Page 1

BLADE MAX MIN. INTAKE

CFM VOL TS WATTS AMPS HP RPM DIA. SHUTTER A TTIC AREA REQUIRED

*1520 120 255 2.6 1/5 1100 16” STD. WOOD 2170 5.1 Sq. Ft.

LOUVER Sq. Ft.

1860 120 250 2.6 1/5 1115 16” METAL 2656 6.2 Sq. Ft.

LOUVER Sq. Ft.

READ AND SAVE THESE INSTRUCTIONS

MODEL GV 16

GABLE MOUNTED

VENTILATOR

READ INSTRUCTIONS CAREFULLY BEFORE ATTEMPTING TO INSTALL, OPERATE OR SERVICE THE

PATTON ATTIC VENTILATOR. FAILURE TO COMPLY WITH INSTRUCTIONS COULD RESULT IN PERSONAL INJURYAND/OR PROPERTY DAMAGE!

RETAIN INSTRUCTIONS FOR FUTURE REFERENCE.

IMPORTANT SAFETY INSTRUCTIONS

WARNING:

TO REDUCE RISK OF FIRE, ELECTRICAL SHOCK OR INJURY

TO PERSONS, OBSERVE THE FOLLOWING:

Description

The Marley Engineered Products gable mounted attic ventilator is

fully automatic and designed for general ventilating use only in the

attic spaces of houses, apartments and other small buildings. Unit

can be installed behind existing attic louvers to exhaust hot air or

pull in cool air. An accessory dehumidistat can be used with this

unit to automatically activate in the winter to help eliminate excessive moisture.

The ventilator comes complete with mounting brackets, 18”

armored flexible cable, prewired automatic thermostat mounted in

junction box, thermally protected motor, and heavy gauge plated

steel housing.

Unpacking

Unpack carefully. Inspect for loose, missing or damaged parts. In

the event of missing components or hidden damage, immediately

contact your distributor or the delivering carrier concerning discrepancies. The motor/fan assembly has been carefully factorybalanced. Care should be taken when handling to avoid damage

resulting in unnecessary vibration and noise.

Specifications

MOTOR

* H.V.I. Certified at 0.03” Static Pressure

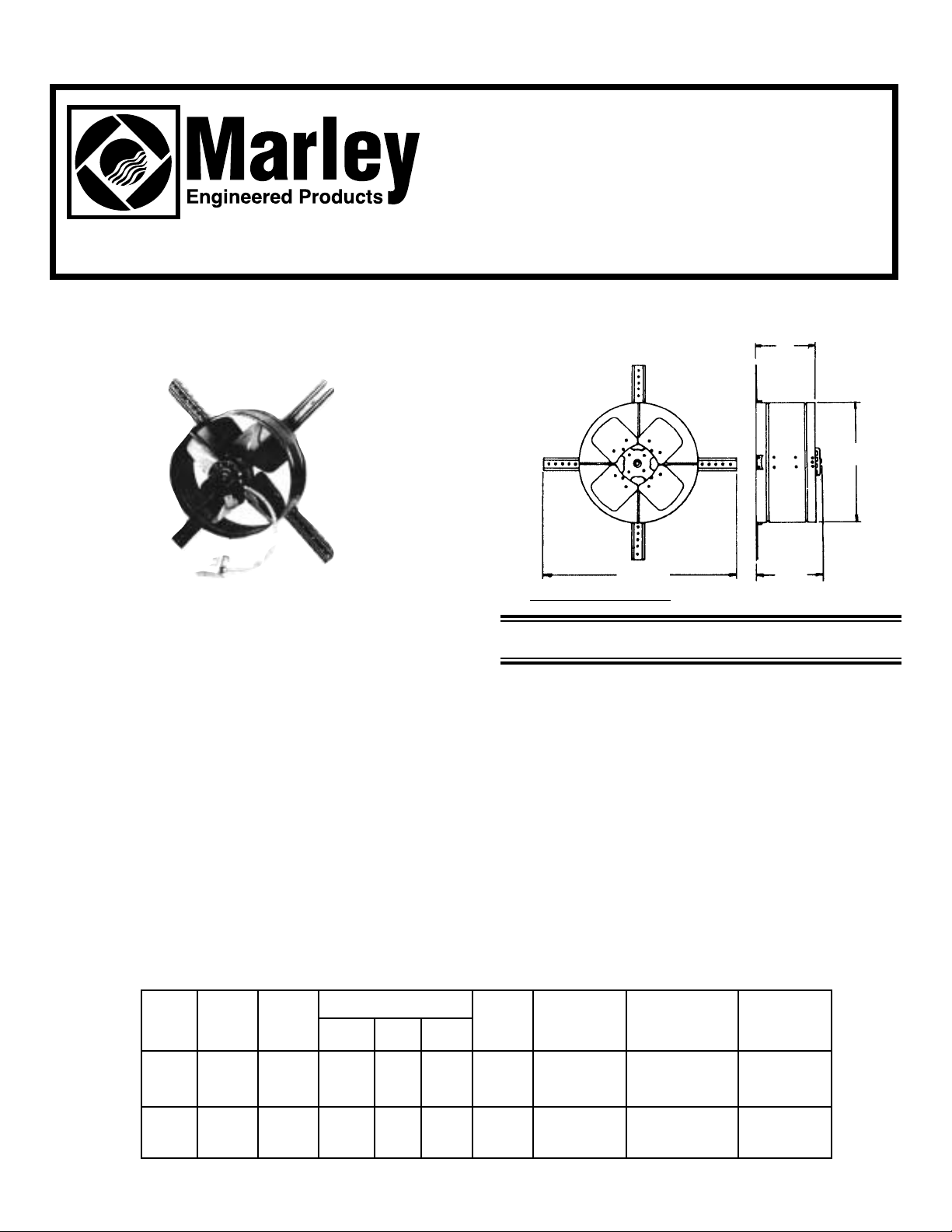

Figure 2

— Dimensions

1. Do not use this fan with any Solid-State Speed Control Device.

2. Use this unit only in the manner intended by the manufacturer. If you

have questions, contact the manufacturer.

3. Before servicing or cleaning unit, switch power off at service panel and

lock service panel to prevent power from being switched on accidentally.

4. Installation work and electrical wiring must be done by qualified person(s) in accordance with all applicable codes and standards, including

fire-rated construction.

5. Sufficient air is needed for proper combustion and exhausting of gases

through the flue (chimney) of fuel burning equipment to prevent back

drafting. Follow the heating equipment manufacturer’s guideline and

safety standards such as those published by the National Fire Protection

Association (NFPA), and the American Society for Heating and Air

Conditioning Engineers (ASHRAE), and the local code authorities.

Dimensions 7”

16

9

⁄16”

32

13

⁄16”

8

5

⁄8”

Page 2

UNRESTRICTED WOOD LOUVER METAL LOUVER

5.1 Sq. Ft. 6.4 Sq. Ft. 5.9 Sq. Ft.

6. “When cutting or drilling into wall or ceiling, Do Not damage

electrical wiring or other hidden utilities.

7. CAUTION: This unit has an unguarded impeller. Do not use in

locations readily accessible to people or animals.

8. CAUTION: For general ventilation use only! Do not use to exhaust

hazardous or explosive materials and vapors.

INSTALLATION

NOTE: For maximum operating efficiency, proper intake air opening must be provided to allow replacement of exhaust air. One

square foot of free open air inlet per 300 CFM of fan capacity is recommended. The best location for air intake is at the opposite end

of the attic. See:

MINIMUM A TTICINTAKEAREA REQUIRED

section.

1. This gable ventilator is designed to mount behind existing

louvers in an attic. If a louver is not present and one must be

installed, it should be mounted in the center of the uppermost

portion of the gable. The area of the louver should be greater

than outlet area of ventilator. (See Figures 4 and 5.)

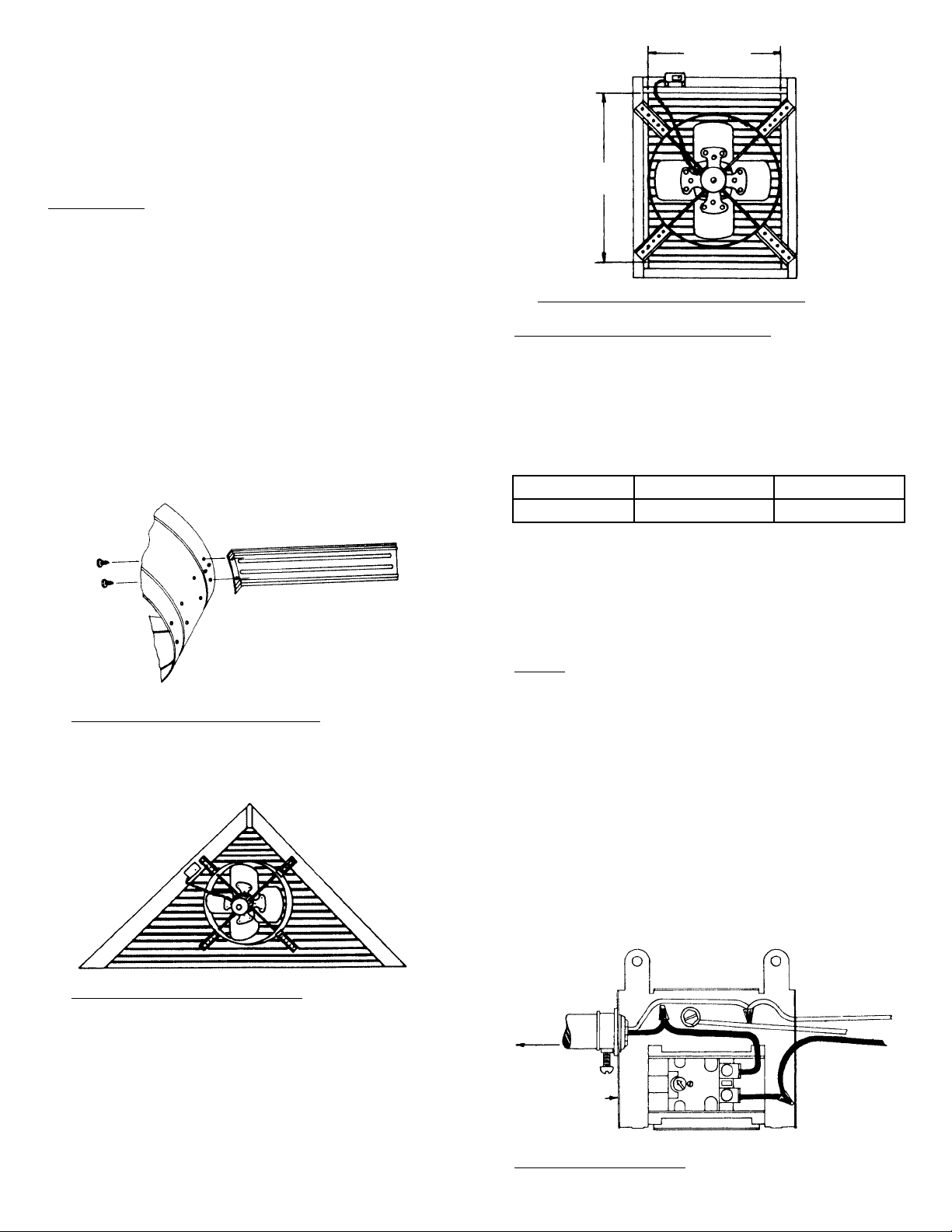

2. There are four sets of holes spaced 90

º apart in housing,

providing a choice of four depth positions. Reversing brackets

produces eight positions. Select proper mounting holes to

align bracket and mounting structure on louvers. (See Fig. 3.)

Figure 3

— Mounting Housing to Brackets

3. Ventilator may be mounted directly against a gable louver as

shown in Figure 4. If louver is sufficiently strong, mounting

brackets may be nailed or screwed onto it.

Figure 4

— Mounting to Gable Louvers

4. If mounting the vent directly to gable louver is undesirable, a

pair of furring strips may be suspended vertically at a minimum

of 16 3/4” apart.

5. Ventilator may also be mounted on rectangular louvers as

shown in Figure 5.

6. For better performance, cover any open louvered area around

vent with plywood or other suitable material. This will improve

efficiency of air exchange between attic and outside air. It will

also prevent thermostat from being directly affected by outside

air.

Figure 5

— Mounting to Rectangular Louvers

MINIMUM ATTIC

INTAKE

AIR REQUIRED

Sufficient intake area must be provided in the attic to ensure that

fan will not be overloaded and that it will deliver its rated CFM. This

can be accomplished with some type of attic venting such as gable

louvers or undereave vents. The table below shows minimum

intake area needed for each fan installed.

MINIMUM ATTIC INTAKE OPENING REQUIRED

Note: If openings are covered with 1/2” hardware cloth or large

mesh expanded metal, increase area by 20%. Double area if fly

screen is used.

WIRING

WARNING: TO REDUCE RISK OF FIRE OR ELECTRIC

SHOCK, DO NOT USE THIS FAN WITH ANY SOLID STATE

SPEED CONTROL DEVICE.

Note: This fan is designed to run on 120V, 60 HZ power only.

1. Thermostat box can be screwed or nailed to a rafter by

mounting bracket provided. If nailed, remove thermostat from

box before nailing to avoid damage. Connection to existing

circuit must conform to local electrical code regulations.

2. Wiring of this unit is done inside attic. Remove cover from

thermostat/junction box. Bring power cable at least 6 inches

into the box. Fasten power cable to box with appropriate

connector.

3. For standard installation, connect the two leads in thermostat/

junction box to the two supply leads. Attach ground wire from

the supply to the green ground screw in the box. (See Fig. 6.)

F

igure 6 — Wiring Diagram

163⁄4” MIN.

16

3

⁄4” MIN.

120V, 60 Hz

SUPPLY

WHITE

GROUND

BLACK

TO FAN

MOTOR

THERMOSTAT &

JUNCTION BOX

ASSEMBLY

Page 3

Excessive 1. Propeller blade contacting 1. Realign or replace.

noise. housing.

2. Foreign material inside 2. Clean.

housing.

3. Motor loose. 3. Secure properly.

4. Motor needs oiling. 4. See Maintenance section.

5. Dirt accumulation on pro- 5. Clean.

peller, causing imbalance.

Insufficient 1. Not enough eave vents to 1. See installation section.

air flow. provide make-up air.

2. Clogged screen. 2. Clean or replace.

Unit fails to 1. Blown fuse or open cir- *1. Replace fuse or reset ciroperate. cuit breaker. cuit breaker.

2. Defective motor. *2. Replace.

3. Improper setting of ther- *3. See Operation section.

mostat. (REMEMBER THE

15

º DIFFERENTIAL)

4. Defective thermostat. *4. Replace

SYMPTOM POSSIBLE CAUSE CORRECTIVE ACTION

MAINTENANCE

WARNING: MOTORS ARE THERMALLY PROTECTED

AND AUTOMATICALLY TEMPERATURE CONTROLLED AND MAY START WITHOUT WARNING.

THEREFORE, MAKE CERTAIN THAT POWER SOURCE

IS DISCONNECTED BEFORE ANY ATTEMPT TO SERVICE OR DISASSEMBLE ANY COMPONENTS! IF

POWER DISCONNECT IS OUT-OF-SIGHT, LOCK IT IN

THE OPEN POSITION AND TAG TO PREVENT APPLICATION OF POWER.

Lubricate motor every 6 months using SAE 20 non-detergent oil.

Insert 2-3 drops of oil in the oiling hole on the back plate of the

motor.

4. See Fig. 7 for wiring dehumidistat to ventilator.

TROUBLESHOOTING CHART

WARNING: ITEMS MARKED WITH AN ASTERISK (*)

SHOULD BE PERFORMED ONLY BY EXPERIENCED AND

QUALIFIED PERSONNEL.

Figure 7 — W

iring Diagram for Dehumidistat

5. Replace cover to thermostat/junction box.

OPERATION

Set automatic thermostat to meet your requirements. The thermostat has an adjustable range from 60

º to 120º and operates on

a 15

º differential. For example, factory setting is 100º. At this set-

ting, as soon as temperature reaches 115

º, thermostat will close

and start ventilator. When temperature has been reduced to 100

º,

thermostat will open and ventilator will stop. Dial pointer may be

set at temperature that is best for local conditions.

NOTE: Remember the 15

º differential. If dial point is set on 120º,

ventilator will start at 135

º and operate until temperature has been

reduced to 120

º, a difference of 15º. (See Figure 8.)

Figure 8

— Thermostat

120V, 60 Hz

SUPPLY

WHITE

GROUND

BLACK

DEHUMIDISTAT

TO FAN

MOTOR

THERMOSTAT &

JUNCTION BOX

ASSEMBLY

F

A

N

O

F

F

90

60ºF

120

Page 4

Part No. 5200-2550-000 PPD 035

3-00

PARTS LIST

REF. NO. DESCRIPTION QTY.

1 FAN BLADE ASSEMBLY 1

2 SHROUD ASSEMBLY 1

3 + SHROUD 1

4 + POP RIVET, 1/8 X 1/8 STEEL 8

5 * SCREW 1/4”- 20 X 1.5” 2

6 + MOTOR BAND 1

7 + MOTOR BRACKET 4

8 SPEED NUT, 1/4 X 20 1

9 + RIVET, 1/8 X 5/32 STEEL 8

10 MOTOR, PSC 115V 1/5 HP 1

11 BOOT, CAPACITOR TERMINALCOVER 1

12 CAPACITOR, 4 MFD, 370 VAC 1

13 * KEPS NUT, #8-32 1

14 CUP, BX 1

15 CONDUIT, FLEXIBLE 1

16 THERMOSTAT ASSEMBLY 1

17 + BX CONNECTOR 1

18 ANTI SHORT BUSHING 1

19 MOUNTING BRACKET 4

20 * SCREW #8 X 3/8” TYPE AB 8

21 † INSTRUCTION SHEET 1

* STANDARD HARDWARE ITEM AVAILABLE

LOCALLY

+ NOT A VAILABLE AS AREPLACEMENT PART

† ITEM NOT SHOWN

HOW TO ORDER REPAIR PARTS

In order to obtain any needed repair or replacement

parts, warranty service or technical information, please

contact Marley Engineered Products Service Center tollfree by calling 1-800-642-HEAT.

When ordering repair parts, always give the information listed as follows:

1. The Part Number

2. The Model Number

3. The Part Description

4. Date of Manufacture

SPX Corporation

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

Loading...

Loading...