Marley Engineered Products MUH0381, MUH0321, MUH0371, MUH0341, MUH0581 Installation Manual

...

MUH Series

Modular Unit Heaters

Installation, Operation & Maintenance Instructions

Specifications

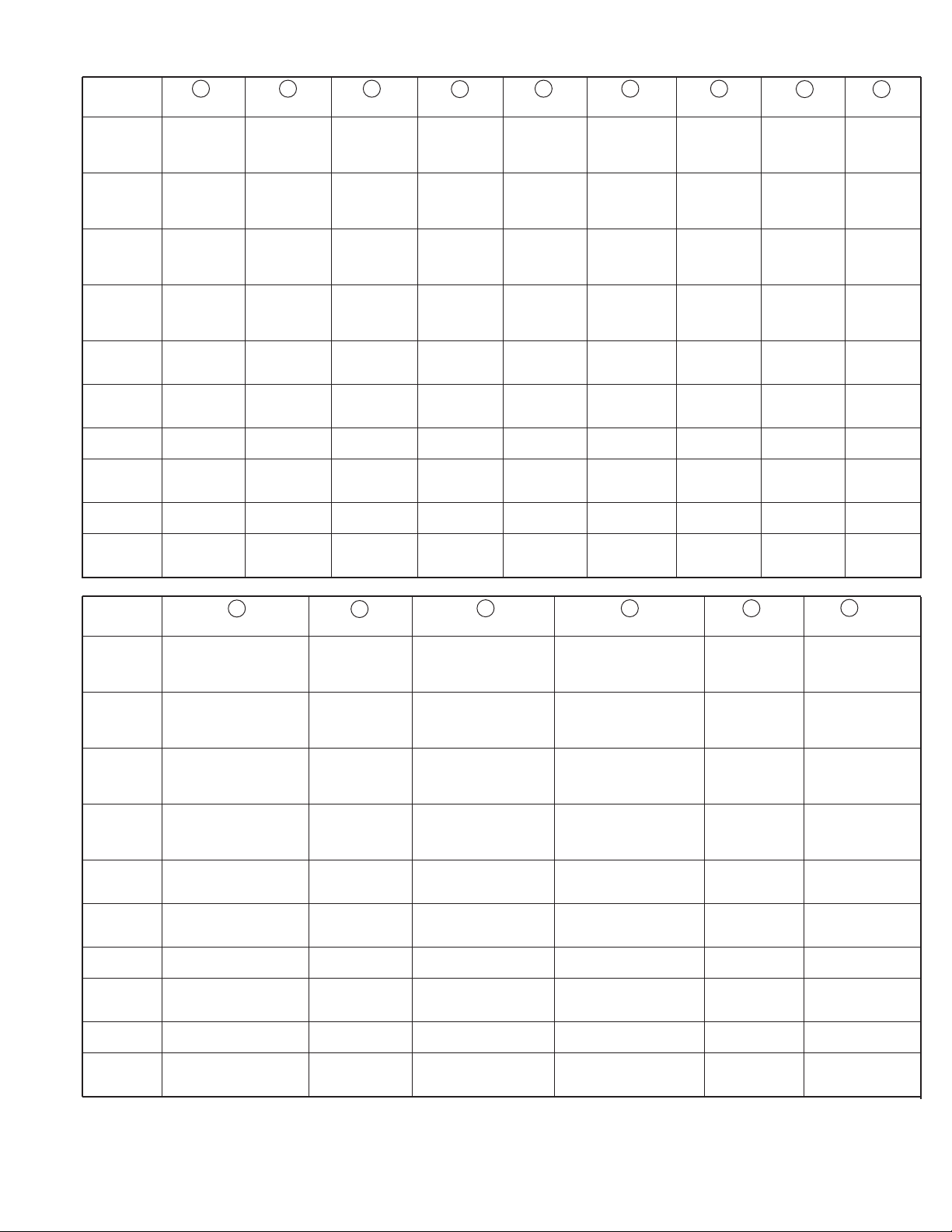

asic Model Height Width Depth Weight Compartment

B

No. in (mm) in. (mm) in. (mm) lbs. (kg) Volume

MUH0381 27 (12.2)

UH0321 27 (12.2)

M

MUH0371 27 (12.2)

MUH0341 30 (13.6)

MUH0581 27 (12.2)

MUH0521

MUH0571

16 14 7

(406.4) (355.6) (190.5)

MUH0541 30 (13.6)

MUH0331 30 (13.6)

MUH0361 30 (13.6)

MUH0531 30 (13.6)

MUH0561 30 (13.6)

MUH078 38 (17.2)

MUH072 38 (17.2)

MUH077 38 (17.2)

MUH074 38 (17.2)

MUH108

MUH102

3

/

4

19 71/

21

(552.5) (482.6) (190.5)

MUH107 38 (17.2)

MUH104 38 (17.2)

MUH073 38 (17.2)

MUH076 38 (17.2)

MUH103 38 (17.2)

MUH106 38 (17.2)

Mounting Wiring

1

27 (12.2)

/

2

27 (12.2)

38 (17.2) 100 in

2

38 (17.2)

90 in

(14.70 cm

(1639 cm

ounting Wiring

Basic Model Height Width Depth Weight Compartment

M

No. in (mm) in. (mm) in. (mm) lbs. (kg) Volume

MUH158 54 (24.5)

MUH152 50 (22.7)

MUH154 50 (22.7)

MUH208

MUH202

3

MUH204 55 (24.9)

3

)

MUH156 55 (24.9)

3

21

/

19 123/

4

(552.5) (482.6) (323.9)

60 (27.2)

4

55 (24.9)

140 in

(2295 cm

3

3

)

MUH206 55 (24.9)

MUH252 89 (40.4)

MUH254 89 (40.4)

MUH308

MUH302

MUH304 89 (40.4)

30 26

(76.2) 676.4) (298.5)

5

/

113/

8

89 (40.4)

3

4

89 (40.4)

504 in

(8260 cm

3

)

MUH256 89 (40.4)

MUH306 89 (40.4)

MUH402 119 (54.0)

3

MUH404 119 (54.0)

3

)

MUH508

MUH502

MUH504 119 (54.0)

30 26

(76.2) 676.4) (435.1)

5

/

8

171/

4

119 (54.0)

119 (54.0)

648 in

(10620 cm

3

3

)

MUH406 119 (54.0)

MUH506 119 (54.0)

ECR 40559 07/15 5200-11106-001

IMPORTANT INSTRUCTIONS

WARNING

WHEN USING ELECTRIC APPLIANCES, BASIC PRECAUTIONS SHOULD ALWAYS BE FOLLOWED TO REDUCE THE

RISK OF FIRE, ELECTRIC SHOCK, AND INJURY TO PERSONS, INCLUDING THE FOLLOWING:

1. Read all instructions before installing or using this heater.

2. This heater is a commercial/industrial product not intended

for use in a residential setting.

3. This heater is hot when in use. To avoid burns, do not let

bare skin touch hot surfaces. Keep combustible materials,

such as furniture, pillows, bedding, papers, clothes, etc. and

curtains at least 3 feet (0.9 m) from the front of the heater.

4. Extreme caution is necessary when any heater is used by or

near children or invalids and whenever the heater is left

operating and unattended.

5. This heater has hot and arcing or sparking parts inside and

is not intended for use in hazardous atmospheres where

flammable vapors, gases, liquids or other combustible

atmospheres as defined in the National Electrical Code are

used or stored. Failure to comply can result in explosion or

fire.

6. Do not operate any heater after it malfunctions. Disconnect

power at service panel and have heater inspected by a reputable electrician before using.

!

7. Do not use outdoors.

8. To disconnect heater, turn controls to off, and turn off power

to heater circuit at main disconnect panel.

9. Do not insert or allow foreign objects to enter any ventilation

or exhaust opening as this may cause an electric shock, fire,

or damage to the heater.

10. To prevent a possible fire, do not block air intake or exhaust

in any manner.

11. Use this heater only as described in this manual. Any other

use not recommended by the manufacturer may cause fire,

12. This heater is not intended for use in special environments.

Do not use in damp or wet locations such as marine or

greenhouse or in areas where corrosive or chemical agents

are present.

13. When installing, see INSTALLATION INSTRUCTIONS for

additional warnings and precautions.

14. For safe and efficient operation, and to extend the life of your

heater, keep your heater clean - See MAINTENANCE

INSTRUCTIONS.

SAVE THESE INSTRUCTIONS

INSTALLATION INSTRUCTIONS

WARNING

To prevent a possible fire, injury to persons or damage to the

heater, adhere to the following:

1. Disconnect all power coming to heater at main service panel

before wiring or servicing.

Important Note: This heater must be installed by a qualified

person.

2. All wiring procedures and connections must be in accordance with the National and Local Codes having jurisdiction

and the heater must be grounded.

3. Verify the power supply voltage coming to heater matches

the ratings as shown on the heater nameplate.

CAUTION: ENERGIZING HEATER AT A VOLTAGE GREATER

THAN THE VOLTAGE PRINTED ON THE NAMEPLATE WILL

DAMAGE THE HEATER AND VOID THE WARRANTY AND

COULD CAUSE A FIRE.

Heater Location Instructions

Arrange units so that discharge air streams:

a. are subjected to a minimum of interference from columns,

machinery and partitions;

b. wipe exposed walls without blowing directly at them;

c. are directed away from room occupants in comfort heating;

d. are directed along the windward side when installed in a

building exposed to a prevailing wind.

!

4. To reduce the risk of fire, do not store or use gasoline or

other flammable vapors and liquids in the vicinity of the

heater.

5. The ceiling or wall mounting structure and the anchoring

provisions must be of sufficient strength to support the combined weight of the heater and mounting bracket.

6. All built-in thermostats: If the heater is used to prevent piping or liquids from freezing, and if the thermostat is set

below 45° F (7°C), the fan must run continuously.

7. The heater must be mounted at least 7’ (2134 mm) above

the floor to avoid accidental contact with the fan blade which

could cause injury.

8. Keep at least 5’ clearance in front of the heater. Refer to

Table 1 for side, top and back clearance requirements.

9. Do not mount mercury type thermostat directly on unit.

Vibration could cause heater to malfunction.

Locate thermostats approximately 5' (1524mm) above the floor

on interior partition walls or post away from cold drafts, internal

heat sources and away from heater discharge air streams.

Small rooms can be heated by one unit heater.

Large rooms require multi-unit installations. Number and capaci-

ty of units will be determined by volume of building and square

feet of floor area to be heated. Arrange units to provide perimeter

air circulation where each unit supports the air stream from

another.

2

Mounting the Heater - General

A

B

C

D

The heater may be mounted to discharge the heated air either

horizontally or vertically. When the heater is mounted for vertical

discharge, it is recommended that the heater be positioned so

that the access door will open away from the wall to provide

greater access to the wiring and control compartment. If the

heater is to be mounted with the access door facing a wall, the

heater must be mounted far enough from that wall to allow full

opening of the access door (a distance approximately equal to

the width of the heater, check clearance before installing). Refer

to Table 1 for wall and ceiling clearances before mounting heater.

The heater may be mounted for either vertical or horizontal discharge by the use of threaded rods. (Refer to Table 2 for threaded rod sizes required.) Observe the detailed procedures in the

following installation instructions.

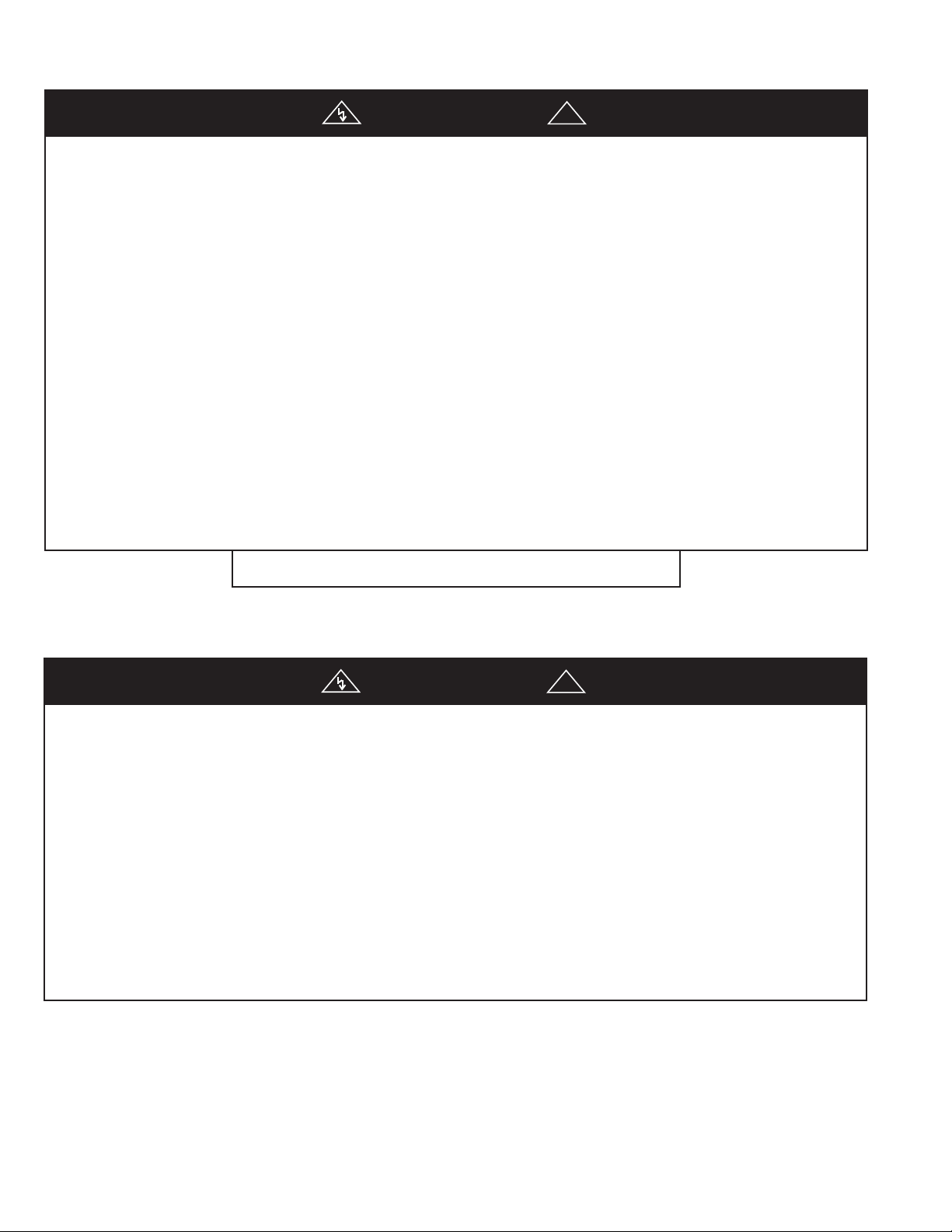

Horizontal Discharge (Rod-mount from Ceiling)

1. Install four threaded mounting rods in the threaded holes and

secure in place using lock nuts. (See Table 2).

2. Securely attach the four mounting rods to the ceiling. (Refer

to Table 1 for wall and ceiling clearances, and Table 2 for

mounting rod spacing).

Table 3. Rod Thread and Spacing Dimensions, inches (mm)

for Vertical Discharge

Rod Thread

Unit Type EFGH

3 - 5 kW

7.5 - 20 kW

145/

3

/

4

8

24

25

69

152.4) 247.7) (50.8) (103.1)

5

/

- 18

6

1

(

7

8

/

8

225.6) (371.6) (50.8) (130.3)

(

1

/

16

1

/

8

The heater may also be suspended from the wall or ceiling by

means of an optional mounting bracket (type MMB or MCMB)

which permits horizontal pivoting of the heater.

After the heater is installed, the louvers may be positioned to

direct the heated air in the desired direction. When the heater is

installed for horizontal discharge, the louvers should direct the

air either straight ahead or downward. Directing the air upward

may cause the heated air to remain in the ceiling area and waste

energy.

Table 1. Wall and Ceiling Clearance, inches (mm)

nit Discharge Ceiling Side Wall Back Wall

U

Horiz. 2 (50.8) 6 (152.4) 9 (228.6)

3 & 5 kW

Vert. 6 (152.4) 18 (457.2) 18 (457.2)

Horiz. 6 (152.4) 6 (152.4) 13 (330.2)

7.5 to 10 kW

15 to 10 kW

25 to 50 kW

MOUNTING

ROD

LOCK NUT

B

A

C

K

W

A

L

L

Vert. 6 (152.4) 24 (609.6) 24 (609.6)

Horiz. 6 (152.4) 9 (228.6) 12

1

/2(317.5)

Vert 6 (152.4) 24 (609.6) 24 (609.6)

Horiz. 16 (406.4) 12 (304.8) 18

1

/2(470.0)

Vert. 12 (304.8) 39 (914.4) 39 (914.4)

CEILING

UNIT HEATER

THREADED

OUNTING

M

HOLES

A

BACK WALL

B

(TOP VIEW)

D

C

S

I

D

E

W

A

L

L

Figure 1. Horizontal Discharge Mounting and Spacing.

Table 2. Rod Thread and Spacing Dimensions, inches (mm)

for Horizontal Discharge

Rod Thread

Unit Type ABCD

1

51/

/

16

16

16

3 - 5 kW

7.5 - 10 kW

5

/16- 18

15 - 20 kW

25 - 30 kW

3

/8- 16

40 - 50 kW

61/

16

(153.9)

3

/

11

(289.0)

9

10

/

16

(268.2) (368.3) (157.2) (16.0)

1515/

(404.9) (368.3) (157.2) (16.0)

64

(152.4) (103.1) (19.0)

87/

8

(225.6) (130.3) (19.0)

8

14 - 12 63/

14 - 12 63/

16

3

/

4

3

8

/

4

5

/

8

5

/

8

25 - 30 kW

CEILING

ACCESS

DOOR

B

A

C

K

W

A

L

L

CLEARANCE EQUAL TO WIDTH OF

HEATER TO PERMIT FULL OPENING OF THE ACCESS DOOR

Figure 2. Vertical Discharge Mounting and Rod Spacing

Vertical Discharge (Rod-Mount from Ceiling)

1. Remove bolts from the threaded holes in the back of the

heater.

2. Install four threaded mounting rods in the threaded holes and

and secure in place using lock nuts.

3. Securely attach the four mounting rods to the ceiling. (Refer

to Table 1 for wall and ceiling clearances, and Table 3 for

mounting rod spacing dimensions.)

Wiring Branch Circuit (Power)

1. Connect heater only to the voltage, amperage and frequency

specified on the nameplate.

2. Field wiring must be properly sized to carry the amperage in

accordance with the NEC.

3. The access door is hinged. There are either one or two screws

accessible from the side that must be loosened to gain access.

These screws are the captive type; do not try to remove them.

4. A knockout is provided in the back of the heater close to the

power terminal block and the control terminal board. The control terminal board knockout is 1/2 inch (12.7 mm) conduit size.

The power terminal block knockout is multiple diameter. Use

the diameter that fits the required conduit size.

5. A ground terminal is provided near the power terminal board.

The ground wire should be connected before other connections

are made.

6. The power terminal block is equipped with box terminals sized

to accept the correct size power supply wire. Branch circuit

wire rated min 600V, 60° C is acceptable for heaters rated up to

80 amps. For heaters rated more than 80 amps, branch circuit

wire must be rated at least 75°C. Either aluminum or copper

wire is satisfactory for connection to the heater power terminal

block box terminal. Copper wire is recommended and must be

used with built-in disconnect switch.

3

LOCK NUT

3

/8- 16

1

14

/

211/

2

368.3) (539.8) (56.0) (157.2)

(

MOUNTING

ROD (4)

THREADED

MOUNTING

HOLES

G

(TOP VIEW)

23/

4

16

ACK WALL

B

E

63/

16

S

I

D

E

W

F

A

L

L

H

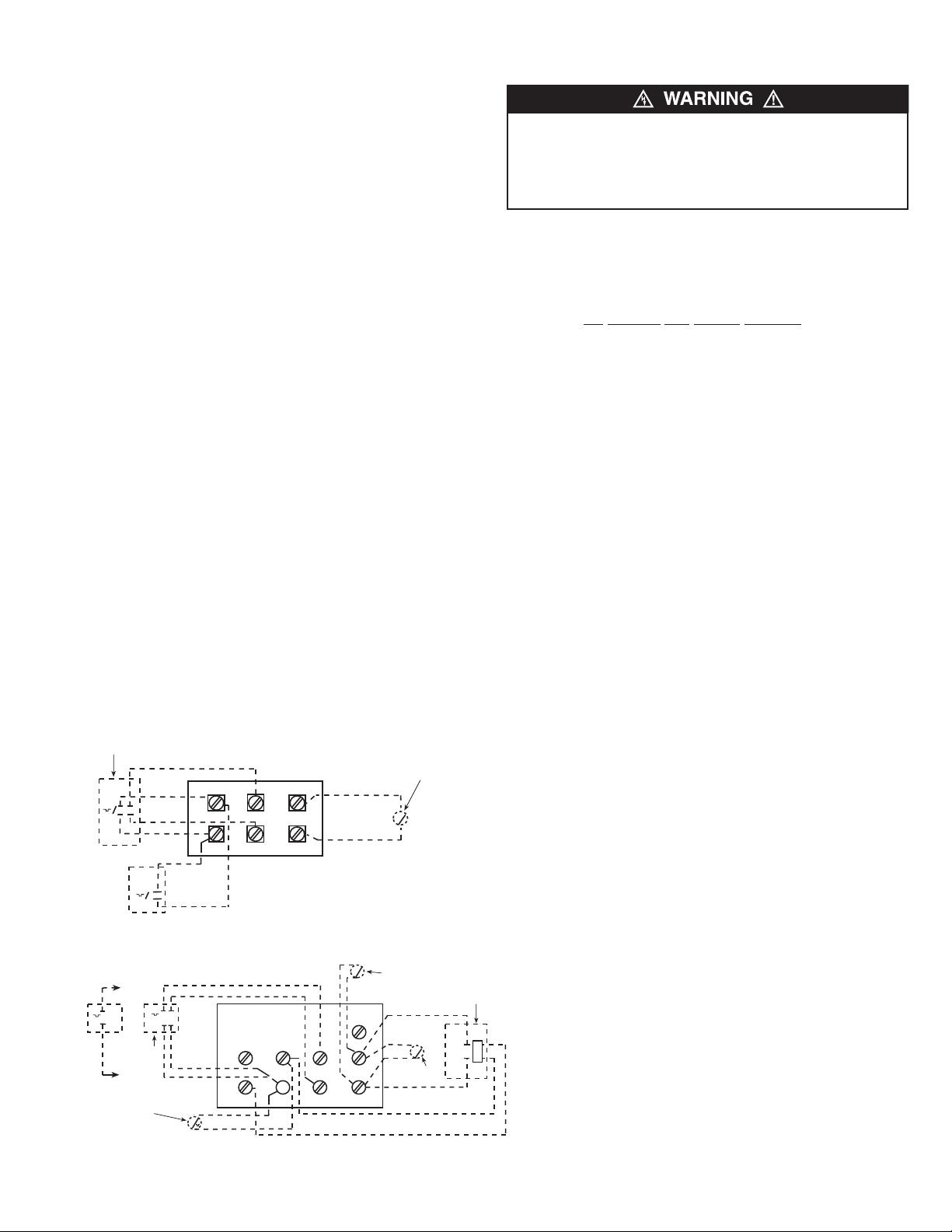

7. Each heater has a wiring diagram affixed to the inside of the

A

B

LEAD WIRE

"B1"

ELEMENTS

CONTACTOR

(OR P2)

POWER TERMINAL BLOCK

HEATER FRONT

LEAD WIRE

"A1"

3 PHASE BLOCK

TO ELEMENTS

A

B

LEAD WIRE

"B1"

ELEMENTS

CONTACTOR

(OR P2)

POWER TERMINAL BLOCK

HEATER FRONT

LEAD WIRE

"A1"

3 PHASE BLOCK

TO ELEMENTS

FACTORY-WIRED FOR SINGLE-PHASE POWER FIELD-WIRED FOR THREE-PHASE POWER

B

3 PHASE BLOCK

FACTORY-WIRED FOR SINGLE-PHASE POWER

C

1

D

1

D

1

C

1

C

D

B

C

D

3 PHASE BLOCK

B

3 PHASE BLOCK

FIELD-WIRED FOR THREE-PHASE POWER

C

1

D

1

D

1

C

1

C

D

B

C

D

3 PHASE BLOCK

access door. Consult this diagram before making any field

connections.

Important Note - Installation Screw Lug Torque:

During transportation it is possible screw lug connections can

loosen. After installation, before power is turned on to the heater,

check all screw lug connections for tightness to a recommended

minimum torque of 35 in-lbs. (3.9 N-m). Loose connections may

present a hazard.

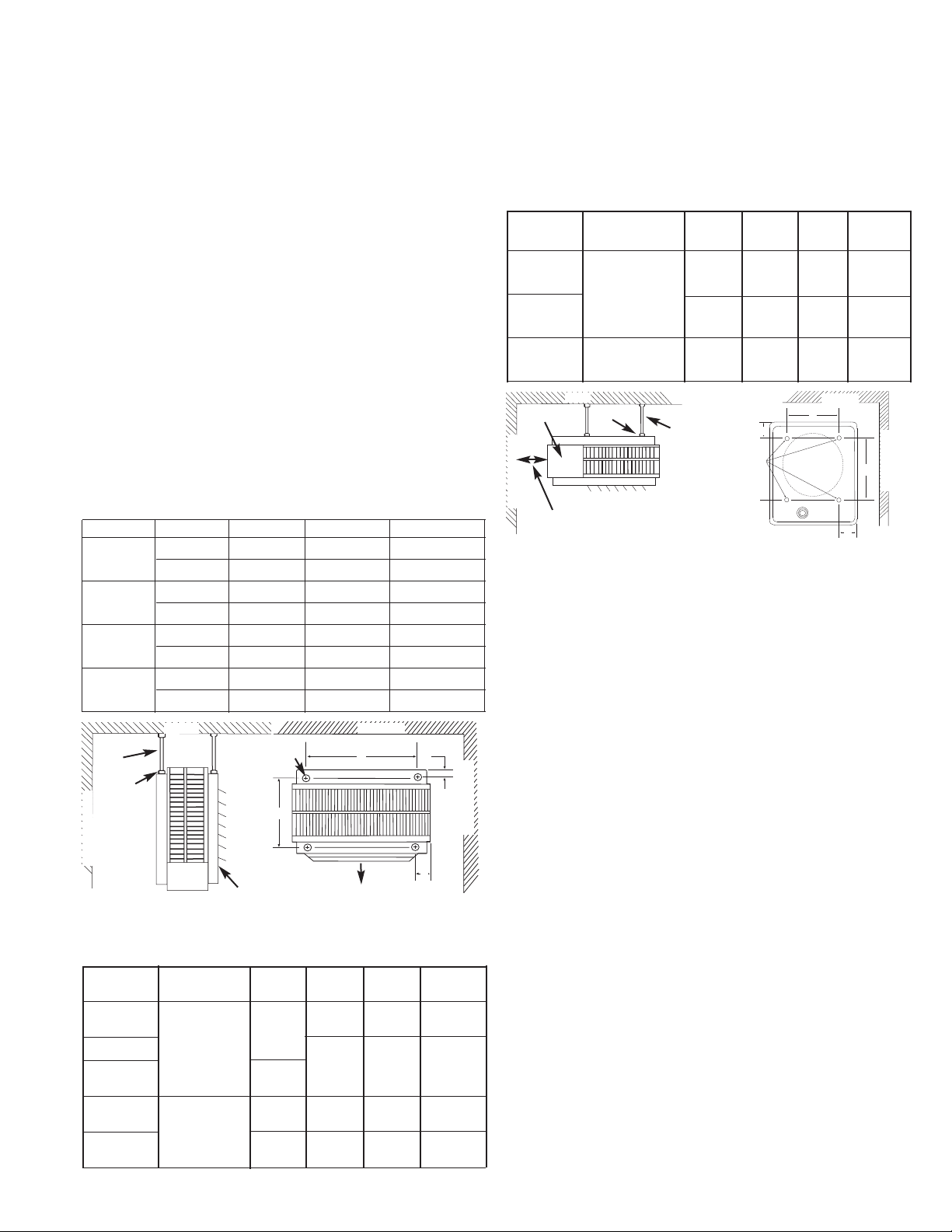

8. Single or three-phase power connections may be used with

heater models MUH0521, MUH0581, MUH072, MUH078,

MUH102, MUH108, and MUH158. These units are factory

wired for single-phase operation. If these heaters are for

use with three-phased power, reconnect the wires as indicated in the wiring diagram attached to the heater. Additional

information can be found by looking at the wiring illustrations

in Figures 3a and 3b and following the directions shown

below.

On models MUH0521,MUH0581, MUH072, MUH078, MUH102,

and MUH108 (Figure 3a), move only the two wires marked “A1”

and marked “B1”; do not move or change any other wiring. The

element lead wire marked “B1” which is factory connected to the

power terminal block (terminal located closest to the elements)

must be moved to terminal “B” on the three-phase terminal block.

Figure 3a. Wiring Connections for Single-Phase and Three -Phase Power(MUH0521, MUH0581, MUH072, MUH078, MUH102

and MUH108)

Figure 3b. Wiring Connections for Single-Phase and Three -Phase Power (MUH158)

4

The relay (contactor) lead wire “A1” must be moved from the end

MT-1

MT-2

2-STAGE

INTERNAL

THERMOSTAT

BLACK

RED

RED

BLACK

P2

H2

F 1

F 2

S

REMOTE SUMMER

FAN SWITCH (MRFS-1)

OR SUMMER FAN

SWITCH MCFS (MANUAL)

P1

H1

T

T

MT-1

MT-2

BLACK TO W1

RED TO R

2-STAGE

INTERNAL

THERMOSTAT

MHRT HEAT RECOVERY

THERMOSTAT OR

REMOTE FAN

SWITCH (MRFS-2)

BLACK

RED

RED

BLACK

C

RW1

W2

F 2

F 1

G

T R

T

S

S

REMOTE SUMMER FAN

SWITCH (MRFS-1)

FAN RELAY

(FOR MRFS-2 AMD MHRT)

SUMMER

FAN

SWITCH

terminal of the power terminal block (terminal closest to the contactor or control terminal board) to the “A” terminal of the lower

terminal block (center terminal).

Model MUH158 (Figure 3b) has two three-phase terminal blocks

located adjacent to the relays (contactors). Move only the two

wires marked “C1” and “D1” on each of these two three-phase

terminal blocks to terminal “B”. Do not move or change any other

wires.

9. Electrical Accessories, either kits or factory-installed

options, are shown connected by a dash line on the heater

wiring diagram.

10. 208/240 VOLT HEATER: The heaters are wired for 240V

from factory. When heater is to be connected to 208V supply, the transformer leads MUST BE interchanged. For units

rated 30/40kW or higher, interchange ORANGE and RED

primary leads. The black colored lead is the COMMON for

the transformer (50VA) provided with the high wattage units.

For lower kW rated heaters, interchange BLACK and RED

primary leads. The WHITE colored lead is the COMMON for

the control transformer provided with these heaters. Always

refer to the wiring diagram on the cover of the heater before

making this reconnection of tranformer primary leads.

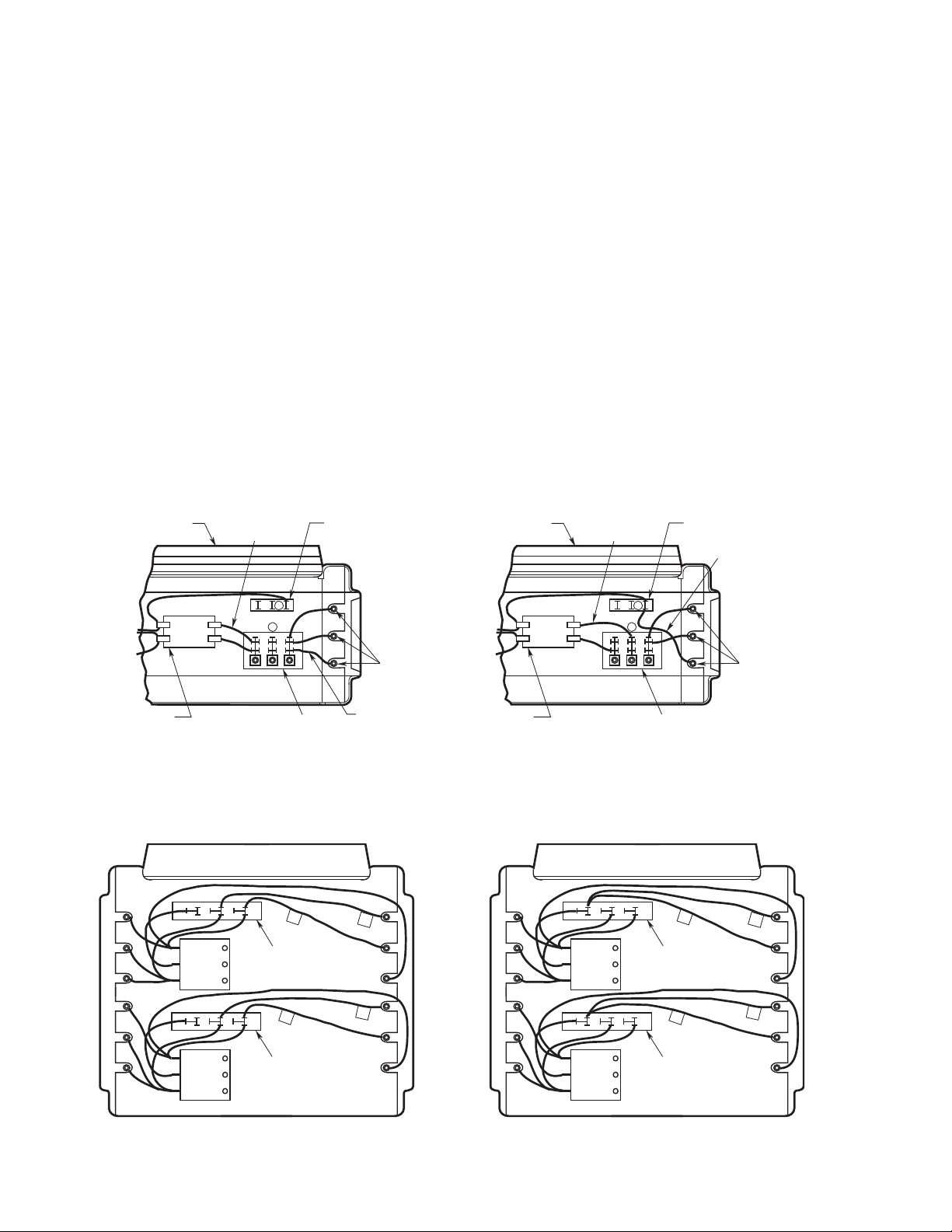

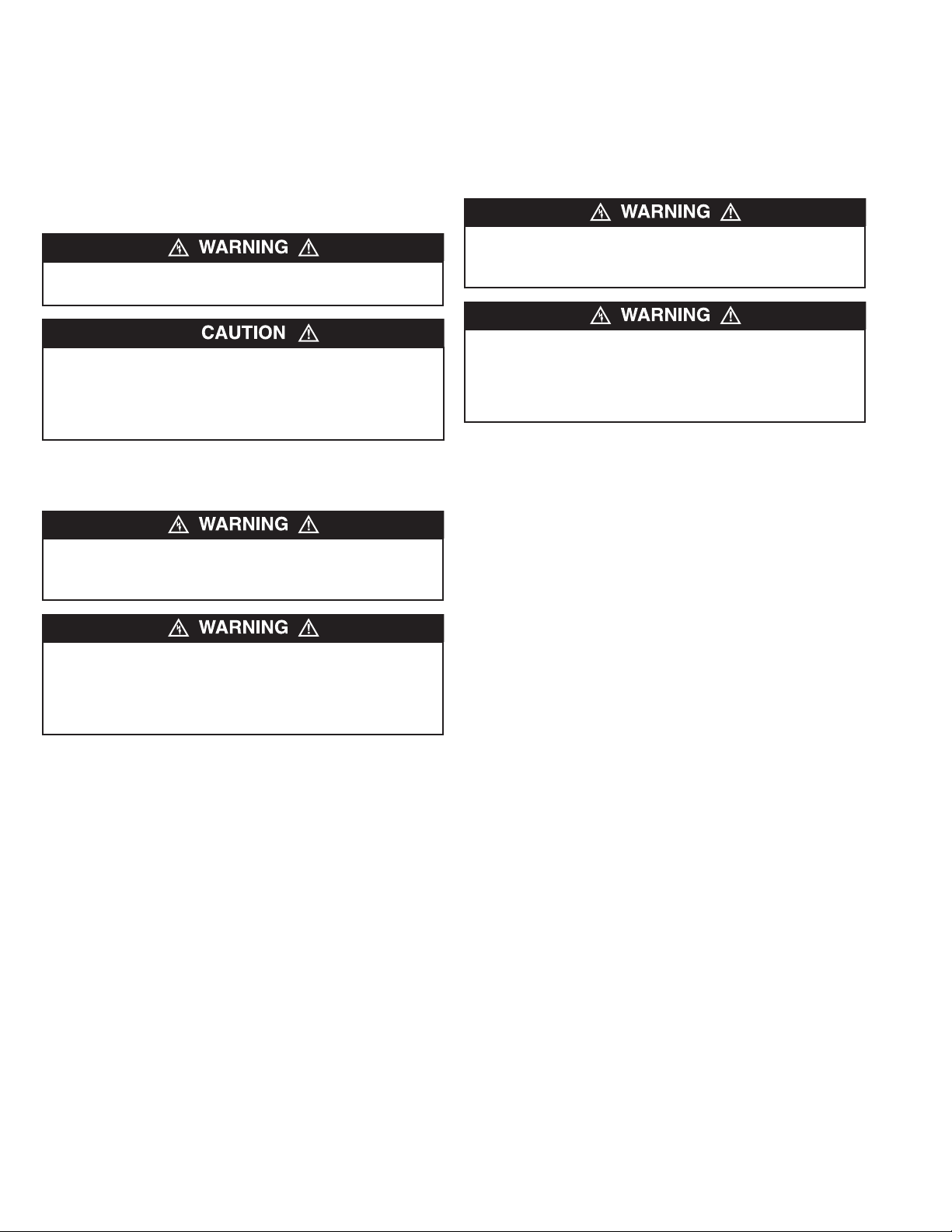

Control Wiring

LINE VOLTAGE IS PRESENT ON SOME OF THE TERMINALS

ON THE CONTROL TERMINAL BOARD. ALWAYS DISCONNECT THE POWER FROM THE HEATER BEFORE MAKING

ANY CONNECTIONS TO THE CONTROL BOARD TO PREVENT ELECTRIC SHOCK HAZARD.

1. Use min. 600 volts, NEC Class 1 insulated wire for all control

circuit wiring.

2. Use a crimp-on type fork terminal on the wire ends that

attach to the control terminal board if more than one connection is to be made under the terminal screw.

3. On units not

provided with internal contactor (3 & 5 KW),

refer to Figure 4 for wiring diagram.

NOTE: Thermostat and control circuit wiring must be suitable to

handle the full load of the heater (example MUH0581 is rated 24

amps)

4. On units provided with internal contactor (units rated 7 KW

and higher) refer to Figure 5 for wiring diagram. Control

wiring must be rated minimum 18 AWG.

OPERATING

Figure 4. Control Terminal Board (for Heaters Without Contactors)

Figure 5. Control Terminal Board (for Heaters With Contactors)

INSTRUCTIONS

1. Heater must be properly installed before operation.

2. Turn power supply to heater “ON” at main switch panel.

3. Where applicable, refer to control accessory instructions

regarding proper operation of any controls or accessories

used with the heater.

NOTES:

1. THIS STYLE CONTROL TERMINAL BOARD USED WITH MODELS

MUH0321, MUH0371, MUH0381, MUH0521, MUH0571, AND

MUH0581.

2. WHEN UNIT IS WIRED FOR SINGLE-PHASE, JUMPER H1 TO H2.

IF SINGLE-POLE THERMOSTAT IS USED WITH SINGLE-PHASE

UNIT, CONNECT THERMOSTAT LEADS TO P1 AND H1.

3. EXTERNAL LINE VOLTAGE THERMOSTATS SHOULD BE TREAT-

ED AS SINGLE STAGE ONLY.

NOTES:

1. THIS STYLE CONTROL TERMINAL BOARD USED

WITH MODELS EXCEPT MUH0321, MUH0371,

MUH0381, MUH0521, MUH0571, AND MUH0581.

2. REMOVE JUMPER W1 TO W2 WHEN 2-STAGE THERMOSTAT IS USED.

3. *ONLY ONE OF THESE ACCESSORIES MAY BE

INSTALLED IN A SINGLE HEATER.

4. EXTERNAL LINE VOLTAGE THERMOSTATS SHOULD

BE TREATED AS SINGLE STAGE ONLY.

5

How To Reset Over -Temperature Safety Control

(Factory Installed Option Only.):

The limit switch is located internally on the rear of the heater.

On the 3KW and 5KW models, the access to the reset button is

on the right side (when facing rear of heater); on all other models it is near the top rear of the heater.

The manual reset limit is in series with the automatic recycling

protector (limit). The manual reset limit will not reset until the

heater has cooled and the button is pushed in.

DO NOT TAMPER WITH OR BYPASS ANY SAFETY LIMITS

INSIDE HEATER.

CAUTION - DO NOT CONTINUE TO ATTEMPT TO USE THE

HEATER IF THE SAFETY CONTROL REPEATEDLY OPERATES AFTER BEING RESET. TO DO SO COULD PERMANENTLY DAMAGE THE HEATER OR CREATE A FIRE OR

SAFETY HAZARD.

It is important to keep this heater clean. Your heater will give you

years of service and comfort with only minimum care. To assure

efficient operation follow the simple instructions below.

ALL SERVICING BEYOND SIMPLE CLEANING THAT

REQUIRES DISASSEMBLY SHOULD BE PERFORMED BY

QUALIFIED SERVICE PERSONNEL.

MAINTENANCE

INSTRUCTIONS

It is important to keep this heater clean. Your heater will give you

years of service and comfort with only minimum care. To assure

efficient operation follow the simple instructions below.

ALL SERVICING BEYOND SIMPLE CLEANING THAT

REQUIRES DISASSEMBLY SHOULD BE PERFORMED BY

QUALIFIED SERVICE PERSONNEL.

TO REDUCE RISK OF FIRE AND ELECTRIC SHOCK OR

INJURY, DISCONNECT ALL POWER COMING TO HEATER

AT MAIN SERVICE PANEL AND CHECK THAT THE ELEMENT

IS COOL BEFORE SERVICING OR PERFORMING

MAINTENANCE.

User Cleaning Instructions:

1. After the heater has cooled, a vacuum cleaner with brush

attachment may be used to remove dust and lint from exterior

surfaces of the heater including the grille openings.

2. With a damp cloth, wipe dust and lint from grille and exterior

surfaces.

3. Return power to heater and check to make sure it is operating properly.

TO REDUCE RISK OF FIRE AND ELECTRIC SHOCK OR

INJURY, DISCONNECT ALL POWER COMING TO HEATER

AT MAIN SERVICE PANEL AND CHECK THAT THE ELEMENT

IS COOL BEFORE SERVICING OR PERFORMING

MAINTENANCE.

User Cleaning Instructions:

1. After the heater has cooled, a vacuum cleaner with brush

attachment may be used to remove dust and lint from exterior

surfaces of the heater including the grille openings.

2. With a damp cloth, wipe dust and lint from grille and exterior

surfaces.

3. Return power to heater and check to make sure it is operating properly.

Maintenance Cleaning Instructions:

(To be performed only by Qualified Service Personnel)

At least annually, the heater should be cleaned and serviced by

a qualified service person to assure safe and efficient operation.

This should include as necessary, vacuuming dust and debris

from the elements and fan, and checking all screw lug connections for tightness to a recommended minimum torque of 35 inlbs. (3.9 N-m). After completing the cleaning and servicing, the

heater should be fully reassembled and checked for proper

operation.

6

2

4

3

1

5

9

7

12

11

9

10

8

6

MUH

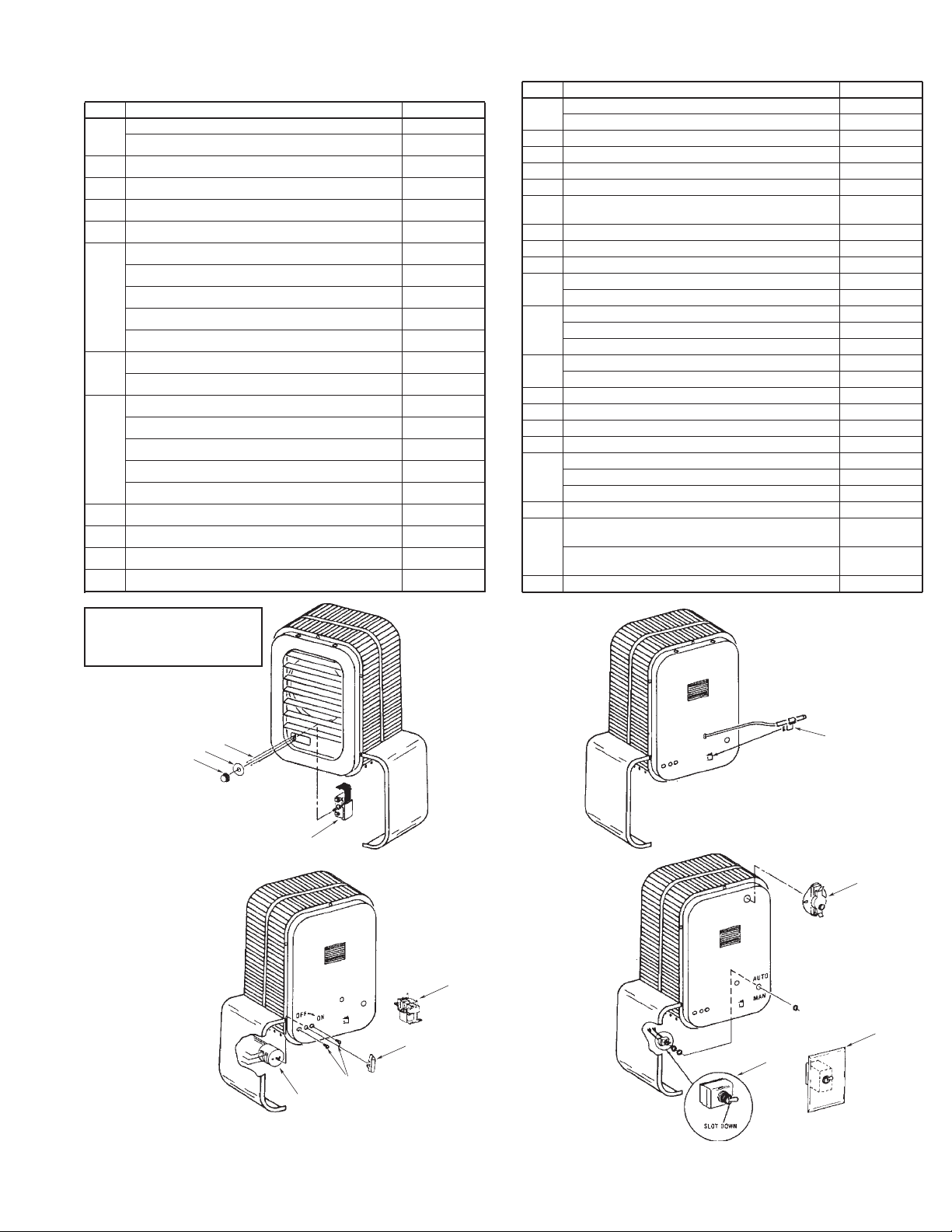

Built-in Controls

Key No. Description Part Number

1 Thermostat, One Pole (MT-1) 5813-0036-000

Thermostat, Two Stage (MT-2) 5813-0035-000

2 Knob, Thermostat 3301-0060-000

3 Label, Thermostat 3502-1781-000

4 Screws, Fl. Hd., 6-32 x 1/4 5202-7009-021

5 Clip, Thermostat 1403-0041-000

6 Switch, 25A, OEM 5216-0132-000

Switch, 25A, K & N 5216-0204-000

Switch, 63A, OEM 5216-0131-000

Switch, 63A, K & N 5216-0203-000

Switch 25A, Electro 5216-0200-000

7 Screw, M4 x 10, Rd. Hd., (25A) —

Screw, 63A, M5 x 16, Rd. Hd. —

8 Knob, 25A, OEM “T1” OEM “T1”

Knob, 25A, K & N K & N S1B 6001

nob, 63A, OEM OEM “S4”

K

nob, 63A, K & N K & N S2B G001

K

nob, Electro EI 141747

K

Switch, Toggle, 600V 5216-0130-000

9

10 Relay, Fan, 24V Coil 5018-0008-000

11 Switch Assembly 5216-0199-000

12 Manual Reset Limit 4520-0012-000

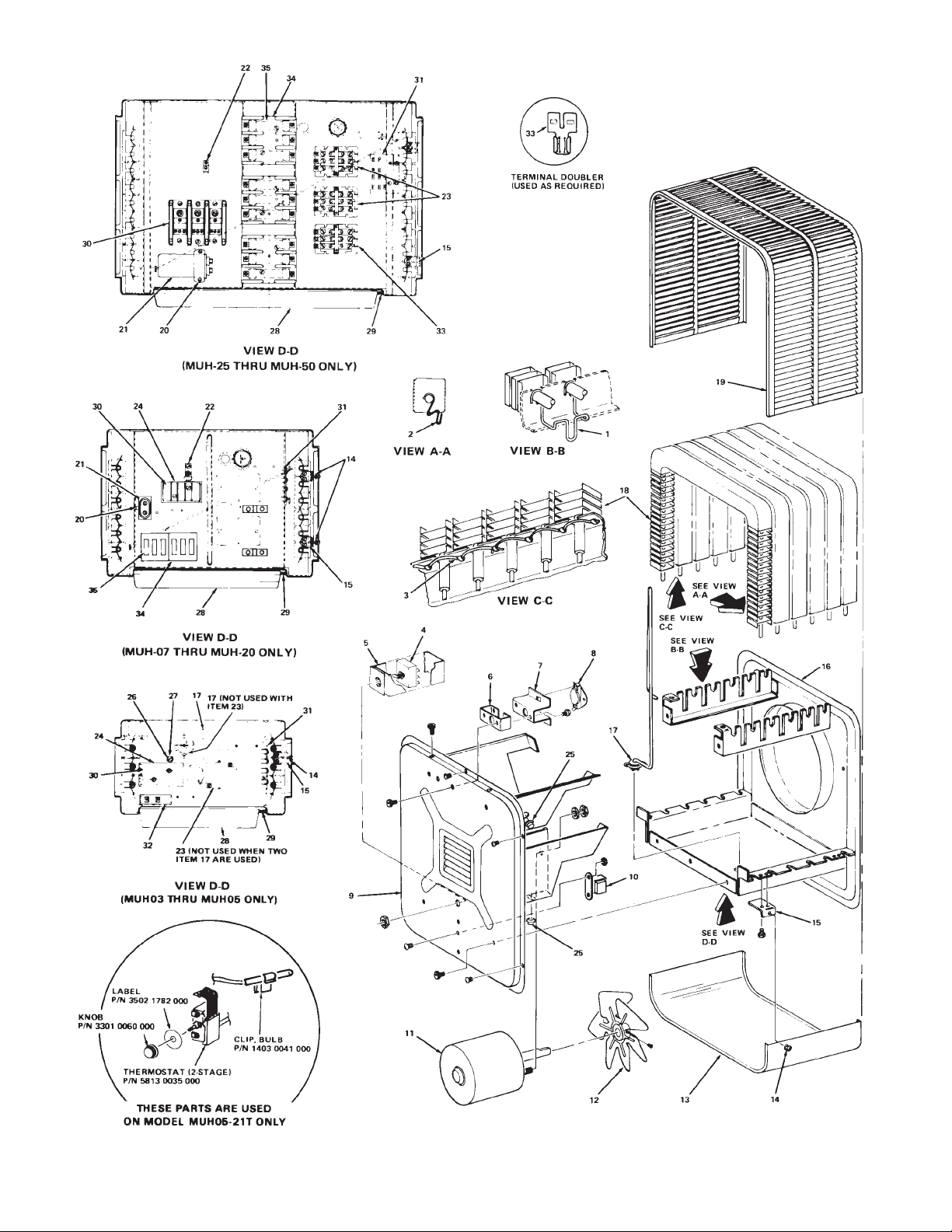

Heater Replacement Parts

ey No. Description Part Number

K

Spring, Element (used on MUH03 thru MUH-20 only) 5208-0073-000

1

pring, Element (used on MUH-25 thru MUH-50 only) 5208-0073-001

S

Spring, Capillary Tube 5208-0072-000

2

Spring, Element Retainer 5208-0074-000

3

Switch (used on MUH-25 thru MUH-50 only) 5216-7076-001

4

Insulator (used on MUH-25 thru MUH-50 only) 2900-0031-000

5

Bracket Extension

6

(used on MUH-15, MUH-20, MUH-40 and MUH-50 only) 1215-0282-000

7 Switch Bracket 1215-0256-000

8 Fan Delay 4520-0010-000

14 Speed Nut 4100-7036-026

15 Bracket, Captive Screw (used on MUH-03 thru MUH-20 only) 1215-0291-000

Bracket, Captive Screw (used on MUH-25 thru MUH-50 only) 1215-0289-000

17 Protector, Linear Limit (used on MUH03 thru MUH05 only) 4520-0011-000

Protector, Linear Limit (used on MUH-07 thru MUH-20 only) 4520-0011-001

Protector, Linear Limit (used on MUH-25 thru MUH-50 only) 4520-0011-002

20 Clamp (used on MUH-20 thru MUH-50 only) 1417-5004-000

Bracket, Mounting Capacitor (used on MUH-20-8 only) 1215-0314-000

22 Terminal Lug (used on MUH-07 thru MUH-50 only) 3504-7002-001

25 Bushing (used on MUH-20 thru MUH-50 only) 25221-60131

26 Washer, Ground (used on MUH03 thru MUH05 only) 6401-0084-000

27 Screw, Ground (used on MUH03 thru MUH05 only) 5202-0290-002

28 Louver (used on MUH03 thru MUH05 only) 3503-0036-000

Louver (used on MUH-07 thru MUH-20 only) 3503-0036-001

Louver (used on MUH-25 thru MUH-50 only) 3503-0036-002

29 Spring, Louver 5208-7005-001

32 Terminal Block, 3-Phase (used on MUH05-21,

MUH-07-02,and MUH-10-2 only) 5823-0003-000

Terminal Block, 3-Phase (used on MUH05-81,

MUH-07-8, and MUH-15-8 only) 5823-0003-000

33 Terminal Doublers (used where required) 5819-7012-005

BUILT-IN CONTROLS —

Made-to-Order Units Only

POWER

DISCONNECT

SWITCH

SINGLE-POLE

THERMOSTAT, TWO-STAGE

THERMOSTAT, HEAT

RECOVERY THERMOSTAT

SUMMER

FAN

SWITCH

7

7

8

9 10 11 12 13 16 18 19 21

odel No. Back Case Transformer** Motor Fan Blade Cover Front Case Element Assy. Element Guard Capacitor

M

UH03-21 1425-2004-000 – 3900-2002-006 1210-2000-000 1402-0336-001 1425-0009-005 1802-0087-000 2504-0011-000 –

M

MUH03-41 1425-2004-000 5814-0003-002 3900-2005-000 1210-2000-000 1402-0336-001 1425-0009-005 1802-0087-002 2504-0011-000 –

UH03-71 1425-2004-000 – 3900-2002-007 1210-2000-000 1402-0336-001 1425-0009-005 1802-0087-001 2504-0011-000 –

M

MUH03-81 1425-2004-000 – 3900-2002-006 1210-2000-000 1402-0336-001 1425-0009-005 1802-0087-024 2504-0011-000 –

MUH05-21MG 1425-2004-000 – 3900-2002-006 1210-2000-000 1402-0336-001 1425-0009-005 1802-0087-003 2504-0011-000 –

UH05-41 1425-2004-000 5814-0003-002 3900-2005-000 1210-2000-000 1402-0336-001 1425-0009-005 1802-0087-005 2504-0011-000 –

M

MUH05-71 1425-2004-000 – 3900-2002-007 1210-2000-000 1402-0336-001 1425-0009-005 1802-0087-004 2504-0011-000 –

UH05-81MG 1425-2004-000 – 3900-2002-006 1210-2000-000 1402-0336-001 1425-0009-005 1802-0087-025 2504-0011-000 –

M

UH-07-2 1425-0010-004 5814-0003-000 3900-2014-002 1210-0090-000 1402-0339-002 1425-0009-006 1802-0087-006 2504-0013-001 –

M

MUH-07-4 1425-0010-004 5814-0003-002 3900-0347-005 1210-0090-000 1402-0339-002 1425-0009-006 1802-0087-008 2504-0013-001 –

UH-07-7 1425-0010-004 5814-0003-001 3900-2014-003 1210-0090-000 1402-0339-002 1425-0009-006 1802-0087-007 2504-0013-001 –

M

MUH-07-8 1425-0010-004 5814-0003-000 3900-2014-001 1210-0090-000 1402-0339-002 1425-0009-006 1802-0087-031 2504-0013-001 –

MUH-10-2 1425-0010-004 5814-0003-000 3900-2014-002 1210-0090-000 1402-0339-002 1425-0009-006 1802-0087-031 2504-0013-001 –

MUH-10-4 1425-0010-004 5814-0003-002 3900-0347-005 1210-0090-000 1402-0339-002 1425-0009-006 1802-0087-011 2504-0013-001 –

MUH-10-7 1425-0010-004 5814-0003-001 3900-2014-003 1210-0090-000 1402-0339-002 1425-0009-006 1802-0087-010 2504-0013-001 –

MUH-10-8 1425-0010-004 5814-0003-000 3900-2014-001 1210-0090-000 1402-0339-002 1425-0009-006 1802-0087-036 2504-0013-001 –

UH-15-2 1425-0014-000 5814-0003-000 3900-0361-000 1210-0090-001 1402-0339-003 1425-0009-007 1802-0087-012 2504-0012-001 –

M

MUH-15-4 1425-0014-000 5814-0003-002 3900-0361-001 1210-0090-001 1402-0339-003 1425-0009-007 1802-0087-013 2504-0012-001 –

MUH-15-8 1425-0014-000 5814-0003-000 3900-0361-002 1210-0090-001 1402-0339-003 1425-0009-009 1802-0087-031 2504-0012-001 –

UH-20-2 1425-0013-000 5814-0003-000 3900-0362-000 1210-0096-000 1402-0339-003 1425-0009-007 1802-0087-014 2504-0012-001 1432-0002-003

M

MUH-20-4 1425-0013-000 5814-0003-002 3900-0362-001 1210-0096-000 1402-0339-003 1425-0009-007 1802-0087-015 2504-0012-001 1432-0002-003

MUH-20-8 1425-0013-000 5814-0003-000 3900-0362-002 1210-0096-000 1402-0339-003 1425-0009-011 1802-0087-026 2504-0012-001 1432-0002-003

MUH-25-2 1425-0011-003 5814-0003-000 3900-0364-000 1210-0098-000 1402-0340-002 1425-0012-003 1802-0087-016 2504-0014-001 1432-0002-001

MUH-25-4 1425-0011-003 5814-0003-002 3900-0363-001 1210-0098-000 1402-0340-002 1425-0012-003 1802-0087-017 2504-0014-001 1432-0002-003

UH-30-2 1425-0011-003 5814-0003-000 3900-0364-000 1210-0098-000 1402-0340-002 1425-0012-003 1802-0087-018 2504-0014-001 1432-0002-001

M

MUH-30-4 1425-0011-003 5814-0003-002 3900-0363-000 1210-0098-000 1402-0340-002 1425-0012-003 1802-0087-019 2504-0014-001 1432-0002-003

MUH-30-8 1425-0011-003 5814-0003-000 3900-0364-000 1210-0098-000 1402-0340-002 1425-0009-009 1802-0087-028 2504-0014-001 1432-0002-001

UH-40-2 1425-0011-001 5814-0003-000 3900-0350-000 1210-0097-000 1402-0340-003 1425-0012-002 1802-0087-020 2504-0015-001 1432-0002-004

M

MUH-40-4 1425-0011-001 5814-0003-002 3900-0350-001 1210-0097-000 1402-0340-003 1425-0012-002 1802-0087-021 2504-0015-001 1432-0002-004

MUH-50-2 1425-0011-001 5814-0003-000 3900-0350-000 1210-0097-000 1402-0340-003 1425-0012-002 1802-0087-022 2504-0015-001 1432-0002-004

MUH-50-4 1425-0011-001 5814-0003-002 3900-0350-001 1210-0097-000 1402-0340-003 1425-0012-002 1802-0087-023 2504-0015-001 1432-0002-004

MUH-50-8 1425-0011-001 5814-0003-000 3900-0350-002 1210-0097-000 1402-0340-003 1425-0012-002 1802-0087-030 2504-0015-001 1432-0002-004

23 24 30 31 34 35

Model No. Relay*** Insulator Terminal Block, Power Terminal Block, Control Fuse Block Fuse

MUH03-21 ––5823-0004-000 5823-0001-000 ––

MUH03-41 5018-0004-100 2900-0030-000 5823-0004-000 5823-0002-000 ––

MUH03-71 – 2900-0030-000 5823-0004-000 5823-0001-000 ––

MUH03-81 ––5823-0004-000 5823-0001-000 ––

MUH05-21MG 5018-0003-002 – 5823-0004-000 5823-0002-000 ––

MUH05-41 5018-0004-100 2900-0030-000 5823-0004-000 5823-0002-000 ––

MUH05-71 – 2900-0030-000 5823-0004-000 5823-0001-000 ––

MUH05-81MG 5018-0003-002 – 5823-0004-000 5823-0002-000 ––

MUH-07-2 5018-0003-000 – 5823-0004-000 5823-0002-000 ––

MUH-07-4 5018-0004-100 2900-0030-000 5823-0004-000 5823-0002-000 ––

MUH-07-7 5018-0004-100 2900-0030-000 5823-0004-000 5823-0002-000 ––

MUH-07-8 5018-0003-000 – 5823-0004-000 5823-0002-000 ––

MUH-10-2 5018-0003-000 – 5823-0004-000 5823-0002-000 ––

MUH-10-4 5018-0004-100 2900-0030-000 5823-0004-000 5823-0002-000 ––

MUH-10-7 5018-0003-000 2900-0030-000 5823-0004-000 5823-0002-000 ––

MUH-10-8 5018-0004-100 – 5823-0004-000 5823-0002-000 ––

MUH-15-2 5018-0005-004 – 5823-0004-001 5823-0002-000 ––

MUH-15-4 5018-0004-100 2900-0030-000 5823-0004-000 5823-0002-000 ––

MUH-15-8 5018-0005-008 – 5823-0004-003 5823-0002-000 2025-0002-000 2019-0007-010

MUH-20-2 5018-0006-000 – 5823-0004-002 5823-0002-000 ––

MUH-20-4 5018-0004-100 2900-0030-000 5823-0004-000 5823-0002-000 ––

MUH-20-8 5018-0005-000 – 5823-0004-002 5823-0002-000 2025-0002-000 2019-0007-008

MUH-25-2 5018-0005-004 – 5823-0004-002 5823-0002-000 2025-7002-000 2019-7008-077

MUH-25-4 5018-0005-004 2900-0030-000 5823-0004-001 5823-0002-000 ––

MUH-30-2 5018-0005-004 – 5823-0004-003 5823-0002-000 2025-7002-000 2019-7008-079

MUH-30-4 5018-0005-004 2900-0030-000 5823-0004-001 5823-0002-000 ––

MUH-30-8 5018-0006-000 – 5823-0005-000 5823-0002-000 2025-7002-000 2019-7008-080

MUH-40-2 5018-0005-004 – 5823-0005-000 5823-0002-000 2025-7002-000 2019-7008-079

MUH-40-4 * 2900-0030-000 5823-0004-002 5823-0002-000 2025-7002-000 2019-7008-079

MUH-50-2 5018-0005-004 – 5823-0005-000 5823-0002-000 2025-7002-000 2019-7008-080

MUH-50-4 * 2900-0030-000 5823-0004-002 5823-0002-000 ––

MUH-50-8 5018-0006-000 – 5823-0005-000 5823-0002-000 2025-7002-000 2019-7008-078

* Two relays are used: 35A relay P/N 5018-0004-000 and 40A relay P/N 5018-0006-000.

** 24V secondary shown. For 120V secondary, increase last digit by 3. (i.e. for MUH03-41, 24V secondary use 5814-0003-002; for 120V secondary use 5814-0003-005.)

*** 24V H.C. shown. For 120 H.C., increase last digit by 1. (i.e.: for MUH03-41, 24V H.C. use 5018-0004-000; for 120V H.C. use 5018-0004-001.)

9

Loading...

Loading...