Page 1

Dash3000/4000

Patient Monitor

Service Manual

2000966-035 Revision A

Page 2

NOTE: Due to continuing product innovation, specifications in this

manual are subject to change without notice.

Listed below are GE Medical Systems Information Technologies’ trademarks. All other trademarks contained

herein are the property of their respective owners.

900 SC, ACCUSKETCH, AccuVision, APEX, AQUA-KNOT, ARCHIVIST, Autoseq, BABY MAC, C Qwik

Connect, CardioServ, CardioSmart, CardioSys, CardioWindow, CASE, CD TELEMETRY, CENTRA, CHART

GUARD, CINE 35, CORO, COROLAN, COROMETRICS, Corometrics Sensor Tip, CRG PLUS, DASH,

Digistore, Digital DATAQ, E for M, EAGLE, Event-Link, FMS 101B, FMS 111, HELLIGE, IMAGE STORE,

INTELLIMOTION, IQA, LASER SXP, MAC, MAC-LAB, MACTRODE, MANAGED USE, MARQUETTE,

MARQUETTE MAC, MARQUETTE MEDICAL SYSTEMS, MARQUETTE UNITY NETWORK, MARS,

MAX, MEDITEL, MEI, MEI in the circle logo, MEMOPORT, MEMOPORT C, MINISTORE, MINNOWS,

Monarch 8000, MULTI-LINK, MULTISCRIPTOR, MUSE, MUSE CV, Neo-Trak, NEUROSCRIPT,

OnlineABG, OXYMONITOR, Pres-R-Cuff, PRESSURE-SCRIBE, QMI, QS, Quantitative Medicine,

Quantitative Sentinel, RAC RAMS, RSVP, SAM, SEER, SILVERTRACE, SOLAR, SOLARVIEW, Spectra

400, Spectra-Overview, Spectra-Tel, ST GUARD, TRAM, TRAM-NET, TRAM-RAC, TRAMSCOPE, TRIM

KNOB, Trimline, UNION STATION, UNITY logo, UNITY NETWORK, Vari-X, Vari-X Cardiomatic,

VariCath, VARIDEX, VAS, and Vision Care Filter are trademarks of GE Medical Systems Information

Technologies registered in the United States Patent and Trademark Office.

12SL, 15SL, Access, AccuSpeak, ADVANTAGE, BAM, BODYTRODE, Cardiomatic, CardioSpeak, CD

TELEMETRY

Cumulus, Event-Link Nimbus, HI-RES, ICMMS, IMAGE VAULT, IMPACT.wf, INTER-LEAD, IQA,

LIFEWATCH, Managed Use, MARQUETTE PRISM, MARQUETTE

MMS, MRT, MUSE CardioWindow, NST PRO, NAUTILUS, O

®

-LAN, CENTRALSCOPE, Corolation, EDIC, EK-Pro, Event-Link Cirrus, Event-Link

®

RESPONDER, MENTOR, MicroSmart,

SENSOR, Octanet, OMRS, PHi-Res,

2

Premium, Prism, QUIK CONNECT V, QUICK CONNECT, QT Guard, SMART-PAC, SMARTLOOK, Spiral

Lok, Sweetheart, UNITY, Universal, Waterfall, and Walkmom are trademarks of GE Medical Systems

Information Technologies.

© GE Medical Systems Information Technologies, 2000. All rights reserved.

T-2 Dash 3000/4000 Patient Monitor Revision A

2000966-035 27 November 2000

Page 3

CONTENTS

1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Manual Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Manual Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Responsibility of the Manufacturer . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Warnings, Cautions, and Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Equipment Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

Service Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

Service Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

Equipment Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

2 EQUIPMENT OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

The Monitoring System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

The Patient Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Optional RAC 2A Module Housing . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Optional Wireless LAN System . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

ECG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

Invasive Blood Pressure (BP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Noninvasive Blood Pressure (NBP) . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Pulse Oximetry (SPO2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

Cardiac Output (CO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Respiration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-13

Temperature (TEMP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Carbon Dioxide (CO2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-13

Analog Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Defibrillator Synchronization Pulse . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-16

Paper Recorder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-16

RF Wireless LAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-16

Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-17

Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-19

Revision A Dash 3000/4000 Patient Monitor i

2000966-035

Page 4

CONTENTS:

3 INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Back Panel Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Front Panel Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Power Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Ethernet Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

Twisted Pair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Concentrator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Node . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Segment and Branch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

Repeater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Bridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

Twisted Pair Cabling (10BaseT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Symbol PC Card (Wireless LAN) . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

4 MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Manufacturer Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Manufacturer Responsibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Visual Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Cleaning Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Cleaning the Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Exterior Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Cleaning the Print Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

Battery Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

Charging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Conditioning the Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

Replacing the Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

Electrical Safety Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-9

Wall Receptacle Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Ground (Earth) Integrity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Ground (Earth) Wire Leakage Current Tests . . . . . . . . . . . . . . . . . . 4-13

Enclosure Leakage Current Test . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Patient (Source) Leakage Current Test . . . . . . . . . . . . . . . . . . . . . .4-17

Patient (Sink) Leakage Current Test

(Mains Voltage on the Applied Part) . . . . . . . . . . . . . . . . . . . . . . .4-19

Test Completion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-20

Hi-Pot (Dielectric Withstand) Test . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

DAS Assembly AC Hi-Pot Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

Processor/Power Management PCB Hi-Pot Test . . . . . . . . . . . . . .4-23

AC Mains Hi-Pot Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

Checkout Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-25

Manufacturer Recommended Test Equipment . . . . . . . . . . . . . . . . . 4-25

Monitor Power-up Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

ECG Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-27

ii Dash 3000/4000 Patient Monitor Revision A

2000966-035

Page 5

CONTENTS:

Respiration Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

Temperature Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-31

Cardiac Output Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-32

Invasive Blood Pressure Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-34

Pulse Oximetry Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-36

Noninvasive Blood Pressure Tests . . . . . . . . . . . . . . . . . . . . . . . . . 4-38

Analog Output and Defibrillator Synchronization Tests . . . . . . . . . . 4-40

Battery Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-43

Graph Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-43

Graph Speed Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-43

Display Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-44

Speaker Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-44

Network Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-44

RF LAN Test (option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-44

RAC 2A Module Housing Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-45

Completion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-45

PM Form . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-45

Repair Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-46

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Service Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Boot Loader Service Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Main Menu Service Mode Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Review Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

Error Log Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Error Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Battery Alarms and Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Alarm Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-10

Error Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-11

Power Source Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-12

Wall Receptacle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-12

Power Cord and Plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-13

Data Acquisition Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

ECG Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-14

Lead Fail Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-15

Pace Detect Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-16

Invasive Blood Pressure Functions . . . . . . . . . . . . . . . . . . . . . . . . .5-17

Respiration Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

Noninvasive Blood Pressure Functions . . . . . . . . . . . . . . . . . . . . . . 5-21

Wireless LAN Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-22

Service Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

Fault/Symptom Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

Acquisition PCB Symptoms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-25

Processor PCB Symptoms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-25

Troubleshooting Software Updates - Problems and Solutions . . . . . . . .5-26

Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-29

Revision A Dash 3000/4000 Patient Monitor iii

2000966-035

Page 6

CONTENTS:

6 CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

Loading Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

Software Loading/Updating Methods . . . . . . . . . . . . . . . . . . . . . . . . .6-3

Software Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Monitor Software Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Maintain Patient Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Problems While Loading Software . . . . . . . . . . . . . . . . . . . . . . . . . . .6-6

Record Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Load Software From Diskette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

About the Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-7

Connect the PC to the Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-7

Software Diskettes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-8

Update Program Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-9

Setup Monitor To Accept Download Files . . . . . . . . . . . . . . . . . . . .6-11

Download Files to the Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-12

Load Software Over The Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-13

About the Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-13

Network Update Diskettes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

Copy Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

Download Files to the Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-15

Complete the Software Download . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

Activate Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

Configuring a Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-19

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

Main Menu Selections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-21

Set Unit Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-21

Set Bed Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-21

Patient-Monitor Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-22

Set Graph Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-23

Admit Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-24

Boot Code Selections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-25

Set Defib Sync Voltage and Pulse Width . . . . . . . . . . . . . . . . . . . . .6-25

Set Line Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-25

Set CIC and QS Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-25

Set MUSE Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-26

Transcutaneous Pace Blank Length . . . . . . . . . . . . . . . . . . . . . . . . 6-26

Set Country Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-27

Wireless LAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-27

Completion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-27

Advanced User Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-28

Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-28

Set Time and Date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-28

Change Software Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-29

Change Ethernet Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-30

Review Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-30

Transferring Error Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-34

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-34

Access the COPY LOGS Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-35

Select the Care Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-35

Select the Monitoring Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-35

iv Dash 3000/4000 Patient Monitor Revision A

2000966-035

Page 7

CONTENTS:

Select the Error Log Date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-36

Copy Error Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-36

Eject Floppy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-36

7 CALIBRATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Hardware Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

NBP, ECG, BP, and End-tidal CO2 Software Calibration . . . . . . . . . . . . . 7-4

NBP Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

ECG or BP Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-7

End-tidal CO2 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

8 FIELD REPLACEABLE UNITS AND UPGRADES . . . . . . . . . . . . . . . . . . 8-1

Disassembly Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-3

Before Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-3

Hardware Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

PCB Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-3

After Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-5

Handle Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-7

Removing the Handle Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-7

Replacing or Upgrading the Dash 3000 Alarm Light Option . . . . . . .8-8

Display Assembly Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

Removing the Display Assembly from the Main Unit . . . . . . . . . . . . . 8-9

Replacing the Backlight Inverter PCB . . . . . . . . . . . . . . . . . . . . . . .8-13

Replacing the Key Pad Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . 8-14

Replacing the LCD Color Display . . . . . . . . . . . . . . . . . . . . . . . . . . .8-15

Replacing or Upgrading the Dash 4000 Alarm Light Option . . . . . .8-16

Replacing the Dash 4000 Front Panel PCB . . . . . . . . . . . . . . . . . . .8-17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-17

Main Unit Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

DAS and NBP Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-18

Main and/or Power Supply Assemblies, Speaker or

RF LAN Upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-21

Processor/Power Management PCB and Battery Assembly . . . . . .8-22

Power Supply Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-24

Speaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-25

RF LAN Upgrade Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-26

Optional DDW Writer Replacement/Upgrade . . . . . . . . . . . . . . . . . . . . .8-36

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-36

Upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-36

Revision A Dash 3000/4000 Patient Monitor v

2000966-035

Page 8

CONTENTS:

9 ASSEMBLY DRAWINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

Theory Of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-4

General Monitor Block Theory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-5

Overall Monitor Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-5

User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-8

Data Acquisition System (DAS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-8

Processor/Power Management Subsystem . . . . . . . . . . . . . . . . . . . 9-13

Optional Thermal Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-20

Speaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-20

Handle Subassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-20

Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-20

Setup and Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-21

Electrical Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-22

Dash 3000 Exploded Views, PN 420000-xxx . . . . . . . . . . . . . . . . . . . . . 9-23

Dash 3000 Display Bezel Assembly, PN 419031-001 . . . . . . . . . . . . . .9-28

Dash 3000 Display Bezel Parts List, PN 419031-001 . . . . . . . . . . . . . . 9-29

Dash 3000 Display Bezel Part List , PN 419031-003 . . . . . . . . . . . . . . . 9-31

Dash 4000 Parts List PN 2004323-xxx . . . . . . . . . . . . . . . . . . . . . . . . . . 9-34

Dash 4000 Display Assembly, PN 2004272-001 . . . . . . . . . . . . . . . . . . 9-36

Dash 4000 Display Bezel Parts List, PN 2004272-001 . . . . . . . . . . . . . 9-37

Field Replaceable Units (FRU’s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-38

Dash 3000 FRUs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-38

Dash 4000 FRUs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-38

Port Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-40

Invasive Blood Pressure Cable Connector . . . . . . . . . . . . . . . . . . . . 9-40

Pulse Oximetry (SpO2) Cable Connector . . . . . . . . . . . . . . . . . . . . 9-41

Temperature/CO Cable Connector . . . . . . . . . . . . . . . . . . . . . . . . . 9-41

Capnostat III (CO2) Cable Connector . . . . . . . . . . . . . . . . . . . . . . . 9-42

NBP Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-43

ECG Cable Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-43

Input Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-44

Network Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-44

Auxiliary Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-45

Defib Sync . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-45

Peripheral Expansion Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-46

vi Dash 3000/4000 Patient Monitor Revision A

2000966-035

Page 9

1 INTRODUCTION

Revision A Dash 3000/4000 Patient Monitor 1-1

2000966-035

Page 10

For your notes

INTRODUCTION:

1-2 Dash 3000/4000 Patient Monitor Revision A

2000966-035

Page 11

INTRODUCTION: Manual Information

Manual Information

Revision History

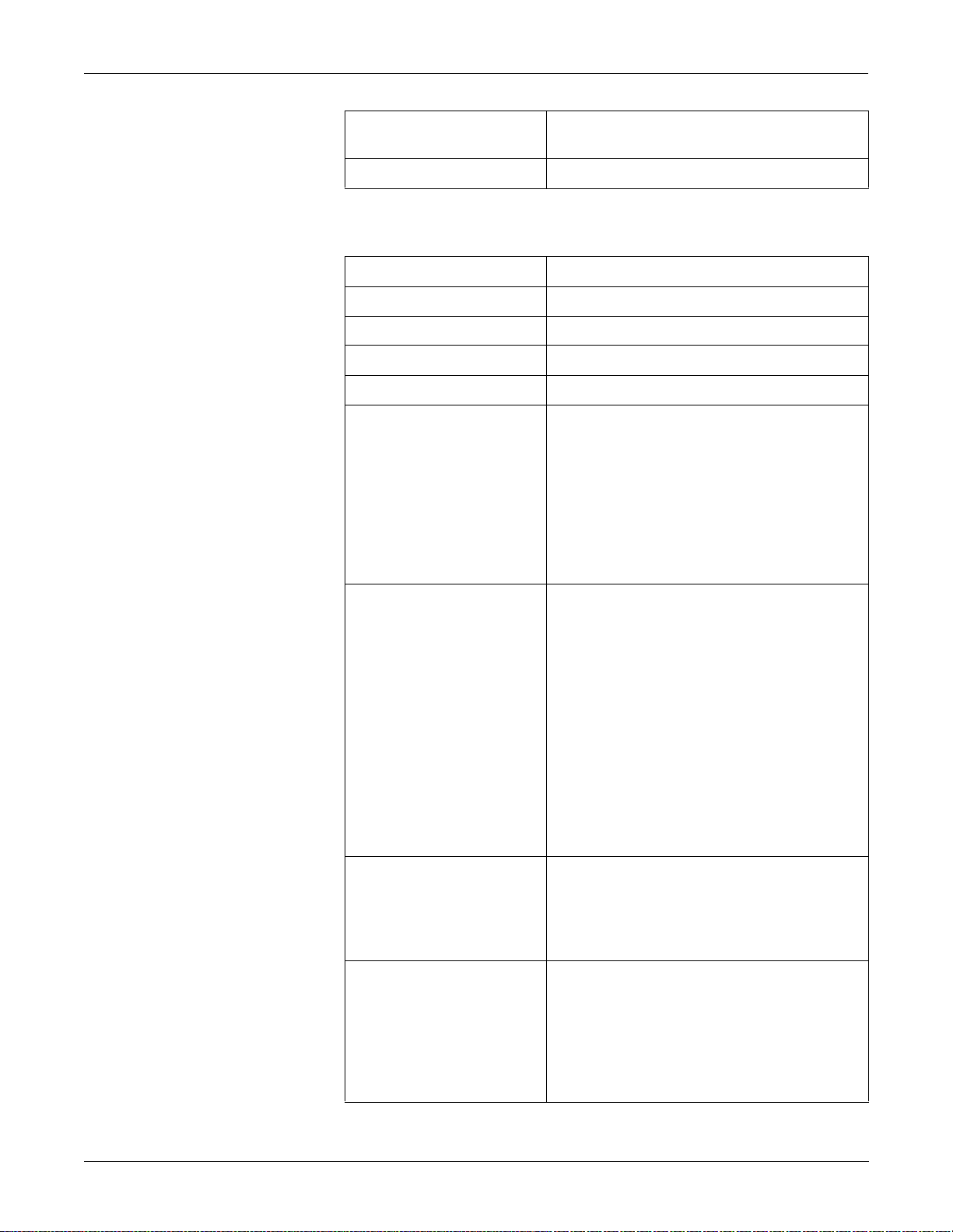

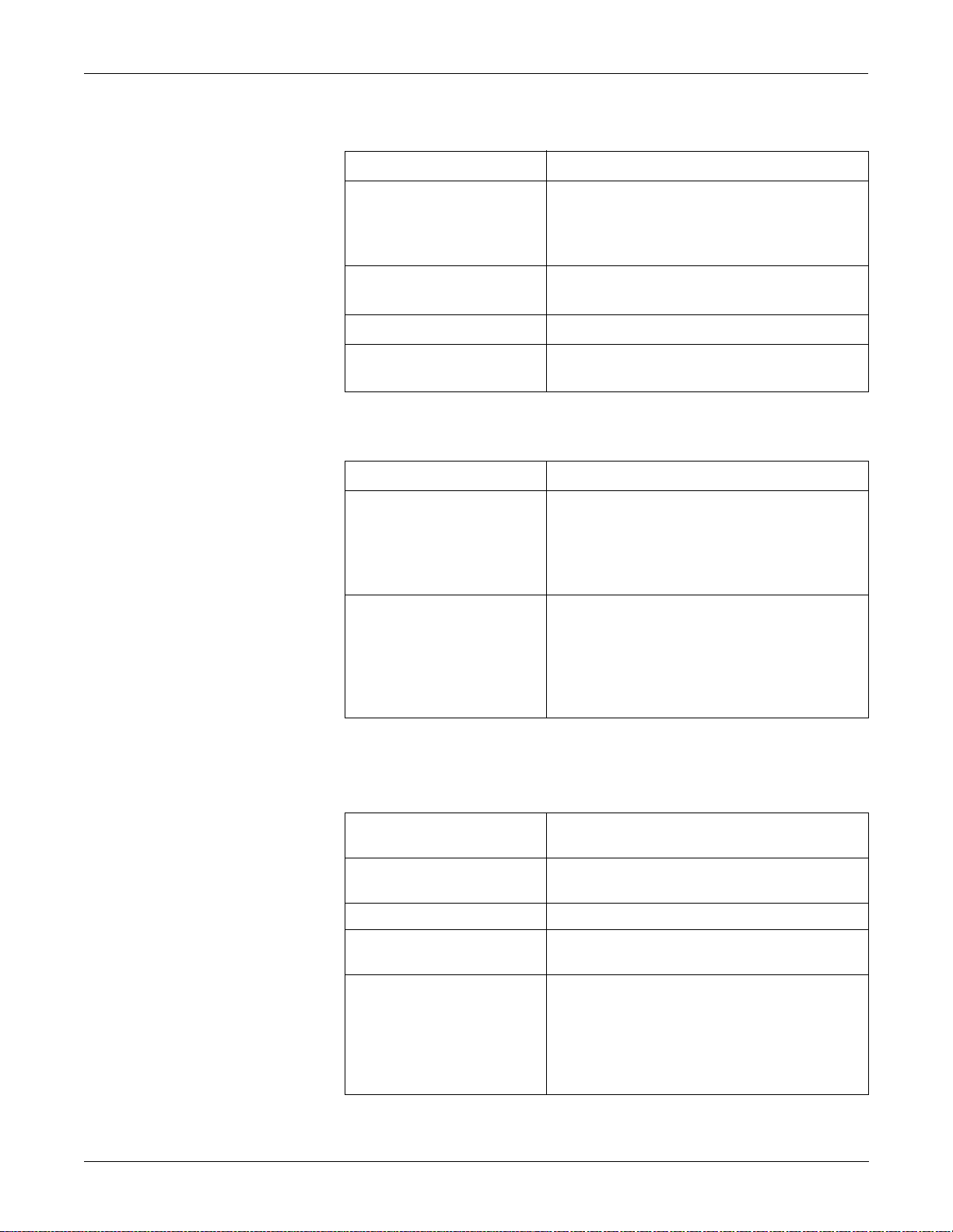

Revision Date Comment

A 27 November 2000 Initial release of this manual.

Manual Purpose

Intended Audience

Each page of this manual has the document part number and revision

letter at the bottom of the page. The revision letter identifies the

document’s update level. The revision history of this document is

summarized below.

Revision History

This manual supplies technical information for service representatives

and technical personnel so they can maintain the equipment to the

assembly level. Use it as a guide for maintenance and electrical repairs

considered field repairable. Where necessary the manual identifies

additional sources of relevant information and technical assistance.

See the operator’s manual for the instructions necessary to operate the

equipment safely in accordance with its function and intended use.

This manual is intended for service representatives and technical

personnel who maintain, troubleshoot, or repair this equipment.

Revision A Dash 3000/4000 Patient Monitor 1-3

2000966-035

Page 12

Safety Information

INTRODUCTION: Safety Information

Responsibility of the Manufacturer

General

GE Medical Systems Information Technologies is responsible for the

effects of safety, reliability, and performance only if:

• Assembly operations, extensions, readjustments, modifications, or

repairs are carried out by persons authorized by GE Medical Systems

Information Technologies.

• The electrical installation of the relevant room complies with the

requirements of the appropriate regulations.

• The equipment is used in accordance with the instructions for use.

This device is intended for use under the direct supervision of a licensed

health care practitioner.

This device is not intended for home use.

Federal law restricts this device to be sold by or on the order of a

physician.

Contact GE Medical Systems Information Technologies for information

before connecting any devices to the equipment that are not

recommended in this manual.

Parts and accessories used must meet the requirements of the applicable

IEC 601 series safety standards, and/or the system configuration must

meet the requirements of the IEC 60601-1-1 medical electrical systems

standard.

Periodically, and whenever the integrity of the device is in doubt, test all

functions.

The use of ACCESSORY equipment not complying with the equivalent

safety requirements of this equipment may lead to a reduced level of

safety of the resulting system. Consideration relating to the choice shall

include:

• use of the accessory in the PATIENT VICINITY; and

• evidence that the safety certification of the ACCESSORY has been

performed in accordance to the appropriate IEC 60601-1 and/or IEC

60601-1-1 harmonized national standard.

If the installation of the equipment, in the USA, will use 240V rather

than 120V, the source must be a center-tapped, 240V, single-phase

circuit.

1-4 Dash 3000/4000 Patient Monitor Revision A

2000966-035

Page 13

INTRODUCTION: Safety Information

Warnings, Cautions, and Notes

The terms danger, warning, and caution are used throughout this

manual to point out hazards and to designate a degree or level or

seriousness. Familiarize yourself with their definitions and significance.

Hazard is defined as a source of potential injury to a person.

DANGER indicates an imminent hazard which, if not avoided, will

result in death or serious injury.

WARNING indicates a potential hazard or unsafe practice which, if not

avoided, could result in death or serious injury.

CAUTION indicates a potential hazard or unsafe practice which, if not

avoided, could result in minor personal injury or product/property

damage.

NOTE provides application tips or other useful information to assure

that you get the most from your equipment.

Revision A Dash 3000/4000 Patient Monitor 1-5

2000966-035

Page 14

INTRODUCTION: Safety Information

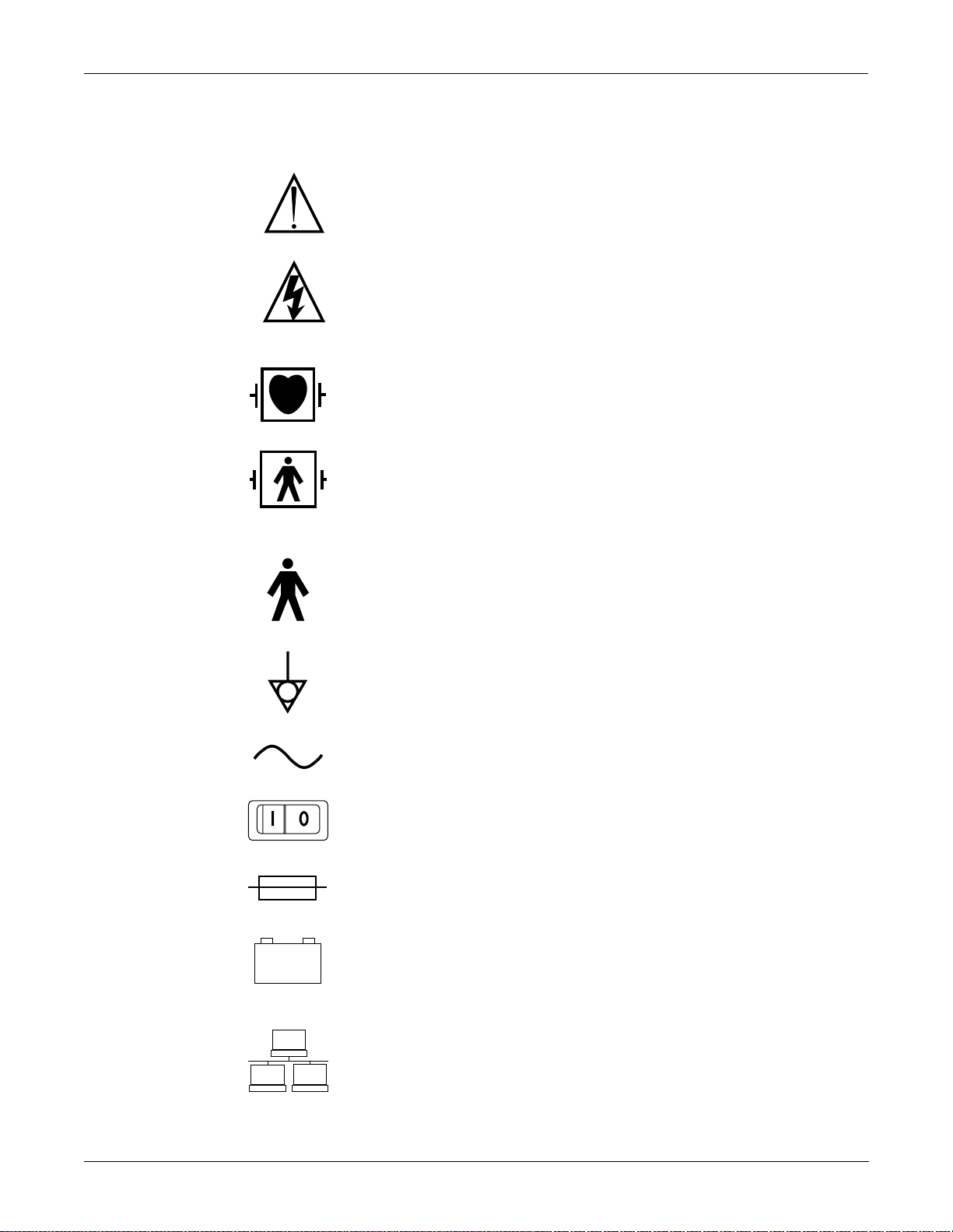

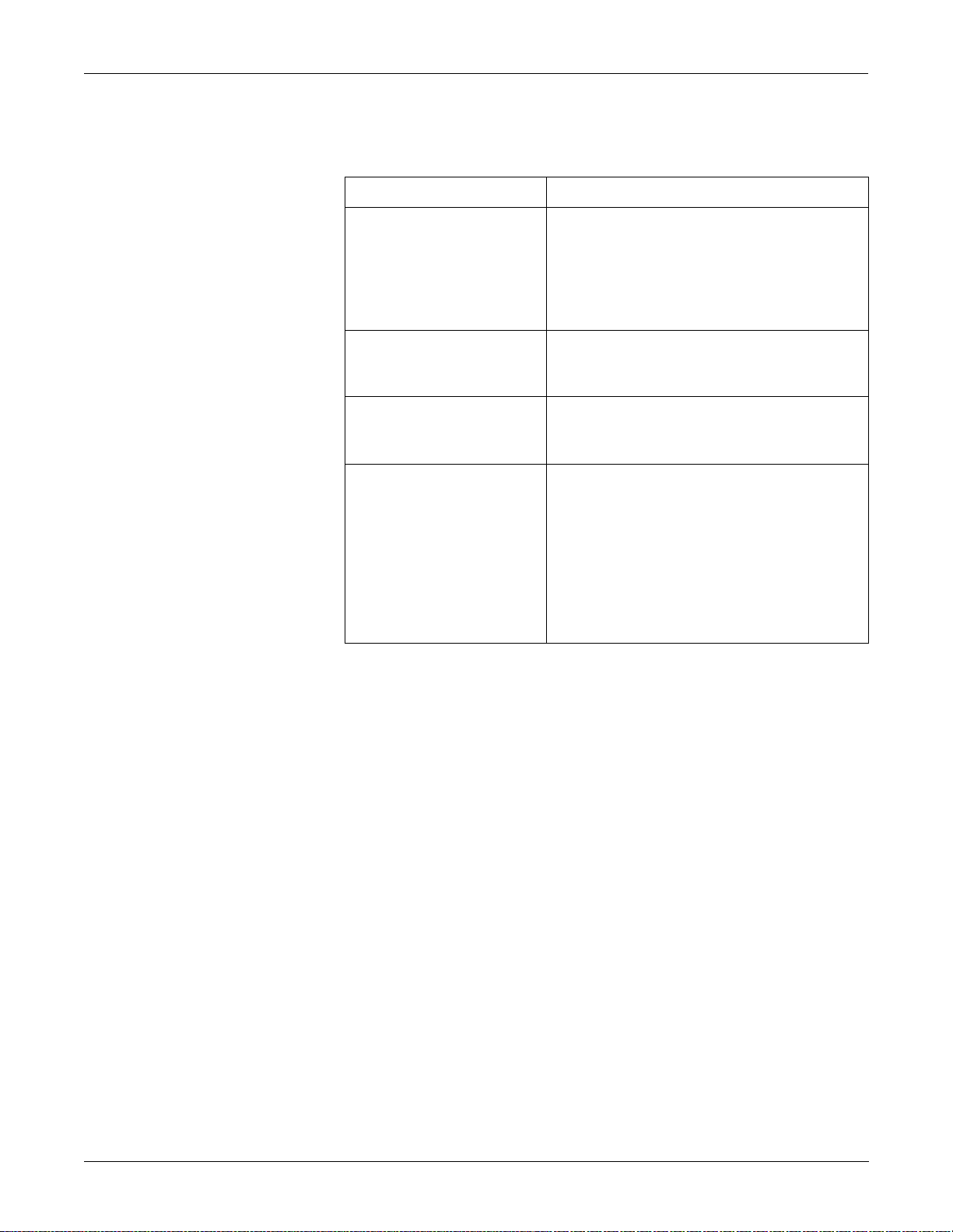

Equipment Symbols

Some of the following symbols appear on the equipment.

ATTENTION: Consult accompanying documents before using the

equipment.

In Europe, this symbol means dangerous or high voltage. In the United

States, this symbol represents the caution notice below:

To reduce the risk of electric shock, do NOT remove cover (or back).

Refer servicing to qualified personnel.

Defibrillator-proof type CF equipment; type CF equipment is

specifically designed for applications where a conductive connection

directly to the heart is established. The paddles indicate the equipment

is defibrillator proof.

Defibrillator-proof type BF equipment; type BF equipment is suitable

for intentional external and internal application to the patient,

excluding direct cardiac application. Type BF equipment is type B

equipment with an F-type isolated (floating) part. The paddles indicate

the equipment is defibrillator proof.

Type B equipment; type B equipment is suitable for intentional

external and internal application to the patient, excluding direct

cardiac application.

Equipotentiality

Alternating current (AC)

Power;

Fuse

Battery

Indicates the Ethernet connection for the monitor.

I = ON; O= OFF

1-6 Dash 3000/4000 Patient Monitor Revision A

2000966-035

Page 15

INTRODUCTION: Safety Information

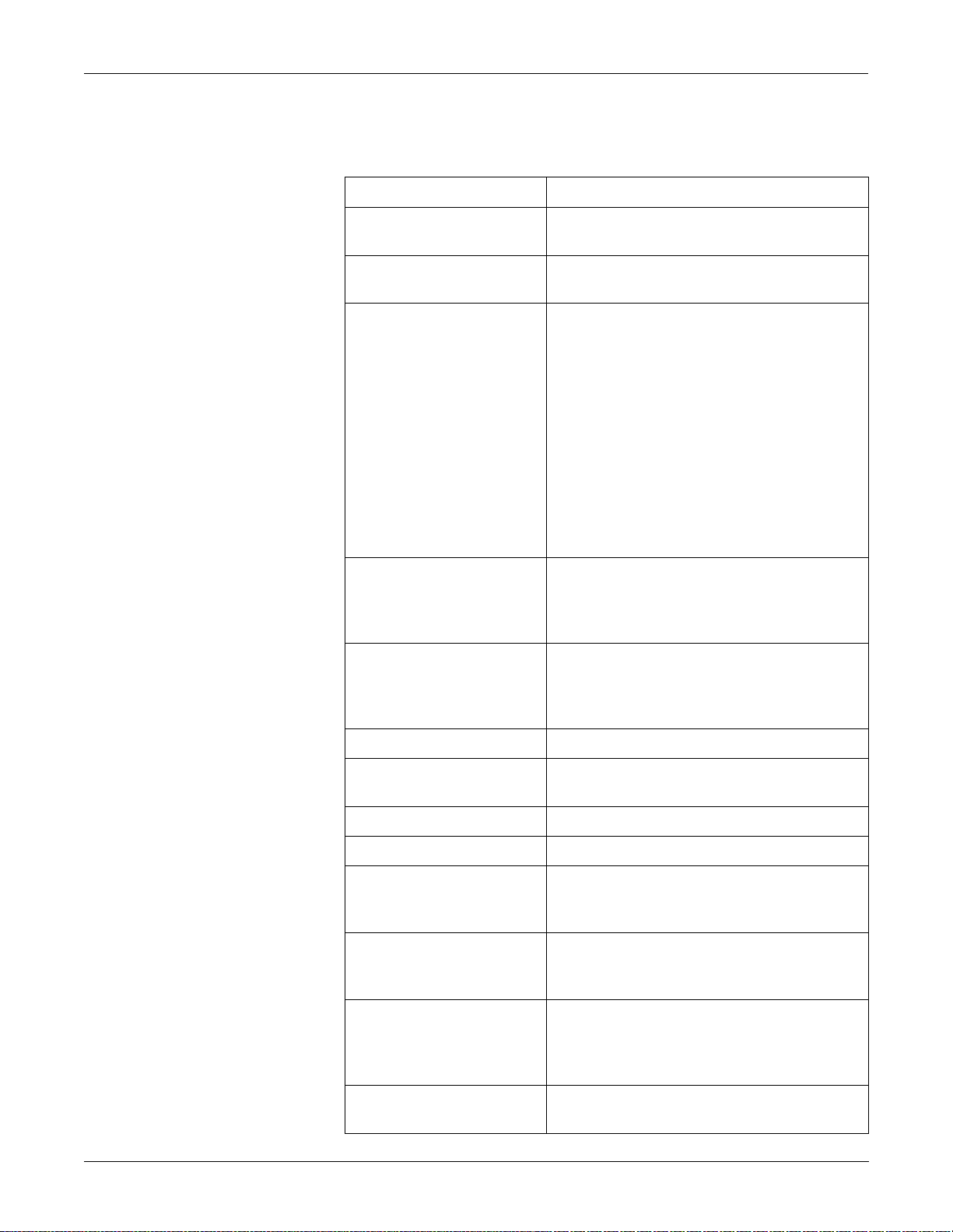

PRESS

814A

815A

816A

817A

818A

Press to open.

Power

Graph Go/Stop

NBP Go/Stop

Function

Silence Alarm

Classified by Underwriters Laboratories Inc. with respect to electric

shock, fire, mechanical and other specified hazards, only in accordance

with UL 2601-1, CAN/CSA C22.2 No. 601.1, IEC 60601-1, and, if

required, IEC 60601-2-27, IEC 60601-2-30, IEC 60601-2-34, IEC 606011-1.

Revision A Dash 3000/4000 Patient Monitor 1-7

2000966-035

Page 16

INTRODUCTION: Service Information

Service Information

Service Requirements

Equipment Identification

Follow the service requirements listed below.

• Refer equipment servicing to GE Medical Systems Information

Technologies’ authorized service personnel only.

• Any unauthorized attempt to repair equipment under warranty voids

that warranty.

• It is the user’s responsibility to report the need for service to GE

Medical Systems Information Technologies or to one of their

authorized agents.

• Failure on the part of the responsible individual, hospital, or

institution using this equipment to implement a satisfactory

maintenance schedule may cause undue equipment failure and

possible health hazards.

• Regular maintenance, irrespective of usage, is essential to ensure

that the equipment will always be functional when required.

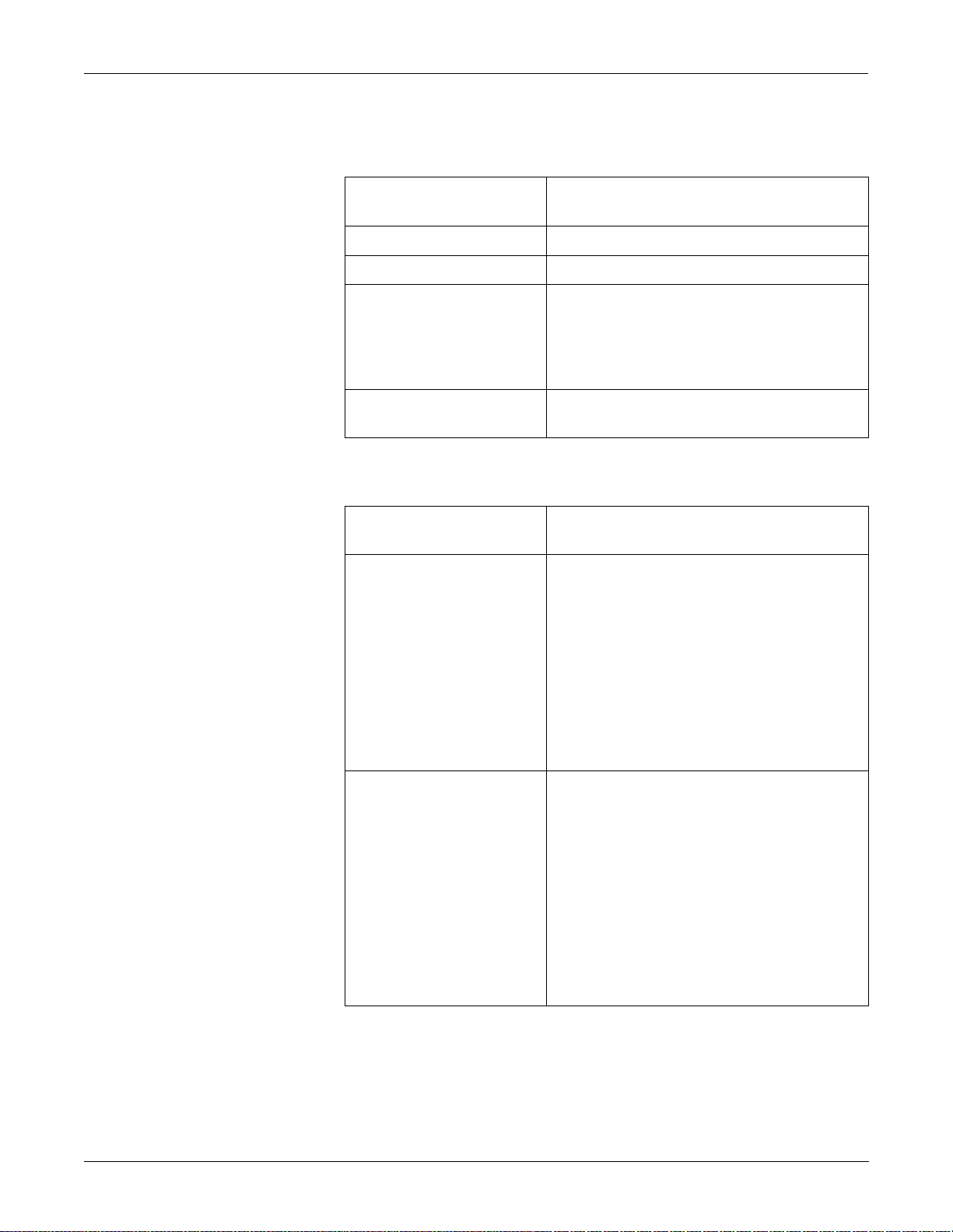

Every GE Medical Systems Information Technologies device has a unique

serial number for identification. A sample of the information found on a

serial number label is shown below.

D 0 XX 0005 G XX

Month

Manufactured

A = January

B = February

C = March

D = April

E = May

F = June

G = July

H = August

J = September

K = October

L = November

M = December

Year

Manufactured

0 = 2000

1 = 2001

2 = 2002

(and so on)

Product Code

Two-character

product

descriptor

Product

Sequence

Number

Manufacturing

number (of total

units

manufactured)

Division

F = Cardiology

G = Monitoring

Device Characteristics

One or two letters that

further describe the unit,

for example:

P = prototype not

conforming to marketing

specification

R = refurbished equipment

S = special product

documented under Specials

part numbers

U = upgraded unit

1-8 Dash 3000/4000 Patient Monitor Revision A

2000966-035

Page 17

2 EQUIPMENT OVERVIEW

Revision A Dash 3000/4000 Patient Monitor 2-1

2000966-035

Page 18

For your notes

EQUIPMENT OVERVI EW:

2-2 Dash 3000/4000 Patient Monitor Revision A

2000966-035

Page 19

Components

EQUIPMENT OVERVIEW: Components

The Monitoring System

The Patient Monitor

The Dash 3000/4000 patient monitor can function by itself with a built-in

writer, or it can be cabled in with the Unity Network via Ethernet.

Optional components are, if using Wireless LAN or cabled to Ethernet, a

Centralscope central station and the Clinical Information Center.

This device is designed to monitor a fixed set of parameters including

ECG, noninvasive blood pressure, impedance respiration, SpO2, and

temperature. Invasive pressure and EtCO2 are optional features.

Additional specialized features include cardiac output, cardiac

calculations, pulmonary calculations, dose calculations, PA wedge (PA

wedge is only available with the invasive pressure option), and SAM

module interface.

001A

Dash 3000 Monitor

Revision A Dash 3000/4000 Patient Monitor 2-3

2000966-035

Dash 4000 Monitor

051A

Page 20

EQUIPMENT OVERVIEW: Components

Right Side View

Left Side View

All of the patient cable connectors are located on the right side of the

monitor. A Trim Knob control provides single control operation of

virtually all monitor functions.

Patient Cable

Connectors

002A

On the left of the monitor, you can find the built-in writer and the

battery compartment.

Optional Built-in Writer—

The built-in, 4 channel

writer is located in the

center of the left side of the

monitor .

Battery Compartment—

The battery packs are

located in this

compartment.

003A

2-4 Dash 3000/4000 Patient Monitor Revision A

2000966-035

Page 21

EQUIPMENT OVERVIEW: Components

Back Vie w

Network Connector—A cable

can be connected to this port

for monitors used in patient

monitoring network

configurations.

Equipotential Terminal—For

measurements in or near the heart

we recommend connecting the

monitor to the potential

equalization system. U se the

green and yellow potential

equalization cable and connect it

to this pin.

AC Power Connector

On the back of the monitor you will find all connectors for equipment and

network.

Line V oltage Selector—This s elector

is factory set to match the line

voltage and frequency rating for

your country.

Audible Alarm Enunciator—The

internal speaker provides sound

for audible alarms. For better

sound quality do not block

speaker.

Aux Port—Used for

RAC 2A and software

updates.

Defib Sync Connector—Provides

ECG analog output signals to

004A

Peripheral Expansion Port

user-supplied equipment. A 5volt, 2-millisecond artificial pacer

spike is added to the analog

output when PACE is on and

detection occurs.

Optional Alarm Indicator

An optional alarm indicator can be built into the handle of the Dash 3000

monitor or into the display bezel of the Dash 4000 monitor. When

activated, the LED indicator flashes red for CRISIS and WARNING

patient status alarms and yellow for all other alarms.

Alarm Indicator

Dash 3000 Monitor

Revision A Dash 3000/4000 Patient Monitor 2-5

2000966-035

Dash 4000 Monitor

052A

Page 22

EQUIPMENT OVERVIEW: Components

Optional RAC 2A Module Housing

The RAC 2A module housing currently supports the SAM module.

006A

An integral power supply is used to run the RAC 2A and support the

needed voltages.

2-6 Dash 3000/4000 Patient Monitor Revision A

2000966-035

Page 23

EQUIPMENT OVERVIEW: Components

Optional Wireless LAN System

Access Points

The flexibility of the GE Medical Systems Information Technologies

Unity Network is increased by using the Wireless LAN system. The

Wireless LAN system allows the user to roam from one access point to

another, maintaining a strong, seamless connection to the Unity

network.

The monitor, with its optional built-in Wireless LAN, functionally

performs the same as a monitor connected directly to the Unity network.

It can be viewed at the central station and by other GE Medical Systems

Information Technologies’ monitors on the network (i.e. Dash 3000/4000,

Eagle 4000, and Solar patient monitors). Monitors with Wireless LAN

sends and receives patient data via the access points of the Unity

network.

NOTE: Wireless patient monitors that are moved from room to room

must have the monitor type configured as Rover or Rover/Combo

monitoring.

To integrate the wireless network with the wired network, one or more

access points are necessary. An access point connects the wireless

monitor to the wired network infrastructure within the building, and

acts as a bridge between the wired and wireless networks. The areas

covered by each access point overlap to insure continuous coverage.

NOTE: The monitor will only work with a Symbol Access Point. The

monitor will not communicate directly with a Wireless LAN

device from Aironet.

050A

Revision A Dash 3000/4000 Patient Monitor 2-7

2000966-035

Page 24

EQUIPMENT OVERVIEW: Technical Specifications

Technical Specifications

Due to continual product innovation, specifications are subject to change

without notice. The following specifications are accurate as of the date of

this publication, and pertain to the Dash 3000/4000 Patient Monitor.

Performance Specifications

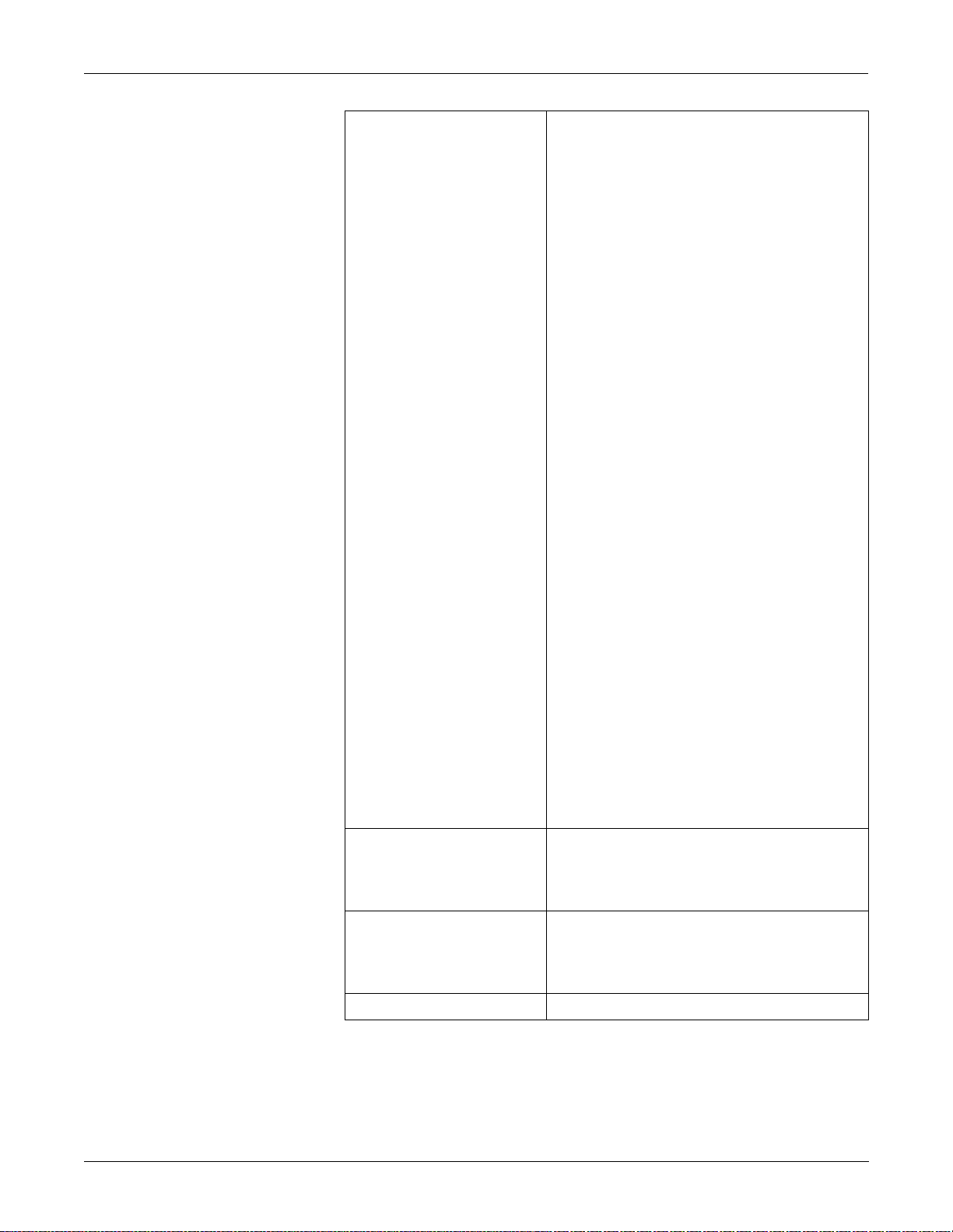

Display

Size:

Type:

Color: Active-Matrix Liquid Crystal Display (LCD)

Resolution: 640 by 480 pixels

Dash 3000:

Dash 4000:

8.4-inch diagonal

10.4-inch diagonal

Controls

Alarms

Number of traces: 6 (maximum)

Number of seconds/trace:

Dash 3000:

Dash 4000:

Sweep speed:

All waveforms 6.25, 12.5 or 25 mm/sec (with erase bar)

Waveform display options: Individual 6 waveforms, individual 3 waveforms, full,

Information window: Displays non-real-time information without obstructing

Display organization: Prioritized by parameter

Standard: Trim Knob control plus 5 hard keys: Power, NBP Go/

Categories: Patient Status and System Status

4.9 at 25 mm/sec

5.9 at 25 mm/sec

and full grid modes

the display of real-time information

Stop, Function, Silence Alarm, and Graph Go/Stop

Priorities: 4 levels — Crisis, Warning, Advisory, and Message

Notification: Audible and visual

Setting: Default and individual

Silencing: 1 minute, current alarm only

2-8 Dash 3000/4000 Patient Monitor Revision A

2000966-035

Page 25

ECG

EQUIPMENT OVERVIEW: Technical Specifications

Pause: 5 minutes (adult); 3 minutes (neonatal); 5, 15 minutes,

permanent (OR mode)

Volume: Default 70%, 70 dB measured at 1 meter

5 Leadwire cable: I, II, III, V, aVR, aVL, and aVF

10 Leadwire cable (12SL option): V2, V3, V4, V5 and V6

Leads analyzed simultaneously: I, II, III, and V (multi-lead mode)

Lead fail: Identifies failed lead

Alarms: User-selectable upper and lower heart rate limits

Input specifications:

Voltage range:

Signal width:

Heart rate range:

Accuracy:

Input impedance:

Common mode:

Differential:

Common mode rejection:

±0.5 mV to ±5 mV

40 ms to 120 ms (Q to S)

30 to 300 BPM

±1% or ±1 BPM, whichever is greater

>10 M

Ω

at 50/60 Hz

>2.5 M

Ω

from dc to 60 Hz

90dB minimum at 50 Hz or 60 Hz

Output specifications:

Frequency response:

Display:

Diagnostic:

Monitoring:

Moderate:

Maximum:

Paper Recorder:

Diagnostic:

Monitoring:

Moderate:

Maximum:

Linearity deviation:

Noise:

ST segment measurement:

Measurement point:

Measurement range:

Measurement accuracy:

Pacemaker detection/rejection:

Input voltage range:

Input pulse width:

Rise time:

Over/under shoot:

Baseline drift:

0.05 to 40 Hz

0.05 to 40 Hz

0.05 to 25 Hz

5 to 25 Hz

0.05 to 100 Hz

0.05 to 40 Hz

0.05 to 25 Hz

5 to 25 Hz

±3% (maximum)

<30 µV (referred to input)

Adjustable from 0 to 120 ms past the J-point

(default: 60 ms adult, 30 ms neonatal)

–12.0 to +12.0 mm

±10% or 0.5 mm, whichever is greater

±2 mV to ±700 mV

0.1 ms to 2 ms

10 µs to 100 µs

2 mV (max)

<0.5 mV/hour with a ±700-mV, 2-ms pacemaker pulse

applied

Revision A Dash 3000/4000 Patient Monitor 2-9

2000966-035

Page 26

Invasive Blood Pressure (BP)

EQUIPMENT OVERVIEW: Technical Specifications

Number of channels: 2

Transducer sites: Arterial (ART), femoral artery (FEM), pulmonary artery

(PA), central venous (CVP), right atrial (RA), left atrial

(LA), intracranial (ICP), and special (SP)

In neonatal mode: umbilical artery catheter (UAC) and

umbilical venous catheter (UVC)

Transducer requirements:

Excitation voltage:

Transducer output:

Input specifications:

Range:

Offset:

Output specifications:

Frequency response:

Zero balance range:

Zero balance accuracy:

Zero balance drift:

Accuracy:

Alarms:

5.0 Vdc ±0.1%

5 µV/V/mmHg

–25 mmHg to 300 mmHg

±150 mmHg

dc to 50 Hz

±150 mmHg

±1 mmHg

±1 mmHg over 24 hours

±2% or ±1 mmHg, whichever is greater (exclusive of

transducer)

User-selectable upper and lower limits for systolic,

diastolic, and mean pressures

2-10 Dash 3000/4000 Patient Monitor Revision A

2000966-035

Page 27

EQUIPMENT OVERVIEW: Technical Specifications

Noninvasive Blood Pressure (NBP)

Measurement technique: Oscillometric

Displayed parameters: Systolic, diastolic, and mean pressures, pulse rate, time

of last measurement

Measurement modes: Manual, auto, and stat in adult and OR modes; manual

and auto in neonatal mode

NBP pressure range:

Systolic pressure range

Adult:

Pediatric:

Neonatal:

Diastolic pressure range

Adult:

Pediatric:

Neonatal:

Mean pressure range

Adult:

Pediatric:

Neonatal:

30 to 275 mmHg

30 to 235 mmHg

30 to 135 mmHg

10 to 220 mmHg

10 to 220 mmHg

10 to 110 mmHg

20 to 260 mmHg

20 to 260 mmHg

20 to 125 mmHg

Cuff pressure range:

Adult:

Pediatric:

Neonatal:

Pressure accuracy:

Static:

Clinical:

Heart rate detection: 30 to 200 beats per minute

Total cycle time: 20 to 40 seconds typical (dependent on heart rate and

Automatic cycle times: 0 to 8 hours

Auto zero: Zero pressure reference prior to each cuff inflation

Tubing length:

Adult:

Neonatal:

Automatic cuff deflation: Cycle time exceeding 3 minutes (90 seconds neonatal),

Cuff sizes:

Disposable:

Reusable:

0 to 275 mmHg

0 to 235 mmHg

0 to 135 mmHg

±2% or ±3 mmHg, whichever is greater

±5 mmHg average error

8 mmHg standard deviation

motion artifact)

12 feet

8 feet

power off, or cuff pressure exceeds 294 mmHg (±6

mmHg) adult, 147 mmHg (±3 mmHg) neonatal

Large adult, adult, small adult, pediatric, small pediatric,

and infant

Thigh, large adult, adult, child, and infant

Alarms: User-selectable upper and lower limits for systolic,

diastolic, and mean pressures

Revision A Dash 3000/4000 Patient Monitor 2-11

2000966-035

Page 28

Pulse Oximetry (SPO2)

EQUIPMENT OVERVIEW: Technical Specifications

Parameters monitored: Arterial oxygen saturation (SpO2) and peripheral pulse

rate (PPR)

SpO2 range: 50 - 100%

PPR range: 30 - 300 beats per minute

Cardiac Output (CO)

Accuracy:

SpO2:

PPR:

Alarms: User-selectable upper and lower limits for SpO2 and

Availability: Included in 7020 and 7025 software packages. Not

Input specifications:

Probe type:

Catheter manufacturers:

Catheter sizes:

Abbott catheter sizes:

Arrow catheter sizes:

Baxter catheter sizes:

Ohmeda catheter sizes:

Other catheter sizes:

Injectate volume:

Actual accuracy depends on probe. Please reference

manufacturer’s specifications.

± 2% (70 - 100% SpO2) ±1 standard deviation

± 3% (50 - 69% SpO2) ±1 standard deviation

± 3 beats per minute

PPR

available in 7015 software package.

In-line or bath probe

Abbott, Arrow, Baxter, Ohmeda, or other

5.5F (75 cm), 7F (85 cm), 7.5F (110 cm), and

8F (110 cm)

5, 6, 7, or 7.5F

5, 6, 7, 7.5 or 8F

5, 7, or 7.5F

Cardiac coefficient entered manually

3, 5, or 10 cc

Output specifications:

Parameters displayed:

Range:

Cardiac output:

Blood temperature:

Injectate temperature:

Accuracy:

Cardiac output:

Blood temperature:

Injectate temperature:

Frequency response:

2-12 Dash 3000/4000 Patient Monitor Revision A

2000966-035

Cardiac output, blood temperature, injectate

temperature, trial number

0.2 - 15 liters per minute

30 - 42°C

0 - 30°C

±5% (liters of blood/min)

±0.2°C

±0.3°C

dc to 15 Hz ±2 Hz

Page 29

EQUIPMENT OVERVIEW: Technical Specifications

Respiration

Temperature (TEMP)

Measurement technique: Impedance variation detection

Range:

Respiration rate:

Base impedance:

Detection sensitivity:

Accuracy:

Respiration rate ±1 BrPM

Waveform display bandwidth: 0.1 to 1.8 Hz (–3 dB)

Alarms: User-selectable upper and lower respiration rate limits,

Number of channels: 2

Input specifications:

Probe type:

Temperature range:

Resolution:

0 - 200 breaths per minute

100 - 1000

0.4 to 10

and user-selectable apnea limit

YSI Series 400 or 700 thermistor (determined by input

cable)

0°C to 45°C (32°F to 113°F)

±0.1°C

Ω

at 52.6 kHz excitation frequency

Ω

variation

Carbon Dioxide (CO2)

Output specifications:

Parameters displayed:

Accuracy:

Alarms:

Information displayed: Inspired and expi red car bon diox ide co ncen tra tion s in %,

Measurement technique: Non-dispersive infrared absorption, dual wavelength

Sensor type: Novametrix Medical Systems’ Capnostat III

Patient interface: Compatible with Novametrix Medical Systems’

Airway adaptors

Types:

Dead space/chamber volumes:

Adult reusable:

Adult disposable:

Neonatal:

T1, T2

(independent of source)

±0.1°C for YSI series 400 probes;

±0.3°C for YSI series 700 probes

User-selectable upper and lower limits for T1, T2

mmHg or kPa, respiration rate, continuous CO2 wavef orm

ratiometric

Capnogard monitoring product

Adult reusable (standard), adult disposable, neonatal

<5 cc

<5 cc

<0.5 cc

Revision A Dash 3000/4000 Patient Monitor 2-13

2000966-035

Page 30

EQUIPMENT OVERVIEW: Technical Specifications

CO2 measurement specifications:

Measurement range:

Pi CO2/Fi CO2:

Pe CO2/Fe CO2:

RR:

Accuracy:

Display update interval:

CO2 waveform sweep speed:

CO2 averaging:

CO2 measurement stability:

Resolution:

Noise:

0 to 100 mmHg/0 to 13%

0 to 100 mmHg/0 to 13%

0 to 120 breaths/min

±5% of reading or ±2 mmHg, whichever is greater

2 sec

Selectable 6.25, 12.5, or 25 mm/sec

Selectable from single breath, 10 sec, or 20 sec

Accuracy maintained over 8 hours

1 mmHg

2% of reading or 0.5 mmHg (maximum), whichever is

greater

60 Hz interference:

<0.5 mmHg at 38 mmHg

Step response time:

Adult:

Neonatal

<60 ms (10-90%)

<50 ms (10-90%)

Interference:

N2O gas:

±5% of reading or ±2 mmHg (maximum), whichever is

greater, with N2O compensation enabled

O2 gas:

±5% of reading or ±2 mmHg (maximum), whichever is

greater, with O2 compensation enabled

Barometric pressure:

Water vapor:

±2 mmHg (maximum) from 500 to 800 mmHg

±1.5% of reading or ±0.5 mmHg (maximum),

whichever is greater

Anesthetic agent:

±0.5 mmHg (maximum) for concentration of no more

than 5% of halogenated agents

Airway adapter variability:

±3% of reading or ±1.5 mmHg (maximum), whichever

is greater, with same or different adapter; not applicable

after adapter zero

Warm-up time:

Less than 15 seconds to initial CO2 indication, full

specification within 120 seconds; waveform immediate

upon power up

Calibration:

Factory settings:

Factory calibration settings stored in nonvolatile

memory within the sensor; 15 second adaptor

calibration when switching airway types

Verification:

Zero and span performance check with on-cable verifier

Respiration rate specifications:

Range (for 5% step size):

Accuracy:

Resolution:

0-120 breaths per minute

±1 breath per minute

±1 breath per minute

Barometric pressure sensor

specifications:

Range:

Accuracy:

425 to 817 mmHg (56 to 109 kPa)

±25 mmHg

Alarms: User-selectable upper and lower limits for CO2 and RR.

2-14 Dash 3000/4000 Patient Monitor Revision A

2000966-035

Page 31

Analog Output

Defibrillator Synchronization Pulse

EQUIPMENT OVERVIEW: Technical Specifications

ECG:

Gain:

DC offset:

Noise:

Frequency response:

Time delay:

Blood pressure:

Gain:

DC offset:

Noise:

Frequency response:

Time delay:

1 V/mV ±10%

±100 mV (max)

<5 mVp-p (0-300 Hz)

0.05 Hz to 100 Hz +7/–0 Hz

40 ms monitoring filter, 35 ms diagnostic filter

10 mV/mmHg ±2%

±20 mV (max)

<5 mVp-p (0-300 Hz)

dc to 50 Hz +2/–0 Hz

40 Hz filter, 37 ms

Marker out:

Time delay:

Amplitude (selectable in Service

menu):

+5 V selection:

+12 V selection:

Pulse width:

Output impedance:

Current limit:

Marker in:

Input threshold:

Input hysteresis:

Maximum input voltage:

Input impedance:

Pulse width:

35 ms (maximum), R-wave peak to leading edge of

pulse.

3.5 V (min) at 1 mA sourcing; 0.5 V (max) at 5 mA

sinking.

11.0 V (min) at 1 mA sourcing; 0.75 V (max) at 5 mA

sinking.

10 ms ±10% or 100 ms ±10% (selectable in Service

menu).

50

Ω

nominal

15 mA nominal, both sourcing and sinking.

V

= ±2.5 V (min); VIL = ±1.5 V (max)

IH

650 mV typical

±30 V (with respect to ground on pin 3)

10 k

Ω

(min) for -25 V < VIN < 25 V

1.0 ms (min), VIN > 2.5 V

Revision A Dash 3000/4000 Patient Monitor 2-15

2000966-035

Page 32

Battery

Paper Recorder

EQUIPMENT OVERVIEW: Technical Specifications

Battery type: Exchangeable Lithium-Ion

Number of batteries: 2

Battery weight: 0.36 kg (0.8 lbs) each

Voltage: 11.1 V (nominal)

Capacity: 3.9 Ah

Charge time: Less than 4 hours each

Run time: 4 to 5 hrs

Method: Thermal dot array

Horizontal resolution: 480 dots/in at 25 mm/sec

Vertical resolution: 200 dots/in

RF Wireless LAN

Number of waveform channels: 4

Paper width: 50 mm (1.97 in)

Paper length: 30 m (100 ft)

Paper speed: 0.1, 0.5, 1, 5, 10, 12.5, 25, and 50 mm/sec (± 2%)

Transmission technique: Frequency hopping spread spectrum

Frequency: Country dependent, specific settings received from

access point. Within 2400 to 2500 MHZ range.

Frequency hopping

characteristics:

Radio data rate: 1 and 2 Mbps

Radio output power: 160 mW (including antenna gain)

1 Mbps range: Open environment: over 850 ft. (260)

2 Mbps range: Open environment: over 425 ft. (130)

Country dependent, specific settings received from

access point. IEEE 802.11 compliant

Typical hospital environment: between 150 and 200 ft.

(45 to 60 m)

Typical hospital environment: between 100 and 150 ft.

(30 to 45 m)

Modulation: Binary GFSK

Applicable standards: US: FCC Part 15 Class B

Europe: ETS 300 328 and ETS 300 826

2-16 Dash 3000/4000 Patient Monitor Revision A

2000966-035

Page 33

Environmental Specifications

EQUIPMENT OVERVIEW: Technical Specifications

NOTE: The system may not meet its performance specifications if

stored or used outside the manufaturer’s specified temperature

and humidity range.

Power requirements:

90-132VAC

190-264 VAC

Power consumption: 75 watts (fully loaded)

Cooling: Convection

Heat dissipation: 240 Btu/hr (max)

Battery operation time:

General: Battery age will affect operating time.

Operating conditions:

Ambient temperature:

While charging batteries:

Capnostat III sensor

Relative humidity:

Vibration:

Altitude:

50/60 Hz 2.0A

50/60 Hz 1.0A

0 to 40°C (32 to 104°F)

0 to 35°C (32 to 95°F)

10° to 40° C (50° to 104°F)

5 to 95% at 40°C

MIL-STD 810E, Method 514.4, Category 1

-610 to 4, 570 m (-2,000 to 15,000 ft)

Physical Specifications

Storage conditions (Do not

exceed):

Maximum:

Minimum:

CO2 Sensor:

Batteries:

Equipment Type: Portable per IEC 60601-1

Height:

Dash 3000

Dash 4000

Width:

Dash 3000

Dash 4000

Depth:

Dash 3000

Dash 4000

Weight (without batteries)

Dash 3000

Dash 4000

70°C (158°F) at 95% relative humidity

–40°C (–40°F) at 15% relative humidity

–30 to 65°C (–22 to 149°F)

–20 to 60°C (–4 to 140°F)

26 cm (10.25 inches)

27.38 cm (10.78 inches)

28 cm (11.0 inches)

29.26 cm (11.5 inches)

20 cm (8 inches)

24.26 cm (9.55 inches)

5.08 kg (11.2 lbs)

5.53 kg (12.2 lbs)

Revision A Dash 3000/4000 Patient Monitor 2-17

2000966-035

Page 34

Certification

Safety

EQUIPMENT OVERVIEW: Technical Specifications

UL 2601-1 classified.

UL classified for CAN/CSA C22.2 No. 601.1

IEC 60601-1 and EN 60601-1 Certified

CE marking for Council Directive 93/42/EEC concerning medical devices

Radio and Telecommunication Terminal Equipment Directive

Electromagnetic Compatibility Compliance (EMC)

The Dash 3000/4000 system meets the requirements of EN 60601-1-2

(1993–04) Medical Electrical Equipment, Part 1: General Requirements

for Safety, 2. Collateral Standard: Electromagnetic compatibility—

Requirements and tests.

Exceptions

SpO2 Parameter — EN 60601-1-2 clause 36.202.1—IMMUNITY:

Radiated Immunity:

• The level of compliance is 1 volt per meter. If operating under the

conditions defined in EMC Standard EN60601-1-2 (Radiated

Immunity 3 volts per meter), field strength above 1 volt per meter

may cause waveform distortions and erroneous numeric data at

various electromagnetic interference (EMI) frequencies.

CO2 Parameter — EN 60601-1-2 clause 36.202.1—IMMUNITY:

Radiated Immunity:

• ‘The level of compliance is 1 volt per meter. If operating under the

conditions defined in EMC Standard EN60601-1-2 (Radiated

Immunity 3 volts per meter), field strength above 1 volt per meter

may cause waveform distortions and erroneous numeric data at

various electromagnetic interference (EMI) frequencies.

Recommendations

Review the AAMI EMC Committee technical information report (TIR-18)

titled Guidance on electromagnetic compatibility of medical devices for

clinical/biomedical engineers - Part 1: Radiated radio-frequency

electromagnetic energy. This TIR provides a means to evaluate and

manage the EMI environment in the hospital.

The following actions can be taken:

• managing (increasing) distance between sources of EMI and

susceptible devices.

• managing (removing) devices that are highly susceptible to EMI

• lower power from internal EMI sources under hospital control (i.e.

paging systems)

• labeling devices susceptible to EMI

• educate staff (nurses and doctors) to be aware of, and to recognize,

2-18 Dash 3000/4000 Patient Monitor Revision A

2000966-035

Page 35

Warranty

EQUIPMENT OVERVIEW: Technical Specifications

potential EMI related problems

Standard: One year. Other options are available. Contact your

sales representative for more information.

Revision A Dash 3000/4000 Patient Monitor 2-19

2000966-035

Page 36

EQUIPMENT OVERVIEW: Technical Specifications

2-20 Dash 3000/4000 Patient Monitor Revision A

2000966-035

Page 37

3 INSTALLATION

Revision A Dash 3000/4000 Patient Monitor 3-1

2000966-035

Page 38

For your notes

INSTALLATION:

3-2 Dash 3000/4000 Patient Monitor Revision A

2000966-035

Page 39

Connections

INSTALLATION: Connections

Back Panel Connections

ETHERNET

On the back of the monitor you will find all connectors for equipment and

network.

AC Power Connector

Aux Port

Defib Sync Connector

004A

Peripheral Expansion Port

ETHERNET

RAC 2A Housing Connectors

The ETHERNET connector provides an ANSI/IEEE 802.3 10BaseT

Ethernet standard interface to the Unity Network.

The RAC 2A module housing connects to the monitor via a standard

category 5 patch cable (PN 418335-002) which plugs into the AUX port

on the monitor and to the Auto Port on the back of the RAC 2A module

housing.

The RAC 2A module housing does not have an Analog Output connector.

Power Switch

AC Power

Auto Port to the

monitor’s Aux Port

Async Comm

007A

Revision A Dash 3000/4000 Patient Monitor 3-3

2000966-035

Page 40

INSTALLATION: Connections

Defib Sync

AC Pow er

The connector provides ECG analog output signals to user-supplied

equipment.

CAUTION

Equipment damage. Connect all peripheral equipment

before plugging the power cord into an AC outlet.

Otherwise, connectors may be damaged.

Use this connector to apply power to the monitor. The monitor will be

powered at all times when using AC power (there is no AC power switch).

The monitor is preset at the factory for a specific AC voltage. Before

applying power, be sure the power requirements match your power

supply. Refer to the label on the back of the unit for the voltage and

current requirements.

3-4 Dash 3000/4000 Patient Monitor Revision A

2000966-035

Page 41

INSTALLATION: Connections

Front Panel Indicators

AC/ Battery Power

Indicators

Battery A and B Charge

Status Indicators

009A

Dash 3000 Monitor’s Front Panel

AC Power Indicator

Battery Power Indicator

Power and battery indicators are located on the front panel of the

monitor.

Battery A and Battery B Charge S tatus

Indicators

Dash 4000 Monitor’s Front Panel

The indicator illuminates green when AC power is applied to the

monitor. The indicator is not illuminated when the monitor is not

powered.

The indicator illuminates yellow when the monitor is battery powered.

The indicator is not illuminated when the monitor is not powered or

when AC power is applied.

AC/Battery Power

Indicator

053A

Battery Charging/Ready Indicators

Power Up

An icon for each battery pack indicates its charging status. The battery

icon illuminates yellow when the respective battery is being charged. If

both batteries are present and require charging, then both icons will

illuminate even though they will be charged sequentially. The battery

icon illuminates green when the respective battery is fully charged.

When the monitor is operating under battery power the battery icons will

not be illuminated. The icons are also not illuminated when the

respective battery is either not being charged, not installed, or has failed.

NOTE

No specific information is given to distinguish a failed

battery pack condition from a condition where the

battery is not installed or is not being charged.

After making all connections, plug the power cord into an AC wall outlet.

When all cables are properly connected, press the power button to turn

the monitor on. All four front panel indicators will illuminate until the

power-up sequence is complete. After approximately 10 seconds you

should see a display on the screen.

Revision A Dash 3000/4000 Patient Monitor 3-5

2000966-035

Page 42

INSTALLATION: Ethernet Communication

Ethernet Communication

Overview

Twisted Pair

Concentrator

Ethernet is a local area network used as the main link of the GE Medical

Systems Information Technologies’ Unity network, a comprehensive

information communication system. The Unity network offers the high

rate of communication of 10 megabits per second. The Ethernet

connector connects to an Ethernet transceiver directly or via a

transceiver cable. This local area network links all patient monitors,

central stations, and other GE Medical Systems Information

Technologies’ equipment throughout the hospital. Depending on the

construction of the hospital, thick-net, thin-net, or twisted pair cabling is

used.

Twisted pair is the most popular cabling because it is easy to install and

flexible to work with. It uses the star topology with a concentrator as the

hub of the segment. Each of the network devices is connected directly to

the concentrator so longer lengths of cable are required. A maximum of

100 meters or 328 feet is the longest length of twisted pair cable used.

The number of devices is limited to the amount of connectors at the

concentrator.

The concentrator is simply a transceiver that passes all network data

between any two branches in the LAN. Note that the concentrator passes

all network data between the two branches, regardless of whether or not

one node is sending data to another node on the same branch.

To implement the star topology, each network device is connected to a

concentrator. The concentrator functions as a central hub and simply

passes all network data between each network device in the star

segment. Typically, the concentrator supports 8 to 12 network devices

and may be linked to other concentrators to form larger networks.

3-6 Dash 3000/4000 Patient Monitor Revision A

2000966-035

Page 43

INSTALLATION: Ethernet Communication

Node

Segment and Branch

Each network device or node is assigned an address number and requires

a transceiver to interface between the network device and the network.

For thick-net and thin-net cabling a transceiver and a serial drop cable

connects to the main trunk. The serial drop cable is sometimes referred

to as an AUI (attachment unit interface) transceiver cable. For twisted

pair cabling, the transceiver to connected directly to the network device.

Some Ethernet systems are comprised of smaller, stand-alone Ethernet

systems (called branches or segments) that are connected by bridges,

concentrators, or repeaters. Many nodes on the Ethernet network may be

serviced by one segment or branch. Each segment may support many

patient monitors, central stations, and auxiliary devices.

For example, one segment may connect all the patient monitors and

central stations in the ICU (Intensive Care Unit) and another may

connect the monitoring system in the CCU (Critical Care Unit). Each

segment could be a fully-functioning stand-alone system if they were not

connected to each other. However, with a bridge or repeater to connect

the ICU (one segment) with the CCU (the other segment), information

can pass between any of the nodes (patient monitors and central

stations) on either branch similar to a patient transfer from one unit to

another.

A section is a single length of twisted pair cable with a RJ-45 connector

on each end. A section goes from one twisted pair transceiver to the

concentrator. A segment is comprised of all the sections of twisted pair

cable connected in a star formation to one concentrator.

Repeater

A repeater is used to extend the length of cabling when the distance

required exceeds the length of the cable specifications. It is simply a

transceiver that passes all network data between any two segments.

Note that the repeater passes all network data between the two

segments, regardless of whether or not the one node is sending data to

another node on the same segment.

Revision A Dash 3000/4000 Patient Monitor 3-7

2000966-035

Page 44

INSTALLATION: Ethernet Communication

Bridge

Twisted Pair Cabling (10BaseT)

A bridge is more selective than a repeater with the data that it passes

between segments. It also acts as a transceiver between two segments,

but it only passes signals if a node on one of the segments is attempting

to communicate with a node on the other segment. Since the majority of

communication on the network occurs within a single segment, the

bridge does not pass all of the data from one segment to the other. This

lowers the amount of data traffic passing between segments, and makes

the network more efficient than a system that is connected with

repeaters.

Twisted pair is an IEEE 802.3 local area network that uses flat and

small diameter cable containing four pairs of twisted wires to connect

devices. Twisted pair operates at the same speed as thin-net and thicknet (10 megabits/second), but the cable distances extended up to 100

meters (328 feet).

A twisted pair transceiver passes data back and forth between the

network device and the LAN. It is attached directly to the network device

at the at the 15-pin D-type connector. The twisted pair cable is connected

from the RJ-45 connector at the transceiver and the RJ-45 connector at

the concentrator.

NOTE: Some devices (like Octacomm/Solar 8000M patient monitor)

have 10BaseT standard meaning that the RJ-45 connector is

part of the product and the twisted pair transceiver is not

required.

Symbol PC Card (Wireless LAN)

The Symbol PC card, installed in the monitor, uses a 2.4 GHz frequency

band and a Frequency Hopping spread spectrum (FHSS). The Frequency

Hopping spread spectrum meets IEEE 802.11 standards.

Two diversity antennas, installed in the handle of the monitor, radiates

the RF energy through the air to a Symbol Access Point. The Symbol

Access Point also uses a 2.4 GHz frequency band and the Frequency

Hopping spread spectrum.

NOTE: Refer to the Wireless LAN (Symbol Access Point) Installation

and Service Manual for detailed information on the Symbol

Access point.

NOTE: The following is required for the monitor to roam from access

point to access point while maintaining Wireless LAN

communication with the Unity Network.

• Installation of the RF LAN (Wireless LAN) option.

• Configuration and verification of the monitor’s RF LAN

operation.

• Activation of the RF LAN by disconnecting the monitor’s

Ethernet cable.

3-8 Dash 3000/4000 Patient Monitor Revision A

2000966-035

Page 45

4 MAINTENANCE

Revision A Dash 3000/4000 Patient Monitor 4-1

2000966-035

Page 46

For your notes

MAINTENANCE:

4-2 Dash 3000/4000 Patient Monitor Revision A

2000966-035

Page 47

MAINTENANCE: Maintenance Schedule

Maintenance Schedule

Manufacturer Recommendations

To ensure the monitor is always functional when required, qualified

service personnel should perform the following regular maintenance.

• Visual Inspection: Perform a visual inspection upon receipt of the

equipment, every 12 months thereafter, and prior to servicing the

unit.

• Cleaning: Clean the unit upon receipt of the equipment, every 12

months thereafter, and each time the unit is serviced.

• Conditioning the Batteries: Condition the batteries once every

two months or as needed.

• Calibrating the NBP, BP, ECG, and End-tidal CO2 Software:

Calibrate the software upon receipt of the equipment, every 12

months thereafter, and each time the unit is opened for service.

• Electrical Safety Tests: Perform safety tests upon receipt of the

equipment, every 12 months thereafter, and each time the unit is

serviced.

• Checkout Procedure: Perform the checkout upon receipt of the

equipment, every 12 months thereafter, and each time the unit is

serviced.

• Clearing the Stored Patient Data Memory: Admit and discharge

a test patient every 12 months to clear the monitor’s stored patient

data memory.

Manufacturer Responsibility

CAUTION

Failure on the part of all responsible individuals,

hospitals or institutions, employing the use of this device,

to implement the recommended maintenance schedule

may cause equipment failure. The manufacturer does

not, in any manner, assume the responsibility for

performing the recommended maintenance schedule,

unless an Equipment Maintenance Agreement exists.

The sole responsibility rests with the individuals,

hospitals, or institutions utilizing the device.

Revision A Dash 3000/4000 Patient Monitor 4-3

2000966-035

Page 48

Visual Inspection

MAINTENANCE: Visual Inspection

The monitor and it’s components should be carefully inspected prior to

installation, once every 12 months thereafter and each time the

equipment is serviced.

• Carefully inspect the equipment for physical damage to the case, the

display screen, and the keypad. Do not use the monitor if damage is

determined. Refer damaged equipment to qualified service

personnel.

• Inspect all external connections for loose connectors or frayed cables.

Have any damaged connectors or cables replaced by qualified service

personnel.

• Inspect the display face for marks, scratches, or other damage.

Physical damage to a CRT display face may pose an implosion

hazard. Have the CRT replaced by qualified service personnel if

necessary.

• Safety labels and inscription on the device are clearly legible.

4-4 Dash 3000/4000 Patient Monitor Revision A

2000966-035

Page 49

Cleaning

MAINTENANCE: Cleaning

Cleaning Precautions