB Assembly ........................ 13-1

Parts List (PN 403861-002G) ................................................ 13-2

Parts Location Diagram (PN 403861-002G) ........................... 13-4

Schematic Diagram (PN 403861-003E)................................. 13-5

ii

SMART-PAC TRANSPORT DISPLAY

403596-036

Revision E

Page 5

Introduction

WHAT IS IN THIS CHAPTER?

This introduction contains information to help you use this

manual more effectively.

Contents

Manual Information................................................................ iv

Safety Information ................................................................ viii

Service Information .................................................................. x

How to Reach Us… ................................................................. xi

Abbreviations ........................................................................ xiii

SMART-PAC TRANSPORT DISPLAY

403596-036

iiiRevision E

Page 6

Manual Information

Introduction

Revision History

Each page of this manual has a revision letter, located at the

bottom of the page, that identifies its update level. This may be

important if you have different updates to a manual and don’t

know which is the most current.

For the initial release, all pages have the revision letter A. For the

first update of the manual all pages receive the revision letter B.

The latest letter of the alphabet added corresponds to the most

current revision.

At the time of this writing, there are five revisions of this manual:

Revision A 12 March 1993

Revision B 12 March 1994

Revision C 2 August 1995

Revision D 21 June 1996

Revision E 26 November 1997

SMART-PAC TRANSPORT DISPLAY

403596-036

Revision Eiv

Page 7

➔ Manual Information

Introduction

Manual Purpose

Chapter Contents

General Information

Troubleshooting

Chapter 1:

Chapter 2:

Chapter 3:

Calibration

This service manual has been prepared by the Technical

Publications staff of Marquette Medical Systems, Inc. It is intended

for qualified service representatives and technical personnel

involved in maintaining and repairing the Smart-pac transport

display (hereafter referred to as the transport display).

This manual is geared toward trained biomedical engineers. Users

are expected to have a strong background in electronics, including a

strong background in analog circuitry, digital circuitry, and

microprocessor and microcontroller architecture.

The manual contains several chapters. The first of these chapters,

General Information, gives a description of the transport display,

including technical specifications.

Chapter Two, “Troubleshooting,” contains information about how to

disassemble, repair, and re-assemble the transport display more

effectively.

Chapter Three, “Calibration,” explains how to adjust the transport

display periodically to keep the data that it presents accurate.

Chapter 4:

Preventive Maintenance

The Remaining Chapters:

Mechanical and Electronic

Assemblies

Chapter Four, “Maintenance,” describes how to maintain the

transport display and keep it in good working order.

Chapters five through thirteen describe the major electronic and

mechanical assemblies of the equipment.

• Chapter five describes the Smart-pac Transport Display which

consists of the Tram Transport Display and Battery Backpack

assemblies. It lists all of the parts that comprise the upperlevel assembly and an exploded view.

• Chapter six describes the Smart-pac Transport Display. It

lists all of the parts that comprise the assembly and an

exploded view.

• Chapters seven through Nine describe the printed circuit

board assemblies in Tram Transport Display assembly. These

chapters include parts lists, parts location diagrams, and

schematic diagrams. Some of them may contain additional

details, like theory of operation and a list of inputs and

outputs.

• Chapters ten through thirteen describe the Battery Backpack

assembly and its related circuits. These chapters list all of the

parts that comprise the assemblies and show exploded views

to assist you in disassembly, parts replacement, and reassembly.

Revision E

SMART-PAC TRANSPORT DISPLAY

403596-036

v

Page 8

➔ Manual Information

Introduction

Related Manuals

403596-030

403596-033

404232-001

404422-065

The following is a list of manuals related to the Smart-pac

Transport Display.

Smart-pac Charger Service Manual

This manual includes all data relating to the Smart-pac charger.

Smart-pac Power Supply Service Manual

This manual includes all data relating to the Smart-pac power

supply.

Smart-pac Installation Instructions

This manual includes all data relating to installing a Smart-pac

Transport Display.

Tram 100-850 A and SL Modules Service Manual

This manual includes data relating to all 100 through 850 A and SL

versions of the Tram modules.

404422-108

Smart-pac Transport Display Operator's Manual

This manual includes all operating information for the Smart-pac

Transport Display using V6 through V10 software.

SMART-PAC TRANSPORT DISPLAY

403596-036

Revision Evi

Page 9

Safety Information

Introduction

Manufacturer’s

Responsibility

Intended Use

Marquette Medical Systems, Inc is responsible for the effects on

safety, reliability, and performance only if:

✓ assembly operations, extensions, readjustments,

modifications, or repairs are carried out by persons authorized

by Marquette Medical Systems, Inc;

✓ the electrical installation of the relevant room complies with

the requirements of the appropriate regulations; and

✓ the Smart-pac transport display is used in accordance with

the instructions for use.

This device is intended for used under the direct supervision of a

licensed health care practitioner.

To ensure patient safety, use only parts and accessories

manufactured or recommended by Marquette Medical Systems.

Contact Marquette Medical Systems for information before

connecting any devices to the equipment that are not recommended

in this manual.

Revision E

SMART-PAC TRANSPORT DISPLAY

403596-036

vii

Page 10

Introduction

Equipment Symbols

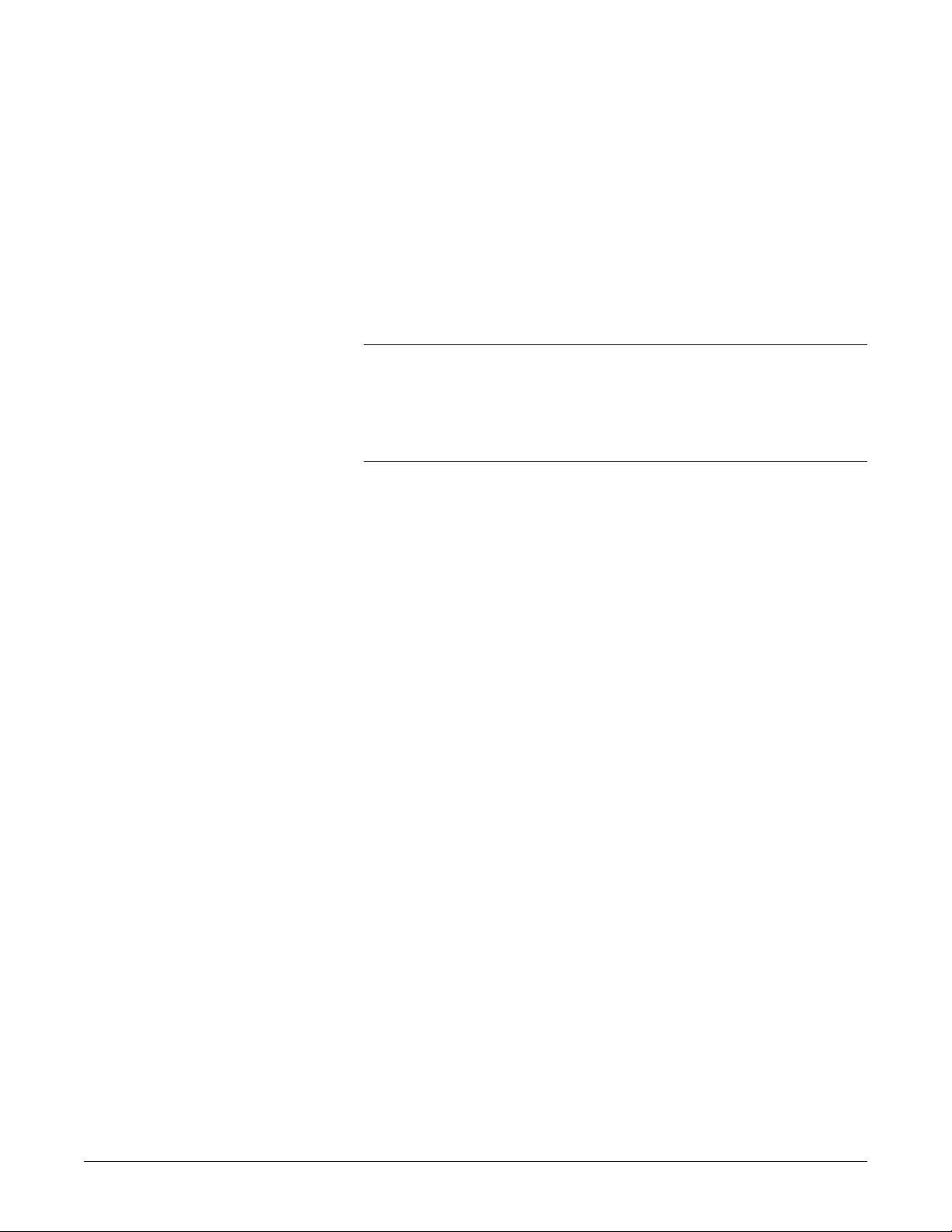

The following symbols appear on the equipment.

ATTENTION: Consult accompanying documents before using the

equipment.

TYPE CF APPLIED PART: Isolated (floating) connection suitable for

intentional external and internal application to the patient including direct cardiac application. “Paddles” outside the box indicate the

applied part is defibrillator proof.

Medical Standard Definition: F-type applied part (floating/isolated)

complying with the specified requirements of IEC 601-1/UL 26011/CSA 601.1 Medical Standards to provide a higher degree of

protection against electric shock than that provided by type BF

applied parts.

TYPE BF APPLIED PART: Isolated (floating) connection suitable for

intentional external and internal application to the patient excluding direct cardiac application. “Paddles” outside the box indicate the

applied part is defibrillator proof.

Medical Standard Definition: F-type applied part (floating/isolated)

complying with the specified requirements of IEC 601-1/UL 26011/CSA 601.1 Medical Standards to provide a higher degree of

protection against electric shock than that provided by type B

applied parts.

TYPE B APPLIED PART: Non-isolated connection suitable for intentional external and internal application to the patient excluding

direct cardiac application.

Medical Standard Definition: Applied part complying with the

specified requirements of IEC 601-1/UL 2601-1/CSA 601.1 Medical

Standards to provide protection against electric shock, particularly

regarding allowable leakage current.

Equipotentiality

Alternating current (AC)

Fuses

SMART-PAC TRANSPORT DISPLAY

403596-036

Revision Eviii

Page 11

Introduction

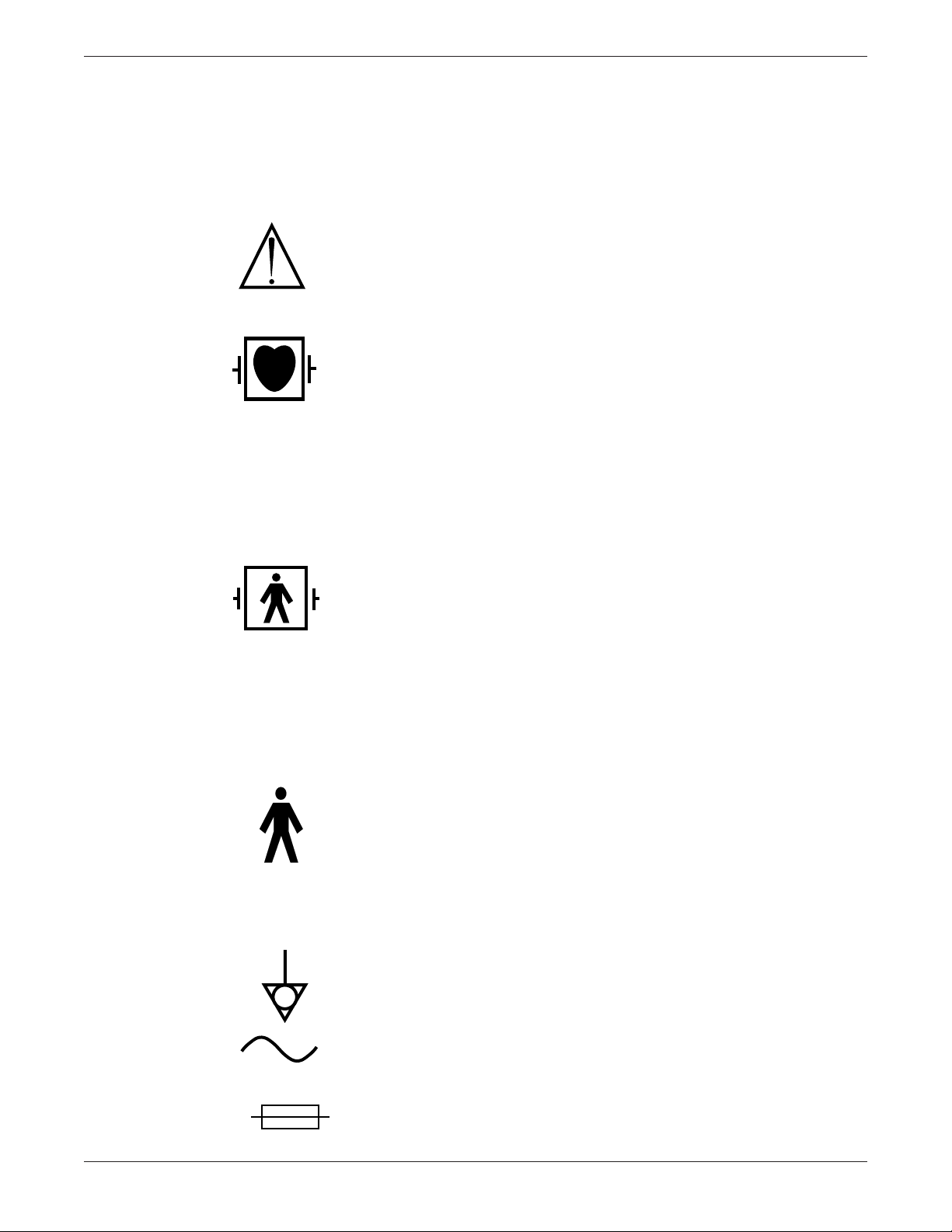

Power; I = ON; O = OFF

Explosion hazard; Do NOT incinerate battery.

Do NOT directly connect the negative and the positive terminals of

the battery.

Recycle internal battery.

Revision E

SMART-PAC TRANSPORT DISPLAY

403596-036

ix

Page 12

➔ Safety Information

Introduction

Warnings, Cautions, and

Notes

Danger

Warning

Caution

Warnings, cautions, and notes are used in this manual to provide

additional information to service personnel.

DANGER

Danger indicates an imminent hazard which, if not

avoided, will result in death or serious injury.

WARNING

Warning indicates a potential hazard or unsafe practice

which, if not avoided, could result in death or serious

injury.

CAUTION

Caution indicates a potential hazard or unsafe practice

which, if not avoided, could result in minor personal

injury or product/property damage.

Note

NOTE

Notes provide application tips or other useful

information to assure that you get the most from your

equipment.

SMART-PAC TRANSPORT DISPLAY

403596-036

Revision Ex

Page 13

Service Information

Introduction

Service Requirements

Equipment Identification

Follow the service requirements listed below.

• Refer equipment servicing to Marquette Medical Systems’

authorized service personnel only.

• Any unauthorized attempt to repair equipment under

warranty voids that warranty.

• It is the user’s responsibility to report the need for service to

Marquette Medical Systems or to one of their authorized

agents.

• Failure on the part of the responsible individual, hospital, or

institution using this equipment to implement a satisfactory

maintenance schedule may cause undue equipment failure

and possible health hazards.

• Regular maintenance, irrespective of usage, is essential to

ensure that the equipment will always be functional when

required.

Every Marquette Medical Systems device has a unique serial

number for identification. The serial number appears on the back of

the Tram Transport display. Refer to “Disassembly Procedure” in

Chapter 2, “Troubleshooting,” to disassemble the Tram Transport

display from the Smart-pac battery backpack.

Month

Manufactured

A = January

B = February

C = March

D = April

E = May

F = June

G = July

H = August

J = September

K = October

L = November

M = December

Revision E

D 1 XX 0005 G XX

Year

Manufactured

9 = 1989

0 = 1990

1 = 1991

2 = 1993

(and so on)

Product

Code

Two-character

product

descriptor

SMART-PAC TRANSPORT DISPLAY

Product

Sequence

Number

Manufacturing

number (of

total units

manufactured.)

403596-036

Division

F = Cardiology

G = Monitoring

Device

Characteristics

One or two letters

that further describe

the unit.

For example:

P = Prototype - not

conforming to

marketing

specification

R = Refurbished

equipment

S = Special product

documented under

SPECIALS part

numbers.

xi

Page 14

Introduction

How to Reach Us

Customer Support and Equipment Repair Information

If you have questions about your monitoring equipment or if you need service for equipment repair

call:

U.S.A. and Canada: 800-558-7044 (24-hour service)

Other countries: 561-575-5000 (During U.S. business hours only) or contact your

local sales and service reprsntative

Local sales and

service representative:__________________________________________________________________

(Name and phone number)

Ordering Service Parts

Service parts are items that are not expended in the normal operation of the product. They are

generally replacements for defective or malfunctioning items inside the product. Service parts include

PCB assemblies, electronic components, internal cables and harnesses, software or firmware, and

operator and service manuals.

A part number for the item to be replaced is necessary for ordering a service part. If the part number

for the desired item is unobtainable, the following will be necessary to order the item:

• model and serial number of the equipment

• part number/name of the assembly where the item is used,

• item name, and where applicable, reference designation (e.g., R13, S12, U32).

Supplies Information

Supply items are generally those items used during normal operation of a product. Leadwires,

electrodes, patient cables, printer paper, Aqua-Knot water traps, airway adapters, and calibration

gases are examples of supply items.

Make telephone inquiries about supply items at:

U.S. only: 800-558-5102

Outside U.S.: 561-575-5070 (or contact your local sales and service representative)

Address orders or inquiries in the U. S. to:

Marquette Medical Systems Service and Supplies

Attention: Supplies Department

100 Marquette Drive

Jupiter , Florida 33468-9100

Fax: 561-575-5050

SMART-PAC TRANSPORT DISPLAY

403596-036

Revision Exii

Page 15

Abbreviations

Introduction

A

AAMI Association for the

Advancement of

Medical

Instrumentation

Ahr ampere-hour

Al aluminum

Ampl amplifier

ANSI American National

Standards Institute,

Inc

AWG American Wire Gage

B

BDGH binding head

BP blood pressure

BPM beats per minute

C

Cap capacitor

Cer ceramic

CMOS complimentary metal-

oxide semiconductor

Comp composition

CSA Canadian Standards

Association

D

dc direct current

DDW Direct Digital Writer

Dia diameter

DIP dual in-line package

E

ECG electrocardiogram,

electrocardiograph

EPLD electronically

programmable logic

device

ESD electro static

discharge

F

FL Florida

FLH flat head

I

IEC International

Electrotechnical

Commission

in inch

Inc incorporated

K

K kilo, kilohm

kg kilogram

L

lb pound

LCD liquid crystal display

LED light-emitting diode

M

MEI Marquette

Electronics, Inc

MF metal film

MHz megahertz

mm millimeter

mm millimeter

mmHg millimeter of mercury

MMS Marquette Medical

Systems

MPE metallized

polycarbonate

epitaxial

mV millivolt

mW milliwatt

N

No number

Ntwk network

P

PAL programmable array

logic

PC printed circuit,

personal computer

pcb, PCB printed circuit board

PLCC plastic leaded chip

carrier

pn, PN part number

PNH pan head

POS positive

R

RAM random access

memory

Res resistor

Rgltr regulator

S

SD schematic diagram

sec second

SIP single in-line package

SM surface mount

SST stainless steel

T

Tant tantalum

Tram,

TRAM Transport Remote

Acquisition Monitor

TTL transistor-transistor

logic

U

UL Underwriters

Laboratories, Inc

V

V volt, voltage

V volt, voltage

Var variable

W

W watt, West

w/ with

w/o without

WI Wisconsin

WW wire wound

Z

ZIF zero insertion force

Other

˚C degrees Celsius

˚F degrees Fahrenheit

µF microfarad

Ω ohm

% percent

Revision E

SMART-PAC TRANSPORT DISPLAY

403596-036

➔

xiii

Page 16

For your notes

Introduction

SMART-PAC TRANSPORT DISPLAY

403596-036

Revision Exiv

Page 17

1 General Information

WHAT IS IN THIS CHAPTER?

This chapter describes the equipment and lists the technical

specifications.

Contents

About the Smart-pac Transport Display ............................. 1-2

Caring for Your Smart-pac Battery Pack ............................ 1-5

Technical Specifications ...................................................... 1-7

Revision E

SMART-PAC TRANSPORT DISPLAY

403596-036

1-1

Page 18

General Information

TRIM KNOB

BP ZERO

FREEZE

ALARM RESET

CONTRAST

T1

T2

+

-

R

E

S

T

M

P

E

C

G

70

P

A

2

34/ 14

( 22 )

40

23.4°C

39.4°C

II

1X

150

AR1

0

60

PA2

0

RESP

ICU-5

9-JAN-92 14:36

ALARMS OFF

ALARM

PAUSE

MONITOR DISPLAY

HELP

TRENDS GRAPH

OFF

N

B

P

120/ 80

( 94 )

A

R

1

137/ 73

( 95 )

16:08

LEAD II

mmHg

*

marquette

About the Smart-pac T ransport Display

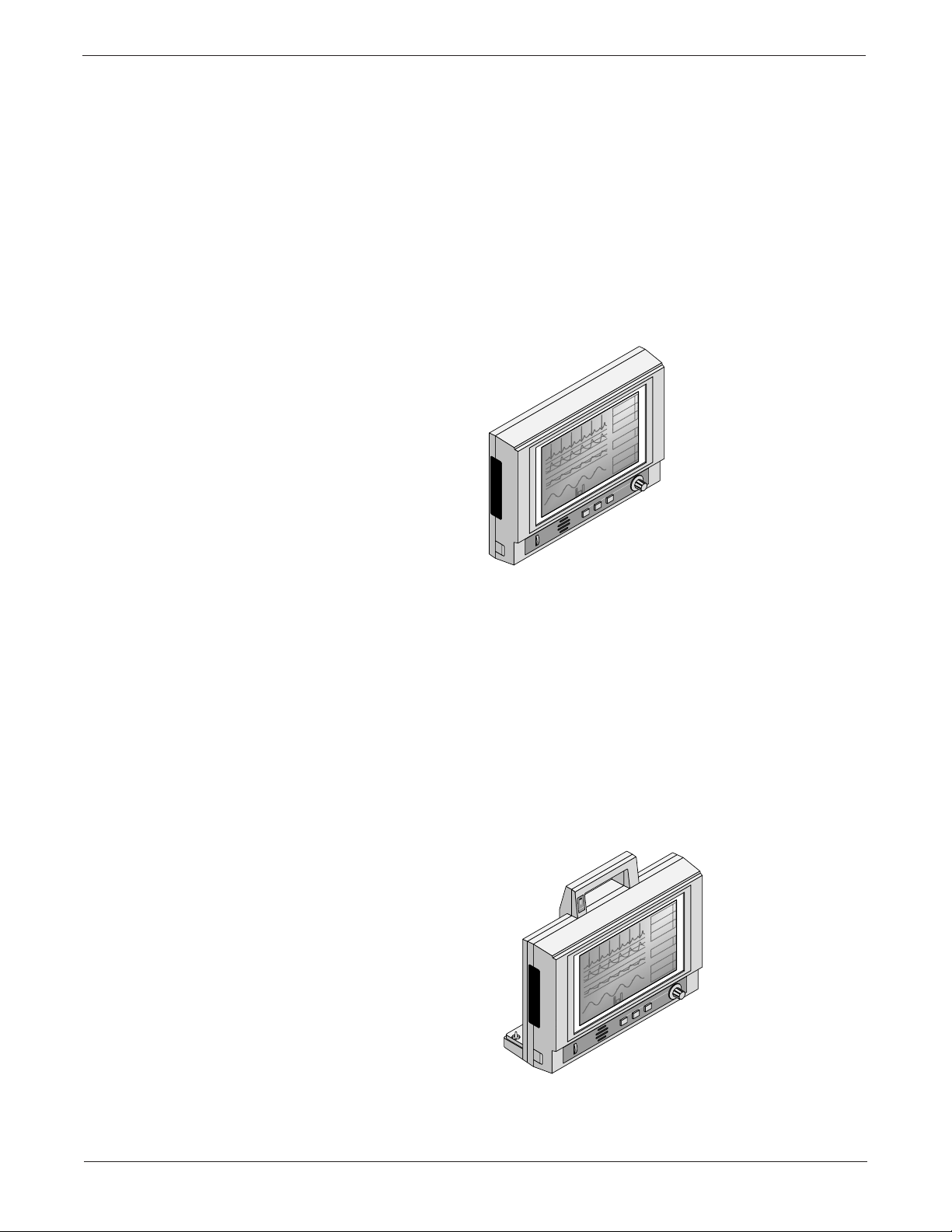

What is a Tram T ransport

Display?

In a Tram Critical Care Monitoring system, bedside and surgical

monitors use Tram modules to collect patient data at the bedside

area. The Tram Transport display presents the patient vital signs

and waveforms collected by the Tram module on a backlit,

supertwist LCD display. The name Tram Transport Display refers

to the display only. For more details about the Tram Transport

display, refer to chapter six in this manual.

What is a Smart-pac

Transport Display?

1-2

When a Tram Transport display is connected to the Smart-pac

battery backpack, the entire unit is referred to as a Smart-pac

Transport display. The Tram module is then connected to the

Smart-pac transport display when a patient is transported from one

hospital area to another. For more details about the Smart-pac

Transport display, refer to Chapter Five, “Smart-pac Transport

Display,” in this manual.

9-JAN-92 14:36

TRENDS GRAPH

FREEZE

E

C

G

70

*

A

R

1

P

( 95 )

137/ 73

A

2

34/ 14

( 22 )

N

B

P

( 94 )

120/ 80

mmHg

R

16:08

E

S

40

T

M

T1

P

T2

23.4°C

LEAD II

39.4°C

OFF

TRIM KNOB

BP ZERO

marquette

Revision E

CONTRAST

SMART-PAC TRANSPORT DISPLAY

403596-036

BATTERY

CHARGING

ALARMS OFF

ICU-5

II

1X

150

AR1

0

60

HELP

PA2

0

-

+

RESP

MONITOR DISPLAY

ALARM

ALARM RESET

PAUSE

➔

Page 19

General Information

➔ About the Smart-pac Transport Display

What is a Smart-pac Battery

Backpack?

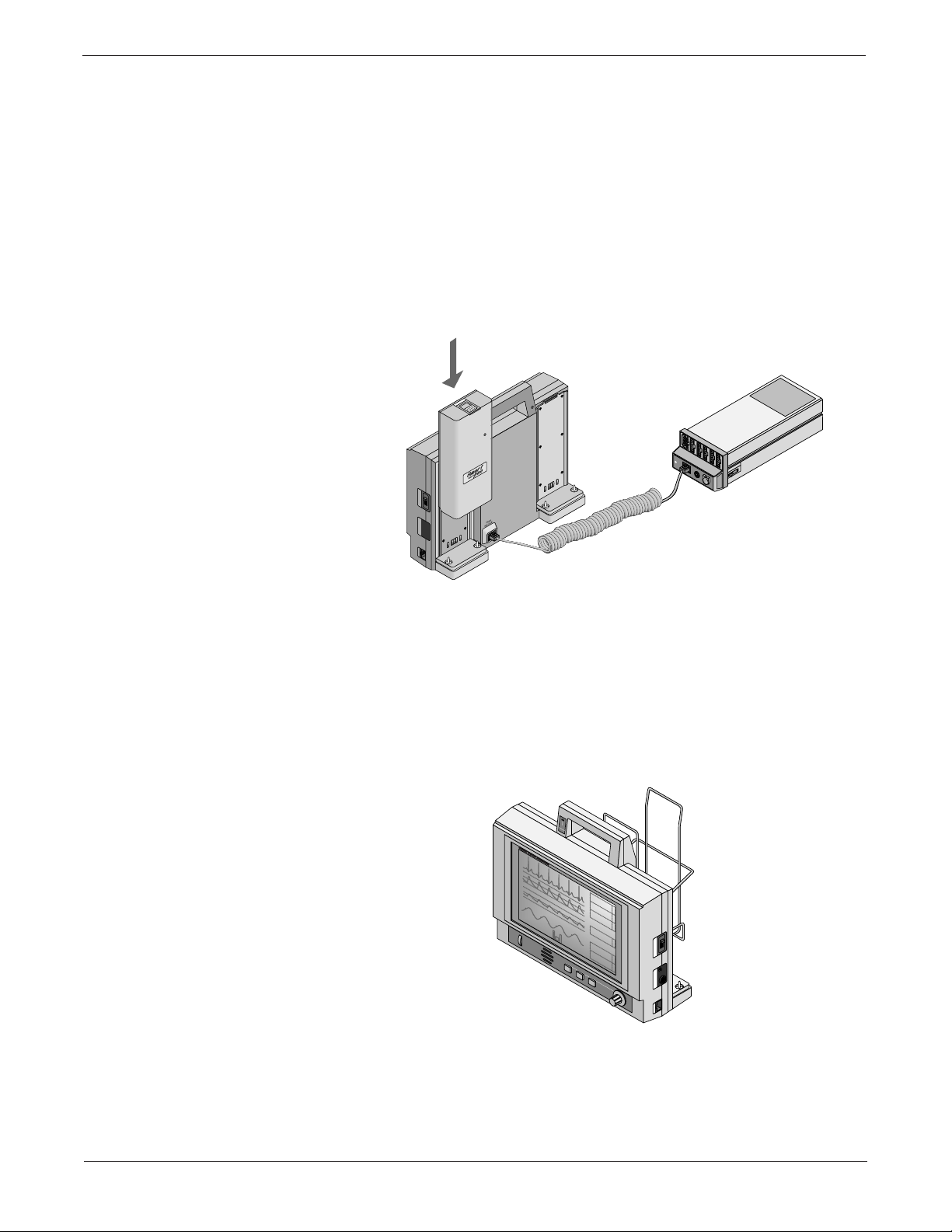

By sliding a Smart-pac battery pack or power supply into either slot

at the back of the Smart-pac Transport display, both the Tram

module and display receive power. Pictured below is a Smart-pac

Transport Display with the battery backpack connected to a Tram

module. For more details about the Smart-pac Battery backpack,

refer to “Caring for Your Smart-pac Battery Pack” on the following

pages and in Chapter 10 in this manual.

I

O

WRITER DISPLAY POWER

For more details about the Smart-pac charger and power supply,

refer to the Smart-pac Charger Service Manual, (pn 403596-030) or

Smart-pac Power Supply Service Manual, (pn 403596-033).

What is a module holder?

How do I graph the

waveforms?

Pictured below is the Smart-pac Transport display with battery

pack and module holder assembly. For more details about the

module holder assembly, refer to Chapter 10 in this manual.

BATTERY

CHARGING

ICU-5

II

1X

ALARMS OFF

150

AR1

0

60

PA2

0

RESP

ALARM

PAUSE

CONTRAST

CONTRAST

MONITOR DISPLAY

9-JAN-92 14:36

marquette electronics

mmHg

16:08

+

HELP

-

TRENDS GRAPH

DANGER Risque d'explosion. Ne pas employer en presence d'anesthesiques inflammables.

LEAD II

OFF

ALARM RESET

FREEZE

BP ZERO

137/ 73

120/ 80

23.4°C

39.4°C

*

70

E

C

G

( 95 )

A

R

34/ 14

1

( 22 )

P

A

2

( 94 )

N

B

I

P

40

TRIM KNOB

marquette

O

R

E

S

T1

T

M

T2

P

WRITER DISPLAY POWER

The Smart-pac Transport display may also connect to a Direct

Digital Writer (DDW) for graphing patient data. The following pages

describe the DDW connector. To use the Smart-pac with a DDW,

refer to the appropriate Smart-pac transport display operator’s

manual.

➔

SMART-PAC TRANSPORT DISPLAY

403596-036

1-3Revision E

Page 20

General Information

➔ About the Smart-pac Transport Display

Parts of the Smart-pac

Transport Display

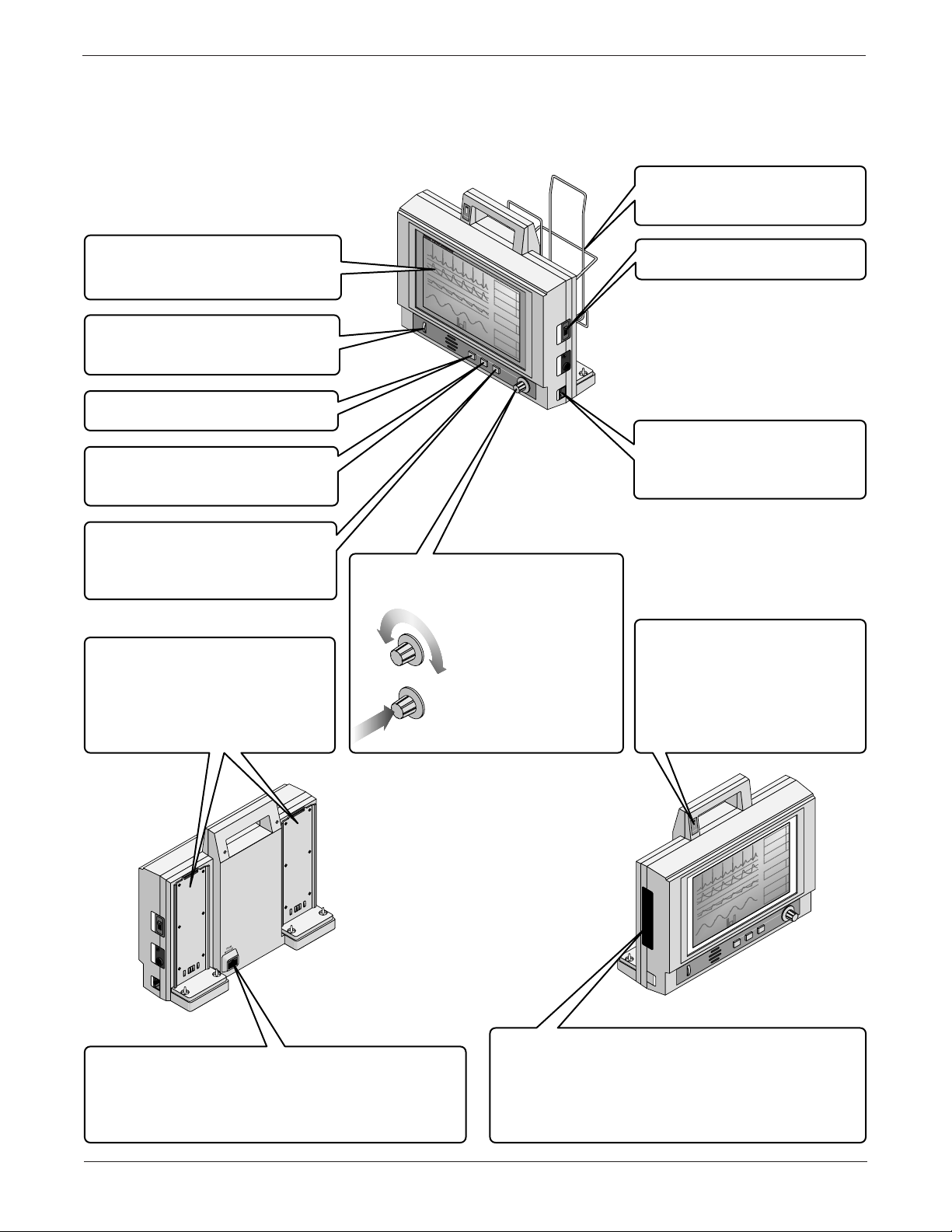

Display. A fluorescent-backlit,

double super-twisted LCD

display for showing patient data.

CONTRAST

control to get the best image for

your viewing angle.

ALARM RESET

key to clear alarms.

FREEZE

stop the waveforms on the

display.

BP ZERO

set the zero reference point of

all pressure inputs for the Tram

module.

Smart-pac Rails. Slide a

Smart-pac battery pack or

power supply onto one or both

of these to supply the transport

display and Tram module with

power.

Control. Adjust this

Key. Press this

Key. Press this key to

Key. Press this key to

BATTERY

CHARGING

ICU-5

II

1X

ALARMS OFF

150

AR1

CONTRAST

TRIM KNOB

0

60

PA2

0

RESP

ALARM

PAUSE

CONTRAST

9-JAN-92 14:36

marquette electronics

*

70

E

137/ 73

C

G

( 95 )

A

R

MONITOR DISPLAY

mmHg

16:08

+

HELP

-

TRENDS GRAPH

DANGER Risque d'explosion. Ne pas employer en presence d'anesthesiques inflammables.

LEAD II

OFF

ALARM RESET

FREEZE

BP ZERO

120/ 80

23.4°C

39.4°C

34/ 14

1

( 22 )

P

A

2

( 94 )

N

B

I

P

40

TRIM KNOB

marquette

O

R

E

S

T1

T

M

T2

P

WRITER DISPLAY POWER

Control. Use this

control to choose items from the

menu at the bottom of the display.

Rotate the control

until the item that you

want is highlighted.

Press the control to

select the highlighted

item.

Module Holder. The Tram

module is usually stored in

here during transport.

POWER

Switch. Turns the

transport display on and off.

DDW

Connector. Plug a

DDW (Direct Digital Writer) in

here to graph the patient’s

vital signs and waveforms.

CHARGING

Indicator. If you

install a Smart-pac battery

pack on one rail, and a

Smart-pac power supply on

the other rail, this indicator

lights to show when the

battery is charging.

I

O

WRITER DISPLAY POWER

TRAM MODULE

Connector. Make sure you plug

the Tram module into this connector. If you plug

it into one of the other connectors, you’ll see a

big

COMMUNICATION FAILURE

message on the

display.

1-4

SMART-PAC TRANSPORT DISPLAY

403596-036

9-JAN-92 14:36

TRENDS GRAPH

FREEZE

E

C

G

70

*

A

R

1

P

( 95 )

137/ 73

A

2

34/ 14

( 22 )

N

B

P

( 94 )

120/ 80

mmHg

R

16:08

E

S

40

T

M

T1

P

T2

23.4°C

LEAD II

39.4°C

OFF

TRIM KNOB

BP ZERO

marquette

SOFTWARE CARTRIDGE

BATTERY

CHARGING

ALARMS OFF

ICU-5

II

1X

150

AR1

0

60

HELP

PA2

0

-

+

RESP

MONITOR DISPLAY

ALARM

ALARM RESET

PAUSE

CONTRAST

Cover. The software

cartridge lives under this cover. You might

replace it if you do your own software updates.

If you do, make sure you read the Update

Instructions that come with the new software

cartridge before you replace it.

Revision E

➔

Page 21

General Information

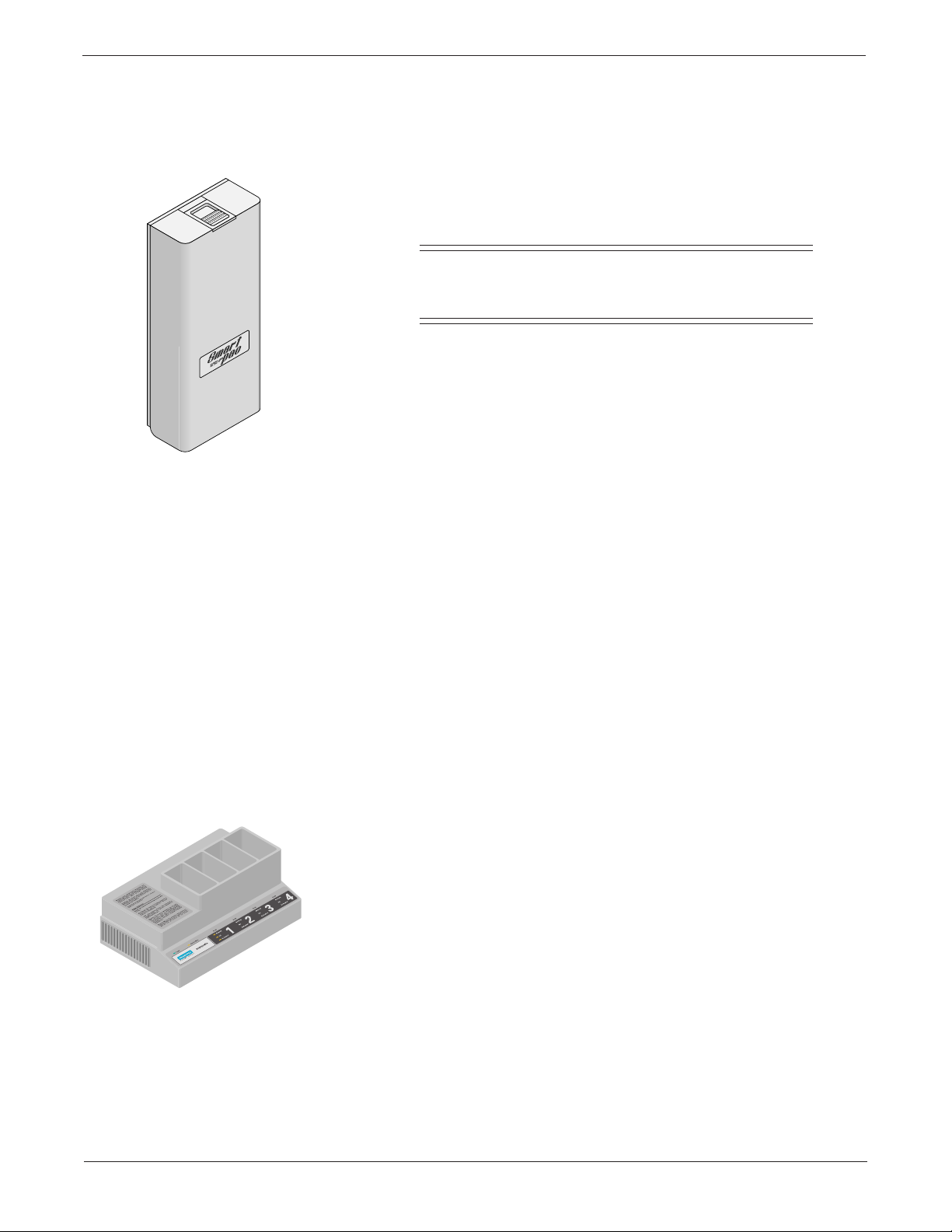

Caring for Your Smart-pac Battery Pack

The Smart-pac battery pack is shipped fully charged. To ensure

optimum performance, please recharge in a Smart-pac Charger

before the battery is put into service.

NOTE

Always make sure you fully charge this battery pack

before you use it with a patient.

The following tips should help you get the longest life and best

performance from your Smart-pac battery pack.

Storing the Battery Pack

Using the Smart-pac

Charger

We recommend that you store the battery pack in a Smart-pac

battery charger when you are not using it. The shelf life of the

battery is four weeks, and it is very important that you fully charge it

in a Smart-pac battery charger at least once every four weeks.

Smart-pac 2 batteries require the following Smart-pac Backpack

and Smart-pac Charger software:

• Smart-pac Backpack Version 2A or later.

• Smart -pac Charger V ersion 2A or later.

• Series 7240 Charger V ersion 2A or later.

• Series 7250 Charger V ersion 1A or later.

If you place your battery pack in a Smart-pac charger, and its

voltage is below 10 volts, the charger NOT READY indicator should

light for about 10 minutes while it trickle-charges the battery.

It takes about 75 minutes to charge a fully discharged Smart-pac

battery pack with a Smart-pac charger .

When you place your battery pack into a Smart-pac charger, and

you have not exercised the battery pack for 50 days or 100 charge

cycles, the charger EXERCISE indicator lights. exercising the

battery pack prolongs its life by first charging the battery, fully

discharging it,and then fully charging it again.

Press the EXERCISE key on the charger rear panel to start the

exercise cycle. An exercise cycle may take up to three hours,

depending on the battery pack’s capacity. The charger always fully

charges all batteries before it begins any exercise cycles.

SMART-PAC TRANSPORT DISPLAY

403596-036

1-5Revision E

Page 22

General Information

➔ Caring for Y our Smart-pac Battery Pack

Using a Smart-pac Power

Supply

Using a Smart-pac T ransport

Display

BATTERY

CHARGING

ICU-5

II

1X

ALARMS OFF

150

AR1

0

60

PA2

0

RESP

ALARM

PAUSE

DANGER Explosion risk if used with flammable anesthetics.

CONTRAST

US Patent 4,715,385.

Other Patents Pending

MONITOR DISPLAY

9-JAN-92 14:36

marquette electronics

mmHg

16:08

+

HELP

-

TRENDS GRAPH

DANGER Risque d'explosion. Ne pas employer en presence d'anesthesiques inflammables.

LEAD II

OFF

ALARM RESET

FREEZE

For use by qualified medical personnel only. See operator's guide for instructions.

BP ZERO

137/ 73

120/ 80

23.4°C

39.4°C

*

70

E

C

G

( 95 )

A

R

34/ 14

1

( 22 )

P

A

2

( 94 )

N

B

I

P

O

40

TRIM KNOB

DISPLAY POWER

R

E

S

T1

T

M

T2

P

REMOTE CONTROL

WRITER

If you use a Smart-pac power supply with your Smart-pac transport

display, the power supply can charge a Smart-pac battery pack

while it runs the transport display. However, it can take up to 16

hours to fully charge the battery.

Even if you use a power supply with your battery pack and

transport display, you still need to place your battery pack in a

Smart-pac battery charger at least once every four weeks, so the

battery charger can exercise your battery pack.

If the battery pack does not work with your Smart-pac display,

make sure the battery backpack on your transport display has the

latest version of software. Call your sales representative for software

updates.

NOTE

It is very important to make sure you fully charge this

battery pack before you use it on a patient.

For technical advice concerning your monitoring system, contact

Tech Support—Monitoring Hardware.

1-6

SMART-PAC TRANSPORT DISPLAY

403596-036

➔

Revision E

Page 23

Technical Specifications

Performance Specifications

Size: 9-inch diagonal

Type: Fluorescent backlit passive monochrome LCD

Resolution: 640 x 400 pixels

Number of traces: 4

Number of seconds/trace: 5

Sweep speed: 24.8 mm/sec, crystal controlled ±0.1%

Operating time: Using one Smart-pac 2.4-Ahr battery pack

Typical: 75 to 105 minutes with battery charged to 100% of rated capacity

Nominal: 60 to 75 minutes with battery charged to 80% of rated capacity

Environmental Specifications

Operating Conditions

Ambiant temperature: 10˚C to 35˚C (50˚F to 95˚F)

Relative humidity: 40% to 95% (noncondensing)

Storage Conditions

Ambiant temperature: –10˚C to 50˚C (15˚F to 122˚F)

Relative humidity: 0% to 95% (noncondensing)

General Information

Power Requirements

Voltage: 12V DC

Power: 6 watts

Physical Specifications

Height: 25.4 cm (10 in)

Width: 31.8 cm (12.5 in)

Depth: 9.5 cm (3.3 in)

Approx. weight: 5.7 kg (12.5 lb)

Certification

UL: UL544 Listed

CSA: CSA No 125 Certified

IEC: IEC 601-1 Certified

(with two batteries)

➔

SMART-PAC TRANSPORT DISPLAY

403596-036

1-7Revision E

Page 24

General Information

➔ T echnical Specifications

Classification

The Smart-pac Power Supply is classified, according to IEC 601-1,

as:

Type of protection against

electrical shock: Class I Equipment or Internally Powered Equipment

Degree of protection against

electrical shock: Not Marked

Degree of protection against

harmful ingress of water: Ordinary Equipment (enclosed equipment without protection

against ingress of water)

Degree of safety of application

in the presence of a flammable

anesthetic mixture with air or

with oxygen or nitrous oxide: Equipment not suitable for use in the presence of a flammable

anesthetic mixture with air or with oxygen or nitrous oxide.

Method(s) of sterilization or

disinfection recommended

by the manufacturer: Not Applicable

Mode of operation Continuous operation

1-8

SMART-PAC TRANSPORT DISPLAY

403596-036

Revision E

Page 25

2 Troubleshooting

WHAT IS IN THIS CHAPTER?

This chapter contains information that can help you repair the

Smart-pac transport display more effectively. It includes

information about some types of components that are used in

Smart-pac transport display, but not yet widely used in the field,

and some troubleshooting tips for communication problems.

Contents

Considerations for Special Components ............................. 2-2

Replacing the LCD Display.................................................. 2-4

Disassembly Procedure ........................................................ 2-5

Problems and Solutions..................................................... 2-11

Revision E

SMART-PAC TRANSPORT DISPLAY

403596-036

2-1

Page 26

Troubleshooting

Considerations for Special Components

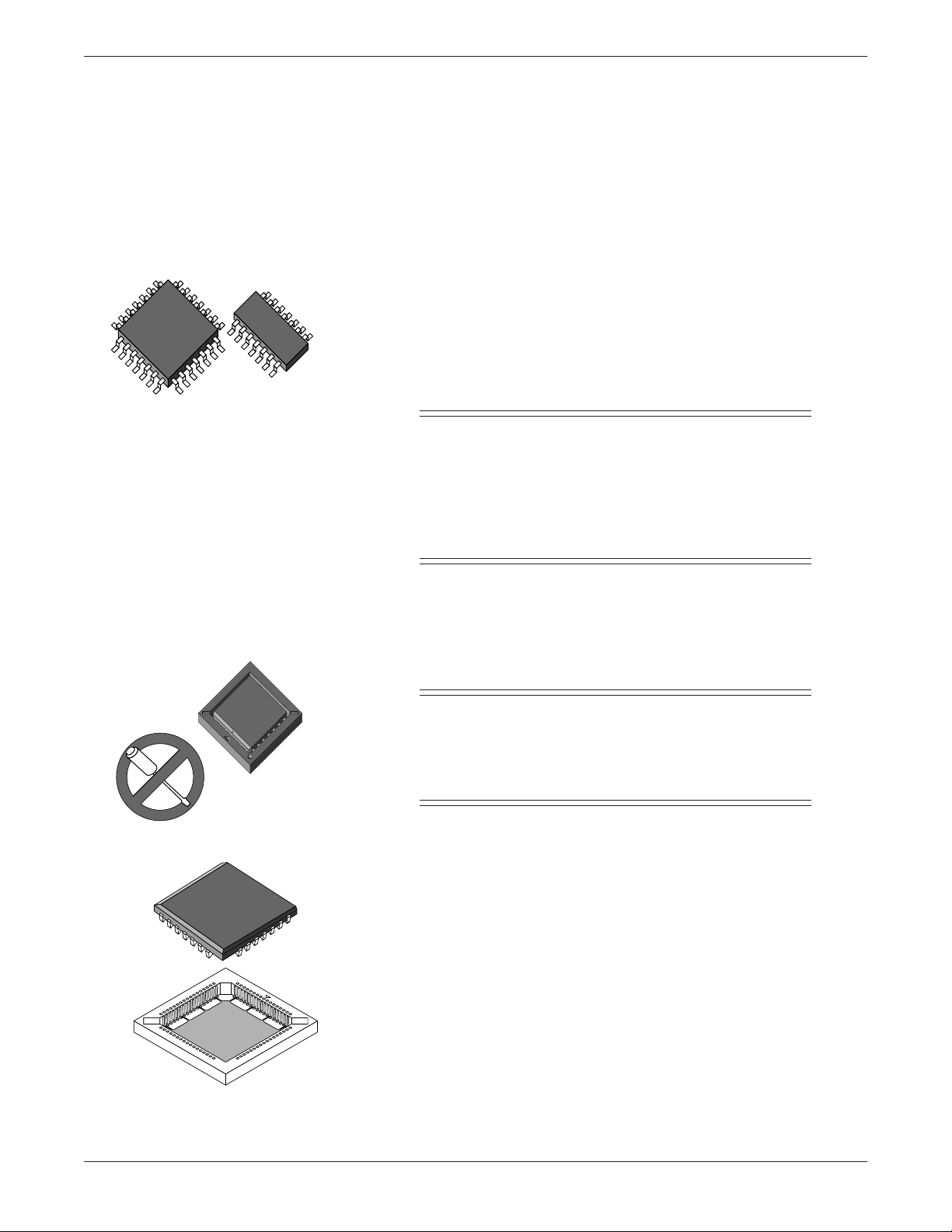

CMOS Components

The Smart-pac transport display makes extensive use of CMOS

components. CMOS components are more immune to noise and

consume less power than standard TTL or NMOS components.

However , CMOS components are inherently more susceptible to

electrostatic discharge (ESD) damage than other semiconductors.

ESD damage, usually a subtle weakening of semiconductor

junctions, can range from corruption of digital memory to

catastrophic failure and can render one (or more) components

permanently unusable. Although it is more common for CMOS

components to fail from ESD damage, no semiconductor device is

completely immune to ESD damage.

The inputs and outputs of the Smart-pac transport display are

protected from ESD damage; they are no more susceptible to ESD

damage during normal operation than other devices. However, when

you service the equipment, the components within are exposed to

several sources of static electricity, ranging from human hands to

improperly grounded test equipment. For this reason, it is

suggested that all service workstations be as static-free as possible.

The following guidelines can help make your workstation more

resistant to the damage that can be caused by static electricity.

• A grounded, antistatic wristband (3M part number 2046 or

equivalent) or heelstrap should be worn at all times when

repairing assemblies containing semiconductors.

• Discharge any built up static charge before handling

semiconductors or assemblies containing semiconductors.

• Use only properly grounded soldering and test equipment.

• Use a static-free surface (3M part number 8210 or equivalent)

when working on assemblies containing semiconductors.

• Do not remove semiconductors or assemblies containing

semiconductors from antistatic containers (bags) until needed.

• Make sure power to an assembly is turned off before removing

or inserting a semiconductor.

• Do not slide semiconductors or assemblies containing

semiconductors across any surface.

• Do not touch semiconductor leads unless absolutely

necessary.

• Semiconductors and assemblies containing semiconductors

should be stored only in antistatic bags or boxes.

Although these items cannot ensure a 100% ESD-free workstation,

they can greatly reduce the failure rate of any semiconductors that

are serviced.

SMART-PAC TRANSPORT DISPLAY

403596-036

➔

Revision E2-2

Page 27

Troubleshooting

➔ Considerations for Special Components

Surface Mounted

Components

Plastic Leaded Chip Carriers

Surface mounted components aid in miniaturizing the Smart-pac

transport display.

Surface mounted integrated circuits have legs soldered to

rectangular pads on the surface of the circuit board, rather than

legs that are inserted into holes that go through the circuit board.

Surface mounted integrated circuits can have legs on either two or

four sides of the chip.

Surface mounted resistors, capacitors, and diodes usually have no

legs at all – conductive parts of their bodies are soldered directly to

the circuit board.

CAUTION

Surface mounted components were not designed to be

removed and replaced with standard soldering equipment. Removing a surface mounted component with a

conventional soldering iron could destroy the circuit

board. Special equipment is required to remove and

replace these items.

Plastic leaded chip carriers (PLCCs) also save space. PLCCs have

conductors on all four sides and are usually used with special

sockets. They do not have legs like a conventional integrated circuit,

but rather “loops” that make contact with the socket or circuit

board when they are inserted.

CAUTION

Removing and inserting PLCCs requires a special tool

(Burndy QILEXT-1 or equivalent). If you use a screwdriver to remove or replace a PLCC, you may damage

the PLCC or the socket.

If you must troubleshoot the circuitry under the PLCC socket,

carefully remove the PLCC. Next, carefully break out the square

socket bottom with a knife so you can probe the circuit board

below.

When you finish troubleshooting, make sure to replace the square

bottom socket before you insert the PLCC again or replace the

whole socket with the correct socket replacement part. Refer to the

appropriate parts list in this manual. The socket provides necessary

spacing between the bottom of the PLCC and the circuit board.

Revision E

SMART-PAC TRANSPORT DISPLAY

403596-036

2-3

Page 28

Replacing the LCD Display

If your LCD display is damaged, you need to order one of three

Smart-pac Display Retrofit kits available to replace it. The serial

number located on the back of the Tram Transport display

determines which of the three replacement kits you need.

To view the serial number, use the disassembly procedure provided

later in this chapter to separate the Smart-pac battery backpack

from the Tram Transport display. For an explanation on how to

read the serial number digits, refer to “Equipment Identification” in

the Introduction of this manual.

• If the product code of the serial number is “JW,” order retrofit

kit, pn 414091-001. This kit includes detailed instructions

about how to rework the display processor PCB, pn 85638002 revision M or later . If your display processor PCB is an

earlier version, the PCB cannot be reworked and must be

replaced. Call Tech Support at 1-800-558-7822 for details.

Troubleshooting

• If the product code of the serial number is “LG” and product

sequence number is from 001 to 190 (except 186), order

retrofit kit, pn 414091-002. This kit includes a new flex circuit

and LCD display. The new flex circuit is required because the

older flex circuit was soldered directly to the LCD display and

will be discarded with it. Y ou may use the disassembly

procedure included in this chapter to replace your LCD

display.

• If the product code of the serial number is “LG” and the

product sequence number is 186, 191 or later, order retrofit

kit, pn 414091-003. This kit includes only the LCD and you

may use the disassembly procedure included in this chapter

to replace your LCD display.

SMART-PAC TRANSPORT DISPLAY

403596-036

Revision E2-4

Page 29

Disassembly Procedure

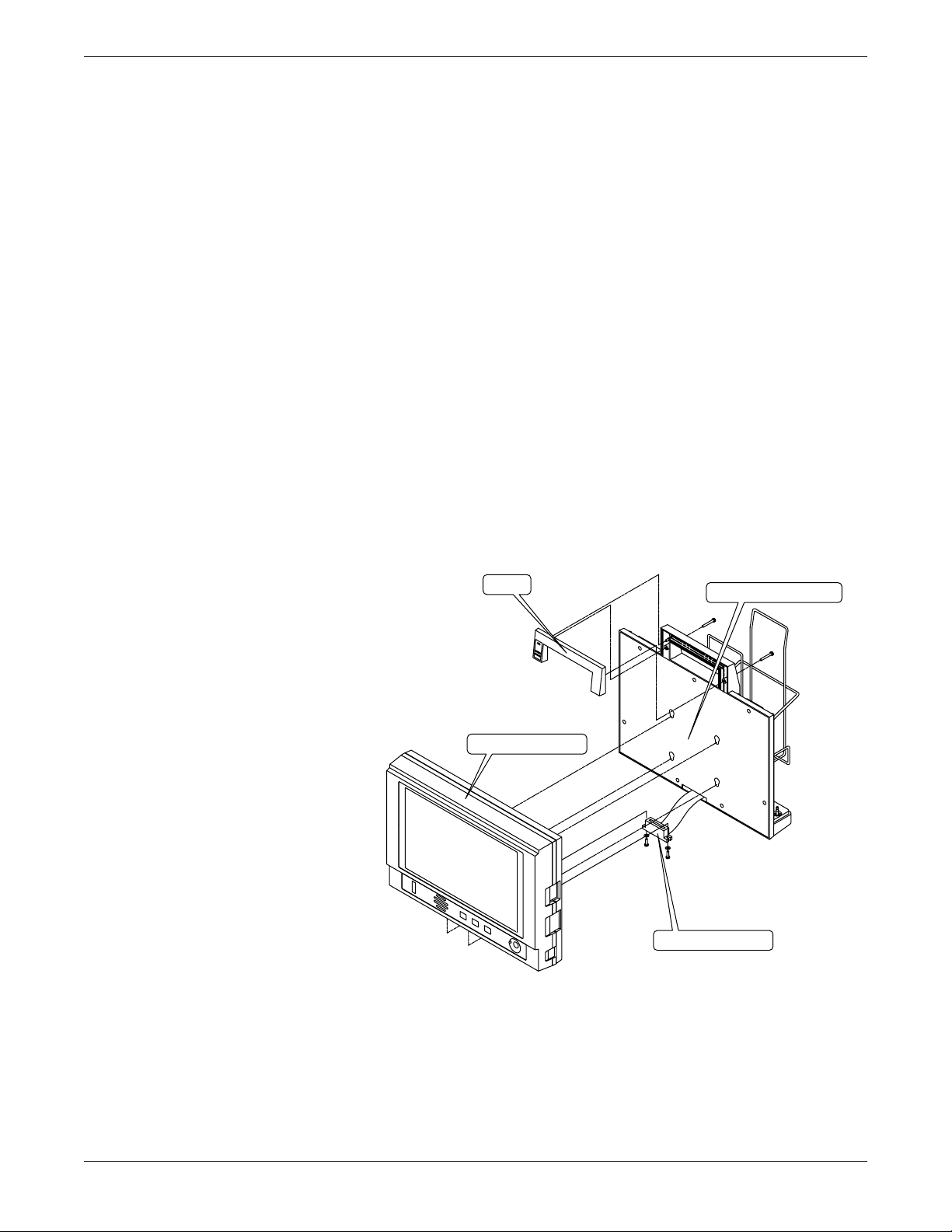

Handle

Smart-pac Battery Backpack

Ribbon Cable Connector

Tram Transport Display

Troubleshooting

Remove Optional Smart-pac

Battery Backpack

These are the recommended steps to disassemble the major

components of the Smart-pac Transport display. Keep all hardware

for re-assembly.

1. Remove the two screws from the rear of the handle and

remove the front of the handle from the Smart-pac battery

backpack.

2. Remove the two screws and washers recessed in the bottom of

the Tram Transport display that secure the ribbon cable

connector from the Smart-pac battery backpack to the Tram

Transport display.

3. Disconnect the ribbon cable connector from the Tram

Transport display board-edge connector.

4. Slide the Smart-pac battery backpack downward to disengage

the mounting buttons from the keyhole-shaped mounting

slots located on the Smart-pac battery backpack front cover.

5. Car efully separate the Tram Transport display from the

Smart-pac battery backpack.

Revision E

SMART-PAC TRANSPORT DISPLAY

➔

2-5

403596-036

Page 30

➔ Disassembly Procedure

Troubleshooting

Disassemble the Tram

Transport Display

1. Remove the six screws from around the rear perimeter of the

Tram Transport display that secures the front and back

display case. Refer to the figure on the next page.

CAUTION

For the next step, there are cables and connectors

inside the Tram Transport display that could possibly

be stressed when the front and back display cases are

separated. As you look at the unit, open it slightly on the

right first instead of opening it along the top edge to

avoid ripping the flex circuit.

2. Car efully separate the case front and back display cases so

you do not damage the cables or connectors.

3. Disconnect the cables/harnesses listed below that provide

interconnection for the display processor PCB and front panel

switches to the display assembly. Refer to the figure on the

next page.

• Disconnect the horizontal 60-pin connector and ribbon

cable from the front display case.

• At the display processor PCB, slide the slip-ring lock

mechanism of the horizontal 20-pin zero insertion force

(ZIF) connector . Gently pull the flex cir cuit from the ZIF

connector ,

• Disconnect the 3-pin display power cable from the

connector on the display processor PCB (disengage the

interlock to release the cable harness).

SMART-PAC TRANSPORT DISPLAY

403596-036

➔

Revision E2-6

Page 31

➔ Disassembly Procedure

Use the figure below to assist with the disassembly procedure.

Troubleshooting

Case Front

5 Screws

Display Assembly

Display

Processor

PCB

Backlight

Power Cable

6 Screws

Ground

20-Pin

ZIF

Connector

Connector

60-Pin

Case Back

6 Screws

Serial Number

3-Pin

Backlight

Power

Connector

➔

Revision E

SMART-PAC TRANSPORT DISPLAY

403596-036

2-7

Page 32

➔ Disassembly Procedure

4. Remove the two screws and washers that secure the center

5. Remove the screw which secures a ground cable ring

6. Remove the three outside screws to replace the display

7. To replace the display processor PCB, remove the five screws

8. While using electrostatic discharge (ESD) protection, remove

Perform any necessary service at this time.

Troubleshooting

support bracket to the display front case.

connector to the display mounting bracket.

assembly.

securing the display processor PCB to the back display case.

the display processor PCB.

Backlight Power

Cable

Display

Assembly

Ground

Wire

Center Support

Bracket

Remove Four

Corner Screws

SMART-PAC TRANSPORT DISPLAY

403596-036

➔

Revision E2-8

Page 33

➔ Disassembly Procedure

Troubleshooting

Re-assemble the Tram

Transport Display

1. Use a lint-free cloth to clean the inside of the protective filter

lens affixed to the front display case. Remove fingerprints,

dust, or smudges from the protective filter lens. Carefully wipe

the outer lens of the retrofit display assembly to remove

fingerprints, dust, or smudges as well.

CAUTION

Apply very light pressure with a continuous motion

over the new display outer lens to remove any fingerprints, dust or smudges. Do not use excessive pressure

when wiping it down because it may damage the

display.

NOTE

Protect the clean surfaces. Fingerprints, dust, or

smudges left on the surfaces mentioned above are

annoyingly visible when the Tram Transport Display is

turned ON when you re-assemble to unit.

2. Install the new display assembly provided in the kit into the

front display case.

NOTE

Orient the new display assembly with the backlight

power cable to the left and the flex circuit to the right of

the display assembly when viewed from the inside of

the front display case.

Revision E

3. Fasten the four screws to the corners of the new display

assembly with the ground cable in the lower left corner when

viewed from the inside of the front display case. Center the

new display assembly with respect to the rectangular opening

in the front display case.

4. Remount the center support bracket with the two screws in

the mounting holes in the front display case.

5. Install the display processor PCB into the back display case

and secure with the hardware you removed earlier. Attach the

other end of the ground cable-ring connector to the mounting

hole of the display processor PCB lower-right corner last.

Orient the ground cable so that it does not interfere with the

front and back display case when assembled together.

6. Connect the cables and harnesses listed below that provide

interconnection between the display processor PCB, front

panel switches, and display assembly.

• Observing correct orientation, connect the two-wire

backlight power cable to the connector on the display

processor PCB.

SMART-PAC TRANSPORT DISPLAY

403596-036

➔

2-9

Page 34

➔ Disassembly Procedure

Troubleshooting

➔ Re-assemble the T ram

Transport Display

• Attach the 60-pin flex circuit connector from the control

panel assembly to connector on the display processor

PCB.

• Carefully insert the 20-pin flex circuit from the display

assembly into ZIF connector on the display processor

PCB with the contact points facing you (away from the

PCB). Ensure the flex circuit aligns properly in the

connector . Orient the flex circuit so that there are no

twists and make sure that it is centered and straight

with respect to the ZIF connector. Secure the flex circuit

into the connector by sliding the slip-ring mechanism

toward the base of ZIF connector locking the flex circuit

into place.

8. W ith the back case on the bottom, carefully fold all flex

circuits, ribbon cables, and cable harnesses into a position

where they cannot get kinked, nicked or compressed.

CAUTION

Do not pinch any internal flex circuits, ribbon cables,

or cable harnesses. Make sure that all internal cables

do not obstruct any of the screws used to secure the

front and back display cases.

Connect Optional Smart-pac

Battery Backpack

Completion

9. Seat the power switch and external connector mounting plates

into the respective openings provided in the front and back

display cases.Secure the front and back display cases with the

hardware you removed earlier.

1. For the optional Smart-pac Battery Backpack, connect the

ribbon cable connector from the Smart-pac Battery Backpack

to the Tram Transport display with the two screws and lock

washers.

2. Align and insert the mounting buttons located on the display

case back into the keyhole-shaped mounting slots on the

Smart-pac Battery Backpack front cover. Slide the Tram

Transport Display down as far as it can go. The tops and

bottoms of the Tram Transport Display and Smart-pac

Battery Backpack should be flush with respect to each other.

3. Install the BATTERY CHARGING indicator LED into the

mounting hole on the Smart-pac Battery Backpack front

handle piece and align the LED cable harness so it cannot

interfere with installation of the handle.

4. Align the front handle piece with the Smart-pac Battery

Backpack housing and secure the front handle piece with

hardware previously removed. Once the front handle piece is

installed, the Tram Transport Display is locked in place to the

Smart-pac Battery Backpack.

Perform the Check Procedure found in Chapter 4, “Preventive

Maintenance,” in this manual before returning to service.

SMART-PAC TRANSPORT DISPLAY

403596-036

Revision E2-10

Page 35

Problems and Solutions

Here are a couple of problems that Marquette service personnel

have encountered with Smart-pac transport displays, and

descriptions of how they solved them.

Troubleshooting

Problem:

Solution:

The transport display shows a big COMMUNICATION FAILURE

message and won’t display any waveforms.

Using the wrong connector on the transport display usually causes

this problem. Make sure that you’re plugging the Tram module into

the connector on the backof the transport display. The two

connectors on the sides do not work for the Tram module.

I

O

WRITER DISPLAY POWER

If you use the correct connector but you still see the

COMMUNICATION FAILURE message, try the following steps.

• Unplug the cable between the Tram module and the transport

display and plug it back in.

• Replace the cable between the Tram module and the transport

display with a known good one.

• Reseat the connector on the bottom of the transport display.

It connects the transport display assembly to the battery

backpack assembly, and all communication signals between

the Tram module and transport display go through it.

• The transport display is designed to withstand the rigors of

transporting patients, but sometimes connectors disconnect

and integrated circuits unseat. Disassemble the battery

backpack assembly. When you’re inside it, disconnect and

reseat all of the connectors. If you have a PLCC extractor, you

can also carefully remove and reseat microcontroller U3 on

the battery interface PCB. If this step works, make sure that

you do the Checkout Procedures listed in Chapter 4,

“Preventive Maintenance.”

➔

Revision E

SMART-PAC TRANSPORT DISPLAY

403596-036

2-11

Page 36

➔ Problems and Solutions

Troubleshooting

➔ Solution:

Problem:

Solution:

• Take the battery backpack assembly off of the transport

display assembly, and try it on a different transport display.

Likewise, you can try a different battery backpack assembly

on the transport display assembly.

∞ If the problem is with the battery backpack assembly,

replace the battery interface PCB with a known good

one.

∞ If the problem is with the transport display assembly,

replace the display processor PCB with a known good

one.

The transport display won’t turn ON.

• Adjust the CONTRAST control on the front panel. If this control

is turned all the way down, the transport display looks like it’s

been turned OFF.

• If you’re using Smart-pac battery packs to power the transport

display, make sure they are fully charged. Make sure the

READY light lights on the Smart-pac charger before you use

the battery pack with a transport display. If the EXERCISE

light is ON for the battery, make sure that you exercise the

battery pack before you use it again (press the EXERCISE

switch by the power cord connector on the Smart-pac

charger).

• If you just bought new battery packs, they were probably

Smart-pac II battery packs. If you want to use the new battery

packs, you might have to update the software in the battery

backpack assembly to version 2A or later . The Smart-pac

Battery Backpack V ersion 002 Update Instructions (pn 403596-

034) shows you how to do this.

• Remove the battery backpack assembly from the transport

display assembly and swap these items with ones from a

working transport display.

∞ If the problem is with the battery backpack assembly,

disassemble the battery backpack assembly. Once

inside it, disconnect and reseat all of the connectors. If

you have a PLCC extractor, you can also carefully

remove and reseat microcontroller U3 on the battery

interface PCB. If this step works, make sure that you do

the Checkout Procedures listed in Chapter 4, “Preventive

Maintenance.” If it doesn’t, swap the battery interface

PCB with a known good one.

∞ If the problem is with the transport display assembly,

replace the display processor PCB with a known good

one. If that doesn’t fix it, the problem is probably in the

LCD display itself.

SMART-PAC TRANSPORT DISPLAY

403596-036

Revision E2-12

Page 37

3 Calibration

WHAT IS IN THIS CHAPTER?

This chapter describes how and when to adjust the equipment.

It also describes the Smart-pac transport display’s internal

switches and jumpers.

There are only two circuit boards in the Smart-pac transport

display that have adjustments, switches, and jumpers: the

display processor PCB (pn 800814 or pn 85638) and the battery

interface PCB (pn 403861).

Contents

Display Processor PCB PN 800814...................................... 3-2

Display Processor PCB PN 85638 ........................................ 3-4

Battery Interface PCB PN 403861 ....................................... 3-9

Revision E

SMART-PAC TRANSPORT DISPLAY

403596-036

3-1

Page 38

Calibration

Display Processor PCB PN 800814

Audio V olume Adjustment

Variable resistor R32 sets the Smart-pac transport to display a

consistent volume level. The speaker volume is adjusted in the

factory to a particular amplitude.

NOTE

This is not a recommended field adjustment, but be

aware that changing the speaker assembly changes the

speaker volume.

If you perform checkout procedures on a transport display after a

repair and you notice that the alarm volume is much louder or

quieter than other transport displays in your hospital, adjust

variable resistor R32 to fix this problem.

CAUTION

Check the alarms after you adjust the speaker voltage.

If the adjustment is too high, it can overdrive the

speaker; if it is low, it can shut off the alarms.

R32

Revision E3-2

Page 39

Calibration

➔ Display Processor PCB PN 800814

Switch Settings

Set switches

according to

language

desired.

English

3456

There is one DIP switch on the display processor PCB. When you

replace a display processor PCB, make sure that the switches on

the new circuit board are correct. The figure below shows how to set

the switches on the new circuit board.

SwedishItalianFrench

3456

3456

12 12 12

3456

ONONON

DutchGermanSpanish

ONON

345612 12 12

ON

3456

ON

3456

12

Revision E

3-3

Page 40

Calibration

Display Processor PCB PN 85638

Earlier versions of the Tram Transport Display used the pn 8563800x display processor PCB. V ariable resistor R84 is used to set the

intensity of the fluorescent backlight to a consistent level in the

factory.

If you replace the LCD display assembly or any of the following

components on the display processor PCB, you should calibrate the

backlight level:

Q3 R84 R87

R100 T1 U69

Display Backlight Intensity

Adjustment

Do the following to calibrate the display backlight intensity:

1. Turn the transport display OFF.

2. Attach all cables to the display processor PCB. This includes

the cable to the backlight of the LCD display assembly, and

the cable to the battery backpack assembly.

3. Attach a digital voltmeter across resistor R100 on the display

processor PCB.

W ARNING

In the following step, apply power to the transport

display. When you apply power, the output side of

inverter T1 develops over 700 volts to dive the fluorescent backlight tubes in the LCD display assembly.

Make sure you do not touch inverter T1, connector

J828, or the bottom side of the circuit board while

power is applied.

4. Turn the transport display ON.

5. Adjust variable resistor R84 until the digital voltmeter reads

140 millivolts.

Revision E3-4

Page 41

Calibration

➔ Display Processor PCB PN 85638

➔ Display Backlight Intensity

Adjustment

Revision E

T1 R84 R100 U69 R87 Q3J828

3-5

Page 42

Calibration

➔ Display Processor PCB PN 85638

Audio V olume Adjustment

Variable resistor R31 is used to set the Smart-pac transport

displays to a consistent volume level. The speaker volume is

adjusted in the factory to a particular amplitude.

NOTE

This is not a recommended field adjustment, but be

aware that changing the speaker assembly changes the

speaker volume.

If you perform a checkout procedure on a transport display after a

repair and you notice that the alarm volume is much louder or

quieter than other transport displays in your hospital, you may

adjust variable resistor R31 to fix this problem.

W ARNING

Recheck the alarms after adjusting the speaker voltage.

Too high an adjustment will overdrive the speaker and

too low will shut off the alarms.

R31

Revision E3-6

Page 43

Calibration

➔ Display Processor PCB PN 85638

Jumper Settings

Memory size jumper

W1 should be in the

left position.

There are several jumpers on the display processor PCB. When you

replace a display processor PCB, always make sure that the

jumpers on the new circuit board are set correctly before you install

the PCB. The figure below shows how to set the jumpers on the new

circuit board.

Watchdog reset enable jumper W4

should be in the

bottom (EN)

position.

Processor/watchdog

clock enable jumper

W5 should be

installed.

DUART U19 clock

enable jumpers W6

and W13 should

both be installed.

Revision E

Display controller

U65 type jumper

W10 should be in

the left position.

Display controller

U65 clock select

jumper W14 should

be installed.

Display controller

U65 clock select

jumper W9 should

be in the left

position.

3-7

Page 44

Calibration

➔ Display Processor PCB PN 85638

Switch Settings

There are two sets of DIP switches on the display processor PCB.

When you replace a display processor PCB, make sure that the

switches on the new circuit board are correct. The figure below

shows how to set the switches on a new circuit board.

DIP Switch S2 sets

the language of the

Smart-pac transport

English

ON1234

DIP switch S1 is set according to

whether the transport display has

a battery backpack installed.

display’s software:

French

ON1234

Italian

ON1234

Swedish

ON1234

Series 7200 Tram transport

ON12

displays without battery

backpacks are set like this.

Spanish

ON1234

German

ON1234

Dutch

ON1234

Smart-pac transport displays

ON12

or Series 7200 Tram transport displays with battery

backpacks are set like this.

Revision E3-8

Page 45

Calibration

Battery Interface PCB PN 403861

Jumper Setting

The battery interface PCB doesn’t have any adjustments or

switches, but it does have one jumper. The watchdog clock disable

jumper, W1 , should not be installed. If you replace a battery

interface PCB, always make sure that the jumper on the new circuit

board is not installed before you install the PCB.

Watchdog clock disable jumper W1

Revision E

3-9

Page 46

For your notes

Calibration

Revision E3-10

Page 47

4 Preventive Maintenance

WHAT IS IN THIS CHAPTER?

This chapter contains preventive maintenance instructions for

the Smart-pac transport display. These instructions describe

how to care for your Smart-pac transport display and how to

make sure that it’s working properly.

Contents

Maintenance Schedule......................................................... 4-2

Inspection ............................................................................ 4-3

Cleaning ............................................................................... 4-4

Check Procedure.................................................................. 4-5

Preventive Maintenance Inspection Form ......................... 4-13

Revision E

SMART-PAC TRANSPORT DISPLAY

403596-036

4-1

Page 48

Maintenance Schedule

Preventive Maintenance

The Smart-pac transport display maintenance schedule must

include all of the items in this table.

What to do When to do it

Inspection Before you transport each patient.

Cleaning Before you transport each patient.

Checkout procedures When you first get your transport display,

every six months thereafter , and when you

remove or replace a circuit board.

W ARNING

Failure on the part of the responsible individual, hospital, or institution employing the uses of this monitoring equipment to implement a satisfactory maintenance schedule may cause undue equipment failure

and possible health hazards. Marquette Medical Systems does not in any manner assume the responsibility

for perfor ming the recommended safety tests, unless

an Equipment Maintenance Contract exists. The sole

responsibility rests with the individual or institution

using the equipment.

4-2

SMART-PAC TRANSPORT DISPLAY

403596-036

Revision E

Page 49

Inspection

Preventive Maintenance

Y ou should inspect the Smart-pac transport display each time you

transport a patient. Follow these guidelines when you inspect the

display :

• Inspect the Smart-pac transport display for obvious physical

damage and replace the damaged items.

• Inspect all connectors for bent pins or prongs. Qualified

service personnel should replace the defective connectors.

• Inspect all cable insulation. Qualified service personnel should

repair or replace damaged or deteriorated cables.

Revision E

SMART-PAC TRANSPORT DISPLAY

403596-036

4-3

Page 50

Cleaning

Preventive Maintenance

Y ou should clean the Smart-pac transport display each time you

transport a patient. Y ou should clean the exterior surfaces with a

lint-free cloth dampened with one of these approved solutions:

• Ammonia (diluted)

• Cidex

• Mild soap (dissolved)

• Sodium hypochlorite bleach (diluted)

CAUTION

Follow these cleaning instructions exactly. Failure to

follow the instructions may melt, distort, or dull the

finish of the case, blur lettering on the labels, or cause

equipment failures.

Always dilute the solutions according to the manufacturer’s

suggestions.

Always wipe off all of the cleaning solution with a dry cloth after

cleaning.

Never pour water or any cleaning solution on the equipment or

permit fluids to run into the connectors or ventilation openings in

the equipment.

Never use these cleaning agents:

• Abrasive cleaners or solvents of any kind

• Alcohol-based cleaning agents

• Wax containing a cleaning substance

• Acetone

• Betadine

4-4

SMART-PAC TRANSPORT DISPLAY

403596-036

Revision E

Page 51

Checkout Procedure

Preventive Maintenance

Getting Started

Required Special Equipment

The following checkout procedures describe how to make sure the

Smart-pac transport display operates correctly. Perform checkout

procedures periodically and after you repair a transport display for

proper operation.

Y ou must use other equipment, like the Digital Display Writer

(DDW) and Smart-pac power supply, in these checkout procedures.

The checkout procedures listed here only fully test the Smart-pac

transport display. You should also perform checkout procedures for

the other equipment to make sure they operate. Refer to the

checkout procedures in the appropriate service manuals.

Throughout this procedure you must connect the transport display

to devices that you would use during normal operation. You may

already have most of these items. The only exception is that you

must connect to a patient simulator instead of a real patient to

get waveforms and vital signs.

Y ou need the following items before you can start the procedures:

✓ A patient simulator. We use a Marquette Multifunction Micro-

Simulator (pn MARQ-1) in the procedure, but you could use a

different one. If you do, you need to change some of the steps

slightly.

✓ A Tram module. We show a Tram 600A module in the

procedure, but you can use any one of these:

• Series 7200 Tram module

• Series 7200 Tram AR module

• Tram 100, 200, 300, 500, or 600 module

• Tram 100-850 A or SL module

✓ An interconnection display cable. It goes between the Tram

module and transport display. Y ou can use any of these cables:

Part Number Length (Feet) Length (Meters)

403495-001 10 3.0

403496-001 15 4.6

406468-002 25 7.6

406468-001 40 12.2

✓ A patient cable to attach ECG leadwires to the Tram module.

• If you use a Tram module with a round ECG connector, you

can use pn 9443-001.

• If you use a Tram module with a rectangular ECG connector,

you can use pn 403061-001.

Revision E

SMART-PAC TRANSPORT DISPLAY

403596-036

➔

4-5

Page 52

➔ Checkout Procedures

Preventive Maintenance

➔ Required Special

Equipment

✓ A set of leadwires. Leadwires pn 403066-005 are shown in this

procedure.

✓ A blood pressure cable to connect the blood pressure output on

the simulator to the input on the Tram module.

• If you use a Tram module with round BP connectors, you can

use pn 6770036.

• If you use a Tram module with rectangular BP connectors,

you can use pn 700095-001.

✓ A Direct Digital Writer (DDW). A Series 7160 DDW is shown in

the procedure, but you can use a Series 7150 DDW as well.

✓ A DDW cable. The cable that you need depends on what kind of

DDW you use:

• If you use a Series 7150 DDW, the DDW cable is the same

type of cable that you use to connect the transport display to a

Tram module, so you’ll need one of these:

Part Number Length (Feet) Length (Meters)

403495-001 10 3.0

403496-001 15 4.6

406468-002 25 7.6

406468-001 40 12.2

• If you use a Series 7160 DDW, you need a pn 700180-001

cable.

✓ A pair of power cables for the DDW and Smart-pac power supply.

4-6

SMART-PAC TRANSPORT DISPLAY

403596-036

➔

Revision E