Page 1

Series 2000 Treadmill

field service manual

PN 409110-004 Revision D

A PART OF THE

MARQUETTE

UNITY

NETWORK

Page 2

NOTE

Due to continuing product innovation,

specifications in this manual are subject to

change without notice.

Copyright Marquette Medical Systems, Inc. 1998. All rights reserved.

Trademarked names appear throughout this document. Rather than list the names and entities that own the

trademarks or insert a trademark symbol with each mention of the trademarked name, the publisher states that

it is using the names only for editorial purposes and to the benefit of the trademark owner with no intention of

improperly using the trademark.

ACCUSKETCH, AccuVision, APEX , AQUA-KNOT, ARCHIVIST, Autoseq, BABY MAC, CardioServ, CardioSmart,

CardioSys, CardioWindow, CASE, CD TELEMETRY, CENTRA, CHART GUARD, CINE 35, CORO, COROMETRICS,

CRG PLUS, Digistore, Digital DATAQ, E for M, EAGLE, Event-Link, HELLIGE, IMAGE STORE, INTELLIMOTION,

LASER SXP, MAC, MAC-LAB, MACTRODE, MARQUETTE, MARQUETTE MAC, MARQUETTE UNITY NETWORK,

MARS, MAX, MEDITEL, MEI, MEI in the circle logo, MEMOPORT, MEMOPORT C, MINISTORE, MINNOWS,

Monarch 8000, MULTI-LINK, MULTISCRIPTOR, MUSE, MUSE CV, Neo-Trak, NEUROSCRIPT, OnlineABG,

OXYMONITOR, Pres-R-Cuff, PRESSURE-SCRIBE, QMI, QS, Quantitative Medicine, Quantitative Sentinel, Qwik

Connect Spiral, RAMS, RSVP, SAM, SEER, SOLAR, SOLARVIEW, Spectra 400, Spectra-Tel, ST GUARD, TRAM,

TRAM-NET, TRAM-RAC, TRAMSCOPE, TRIM KNOB, UNITY logo, UNITY NETWORK, Vari-X, Vari-X

Cardiomatic, VariCath, VAS, and Vision Care Filter are trademarks of Marquette Medical Systems, Inc.,

registered in the United States Patent and Trademark Office.

12SL, 15SL, AccuSpeak, ADVANTAGE, BAM, BODYTRODE, Cardiomatic, CardioSpeak, CD TELEMETRY®-LAN,

CENTRALSCOPE, Corolation, Corometrics Sensor Tip, DASH, EDIC, HI-RES, IMAGE VAULT, IMPACT.wf,

INTER-LEAD, IQA, LIFEWATCH, MARQUETTE MEDICAL SYSTEMS, MARQUETTE® RESPONDER, MENTOR,

MicroSmart, MMS, MRT, MUSE CardioWindow, O2 SENSOR, OMRS, Premium, RAC, SILVERTRACE, SMARTPAC, SMARTLOOK, Spectra-Overview, Trimline, UNITY, and Universal are trademarks of Marquette Medical

Systems, Inc.

T-2

Series 2000 Treadmill

409110-004

Revision D

22 July 1998

Page 3

i

Contents

1

Introduction ................................................ 1-1

Manual Information .................................................................. 1-3

Revision History ................................................................................. 1-3

Manual Purpose ................................................................................. 1-3

Conventions ....................................................................................... 1-4

Safety Information .................................................................... 1-5

Responsibility of the Manufacturer .................................................... 1-5

General ............................................................................................... 1-5

Equipment Symbols ........................................................................... 1-6

Warnings and Cautions ...................................................................... 1-7

Service Information .................................................................. 1-9

Service Requirements ........................................................................ 1-9

Equipment Identification .................................................................... 1-9

Revision D

Series 2000 Treadmill

409110-004

Page 4

ii

2

Equipment Overview ..................................... 2-1

General Description .................................................................. 2-3

Intended Use ...................................................................................... 2-3

Motor Drive System ........................................................................... 2-3

Elevation System ................................................................................ 2-3

Bed Assembly .................................................................................... 2-3

Electronic Assembly ........................................................................... 2-3

Block Diagram .................................................................................... 2-4

Preparation for Use ................................................................... 2-5

Safe Handling Guidelines ................................................................... 2-5

Equipment Assembly ......................................................................... 2-6

Handle Set ............................................................................ 2-6

Emergency Stop Switch ........................................................ 2-7

Connector Locations .......................................................................... 2-8

Operating Instructions ............................................................... 2-9

Electrical Safety Tests ........................................................................ 2-9

Operating Controls ............................................................................. 2-9

Power Switch ....................................................................... 2-9

Emergency Stop Switch ........................................................ 2-9

Controlling the Treadmill .................................................................. 2-10

Emergency Stop Switch Check ........................................................ 2-10

3

Maintenance ............................................... 3-1

Introduction ...................................................................... 3-3

Recommended Maintenance .............................................................. 3-3

Inspection Report ................................................................. 3-3

Required Tools and Supplies ............................................................. 3-3

Inspection and Cleaning ............................................................. 3-4

Visual Inspection ................................................................................ 3-4

Exterior Cleaning ................................................................................ 3-4

Interior Cleaning ................................................................................ 3-4

Domestic Electrical Safety Tests ................................................... 3-5

AC Line Voltage Test .......................................................................... 3-5

120 VAC, 50/60 Hz ............................................................... 3-5

240 VAC, 50/60 Hz ............................................................... 3-5

Leakage Tests .................................................................................... 3-6

Leakage Test Diagrams ...................................................................... 3-7

Series 2000 Treadmill

409110-004

Revision D

Page 5

Test #1 ............................................................................................... 3-7

Ground-Wire-Leakage-to-Ground .........................................3-7

Test #2 ............................................................................................... 3-7

Chassis-Leakage-to-Ground (Exposed Chassis) ................... 3-7

Test #3 ............................................................................................... 3-8

Patient-Cable-Leakage-to-Ground .........................................3-8

Test #4 ............................................................................................... 3-8

Patient Cable-Leakage-into-Patient Leads-from 120 VAC ..... 3-8

Ground Continuity Test ...................................................................... 3-9

Self-Calibration ..................................................................... 3-10

When to Calibrate ............................................................................. 3-10

Activating Self-Calibration ................................................................ 3-10

4

Belt Tracking Adjustments ......................................................... 3-11

When to Adjust ................................................................................ 3-11

Check Treadmill Level ...................................................................... 3-11

Adjust Pulley Screws ....................................................................... 3-12

Miscellaneous Maintenance Forms ............................................... 3-13

Troubleshooting ........................................... 4-1

Power PCB Theory .................................................................... 4-3

General Description ............................................................................ 4-3

Power Distribution/Isolation .............................................................. 4-3

STOP Circuitry ................................................................................... 4-3

Frequency-to-Voltage Converter/Amplifier ......................................... 4-3

Start/Stop Circuitry ............................................................................ 4-4

Elevation Relays ................................................................................. 4-4

Drive Connector ................................................................................. 4-4

Hall Feedback ..................................................................................... 4-4

Power Inlet, Drive Power Outlet, and Mains ....................................... 4-4

Control Board Connector ................................................................... 4-4

Elevation Sensor ................................................................................ 4-5

Isolation Transformer ........................................................................ 4-5

Power Supplies .................................................................................. 4-5

Isolated Serial Link ............................................................................. 4-5

Debug/Serial Link ............................................................................... 4-5

ESD and EMI Compatibility ................................................................ 4-6

Power Supply Requirements .............................................................. 4-6

Precautions ...................................................................................... 4-12

Initial Board Conditions .................................................................... 4-12

Revision D

Series 2000 Treadmill

409110-004

iii

Page 6

iv

Control PCB Theory .................................................................. 4-13

General Description .......................................................................... 4-13

Power Distribution ........................................................................... 4-13

Clock Generator ............................................................................... 4-13

Reset Generator ............................................................................... 4-13

Temperature Sensor ........................................................................ 4-14

Processor Circuitry .......................................................................... 4-14

Analog Inputs ................................................................................... 4-14

Speaker Output ................................................................................ 4-14

Analog Outputs ................................................................................ 4-15

Analog Supplies ............................................................................... 4-15

Supplies ........................................................................................... 4-15

ESD and EMI Compatibility .............................................................. 4-15

Brushless DC Drive Theory ......................................................... 4-16

General Description .......................................................................... 4-16

Phases and Power Switches ............................................................ 4-16

Motor Torque ................................................................................... 4-16

Motor Speed .................................................................................... 4-16

Drive Motor Control Box Description ............................................. 4-17

Power Board .................................................................................... 4-17

Control Board ................................................................................... 4-17

LED Functions .................................................................................. 4-17

User Inputs/Outputs ......................................................................... 4-19

Electrical Requirements ................................................................... 4-21

General Fault Isolation ............................................................. 4-22

Visual Inspection .............................................................................. 4-22

Power Down ....................................................................... 4-22

Shroud Removal .............................................................................. 4-23

Parts Locations ................................................................................ 4-24

Power Supply Voltage Checks .......................................................... 4-25

Speaker Check ................................................................................. 4-25

Service Port ..................................................................................... 4-25

Drive Control Fault LEDs .................................................................. 4-26

DC Motor Replacement ............................................................. 4-27

Replacement Instructions ................................................................ 4-27

Front Roller Replacement .......................................................... 4-29

Replacement Instructions ................................................................ 4-29

Walking Belt and Board Replacement ............................................ 4-30

Walking Belt Replacement Instructions ............................................ 4-30

Walking Board Replacement Instructions ........................................ 4-31

Motor Drive Belt Replacement and Adjustments ............................... 4-32

Tension Adjustments ....................................................................... 4-32

Tracking Adjustments ...................................................................... 4-33

Series 2000 Treadmill

Revision D

409110-004

Page 7

v

Elevation Motor Replacement ..................................................... 4-34

Replacement Instructions ................................................................ 4-34

Electronics Box Replacement ...................................................... 4-35

Replacement Instructions ................................................................ 4-35

Drive Motor Control Box Replacement ........................................... 4-36

Replacement Instructions ................................................................ 4-36

5A

5B

Parts Lists and Drawings for Configuration

without CE ................................................. 5A-1

Ordering Parts ..................................................................... 5A-3

Introduction ..................................................................................... 5A-3

Field Replaceable Units For Product CodeY5 (non-CE) ........................ 5A-4

Rev R Upper-Level Assembly......................................... 5A-5

900433-001G Full Handrail Kit................................................. 5A-6

900367-001T Treadmill Assembly ............................................ 5A-7

900418-101B Electronics Box Assembly ................................... 5A-14

88380-006B Stop Switch Assembly........................................ 5A-16

Parts Lists and Drawings for Configuration

with CE ..................................................... 5B-1

Ordering Parts ..................................................................... 5B-3

Introduction ..................................................................................... 5B-3

Revision D

Field Replaceable Units for Product Code Y5 w/CE ............................ 5B-4

Rev R Upper-Level Assembly......................................... 5B-5

900444-00XG 50/60 Hz Full Handle Assembly............................... 5B-6

900433-001G Full Handrail Kit................................................. 5B-6

900367-002T Treadmill Assembly w/CE ..................................... 5B-7

900418-102B Electronics Box Assembly w/CE ............................ 5B-14

88380-006B Stop Switch Assembly........................................ 5B-16

Series 2000 Treadmill

409110-004

Page 8

vi

6

Appendices

PCB Assemblies ........................................... 6-1

800320-001H Control PCB....................................................... 6-3

SD800320-001G Control PCB Schematic ......................................... 6-6

800334-003A Power PCB ....................................................... 6-12

SD800334-003A Power PCB Schematic ......................................... 6-16

Appendix A: Abbreviations ............................... A-1

Standard Abbreviations .............................................................. A-3

Appendix B: Technical Description ......................B-1

Technical Specifications ............................................................ B-3

Series 2000 Treadmill

409110-004

Revision D

Page 9

1

Introduction

Manual Information ..................................................................... 3

Manual Purpose ..................................................................................... 3

Conventions ........................................................................................... 4

Safety Information ....................................................................... 5

General ................................................................................................... 5

Equipment Symbols ............................................................................... 6

Warnings and Cautions .......................................................................... 7

Service Information ..................................................................... 9

Equipment Identification ........................................................................ 9

Revision D

Series 2000 Treadmill

409110-004

1-1

Page 10

1-2

Series 2000 Treadmill

409110-004

Revision D

Page 11

Manual Information

Introduction : Manual Information

Revision History

Revision Date Comment

A 30 January 1997 Initial release of manual. This manual covers the Y% product code (Thor controller). This

replaces the -003 and includes RS232 port. There are two parts lists chapters for CE and non-CE.

B 21 February 1997 Changed page 2-8 due to product label correction of the fuse. F2 is 0.5ASB.

C 6 June 1997 Added “Intended Use” and recommendations on use of rails and emergency stop switch from

American Heart Association.

D 22 July 1998 Removed CE page, updated parts lists and technical specifications.

Manual Purpose

Each page of the document has the document part number followed by

a revision letter at the bottom of the page. This letter identifies the

document’s update level. The latest letter of the alphabet corresponds

to the most current revision of the document.

The revision history of this document is summarized in the table below.

Table 1-1. Revision History PN 409110-004

This manual supplies technical information for service representatives

and technical personnel so they can maintain the equipment at the

assembly and subassembly level. It is intended to function primarily as a

guide for maintenance and electrical repairs considered field repairable.

The manual includes: maintenance and troubleshooting guides, parts

lists, illustrations of assembly parts, and some schematics.

Revision D

Series 2000 Treadmill

409110-004

1-3

Page 12

Introduction : Manual Information

Conventions

These are the conventions used in this manual.

Safety Messages

DANGER safety messages indicate an imminently hazardous situation

which, if not avoided, WILL result in death or serious injury.

WARNING safety messages indicate a potentially hazardous situation

which, if not avoided, COULD result in death or serious injury.

CAUTION safety messages indicate a potentially hazardous situation

which, if not avoided may result in minor or moderate injury.

NOTE messages provide additional user information.

Definitions

Items shown in Black text are keys on the keyboard, text to be

■

entered, or hardware items such as buttons or switches on the

equipment.

■

Items shown in Italicized text are software terms which identify

menu items, buttons, or options in various windows.

■

To perform an operation which appears with a plus (+)sign

between the names of two keys, you press and hold the first key

while pressing the second key once. This is called a keystroke

combination.

For example, “Press Ctrl + Esc ” means to press and hold down

the Ctrl key while pressing the Esc key.

When instructions are given for typing a precise text string with

■

one or more spaces, the point where the spacebar must be

pressed is indicated as: <Space>. The purpose of the < >

brackets is to ensure you press the spacebar when required.

Enter means to press the “Enter” or “Return” key on the

■

keyboard. Do not type “enter”.

1-4

Series 2000 Treadmill

409110-004

Revision D

Page 13

Safety Information

Introduction : Safety Information

Responsibility of the

Manufacturer

General

Marquette Medical Systems, is responsible for the effects of safety,

reliability, and performance only if:

Assembly operations, extensions, readjustments, modifications,

■

or repairs are carried out by persons authorized by Marquette.

The electrical installation of the relevant room complies with

■

the requirements of the appropriate regulations.

The equipment is used in accordance with the instructions for

■

use.

To ensure patient safety, use only parts and accessories manufactured

or recommended by Marquette Medical Systems.

Contact Marquette Medical Systems for information before connecting

any devices to this equipment that are not recommended in this

manual.

The use of ACCESSORY equipment not complying with the equivalent

safety requirements of this equipment may lead to a reduced level of

safety of the resulting system. Consideration relating to the choice shall

include:

■

use of the accessory in the PATIENT VICINITY; and

evidence that the safety certification of the ACCESSORY has

■

been performed in accordance to the appropriate IEC 601-1

and/or IEC 601-1-1 harmonized national standard.

Revision D

Series 2000 Treadmill

409110-004

1-5

Page 14

Introduction : Safety Information

Equipment Symbols

The following symbols appear on the equipment.

This symbol means that you must pay attention to the documents delivered with this

equipment. It calls attention to the things to which you must pay special attention

during operation and when the equipment is operated in conjunction with other

equipment.

In Europe, this symbol means dangerous or high voltage. In the United States, this

symbol represents the caution notice below:

CAUTION

To reduce the risk of electric shock,

do NOT remove cover (or back).

Refer servicing to qualified

personnel.

Type B equipment. Type B equipment is suitable for intentional external and internal

application to the patient, excluding direct conductive connection to the patient’s

heart.

M15287-16A

Alternating current (AC)

Equipotential (This is the ground lug.)

Protective earth (ground)

M13495, M13504, M13864, M13571, M13574, M13573

1-6

Series 2000 Treadmill

409110-004

Revision D

Page 15

Warnings and Cautions

Introduction : Safety Information

DANGER

Do NOT use in the

presence of flammable

anesthetics.

WARNING

Replace only with the

same type and rating

of fuse.

WARNING

This is Class I

equipment. The mains

plug must be connected

to an appropriate power

supply.

M15287-1B

M15287-2B

M15287-5C

WARNING

Total system leakage

current must not

exceed 300

microamperes.

M15287-76A

WARNING

Wait until treadmill belt

is moving before

placing feet on belt.

M15287-11B

WARNING

Keep hands, hair,

jewelry, and loose

clothing away from

moving parts.

M15287-26B

WARNING

Keep leakage current

within acceptable limits

when connecting

auxiliary equipment to

this device.

WARNING

Do NOT contact unit or

patient during

defibrillation.

Revision D

M15287-7C

M15287-8C

Series 2000 Treadmill

409110-004

WARNING

Do not place feet under

treadmill during

elevation changes.

Otherwise, serious

injury could result.

M15287-36A

WARNING

Route the AC power

cable away from

moving parts.

M15287-64A

1-7

Page 16

Introduction : Safety Information

WARNING

Verify proper operation

of the stop switch

assembly, pn 88380-006,

every month.

M15287-065A

WARNING

Operate the treadmill

with 6 feet of clearance

at the rear (end opposite

the motor).

M15287-066A

1-8

Series 2000 Treadmill

409110-004

Revision D

Page 17

Service Information

Introduction : Service Information

Service Requirements

Equipment Identification

Refer equipment servicing to Marquette Medical Systems’ authorized

service personnel only. Any unauthorized attempt to repair equipment

under warranty voids that warranty.

It is the user’s responsibility to report the need for service to Marquette

Medical Systems or to one of their authorized agents.

Failure on the part of the responsible individual, hospital, or institution

using this equipment to implement a satisfactory maintenance schedule

may cause undue equipment failure and possible health hazards.

Regular maintenance, irrespective of usage, is essential to ensure that

the Series 2000 treadmill will always be functional when required.

Every Marquette Medical Systems device has a unique serial number for

identification. The serial number appears on the product label on the

base of each unit.

A

B

C

IH G F ED

Table 1-2. Equipment Identifications

Item Name Description

A name of device Series 2000 treadmill

B manufacturer Marquette Medical Systems

C serial number Unique identifier

D device characteristics One or two letters that further describe the unit, for example: P = prototype not

conforming to marketing specification; R = refurbished equipment; S = special

product documented under Specials part numbers; U = upgraded unit

E division F = Cardiology G = Monitoring J = GW Labs

F product sequence number Manufacturing number (of total units manufactured.)

G product code Two-character product descriptor Y5 = Treadmill

H year manufactured 6 = 1996, 7 = 1997, 8 = 1998, (and so on)

I month manufactured A = January, B = February, C = March, D = April, E = May, F = June, G = July,

H = August, J = September, K = October, L = November, M = December

MD1113-022B

Revision D

Series 2000 Treadmill

409110-004

1-9

Page 18

Introduction : Service Information

1-10

Series 2000 Treadmill

409110-004

Revision D

Page 19

2

Equipment Overview

General Description ..................................................................... 3

Intended Use .......................................................................................... 3

Motor Drive System ............................................................................... 3

Elevation System .................................................................................... 3

Bed Assembly ........................................................................................ 3

Electronic Assembly ............................................................................... 3

Block Diagram ........................................................................................ 4

Preparation for Use ...................................................................... 5

Equipment Assembly ............................................................................. 6

Handle Set ................................................................................6

Emergency Stop Switch ............................................................7

Connector Locations .............................................................................. 8

Operating Instructions .................................................................. 9

Operating Controls ................................................................................. 9

Power Switch ...........................................................................9

Emergency Stop Switch ............................................................9

Controlling the Treadmill ...................................................................... 10

Emergency Stop Switch Check ............................................................ 10

Revision D

Series 2000 Treadmill

409110-004

2-1

Page 20

2-2

Series 2000 Treadmill

409110-004

Revision D

Page 21

General Description

Equipment Overview : General Description

Standard features include the emergency stop switch, a full handrail set,

and a long, 60-inch walking surface. Designed for simplified

serviceability, the Series 2000 Treadmill has fewer moving parts than

other treadmills, built-in self-calibration, and easy-to-replace

assemblies.

Intended Use

Motor Drive System

The Series 2000 Treadmill is intended for use with any one of the several

Marquette Medical Systems exercise testing systems or the MTC-1

(manual treadmill controller) for administering a controlled exercise

load during a diagnostic stress test.

The emergency stop switch is intended for emergency situations where

immediately stopping the treadmill is required to deliver appropriate

emergency care to the patient or health care provider, as implied by the

American Heart Association “Guidelines for Clinical Exercise Testing

Laboratories” (1995). It is not intended for routinely stopping the

treadmill.

The 3 HP, brushless, DC motor is controlled by a separate control box,

and it connects directly to the front roller with a drive belt. An 11-pound

flywheel, attached to the motor’s drive shaft, keeps “footfall” variance to

a minimum. An “adjustment plate” between the motor and the

treadmill frame contains two bolts for adjusting the drive belt tension.

The increase of horsepower raises the weight capacity from 350 lbs. for

previous treadmills to 450 lbs.

Elevation System

Bed Assembly

Electronic Assembly

Revision D

The elevation system uses a rack and pinion operation to raise and

lower the treadmill rather than jack screws and chains. The elevation

motor attaches to a small gearbox that connects to the pinion shaft.

The upper- and lower-limit switches ride along one of the pinion “legs,”

making them easy to reach and adjust. Replacing the elevation motor

only requires the removal of the three mounting bolts and detaching the

motor from the pinion shaft coupling.

The one-piece bed assembly, with side rails and struts welded together,

enables quick parts replacement for field service personnel.

An isolated “electronics box” contains the power supply PCB and the

control PCB. The box is instantly accessible with the shroud removed

and can be replaced as a complete assembly.

Series 2000 Treadmill

409110-004

2-3

Page 22

Equipment Overview : General Description

Block Diagram

DRIVE MOTOR

CONTROL BOX

2TB

1TB

TB1-4

TB1-5

TB1-6

800334-00X POWER BOARD

EMI

FILTER

L-C FILTERS

ELECTRONICS BOX

30 M

FL 1

FL 2

(3) 10M Ohm

F4, F5

FUSES

CHASSIS

L1

L2

TB1-1

TB1-2

TB1-3

SCREWS

TERMINALS

SCREW

TERMINALS

5 V distributed

BLEED–OFF

RESISTORS

GND

3TB

RIBBON

J5

both PCBs

throughout

U9

5 VOLT

POWER

HALLS

1, 2, 3, 4, 5

U1

SUPPLY

T1

XFMR

RT1

F1

0.5ASB

EXTERNAL

J12

U7

5 VOLT

LIMITER

F2

FUSES

PULSED

4, 5

HALLS

TACH_A

POWER

SUPPLY

ISOLATED

8 - PIN

RS - 232

ISOLATED

POWER BOARD

320V

J6

CONTROL RELAYS

ELEVATION MOTOR

TACH_B

F6, F7

FUSES

PCB

MINI-DIN

OR

OPTION

800334-003

other PCBs)

(located behind

RUN CAP

(mounted to

10 µF MOTOR

K1, K2, K4

STOP-PB

K3

STOP RELAY

OPTO-

U10, U11

COUPLERS

PLASTIC

9 - PIN “D”

J1

RS - 422

ISOLATED

STRESS

SYSTEM

chassis)

TXCOMM

RXCOMM

J3

U5,U6

FREQ TO

U12

E - STOP

J8

SPEED/0-10V

VOLT

AMPL

CONV/

OPTO-

COUPLER

5V

(OPT)

REMOTE

DRIVE ROLLER

INSULATED

DRIVE BELT

MOTOR

DRIVE SYSTEM

3.0 HP BRUSHLESS

HALLS

1 THRU 5

J7

SPEAKER

U2

J1/J9 - CPU I/F

-7.5 V

J4 SELF–CAL

J2

9-PIN "D"

SERVICE PORT

DEBUG/ANA OUT

COVER

SERVICE

ELEVATION RACKS

ELEVATION SYSTEM

LS1

(located on

Power PCB)

DRIVER

SPEAKER

5V

16.5 V

RS-232 AND

ANALOG OUTPUTS

U1, U3, U7, U8, U12

ELEVATION MOTOR

U10

SRAM

62256

U9

78310

PROCESSOR

VOLTAGE

DOUBLERS

(–7.5 V and +16.5 V)

COUPLING

INSULATED

1/8 HP

220 V 50/60 HZ

CHASSIS

INSULATED SPACERS

“FLOATING GROUND”

U13

8K X 8

EEPROM

800320-00X CONTROL BOARD

U12, U16

TEMP SENSOR

CB1

20ASB

SWITCH

LIGHTED

INPUT

POWER

50/60 Hz

200-240 V

LOW LIMIT SWITCH

HIGH LIMIT SWITCH

2 -2 .5 KVA

ELEVATION FEEDBACK

(International

AEROVOX EMI

FILTER MODULE

DOMESTIC UNITS

INLET

POWER

CABLE

POWER

5 - TURN POT

Units w/CE)

20 AMP

NEMA 6-20R

WALL OUTLET:

MD1129-007E

2-4

Series 2000 Treadmill

409110-004

Revision D

Page 23

Preparation for Use

Equipment Overview : Preparation for Use

Safe Handling

Guidelines

The Series 2000 Treadmill ships preset with an approximate 2% grade.

This slight elevation provides for free wheel movement and prevents the

shroud from scraping the floor.

If you are moving the treadmill after it has been in operation, use the

controlling equipment to set the grade to approximately 7%. Then

remove power and disconnect all cables to the treadmill before moving

the unit.

Follow the steps below to move the treadmill. We recommend that two

people work together since the treadmill may be too heavy for some

individuals to lift and lower safely.

1. Lift the end of the bed assembly to about knee height, keeping

knees bent and backs straight as you lift.

2. Rotate the treadmill in the direction you want to go (the

treadmill will pivot on its wheels) and push forward.

3. When you have maneuvered the treadmill into its new location,

gently lower the end of the bed assembly to the floor.

Revision D

Series 2000 Treadmill

409110-004

Lift up

MD1128-022

2-5

Page 24

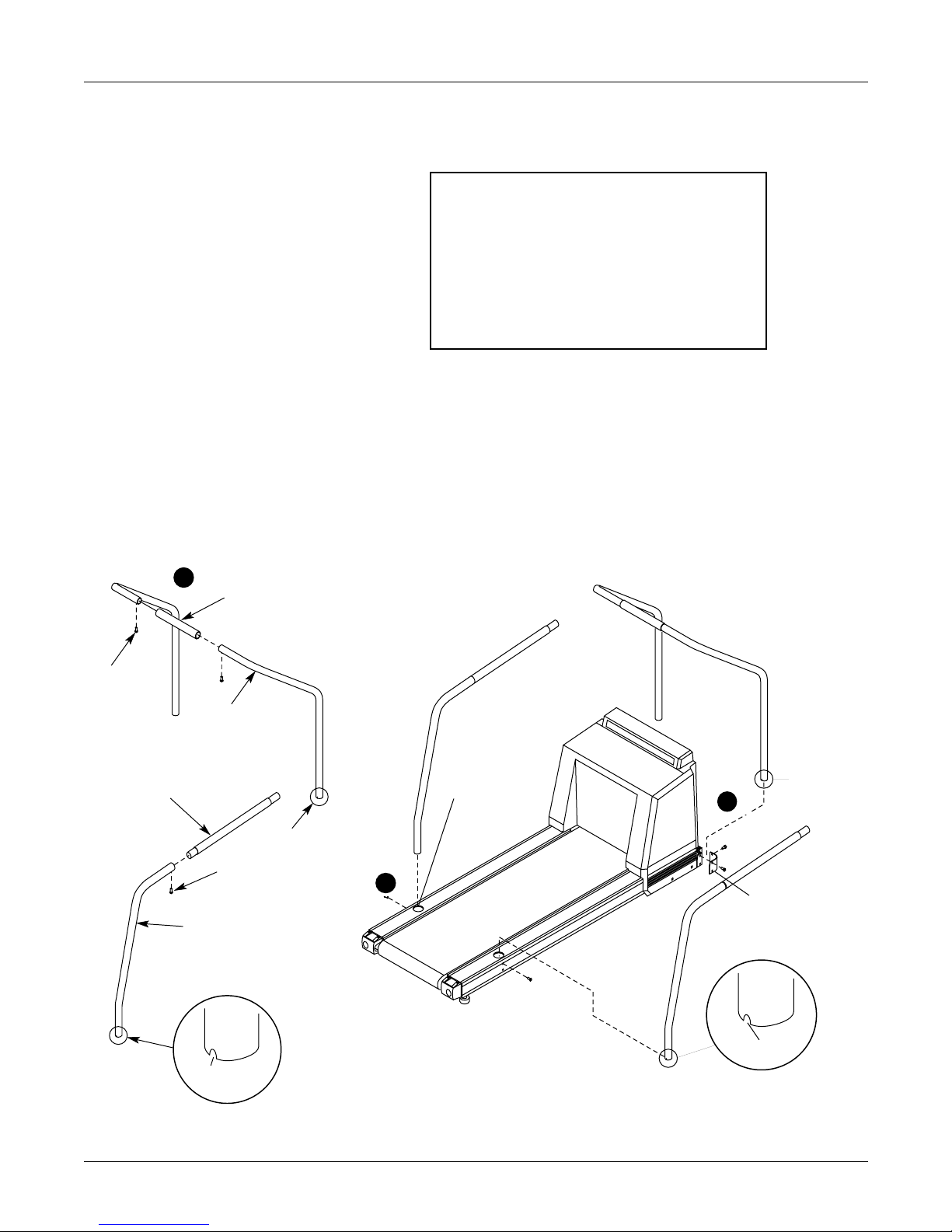

NOTE

As recommended by the American Heart

Association Exercise Standards (Special

Report, Vol 82, No 6), the treadmill

should have front and side rails installed

for patients to steady themselves. An

emergency stop switch must be visible

and readily accessible.

Equipment Overview : Preparation for Use

Equipment Assembly

Handle Set

The Series 2000 Treadmill ships completely assembled except for the

handle set and the emergency stop switch. Attach the handle set and

emergency stop switch before applying power to the unit.

1. Insert the wood front handrail into the metal side rails, then

align the predrilled holes and screw in the two Phillips screws on

both sides. Assemble the optional side rails in the same way.

2. Place the assembled front handrail into the metal mounting

brackets on the front corners of the shroud. Using the supplied

Allen wrench and four bolts, secure the handrail to the brackets.

3. Place the assembled side rails into the side mounting holes and

screw in the two bolts on each side.

1

Screw

Wood Side Handrail

Metal Side Rail

Wood Front Handrail

Metal Front Rail

Right Side

Notch

Screw

Side Rail

Mounting Hole

Left Side

2

Notch

3

Front Handrail

Mounting Bracket

Right Side

Right Side

MD1128-003C

Notch

2-6

Series 2000 Treadmill

409110-004

Notch

Notch Represents

Right Side

MD1128-004B

Revision D

Page 25

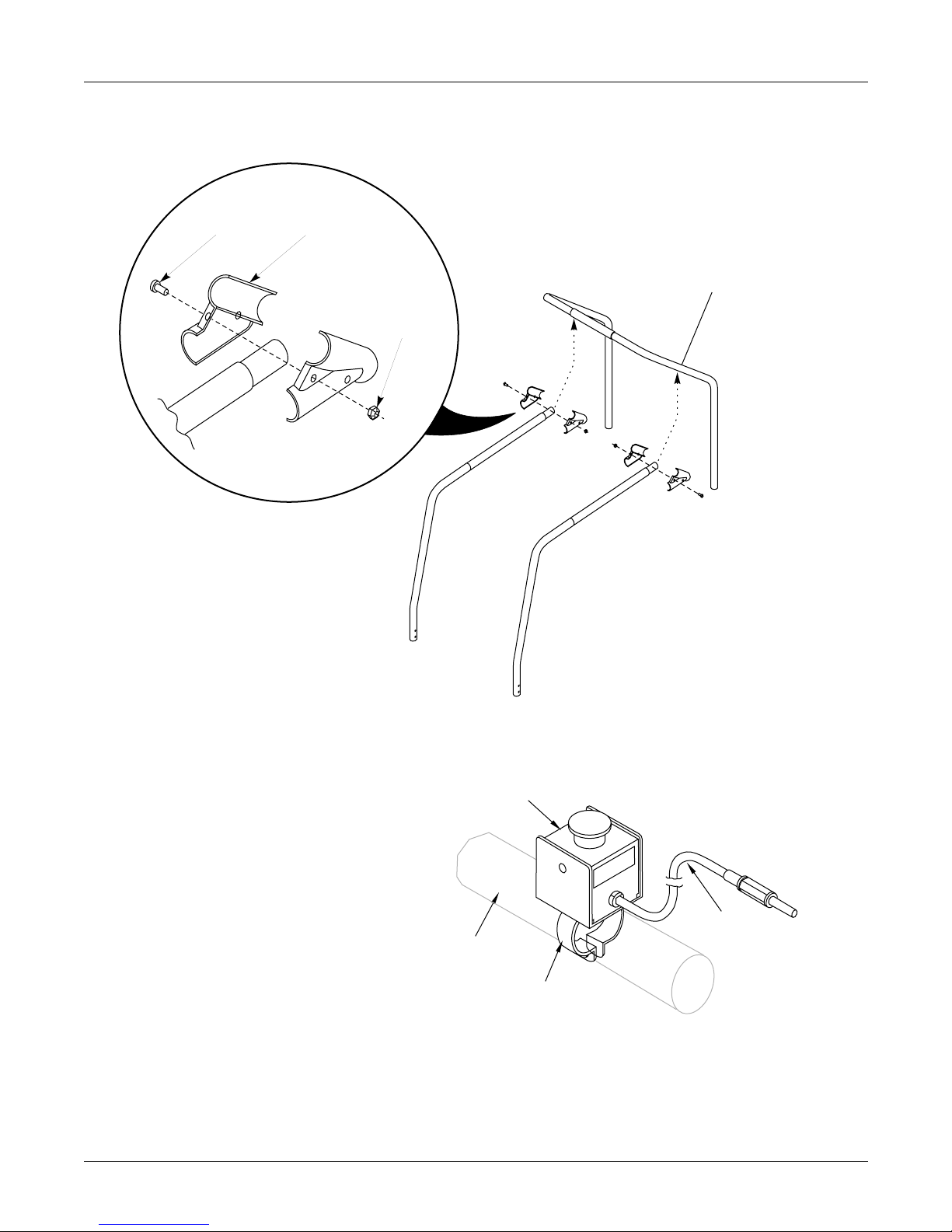

Equipment Overview : Preparation for Use

4. Attach the side rails to the front rail with the mated T-brackets.

Tighten the two T-bracket bolts with the Allen wrench.

Bolts

2 Places

Typical two places

T-bracket

Align the side rails to the

predrilled guide holes in the

front rails.

Nuts

2 Places

Emergency Stop Switch

MD1128-005C

1. Attach the two clamp pieces to the assembled, latching

emergency stop switch.

Emergency Stop

Switch Assembly

Cable

Handrail

Clamp

MD1128-006A+

2. Position the clamps around the treadmill front handrail and

secure with the supplied screw and nut.

3. Connect the cable from the emergency stop switch to the

mating connector on the treadmill’s rear connector panel.

4. Use the cord clips to attach the cable along the front handrail.

Revision D

Series 2000 Treadmill

409110-004

2-7

Page 26

WARNING

M15287-64A

Route the AC power

cable away from

moving parts.

Equipment Overview : Preparation for Use

Connector Locations

The illustration below shows the various input connectors on the rear

panel of the treadmill. Attach the appropriate controller cable from the

stress system or MTC-1 and the AC power cable.

SERIES

treadmil

F1 0.5ASB

250V

F2 0.5ASB

250V

WARNING: FOR CONTINUED

PROTECTION AGAINST RISK OF

FIRE REPLACE ONLY WITH FUSE

OF SAME TYPE AND RATING.

ON/OFF Power Switch

CAUTION: ELECTRICAL SHOCK HAZARD.

DO NOT REMOVE COVER. REFER

SERVICING TO QUALIFIED PERSONNEL.

CAUTION: DO NOT USE BOTH

CONNECTORS AT THE SAME TIME.

RS-232

SERIAL CONT

RS-422

SERIAL CONT

STOP

220-240V~ 50-60Hz 16A

RS-232 Port

(Connection to: CardioSys, MAC VU,

MAX-1, MAX Personal)

RS-422 Serial Port

(Connection to: MTC-1, CASE 15,

CENTRA)

Emergency Stop Switch Connection

Service Port

SERVICE

Equipotential (ground lug)

AC Power Connection

(220–240V, 50–60Hz, 20A)

MD1128-001E

2-8

Series 2000 Treadmill

409110-004

Revision D

Page 27

Operating Instructions

Equipment Overview : Operating Instructions

Electrical Safety Tests

Operating Controls

The electrical safety of this installation is the responsibility of the

customer, not Marquette Medical Systems. In hospitals, contact your inhouse biomedical technician, electrician, or technically qualified

personnel. Outside of hospitals, contact your hospital affiliation for

these services. Otherwise, contact Marquette Medical Systems and open

a customer-billable service call.

Before using the treadmill, perform the tests listed below.

AC line voltage test to verify the power outlet is properly wired.

■

Ground continuity test to verify all exposed metal is properly

■

grounded.

Leakage tests to verify the equipment passes all applicable

■

leakage tests.

Your in-house biomedical technician, electrician, or technically

qualified personnel can find instructions for performing these tests in

chapter 3, “Maintenance.”

The treadmill has two operating controls, the power switch and the

emergency stop switch. The power switch is located on the rear panel,

and the emergency stop switch is on the front handrail.

Power Switch

Emergency Stop Switch

The power switch controls the AC power to the treadmill. The on

position (1) applies power. The off position (0) removes power.

The emergency stop switch is a safety device for use in emergency

situations to stop the treadmill. Press the “STOP” push-button and the

treadmill promptly stops but the belt will not lock, allowing for removal

of foreign objects. To release the emergency stop switch, turn the pushbutton 1/4-turn in either direction.

Revision D

Series 2000 Treadmill

409110-004

2-9

Page 28

Equipment Overview : Operating Instructions

Turn the power switch on (1).

Controlling the Treadmill

■

Use the controlling equipment to start the treadmill, adjust the

■

treadmill speed and grade, proceed through the exercise phases,

terminate the exercise session, and turn off the treadmill.

WARNING

WARNING

Wait until treadmill belt

is moving before

placing feet on belt.

M15287-11B

Emergency Stop Switch

Check

Do not place feet under

treadmill during

elevation changes.

Otherwise, serious

injury could result.

M15287-36A

WARNING

Keep hands, hair,

jewelry, and loose

clothing away from

moving parts.

M15287-26B

With the belt moving at a relatively high speed, press the

■

emergency stop switch. The treadmill belt will stop promptly

but the belt will not lock, allowing for removal of foreign objects.

To release the switch, turn the button 1/4-inch turn in either

direction.

2-10

Use the controlling equipment to terminate the exercise session

■

and turn off the treadmill.

Series 2000 Treadmill

409110-004

Revision D

Page 29

3

Maintenance

Introduction ............................................................................... 3

Recommended Maintenance .................................................................. 3

Inspection Report .....................................................................3

Required Tools and Supplies ................................................................. 3

Inspection and Cleaning ................................................................ 4

Visual Inspection .................................................................................... 4

Exterior Cleaning .................................................................................... 4

Interior Cleaning .................................................................................... 4

Domestic Electrical Safety Tests ...................................................... 5

AC Line Voltage Test .............................................................................. 5

120 VAC, 50/60 Hz ...................................................................5

240 VAC, 50/60 Hz ...................................................................5

Leakage Tests ........................................................................................ 6

Leakage Test Diagrams .......................................................................... 7

Test #1 ................................................................................................... 7

Ground-Wire-Leakage-to-Ground .............................................7

Test #2 ................................................................................................... 7

Chassis-Leakage-to-Ground (Exposed Chassis) .......................7

Test #3 ................................................................................................... 8

Patient-Cable-Leakage-to-Ground ............................................8

Test #4 ................................................................................................... 8

Patient Cable-Leakage-into-Patient Leads-from 120 VAC .........8

Ground Continuity Test .......................................................................... 9

Revision D

Self-Calibration ........................................................................ 10

When to Calibrate ................................................................................. 10

Activating Self-Calibration .................................................................... 10

Belt Tracking Adjustments ........................................................... 11

When to Adjust .................................................................................... 11

Check Treadmill Level .......................................................................... 11

Adjust Pulley Screws ........................................................................... 12

Miscellaneous Maintenance Forms ................................................. 13

Series 2000 Treadmill

409110-004

3-1

Page 30

3-2

Series 2000 Treadmill

409110-004

Revision D

Page 31

NOTE

Unless you have an Equipment

Maintenance Contract, Marquette Medical

Systems does not in any manner assume

the responsibility for performing the

recommended maintenance procedures.

The sole responsibility rests with the

individual or institution using the equipment.

Marquette Medical Systems service

personnel may, at their discretion, follow the

procedures provided in this manual as a

guide during visits to the equipment site.

Introduction

Maintenance : Introduction

Recommended

Maintenance

Inspection Report

A regular equipment maintenance program helps prevent unnecessary

equipment and power failures and also reduces possible health hazards.

This chapter contains instructions for the following recommended

maintenance:

Inspecting and cleaning the unit

■

Power source integrity test

■

Leakage safety tests

■

Resistance measurements

■

Self-calibration

■

Belt tracking adjustments

■

To help you establish a systematic maintenance routine, Marquette

Medical Systems recommends that, every six months, you perform the

maintenance checks and test procedures on the “Preventive

Maintenance Inspection Report,” included at the end of this chapter.

(Make extra copies of the report form to use as an inspection check-off

list.)

Required Tools and

Revision D

Supplies

To maintain and repair the treadmill, you will need the following:

Standard hand tools

■

DVOM

■

Leakage current tester PN MT-1216-01 (for 120 V), PN MT-1216-

■

02 (for 240 V), or equivalent

Anti-septic cleaner

■

Dust remover (compressed air)

■

Series 2000 Treadmill

409110-004

3-3

Page 32

Maintenance : Inspection and Cleaning

Inspection and Cleaning

Visual Inspection

Exterior Cleaning

Regularly inspect the AC power cord and all other cords and cables for

fraying or other damage. Perform safety tests on any repaired line cords.

Inspect all plugs, cables and connectors for bent prongs or pins. Verify

that all cords, socketed components, and connectors are securely

seated.

Inspect the following for excessive wear or damage:

Walking belt

■

Drive belt

■

Handrail and hardware

■

Test the stop switch assembly monthly.

Turn the treadmill system off. Clean the exterior surfaces with a clean,

soft cloth and a mild dishwashing detergent diluted in water. Wring out

the excess water from the cloth and take care not to drip solutions on

the keyboard or writer assembly. (Use anti-septic cleaner on the

handrails and walking belt.) Avoid contact with open vents, plugs or

connectors. Dry the surfaces with a clean cloth or paper towel.

Interior Cleaning

Complete any pre-service procedures prior to opening the unit or

performing any interior cleaning. Clean the unit as needed, but at least

once per month.

3-4

Series 2000 Treadmill

409110-004

Revision D

Page 33

GROUND

NEUTRAL

LINE

❶❷

❶

MD1128-011

GROUND

HOT

HOT

❶

❶

❷

MD1128-012

Domestic Electrical Safety Tests

Maintenance : Domestic Electrical Safety Tests

AC Line Voltage Test

120 VAC, 50/60 Hz

This test verifies that the domestic wall outlet supplying power to the

equipment is properly wired. For international wiring tests, refer to the

internal standards agencies of that particular country.

Use a digital voltmeter to check the voltages of the 120-volt AC wall

outlet (dedicated circuit recommended). If the measurements are

significantly out of range, have a qualified electrician repair the outlet.

The voltage measurements should be as follows:

1. 120 VAC (± 10 VAC) between the line contact and neutral and

between the line contact and ground.

2. Less than 3 VAC between neutral and ground.

240 VAC, 50/60 Hz

Revision D

Use a digital voltmeter, set to measure at least 300 VAC, to check the

voltages of the NEMA 6-20R, AC wall outlet (dedicated circuit

recommended). If the measurements are significantly out of range, have

a qualified electrician repair the outlet. The voltage measurements

should be as follows:

1. 120 VAC (± 10 VAC) between either “hot” contact and ground.

2. 210 to 230 VAC between the two “hot” contacts.

Series 2000 Treadmill

409110-004

3-5

Page 34

NOTE

The accuracy of the leakage tests depends

on a properly-wired wall outlet. Do not

proceed until you verify the integrity of the

power source.

WARNING

M15287-76A

Total system leakage

current must not

exceed 300

microamperes.

Maintenance : Domestic Electrical Safety Tests

Leakage Tests

The leakage tests are safety tests to ensure that the equipment poses no

electrical health hazards. Use the table below to determine which tests

apply to the unit under test and the maximum allowable leakage

currents. For international leakage limits, refer to the internal standards

agencies of that particular country.

If the unit under test fails the leakage tests, do not allow the customer to

use the equipment. Call Tech Support for assistance. (See the “How to

Reach Us” page in the front of the manual.)

Marquette Medical Systems recommends that you perform these tests:

Before applying power for the first time

■

Every 6 months as part of routine maintenance

■

Whenever internal assemblies are serviced

■

Table 3-1. Leakage Tests and Maximum Allowable Leakage Currents

Test Applies To Maximum Current (µA)

1 Ground-wire-leakage-to-ground MAX-1 stress system 300

2 Chassis-leakage-to-ground MAX-1 stress system 300

3 Patient-cable-leakage-to-ground Acquisition module 10

4 Patient-cable-leakage-into-patient-leads-from-120 V ac Acquisition module 20

3-6

Series 2000 Treadmill

409110-004

Revision D

Page 35

Maintenance : Domestic Electrical Safety Tests

Leakage Test Diagrams

Test #1

Ground-Wire-Leakage-to-Ground

Tester

power

Line

Neutral

Gnd

cord

These diagrams show only a representation of how a typical leakage

current tester functions. Follow the instructions provided with the

leakage current tester that you use.

“To be tested” power connector on back of

tester (may not be labeled on some testers).

Tester

connectors

Meter

Polarity

Norm

Rvs

Neutral

1K

Line

Gnd

UUT

power

cord

Unit

under

test

(UUT)

Test #2

Chassis-Leakage-to-Ground

(Exposed Chassis)

Tester

power

Line

Neutral

Gnd

cord

V

Apply line voltage to the UUT chassis for this test.

“To be tested” power connector on back of

tester (may not be labeled on some testers).

Tester

Meter

connectors

Polarity

Norm

Rvs

Neutral

1K

Line

Gnd

UUT

power

cord

Probe to

exposed chassis

Unit

under

test

(UUT)

M13052-001E

Revision D

V

Series 2000 Treadmill

409110-004

M13052-002E

3-7

Page 36

Maintenance : Domestic Electrical Safety Tests

Test #3

Patient-Cable-Leakage-to-Ground

Line

Neutral

Gnd

Tester

power

cord

Tester

Meter

connectors

Polarity

Norm

Rvs

Neutral

1K

Line

Gnd

“To be tested” power connector on back of

tester (may not be labeled on some testers).

UUT

power

cord

Unit

under

test

(UUT)

Patient cable

Test #4

Patient Cable-Leakage-into-

Patient Leads-from 120 VAC

Tester

power

Line

Neutral

Gnd

cord

V

Patient

cable connectors

M13052-003E

During this test, line voltage is applied to the patient cable connectors.

To prevent erroneous readings, don not allow the leadwires to contact

conductive materials such as metal handles, and do not place the

leadwires on the floor.

“To be tested” power connector on back of

tester (may not be labeled on some testers).

Tester

Polarity

Norm

Rvs

Line

Neutral

Gnd

UUT

power

cord

Unit

under

test

(UUT)

3-8

Meter

connectors

Series 2000 Treadmill

409110-004

1K

V

Patient

cable connectors

Patient cable

M13052-004E

Revision D

Page 37

MD1128-007A+

<0.1Ω

Maintenance : Domestic Electrical Safety Tests

Ground Continuity Test

This test verifies that there is continuity (less than 100 m Ω resistance)

between all the exposed metal surfaces, which have the potential to

become energized, and the ground prong on the mains AC power cord.

If the metal surfaces are anodized or painted, scrape off a small area in

an inconspicuous area on the aluminum casting for the probe to make

direct contact with the metal.

Use a digital multimeter to check all the metal surfaces of the

equipment as illustrated below. Make adjustments for any resistance in

the test leads.

If the measurements are significantly out of range, check for breaks in

the power cord or in the internal connections within the unit.

Revision D

Series 2000 Treadmill

409110-004

3-9

Page 38

Maintenance : Self-Calibration

Self-Calibration

When to Calibrate

Activating

Self-Calibration

Marquette Medical Systems recommends that you activate the

self-calibration feature every time you replace a major assembly or a

circuit board.

To activate the Series 2000 Treadmill self-calibration feature, do the

following:

1. Remove the plate covering the service port on the rear panel of

the treadmill.

2. Remove controlling device (MAX-1, CASE, CENTRA, MTC-1)

cable or turn off the controlling device.

3. Below the service port are two prongs (pins). Place a screwdriver

between the two self-calibration prongs to short the circuit and

activate the self-calibration software.

The software calibrates the speed and grade from the minimum

points to the maximum points.

3-10

Series 2000 Treadmill

409110-004

Revision D

Page 39

Belt Tracking Adjustments

WARNING

Keep hands, hair,

jewelry, and loose

clothing away from

moving parts.

M15287-26B

Maintenance : Belt Tracking Adjustments

When to Adjust

Check Treadmill Level

The treadmill walking-belt tension is set at the factory. However, you

should test the belt tracking every time the treadmill is moved. Run the

treadmill for several minutes with no one exercising. If the belt tracks to

one side or the other, then you must adjust the belt tracking.

It is not unusual for the treadmill belt to move slightly off center while a

person with a heavy gait is exercising. A properly adjusted belt recenters

itself when the person steps off the treadmill. If the belt does not

recenter, check the treadmill level and adjust the belt tracking as

described.

1. Use the controlling equipment to set the treadmill elevation to

0.0%.

2. Check the treadmill level with a carpenter’s level.

3. If the treadmill is uneven, adjust the feet at the rear of the

treadmill until it is stable.

For stability, use one shim of the right thickness (rather than

several thin shims) to achieve the proper level.

If necessary, use longer shims to accommodate the maximum

treadmill elevation. The treadmill wheels must not roll off the

shims. Verify that the shim lengths exceed the wheel movement

when the treadmill is fully elevated.

Revision D

4. If you cannot level the treadmill safely with shims, move the

treadmill to another location.

Series 2000 Treadmill

409110-004

3-11

Page 40

Maintenance : Belt Tracking Adjustments

NOTE

Make adjustments to the pulley screws in

small increments. Over-adjustments and

repeated tightening of the screws can cause

too much tension on the belt.

Pulley Screws

MD1129-016B

Adjust Pulley Screws

1. Use the controlling equipment to set the belt speed to 4 or 5

miles per hour (7 or 8 kilometers per hour).

2. To correct a belt that tracks to the right, turn the right pulley

adjustment screw CLOCKWISE in 1/8-turn increments until the

belt tracks in the center. Wait 2 or 3 minutes between each 1/8turn to allow the belt position to stabilize.

To correct a belt that tracks to the left, turn the left pulley

adjustment screw CLOCKWISE in 1/8-turn increments until the

belt tracks in the center. Wait 2 or 3 minutes between each 1/8turn to allow the belt position to stabilize.

3. If either adjustment in step 2 results in an over-adjustment of

the belt tracking, loosen the pulley screw that was tightened and

wait several minutes for the treadmill belt position to stabilize.

Then tighten the other pulley adjustment screw.

3-12

Series 2000 Treadmill

409110-004

Revision D

Page 41

Maintenance : Miscellaneous Maintenance Forms

Miscellaneous Maintenance Forms

Marquette Medical Systems recommends that every six months you

perform the maintenance checks and test procedures on the

“Preventive Maintenance Inspection Report” (see following page).

These maintenance procedures can be performed more often if

indicated.

Revision D

Series 2000 Treadmill

409110-004

3-13

Page 42

Maintenance : Miscellaneous Maintenance Forms

3-14

Series 2000 Treadmill

409110-004

Revision D

Page 43

Series T2000 Treadmill

Preventive Maintenance I nspection Report

Customer______________________________ Customer Number______________________ Date___________

FE ___________________________________ FE ID________ Call Number______________________________

Equipment Serial Number_________________ Software Revision _________

DPMFRM-003B

31 July 1998

Configuration ()

___ Emergency Stop Switch installed

Tools

1. Leakage tester 3. Standard hand tools 5. ESD Mat and Wrist Strap

2. Multimeter 4. Service Manual (p/n 409110-001)

Visual Insp ection ()

Insp ect the followi ng for excess wea r and/or an y visual signs of damage.

1. ___ Walking belt 3. ___ Connectors 5. ___ Handrail hardware

2. ___ Interface cable 4. ___ AC power cord 6. ___ Drive belt

Cleaning ()

1. ___ Handrails 2. ___ Shroud 3. ___ Walking belt

Page 1 of 3

Calibration ()

1. ___ Speed calibration (2 mph = 10 revolutions in 38 seconds +/- 2 seconds)

2. ___ Grade calibration (@ 10% +/- .75 inches)

Electrical Safety Checks ()

Refer to PM Application Form XPMAPP-001-4 class B for leakage standards for specific voltages.

1. ___ Wall Receptacle Tes t

2. ___ Groun d Continuity (Impedence of protected connection )T est(≤ .1Ω or ≤.2Ω w/power cord)

3. Leakage

Normal Reversed Normal Reversed

Ground(Earth) wire leakage to ground test ___ ___ NA NA

Chassis(Enclosure) leakage to ground test ___ ___ ___ ___

Open Closed

Checkout Procedure ()

1. Perform the applicable checkout procedure(s) listed below using the FRU Checkout Procedure document, after a major

assembly is replaced.

1.____ Increase and decrease speed from minimum to maximum using controlling un it(MAX-1, CASE 15, etc.) to

verify operation.

2.____ Raise and lower elevation from 0% to 25% using controlling unit(MAX-1, CASE 15, etc.) to verify operation.

3.____ Depress emergency stop switch(if installed) while unit running at 3 m.p.h. to confirm operation.

4.____ Monitor walking belt tracking at 3 m.p.h. Adjust, if necessary, usi ng procedure in Field Service manual.

5.____ Verify speed calibration, 2 m.p.h. = 10 revolutions in 38 seconds.

6.____ Verify elevation calibration. Adjust, if necessary, using calibration procedure in Field Service manual.

7.____ Monitor drive belt for slipping, squeaking and mis-alignment. Adjust, if necessary, using procedure in Fiel d

Service manual.

8.____ Perform Self-Calibr ation procedure. Refer t o Field Service Manual for details.

Template Revision C

Page 44

DPMFRM-003B

Page 2 of 3

Comments

Brief ly describe all rep airs/adjustments made and list all parts replaced:

___________________________________________________________________________________________________

___________________________________________________________________________________________________

Additional comments:

___________________________________________________________________________________________________

___________________________________________________________________________________________________

Template Revision C

Page 45

FRU Checkout Procedure

FRU

Description*

Drive Controller Box(Thor)

Control(CPU) Pcb

Power Pc b

Drive Belt

Walking Belt

Walking Board

3 HP Speed Motor

Elevation Motor

Front Roller

Rear Roller

Software

Hardware Upgrades

(Including Firmware)

Supplies

Non-Listed FRU’s

No Parts Replaced

* The FRU Checkout procedure for any listed FRU also applies to it’s internal PCB’s and parts.

Tools Visual

Inspection

1,4 - - 1 3 1,3,8

1,4 - - 1,2 3 1,3,8

1,4 - - 1,2 2 1,3,8

---- - 1,7

---- - 1,4

---- - 1,4

4 - - 1 3 1,5,8

4 - - 2 3 2,6,8

4 - - - - 1,4,5,7

4 - - - - 1,4,5,7

- - - - - 1,2,8

Perform applicable Checkout Procedure(s)

Perform applicable Checkout Procedure(s)

Cleaning Calibration Electrical

Safety Tests

Perform complete PM

Perform complete PM

Checkout

Procedure

Template Revision C

Page 46

Page 47

4

Troubleshooting

Power PCB Theory ....................................................................... 3

General Description ................................................................................ 3

Power Distribution/Isolation .................................................................. 3

STOP Circuitry ....................................................................................... 3

Frequency-to-Voltage Converter/Amplifier ............................................. 3

Start/Stop Circuitry ................................................................................ 4

Elevation Relays ..................................................................................... 4

Drive Connector ..................................................................................... 4

Hall Feedback ......................................................................................... 4

Power Inlet, Drive Power Outlet, and Mains ........................................... 4

Control Board Connector ....................................................................... 4

Elevation Sensor .................................................................................... 5

Isolation Transformer ............................................................................ 5

Power Supplies ...................................................................................... 5

Isolated Serial Link ................................................................................. 5

Debug/Serial Link ................................................................................... 5

ESD and EMI Compatibility .................................................................... 6

Power Supply Requirements .................................................................. 6

Precautions .......................................................................................... 12

Initial Board Conditions ........................................................................ 12

Revision D

Control PCB Theory .................................................................... 13

General Description .............................................................................. 13

Power Distribution ............................................................................... 13

Clock Generator ................................................................................... 13

Reset Generator ................................................................................... 13

Temperature Sensor ............................................................................ 14

Processor Circuitry .............................................................................. 14

Analog Inputs ....................................................................................... 14

Speaker Output .................................................................................... 14

Analog Outputs .................................................................................... 15

Analog Supplies ................................................................................... 15

Supplies ............................................................................................... 15

ESD and EMI Compatibility .................................................................. 15

Brushless DC Drive Theory ........................................................... 16

General Description .............................................................................. 16

Phases and Power Switches ................................................................ 16

Motor Torque ....................................................................................... 16

Motor Speed ........................................................................................ 16

Series 2000 Treadmill

409110-004

4-1

Page 48

Drive Motor Control Box Description ............................................... 17

Power Board ........................................................................................ 17

Control Board ....................................................................................... 17

LED Functions ...................................................................................... 17

User Inputs/Outputs ............................................................................. 19

Electrical Requirements ....................................................................... 21

General Fault Isolation ............................................................... 22

Visual Inspection .................................................................................. 22

Power Down ...........................................................................22

Shroud Removal .................................................................................. 23

Parts Locations .................................................................................... 24

Power Supply Voltage Checks .............................................................. 25

Speaker Check ..................................................................................... 25

Service Port ......................................................................................... 25

Drive Control Fault LEDs ...................................................................... 26

DC Motor Replacement ............................................................... 27

Replacement Instructions .................................................................... 27

Front Roller Replacement ............................................................ 29

Replacement Instructions .................................................................... 29

Walking Belt and Board Replacement .............................................. 30

Walking Belt Replacement Instructions ................................................ 30

Walking Board Replacement Instructions ............................................ 31

Motor Drive Belt Replacement and Adjustments ................................. 32

Tension Adjustments ........................................................................... 32

Tracking Adjustments .......................................................................... 33

Elevation Motor Replacement ....................................................... 34

Replacement Instructions .................................................................... 34

Electronics Box Replacement ........................................................ 35

Replacement Instructions .................................................................... 35

Drive Motor Control Box Replacement ............................................. 36

Replacement Instructions .................................................................... 36

4-2

Series 2000 Treadmill

409110-004

Revision D

Page 49

Power PCB Theory

Troubleshooting : Power PCB Theory

General Description

Power Distribution/

Isolation

The 800334-002 power board and the 800320-001 control board

function together as part of the electronics box to control the Series 2000

Treadmill. The power board contains the following:

Mains components

■

Isolation transformer

■

Elevation and drive interface circuitry

■

Speaker (for error codes)

■

Serial control links

■

The serial control links receive inputs from a stress system controller

along with feedback from the treadmill sensors, send the inputs to the

control board, and then receive the control signals for the drive and

elevation motors.

The power board receives 185 V to 265 VAC power (nominal 220V). The

isolation transformer supplies 5 V to both the isolated communication

link and the control board.

Bypass caps are distributed across the board to minimize EMI and

power supply noise. All other supplies are created on the 800320-001

control board.

STOP Circuitry

Frequency-to-Voltage

Converter/Amplifier

When the belt is moving, pushing the normally-closed STOP switch

activates (and latches) the dynamic braking on the drive system. This

takes place as soon as the stop relay K3 is released. The K3 relay also can

be released with a processor RESET* or when the +5 voltage drops too

low.

When a stop occurs, the 4538 timer and frequency-to-voltage converter

disables the output speed (0-10 .3V) for 2.2 seconds and signals the

processor that a stop occurred, even if the switch was only momentarily

depressed.

The 4538 receives variable frequency (0–2 kHz) pulses from the

processor timer and converts them to 470 µs pulses. The 470 µs pulses

are applied to a low-pass filter/integrator (output 0–5 volt) and passed

through a noninverting op amp (Gain=2) to produce a 0–10.3 volt drive

signal. The drive signal is sent to the drive system as an analogrequested speed voltage. The circuitry can be disabled for 2.2 seconds

by a system RESET*, a BRAKE* signal, or by releasing the stop relay. This

permits the watchdog timer to maintain a zero-speed command to the

drive during system power-up and guarantees a zero-speed command

during stop conditions.

Revision D

Series 2000 Treadmill

409110-004

4-3

Page 50

Troubleshooting : Power PCB Theory

Start/Stop Circuitry

Elevation Relays

Drive Connector

When COAST* and BRAKE* are not active (low), the START pulse

command can engage the drive system. These signals are level

converted from CMOS/TTL (0–5 V) levels to (-15 V–0 V) logic by the

74HC14 drivers and level shifting transistors. The 750-ohm resistors