Marley Engineered Products E3609-1125HFD, E3806-1125HFD, E6012-2125HFD, E4209-1125HFD, E4812-1125HFD User Manual

...Page 1

Description

Specifications and Performance

INSTALLATION & OPERATING INSTRUCTIONS & PARTS MANUAL

MODELS: E3606-1125HFD, E3609-1125HFD, E3612-1125HFD

E3806-1125HFD, E3809-1125HFD, E3812-1125HFD

E4206-1125HFD, E4209-1125HFD, E4212-1125HFD

E4806-1125HFD, E4809-1125HFD, E4812-1125HFD

E6006-2125HFD, E6009-2125HFD, E6012-2125HFD

READ CAREFULLY BEFORE ATTEMPTING TO ASSEMBLE, INSTALL, OPERATE OR MAINTAIN THE

PRODUCT DESCRIBED.PROTECT Y OURSELF AND OTHERS BY OBSERVING ALL SAFETY INFORMATION.

FAILURE TO COMPLY WITH INSTRUCTIONS COULD RESULT IN PERSONAL INJURY AND/OR PROPERTY

DAMAGE!

RETAIN INSTRUCTIONS FOR FUTURE REFERENCE.

REFER TO INDIVIDUAL MODEL NUMBERS

FOR UNIT WIDTH

117/8”

31/4”

153/4”

121/2”

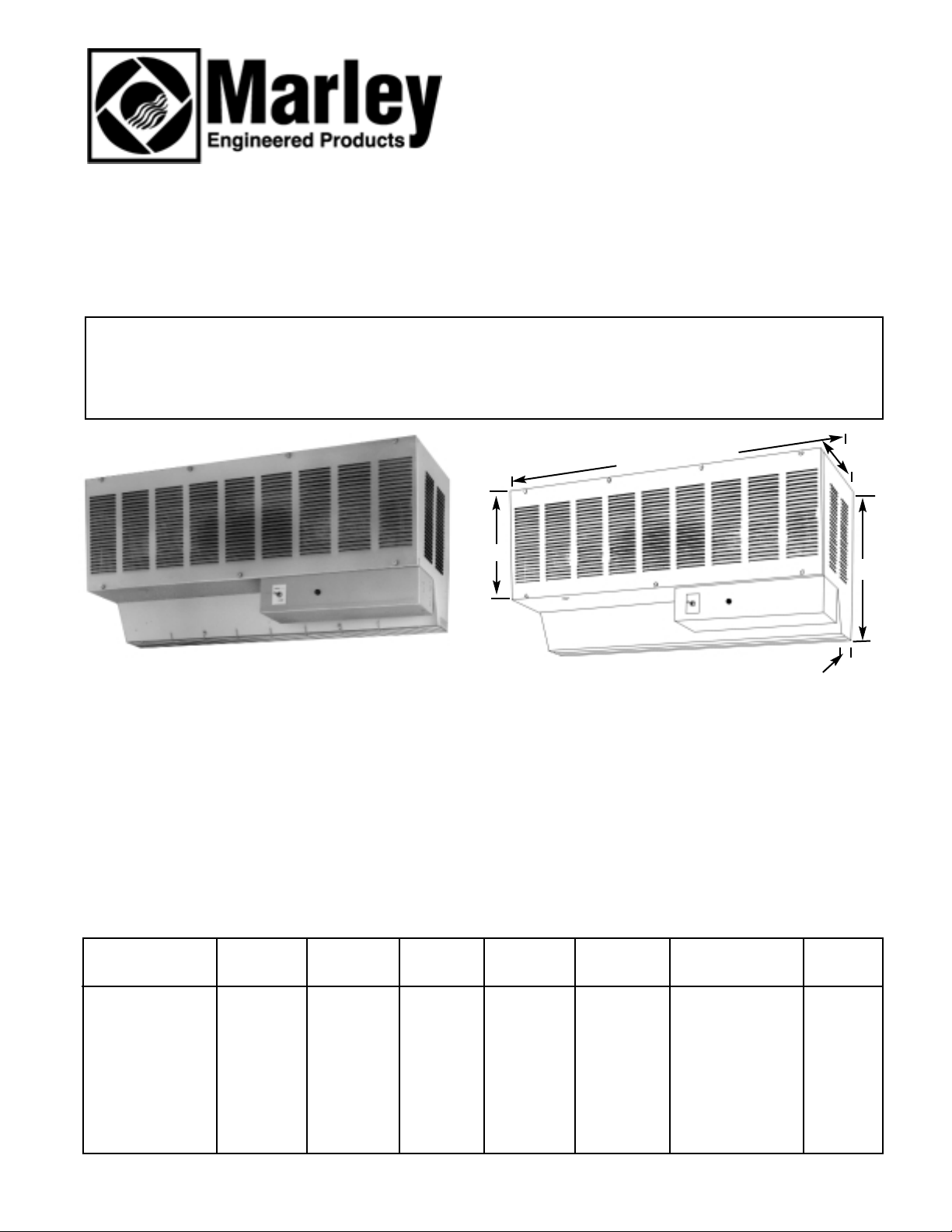

Figure 1

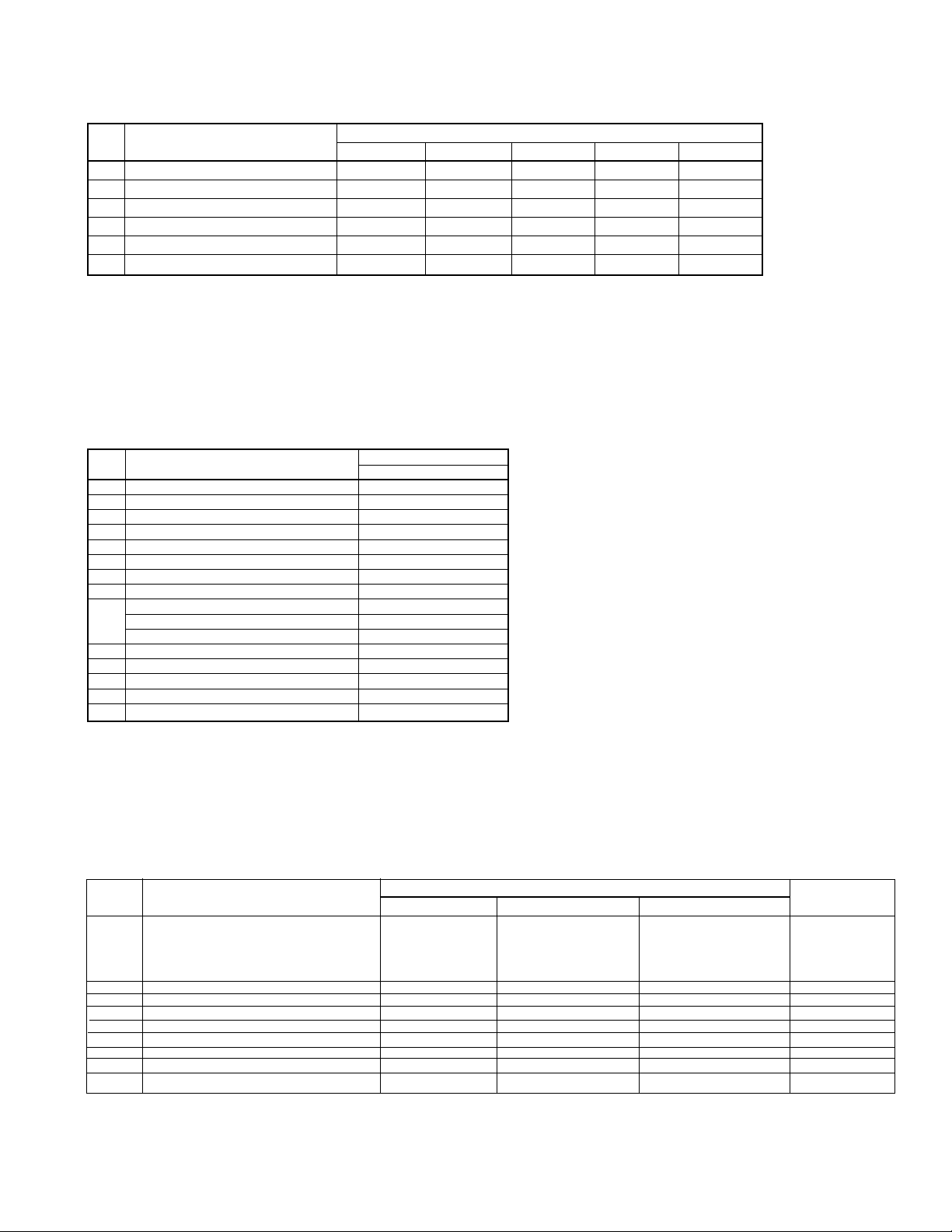

Heated Air Curtains

MODEL HEATER MOTOR HEATER HEATER HEATER CFM AT NOZZLE MOTOR

NUMBER VOLTAGE VOLTAGE WATTS BTU/HR AMPS (HI/LOW) SIZE

E3606-1125HFD 240/1 120 6000 20,478 25.0 2025/1500 1/4HP

E3609-1125HFD 240/1 120 9000 30,717 37.5 2025/1500 1/4HP

E3612-1125HFD 240/1 120 10,800 36,860 45.0 2025/1500 1/4HP

E4806-1125HFD 240/1 120 6,000 20,470 25.0 2700/2000 1/4HP

E4809-1125HFD 240/1 120 9,000 30,717 37.5 2700/2000 1/4HP

E4812-1125HFD 240/1 120 10,800 36,860 45.0 2700/2000 1/4HP

E6006-2125HFD 240/1 120 6000 20,478 25.0 3375/2500 1/4HP

E6009-2125HFD 240/1 120 9000 30,717 37.5 3375/2500 1/4HP

E6012-2125HFD 240/1 120 10,800 36,860 45.0 3375/2500 1/4HP

Note: For multiple unit installations, recommended spacing between units should be a minimum of 3-inches and a maximum of 6-inches.

Unit is allowed to extend beyond doorway width. Each unit must have individual power supply.

Air curtains produce a wall of continuously flowing air

that acts as a thermal barrier against outside air and

provides protection against insects, dust, odor, fumes

and other contaminant’s and maintains interior

conditioned temperature by preventing heated or

cooled air from escaping through open doorways.

Heated air curtains are engineered to treat incoming

cold air at customers’ entrance areas. Used over front

door entrances, heated air curtains supplement existing

heat to prevent infiltration of colder outside air. Heated

units are not recommended for areas subject to high

winds.

Figure 2 Dimensions

Note that all dimensions are the same on all environmental

series units. Model number indicates width of unit.

(Example: E4800 indicates a 48” wide unit.)

Page 2

2

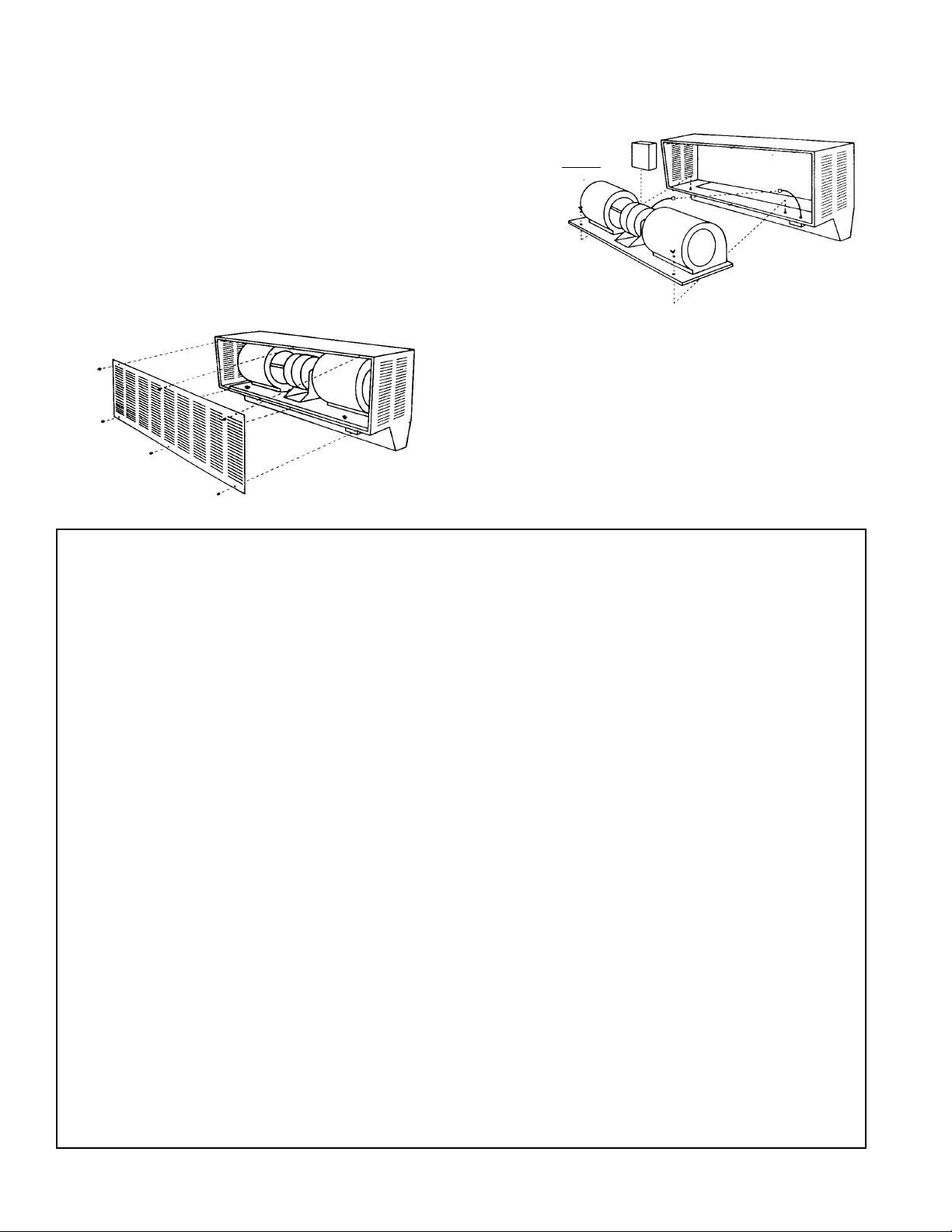

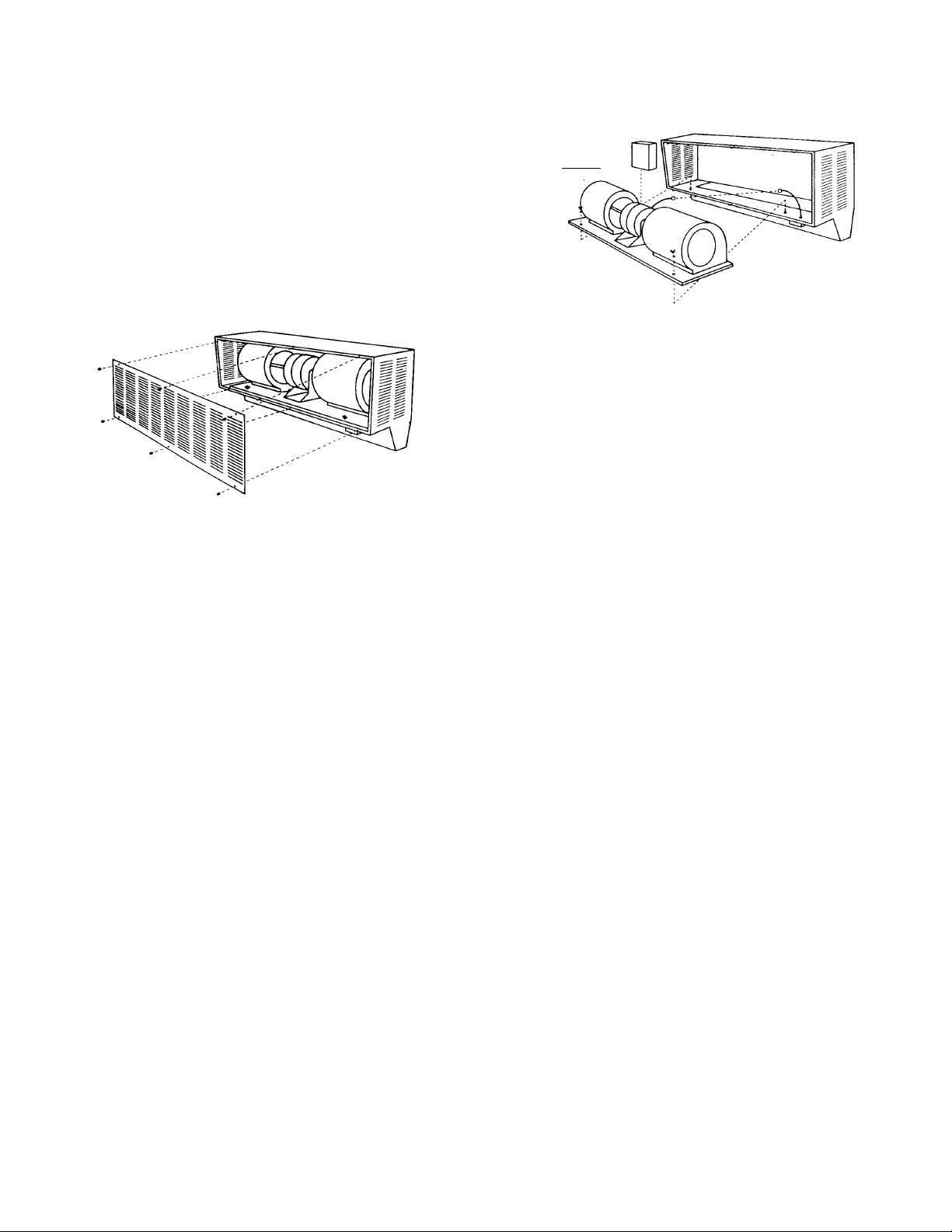

5. Carefully disconnect motor electric cord and heater

plug assembly and remove two wing nuts on blower

base. (See Figure 4.)

Figure 4 - Removing Motor/Blower Assembly

NOTE: Unit is shipped with styrofoam motor support

block which must be discarded at this time.

6. To remove motor/blower assembly, lift from rear of

motor housing to prevent damage and mis-alignment

to shaft and blower wheels.

NOTE: After unpacking unit, inspect carefully for any

damage that may have occurred during transit.

Check for loose, missing or damaged par ts.

6. All wiring should be done by a qualified electrician,

using copper wire only and in accordance with the

National Electrical Code (NEC), all applicable code

and ordinances, and all sections of this manual. Any

variance voids the warranty and may create unsafe

conditions.

7. Special attention must be given to any grounding

information pertaining to this product. To prevent the

risk of electrocution, the unit must be securely

and adequately grounded. This should be

accomplished by connecting a

grounded conductor between the service

panel and the grounding lug or green leadwire

provided in the wiring compartment. To ensure a

proper ground, the grounding means must be tested

by a qualified electrician.

8. Do not insert fingers or foreign objects into the air

curtain. Do not block or tamper with it in any manner

while it is in operation. Do not touch it while in operation or just after it has been turned off, as some parts

may be hot enough to cause injury.

9. This product must NOT be used in potentially danger-

ous locations such as flammable, explosive chemical

laden, or wet atmospheres.

10.Do not attach ductwork to this product or attempt to

use it as a make-up air heater. Such use voids the

warranty and may create unsafe conditions.

WARNING: TO REDUCE THE RISK OF FIRE OR

ELECTRIC SHOCK, DO NOT USE THIS AIR CURTAIN

WITH ANY SOLID STATE SPEED CONTROL DEVICE.

1. With packaged unit on the floor, carton arrows should

point upward.

2. Carefully remove staples from top of carton and fold

back sides.

3. Carefully remove cabinet from carton by lifting out

unit using finger holes in styrofoam side inset and

place on work surface.

CAUTION:Do not attempt to lift this air curtain by its

louver or damage may result.

4. Unscrew six (6) knurled nuts and remove air intake

grille. (See Figure 3.)

WARNING - TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSONS OBSERVE

THE FOLLOWING:

1. Use this unit only in the manner intended by the manufacturer. If you have questions contact the manufacturer.

2. Before servicing or cleaning unit, switch power off at

service panel and lock service panel to prevent power

from being switched on accidentally.

3. Installation work and electrical wiring must be done by

qualified persons in accordance with all applicable

codes and standards, including fire rated construction.

4. When cutting or drilling into wall or ceiling, do not

damage electrical wiring or other hidden utilities.

5. Make certain that the power source conforms to the

electrical requirements of the unit. Disconnect power

before installing or servicing. If the power disconnect

is out of sight, lock it in the open position and tag it to

prevent unexpected application of power. Failure to do

so could result in fatal electrical shock.

WARNING: DO NOT DEPEND UPON A THERMOSTAT

OR OTHER SWITCH AS THE SOLE MEANS OF

DISCONNECTING POWER WHEN INSTALLING OR

SERVICING THE UNIT. ALWAYS DISCONNECT

POWER AT THE MAIN CIRCUIT BREAKER AS

DESCRIBED ABOVE. FAILURE TO DO SO COULD

RESULT IN FATAL ELECTRIC SHOCK.

General Safety Information

Unpacking

STYROFOAM

SUPPORT

BLOCK

Figure 3 - Removing Air Intake Grille

Page 3

Installation

1. Using template provided, determine mounting

location.

2. Drill holes and attach mounting hardware (not

included).

IMPORTANT: THE HARDWARE AND THE

SUPPORTING STRUCTURE MUST BE CAPABLE OF

SUPPORTING A MINIMUM 150 LB. LOAD.

NOTE: All installation should be done to meet local

building code

.

3. Mount cabinet on wall and securely tighten hardware.

4. Replace motor/blower assembly in cabinet. Secure

two wing nuts on blower base. Reconnect motor

electric cord plug assembly and heater plug.

5. Replace intake grille with louvers facing down and

refasten knurled nuts.

FIELD POWER WIRING

WARNING: ALL AIR CURTAINS SHOULD BE

INSTALLED BY QUALIFIED PERSONNEL

.

1. Before wiring, be sure that available power supply,

voltage, phase, and frequency corresponds to that

specified on heater rating plate. In addition, make certain that service capacity is sufficient to handle load

imposed by the equipment.

2. Install all wiring, protection and grounding in accordance with the National Electrical Code (NEC) and

all local requirements.

WARNING: THIS FAN HAS AN INTERNAL SELF

RESETTING THERMAL OVERLOAD PROTECTOR.

ALWAYS DISCONNECT FROM POWER SUPPLY

BEFORE SERVICING.

3. Remove two screws from switch box and remove

cover.

4. Run proper size copper power supply conductors from

the field power supply disconnects, (supplied by

others) with insulation rated minimum 75˚C (167.0˚F).

One set of conductors from 240VAC, 50/60Hz supply

source shall be routed through the 3/4 inch conduit

knockout, using a suitable knockout connected to the

contactor contact terminals marked L1, L2. A

separated set of supply conductors from a 120VAC,

50/60 Hz supply source shall be routed through 1/2

inch knockout using a suitable knockout connector, for

connection of the fan circuit. The fan supply

conductors are to be marked L1, N (see diagram on

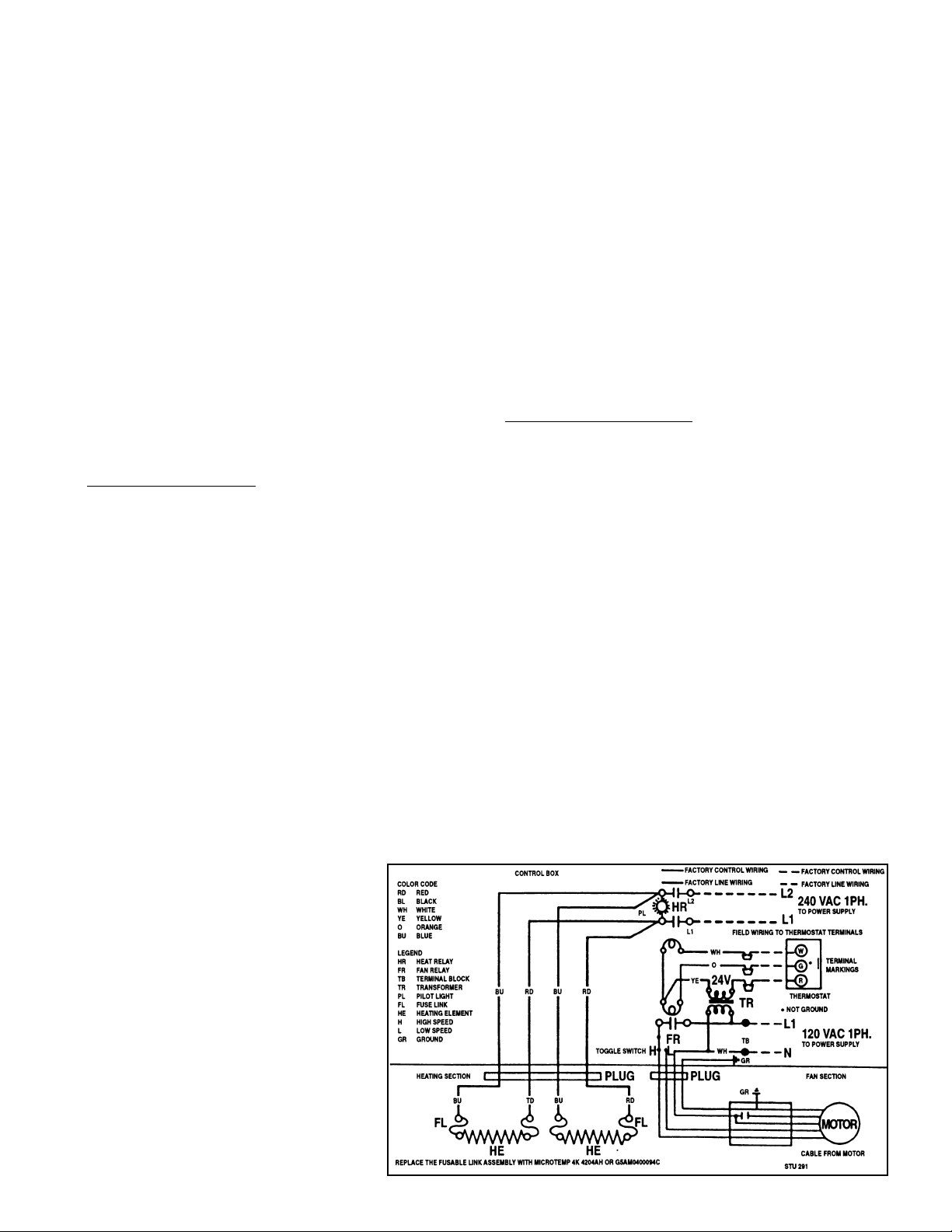

inside heater wiring compartment cover and Figure 5).

5. The heater control box must have an unbroken

electrical ground to minimize personal injury if an

electrical fault should occur.

FIELD CONTROL WIRING

Electric heater is equipped with a step-down transformer

for 24V control circuit. Thermostat model number RSV130-R-54 must be used to energize heater with the fan

motor. Connect thermostat wiring from thermostat to

control leads in heated air curtain control box by means

of conduit or equivalent. A1/2 inch knockout is provided.

Class1 wiring is required.

6. Replace heater control box cover.

7. Unit is ready for operation.

8. Restore power.

NOTE: Air curtain has high/low selector switch. See

Operation section for proper setting instructions.

9. Upon completion of all installation, inspect unit for

excessive vibration during operation. If excessive

vibration is noticeable, disconnect power supply.

Inspect mounting installation and refer to

Troubleshooting Chart for probable cause.

Figure 5 - Wiring Diagram

Page 4

Operation

1. After power has been connected to unit, fans will start

in either preset (high/low) speed selection.

2. Air velocity is controlled by selection of high or low

speed indicator. This feature allows the setting of air

velocity to individual desired performance and energy

efficiency.

3. Air direction at outlet can be controlled by adjustable

vanes at the nozzle which compensates for possible

draft conditions.

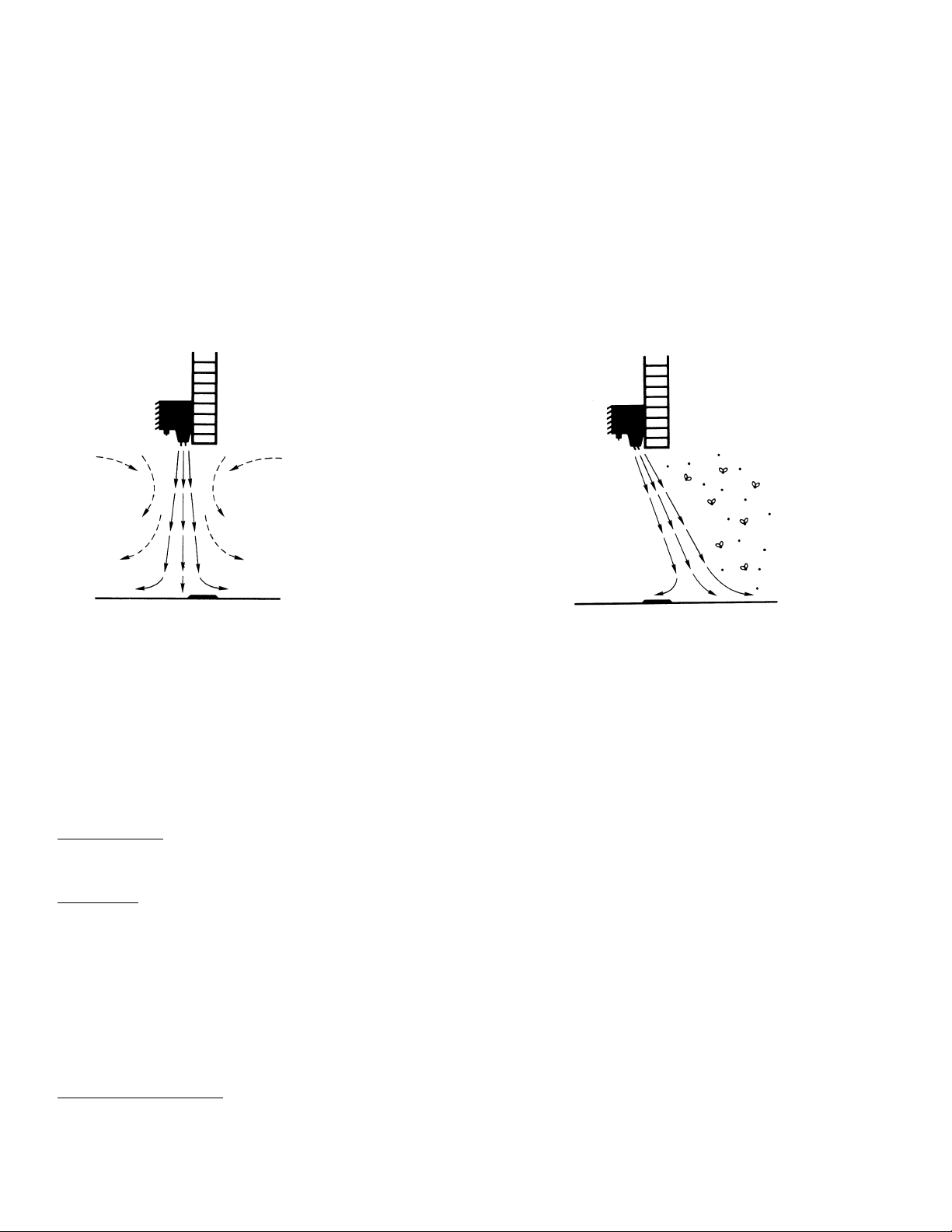

NOTE: Air direction settings shown in Figures 6 & 7.

NOTE: Cold air will try to escape near floor level.

Warm air will try to penetrate curtain near top of

doorway. Air flow can be controlled by direction of

nozzle louvers and by high/low settings.

4. For multiple unit applications (wide openings), mount

units a minimum of 3” apart to allow for proper air

intake and discharge.

Maintenance

WARNING: ALL ELECTRIC POWER MUST BE

DISCONNECTED WHEN INSTALLING OR SERVICING

THIS EQUIPMENT. MORE THAN ONE DISCONNECT

SWITCH MAY BE REQUIRED TO REMOVE POWER

FROM THE UNIT.

LUBRICA

TION

Ball bearings are permanently lubricated and require no

further lubrication.

CLEANING

1. The air door cabinet may be wiped off with a damp

cloth. Do not allow motor to get wet. Do not use solvents or harsh detergents.

NOTE: Keep air intake louvers clear of dirt and dust

accumulation which could affect performance.

2. Check blower wheels for accumulated dirt twice a year

and clean. If disassembly is required, see GENERAL

SERVICING section.

GENERAL SERVICING

WARNING: IF SERVICING IS REQUIRED, IT SHOULD

BE DONE BY QUALIFIED PERSONS ONLY.

WARNING: ALWAYS DISCONNECT POWER SUPPLY

BEFORE SERVICING.

1. To remove motor/blower heater assembly,

repeat steps 4, 5 and 6 in Unpacking section.

2. Place motor/blower assembly on workbench.

3. To replace blower wheel, remove the three slotted hex

head screws on outer blower ring assembly (See

Figure 8, Replacement Parts Illustration.) The wheel

is held onto shaft by two hex head screws.

NOTE: To re-assemble repeat steps 4 & 5 in

installation section page 3.

IMPORTANT: NOTE POSITION OF WHEELS TO

PREVENT RUBBING WHEN REPLACED.

4. To remove motor:

a. Remove blower wheels. (See Step 3 above.)

b. Remove blower scrolI (six hex head screws).

c. Unscrew and remove motor mounts.

5. Replace motor/blower.

Figure 6 - Desired Air Flow

Adjustment for Temperature and

Humidity Control.

Figure 7 - Desired Air Flow Adjustment

for Insect and Dust Control.

4

Page 5

Troubleshooting Chart

SYMPTOM POSSIBLE CAUSE(S) CORRECTIVE ACTION

Fan inoperative

1. Blown fuse or open circuit breaker.

2. Electricity turned off.

3. Loose cord connection.

4. Defective capacitor or motor.

1. Replace fuse or reset circuit breaker.

2. Contact local power company.

3. Re-check all connections.

4. Replace.

1. Center wheel.

2. Tighten mounting bolts.

3. Replace motor.

1. Wheel rubbing on housing.

2. Motor base or blower not securely

anchored.

3. Defective motor bearings.

Excessive noise

1. Reconnect to proper voltage.

2. Open.

3. Remove any obstruction.

4. Position toggle switch to high.

5. Clean.

1. Improper voltage.

2. Outlet louvers closed.

3. Intakes obstructed.

4. Motor speed setting on low.

5. Dirty blower wheels

Insufficient air flow

1. Position toggle switch to low.1. Motor speed setting on high.

Too much air flow

1. Verify correct wire size.

2. Remove obstruction.

1. Low voltage.

2. Obstruction to blower wheel.

Fans cut out on

thermal overload

(self-resets)

5

1. Replace with 4K4204H or 4K9204H.

2. Replace with proper Ga. and watts.

3. Replace with proper item.

1. Fuse link open.

2. Heater element broken.

3. Control Transformer

No heat

Page 6

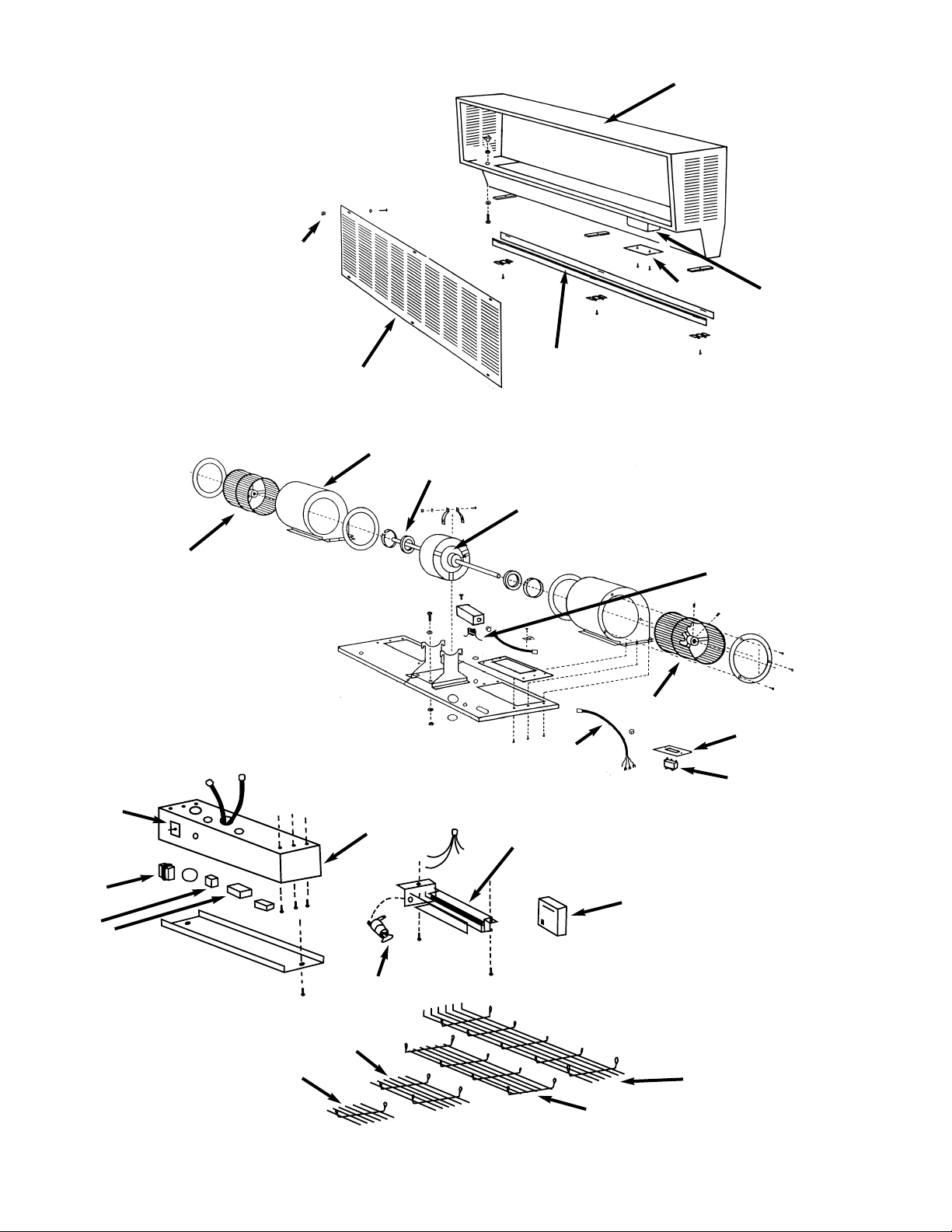

Replacement Parts

For Motor Blower Assemblies (7)

6

Replacement Parts

For Heater Units

1.

2

4

5

6

3

14

12

11

13

15

8

9

10

16

Replacement Parts

For Air Curtain Cabinets

9

3

4

5

2

7

6

8

1D

1C

1B

1A

Figure 8 - Replacement Parts.

Page 7

Replacement Parts List For Air Curtain Cabinets

Replacement Parts For 120 Volt Single Phase Motor Blower Assemblies

Replacement Parts List For Heater Units

7

REF. DESCRIPTION REPLACEMENT PARTS FOR 240V 1-PH HEATERS

NO. 6 KW 9 KW 10.8 KW QTY.

1 Wire Guards

A. 18” APG0018 APG0018 APG0018 -

B. 12” APG0012 APG0012 APG0012 C. 6” APG0006 APG0006 APG0006 -

D. 2” APG0002 APG0002 APG0002 -

2 Heater Control Box APHC240-1 APHC240-1 APHC240-1 1

3 Heater Transformer AP0018 AP0018 AP0018 1

4 Heater Fan Relay AP0020 AP0020 AP0020 1

5 Heater Contactor AP0021 AP0021 AP0021 1

6 Heater Element Set APHE06240-1 APHE09240-1 APHE105240-1 1

7 Heater Coil Fuse Link AP0016 AP0016 AP0016 4

8 Wall Thermostat AP364860-T AP364860-T AP364860-T 1

9 Toggle Switch (Hi-Low) 410024000 410024000 - 1

Key Part Numbers

No. Description 1/4HP

7 Motor/Blower Assembly

120V 1-ph ACMB125

220V 1-ph ACMB225

208-230/460V 3-ph ACMB325

8 Switch plate cover ACFPSH

9 Rocker switch C1220

10 Cord, female plug ACW316

11 Motor Assembly

120V 1-ph ACM1025

220V 1-ph ACM2025

208-230/460V 3-ph ACM3025

12 Resilient motor ring kit AP058

13 Capacitor ACCP1025

14 Blower housing ACBH67

15 Blower wheel-right ACBW67R

16 Blower wheel-left ACBW67L

Key Part Numbers for Cabinets (length)

No. Description 36" 38" 42" 48" 60"

1 Cabinet box assembly ACCA36A ACCA38A ACCA42A ACCA48A ACCA60A

2 Cabinet Intake Grille API3685 API3885 API4285 API4885 API6085

3 Cabinet Intake grill knurled nut AP0002 AP0002 AP0002 AP0002 AP0002

4 Cabinet louver kit ACL36 ACL38 ACL42 ACL48 ACL60

5 Electric box ACEB ACEB ACEB ACEB ACEB

6 Electric box cover ACFPSPC ACFPSPC ACFPSPC ACFPSPC ACFPSPC

Page 8

8

HOW TO ORDER REPAIR PARTS

In order to obtain any needed repair or

replacement parts, warranty service or technical

information, please contact Marley Engineered

Products Service Center toll-free by calling 1-800642-HEAT.

Part No. 5200-2418-001 03-02

ECR 35189

LIMITED W ARRANTY

All products manufactured by Marley Engineered Products are warranted against defects in workmanship and materials for

eighteen months from date of installation. This warranty does not apply to damage from accident, misuse, or alteration; nor

where the connected voltage is more than 5% above the nameplate voltage; nor to equipment improperly installed or wired or

maintained in violation of the product’s installation instructions. All claims for warranty work must be accompanied by proof of

the date of installation.

The customer shall be responsible for all costs incurred in the removal or reinstallation of products, including labor costs, and

shipping costs incurred to return products to Marley Engineered Products Service Center. Within the limitations of this warranty,

inoperative units should be returned to the nearest Marley authorized service center or the Marley Engineered Products Service

Center, and we will repair or replace, at our option, at no charge to you with return freight paid by Marley. It is agreed that such

repair or replacement is the exclusive remedy available from Marley Engineered Products.

THE ABOVE WARRANTIES ARE IN LIEU OF ALL OTHER WARRANTIES EXPRESSED OR IMPLIED, AND ALL IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR APARTICULAR PURPOSE WHICH EXCEED THE AFORESAID

EXPRESSED WARRANTIES ARE HEREBY DISCLAIMED AND EXCLUDED FROM THIS AGREEMENT. MARLEY

ENGINEERED PRODUCTS SHALLNOT BE LIABLE FOR CONSEQUENTIALDAMAGES ARISING WITH RESPECTTO THE

PRODUCT, WHETHER BASED UPON NEGLIGENCE, TORT, STRICT LIABILITY, OR CONTRACT.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above exclusion or limitation

may not apply to you. This warranty gives you specific legal rights, and you may also have other rights which vary from state

to state.

For the address of your nearest authorized service center, contact Marley Engineered Products in Bennettsville, SC, at 1-800642-4328. Merchandise returned to the factory must be accompanied by a return authorization and service identification tag,

both available from Marley Engineered Products. When requesting return authorization, include all catalog numbers shown on

the products.

SPX Corporation

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

Page 9

Specifications and Performance

INSTALLATION & OPERATING INSTRUCTIONS & PARTS MANUAL

MODELS: E3606-1325HFD, E3609-1325HFD

E3806-1325HFD, E3809-1325HFD

E4206-1325HFD, E4209-1325HFD

E4806-1325HFD, E4809-1325HFD

E6006-2325HFD, E6009-2325HFD

READ CAREFULLY BEFORE ATTEMPTING TO ASSEMBLE, INSTALL, OPERATE, OR MAINTAIN THE PRODUCT DESCRIBED.

PROTECT YOURSELF AND OTHERS BY OBSERVING ALL SAFETY INFORMATION. FAILURE TO COMPLY WITH INSTRUCTIONS

COULD RESULT IN PERSONAL INJURY AND/OR PROPERTY DAMAGE!

RETAIN INSTRUCTIONS FOR FUTURE REFERENCE.

Air curtains produce a wall of continuously flowing air

that acts as a thermal barrier against outside air and

provides protection against insects, dust, odor, fumes

and other contaminant’s. Maintains interior conditioned

temperature by preventing heated or cooled air from

escaping through open doorways.

Heated air curtains are engineered to treat incoming

cold air at customers’ entrance areas. Used over front

door entrances, heated air curtains supplement existing

heat to prevent infiltration of colder outside air. Heated

units are not recommended for areas subject to high

winds.

Figure 2 Dimensions

Note that all dimensions are the same on all environmental

series units. Model number indicates width of unit.

(Example: E4800 indicates a 48” wide unit.)

MODEL

NUMBER

E3606-1325HFD

E3609-1325HFD

E4206-1325HFD

E4209-1325HFD

E4806-1325HFD

E4809-1325HFD

E6006-2325HFD

E6009-2325HFD

HEATER

VOLTAGE

208/3

208/3

208/3

208/3

208/3

208/3

208/3

208/3

MOTOR

VOLTAGE

208/3

208/3

208/3

208/3

208/3

208/3

208/3

208/3

HEATER

WATTS

6000

9000

6000

9000

6000

9000

6000

9000

HEATER

BTU/HR

HEATER

AMPS

20,478

30,717

20,478

30,717

20,478

30,717

20,478

30,717

16.7

25.0

16.7

25.0

16.7

25.0

16.7

25.0

CFM AT NOZZLE

(HI/LOW)

2025

2025

2360

2360

2700

2700

3375

3375

MOTOR

SIZE

1/4HP

1/4HP

1/4HP

1/4HP

1/4HP

1/4HP

1/4HP

1/4HP

Heated

Air Curtains

Note: For multiple unit installations, recommended spacing between units should be a minimum of 3-inches and a maximum of 6-inches.

Unit is allowed to extend beyond doorway width. Each unit must have individual power supply.

Description

REFER TO INDIVIDUAL MODEL NUMBERS

FOR UNIT WIDTH

117/8”

153/4”

121/2”

Figure 1

Page 10

5. Carefully disconnect motor electric cord and heater

plug assembly and remove two wing nuts on blower

base. (See Figure 4.)

Figure 4 - Removing Motor/Blower Assembly

NOTE: Unit is shipped with styrofoam motor support

block which must be discarded at this time.

6. T o remove motor/blower assembly, lift from rear of

motor housing to prevent damage and mis-alignment

to shaft and blower wheels.

NOTE: After unpacking unit, inspect carefully for any

damage that may have occurred during transit.

Check for loose, missing or damaged par ts.

6. All wiring should be done by a qualified electrician,

using copper wire only and in accordance with the

National Electrical Code (NEC), all applicable code

and ordinances, and all sections of this manual. Any

variance voids the warranty and may create unsafe

conditions.

7. Special attention must be given to any grounding

information pertaining to this product. To prevent the

risk of electrocution, the unit must be securely

and adequately grounded. This should be

accomplished by connecting a

grounded conductor between the service

panel and the grounding lug or green leadwire

provided in the wiring compartment. To ensure a

proper ground, the grounding means must be tested

by a qualified electrician.

8. Do not insert fingers or foreign objects into the air

curtain. Do not block or tamper with it in any manner

while it is in operation. Do not touch it while in operation or just after it has been turned off, as some parts

may be hot enough to cause injury.

9. This product must NOT be used in potentially danger-

ous locations such as flammable, explosive chemical

laden, or wet atmospheres.

10.Do not attach ductwork to this product or attempt to

use it as a make-up air heater. Such use voids the

warranty and may create unsafe conditions.

WARNING: TO REDUCE THE RISK OF FIRE OR

ELECTRIC SHOCK, DO NOT USE THIS AIR CURTAIN

WITH ANY SOLID STATE SPEED CONTROL DEVICE.

1. With packaged unit on the floor, carton arrows should

point upward.

2. Carefully remove staples from top of carton and fold

back sides.

3. Carefully remove cabinet from carton by lifting out

unit using finger holes in styrofoam side inset and

place on work surface.

CAUTION:Do not attempt to lift this air curtain by its

louver or damage may result.

4. Unscrew six (6) knurled nuts and remove air intake

grille. (See Figure 3.)

Figure 3 - Removing Air Intake Grille

WARNING - TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSONS OBSERVE

THE FOLLOWING:

1. Use this unit only in the manner intended by the manufacturer. If you have questions contact the manufacturer.

2. Before servicing or cleaning unit, switch power off at

service panel and lock service panel to prevent power

from being switched on accidentally .

3. Installation work and electrical wiring must be done by

qualified persons in accordance with all applicable

codes and standards, including fire rated construction.

4. When cutting or drilling into wall or ceiling, do not

damage electrical wiring or other hidden utilities.

5. Make certain that the power source conforms to the

electrical requirements of the unit. Disconnect power

before installing or servicing. If the power disconnect

is out of sight, lock it in the open position and tag it to

prevent unexpected application of power. Failure to do

so could result in fatal electrical shock.

WARNING: DO NOT DEPEND UPON A THERMOSTAT

OR OTHER SWITCH AS THE SOLE MEANS OF

DISCONNECTING POWER WHEN INSTALLING OR

SERVICING THE UNIT. ALWAYS DISCONNECT

POWER AT THE MAIN CIRCUIT BREAKER AS

DESCRIBED ABOVE. FAILURE TO DO SO COULD

RESULT IN FATAL ELECTRIC SHOCK.

General Safety Information

Unpacking

2

STYROFOAM

SUPPORT

BLOCK

Page 11

Installation

1. Using template provided, determine mounting location.

2. Drill holes and attach mounting hardware (not included).

IMPORTANT: THE HARDWARE AND THE SUPPORTING STRUCTURE MUST BE CAPABLE OF SUPPORTING A MINIMUM 150 LB. LOAD.

NOTE: All installation should be done to meet local

building code.

3. Mount cabinet on wall and securely tighten hardware.

4. Replace motor/blower assembly in cabinet. Secure

two wing nuts on blower base. Reconnect motor

electric cord plug assembly & heater plug.

5. Replace intake grille with louvers facing down and

refasten knurled nuts.

FIELD POWER WIRING

WARNING: ALL AIR CURTAINS SHOULD BE

INSTALLED BY QUALIFIED PERSONNEL.

1. Before wiring be sure that available power supply,

voltage, phase and frequency corresponds to that

specified on heater rating plate. In addition, make

certain that service capacity is sufficient to handle load

imposed by the equipment.

2. Install all wiring, protection and grounding in accordance with the National Electrical Code (NEC) and

all local requirements.

WARNING: THIS FAN HAS AN INTERNAL SELF

RESETTING THERMAL OVERLOAD PROTECTOR.

ALWAYS DISCONNECT FROM POWER SUPPLY

BEFORE SERVICING.

3. Run proper size copper power supply conductors from

the field power supply disconnects, (supplied by

others) with insulation rated minimum 75°C (167.0°F).

One set of conductors from 208VAC, 50/60Hz supply

source shall be routed through the 3/4 inch conduit

knockout, using a suitable knockout connected to the

contactor contact terminals marked L1, L2, L3.

4. The heater control box must have an unbroken

electrical ground to minimize personal injury if an

electrical fault should occur.

FIELD CONTROL

WIRING

Electric heater is equipped with a step-down transformer

for 24V control circuit. Thermostat model number RSV130-R-54 must be used to energize heater with the fan

motor. Connect thermostat wiring from thermostat to

control leads in heated air curtain control box by means

of conduit or equivalent. A 1/2 inch knockout is provided.

Class 1 wiring is required.

5. Replace heater control box cover.

6. Unit is ready for operation.

7. Restore power.

NOTE: Air curtain has high/low selector switch. See

Operation section for proper setting instructions.

8. Upon completion of all installation, inspect unit for

excessive vibration during operation. If excessive

vibration is noticeable, disconnect power supply.

Inspect mounting installation and refer to

Troubleshooting Chart for probable cause.

3

Figure 5 - Wiring Diagram

BU

COLOR CODE

RE - RED

WH - WHITE

BK/RD - BLACK W/ RED TRACER

YE - YELLOW

OR - ORANGE

BU - BLUE

LEGEND

HR - HEAT RELAY

TB - TERMINAL BLOCK

TR TRANSFORMER

PL - PILOT LIGHT

FL - FUSE LINK

HE - HEAT ELEMENT

HEATER SECTION

FIELD WIRING TO THERMOSTAT

THERMOSTA T

TERMINAL MARKING

TO POWER

SUPPLY

PLUG

TB

L1

L2

L3

GR

Page 12

Operation

1. After power has been connected to unit, fans will start

in either preset (high/low) speed selection.

2. Air velocity is controlled by selection of high or low

speed indicator. This feature allows the setting of air

velocity to individual desired performance and energy

efficiency .

3. Air direction at outlet can be controlled by adjustable

vanes at the nozzle which compensates for possible

draft conditions.

NOTE: Air direction settings shown in Figures 6 & 7.

NOTE: Cold air will try to escape near floor level.

Warm air will try to penetrate curtain near top of

doorway. Air flow can be controlled by direction of

nozzle louvers and by high/low settings.

4. For multiple unit applications (wide openings), mount

units a minimum of 3” apart to allow for proper air

intake and discharge.

Maintenance

WARNING: ALL ELECTRIC POWER MUST BE

DISCONNECTED WHEN INSTALLING OR SERVICING

THIS EQUIPMENT. MORE THAN ONE DISCONNECT

SWITCH MAY BE REQUIRED TO REMOVE POWER

FROM THE UNIT.

LUBRICA

TION

Ball bearings are permanently lubricated and require no

further lubrication.

CLEANING

1. The air door cabinet may be wiped off with a damp

cloth. Do not allow motor to get wet. Do not use solvents or harsh detergents.

NOTE: Keep air intake louvers clear of dirt and dust

accumulation which could affect performance.

2. Check blower wheels for accumulated dirt twice a year

and clean. If disassembly is required, see GENERAL

SERVICING section.

GENERAL SERVICING

WARNING: IF SERVICING IS REQUIRED, IT SHOULD

BE DONE BY QUALIFIED PERSONS ONLY.

WARNING: ALWAYS DISCONNECT POWER SUPPLY

BEFORE SERVICING.

1.T o remove motor/blower heater assembly, repeat

Steps 4, 5 and 6 in Unpacking section.

2. Place motor/blower assembly on workbench.

3. To replace blower wheel, remove the three slotted hex

head screws on outer blower ring assembly (See

Figure 8, Replacement Parts Illustration.) The wheel

is held onto shaft by two hex head screws.

NOTE: To re-assemble repeat steps 4 & 5 in

installation section page 3.

IMPORTANT: NOTE POSITION OR WHEELS TO

PREVENT RUBBING WHEN REPLACED.

4. To remove motor:

a. Remove blower wheels. (See Step 3 above.)

b. Remove blower scrolI (six hex head screws).

c. Unscrew and remove motor mounts.

5. Replace motor/blower assembly

Figure 6 - Desired Air Flow

Adjustment for Temperature and

Humidity Control.

Figure 7 - Desired Air Flow Adjustment

for Insect and Dust Control.

4

Page 13

Troubleshooting Chart

SYMPTOM POSSIBLE CAUSE(S) CORRECTIVE ACTION

Fan inoperative

1. Blown fuse or open circuit breaker.

2. Electricity turned off.

3. Loose cord connection.

4. Defective capacitor or motor.

1. Replace fuse or reset circuit breaker.

2. Contact local power company .

3. Re-check all connections.

4. Replace.

1. Center wheel.

2. Tighten mounting bolts.

3. Replace motor.

1. Wheel rubbing on housing.

2. Motor base or blower not securely

anchored.

3. Defective motor bearings.

Excessive noise

1. Reconnect to proper voltage.

2. Open.

3. Remove any obstruction.

4. Clean.

5. Reverse red and black power leads.

1. Improper voltage.

2. Outlet louvers closed.

3. Intakes obstructed.

4. Dirty blower wheels.

5. Motor rotating in reverse direction.

Insufficient air flow

1. Verify correct wire size.

2. Remove obstruction.

1. Low voltage.

2. Obstruction to blower wheel.

Fans cut out on

thermal overload

(self-resets)

1. Replace with 4K4204H or 4K9204H.

2. Replace with proper Ga. and watts.

3. Replace with proper item.

1. Fuse link open.

2. Heater element broken

3. Control Transformer

No heat

* 120-220 volt models only.

5

Page 14

6

Replacement Parts

For Motor Blower Assemblies (7)

Replacement Parts

For Heater Units

1.

2

4

5

6

3

14

12

11

13

15

8

9

10

16

Replacement Parts

For Air Curtain Cabinets

9

3

4

5

2

7

6

8

1D

1C

1B

1A

Figure 8 - Replacement Parts.

Page 15

7

Replacement Parts List For Air Curtain Cabinets

Replacement Parts For 120 Volt Single Phase Motor Blower Assemblies

Replacement Parts List For Heater Units

REF. DESCRIPTION REPLACEMENT PARTS FOR 208V 3-PH HEATERS

NO. 6 KW 9 KW QTY.

1 Wire Guards

A. 18” APG0018 APG0018 -

B. 12” APG0012 APG0012 C. 6” APG0006 APG0006 -

D. 2” APG0002 APG0002 -

2 Heater Control Box APHC208-3 APHC208-3 1

3 Heater Transformer AP0018 AP0018 1

4 Heater Fan Relay AP0020 AP0020 1

5 Heater Contactor AP0021 AP0021 1

6 Heater Element Set APHE06208-3 APHE09208-3 1

7 Heater Coil Fuse Link AP0016 AP0016 4

8 Wall Thermostat AP364860-T AP364860-T 1

Key Part Numbers

No. Description 1/4HP

7 Motor/Blower Assembly

120V 1-ph ACMB125

220V 1-ph ACMB225

208-230/460V 3-ph ACMB325

8 Switch plate cover ACFPSH

9 Rocker switch C1220

10 Cord, female plug ACW316

11 Motor Assembly

120V 1-ph ACM1025

220V 1-ph ACM2025

208-230/460V 3-ph ACM3025

12 Resilient motor ring kit AP058

13 Capacitor ACCP1025

14 Blower housing ACBH67

15 Blower wheel-right ACBW67R

16 Blower wheel-left ACBW67L

Key Part Numbers for Cabinets (length)

No. Description 36" 38" 42" 48" 60"

1 Cabinet box assembly ACCA36A ACCA38A ACCA42A ACCA48A ACCA60A

2 Cabinet Intake Grille API3685 API3885 API4285 API4885 API6085

3 Cabinet Intake grill knurled nut AP0002 AP0002 AP0002 AP0002 AP0002

4 Cabinet louver kit ACL36 ACL38 ACL42 ACL48 ACL60

5 Electric box ACEB ACEB ACEB ACEB ACEB

6 Electric box cover ACFPSPC ACFPSPC ACFPSPC ACFPSPC ACFPSPC

Page 16

8

HOW TO ORDER REPAIR PARTS

In order to obtain any needed repair or replacement

parts, warranty service or technical information, please

contact Marley Engineered Products Service Center

toll-free by calling 1-800-642-HEAT.

Part No. 5200-2420-001 03-02

ECR 35189

LIMITED W ARRANTY

All products manufactured by Marley Engineered Products are warranted against defects in workmanship and

materials for eighteen months from date of installation. This warranty does not apply to damage from accident,

misuse, or alteration; nor where the connected voltage is more than 5% above the nameplate voltage; nor to

equipment improperly installed or wired or maintained in violation of the product’s installation instructions. All claims

for warranty work must be accompanied by proof of the date of installation.

The customer shall be responsible for all costs incurred in the removal or reinstallation of products, including labor

costs, and shipping costs incurred to return products to Marley Engineered Products Service Center. Within the

limitations of this warranty, inoperative units should be returned to the nearest Marley authorized service center

or the Marley Engineered Products Service Center, and we will repair or replace, at our option, at no charge to you

with return freight paid by Marley. It is agreed that such repair or replacement is the exclusive remedy available

from Marley Engineered Products.

THE ABOVE WARRANTIES ARE IN LIEU OF ALL OTHER WARRANTIES EXPRESSED OR IMPLIED, AND ALL

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE WHICH

EXCEED THE AFORESAID EXPRESSED WARRANTIES ARE HEREBY DISCLAIMED AND EXCLUDED FROM

THIS AGREEMENT. MARLEY ENGINEERED PRODUCTS SHALL NOT BE LIABLE FOR CONSEQUENTIAL

DAMAGES ARISING WITH RESPECT TO THE PRODUCT, WHETHER BASED UPON NEGLIGENCE, TORT,

STRICT LIABILITY, OR CONTRACT.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above

exclusion or limitation may not apply to you. This warranty gives you specific legal rights, and you may also have

other rights which vary from state to state.

For the address of your nearest authorized service center, contact Marley Engineered Products in Bennettsville,

SC, at 1-800-642-4328. Merchandise returned to the factory must be accompanied by a return authorization and

service identification tag, both available from Marley Engineered Products. When requesting return authorization,

include all catalog numbers shown on the products.

SPX Corporation

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

Page 17

REFER TO INDIVIDUAL MODEL NUMBERS

FOR UNIT WIDTH

117/8”

31/4”

153/4”

121/2”

Specifications and Performance

INSTALLATION & OPERATING INSTRUCTIONS & PARTS MANUAL

MODELS: E3606-1425HFD, E3609-1425HFD

E3806-1425HFD, E3809-1425HFD

E4206-1425HFD, E4209-1425HFD

E4806-1425HFD, E4809-1425HFD

E6006-2425HFD, E6009-2425HFD

READ CAREFULLY BEFORE ATTEMPTING TO ASSEMBLE, INSTALL, OPERATE, OR MAINTAIN THE PRODUCT DESCRIBED.

PROTECT YOURSELF AND OTHERS BY OBSERVING ALL SAFETY INFORMATION. FAILURE TO COMPLY WITH INSTRUCTIONS

COULD RESULT IN PERSONAL INJURY AND/OR PROPERTY DAMAGE!

RETAIN INSTRUCTIONS FOR FUTURE REFERENCE.

Figure 1

Air curtains produce a wall of continuously flowing air

that acts as a thermal barrier against outside air and

provides protection against insects, dust, odor, fumes

and other contaminant’s. Maintains interior conditioned

temperature by preventing heated or cooled air from

escaping through open doorways.

Heated air curtains are engineered to treat incoming

cold air at customers’ entrance areas. Used over front

door entrances, heated air curtains supplement existing

heat to prevent infiltration of colder outside air. Heated

units are not recommended for areas subject to high

winds.

Figure 2 Dimensions

Note that all dimensions are the same on all environmental

series units. Model number indicates width of unit.

(Example: E4800 indicates a 48” wide unit.)

MODEL

NUMBER

E3606-1425HFD

E3609-1425HFD

E4206-1425HFD

E4209-1425HFD

E4806-1425HFD

E4809-1425HFD

E6006-1425HFD

E6009-1425HFD

HEATER

VOLTAGE

230/3

230/3

230/3

230/3

230/3

230/3

230/3

230/3

MOTOR

VOLTAGE

230/3

230/3

230/3

230/3

230/3

230/3

230/3

230/3

HEATER

WATTS

6000

9000

6000

9000

6000

9000

6000

9000

HEATER

BTU/HR

20,478

30,717

20,478

30,717

20,478

30,717

20,478

30,717

HEATER

AMPS

15.1

22.7

15.1

22.7

15.1

22.7

15.1

22.7

CFM AT NOZZLE

(HI/LOW)

2025

2025

2360

2360

2700

2700

3375

3375

MOTOR

SIZE

1/4HP

1/4HP

1/4HP

1/4HP

1/4HP

1/4HP

1/4HP

1/4HP

Heated

Air Curtains

Note: For multiple unit installations, recommended spacing between units should be a minimum of 3-inches and a maximum of 6-inches.

Unit is allowed to extend beyond doorway width. Each unit must have individual power supply.

Description

Page 18

5. Carefully disconnect motor electric cord and heater

plug assembly and remove two wing nuts on blower

base. (See Figure 4.)

Figure 4 - Removing Motor/Blower Assembly

NOTE: Unit is shipped with styrofoam motor support

block which must be discarded at this time.

6. T o remove motor/blower assembly, lift from rear of

motor housing to prevent damage and mis-alignment

to shaft and blower wheels.

NOTE: After unpacking unit, inspect carefully for any

damage that may have occurred during transit.

Check for loose, missing or damaged par ts.

6. All wiring should be done by a qualified electrician,

using copper wire only and in accordance with the

National Electrical Code (NEC), all applicable code

and ordinances, and all sections of this manual. Any

variance voids the warranty and may create unsafe

conditions.

7. Special attention must be given to any grounding

information pertaining to this product. To prevent the

risk of electrocution, the unit must be securely

and adequately grounded. This should be

accomplished by connecting a

grounded conductor between the service

panel and the grounding lug or green leadwire

provided in the wiring compartment. To ensure a

proper ground, the grounding means must be tested

by a qualified electrician.

8. Do not insert fingers or foreign objects into the air

curtain. Do not block or tamper with it in any manner

while it is in operation. Do not touch it while in operation or just after it has been turned off, as some parts

may be hot enough to cause injury.

9. This product must NOT be used in potentially danger-

ous locations such as flammable, explosive chemical

laden, or wet atmospheres.

10.Do not attach ductwork to this product or attempt to

use it as a make-up air heater. Such use voids the

warranty and may create unsafe conditions.

WARNING: TO REDUCE THE RISK OF FIRE OR

ELECTRIC SHOCK, DO NOT USE THIS AIR CURTAIN

WITH ANY SOLID STATE SPEED CONTROL DEVICE.

1. With packaged unit on the floor, carton arrows should

point upward.

2. Carefully remove staples from top of carton and fold

back sides.

3. Carefully remove cabinet from carton by lifting out

unit using finger holes in styrofoam side inset and

place on work surface.

CAUTION:Do not attempt to lift this air curtain by its

louver or damage may result.

4. Unscrew six (6) knurled nuts and remove air intake

grille. (See Figure 3.)

Figure 3 - Removing Air Intake Grille

WARNING - TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSONS OBSERVE

THE FOLLOWING:

1. Use this unit only in the manner intended by the manufacturer. If you have questions contact the manufacturer.

2. Before servicing or cleaning unit, switch power off at

service panel and lock service panel to prevent power

from being switched on accidentally .

3. Installation work and electrical wiring must be done by

qualified persons in accordance with all applicable

codes and standards, including fire rated construction.

4. When cutting or drilling into wall or ceiling, do not

damage electrical wiring or other hidden utilities.

5. Make certain that the power source conforms to the

electrical requirements of the unit. Disconnect power

before installing or servicing. If the power disconnect

is out of sight, lock it in the open position and tag it to

prevent unexpected application of power. Failure to do

so could result in fatal electrical shock.

WARNING: DO NOT DEPEND UPON A THERMOSTAT

OR OTHER SWITCH AS THE SOLE MEANS OF

DISCONNECTING POWER WHEN INSTALLING OR

SERVICING THE UNIT. ALWAYS DISCONNECT

POWER AT THE MAIN CIRCUIT BREAKER AS

DESCRIBED ABOVE. FAILURE TO DO SO COULD

RESULT IN FATAL ELECTRIC SHOCK.

General Safety Information

Unpacking

2

STYROFOAM

SUPPORT

BLOCK

Page 19

Installation

1. Using template provided, determine mounting location.

2. Drill holes and attach mounting hardware (not included).

IMPORTANT: THE HARDWARE AND THE SUPPORTING STRUCTURE MUST BE CAPABLE OF SUPPORTING A MINIMUM 150 LB. LOAD.

NOTE: All installation should be done to meet local

building code.

3. Mount cabinet on wall and securely tighten hardware.

4. Replace motor/blower assembly in cabinet. Secure

two wing nuts on blower base. Reconnect motor

electric cord plug assembly & heater plug.

5. Replace intake grille with louvers facing down and

refasten knurled nuts.

FIELD POWER WIRING

WARNING: ALL AIR CURTAINS SHOULD BE

INSTALLED BY QUALIFIED PERSONNEL.

1. Before wiring be sure that available power supply,

voltage, phase and frequency corresponds to that

specified on heater rating plate. In addition, make

certain that service capacity is sufficient to handle load

imposed by the equipment.

2. Install all wiring, protection and grounding in accordance with the National Electrical Code (NEC) and

all local requirements.

WARNING: THIS FAN HAS AN INTERNAL SELF

RESETTING THERMAL OVERLOAD PROTECTOR.

ALWAYS DISCONNECT FROM POWER SUPPLY

BEFORE SERVICING.

3. Run proper size copper power supply conductors from

the field power supply disconnects, (supplied by

others) with insulation rated minimum 75°C (167.0°F).

One set of conductors from 240VAC, 50/60Hz supply

source shall be routed through the 3/4 inch conduit

knockout, using a suitable knockout connected to the

contactor contact terminals marked L1, L2, L3.

4. The heater control box must have an unbroken

electrical ground to minimize personal injury if an

electrical fault should occur.

FIELD CONTROL

WIRING

Electric heater is equipped with a step-down transformer

for 24V control circuit. Thermostat model number RSV130-R-54 must be used to energize heater with the fan

motor. Connect thermostat wiring from thermostat to

control leads in heated air curtain control box by means

of conduit or equivalent. A 1/2 inch knockout is provided.

Class 1 wiring is required.

5. Replace heater control box cover.

6. Unit is ready for operation.

7. Restore power.

NOTE: Air curtain has high/low selector switch. See

Operation section for proper setting instructions.

8. Upon completion of all installation, inspect unit for

excessive vibration during operation. If excessive

vibration is noticeable, disconnect power supply.

Inspect mounting installation and refer to

Troubleshooting Chart for probable cause.

3

Figure 5 - Wiring Diagram

BU

COLOR CODE

RE - RED

WH - WHITE

BK/RD - BLACK W/ RED TRACER

YE - YELLOW

OR - ORANGE

BU - BLUE

LEGEND

HR - HEAT RELAY

TB - TERMINAL BLOCK

TR TRANSFORMER

PL - PILOT LIGHT

FL - FUSE LINK

HE - HEAT ELEMENT

HEATER SECTION

FIELD WIRING TO THERMOSTAT

THERMOSTA T

TERMINAL MARKING

TO POWER

SUPPLY

PLUG

TB

L1

L2

L3

GR

Page 20

Operation

1. After power has been connected to unit, fans will start

in either preset (high/low) speed selection.

2. Air velocity is controlled by selection of high or low

speed indicator. This feature allows the setting of air

velocity to individual desired performance and energy

efficiency .

3. Air direction at outlet can be controlled by adjustable

vanes at the nozzle which compensates for possible

draft conditions.

NOTE: Air direction settings shown in Figures 6 & 7.

NOTE: Cold air will try to escape near floor level.

Warm air will try to penetrate curtain near top of

doorway. Air flow can be controlled by direction of

nozzle louvers and by high/low settings.

4. For multiple unit applications (wide openings), mount

units a minimum of 3” apart to allow for proper air

intake and discharge.

Maintenance

WARNING: ALL ELECTRIC POWER MUST BE

DISCONNECTED WHEN INSTALLING OR SERVICING

THIS EQUIPMENT. MORE THAN ONE DISCONNECT

SWITCH MAY BE REQUIRED TO REMOVE POWER

FROM THE UNIT.

LUBRICA

TION

Ball bearings are permanently lubricated and require no

further lubrication.

CLEANING

1. The air door cabinet may be wiped off with a damp

cloth. Do not allow motor to get wet. Do not use solvents or harsh detergents.

NOTE: Keep air intake louvers clear of dirt and dust

accumulation which could affect performance.

2. Check blower wheels for accumulated dirt twice a year

and clean. If disassembly is required, see GENERAL

SERVICING section.

GENERAL SERVICING

WARNING: IF SERVICING IS REQUIRED, IT SHOULD

BE DONE BY QUALIFIED PERSONS ONLY.

WARNING: ALWAYS DISCONNECT POWER SUPPLY

BEFORE SERVICING.

1.T o remove motor/blower heater assembly, repeat

Steps 4, 5 and 6 in Unpacking section.

2. Place motor/blower assembly on workbench.

3. To replace blower wheel, remove the three slotted hex

head screws on outer blower ring assembly (See

Figure 8, Replacement Parts Illustration.) The wheel

is held onto shaft by two hex head screws.

NOTE: To re-assemble repeat steps 4 & 5 in

installation section page 3.

IMPORTANT: NOTE POSITION OR WHEELS TO

PREVENT RUBBING WHEN REPLACED.

4. To remove motor:

a. Remove blower wheels. (See Step 3 above.)

b. Remove blower scrolI (six hex head screws).

c. Unscrew and remove motor mounts.

5. Replace motor/blower.

Figure 6 - Desired Air Flow

Adjustment for Temperature and

Humidity Control.

Figure 7 - Desired Air Flow Adjustment

for Insect and Dust Control.

4

Page 21

Troubleshooting Chart

SYMPTOM POSSIBLE CAUSE(S) CORRECTIVE ACTION

Fan inoperative

1. Blown fuse or open circuit breaker.

2. Electricity turned off.

3. Loose cord connection.

4. Defective capacitor or motor.

1. Replace fuse or reset circuit breaker.

2. Contact local power company .

3. Re-check all connections.

4. Replace.

1. Center wheel.

2. Tighten mounting bolts.

3. Replace motor.

1. Wheel rubbing on housing.

2. Motor base or blower not securely

anchored.

3. Defective motor bearings.

Excessive noise

1. Reconnect to proper voltage.

2. Open.

3. Remove any obstruction.

4. Clean.

5. Reverse red and black power leads.

1. Improper voltage.

2. Outlet louvers closed.

3. Intakes obstructed.

4. Dirty blower wheels.

5. Motor rotating in reverse direction.

Insufficient air flow

1. Verify correct wire size.

2. Remove obstruction.

1. Low voltage.

2. Obstruction to blower wheel.

Fans cut out on

thermal overload

(self-resets)

1. Replace with 4K4204H or 4K9204H.

2. Replace with proper Ga. and watts.

3. Replace with proper item.

1. Fuse link open.

2. Heater element broken

3. Control Transformer

No heat

5

Page 22

6

Replacement Parts

For Motor Blower Assemblies (7)

Replacement Parts

For Heater Units

1.

2

4

5

6

3

14

12

11

13

15

8

9

10

16

Replacement Parts

For Air Curtain Cabinets

9

3

4

5

2

7

6

8

1D

1C

1B

1A

Figure 8 - Replacement Parts.

Page 23

7

Replacement Parts List For Air Curtain Cabinets

Replacement Parts For 120 Volt Single Phase Motor Blower Assemblies

Key Part Numbers

No. Description 1/4HP

7 Motor/Blower Assembly

120V 1-ph ACMB125

220V 1-ph ACMB225

208-230/460V 3-ph ACMB325

8 Switch plate cover ACFPSH

9 Rocker switch C1220

10 Cord, female plug ACW316

11 Motor Assembly

120V 1-ph ACM1025

220V 1-ph ACM2025

208-230/460V 3-ph ACM3025

12 Resilient motor ring kit AP058

13 Capacitor ACCP1025

14 Blower housing ACBH67

15 Blower wheel-right ACBW67R

16 Blower wheel-left ACBW67L

Key Part Numbers for Cabinets (length)

No. Description 36" 38" 42" 48" 60"

1 Cabinet box assembly ACCA36A ACCA38A ACCA42A ACCA48A ACCA60A

2 Cabinet Intake Grille API3685 API3885 API4285 API4885 API6085

3 Cabinet Intake grill knurled nut AP0002 AP0002 AP0002 AP0002 AP0002

4 Cabinet louver kit ACL36 ACL38 ACL42 ACL48 ACL60

5 Electric box ACEB ACEB ACEB ACEB ACEB

6 Electric box cover ACFPSPC ACFPSPC ACFPSPC ACFPSPC ACFPSPC

Replacement Parts List For Heater Units

REF. DESCRIPTION REPLACEMENT PARTS FOR 230V 3-PH HEATERS

NO. 6 KW 9 KW QTY.

1 Wire Guards

A. 18” APG0018 APG0018 -

B. 12” APG0012 APG0012 C. 6” APG0006 APG0006 -

D. 2” APG0002 APG0002 -

2 Heater Control Box APHC230-3 APHC230-3 1

3 Heater Transformer AP0018 AP0018 1

4 Heater Fan Relay AP0020 AP0020 1

5 Heater Contactor AP0021 AP0021 1

6 Heater Element Set APHE06230-3 APHE09230-3 1

7 Heater Coil Fuse Link AP0016 AP0016 4

8 Wall Thermostat AP364860-T AP364860-T 1

Page 24

8

HOW TO ORDER REPAIR PARTS

In order to obtain any needed repair or replacement

parts, warranty service or technical information, please

contact Marley Engineered Products Service Center

toll-free by calling 1-800-642-HEAT.

Part No. 5200-2421-001 03-02

ECR 35189

LIMITED W ARRANTY

All products manufactured by Marley Engineered Products are warranted against defects in workmanship and

materials for eighteen months from date of installation. This warranty does not apply to damage from accident,

misuse, or alteration; nor where the connected voltage is more than 5% above the nameplate voltage; nor to

equipment improperly installed or wired or maintained in violation of the product’s installation instructions. All

claims for warranty work must be accompanied by proof of the date of installation.

The customer shall be responsible for all costs incurred in the removal or reinstallation of products, including labor

costs, and shipping costs incurred to return products to Marley Engineered Products Service Center. Within the

limitations of this warranty , inoperative units should be returned to the nearest Marley authorized service center

or the Marley Engineered Products Service Center, and we will repair or replace, at our option, at no charge to

you with return freight paid by Marley. It is agreed that such repair or replacement is the exclusive remedy

available from Marley Engineered Products.

THE ABOVE WARRANTIES ARE IN LIEU OF ALL OTHER WARRANTIES EXPRESSED OR IMPLIED, AND ALL

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE WHICH

EXCEED THE AFORESAID EXPRESSED WARRANTIES ARE HEREBY DISCLAIMED AND EXCLUDED FROM

THIS AGREEMENT. MARLEY Engineered Products SHALL NOT BE LIABLE FOR CONSEQUENTIAL

DAMAGES ARISING WITH RESPECT TO THE PRODUCT, WHETHER BASED UPON NEGLIGENCE, TORT,

STRICT LIABILITY, OR CONTRACT.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above

exclusion or limitation may not apply to you. This warranty gives you specific legal rights, and you may also have

other rights which vary from state to state.

For the address of your nearest authorized service center, contact Marley Engineered Products in Bennettsville,

SC, at 1-800-642-4328. Merchandise returned to the factory must be accompanied by a return authorization and

service identification tag, both available from Marley Engineered Products. When requesting return authorization,

include all catalog numbers shown on the products.

SPX Corporation

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

Page 25

REFER TO INDIVIDUAL MODEL NUMBERS

FOR UNIT WIDTH

117/8”

31/4”

153/4”

121/2”

Specifications and Performance

INSTALLATION & OPERATING INSTRUCTIONS & PARTS MANUAL

MODELS: E3606-1525HFD, E3609-1525HFD

E3806-1525HFD, E3809-1525HFD

E4206-1525HFD, E4209-1525HFD

E4806-1525HFD, E4809-1525HFD

E6006-2525HFD, E6009-2525HFD

READ CAREFULLY BEFORE ATTEMPTING TO ASSEMBLE, INSTALL, OPERATE, OR MAINTAIN THE PRODUCT DESCRIBED.

PROTECT YOURSELF AND OTHERS BY OBSERVING ALL SAFETY INFORMATION. FAILURE TO COMPLY WITH INSTR UCTIONS

COULD RESULT IN PERSONAL INJURY AND/OR PROPERTY DAMAGE!

RETAIN INSTRUCTIONS FOR FUTURE REFERENCE.

Figure 1

Air curtains produce a wall of continuously flowing air

that acts as a thermal barrier against outside air and

provides protection against insects, dust, odor, fumes

and other contaminants. Maintains interior conditioned

temperature by preventing heated or cooled air from

escaping through open doorways.

Heated air curtains are engineered to treat incoming

cold air at customers’ entrance areas. Used over front

door entrances, heated air curtains supplement existing

heat to prevent infiltration of colder outside air. Heated

units are not recommended for areas subject to high

winds.

Figure 2 Dimensions

Note that all dimensions are the same on all environmental

series units. Model number indicates width of unit.

(Example: E4800 indicates a 48” wide unit.)

MODEL

NUMBER

E3606-1525HFD

E3609-1525HFD

E4206-1525HFD

E4209-1525HFD

E4806-1525HFD

E4809-1525HFD

E6006-1525HFD

E6009-1525HFD

HEATER

VOLTAGE

460/3

460/3

460/3

460/3

460/3

460/3

460/3

460/3

MOTOR

VOLTAGE

460/3

460/3

460/3

460/3

460/3

460/3

460/3

460/3

HEATER

WATTS

6000

9000

6000

9000

6000

9000

6000

9000

HEATER

BTU/HR

20,478

30,717

20,478

30,717

20,478

30,717

20,478

30,717

HEATER

AMPS

7.5

11.4

7.5

11.4

7.5

11.4

7.5

11.4

CFM AT NOZZLE

(HI/LOW)

2025

2025

2360

2360

2700

2700

3375

3375

MOTOR

SIZE

1/4HP

1/4HP

1/4HP

1/4HP

1/4HP

1/4HP

1/4HP

1/4HP

Heated

Air Curtains

Note: For multiple unit installations, recommended spacing between units should be a minimum of 3-inches and a maximum of 6-inches.

Unit is allowed to extend beyond doorway width. Each unit must have individual power supply.

Description

Page 26

5. Carefully disconnect motor electric cord and heater

plug assembly and remove two wing nuts on blower

base. (See Figure 4.)

Figure 4 - Removing Motor/Blower Assembly

NOTE: Unit is shipped with styrofoam motor support

block which must be discarded at this time.

6. T o remove motor/blower assembly, lift from rear of

motor housing to prevent damage and mis-alignment

to shaft and blower wheels.

NOTE: After unpacking unit, inspect carefully for any

damage that may have occurred during transit.

Check for loose, missing or damaged par ts.

6. All wiring should be done by a qualified electrician,

using copper wire only and in accordance with the

National Electrical Code (NEC), all applicable code

and ordinances, and all sections of this manual. Any

variance voids the warranty and may create unsafe

conditions.

7. Special attention must be given to any grounding

information pertaining to this product. To prevent the

risk of electrocution, the unit must be securely

and adequately grounded. This should be

accomplished by connecting a

grounded conductor between the service

panel and the grounding lug or green leadwire

provided in the wiring compartment. To ensure a

proper ground, the grounding means must be tested

by a qualified electrician.

8. Do not insert fingers or foreign objects into the air

curtain. Do not block or tamper with it in any manner

while it is in operation. Do not touch it while in operation or just after it has been turned off, as some parts

may be hot enough to cause injury.

9. This product must NOT be used in potentially danger-

ous locations such as flammable, explosive chemical

laden, or wet atmospheres.

10.Do not attach ductwork to this product or attempt to

use it as a make-up air heater. Such use voids the

warranty and may create unsafe conditions.

WARNING: TO REDUCE THE RISK OF FIRE OR

ELECTRIC SHOCK, DO NOT USE THIS AIR CURTAIN

WITH ANY SOLID STATE SPEED CONTROL DEVICE.

1. With packaged unit on the floor, carton arrows should

point upward.

2. Carefully remove staples from top of carton and fold

back sides.

3. Carefully remove cabinet from carton by lifting out

unit using finger holes in styrofoam side inset and

place on work surface.

CAUTION:Do not attempt to lift this air curtain by its

louver or damage may result.

4. Unscrew six (6) knurled nuts and remove air intake

grille. (See Figure 3.)

Figure 3 - Removing Air Intake Grille

WARNING - TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSONS OBSERVE

THE FOLLOWING:

1. Use this unit only in the manner intended by the manufacturer. If you have questions contact the manufacturer.

2. Before servicing or cleaning unit, switch power off at

service panel and lock service panel to prevent power

from being switched on accidentally .

3. Installation work and electrical wiring must be done by

qualified persons in accordance with all applicable

codes and standards, including fire rated construction.

4. When cutting or drilling into wall or ceiling, do not

damage electrical wiring or other hidden utilities.

5. Make certain that the power source conforms to the

electrical requirements of the unit. Disconnect power

before installing or servicing. If the power disconnect

is out of sight, lock it in the open position and tag it to

prevent unexpected application of power. Failure to do

so could result in fatal electrical shock.

WARNING: DO NOT DEPEND UPON A THERMOSTAT

OR OTHER SWITCH AS THE SOLE MEANS OF

DISCONNECTING POWER WHEN INSTALLING OR

SERVICING THE UNIT. ALWAYS DISCONNECT

POWER AT THE MAIN CIRCUIT BREAKER AS

DESCRIBED ABOVE. FAILURE TO DO SO COULD

RESULT IN FATAL ELECTRIC SHOCK.

General Safety Information

Unpacking

2

STYROFOAM

SUPPORT

BLOCK

Page 27

Installation

1. Using template provided, determine mounting

location.

2. Drill holes and attach mounting hardware

(not included).

IMPORTANT: THE HARDWARE AND THE SUPPORTING STRUCTURE MUST BE CAPABLE OF SUPPORTING A MINIMUM 150 LB. LOAD.

NOTE: All installation should be done to meet local

building code.

3. Mount cabinet on wall and securely tighten hardware.

4. Replace motor/blower assembly in cabinet. Secure

two wing nuts on blower base. Reconnect motor

electric cord plug assembly & heater plug.

5. Replace intake grille with louvers facing down and

refasten knurled nuts.

FIELD POWER WIRING

WARNING: ALL AIR CURTAINS SHOULD BE

INSTALLED BY QUALIFIED PERSONNEL.

1. Before wiring be sure that available power supply,

voltage, phase and frequency corresponds to that

specified on heater rating plate. In addition, make

certain that service capacity is sufficient to handle load

imposed by the equipment.

2. Install all wiring, protection and grounding in accordance with the National Electrical Code (NEC) and

all local requirements.

WARNING: THIS FAN HAS AN INTERNAL SELF

RESETTING THERMAL OVERLOAD PROTECTOR.

ALWAYS DISCONNECT FROM POWER SUPPLY

BEFORE SERVICING.

3. Run proper size copper power supply conductors from

the field power supply disconnects, (supplied by

others) with insulation rated minimum 75°C (167°F).

One set of conductors from 460VAC, 50/60Hz supply

source shall be routed through the 3/4 inch conduit

knockout, using a suitable knockout connected to the

contactor contact terminals marked L1, L2, L3.

4. The heater control box must have an unbroken

electrical ground to minimize personal injury if an

electrical fault should occur.

FIELD CONTROL

WIRING

Electric heater is equipped with a step-down transformer

for 24V control circuit. Thermostat model number RSV130-R-54 must be used to energize heater with the fan

motor. Connect thermostat wiring from thermostat to

control leads in heated air curtain control box by means

of conduit or equivalent. A 1/2 inch knockout is provided.

Class 1 wiring is required.

5. Replace heater control box cover.

6. Unit is ready for operation.

7. Restore power.

NOTE: Air curtain has high/low selector switch. See

Operation section for proper setting instructions.

8. Upon completion of all installation, inspect unit for

excessive vibration during operation. If excessive

vibration is noticeable, disconnect power supply.

Inspect mounting installation and refer to

Troubleshooting Chart for probable cause.

3

Figure 5 - Wiring Diagram

BU

COLOR CODE

RE - RED

WH - WHITE

BK/RD - BLACK W/ RED TRACER

YE - YELLOW

OR - ORANGE

BU - BLUE

LEGEND

HR - HEAT RELAY

TB - TERMINAL BLOCK

TR TRANSFORMER

PL - PILOT LIGHT

FL - FUSE LINK

HE - HEAT ELEMENT

HEATER SECTION

FIELD WIRING TO THERMOSTAT

THERMOSTA T

TERMINAL MARKING

TO POWER

SUPPLY

PLUG

TB

L1

L2

L3

GR

Page 28

Operation

1. After power has been connected to unit, fans will start

in either preset (high/low) speed selection.

2. Air velocity is controlled by selection of high or low

speed indicator. This feature allows the setting of air

velocity to individual desired performance and energy

efficiency .

3. Air direction at outlet can be controlled by adjustable

vanes at the nozzle which compensates for possible

draft conditions.

NOTE: Air direction settings shown in Figures 6 & 7.

NOTE: Cold air will try to escape near floor level.

Warm air will try to penetrate curtain near top of

doorway. Air flow can be controlled by direction of

nozzle louvers and by high/low settings.

4. For multiple unit applications (wide openings), mount

units a minimum of 3” apart to allow for proper air

intake and discharge.

Maintenance

WARNING: ALL ELECTRIC POWER MUST BE

DISCONNECTED WHEN INSTALLING OR SERVICING

THIS EQUIPMENT. MORE THAN ONE DISCONNECT

SWITCH MAY BE REQUIRED TO REMOVE POWER

FROM THE UNIT.

LUBRICA

TION

Ball bearings are permanently lubricated and require no

further lubrication.

CLEANING

1. The air door cabinet may be wiped off with a damp

cloth. Do not allow motor to get wet. Do not use solvents or harsh detergents.

NOTE: Keep air intake louvers clear of dirt and dust

accumulation which could affect performance.

2. Check blower wheels for accumulated dirt twice a year

and clean. If disassembly is required, see GENERAL

SERVICING section.

GENERAL SERVICING

WARNING: IF SERVICING IS REQUIRED, IT SHOULD

BE DONE BY QUALIFIED PERSONS ONLY.

WARNING: ALWAYS DISCONNECT POWER SUPPLY

BEFORE SERVICING.

1.T o remove motor/blower heater assembly, repeat

Steps 4, 5 and 6 in Unpacking section.

2. Place motor/blower assembly on workbench.

3. To replace blower wheel, remove the three slotted hex

head screws on outer blower ring assembly (See

Figure 8, Replacement Parts Illustration.) The wheel

is held onto shaft by two hex head screws.

NOTE: To re-assemble repeat steps 4 & 5 in

installation section page 3.

IMPORTANT: NOTE POSITION OR WHEELS TO

PREVENT RUBBING WHEN REPLACED.

4. To remove motor:

a. Remove blower wheels. (See Step 3 above.)

b. Remove blower scrolI (six hex head screws).

c. Unscrew and remove motor mounts.

5. Replace motor/blower.

Figure 6 - Desired Air Flow

Adjustment for Temperature and

Humidity Control.

Figure 7 - Desired Air Flow Adjustment

for Insect and Dust Control.

4

Page 29

Troubleshooting Chart

SYMPTOM POSSIBLE CAUSE(S) CORRECTIVE ACTION

Fan inoperative

1. Blown fuse or open circuit breaker.

2. Electricity turned off.

3. Loose cord connection.

4. Defective capacitor or motor.

1. Replace fuse or reset circuit breaker.

2. Contact local power company .

3. Re-check all connections.

4. Replace.

1. Center wheel.

2. Tighten mounting bolts.

3. Replace motor.

1. Wheel rubbing on housing.

2. Motor base or blower not securely

anchored.

3. Defective motor bearings.

Excessive noise

1. Reconnect to proper voltage.

2. Open.

3. Remove any obstruction.

4. Clean.

5. Reverse red and black power leads.

1. Improper voltage.

2. Outlet louvers closed.

3. Intakes obstructed.

4. Dirty blower wheels.

5. Motor rotating in reverse direction.

Insufficient air flow

1. Verify correct wire size.

2. Remove obstruction.

1. Low voltage.

2. Obstruction to blower wheel.

Fans cut out on

thermal overload

(self-resets)

1. Replace with 4K4204H or 4K9204H.

2. Replace with proper Ga. and watts.

3. Replace with proper item.

1. Fuse link open.

2. Heater element broken

3. Control Transformer

No heat

5

Page 30

Figure 8 - Replacement Parts.

6

Replacement Parts

For Motor Blower Assemblies (7)

Replacement Parts

For Heater Units

1.

2

4

5

6

3

14

12

11

13

16

8

9

10

15

Replacement Parts

For Air Curtain Cabinets

9

3

4

5

2

7

6

8

1D

1C

1B

1A

Page 31

7

Replacement Parts List For Air Curtain Cabinets

Replacement Parts For 120 Volt Single Phase Motor Blower Assemblies

Key Part Numbers

No. Description 1/4HP

7 Motor/Blower Assembly

120V 1-ph ACMB125

220V 1-ph ACMB225

208-230/460V 3-ph ACMB325

8 Switch plate cover ACFPSH

9 Rocker switch C1220

10 Cord, female plug ACW316

11 Motor Assembly

120V 1-ph ACM1025

220V 1-ph ACM2025

208-230/460V 3-ph ACM3025

12 Resilient motor ring kit AP058

13 Capacitor ACCP1025

14 Blower housing ACBH67

15 Blower wheel-right ACBW67R

16 Blower wheel-left ACBW67L

Key Part Numbers for Cabinets (length)

No. Description 36" 38" 42" 48" 60"

1 Cabinet box assembly ACCA36A ACCA38A ACCA42A ACCA48A ACCA60A

2 Cabinet Intake Grille API3685 API3885 API4285 API4885 API6085

3 Cabinet Intake grill knurled nut AP0002 AP0002 AP0002 AP0002 AP0002

4 Cabinet louver kit ACL36 ACL38 ACL42 ACL48 ACL60

5 Electric box ACEB ACEB ACEB ACEB ACEB

6 Electric box cover ACFPSPC ACFPSPC ACFPSPC ACFPSPC ACFPSPC

Replacement Parts List For Heater Units

REF. DESCRIPTION REPLACEMENT PARTS FOR 460V 3-PH HEATERS

NO. 6 KW 9 KW QTY.

1 Wire Guards

A. 18” APG0018 APG0018 -

B. 12” APG0012 APG0012 C. 6” APG0006 APG0006 -

D. 2” APG0002 APG0002 -

2 Heater Control Box APHC460-3 APHC460-3 1

3 Heater Transformer AP0018 AP0018 1

4 Heater Fan Relay AP0020 AP0020 1

5 Heater Contactor AP0021 AP0021 1

6 Heater Element Set APHE06460-3 APHE09460-3 1

7 Heater Coil Fuse Link AP0016 AP0016 4

8 Wall Thermostat AP364860-T AP364860-T 1

Page 32

8

HOW TO ORDER REPAIR PARTS

In order to obtain any needed repair or replacement

parts, warranty service or technical information, please

contact Marley Engineered Products Service Center

toll-free by calling 1-800-642-HEAT.

Part No. 5200-2422-001 03-02

ECR 35189

LIMITED W ARRANTY

All products manufactured by Marley Engineered Products are warranted against defects in workmanship and

materials for eighteen months from date of installation. This warranty does not apply to damage from accident,

misuse, or alteration; nor where the connected voltage is more than 5% above the nameplate voltage; nor to

equipment improperly installed or wired or maintained in violation of the product’s installation instructions. All claims

for warranty work must be accompanied by proof of the date of installation.

The customer shall be responsible for all costs incurred in the removal or reinstallation of products, including labor

costs, and shipping costs incurred to return products to Marley Engineered Products Service Center. Within the

limitations of this warranty, inoperative units should be returned to the nearest Marley authorized service center or

the Marley Engineered Products Service Center, and we will repair or replace, at our option, at no charge to you

with return freight paid by Marley. It is agreed that such repair or replacement is the exclusive remedy available

from Marley Engineered Products.

THE ABOVE WARRANTIES ARE IN LIEU OF ALL OTHER WARRANTIES EXPRESSED OR IMPLIED, AND ALL

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE WHICH

EXCEED THE AFORESAID EXPRESSED WARRANTIES ARE HEREBY DISCLAIMED AND EXCLUDED FROM

THIS AGREEMENT. MARLEY ENGINEERED PRODUCTS SHALL NOT BE LIABLE FOR CONSEQUENTIAL

DAMAGES ARISING WITH RESPECT TO THE PRODUCT, WHETHER BASED UPON NEGLIGENCE, TORT,

STRICT LIABILITY, OR CONTRACT.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above exclusion

or limitation may not apply to you. This warranty gives you specific legal rights, and you may also have other rights

which vary from state to state.

For the address of your nearest authorized service center, contact Marley Engineered Products in Bennettsville,

SC, at 1-800-642-4328. Merchandise returned to the factory must be accompanied by a return authorization and

service identification tag, both available from Marley Engineered Products. When requesting return authorization,

include all catalog numbers shown on the products.

SPX Corporation

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

Loading...

Loading...