Marlon 350E Double Head

Spiral Coil Electric

Crimper

Instruction Manual

MARLON 350E AUTO CRIMPER

SERVICE MANUAL

INTRODUCTION

Your new Marlon 350 Auto Crimper is designed to increase

your plastic spiral binding production. The Marlon 350 is an

inexpensive yet extremely versatile tabletop machine. The Marlon

350 cuts and crimps 6mm through 50mm coil, with an adjustable

binding length from 3.5-inches to 14-inches. The Marlon 350 is

capable of 50 cycles per minute, and features a coil waste chute

that uses standard plastic grocery bags for clipping waste

containment. The Marlon 350 is an operator friendly machine that

is easy to set up, allowing for quick changeover from one coil

diameter to another. We are confident that your new Marlon 350

Auto Crimper will be a valuable asset to your plastic coil binding

operation.

The following pages of this manual will cover machine setup,

operating procedures, and trouble shooting your Marlon 350 Auto

Crimper.

WARNING: Changing of cutting blades should be

done only by trained service personnel. Disconnect

power from unit before servicing.

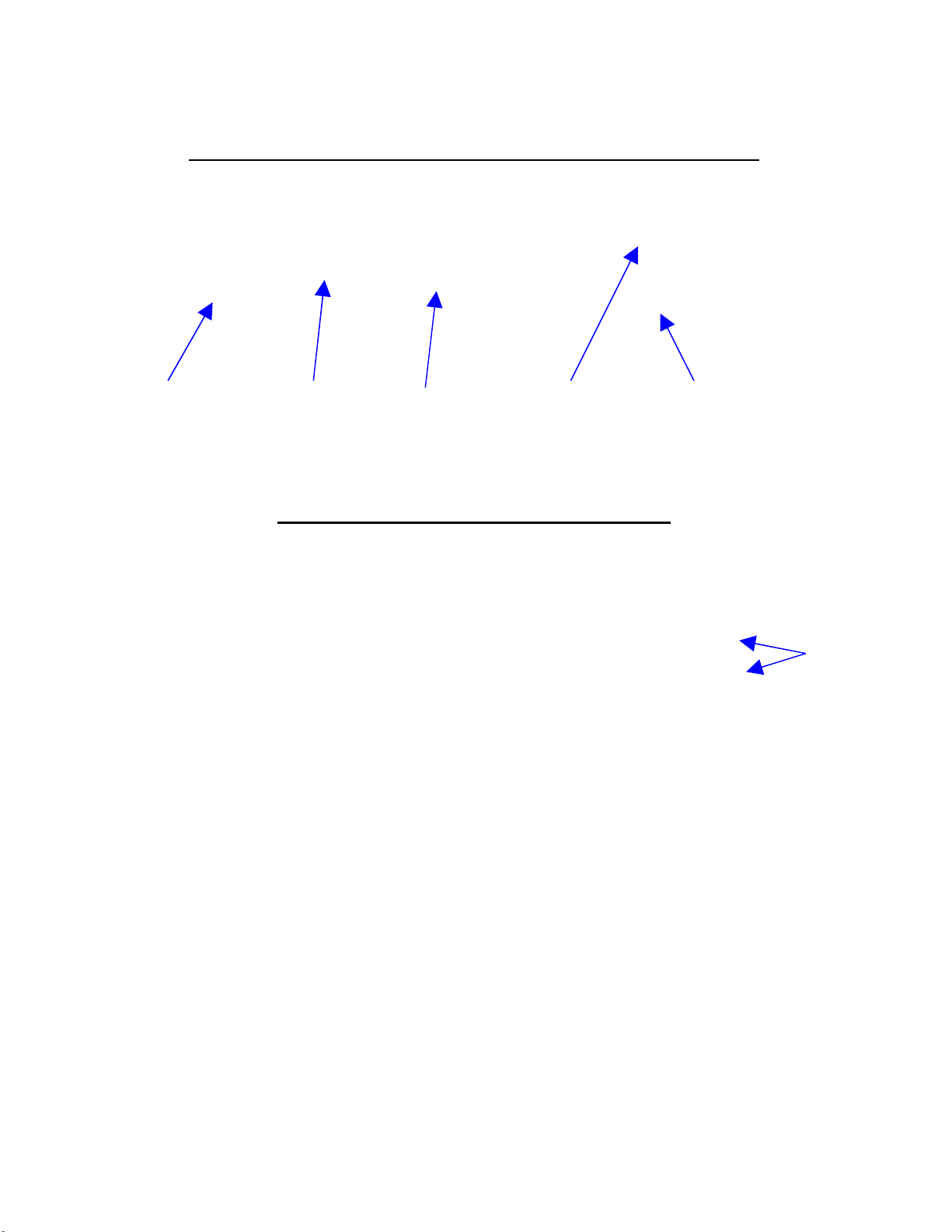

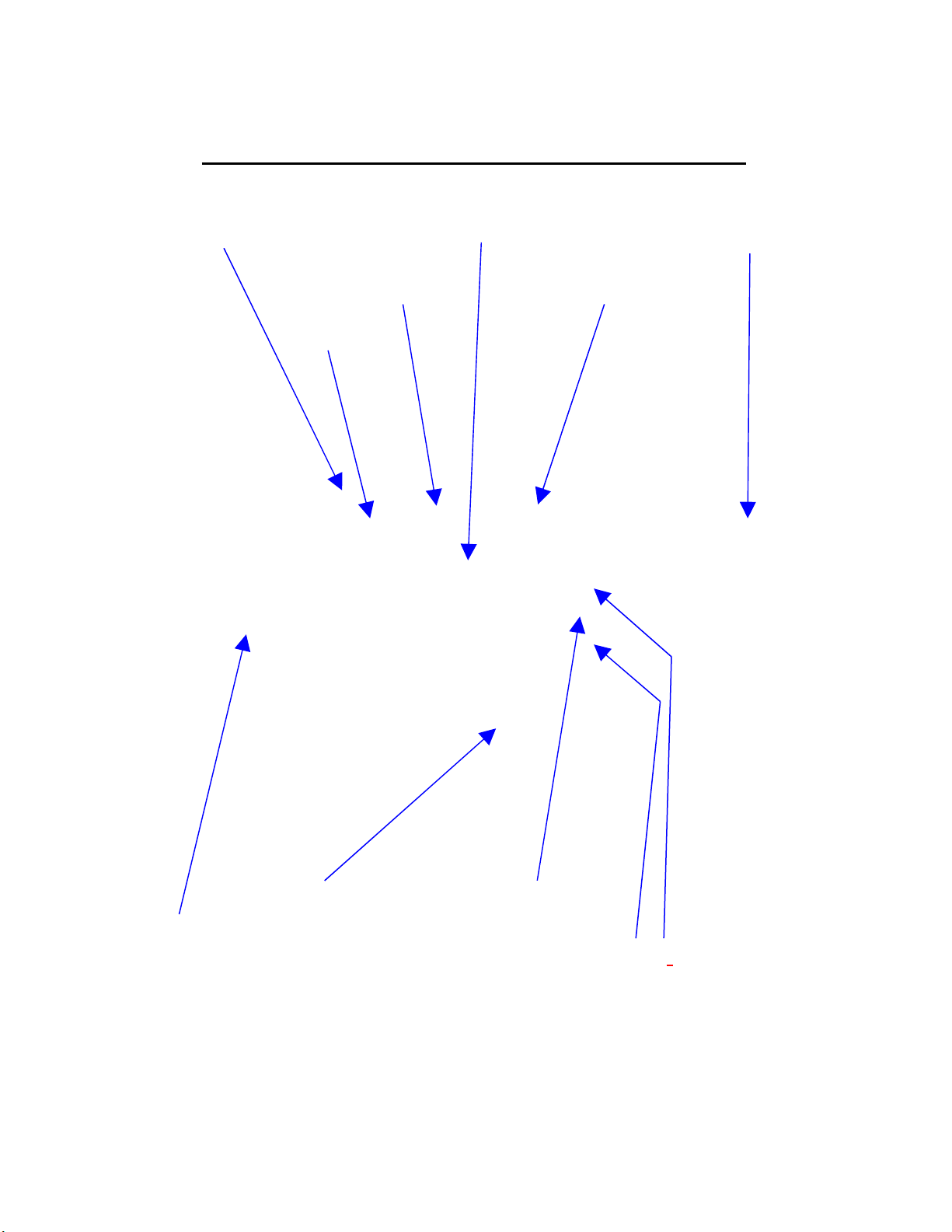

MARLON 350E CONNECTIONS

Power switch AC - in Foot pedal-out AC-fuse DC-fuse

COIL WASTE CHUTE

THE COIL WASTE CHUTE USES STANDARD PLASTIC GROCERY BAGS

FOR CLIPPING CONTAINMENT. PLACE THE HANDLES OF THE BAG

IN THE SLOTS ON BOTH SIDES TO HOLD THE BAG IN PLACE.

PLACE BAG

HANDLES IN

THESE SLOTS

TO HOLD BAG

BLADE SELECTION

The Marlon 350 Auto Crimper features interchangeable

cutter blades. Your Marlon 350 was shipped with the B-size cutter

blades installed. Use the following chart to determine what blade

size is required for the coil diameter your crimping.

A-size blades: 6mm and 7mm coil

Note: Over sized punch patterns (.248) or punch patterns with a large backstop (distance

from paper edge to hole) will not work well with the A – size cutter head.

B-size blades: 8mm through 25mm coil

C-size blades: 12mm through 50mm coil

The cutter blades and cutter head assemblies have been color

coded to reduce the chance of improper assembly.

1.)Universal parts of the cutter head assembly that are used for all

three sets of knives are marked white. These parts are used all of

the time.

2.)A-size parts of the cutter assembly are marked red.

3.)B-size parts of the cutter assembly are marked green.

4.)C-size parts of the cutter assembly are marked yellow.

Note: Some parts of the cutter assembly are marked with two

colors. These parts are used on two of the three cutter

assembly configurations.

CUTTER HEAD ASSEMBLY

Drive Cam Clamp blade spring Motor connector

Cam Arm Cutter drive pin

Arm drive

Screw

Cutter blade assembly Clamp blade stop

Cam micro switch

Clamp blade stop mtg. holes 1, 2

Hole # 1, will provide a wider blade gap

Suitable for larger coil / filament

Hole # 2 accommodates smaller coils /

Filament size

B-SIZE CUTTER BLADE ASSEMBLY

LEFT CUTTER HEAD

LEFT BASE PLATE

A, B & C – SIZE ANVIL BLADE

B – SIZE .126” SPACERS

B – SIZE CUTTER BLADE

B & C – SIZE-FORMING BLADE

CLAMP SPRING

B & C – SIZE CLAMP BLADE

CLAMP STOP 1/4 X 1-1/2

SHOULDER BOLT

FOR B – SIZE ASSEMBLY

ONLY .062 SPACER

RIGHT CUTTER HEAD

RIGHT BASE PLATE

CLAMP SPRING

B & C – SIZE CLAMP BLADE

B & C – SIZE-FORMING BLADE

B – SIZE CUTTER BLADE

B – SIZE .126” SPACERS

A, B & C – SIZE ANVIL BLADE

CLAMP STOP 1/4 x 1-1/2

SHOULDER BOLT

10-24 NYLOCK NUTS

NOTE: THE RIGHT CUTTER BLADE ASSEMBLY IS UP SIDE

DOWN. THE SAME FOUR BLADES ARE USED ON BOTH SIDES,

BUT THEY ARE INSTALLED IN EXACTLY THE OPPOSITE ORDER.

10-24 NYLOCK NUTS

Pictured above is the B-size cutter blade assembly. The following information describes the

changes needed to switch from the B to A-size and B to C-size cutter assemblies. Refer to the color codes

on page four to select the proper parts when changing from one blade configuration to another. Refer to

pages five and six for part descriptions.

Changing from B to A-size blades:

1.)Disconnect the power cord from Marlon 350.

2.)Remove the top cover from the machine.

3.)Remove the clamp stop shoulder bolts from each side

4.)Remove the three 10-24 nylock nuts from each side.

5.)The left clamp blade is now free and can be removed.

6.)Remove the right anvil blade by lifting it straight up.

7.)Remove the left forming blade by lifting it straight up.

8.)Detach the right cutter blade from the drive pin. (the right cutter blade is now

free.)

9.)Remove the two .126” B-size spacers from each side.

10.)Remove the right forming blade by lifting it straight up. The right clamp

blade is now free.

11.)Detach the left cutter blade from the drive pin, the arm drive screw must be

loosened to free cutter blade. (See step 8 for details.)

12.)Leave the left anvil blade on, because it’s used in all three setups.

13.)Reassemble the cutter blade assemblies in reverse order using the correct

color-coded parts.

14.)Use the fifth .094” A-size spacer instead of .062spacer on the left hand

shoulder bolt.

A-KIT COIL GUIDE INSTALLATION

PICTURED ABOVE ARE THE COIL GUIDES INSTALLED ON

THE CUTTER ASSEMBLY. THESE GUIDES ARE ONLY USED

WITH THE A-SIZE BLADE CONFIGURATION. THE COIL

GUIDES ARE STAMPED “L” FOR LEFT AND “R” FOR RIGHT

AND ARE ALWAYS INSTALLED WITH THE LETTERS UP. YOU

HAVE TWO “L” GUIDES ONE MARKED

“L” AND ONE MARKED “L 6”. THE “L 6” IS USED FOR

6mm DIA. COILS ONLY.

Changing from B to C-size blades:

1.)Disconnect the power cord from Marlon 350.

2.)Remove top cover from machine.

3.)Remove the clamp stop shoulder bolts on both sides.

4.)Remove the three 10-24 nylock nuts from each side.

5.)The left clamp blade is now free and can be removed.

6.)Remove the right anvil blade by lifting it straight up.

7.)Remove the left forming blade by lifting it straight up.

8.)Detach the right cutter blade from the drive pin. (The right

cutter blade is now free.)

9.)Remove the two .126” B-size spacers from each side.

10.)Remove the right forming blade by lifting it straight up. The

right clamp blade is now free.

11.)Detach the left cutter blade from the drive pin, the arm

drive screw must be loosened to free cutter blade (See step 8

for details.)

12.)Leave the left anvil blade on, because it is used in all three

setups.

13.)Change the clamp stop to its correct hole position.

14.)Reassemble the cutter blade assemblies in reverse order

using the correct color-coded parts.

15.)Note: No washers or spacer is used on the left-hand

shoulder bolt when using the C-size blade configuration.

C-CUTTER BLADE INSTALLATION

REAR HOLE OF THE

C-CUT BLADE IS

NOT USED IN THIS

MODEL.

IN YOUR “C” KIT

THIS HOLE IS

PLUGGED.

INSTALL THE DRIVE

PIN IN THE OPEN

HOLE.

PICTURED ABOVE ARE THE C-SIZE CUTTER BLADES AS

FURNISHED IN THE “C” KIT SHIPPED WITH YOUR

MACHINE.

CLAMP STOP POSITIONS

Mount the clamp stop in the first hole for C-size blade configuration.

Mount the clamp stop in the second hole for A and B-size blade

configurations.

These stop positions allow adjustment of blade opening for coil

Insertion and the above are suggested settings. Some B size coils

Might work well in the first hole position. Filament size and coil

Pitch will be the factors involved.

TABLE ADJUSTMENTS

Now that you have the correct blade configuration ready for the coil

diameter you are crimping you need to adjust the table height and cutter

head spacing (width) for your book. Refer to page 13 for table adjustment

details.

1.)Loosen the two clamp knobs on the left-hand book guide; position the

guide so your book will be approximately centered on the machine. Re

tighten the two clamp knobs.

2.)Using the same procedure position the right-hand book guide so it just

touches the right edge of the book. The book should lay flat on the table

between the book guides and be able to slide in and out, but not side to side.

3.)Use a #3 Phillips screwdriver to loosen the two bolts located under the

two access holes in the top cover. The two cutter heads will now be able to

slide from side to side. Slide the two cutter heads so the cutter blades are

close to the correct loop of the coil at each end of the book.

4.)Make a rough adjustment on the table height by turning the two table

height knobs. Turn the knobs clock-wise to lower the table and counter

clock-wise to raise the table. Adjust the table height so the coil in the book is

in the center of the cutter blade assembly on both sides. The right side of the

table will always be adjusted higher than the left side.

5.)Adjust the two cutter heads from side to side until the coil in the book

slides into the cutter blades at the correct loop of the coil on each side of the

book

6.)Make a finer adjustment to the table height so the coil in the book is

properly positioned in the center of the cutter blades.

7.)Make your final cutter head adjustments side to side if needed and then re

tighten the two bolts under the access holes of the top cover using the #3

Phillips screwdriver.

8.)Test crimp a book by depressing the foot pedal.

9.)Make your final table height adjustments if needed. Then repeat steps #8

and #9 until the desired crimp is achieved.

TABLE ADJUSTMENT DETAILS

TWO ACCESS HOLES

IN TOP COVER

TABLE HEIGHT

ADJUSTER KNOBS:

ONE ON EACH SIDE

BOOK GUIDES: ONE ON

EACH SIDE

CLAMP KNOBS:

TWO ON EACH BOOK

GUIDE

TROUBLE SHOOTING GUIDE

PROBLEM SOLUTION

CRIMPER DOESN’T CYCLE VERIFY THAT POWER IS PLUGGED IN

AND TURNED ON

COIL IS BEING CRIMPED BUT NOT

CUT

POWER ON DOESN’T CYCLE RESET FUSES

ADJUST TABLE HEIGHT FOR PROPER

ALIGNMENT

Heads with A-Blades installed

Left Side Right Side

A-Blade Parts Layout in Order of Use

Left Side Right Side

Heads with B-blades installed

Left Side Right Side

B-Blade Parts Layout in Order of Use

Left Side Right Side

Heads with C-blades installed

Left Side Right Side

C-Blade Parts Layout in Order of Use

Left Side Right Side

MARLON 350E AUTO CRIMPER

MARLON INC.

123 EAST 45

TH

STREET

BOISE, IDAHO 83714

Ph 1-(800) 461-9301

Fax 1 (208) 321-2796

Loading...

Loading...