Page 1

AC/DC True-RMSClamp Meter

Products Code: MCA-207

Instruction Manual

WWW.MARMONIX.CO

Page 2

CONTENTS

1. Measuring Limits

2. Safety Information

3. Features

4. Instrument Layout

5. Specifications

6. DC Current Measurement

7. AC Current Measurement

8. DC Voltage Measurement

9. AC Voltage Measurement

10. Resistance Measurement

11. Capacitance Measurement

12. Frequency Measurement

13. Temperature Measurement

14. Diode Test

15. Continuity Testing

16. Data Hold Functions

17. Peak Hold Functions

18. LCD Backlight

19. Auto Power Off

20. Battery Replacement

1. Measuring Limits

DC Amperes: 0.01A to 1000A

AC Amperes: 0.01A to 1000A

DC Voltage: 0.1mV to 600V

AC Voltage: 0.1mV to 600V

Page 3

Resistance: 0.1Ὠ to 40MὨ

Capacitance: 0.001 nFto 40mF

Frequency: 0.001 kHz to 4kHz

Temperature: -40˚C to 1000˚C

-40˚F to 1832˚F

2. Safety Information

This manual contains information that must be followed

for operating the meter safety and maintaining the

meter in a safe operating condition. If the meter is not

used in a manner specified in this manual, the protection

provided by the meter may be impaired.

The Model has been designed and complies with IEC

61010-1 and EN 61010-1 safety requirements for

Electronic Measuring Apparatus.

WARNING

Read through the operating instructions thoroughly

and understand the instructions before operating the

meter.

Keep the manual at hand so as to enable quick

reference when necessary.

Ensure that the use of the meter is in its intended

applications and follow measuring procedures

described in this manual.

Page 4

Follow all safety and operating instructions to ensure

maximum personal safety during the use and

operation of the meter.

Failure to follow the above instructions may cause

injury. Instrument damage and/or damage to

equipment under test.

The symbol indicated on the meter means that the

user must refer to related parts in the manual for safe

operation of the meter. Be sure to carefully read the

instructions following each symbol in this manual.

DANGER is reserved for conditions and actions that

are likely to cause serious or fatal injury

WARNING is reserved for conditions and actions that

are likely to cause serious or fatal injury.

CAUTION is reserved for conditions and actions that

are likely to cause minor injury

DANGER

Never use the meter to measure voltages on a circuit

above the maximum allowable input value on any

function.

Page 5

Do not exceed the maximum allowable input of any

measurement range.

Never touched exposed wiring, connections or any live

circuit when attempting to take measurement.

Do not attempt to make measurements in flammable

gaseous areas, fumes, vapor or dust. The use of the

instrument in these areas may cause sparking, which

can lead to an explosion.

Do not attempt to use the instrument if its surface or

your hand is wet.

Never open the battery compartment cover when

making measurements.

WARNING

Always inspect the meter and test leads for any signs of

damage or abnormality before use. If the meter or its

accessories have any structural defects such as broken

test leads, cracked cases, exposed metal parts or the

display is not reading, do not attempt to make

measurements.

Do not turn the function switch whilst test leads are

connected to the meter.

Do not install substitute parts or make modifications to

the meter. Return the meter to your distributor for

repair or re-calibration.

Page 6

Ensure the meter is switch off before opening the

battery cover when replacing the battery.

Never replace a battery if the surface of the meter is

wet or moist.

CAUTION

Before making measurements ensure that the function

selector switch is set on the appropriate range position.

Always make sure that the plug of each test lead is

inserted fully into the appropriate terminal of the

meter.

Ensure that the function selector switch is set to the

“OFF” position after use. When the meter will not be in

use for a long period of time, place it in storage after

removing the battery.

Do not expose the meter to direct sunlight, extreme

temperatures or moisture.

Do not abrasives or solvents on the meter. To clean it,

use a damp cloth and mild detergent only.

Qualified and trained service technicians should only

perform calibration and repair for the meter.

Page 7

3. FEATURES

True RMS measurement of AC Current ad AC Voltage

Large 4000 count LCD display with a bargraph and a

bright white LED backlight.

Wide measurement range from 0.01A AC/DC up to

1000A AC/DC

Measures AC and DC Voltage up to 600 volts

Measures resistance from 0.01Ὠ up to 40MὨ.

Capacitance measurements up to 40mF

Temperature measurements from -40˚C to +1000˚C and

-40˚F to +1832˚F.

Designed to the international safety standard IEC61010

CAT III 600V/ CAT II 1000V, Pollution degree 2.

Auto power off after approximately 20 minutes to

conserve battery life.

Continuity Buzzer and Diode Test

Frequency measurement up to 4kHz.

Peak Hold to record the minimum and maximum

readings for current and voltage.

Data Hold switch used to freeze readings on display.

Page 8

4. INSTRUMENT LAYOUT

Page 9

5. SPECIFICATIONS

Clamp Size 30mm Opening Approx

Diode Test Test Current of 0.3mA

typical; Open circuit voltage 1.5V DC

Continuity check Threshold<35Ὠ; Test

current<1mA

Low battery indication “ ” is displayed

Overrange Indication “OL” is displayed

Measurements Rate 2 per second, nominal

Input Impedance 10MὨ (VDC and VAC)

Display 4000 count LCD

AC Current 50/60Hz (AAC)

AC Voltage Bandwidth 50/60 (VAC)

Operating Temperature -10˚C to 50˚C (14˚F to

122˚F)

Storage Temperature -30˚C to 60˚C (-22˚F to

140˚F)

Relative Humidity UP to 85%

Over Voltage Category III 600V

Battery One DC 9V IEC6F22 1604

Battery

Auto Power Off Approx 20 minutes

Dimensions 229 x 80 x 49mm

Weight 303g

Page 10

5.SPECIFICATIONS

Range

Measuring Range

Resolution

Accuracy(% of Readings)

40A

0~40.00A

0.01A

±(2.8%+10digits)

400A

0~400.0A

0.1A

±(2.8%+8digits)

1000A

0~1000A

1A

±(3.0%+8digits)

Range

Measuring Range

Resolution

Accuracy(% of Readings)

40A

0~40.00A

0.01A

±(2.8%+10digits)

400A

0~400.0A

0.1A

±(2.8%+8digits)

1000A

0~1000A

1A

±(3.0%+8digits)

Range

Measuring Range

Resolution

Accuracy(% of Readings)

Range

Measuring Range

Resolution

Accuracy(% of Readings)

DC Current

AC Current

DC Voltage

400mV 0~400.0mV 0.1mV ±(0.8% + 2digits)

4V 0~4.00V 0.001V

±(1.5% + 2digits) 40V 0~40.00V 0.01V

400V 0~400V 0.1V

600V 0~600V 1V ±(2.0% + 2digits)

AC Voltage

400mV 0~400.0mV 0.1mV ±(0.8% + 2digits)

4V 0~4.00V 0.001V

±(1.5% + 2digits) 40V 0~40.00V 0.01V

400V 0~400V 0.1V

600V 0~600V 1V ±(2.0% + 2digits)

Note: No Autoranging on 400mV AC Range

Page 11

Resistance

Range

Measuring Range

Resolution

Accuracy(% of Readings)

Range

Measuring Range

Resolution

Accuracy(% of Readings)

Range

Measuring Range

Resolution

Accuracy(% of Readings)

400Ὠ 0~400.0 Ὠ 0. Ὠ ±(1.0% + 4 digits)

4k Ὠ 0~4.000k Ὠ 1 Ὠ

±(1.5% + 2 digits) 40k Ὠ 0~40.00k Ὠ 10 Ὠ

400kV 0~400.0k Ὠ 100 Ὠ

4M Ὠ 0~4.000M Ὠ 1k Ὠ ±(2.5% + 5digits)

40M Ὠ 0~40.00M Ὠ 10k Ὠ ±(3.5% + 10 digits)

Capacitance

4nF 0~4.000nF 0.001nF ±(5.0% + 30 digits)

40nF 0~40.00nF 0.01nF ±(5.0% + 20 digits)

400nF 0~400.0nF 0.1nF

±(3.0% + 5 digits) 4μF 0~4.000μF 0.001μF

40μF 0~40.00μF 0.01μF

400μF 0~400.0μF 0.1μF ±(4.0% + 10 digits)

4mF 0~4.000mF 0.001mF ±(4.5% + 10 digits)

40mF 0~40.00mF 0.01mF ±(5.0% + 10 digits)

Frequency

4kHz 0~4.000kHz

0.00kHz

±(1.5% + 2 digits)

Sensitivity: 5Vrms min

Page 12

Temperature

Accuracy(% of Readings)

Range Measuring Range Resolution

˚C -40˚C~1000˚C 1˚C ±(2.5˚% + 3˚C)

˚F -40.0˚F~1832˚F 1˚F ±(2.5% + 5˚F)

6. DC Current Measurement

WARNING: Ensure that the test leads are

disconnected from the meter before making

current measurements.

1. Set the function switch to 1000A or 400A or 40A

range position, and make sure that the current

under test does not exceed the upper limit of the

measuring range you have selected. The meter

automatically defaults to DC Current.

2. Press the DC ZERO button once, the sign will

appear on the LCD indicating Range is zero.

3. Press the trigger to open up the transformer jaws

and clamp around the single conductor under

test.

4. Read the display.

Note:

During current measurements keep the

transformer jaws fully closed, otherwise

this will affect the accuracy of the

measurement.

Page 13

When large currents the transformers jaws

may buzz. This is not a fault and does not

affect the accuracy of the reading.

Page 14

7. AC True RMS Current Measurement

WARNING: Ensure that the test leads

are disconnected from the meter

before making current measurements.

1. Set the function switch to 1000A~ or 400A~ or

40A~range position, and make sure that the current

under test does not exceed the upper limit of the

measuring range you have selected.

2. Press the MODE button to select the AC Current range.

The meter automatically defaults to Dc Current.

3. Press the trigger to open up the transformer jaws and

clamp around the single conductor under test.

4. Read the display.

Note:

During current measurements keep the transformer

jaws fully closed, otherwise this will affect the accuracy

of the measurement.

When large currents the transformer jaws may buzz.

This is not a fault and does not affect the accuracy of

the reading.

The meter is set to default to “Auto Range” mode.

Pressing the PEAK hold button will allow the user to

record the peak maximum and minimum readings on

the AC volt range. See page 17 for further instructions

for “PEAK” Hold function.

Page 15

Page 16

8. DC Voltage Measurement

1. Set the function switch to range position. The

meter automatically defaults to DC Volts.

2. Insert the test lead into the “V Ὠ TEMP HZ” input

terminal and the black lead to the “COM” terminal.

3. Connect the other end of the test leads to the circuit

under test.

4. Read the display. If a “-“ sign is displayed, the red leads is

the negative potential.

Page 17

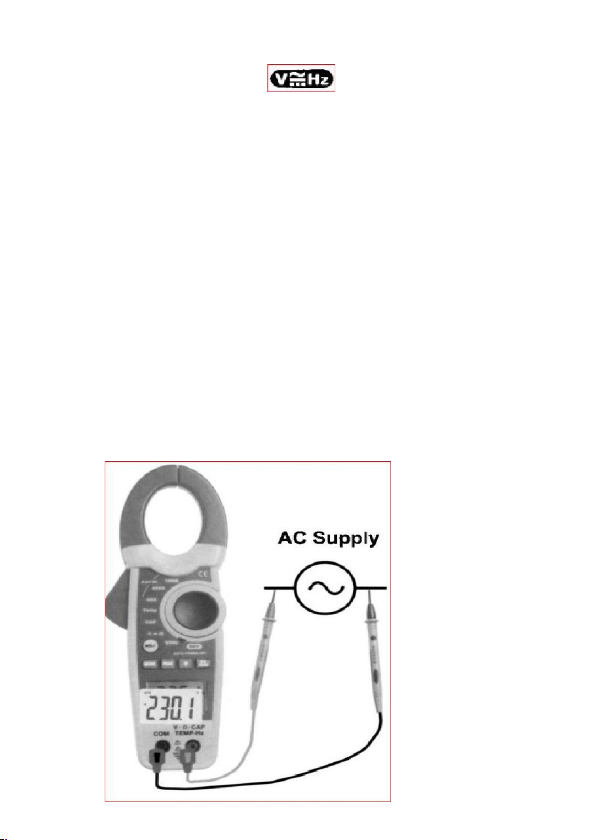

9. AC true RMS voltage measurement

1. Set the function switch range position.

2. Press the MODE button to select the AC Volt range. The

meter automatically defaults to DC Volts.

3. Insert the red test lead into the “V Ὠ TEMP HZ” input

terminal and the black lead to the “COM” terminal.

4. Connect the other end of the test leads to the circuit

under test. Take the reading on the display.

Note:

The meter is set to default to “Auto Range” mode.

Pressing the PEAK hold button will allow the user to

record the peak maximum and minimum readings on

the AC volt range. See page 7 for further instructions for

“PEAK” Hold function.

Page 18

10. Resistance Measurement

1. Set the function switch to range position.

The meter automatically defaults to resistance

range.

2. Insert the test lead into the “V Ὠ TEMP HZ” input

terminal and the black lead to the “COM” terminal.

3. Connect the other end of the test leads to the circuit

or component under test. Take the reading on the

display.

Note:

The meter is set to default to “Auto Range” mode.

WARNING before attempting to make a

resistance measurement, ensure there is no voltage

present on the circuit under test.

Page 19

11. Capacitance Measurement

1. Set the function switch to CAP range position.

2. Insert the test lead into the “V Ὠ TEMP HZ” input

terminal and the black lead to the “COM” terminal.

3. Connect the other end of the test leads to the circuit or

component under test. Take the readings on the

display.

Note:

In capacitance range the meter is Auto Ranging only.

CAUTION to avoid damage to the meter or the

equipment under test, remove all power from the

circuit and discharge all capacitors before measuring

capacitance.

Large value capacitors should be discharged through

an appropriate resistance load. Use the DC Voltage

function to confirm that the capacitors are discharged.

Page 20

12. Frequency Measurement

1. Set the unction switch to range position. The

meter automatically defaults to Frequency range.

2. Press the MODE button for 3 seconds to select the

Frequency range. The meter automatically defaults

to DC Voltage.

3. Insert the test lead into the “V Ὠ TEMP HZ”input

terminal and the black lead to the “COM” terminal.

4. Connect the other end of the test leads to the circuit

or component under test. Take the readings on the

display.

Note:

In the Frequency Range the meter is Auto Ranging

only.

Page 21

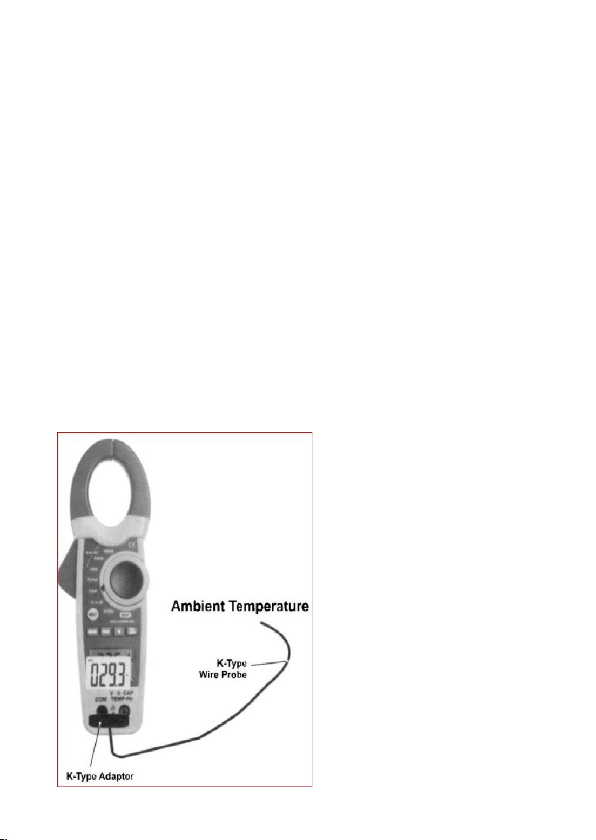

13. Temperature Measurement

1. Set the functions switch to TEMP range position. The meter

automatically defaults to ˚C range.

2. Insert the meter white temperature adaptor into the “V Ὠ

TEMP HZ” input terminal and the “COM” terminal. Ensure

that the “-“ marking on the adaptor is inserted into the

“COM” terminal and the “+” marking on the adaptor is

inserted into the “V Ὠ TEMP HZ” input terminal.

3. Connect any K-Type probe into the meter adaptor and

measure the temperature of the apparatus or area required.

4. Read the temperature directly on the display.

5. To change the measuring unit from ˚C to ˚F, press the MODE

button to select the ˚F unit.

Note:

The meter is set to default to “Auto Range” mode.

Page 22

14. Diode Test

1. Set the function switch to range position.

2. Press the MODE button to select the Diode Test range.

The meter automatically defaults to resistance.

3. Insert the red test lead into the “V Ὠ TEMP HZ” input

terminal and the black lead to the “COM” terminal.

4. Connect the other end of the test leads to the

components under test. Read the display.

Note:

Use the diode test to check diodes, Transistors, silicon

controlled rectifiers (SCR’s) and other semiconductor

devices.

The test sends a current through a semiconductor

junction, then measures the junction’s voltage drop.

Normal forward voltage drop (forward bias) for a good

silicon diode is between 0.4V to 0.9V. a reading higher

than that indicates a leaky (defective) diode. A zero

reading indicates a shorted diode.

Reverse the test leads connection (reverse bias) across the

diode. The display shows “OL” if the diode is good. Any other

readings indicate the diode is shorted or resistive

(defective).

Page 23

15. Continuity Testing

1. Set the function switch to range position.

2. Press the MODE button to select the Continuity Test

range. The meter automatically defaults to Resistance.

3. Insert the red test lead into the “V Ὠ TEMP HZ”input

terminal and the black lead to the “COM” terminal.

4. Short the tip of the test leads and makes sure the

display reads “0” and the buzzer beeps.

5. Connect the tip of the test leads to the circuit or

component under test. The display reads the

resistance and the buzzer beeps when the reading is

not more than about 35Ὠ.

Note:

Using resistance and continuity function in a live circuit

will produce false results and may damage the

instrument.

In many cases the suspicious components must be

disconnected from the circuit under test to obtain

accurate results.

WARNING before attempting to make a test, ensure

there is no voltage present on the circuit.

Page 24

Page 25

16. DATAHOLD

This is a function used to freeze the reading on the

display, ideal for later viewing.

1. Press the HOLD button once. When the HOLD is

activated, the meter beeps, freezes the reading, and

displays the “HOLD” indicator on the LCD.

2. To deactivate the “HOLD” function, press HOLD

button once, the meter will beep and the meter will

start reading new measurements.

17. PEAK HOLD

This is a function used to record the maximum and

minimum readings on the display for the voltage and

current ranges.

1. Press the PEAK button once. This will record the

PEAK maximum, the meter beeps, and displays the

“P MAX” indicator on the LCD.

2. Press the PEEK button again. This will record the

“PEAK” minimum, the meter beeps, and displays the

“P MIN” indicator on the LCD.

3. To deactivate the “PEEK” function, press button for 3

seconds, the meter will beep and the meter will start

reading new measurements.

18. LCD Backlight

The backlight is ideally used in dark or dimly lit areas.

1. Press the button for 3 seconds, and the bright

white light will come on.

Page 26

2. To turn off the backlight press the button for 3

seconds.

Note: the use of the backlight will reduce the battery

life considerably.

19. Auto Power Off

This feature automatically turns off the meter after

approximately 20 minutes from the last measurement

taken. To turn on the meter, press any button or move

the rotary switch to any position. Ensure the test leads

are disconnected from any circuit to avoid injury or

meter damage.

20. Battery Replacement

When the sign appears on the LCD, this indicates

the battery should be replaced. Use the following

procedure to replace the standard 9V battery (IEC 6F

22) battery.

1. Disconnect the test leads from any live source and

remove the leads from the input terminals.

2. Rotate the function switch to the OFF position.

3. The battery cover is secured to the bottom of the

case by a screw. Using a screwdriver remove the

screw from the battery cover and remove the

battery cover from the meter.

4. Remove the old battery and replace it with a new

IEC 6F 22 9V battery.

Page 27

5. Replace the battery cover and reinstall the screw.

Loading...

Loading...