Page 1

CardioSmart/CardioSmart ST

Servicing Instructions

Version 1.2 and 1.3

227 435 11 SA(e) Revision D

Page 2

Caution:

During repairs/service interventions,

observe the protective measures against

damage due to ESD.

* Marquette Hellige GmbH considers itself

responsible for the effects on safety,

reliability , and performance of the equipment, only if:

- assembly operations, extensions,

readjustments, modifications, or

repairs are carried out by

Marquette Hellige GmbH or by

persons authorized by Marquette

Hellige GmbH,

- the electrical installation of the

relevant room complies with the

applicable national and local requirements, and

- the instrument is used in accordance

with the instructions for use.

* This manual contains service informati-

on; operating instructions are provided in

the user manual of the instrument.

* This manual is in conformity with the

instrument at printing date.

* All rights are reserved for instruments,

circuits, techniques, and names appearing in the manual.

©

Marquette Hellige GmbH

Printed in Germany

Page 3

Marquette Hellige GmbH CardioSmart/CardioSmart ST V 1.2/ V 1.3

Page 3

227 435 11 D

Contents

1. Device .................................................................. 6

1.1 Block circuit diagram of entire instrument .................................... 9

1.2 Mechanical Components ................................................. 10

2. Functional description ...................................................... 11

2.1 PCB Power Supply_CS .................................................. 11

2.1.1 Switch on/off circuit ............................................... 11

2.1.2 Charging circuit for NC Battery ...................................... 11

2.1.3 Device behavoir depending on the state of battery charge ................... 12

2.2 PCB Control CS_S ..................................................... 13

2.2.1 Generation of the logic power supply +5V .............................. 13

2.2.2 ECG recording and front-end processing ............................... 13

2.2.3 Controller core .................................................. 14

2.2.4 Real-time clock.................................................. 14

2.2.5 Memory ....................................................... 14

2.2.6 Printhead control ................................................ 15

2.2.7 Motor controller ................................................. 15

2.2.8 RS-232 interface ................................................ 16

2.2.9 Keypad interface ................................................ 16

2.3 PCB Graphics Display_CS ............................................... 17

2.3.1 Power supply ................................................... 17

2.3.2 Background illumination ........................................... 17

2.3.3 Contrast control ................................................. 17

2.4 Internal interfaces ...................................................... 18

2.4.1 Mechanical interfaces ............................................. 18

2.4.2 Electronic interfaces .............................................. 19

2.4.2.1 Interface Character Display ........................................ 19

2.4.2.2 Interface Graphics Display .................................... 21

2.4.2.3 Interface PCB Power Supply_CS ............................... 21

2.4.2.4 Option interfaces .......................................... 23

2.5 Interfaces to peripherals ................................................. 24

2.5.1 Electronic interfaces .............................................. 25

2.5.1.1 RS-232 interface .......................................... 26

2.5.1.2 Patient input .............................................. 27

2.6 Limitations .......................................................... 27

3. System test functions ...................................................... 30

3.1 System test functions with graphics display .................................... 30

3.1.1. General information .............................................. 30

3.1.2 Test start ..................................................... 30

3.1.3 Display test (1) ................................................. 31

3.1.4 Key test (2) ................................................... 32

3.1.5 Motor test (3) .................................................. 32

3.1.6 Test results (4) ................................................. 33

3.1.7 Self-test ................................................ 34

3.1.8 Recording test (5) .............................................. 34

3.1.9 Interface test (6) ................................................ 35

3.1.10 Time and date (7) .............................................. 36

3.1.11 Electrode test (8) ............................................... 37

3.1.12 Test time constants (9) ......................................... 38

3.1.13 Setting the Device model (V) ..................................... 38

Page 4

Ma rque tte H e llige G mbH C a rdioS ma rt/ Ca rdioS ma rt S T V 1 . 2 / V 1. 3

Page 4

227 435 11 D

3.1.14 Switching over the program for Interpretation (C) ...................... 40

3.2 Device test functions with character display ................................... 42

3.2.1 General information ............................................. 42

3.2.2 Test start..................................................... 42

3.2.3 Display test (1) ................................................ 42

3.2.4 Key test (2) .................................................. 43

3.2.5 Motor test (3) ................................................. 43

3.2.6 Test results (4) ................................................. 44

3.2.7 Self-test ..................................................... 45

3.2.8 Recording test (5) ............................................. 45

3.2.9 Interface test (6) ............................................... 46

3.2.10 Time and date (7) ............................................... 47

3.2.11 Electrode test (8) ............................................... 48

3.2.12 Test time constants (9) .......................................... 49

3.2.13 Setting the Device model (V) ..................................... 49

3.2.14 Switching over the program for Interpretation (C) ...................... 51

4. Repair instructions......................................................... 52

4.1. Safety instructions ..................................................... 52

4.2 Replacing components .................................................. 52

5. T r oubleshooting tips ....................................................... 56

6. Adjustment instructions ..................................................... 59

7. S e rvicing a nd ma inte na nce .................................................. 61

7.1 Technical inspection .................................................... 61

7.1.1 Visual check ...................................................... 61

7.1.2 Test functions ..................................................... 62

7.1.2.1 Recommended testing instruments and accessories ...................... 62

7.1.2.2 Test preparations ............................................... 62

7.1.2.3 Operating and display unit performance tests ........................... 62

7.1.2.4 Test for recording speeds 25 and 50 mm/s ........................... 63

7.1.2.5 Device test result check .......................................... 63

7.1.2.6 RS232 interface test............................................. 63

7.1.2.7 Analysis of the ECG signals and HR value ............................ 63

7.1.2.8 Pacemaker identification test....................................... 64

7.1.2.9 Identification of disconnected electrodes .............................. 65

7.1.2.10 Checking the charge status of the NC battery ......................... 65

7.1.2.11 Pump leakage ................................................ 65

7.1.3 Safety Analysis Tests ............................................... 66

7.1.3.1 General information ............................................. 66

7.1.3.2 Protective Earth Resistance Test.................................... 66

7.1.3.3 Measurement of Leakage Current ................................... 66

7.1.3.3.1 Enclosure Leakage Current Test ................................ 67

7.1.3.3.2 Patient Leakage Current Test .................................. 68

7.2 Maintenance, cleaning, disinfection .......................................... 69

8. Parts Lists .............................................................. 70

9. Specifications ............................................................ 73

9.1 Specifications CardioSmart ............................................... 73

9.2 Specifications CardioSmart ST............................................. 79

Page 5

Ma rque tte H e llige G mbH C a rdioS ma rt/ Ca rdioS ma rt S T V 1 . 2 / V 1. 3

Page 5

227 435 11 D

10. Device documents ........................................................ 85

Annexe .................................................................. 86

Page 6

Ma rque tte H e llige G mbH C a rdioS ma rt/ Ca rdioS ma rt S T V 1 . 2 / V 1. 3

227 435 11 D

Re vision H istory

V 1.0 May 1995 Initial Release

V 1.1 March 1996 Update 1

V 1.2 February 1997 Update 2

V 1.2/1.3 August 1997 Update 3

Page 6

Page 7

Ma rque tte H e llige G mbH C a rdioS ma rt/ Ca rdioS ma rt S T V 1 . 2 / V 1. 3

227 435 11 D

Page 7

1. D e vice de scription

This Service Manual for device versions V 1.2 and V1.3 describes both CardioSmart

and CardioSmart ST. Unless indicated s pecifically, the description applies t o both

CardioSmart and CardioSmart ST.

The device version V1.3 hardware components are identic al to those of device version

V1.2. The new combinations of these component s in V1.3 result in new models, socalled regional models. Differences between device v ersions V1.2 and V1.3 are

indicated clearly in the relevant sections .

The CardioSmart is a portable electrocardiograph with an int egrated printing unit.

It is used to acquire, record and process ECG signals.

It is designed for line-power and battery operation. O peration without a battery is not

possible. Power supply unit and battery are integrated into the instrument.

CardioSmart ST has an additional ergometry mode opt ion with its own ergometry

keypad.

The patient cable for the acquisition of E CG signals is connected by means of a 15pin connector as used in earlier ECG recorders. This means that the patient cables

used in the past can still be used.

Stored patient data and ECGs can be transmitted to a PC via an RS-232 int erface.

This requires a CardioProm version with additional patient dat a memory.

CardioSmart and CardioSmart ST are both bas ed on the same hardware platform

V1.2 or V1.3 and represent diff erent types of the basic unit 101 116 x x.

With device version V1.2, the following models are available:

101 116 01 CardioSmart international 230V

101 116 02 CardioSmart US Version 115V

101 116 03 CardioSmart Russian 230V

101 116 04 CardioSmart international 230V wit h integrated pump

101 116 05 CardioSmart Russian 230V with integrat ed pump

101 116 10 CardioSmart ST international 230V

101 116 11 CardioSmart ST international 230V with integrated pump

101 116 12 CardioSmart ST US V ersion 115V

101 116 13 CardioSmart ST US V ersion 115V with integrated pump

With device version V1.3, the following models are additionaly available:

101 116 06 CardioSmart EUROPE 2 230V

101 116 07 CardioSmart EUROPE 2 230V with integrated pump

Page 8

Ma rque tte H e llige G mbH C a rdioS ma rt/ Ca rdioS ma rt S T V 1 . 2 / V 1. 3

227 435 11 D

101 116 14 CardioSmart ST Russian 230V

101 116 15 CardioSmart ST Russian 230V with integrated pump

101 116 16 CardioSmart ST EUROPE 2 230V

101 116 17 CardioSmart ST EUROPE 2 230V with integrated pump

101 116 18 CardioSmart ST A SIA 115V/230V

101 116 19 CardioSmart ST AS IA 115V/230V with int egrated pump

The CardioSmart entire instrument comprises t he following components:

Ca rdioS ma rt Ba sic I nstrume nt, wit hout display and CardioProm

-

-

C ardioP rom S t orage M odule , there are several modules wit h different features,

with or without ECG storage facility

CardioVision Display, there are 2 different dis plays available:

-

- CardioVision Text, LCD module 2-line

- CardioVision Graphics, graphics LCD

Page 8

The CardioSmart ST entire instrument c omprises the following components:

CardioSmart ST Basic Instrument, without display and CardioProm

-

-

C ardioP rom S T S t orage M odule , there are several modules wit h different

features, with or without ECG storage facilit y

C ardioV ision G ra phics, graphics LCD

CardioSmart ST is not enabled for CardioVis ion Text

This concept permits the user to conf igure an instrument himself to meet his own

application specifications. It is also possible to upgrade the basic version.

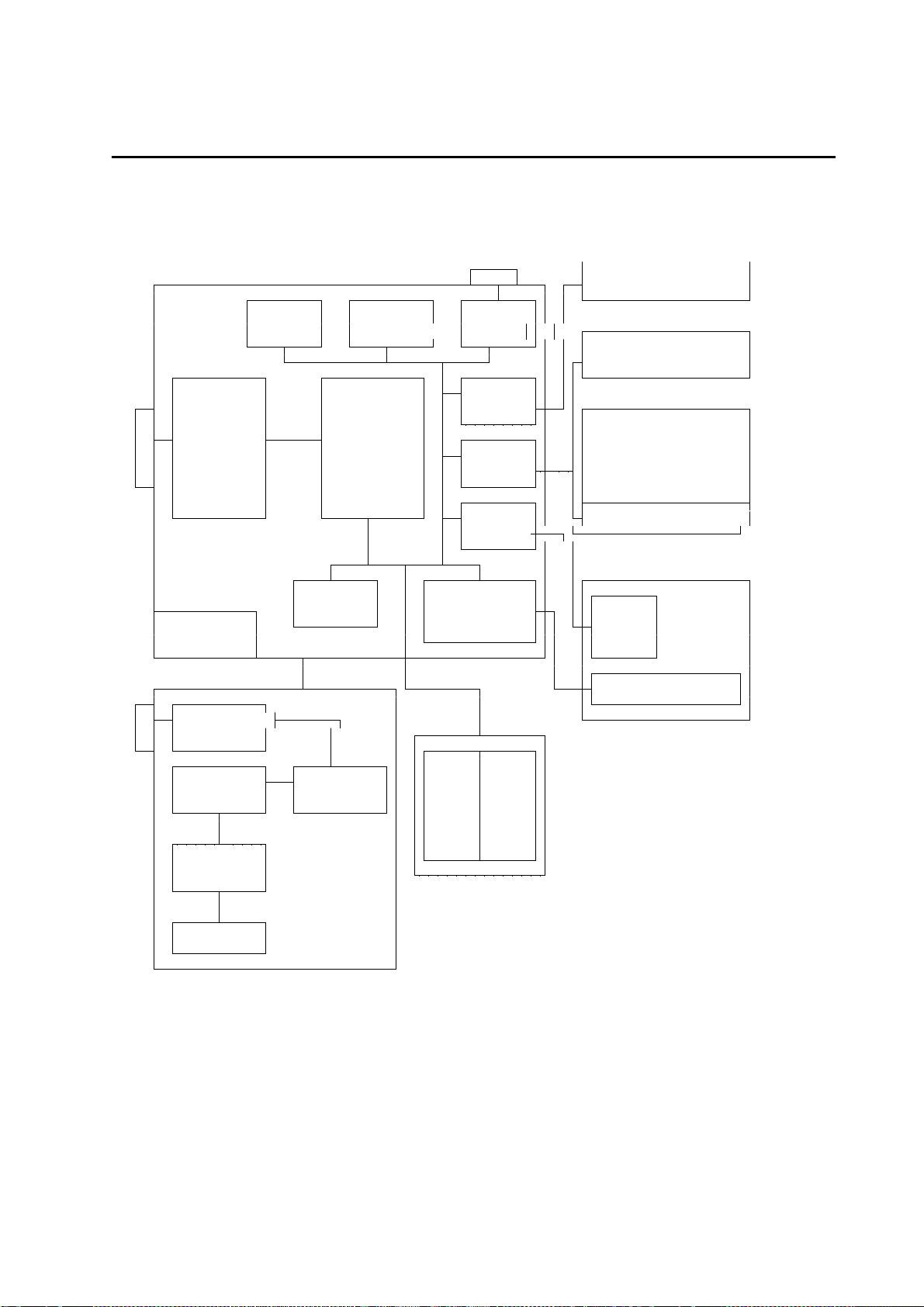

The hardware comprises the following functional blocks:

- P CB Control CS_S (basic instrument)

- P ower supply unit with battery (basic instrument)

- Keypad (basic instrument)

- P rinting unit (basic instrument)

- P CB Energy Storage_CS (storage module)

- D isplay (character or graphics display)

The following functional blocks are constructed directly as PCBs:

- P CB Control_CS

- P CB Energy Storage_CS

- P CB Power Supply_CS with battery charging circuit

- P CB Graphics Display_CS

The applications, functions and operation of the CardioSmart are described in the

User’s Manual.

Page 9

Ma rque tte H e llige G mbH C a rdioS ma rt/ Ca rdioS ma rt S T V 1 . 2 / V 1. 3

Page 9

227 435 11 D

1. 1 Block circuit diagra m of e ntire instrume nt

Config. Clock, RS232

Memory buffered Driver

LCD

Keypad

ECG Interf.

Acquisit. Controller

and Core LCD

Condit- Display

ioning Interf. (optional)

Motor

Contr.

Internal Thermal

RAM Printhead

Generation Controller Motor

+ 5V

Printhead

Line Filt.

Fuse

Generat. Voltage

+ 24V Selector EPROM RAM

(Opt)

Battery

Charge

Battery

PCB Control_CS

Power Supply Unit

Keypad

Character Displ.

Graphics Display

Graphics Controller

Printing Unit

CardioProm

Page 10

Ma rque tte H e llige G mbH C a rdioS ma rt/ Ca rdioS ma rt S T V 1 . 2 / V 1. 3

227 435 11 D

Page 10

1 . 2 M ec hanica l C ompone nts

The main mechanical components comprise the uppe r a nd lowe r she ll of the

Ca rdioS ma rt Ba sic I nstrume nt. The lower shell serves as a basic unit to receive t he

following assemblies:

- M ains input module with instrument On/Off switch

- P CB Power Supply_CS

- Battery

- T hermal printing unit

- P aper container

- P CB Control_CS

The upper shell accommodates the keypad, which is connected to the PCB

Control_CS via a 22-pin connector. The display (c haracter or graphics display) is also

integrated into the upper shell.

CardioProm (program module) also has its own housing, comprising an upper

The

and lower assembly section. It cont ains the PCB Energy Storage_CS , which is

connected to the PCB Control_CS via a multipoint connector when inserted into the

CardioProm slot.

The two available

lower shell. The graphics display contains the graphic s LC display itself, as well as the

associated control electronics, it can be swivelled within the range from 0° to 45° with

5 lock-in positions. The character display only contains the character LCD and cannot

be swivelled. The two displays can be connec ted to the PCB Control_ CS by insert ion

into the depression in the upper shell of the basic instrument provided with a female

multipoint connector.

The 15-pin input connector to

RS-232 interface are located directly on the PCB Control_CS.

the

Models 101 116 04/05 have an added integrated suction pump, comprising the pump

module 303 442 91 and the PCB Pump 388 029 18.

displays are als o located in a housing, comprising an upper and

connect the pa tie nt ca ble and the 9-pin connect or for

Page 11

Ma rque tte H e llige G mbH C a rdioS ma rt/ Ca rdioS ma rt S T V 1 . 2 / V 1. 3

227 435 11 D

Page 11

2 . F unctiona l descr iption

The block circuit diagra m of t he entire instrument in S e ction 1 . 1 and the functional

blocks of the P - pla ns

2 . 1 P C B P owe r S upply_ C S

The PCB Power Supply provides the f ollowing functions:

- S econdary clock-rated power supply unit to generat e the fundamental device

voltage UVERS

- D evice switch on/off circuit

- Charging c ircuit for NC battery

- B attery almost empty identificat ion

- B attery empty instrument swit ch-off

2.1.1 Switch on/off circuit

describe the individual functional blocks.

The device on/off switch (momentary toggle switch) supplies the starting puls e. The

actual stop signal comes from the P CB Control_CS via the DOFF cable.

In the line-power operating mode CardioSmart can be switc hed off by:

- D evice on/off switch

- P rocessor (DOFF)

In the battery operating mode CardioSmart can be s witched off by:

- D evice on/off switch

- P rocessor (DOFF)

- B attery empty identification

In the line-power operating mode recording can be switched off by:

- B attery empty identification

2. 1 . 2 C harging circuit for NC Ba tte ry

A charging IC is used to charge the batt ery. During charging it monitors the battery

voltage function and switches ov er from rapid charging to trickle charging in

conformity with the charging current.

The charging circuit is activated by applying the power supply voltage or battery.

If a recording is made whilst the device is in t he operating mode the charging circuit is

deactivated.

Page 12

Ma rque tte H e llige G mbH C a rdioS ma rt/ Ca rdioS ma rt S T V 1 . 2 / V 1. 3

227 435 11 D

2. 1 . 3 D e vice be ha voir de pe nding on the sta te of ba tte ry cha rge

As a ge ne ra l rule the following a pplie s:

No applied line-power voltage:

Operation of the device without a batt ery is not possible

Applied line-power voltage, battery is charged:

Device completely operational

Applied line-power voltage, battery

depleted:

Device is only partially operational (everything ex cept recording)

Battery charging is triggered by:

Application of line-power voltage

Switching off a current recording, manually with the Stop key

or automatically when the cutoff volt age has been attained

D evice be ha voir:

State 1 Battery depleted, power supply system is connected up:

Battery charged in accelerated mode; when full, switchover to

conservation charging, no time limit

State 2 Battery full, power supply system is connected up:

Battery charged in accelerated mode; when full, switchover to

conservation charging, no time limit

State 3 Batt ery depleted, no line-power supply, device is swit ched on:

Device inoperative

State 4 Batt ery full, no line-power supply, device is swit ched on:

Device fully operative, when battery almos t empty message appears

LEDBAT signal activat ed, when battery empty message appears the

device becomes inoperative

State 5 Battery depleted, power system supply is connected, charging begins,

device is switched on:

All functions except recording, as long as the battery cannot supply the

printhead with sufficient power.

State 6 Battery full, power supply system is connected, device switched on:

Device fully operative. During recording charging is int errupted, at stop

recharging begins until the charging IC switches to conservation

charging.

Page 12

Page 13

Ma rque tte H e llige G mbH C a rdioS ma rt/ Ca rdioS ma rt S T V 1 . 2 / V 1. 3

227 435 11 D

Page 13

2.2 PCB Control CS_S

2. 2 . 1 G e ne ra tion of the logic powe r supply + 5 V

The logic power supply +5V is generated directly on t he PCB Control_CS.

The stabilized voltage UVERS, which is generated by the PC B Power Supply_CS,

serves as the input voltage.

The +5V power supply is generated by the clock -rated

"a djusta ble ve rsion" of the controller is us ed in order to be able to use it later for

The

applications requiring other voltages, the output voltage is determined by appropriate

dimensioning of the voltage divider at the feedbac k input of the voltage controller.

2. 2 . 2 E C G re cording a nd front- e nd proce ssing

The main element of this operational unit is a se t of chips comprising 4 AS I C s located

on the PCB.

The patient lead is connected with a 1 5 - pin conne ctor. Overvoltage arresters at the

electrode inputs provide high-voltage protecti on. A hybrid chip acts as a microfuse f or

each electrode, it serves to identif y a disconnected electrode.

The patient input is classified as cardiac floating and is defibrillation-proof.

Each electrode input is preamplified after t he hybrid chip with a low-noise operational

amplifier with a small input voltage, before it is fed into the two ASICs with t he sigmadelta resistors.

The filter time constants can be adjus ted by the controller core by a command. 8 time

constants are available for selection (system test).

voltage controlle r.

N common-mode compensation ensures suppression of int erference, at the same time

serving to improve the in-phase suppression of t he input electrodes.

To protect patients the ECG recorder and conditioning processor are assembled as

floating components. Digital signals f rom and to the controller core are transmitted via

optoelectronic couplers, the float ing power supply +/-5V is generated by a flyback

converter from the logic power supply +5V.

Page 14

Ma rque tte H e llige G mbH C a rdioS ma rt/ Ca rdioS ma rt S T V 1 . 2 / V 1. 3

227 435 11 D

Page 14

2.2.3 Controller core

The actual core comprises the Motorola Controller 68332, containing the following

integrated components:

- C PU32, computer core, internal 32-bit register, external 16-bit processor

- T PU, an independently operative clock generat or processor

- QSM with SCI to implement a simple RS-232 interface and a serial QSPI

interface with up to 16 channels

- SIM with chipselect generation, system monitoring, clock synthesizer

wat chdog/ re set gene ra tion is implemented with an integrated system monitoring

The

chip. It has the following functi ons:

- P ower-up reset for the 68332 when the instrument is swit ched on

- V oltage monitoring with reset generation

- W atchdog function

- Switchover to battery for buffered RAMs

- A ccess protection for buffered RA Ms

2.2.4 Real-time clock

This provides the time of day and date. When t he device is operative it is powered by

the logic power supply, when the device is sw itched off a 3-V lithium cell is switc hed

in to keep the clock running.

The control signals for the clock (c hipselect read/write signal) are generated in the

PAL RTC_Control, which also contains the release sequenc e for the character display.

2.2.5 Memory

Static RAMs are used as R AM me mory with an internal organiz ation 128kbit x 8. They

are equipped with 4 chips, providing an organisation of 256kbit x 16. It is possible to

add 4 further chips to give a RAM memory area of 1MB yte.

The access time is 70 ns, i.e., access

without wa it sta te s.

Page 15

Ma rque tte H e llige G mbH C a rdioS ma rt/ Ca rdioS ma rt S T V 1 . 2 / V 1. 3

227 435 11 D

Page 15

2.2.6 Printhead control

The printhead controller takes on the complete cont rol of a 216-mm thermal printhead

with a line width of 200 mm. It also contains t he printhead monitor, which reduces the

heating time with increasing printhead temperature, t erminating the printhead power

supply when the printhead temperature reaches 55°C. The printhead power s upply is

reactivated only when the printhead temperature drops below 50°C.

The core is a

The speed-dependent heating parameters are transmitted s erially.

For the printhe ad monitoring t he temperature of the thermal array printhead is

measured by a thermistor located on the printhead. A constant current source effec ts

a temperature-dependent voltage drop at a comparator input, t he switching threshold

being adjusted by hysteresis at the ot her comparator input.

If a printhead temperature of 55°C is exceeded, the message PRINTHEADTE MP is

activated and the current supply to the printhead prevented by the STROBE signal.

Only after the temperature drops below 50°C is the PRI NTHEADTEMP message

disabled and the current supply via STROBE reenabled.

A second comparator generates a VTE MP signal when the temperature reaches

45°C, it is disabled again when the temperature drops below 40°C. It repres ents a

prewarning signal, so that the quantity of data at the printhead is reduced to prevent it

being switched off.

In addition, a continuous reduction in the c urrent activation time occurs with inc reasing

temperature, resulting in a regular type face throughout the entire temperature range.

printhe ad is ope ra te d dire ctly a t the ba tte ry, i.e., the printhead volt age is

The

dependent on the state of battery charge. Compensation is achieved by reducing or

extending the printhead current acti vation time accordingly, ensuring t hat the type face

is maintained within the fluctuation range of t he battery voltage.

gat e a rra y, which t akes on the heating time management for each dot.

2.2.7 Motor controller

This activates the CardioSmart´ s DC motor. This motor does not have a speedo,

control is achieved according to the principle of current compensation.

The main components are the speed selector, motor c ontroller, and motor current

monitoring.

The resistor for the

attached directly to the motor cas ing.

control according to the principle of current c ompensation is

Page 16

Ma rque tte H e llige G mbH C a rdioS ma rt/ Ca rdioS ma rt S T V 1 . 2 / V 1. 3

227 435 11 D

The voltage of +/- 12 V required to send control s ignals is generated from the supply

voltage as follows: An in-phase regulator generates + 12 V, due to the small current

requirements the voltage -12 V is generated by an inv erting voltage pump. The supply

voltage +/-12 V is also used for the temperature monitoring system of the printhead

controller.

It is only enabled during printing!

When the motor current is raised > 140 mA (e.g., as a result of paper jam,

transmission problems) the

transport and the message “Please insert paper and press return key” appears on the

display.

motor current monitoring syste m terminates paper

Page 16

2.2.8 RS-232 interface

The CardioSmart has an RS-232 interface which, except for the RS-232 driver chip, is

directly integrated into the controller.

It has the following attributes:

- S oftware handshake with XON/X OFF

- N o HW handshake

- Transmission speed 1200 .... 19200 B aud

To achieve

additional suppressor diodes.

prote ction a ga inst E S D up to 1 0 kV , the interface is equipped with

2.2.9 Keypad interface

The interface to the keypad is via the 2 2 - pin conne ctor AS . The keypad itself is a

membrane keypad with touch-sensitive chec k-back.

The keypad comprises a

The CardioSmart ST keypad has additional keys for ergometer/treadmill control.

Depending on the keypad used (CardioSmart or CardioSmart S T) the PC receives a

corresponding signal, identifying the devic e used.

Identification of the key press ed is as follows:

The controller activates a column, act ivation is via low-level, simultaneously it reads

out the register for the lines and by a low-level signal ident ifies whether one or more

keys had been pressed. Then the next column is activated. The run procedures are

repeated automatically until all columns have been act ivated.

In addition, the LEDs for start and stop, for the power supply system display and the

battery status control are locat ed directly on the keypad.

mat rix with 7 columns a nd 7 rows.

Page 17

Ma rque tte H e llige G mbH C a rdioS ma rt/ Ca rdioS ma rt S T V 1 . 2 / V 1. 3

227 435 11 D

Page 17

2.3 PCB Graphics Display_CS

This PCB is only used in connecti on with the component parts of the CardioSmart

graphics display unit. It comprises the following functional units:

- V oltage generation

- C PU interface, display control

- B ackground illumination

- C ontrast control

2. 3 . 1 P owe r supply

A negative voltage of -23 V is required for the power supply of the display. It is

generated by an inverting switching controller f rom the 5-V power supply. The output

voltage -23 V is enabled by the additional external wiring of the switching controller.

The voltage -23 V also serves as a voltage s ource for the generation of the negative

contrast volta ge .

The functional unit LC D BLO C K ensures that t he logic power supply +5 V is active at

the graphics display before the negative power supply and the contrast voltage. When

the instrument is switched off the negative power supply and the contrast v oltage are

switched off first.

2 . 3 . 2 Ba ckground illumination

The background illumination of the graphics display is effected by a C F L tube , which

requires an alternating voltage of approx. 800 Vs s.

The alternating voltage is generated by a voltage invert er, driven by 5 V. Since the

CardioSmart is a portable, battery-operated device, t he background illumination can

ena ble d a nd disa ble d (configuration).

be

2.3.3 Contrast control

The contrast control has an additional temperature compensation control. However,

when there are rapid fluctuations in temperature it t akes a certain time until the

compensation is complete, since the dis play itself has a greater thermal time const ant.

Page 18

Ma rque tte H e llige G mbH C a rdioS ma rt/ Ca rdioS ma rt S T V 1 . 2 / V 1. 3

227 435 11 D

Page 18

2.4 Internal interfaces

2.4.1 Mechanical interfaces

The 3 following mechanical interfaces are important within t he CardioSmart:

- I nterface to CardioProm

- Interface to display CardioVision Text

- Interface to display CardioVision Graphic s

Interface to CardioProm

The CardioProm has its own housing, which is conduc ting to prevent damage by ESD.

To shunt any possible static charge it has 3 rails on the underside which, on the PCB

Control_CS in the CardioSmart basic devic e, when inserted make contact with the 3

rails on GND, thereby shunting the charge.

This mechanical insertion of the rails ensures t hat a fail-safe contact is made with the

PCB Control_CS.

Furthermore, mechanical coding ensures that the non-c ompatible CardioProms of the

EK56/EK512 series cannot be inserted into the slot. Similarly, the insertion of

CardioSmart CardioProms into the EK 56/512 slot is not possible.

I nterfa ce to displa y C a rdioV ision T ext

The display CardioVision Text is placed into t he depression provided in the upper

shell of the CardioSmart basic device. The mechanic al rail on the outside of the

display ensures the electrical contac t is automatic and fail-safe. The display

CardioVision Text can be replaced, e.g. , by a CardioVision Graphics using the

appropriate tools without opening the device.

I nte rfac e t o display C a rdioV ision G ra phics

The display CardioVision Graphics is also plac ed in the above-mentioned depression,

the mechanical rail on the outside also ensures a fail-s afe contact. In contrast t o the

CardioVision Text, the CardioVisi on Graphics can only be replaced by opening the

upper shell of the basic device.

Page 19

Ma rque tte H e llige G mbH C a rdioS ma rt/ Ca rdioS ma rt S T V 1 . 2 / V 1. 3

227 435 11 D

Page 19

2.4.2 Electronic interfaces

This section describes the pinning, func tion and significance of the signals of the

internal interfaces of the functi onal components.

2.4.2.1 Interface Character Display

The interface to the character display prov ides all the signals to connect the display

CardioVision Text. It comprises the upper 8 bits of the data bus, control s ignals and

the signal for the contrast cont rol.

Connection denotation:

Female multipoint connector 2 x 7 - pin, upright (180 °), reverse terminal protecti on

achieved mechanically.

The function of the individual pins is given in t he following table. The definition as an

Input/Output is seen with ref erence to PCB Control_CS.

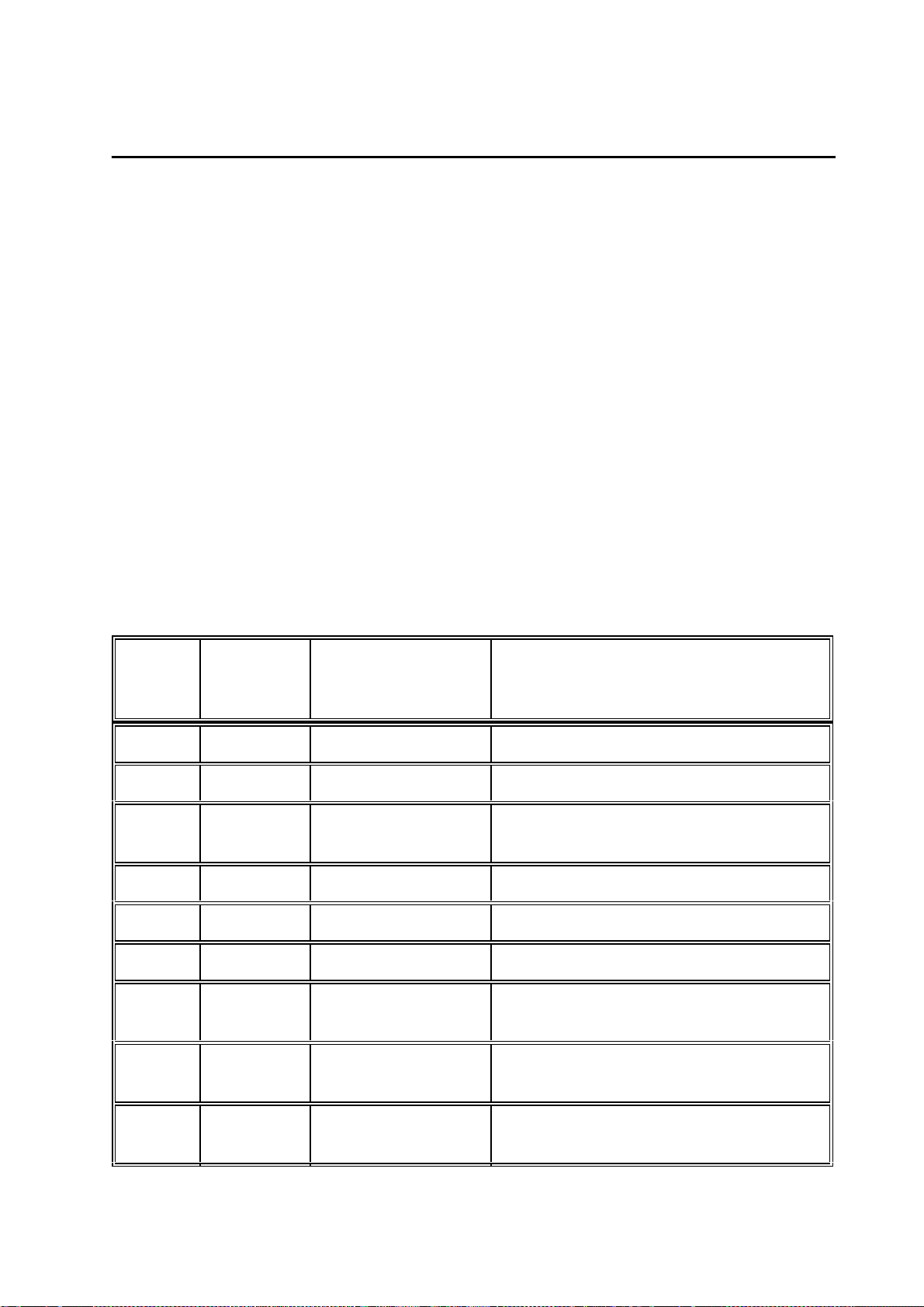

Pin

Number

1 Output GND System ground

2 Output + 5 V Voltage supply

3 Output CHAR_CONTR

4 Output AD_12 Controller address bus bit 12

Input/Output

AG/

Denotation Function

Contrast character display

0 .... 5V

5 Output RW_ Read/write signal

6 Output ENCHARD Enable character display

7 Bi-Direct,

tristate

8 Bi-Direct,

tristate

9 Bi-Direct,

tristate

DB_8 Controller data bus bit 8

DB_9 Controller data bus bit 9

DB_10 Controller data bus bit 10

Page 20

Ma rque tte H e llige G mbH C a rdioS ma rt/ Ca rdioS ma rt S T V 1 . 2 / V 1. 3

227 435 11 D

Page 20

10 Bi-Direct,

tristate

11 Bi-Direct,

tristate

12 Bi-Direct,

tristate

13 Bi-Direct,

tristate

14 Bi-Direct,

tristate

DB_11 Controller data bus bit 11

DB_12 Controller data bus bit 12

DB_13 Controller data bus bit 13

DB_14 Controller data bus bit 14

DB_15 Controller data bus bit 15

2.4.2.2 Interface Graphics Display

The interface to the graphics display provides all the signals to connect the display

CardioVision Graphics. It c omprises the upper 8 bits of the data bus, address bus,

control signals and the signal for the cont rast control.

Connector denotation:

AH/

2. 4 . 2 . 3 I nte rfa ce P C B P owe r S upply_ C S

This has the voltages from the power supply unit to generate the + 5 V and the other

voltages, the control of the LE Ds for the power lamp and battery monitoring, the control

signals for battery charging and switc hing on the printhead and motor power supply as

well as the signal to switch off t he device on the controller´s part.

Connector denotation:

Male multipoint connector 2 x 1 0 - pin, upright (180 °), reverse terminal protection and

coding with coding pin 12.

The function of the individual pins is given in t he following table. The definition as an

Input/Output is seen with ref erence to PCB Control_CS.

AE/

Page 21

Ma rque tte H e llige G mbH C a rdioS ma rt/ Ca rdioS ma rt S T V 1 . 2 / V 1. 3

227 435 11 D

Page 21

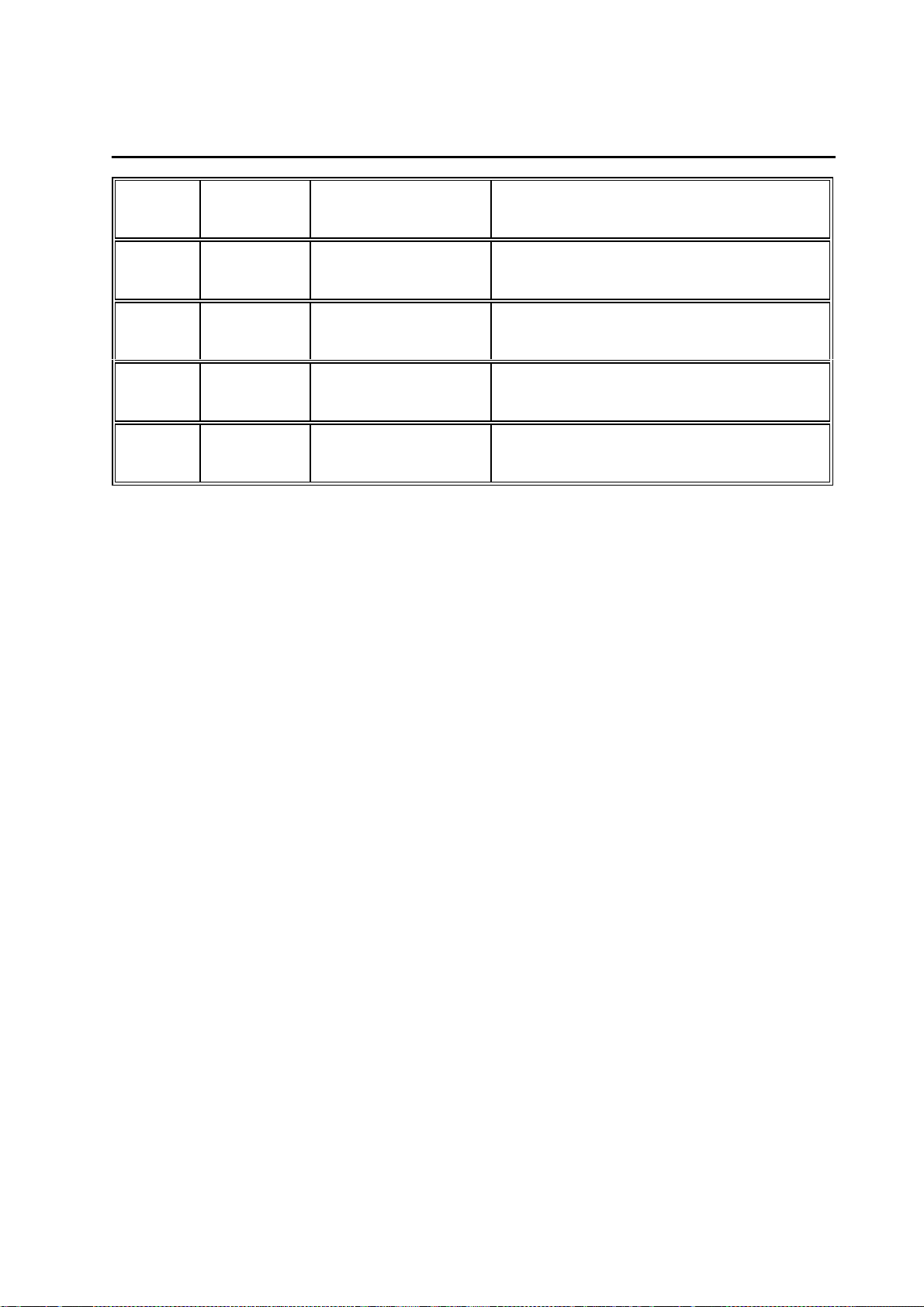

Pin

Number

1 Input LEDLIN Control of LED for power supply system

2 Output REG_ON Printhead power supply, motor enabled by

3 Output GOFF_ Switch on device with controller

4, 5 Input UVERS Input v oltage to generate +5 V

6 Output + 5 V Logic power supply

7,8,9,

10

Input/Output

Input COMMON_IN Input voltage to generate mot or- printhead

Denotation Function

"-" = mains not connected

"AC" = mains connected

controller:

"0" = Enable battery charging

"1" = Enable printhead power supply

"0" = Device off

"1" = Device on

voltage and +/- 12V

11 Input REG_OFF Printhead power supply, motor enabled by

power-supply unit:

"0" = Enable battery charging

"1" = Enable printhead power supply

12 CODE Coding pin

13, 14,

15, 16

17 Input VRAM Buffered voltage to generate the RAM

18 Output COMMON_S Voltage switched in from COMMON_IN

19 NC NC

20 Input LEDBAT Charging status display for BATTERY:

Input GND System ground

standby power supply

"0" = battery needs charging

"1" = battery charged, normal operat.

Page 22

Ma rque tte H e llige G mbH C a rdioS ma rt/ Ca rdioS ma rt S T V 1 . 2 / V 1. 3

227 435 11 D

Page 22

2.4.2.4 Option interfaces

O ption P owe r C heck

This constitutes a service c onnector to enable checking of all the voltages ac tive within

the system. This

power to other components!

is not a n ex te nsion port, the voltages must not be us ed to supply

Connector denotation:

Male multipoint connector 1 x 6 - pin, upright (180 °), for se rvicing purpose s only!

The function of the individual pins is given in t he following table. The definition as an

Input/Output is seen with ref erence to PCB Control_CS.

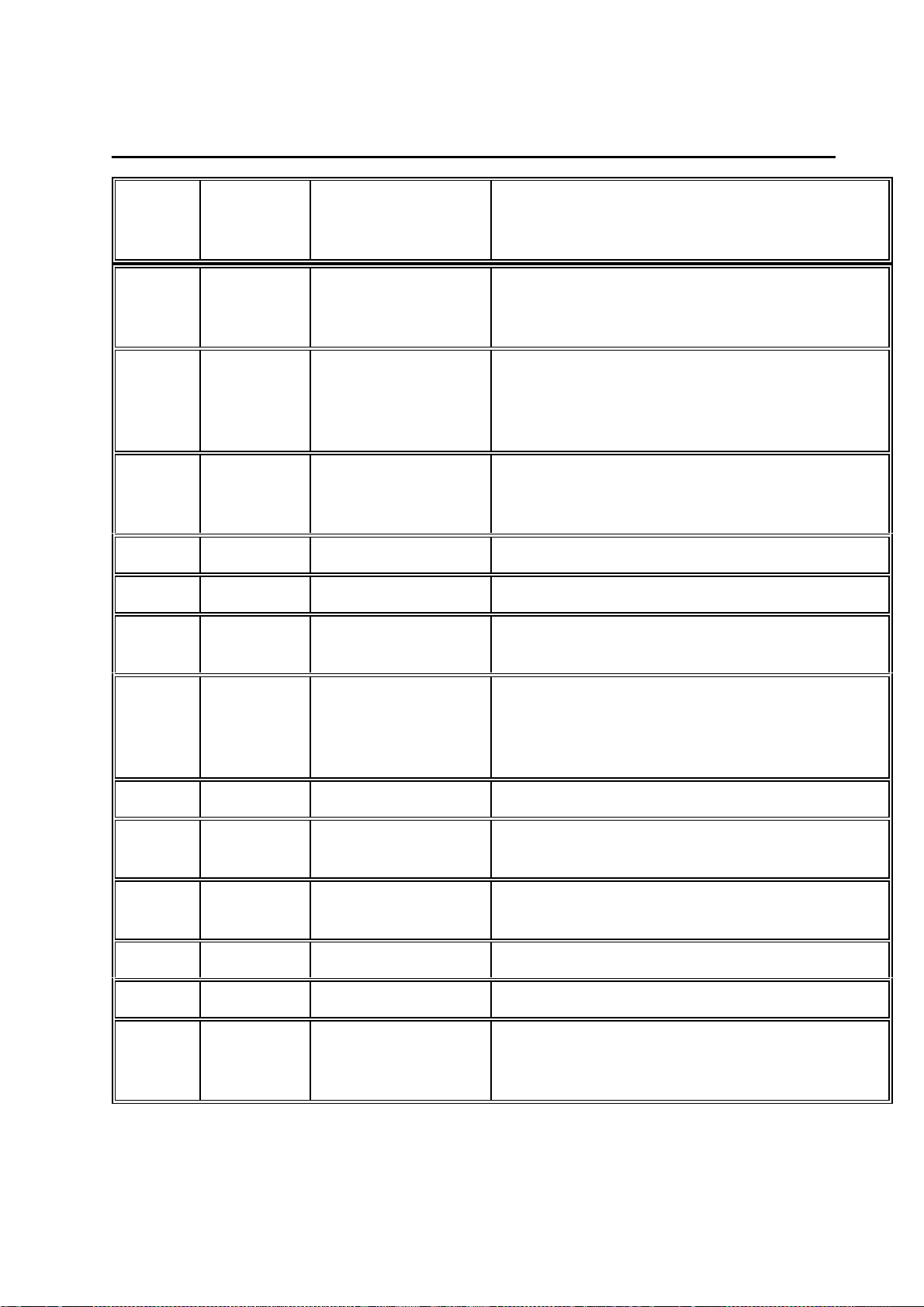

Pin

Number

1 Output + 12 V Testing point power supply + 12 V

2 Output GND System ground

3 Output - 12 V Testing point power supply - 12 V

4 Output COMMON_S Testing point power supply motor voltage

Input/Output

AF/

Denotation Function

5 Output GND System ground

6 Output + 5 V Testing point logic power supply + 5 V

Page 23

Ma rque tte H e llige G mbH C a rdioS ma rt/ Ca rdioS ma rt S T V 1 . 2 / V 1. 3

227 435 11 D

Page 23

2.5 Interfaces to peripherals

The CardioSmart has only 3 interfaces for peripherals :

- M ains input

- P atient Input

- R S-232 interface

mains input int erface on the device is a 3-pin standard cold appliance soc ket

The

connection, which is integrated into t he mains input module. Connection to the mains is

effected via a 3-pin power cord with a non-fused earth c onductor.

Although the mains input is not designed as a "wide range input ", adjustment to the

two mains voltage ranges 110V~ ... 120V~ and 220V~ ... 240V~ is easily achieved without

having to open the device or a wiring change of the bridges:

- C heck voltage setting in the inspection window of the interrupter of the mains

input module

- I f the voltage value is not the same as the mains voltage:

D isconnect ma ins plug!

-

- O pen interrupter with appropriate tool

- T ake out fuse holder with fuses

- I nsert fuses rated according to the rating plat e specifications

- R einsert holder so that the required voltage is visible

- C lose interrupter

- T he required mains voltage should now appear in the inspection window

T his rea djustme nt is to be ca rrie d out by the ma nufa cture r or se rvicing age nt only!

No further description of the mechanical and elec tronic parameters of the mains input

is given in Section 2.5.

The mechanics and the interface configuration as used in the EK53/EK56 and in the

EK512 are implemented in the

used up to date can still be used, this also being true for the suction system with its

integrated pump.

A 9-pin sub-D connector with a standard configurat ion of the signals TXD, RXD and

GND is implemented in the construction of the

attached to the connected plug hous ing by means of threaded inserts. The E K53/56

and EK 512 RS-232 power cables can thus no longer be used.

The cable 223 362 03 is used as an RS-232 cable to the PC.

pat ie nt input. This means that all the pat ient cables

RS-232 interface. In addition, it is

Page 24

Ma rque tte H e llige G mbH C a rdioS ma rt/ Ca rdioS ma rt S T V 1 . 2 / V 1. 3

Page 24

227 435 11 D

2.5.1 Electronic interfaces

2.5.1.1 RS-232 interface

This comprises the transmitter signal TX D, the incoming signal RXD and the reference

ground GND. The pin configuration is the same as t hat used for a standard PC 9-pin

sub-D socket. The interface does not operate with a hardware handshake.

Furthermore, a REMOTE START input is provided at pin 8.

Transmission is in accordance with the st andard V-24 protocol, input and output

voltages are defined as follows:

- m aximum input voltage at RXD: +/- 15V

- minimum out put voltage at TXD: +/ - 5 V

- addit ional input protection against ESD ef fects: +/- 10kV

In addition, there is a REMOTE S TART input at pin 8 with the following specif ications:

- ex ternal short-circuiting contact v ia circuit reference referred to ground

- max. source resistor switch: Ri <300

- m ake time >100 ms

- c ontinuous load limits +/-10 V

- E SD protection to max. +/-10 kV

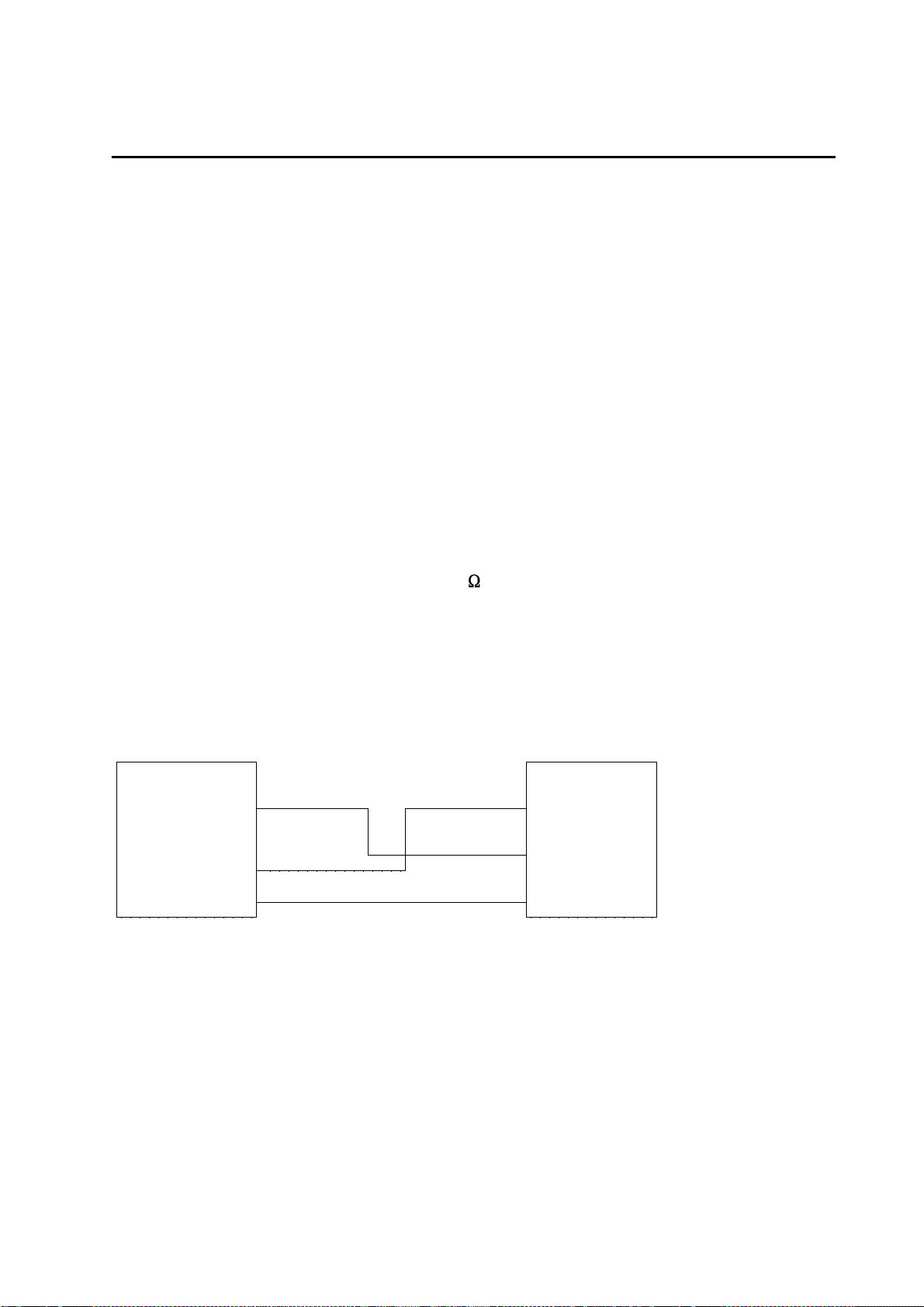

Connection principle to PC

CardioSmart PC

RXDE 2 2 RXD

3 TXD

TXDE 3

GND 5 5 GND

Connection cable 223 362 03

The connector is denoted: AC/

Male multipoint connector sub- D socke t housing, 9 - pin, 9 0° off set

Page 25

Ma rque tte H e llige G mbH C a rdioS ma rt/ Ca rdioS ma rt S T V 1 . 2 / V 1. 3

227 435 11 D

The function of the individual pins is given in t he following table. The definition as an

Input/Output is seen with ref erence to PCB Control_CS.

Page 25

Pin

Number

1 NC NC

2 Input RXDE Receive RS-232 data

3 Output TXDE Transmit RS-232 data

4 NC NC

5 Output GND System ground

6,7,9 NC NC

8 Input REMOTE START Remote Start Input

Input/Output

Denotation Function

Page 26

Ma rque tte H e llige G mbH C a rdioS ma rt/ Ca rdioS ma rt S T V 1 . 2 / V 1. 3

227 435 11 D

2. 5 . 1 . 2 P a tie nt input

Below is a list of the most important features of the patient input:

- Classification: cardiac floating

- Defibrillation-proof

- S imultaneous data acquisition from all leads

- I ndividual electrode monitoring

- V oltage feed for floating power supply via float ing transformer

- C ontrol and data signals from and to floating part via opt oelectronic coupler

Page 26

The connector is denoted:

Male multipoint connector sub- D socke t housing, 1 5 - pin

AA/

Page 27

Ma rque tte H e llige G mbH C a rdioS ma rt/ Ca rdioS ma rt S T V 1 . 2 / V 1. 3

227 435 11 D

The function of the individual pins is given in t he following table. The definition as an

Input/Output is seen with ref erence to PCB Control_CS.

Page 27

Pin

Number

1 Input C2 Input electrode C2

2 Input C3 Input electrode C3

3 Input C4 Input electrode C4

4 Input C5 Input electrode C5

5 Input C6 Input electrode C6

6 Output S Shielding

7 Output PLGND Identification of patient cable used

8 Input PL Identification of patient cable used

9 Input R Input electr ode R

Input/Output

Denotation Function

(Nap for Nehb cables)

10 Input L Input electrode L

11 Input F Input electrode F

12 Input C1 Input electrode C1

13 Input Nst Input elect rode Nst (for Nehb)

14 Output N Output electrode N (common mode

compensation)

15 Input Nax Input electrode Nax ( for Nehb)

Page 28

Ma rque tte H e llige G mbH C a rdioS ma rt/ Ca rdioS ma rt S T V 1 . 2 / V 1. 3

227 435 11 D

2 . 6 Limitations

The following operating modes are not implemented in the CardioSmart:

- N o ergometry

- No SAO2

- N o spirometry

- No late potentials, no RR variability

- N o phono, no US Doppler

A scope output is not available.

No analog inputs.

The existing RS-232 interface does not prov ide an ECG trigger output.

Recording without or with an empty NC battery is not possible.

Page 28

Lead accumulators cannot be used.

Primary cells cannot be used.

Page 29

Ma rque tte H e llige G mbH C a rdioS ma rt/ Ca rdioS ma rt S T V 1 . 2 / V 1. 3

227 435 11 D

Page 29

3 . S yste m te st functions

With country default setting G erman all messages displayed during the self-test are in

German, in all other country settings they appear in English.

3 . 1 Syste m te st functions with gra phics displa y

3 . 1 . 1 . G e ne ra l informa tion

The functions for the system test are mostly menu-guided.

For complete execution some tests require special auxiliary resources. These include

interface testers or PC, c onnection cables, signal generators, etc . The tests that are

necessary are described in the various test descriptions.

3.1.2 Test start

After simultaneously pressing t he keys

the initial display menu appears to enable selection of a s pecific test. (see below)

Keys used for menu selection appear in parenthesis .

(1) Display test

(2) Key test

(3) Motor test

(4) Test results

(5) Recording test

(6) Interface test

(7) Time and date

(8) Electrode test

(9) Time constant test

(V) Device model (from SW V4.21)

(C) 12SL / HEART (from V4.21)

Terminate with SH_MAN or SH_MODE key

S hift + Auto (CardioSmart) or S hift + M ode (CardioSmart ST)

S ystem te st

T est f unctions:

Page 30

Ma rque tte H e llige G mbH C a rdioS ma rt/ Ca rdioS ma rt S T V 1 . 2 / V 1. 3

227 435 11 D

3.1.3 Display test (1)

After pressing the “1" key the f ollowing menu appears:

Page 30

Pressing any other key t han one of those listed in the menu above leads back to the

initial display menu.

Displa y te st

(1) Test pattern

(2) Character set

(3) Delete display

(4) Inverse

(5) Display illumination

Contrast control

- Shift_Cursor_Down

- Shift_Cursor_Up

Terminate with any key

(1) Test pattern

Pressing this key generat es a chessboard pattern. Each s ubsequent pressing

generates the inverse display of its predec essor.

(2) Character set

The character set used for the display is out put.

(3) Delete display

All display pixels are inactive.

(4) Inverse

The contents of the existing dis play appear in reverse video.

( 5) D ispla y illumina tion

The illumination is switched on or off by pressing this key.

C ontrast control

The contrast setting can always be adjus ted as described above (cursor keys).

Page 31

Ma rque tte H e llige G mbH C a rdioS ma rt/ Ca rdioS ma rt S T V 1 . 2 / V 1. 3

227 435 11 D

3.1.4 Key test (2)

By pressing the “2" key the following menu appears :

Page 31

When a key is pressed this key or its f unction is displayed. This can either occ ur by a

triple character display, e.g., “AAA” or as a text, e.g., "CURS_UP". Moreover, pressing

the “P” key tests the bleeper (audible sound) and pres sing the “K” key tests a micro

key to identify whether the cover f or the paper compartment is open or closed. The “E”

key terminates this test and s imultaneously undergoes a self-test.

Key T e s t

(P) Bleeper test

(K) Cover for paper compartment

(E) End

3.1.5 Motor test (3)

When the “3" key is pressed the following menu appears:

Motor/Speed Test

- Speed select key

- Start/Stop

- (A) Measurement marking pulse ON

- (S) Measurement marking pulse OFF

The speed select key is used to set t he required speed and the motor set into motion

with Start/Stop.

Whilst running the motor speed can be controlled by using t he “A” key to activate the

setting of the measurement marking pulse and t o deactivate it with the “S” key. A

making pulse is set once every second. The running speed can then be calculated or

its accuracy checked from t he distance between marking pulses. Any other k ey

pressed not included in this menu leads to the initial dis play menu.

Page 32

Ma rque tte H e llige G mbH C a rdioS ma rt/ Ca rdioS ma rt S T V 1 . 2 / V 1. 3

227 435 11 D

Page 32

3.1.6 Test results (4)

Pressing the “4" key triggers the output of the test res ults.

The output of the test protoc ol supplies data on the software integrat ed in the device

(Part No., Version No., product ion date of the firmware), printhead voltage and the t est

results on the memory test performed during power-up.

The areas listed under RAM have the following meaning:

CardioSmart

0 - 080000h

512 kByte RAM area on the PCB Control CS_S

100000 - 140000h

256 kByte RAM area on the CardioProm (depending on CardioProm type)

140000 - 1C0000h

512 kByte RAM area buffered on the CardioProm (dep. on CardioProm type)

CardioSmart ST

0 - 080000h

512 kByte RAM area on the PCB Control CS_S

100000 - 180000h

256 kByte RAM area on the CardioProm (depending on CardioProm type)

180000 - 200000h

512 kByte RAM area buffered on the CardioProm (dep. on CardioProm ty pe)

Values may deviate from those given above, depending on the device or software

version used.

A specification in the form 100000 - 100000 permits the conclusion that this RAM area

does not exist in the device. However, if it does exist in conformity wit h the software

version implemented, this means that this RAM cell at address 100000H is defective.

The memory could also be defective when the initial and fi nal addresses of the memory

area differ and do not correspond to the above-mentioned limits . This then means, for

example, that the specificat ion 100000 - 123000 on the defective cell at address

123000H.

Following output the initial display menu reappears automatically .

Page 33

Ma rque tte H e llige G mbH C a rdioS ma rt/ Ca rdioS ma rt S T V 1 . 2 / V 1. 3

227 435 11 D

Page 33

3.1.7 Self-test

The test results elucidated in Sect ion 3.1.6 are ascertained during the self-test , which is

always performed on power-up. Should errors be detected, a message appears on the

display after the test, indicat ing the possible errors. The following error codes are used

to identify the error.

E rror code s

The following error codes appear on the display together with the mes sage “Self-test

failed”:

ERROR_CODES: 0 - reserved

1 VEKT - error in vector table

2 ERAM - RAM error on PCB Control

3 LCDR - LCDRAM error (Graphics Display)

4 - reserved

5 - reserved

6 RAMB - RAM error on the CardioProm

7 GRAM - error in buffered RAM on the CardioProm

8 ROMB - ROM error (checksum) on the CardioProm

9 - 10 not used

3.1.8 Recording test (5)

The recording test is activated by pres sing the "5" key and interrupted with the

"Start/Stop" key .

Immediately after pressing the "5" key t he printer begins to record the first channels at

25mm/s and 20mm/mV.

In addition, the message “Recording test ” appears on the display. In this test only t he

first two channels are passed on to t he printer. No other channels can be configured.

Page 34

Ma rque tte H e llige G mbH C a rdioS ma rt/ Ca rdioS ma rt S T V 1 . 2 / V 1. 3

227 435 11 D

Page 34

3.1.9 Interface test (6)

Several possibilities are available to test the serial interface. Moreover, on the one

hand, the signal transmission and rec eiving of the interface can be test ed by an

internal feedback from TXD and RXD and, on t he other hand, the signal transmission

and receiving with a remote station.

For the test with a remote station a st andard PC cable is required for a serial interface

(zero modem cable). In addition, the following trans mission protocol should be adjusted

at the remote station:

1 start bit, 8 data bits, parit y even

1 stop bit

Baud rate 9600

Pressing the “6" key calls up the f ollowing menu:

Interface test

(1) Transmitting and receiving

(2) Transmit test string to device

(3) Transmitting and receiving with device

( 1) T ra nsmitting a nd re ce iving

This test enables complete testing of the RS232 signal path for transmitting and

receiving, including RS232 driver and connector.

This test requires an RS232 connector with an int ernal bridge from pin 2 (RXDE) to pin

(TXDE). Depending on the result of the t est, the following message appears:

Test result : OK

or

Test result : Error

This procedure requires a software version as from V 4.1. Earlier software versions only

permit internal testing of the RS232 interf ace without including the RS232 driver.

(2 ) T ra nsmit te st string to de vice

In this test a remote station, e.g., PC must be connected up and hav e a terminal

program which can receive signals and be configured for the abov e-mentioned

protocol. If the remote stat ion is on receive, then every time the “2" key is pressed the

test string “Interface tes t” is transmitted to the remote st ation. Simultaneously, the

following message appears on the display:

Transmitting : interface test

Page 35

Ma rque tte H e llige G mbH C a rdioS ma rt/ Ca rdioS ma rt S T V 1 . 2 / V 1. 3

227 435 11 D

Page 35

( 3) T ra nsmitting a nd re ce iving with de vice

Transmitting and receiving can be tested with a remot e device by pressing the “3" key.

The device should be connected as described in (2).

After pressing the “3" key a tes t string is sent the remote station. The following

message appears on the display:

Transmitting: interface test

Receiving:

A subsequent input at the remote st ation is sent back to the device and display ed

there. Moreover, it should be noted that an input must take place within 10 s and the

input terminated with “return”. If the k ey is pressed a second time, then the st ring

"CardioSmart Test" is transmitted. Altogether there are three test st rings available,

which are sent in the following sequence with repeated key activation:

"Schnittstellenest", "CardioS mart-Test", "Sieht doch gut aus, oder?"

("Interface Test", CardioSmart Tes t", Looks good, doesn't it?")

The last string corresponds to the expec ted test result.

This test is terminated with any other k ey not used for a test.

3.1.10 Time and date (7)

This section deals with the quick chec king and setting of the time and date.

Pressing the “7" key calls up the f ollowing display:

Time / Date

10:12:03 10.11.1994

(S) Set

End with any key

From this screen the clock can be adjust ed by pressing the “S” key, the following mas k

appearing:

Time Date

[ ] [ ]

The first mask is for the time and t he second for the date.

Example: [1012] [10119] for 10:12 o´clock and 10.11.94

Pressing the return key terminates the entry. The adjusted data are subsequently

accepted and seconds set t o zero.

The test is terminated with any other key not used for a test.

Page 36

Ma rque tte H e llige G mbH C a rdioS ma rt/ Ca rdioS ma rt S T V 1 . 2 / V 1. 3

Page 36

227 435 11 D

3.1.11 Electrode test (8)

The electrode test is started by pres sing the “8" key.

The electrode test is terminated by press ing any key.

To evaluate the electrode states t he following status WORD is available.

Status = 0 -> Electrode OK

Status = 1 -> Electrode disconnected

Bit15 Bit0

----------------------------------------------------------------------| x | x |DAT|ELN|NAP|NST|NAX| C6 | C5 | C4 | C3 | C2 | C1 | F | L | R |

-----------------------------------------------------------------------

And precisely this status WO RD extended to LONG is displayed on the s creen during

the electrode test to be performed. I t is important to note, however, that this status

WORD is not displayed as a binary number but as a hexadec imal number.

However, to make the status of a part icular electrode quickly recognizable, defec tive

electrodes are represented by an ID c ode.

EX_R, for example, stands f or the defective electrode R and C1 for electrode C1.

This permits the identification of ev ery individual electrode. Naturally, since s everal

electrodes can become disconnected simult aneously, it was necessary to set a certain

priority in the display of disconnected elec trodes.

The following display priority was programmed:

EX_R, EL_N, EX_L, EX_F, C1, C2, C3, C4, C5, C6, NAX, NST, NAP

For example, if electrodes R and N have become disconnec ted, then first R is reported

with EX_R as having become disconnect ed. Only after R is OK is E L_N displayed.

Page 37

Ma rque tte H e llige G mbH C a rdioS ma rt/ Ca rdioS ma rt S T V 1 . 2 / V 1. 3

227 435 11 D

Page 37

3.1.12 Test time constants (9)

The test is started by pressing t he “9" key and interrupted with the "Start/S top" key.

Immediately after the “9" key has been act uated the printer begins to record the first

two channels at 25 mm/s and 20 mm/mV.

Moreover, the message “Testing time cons tants” appears on the display.

In this test only the first two channels send signals to the printer. No ot her channels

can be configured. The default time const ant is output on the printout as a control.

S etting the time consta nts

As a general rule, the time const ants are adjusted to 2.04 s.

This setting can be changed with the CORR_CO NFIG key.

The following settings are available:

Time constants:

(1) 0.260s (2) 0.130s (3) 0.033s

(4) 0.004s (5) 4.080s (6) 2.040s

(7) 1.020s (8) 0.510s

The figures given in parentheses indicate the key used to select the corresponding time

constant.

Verification of the currently ac tive time constant is only poss ible by printing out the selftest results (see Section 3. 1.6) or by testing the time constant s.

3.1.13 Setting the Device models (V)

The setting of the Device model is act ivated by pressing the “V” key, t he following

display image appears:

D e v i c e mode l

(1) INT

(2) USA

(3) EU_2

(4) ASIA

(5) RUSS

Terminate with any key.

The currently selected device model appears in reverse v ideo.

Page 38

Ma rque tte H e llige G mbH C a rdioS ma rt/ Ca rdioS ma rt S T V 1 . 2 / V 1. 3

Page 38

227 435 11 D

Warning!

C hanging the de vice mode l a ffe cts the se le ction of the output forma ts a nd la ngua ges

ava ila ble , can switch the program for I nte rpreta tion from HE AR T to 1 2 SL, or vice

versa . Also a ff ecte d a re the de fa ult configura tion se ttings, e . g. , ove rride function

yes/no, line filter 50/60 Hz.

T he de vice mode l configure d during ma nufa cture should only be cha nge d whe n

deemed really necessary.

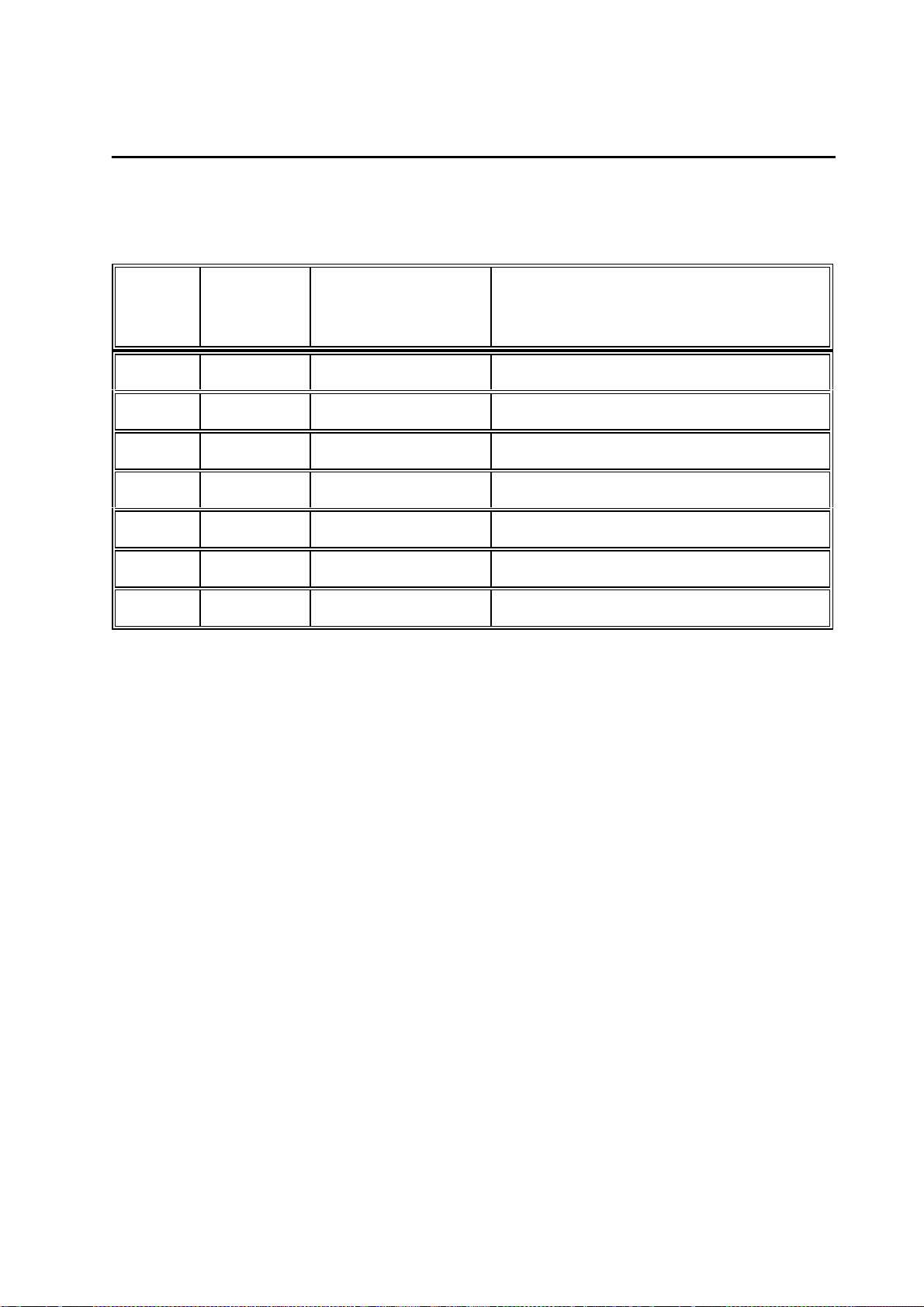

The following table shows the most important combinat ions:

Device model Interpretation Output

formats

01 INT HEART International g,e,f,i,s no 50 Hz

02 USA 12SL USA e,f,s yes 60 Hz

03 EU_2 12SL Int. +H1 +H2 e,g,f,sw yes 50 Hz

04 ASIA HEART International g,e,f no 50 Hz

05 RUSS HEART International g,e,f no 50 Hz

Languages Default settings

Override

function

enabled

Line filter

Output formats: - International: 12_FS, 12_F1, 12_F2, 6_F1, 6_F2, 3_F1

- USA: STND1, STND3, 1x10, 2x5, 2x5_ex, 3RHY1

The required device model is selected by pressing the appropriat e key, “1" to “5".

Quit selection menu by pressing any key .

Quit the self-test with “Shift ” + “Man” or “Shift” + “Mode”.

CardioSmart configures the appropriate items and init iates a cold start automatically.

Thus, when the device is rebooted automatically all the new settings are adopted.

Selecting a particular device model leads to t he configuration of the program for

Interpretation as indicated in the table above, even when the interpretation program

was configured differently beforehand as desc ribed in section 3.1.14.

N ote on sa ve d E C G s whe n configuring the de vice mode l:

Saved ECGs are not los t.

If when a new device model is selected, the program f or Interpretation is switched over,

however, when printing out the saved ECGs t he display in the status line (12SL, or

without in the case of HEART) is related to the currently enabled program for

Page 39

Ma rque tte H e llige G mbH C a rdioS ma rt/ Ca rdioS ma rt S T V 1 . 2 / V 1. 3

227 435 11 D

Interpretation, although the results are based on the program previously configured. In

this case, the saved E CGs should be printed out or transf erred to a PC before

configuration of the new model.

Page 39

3.1.14 Switching over the program for Interpretation(C)

Switching over the program for Interpretat ion is activated by pressing the “C” key , the

following display image appears:

I n t e r p r e t a t i o n

(1) HEART

(2) 12SL

Terminate with any key.

The currently enabled interpretation program appears in reverse video.

Warning!

S witching ove r to anot her progra m for I nte rpre ta tion a ffe cts the me a sure me nt re sults

and the inte rpreta tion!

T he progra m for I nt erpre ta tion conf igured during ma nufa cture should only be cha nge d

when deemed really necessary!

The required program for Interpretation is selected by pres sing the appropriate key, “1"

or “2".

Quit the selection menu by pressing any key.

Quit the self-test with “Shift ” + “Man” or “Shift” + “Mode”.

CardioSmart configures the appropriate items and init iates a cold start automatically.

Thus, when the device is rebooted automatically all the new settings are adopted.

N ote on sa ve d E C G s whe n switching ove r the progra n for I nte rpre ta tion:

Saved ECGs are not los t.

After switching over to a diff erent program for Interpretation when printing the saved

ECGs the display in the st atus line (12SL, or without in the case of HE ART) is related

to the newly selected interpretation program, alt hough the results are based on the

program previously configured. In this cas e the saved ECGs should be printed out or

transferred to a PC before switc hing over to the new program for Interpretation.

Page 40

Ma rque tte H e llige G mbH C a rdioS ma rt/ Ca rdioS ma rt S T V 1 . 2 / V 1. 3

227 435 11 D

Page 40

3 . 2 D evice te st functions with cha ra cte r displa y

( only Ca rdioS ma rt)

3 . 2 . 1 G e ne ra l informa tion

In contrast to the graphics display , at the current time the device tes t functions all

require menu-guided execution. This is because the renditi on of the character display

of max. 80 characters is very limit ed.

To be performed in their entirety some tests require special auxiliary aids, e.g.,

interface tester or PC, connec tion cables, signal generators, etc. Just what is required

for which test are given in the various tes t descriptions.

3.2.2 Test start

After simultaneous pressing of t he keys

S hift + Auto (CardioSmart) or S hift + M ode (CardioSmart ST)

the following initial display image appears:

END TEST: with Shift MAN

(CardioSmart ST)

Key used to select menu options are given in parentheses.

S Y S T E M T E S T

(CardioSmart) or Shift + Mode

3.2.3 Display test (1)

After pressing the “1" key the f ollowing menu appears:

Display test

(3) Delete display (4) Inverse

Pressing any other key than thos e given above leads back to the initial display image.

(3) Delete display

All the display pixels are disabled.

(4) Inverse

Inverse here does not mean inverse display of the rendered t ext, but inverse to delete

display, i.e., all the display pixels are enabled.

Page 41

Ma rque tte H e llige G mbH C a rdioS ma rt/ Ca rdioS ma rt S T V 1 . 2 / V 1. 3

227 435 11 D

C ontrast control

Furthermore, the contrast control c an also be adjusted under this option “Display test”.

Moreover, there are 7 levels available which can be run though with the CURSOR_UP

and CURSOR_DOWN keys.

3.2.4 Key test (2)

Pressing the “2" key calls up the f ollowing screen:

Page 41

(E) End

When a key is pressed this or its meaning is display ed. This can either occur by a

triple character display, e.g., “AAA” or as a text, e.g., "CURS_UP". Moreover, pressing

the “P” key tests the bleeper (audible sound) and pres sing the “K” key tests a micro

key to identify whether the cover f or the paper compartment is open or closed. The “E”

key terminates this test and s imultaneously undergoes a self-test. The initial dis play

image appears.

K e y T e s t

3.2.5 Motor test (3)

When the “3" key is pressed the following menu appears:

The speed select key is used to set t he required speed and the motor set into motion

with Start/Stop.

Whilst running the motor speed can be controlled by using t he “A” key to activate the

setting of the measurement marking pulse and t o deactivate it with the “S” key. A

marking pulse is set once every second. The running s peed can then be calculated or

its accuracy checked from t he distance between marking pulses.

Any other key pressed not included in t his menu leads to the initial display menu.

Motor/Speed Test

Page 42

Ma rque tte H e llige G mbH C a rdioS ma rt/ Ca rdioS ma rt S T V 1 . 2 / V 1. 3

227 435 11 D

Page 42

3.2.6 Test results (4)

Pressing the “4" key triggers the output of the test res ults.

The output of the test protoc ol supplies data on the software integrat ed in the device

(Part No., Version No., product ion date of the firmware), printhead voltage and the t est

results on the memory test performed during power-up.

The areas listed under RAM have the following meaning:

Car dioSmart

0 - 080000h

512 kByte RAM area on the PCB Control CS_S

100000 - 140000h

256 kByte RAM area on the CardioProm (depending on CardioProm type)

140000 - 1C0000h

512 kByte RAM area buffered on the CardioProm (dep. on CardioProm

type)

CardioSmart ST

0 - 080000h

512 kByte RAM area on the PCB Control CS_S

100000 - 180000h

256 kByte RAM area on the CardioProm (depending on CardioProm type)

180000 - 200000h

512 kByte RAM area buffered on the CardioProm (dep. on CardioProm

type)

Values may deviate from those given above depending on t he device or software

version used.

A specification in the form 100000 - 100000 permits the conclusion that this RAM area

does not exist in the device. However, if it does exist in conformity wit h the software

version implemented, this means that this RAM cell at address 100000H is defective.

The memory could also be defective when the initial and fi nal addresses of the memory

area differ and do not correspond to the above-mentioned limits . This then means, for

example, that the specificat ion 100000 - 123000 on the defective cell at address

123000H.

The output can be interrupted with the Start /Stop key. Following output the initial

Page 43

Ma rque tte H e llige G mbH C a rdioS ma rt/ Ca rdioS ma rt S T V 1 . 2 / V 1. 3

227 435 11 D

display menu reappears automatically.

Page 43

3.2.7 Self-test

The test results elucidated in Sect ion 3.2.6 are ascertained during the self-test , which is

always performed on power-up. Should errors be detected, a message appears on the

display after the test indicating t he possible errors. The following error codes are used

to identify the error.

E rror code s

The following error codes appear on the display together with the mes sage “Self-test

failed”:

ERROR_CODES: 0 - reserved

1 VEKT - error in vector table

2 ERAM - RAM error on PCB Control

3 LCDR - LCDRAM error (G raphics Display)

4 - reserved

5 - reserved

6 RAMB - RAM error on the CardioProm

7 GRAM - error in buffered RAM on the CardioProm

8 ROMB - ROM error (checksum) on the CardioProm

9 - 10 not used

3.2.8 R e cor ding te st (5)

The recording test is activated by pres sing the "5" key and interrupted with the

"Start/Stop" key .

Immediately after pressing the "5" key t he printer begins to record the first channels at

25mm/s and 20mm/mV.

In addition, the message “Recording test ” appears on the display. In this test only t he

first two channels are passed on to t he printer. No other channels can be configured.

Page 44

Ma rque tte H e llige G mbH C a rdioS ma rt/ Ca rdioS ma rt S T V 1 . 2 / V 1. 3

227 435 11 D

Page 44

3.2.9 Interface test (6)

Several possibilities are available to test the serial interface. Moreover, on the one

hand, the signal transmission and rec eiving of the interface can be test ed by an

internal feedback from TXD and RXD and, on t he other hand, the signal transmission

and receiving with a remote station.

For the test with a remote station a st andard PC cable is required for a serial interface

(zero modem cable). In addition, the following trans mission protocol should be adjusted

at the remote station:

1 start bit, 8 data bits, parity even

1 stop bit

Baud rate 9600

Pressing the “6" key calls up the f ollowing menu:

Interface test Keys (1), (2), (3)

‘1' key te sts transmission and re ce iving

( 1) T ra nsmitting a nd re ce iving

This test enables complete testing of the RS232 signal path for transmitting and

receiving, including RS232 driver and connector.

This test requires an RS232 connector with an int ernal bridge from pin 2 (RXDE) to pin

(TXDE). Depending on the result of the t est, the following message appears:

Test result : OK

or

Test result : Error

This procedure requires a software version as from V 4.1. Earlier software versions only

permit internal testing of the RS232 interf ace without including the RS232 driver.

(2 ) T ra nsmit te st string to de vice

In this test a remote station, e.g., PC must be connected up and hav e a terminal

program which can receive signals and be configured for the abov e-mentioned

protocol. If the remote stat ion is on receive, then every time the “2" key is actuated the

test string “Interface tes t” is transmitted to the remote st ation. Simultaneously, the

following message appears on the display:

Transmitting : interface test

Page 45

Ma rque tte H e llige G mbH C a rdioS ma rt/ Ca rdioS ma rt S T V 1 . 2 / V 1. 3

227 435 11 D

( 3) T ra nsmitting a nd re ce iving with de vice

Transmitting and receiving can be tested with a remot e device by pressing the “3" key.

The device should be connected as described in (2).

After pressing the “3" key a tes t string is sent the remote station. The following

message appears on the display:

Interface test Keys (1), (2), (3)

A subsequent input at the remote st ation is sent back to the device and display ed

there. A received text would then be dis played on the second line of the screen.

Moreover, it should be noted that an input must take place within 10 s and the input

terminated with “return”. If the key is actuated a second time then the string

"CardioSmart Test" is transmitted. Altogether there are three test st rings available,

which are sent in the following sequence with repeated key actuation:

"Interface Test", "CardioSmart Tes t", "Looks good, doesn´t it?"

The last string corresponds to the expec ted test result.

This test is terminated with any other k ey not used to start a test.

Page 45

3.2.10 Time and date (7)

This section deals with the quick chec king and setting of the time and date.

Pressing the “7" key calls up the f ollowing display:

Time / Date

10:12:03 10.11.1994

From this screen the clock can be adjust ed by pressing the “S” key the following mask

appearing:

Time Date

[ ] [ ]

The first mask is for the time and t he second for the date.

Example: [1012] [10119] for 10:12 o´clock and 10.11.94

Pressing the return key terminates the entry. The adjusted data are subsequently

accepted and seconds set t o zero.

The test is terminated with any other key not used for a test.

Page 46

Ma rque tte H e llige G mbH C a rdioS ma rt/ Ca rdioS ma rt S T V 1 . 2 / V 1. 3

Page 46

227 435 11 D

3.2.11 Electrode test (8)

The electrode test is started by pres sing the “8" key.

The electrode test is terminated by press ing any key.

To evaluate the electrode states t he following status WORD is available.

Status = 0 -> Electrode OK

Status = 1 -> Electrode disconnected

Bit15 Bit0

----------------------------------------------------------------------| x | x |DAT|ELN|NAP|NST|NAX| C6 | C5 | C4 | C3 | C2 | C1 | F | L | R |

-----------------------------------------------------------------------

And precisely this status WO RD extended to LONG is displayed on the s creen during

the electrode test to be performed. I t is important to note, however, that this status

WORD is not displayed as a binary number but as a hexadec imal number.

However, to make the status of a part icular electrode quickly recognizable, defec tive

electrodes are represented by an ID c ode.

EX_R, for example, stands f or the defective electrode R and C1 for electrode C1.

This permits the identification of ev ery individual electrode. Naturally, since s everal

electrodes can become disconnected simult aneously, it was necessary to set a certain

priority in the display of disconnected elec trodes.

The following display priority was programmed:

EX_R, EL_N, EX_L, EX_F, C1, C2, C3, C4, C5, C6, NAX, NST, NAP

For example, if electrodes R and N have become disconnec ted, then first R is reported

with EX_R as having become disconnect ed. Only after R is OK is E L_N displayed.

3.2.12 Test time constants

(9)

The test is started by pressing t he “9" key and interrupted with the "Start/S top" key.

Immediately after the “9" key has been act uated the printer begins to record the first

two channels at 25 mm/s and 20 mm/mV.

Moreover, the message “Testing time cons tants” appears on the display.

In this test only the first two channels send signals to the printer. No ot her channels

can be configured. The default time const ant is output on the printout as a control.

Page 47

Ma rque tte H e llige G mbH C a rdioS ma rt/ Ca rdioS ma rt S T V 1 . 2 / V 1. 3

227 435 11 D

S etting the time consta nts

As a general rule, the time const ants are adjusted to 2.04 s.

This setting can be changed with the CORR_CO NFIG key.

The following settings are available:

Time constants:

(1) 0.260s (2) 0.130s (3) 0.033s

(4) 0.004s (5) 4.080s (6) 2.040s

(7) 1.020s (8) 0.510s

The figures given in parentheses indicate the key used to select the corresponding time

constant.

Verification of the currently ac tive time constant is only poss ible by printing out the selftest results (see Section 3. 2.6) or by testing the time constant s (see Section 5.2.8).

Page 47

3.2.13 Setting the Device model (V)

This setting is only available form Sof tware Release V4.21.

Setting the Device model is acti vated by pressing the “V” key, the f ollowing display

image appears:

D e v i c e M o d e l --> (1) INT

(1) INT (2) USA (3) EU_2 (4) ASIA (5) RUSS

Terminate with any key.

The currently enabled device model appears in line 1.

Warning!

C hanging the de vice mode l a ffe cts the se le ction of the output forma ts a nd la ngua ges