Page 1

READ AND SAVE THESE INSTRUCTIONS

MODELS 761, 763, 765, 7100, 7130, 7150,

8090 & 8100 FANS

MODELS 768IC, 770IC, 7100L, 7150L, 7100FL, 7150FL,

8090L & 8100L FAN/LIGHTS

MODELS 7100H, 7100FLH, 7150H & 7150FLH

FANS & FAN/LIGHTS with HUMIDITY SENSOR

DESCRIPTION

The FAN and FAN/LIGHT models listed in these instructions

are intended for use in bathrooms. However, they can also be

used in other areas where ventilation is required. These units

are approved for installation in the ceiling above a bathtub or

shower stall only when connected to a U.L. Listed GFCI protected branch circuit. ALLFAN/LIGHT models are U.L. Listed

Type I.C. (Inherently Protected) for installation in insulated ceilings.

UNP ACKING

Unpack carefully. If there are missing components or hidden

damage, immediately contact your distributor or the delivering

carrier concerning discrepancies.

IMPORTANT SAFETY INSTRUCTIONS

WARNING:

TO REDUCE RISK OF FIRE, ELECTRICAL SHOCK OR

INJURY TO PERSONS, OBSERVE THE FOLLOWING:

1. Do not use this fan with any Solid-State speed control

device.

2. Use this unit only in the manner intended by the manufacturer. If you have any questions, contact the

manufacturer.

3. Before servicing or cleaning unit, switch power off at

service panel and lock service panel to prevent power

from being switched on accidentally.

4. Installation work and electrical wiring must be done by

qualified person(s) in accordance with all applicable

codes and standards, including fire-rated construction.

5. Sufficient air is needed for proper combustion and

exhausting of gases through the flue (chimney) of fuel

burning equipment to prevent back drafting. Follow the

heating equipment manufacturer’s guideline and safety

standards such as those published by the

National Fire Protection Association (NFPA), and the

American Society for Heating and Air Conditioning

Engineers (ASHRAE), and the local code authorities.

6. When cutting or drilling into wall or ceiling, do not damage

electrical wiring or other hidden utilities.

7. Ducted fans must always be vented to the outdoors.

8. If this unit is installed over a tub or shower, it must be

marked as appropriate for the application. See product

label.

9. NEVER place a switch where it can be reached from a tub

or shower.

10. CAUTION: For General Ventilation Use Only! Do not

use to exhaust hazardous or explosive materials or vapors.

11. Not for use in kitchens.

TOOLS

Installation of your Marley Engineered Products fan is easy . No

special technical knowledge is needed; only a few ordinary

tools are required:

Screwdriver

Hammer

Saber saw, Keyhole saw, or Jig saw

Electric drill with bit

Wire cutters

Wire stripper

Wire nuts and general electrical supplies

Safety glasses

Ruler and straight edge

All hand tools should be insulated. Power tools should display

the UL Listing Mark.

Page 2

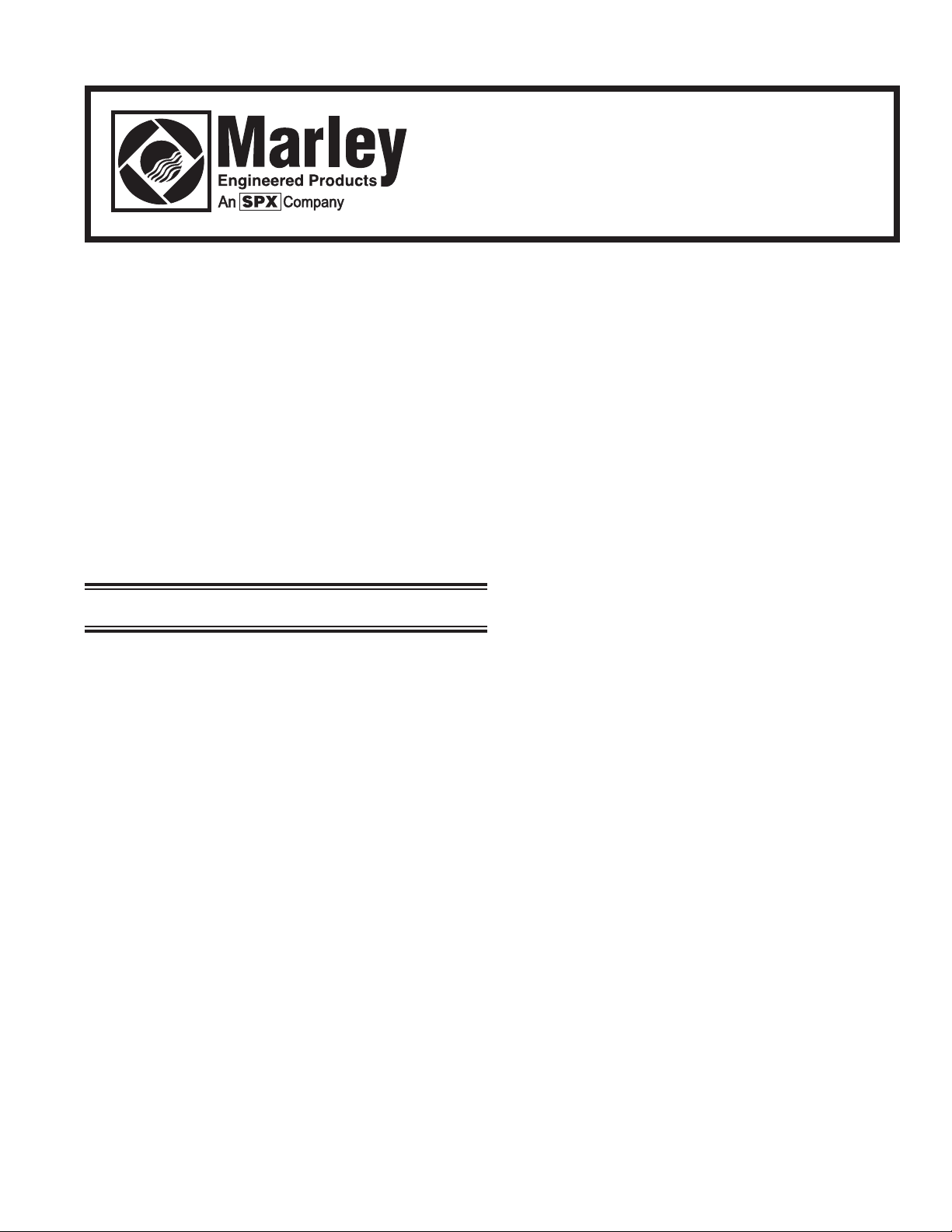

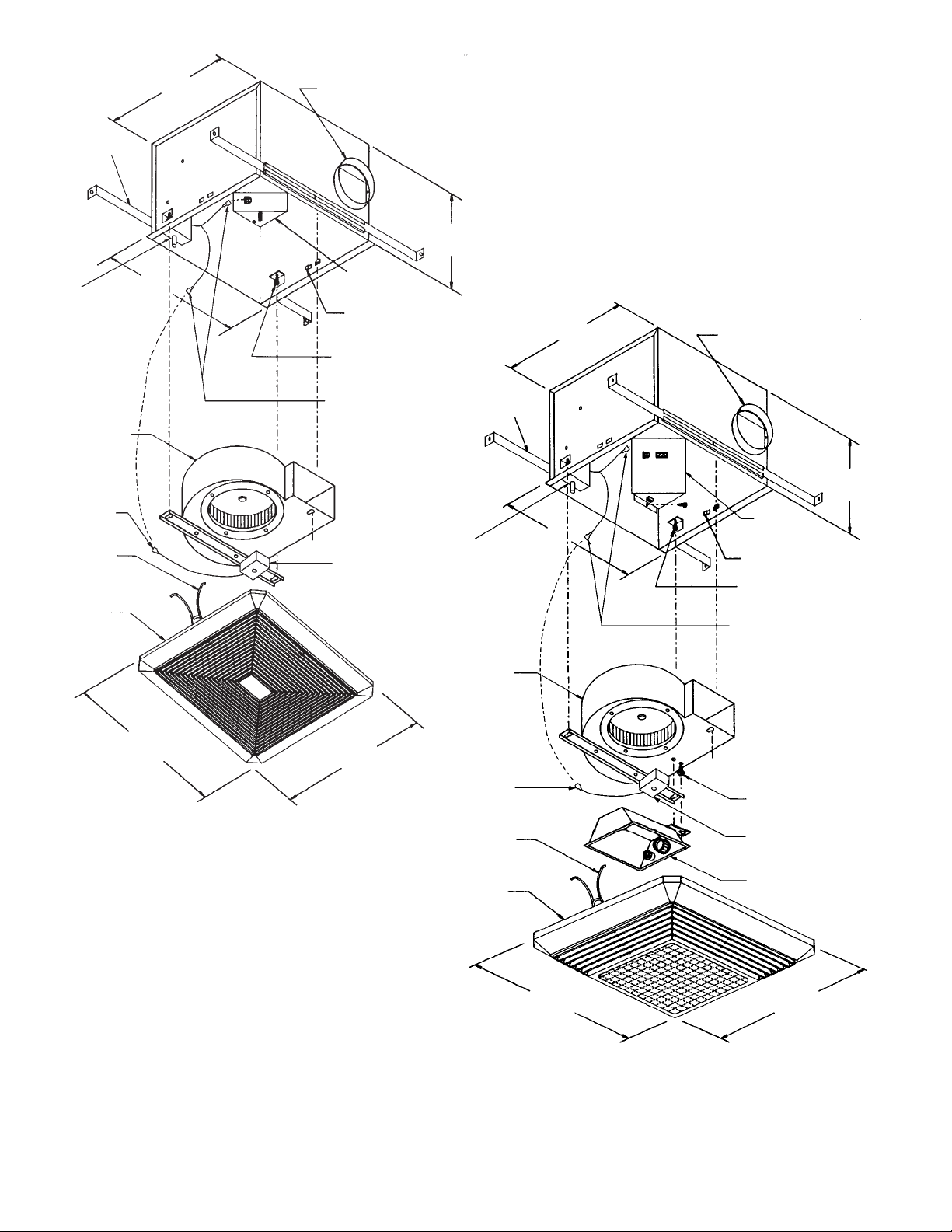

BLOWER MOUNTING

SCREWS

GRILLE MOUNTING

TABS

GRILLE

MOUNTING

BRACKET

AIR DISCHARGE

OUTLET

AIR DISCHARGE

OUTLET

MOUNTING

BRACKETS

MOUNTING

BRACKETS

OUTLET BOX

COVER

OUTLET BOX

COVER

BLOWER

MOUNTING

SCREWS

BLOWER UNIT

BLOWER

UNIT

REFLECTOR

ASSEMBLY

GRILLE SPRING

GRILLE

GRILLE

LENS

11

1

⁄2

12 1⁄

2

11 1⁄2

12 1⁄2

MODELS:

761, 763 AND 765

FIG. 1

MODELS:

768IC AND 770IC

FIG. 2

10 5⁄8

7 1⁄2

9 5⁄8

REFLECTOR

MOUNTING

SCREW

10 5⁄8

4 7⁄8

9 5⁄8

Page 3

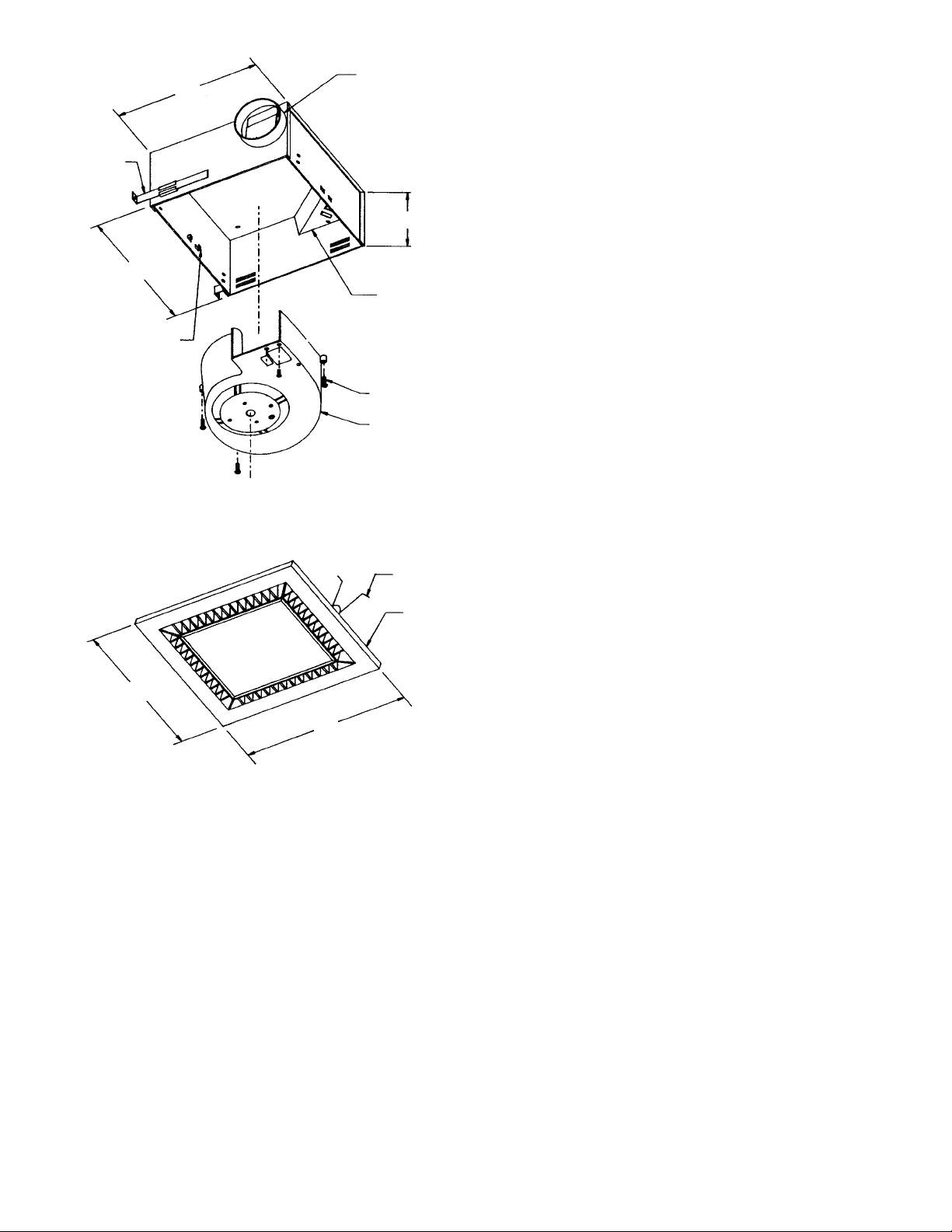

NEW HOME INSTALLA TION

MODELS 761, 763, 765, 768IC, AND 770IC

NOTE: Plastic scroll and motor assembly can be removed from

the metal housing prior to step one if desired. Simply loosen four

mounting screws securing scroll to housing and slide it towards

the outlet box. Carefully lift and tilt scroll, motor and wheel assembly to remove it from housing. (See Fig. 1 & 2.)

1. Pull motor plug from receptacle. Remove outlet box cover and

desired knockout from housing.

2. If the duct adapter is attached, disregard this note. Attach

duct adapter to housing by first hooking mounting flange

over edge of air discharge opening. Pivot duct adapter

insuring (2) aligning tabs are inside opening and align (2)

locking tabs with small rectangular holes. Press firmly into

holes to lock. See Fig. 3. Remove tape securing damper.

NOTE: The attachment of the duct adapter to the housing may

be reinforced if desired, by installing a #8AB screw through the

oblong hole in the duct adapter and the small round hole in

the housing.

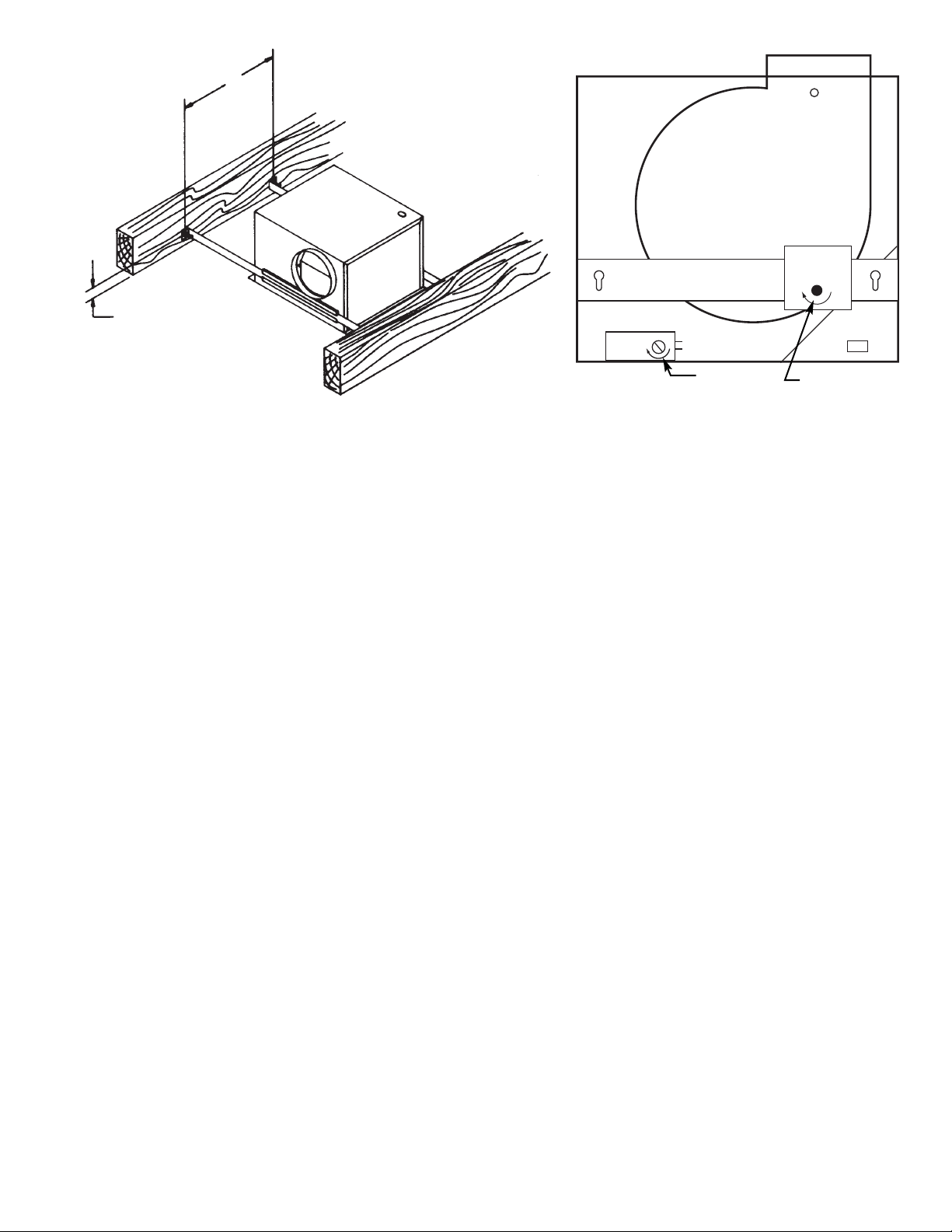

3. Insert mounting brackets with angle pointing away from

housing. Position housing into ceiling location. Housing is

stamped to show a line at 3/8” for drywall and 3/4” for standard

sheetrock and plaster. Fasten securely through mounting

holes provided in housing. (Fig. 4.) Pull mounting brackets

against adjacent ceiling joist and fasten securely. (Fig. 5.)

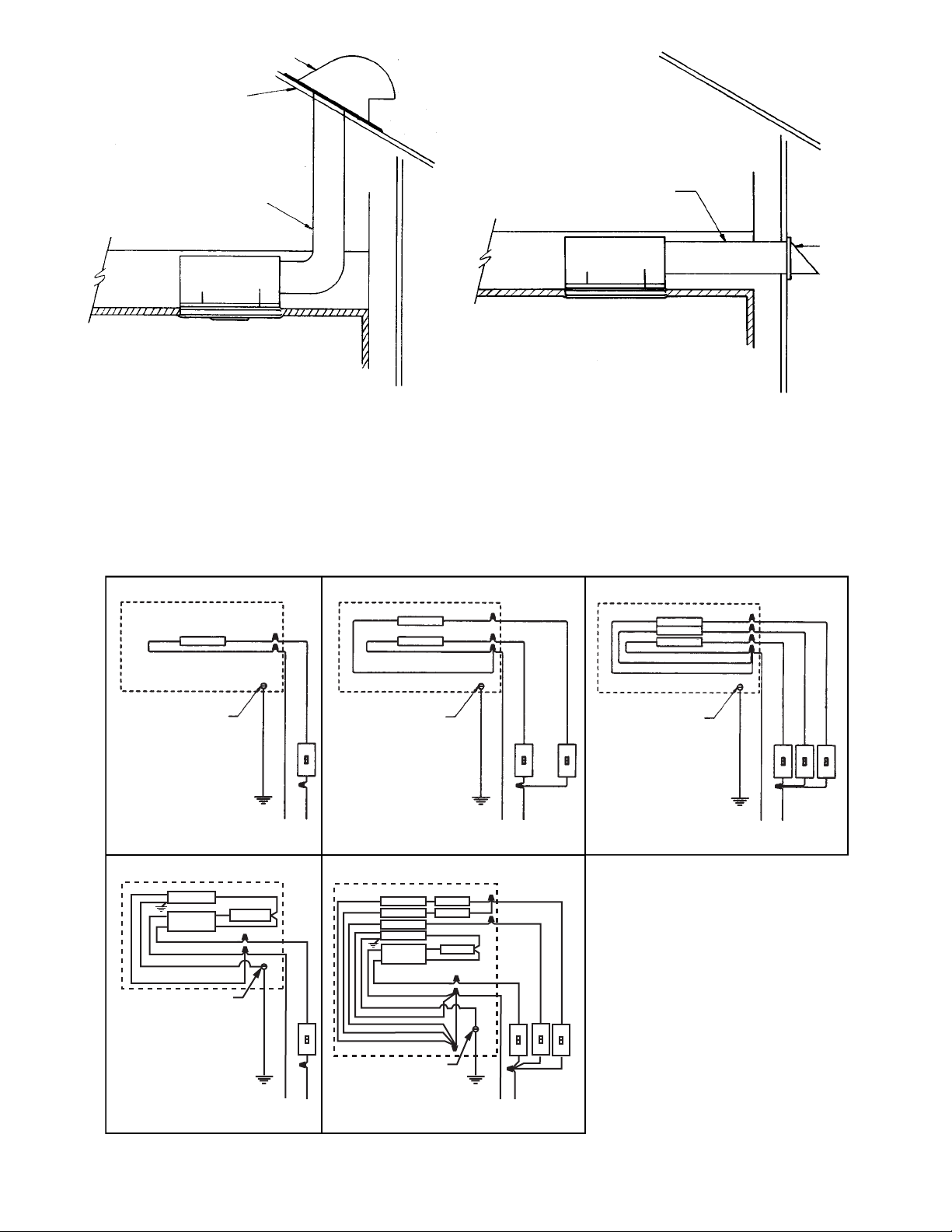

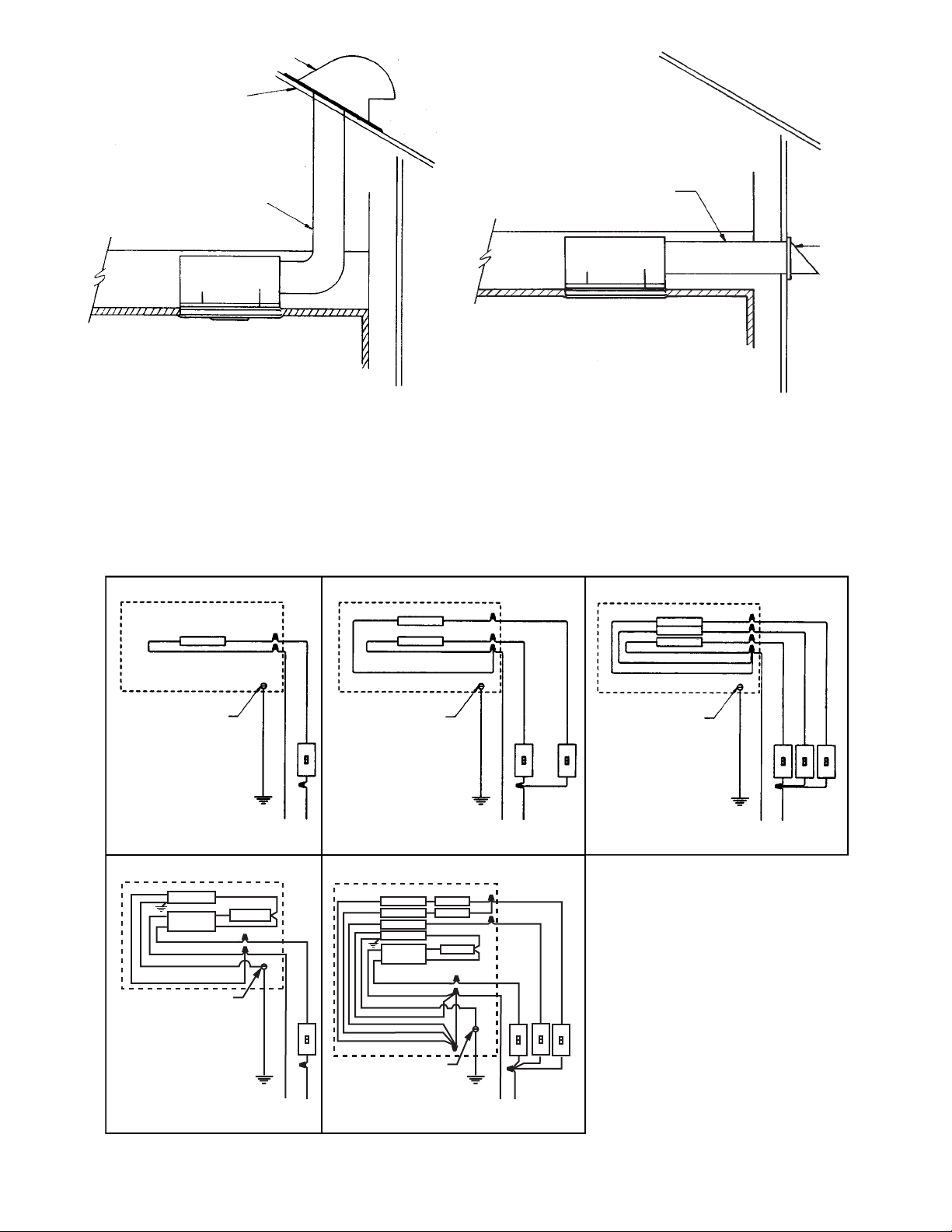

4. Run 120vAC, 60 Hz power cables from wall switch/switches to

appropriate knockout in housing. Use a BX or Romex connector. (Refer to wiring diagram designated for the model

being installed.) Connect cables from wall switch/switches to

receptacle wires using approved wire connectors. Connect

ground wire to green screw or lead in outlet box. Install outlet

box cover and secure with screw provided.

5. Run four inch round duct from fan air discharge outlet to wall

cap or roof cap. See Figs. 6 & 7.

IMPORT ANT: Be sure nothing obstructs the discharge of the fan.

Take precautions to insure that insulation does not get into

duct work or fan discharge opening, and damper opens and

closes freely.

6. Carefully replace plastic scroll, motor and wheel assembly if

unit was disassembled for installation. Reverse procedure as

noted. Tighten screws securely and push plug into motor

receptacle.

7. (MODELS 761, 763 & 765 ONLY)

Squeeze springs on grille and insert in tabs located in housing.

See Fig. 1. Press grille firmly into place.

8. (MODELS 768IC & 770IC ONLY)

Center reflector in center of grille. Push light plug into receptacle. Center reflector/grille assembly over housing and engage

1” mounting bolt through center hole in reflector into metal

mounting bracket located on plastic scroll and motor

assembly. Tighten bolt until grille is firmly pulled against the

ceiling. See Fig. 2.

9. Install light bulb. (Type A-19, 100 watts maximum.)

10. Install the snap-on lens by engaging lens tabs into grille

slots.

FIG. 3

FIG. 4

FIG. 5

LOCKING

TABS

MOUNTING

FLANGE

DUCT ADAPTER

ALIGNING

Page 4

FIG. 6

FIG. 7

CAUTION!

BE SURE ALL WIRING COMPLIES WITH LOCAL AND NATIONAL ELECTRICAL

CODES, AND HOUSING IS PROPERLY GROUNDED.

ROOF CAP

WALL

CAP

4” ROUND

DUCT

4” ROUND

DUCT

ROOF

OUTLET BOX

RECEPTACLE

WIRING DIAGRAM

MODELS 768IC, 770IC

LIGHT

GREEN

WHITE

WHITE

WHITE

GREEN

BLACK

WIRING DIAGRAM

MODELS 7100H, 7150H

SENSOR

TIMER

BLACK

WHITE

WHITE

WHITE

WIRING DIAGRAM

MODELS 7100L, 7150L,

7100FL, 7150FL, 8090L

AND 8100L

LIGHT

NIGHT LIGHT

BLUE

BROWN

WHITE

WHITE

WHITE

WHITE

BLACK

WIRING DIAGRAM

MODELS 7100FLH, 7150FLH

LIGHT

BALLAST

BALLAST

LIGHT

NIGHT LIGHT

BLU

BLU

BROWN

VENTILATOR

BLACK

WHITE

GROUND SCREW

GROUND

WHITE

BLACK

BLACK

WIRING DIAGRAM

MODELS 761, 763, 765

7100, 7130, 7150, 8090

AND 8100

WALL

SWITCH

WALL

SWITCH

WALL

SWITCH

WALL

SWITCH

WALL

SWITCH

WALL

SWITCH

120V AC

60 HZ

SUPPLY

OUTLET BOX

RECEPTACLE

VENTILATOR

GROUND SCREW

GROUND

WHITE

BLACK

BLACK

BLACK

120V AC

60 HZ

SUPPLY

OUTLET BOX

RECEPTACLE

VENTILATOR

GROUND SCREW

GROUND

WHITE

BLACK

BLACK

BLACK

BLACK

120V AC

60 HZ

SUPPLY

WALL

SWITCH

WALL

SWITCH

WALL

SWITCH

WALL

SWITCH

OUTLET BOX

VENTILATOR

TIMER

GROUND SCREW

GROUND

WHITE

BLACK

BLACK

120V AC

60 HZ

SUPPLY

OUTLET BOX

RECEPTACLE

VENTILATOR

SENSOR

GROUND SCREW

GROUND

WHITE

BLACK

BLACK

BLACK

BLACK

120V AC

60 HZ

SUPPLY

BLACK

WHITE

BLACK

WHITE

Page 5

INSTALLA TION IN EXISTING HOMES

(MODELS: 761, 763, 765, 768IC & 770IC)

1. Review the section: “New Home Installation” and follow instructions where applicable.

2. Refer to wiring diagrams for wiring and Fig. 6 & 7 for duct work.

3. Determine location of ventilator, remembering that the housing must be installed next to a joist.

4. Drill a small hole in ceiling in proposed location, then locate this hole in the attic.

5. In the attic, position housing against ceiling joist and over drilled hole. Using the housing as a template, mark ceiling for

cutout. Make cutout on this line.

6. Remainder of installation is the same as steps 1 through 10 under “New Home Installation” above. Cracks between

housing and ceiling may be plastered or caulked.

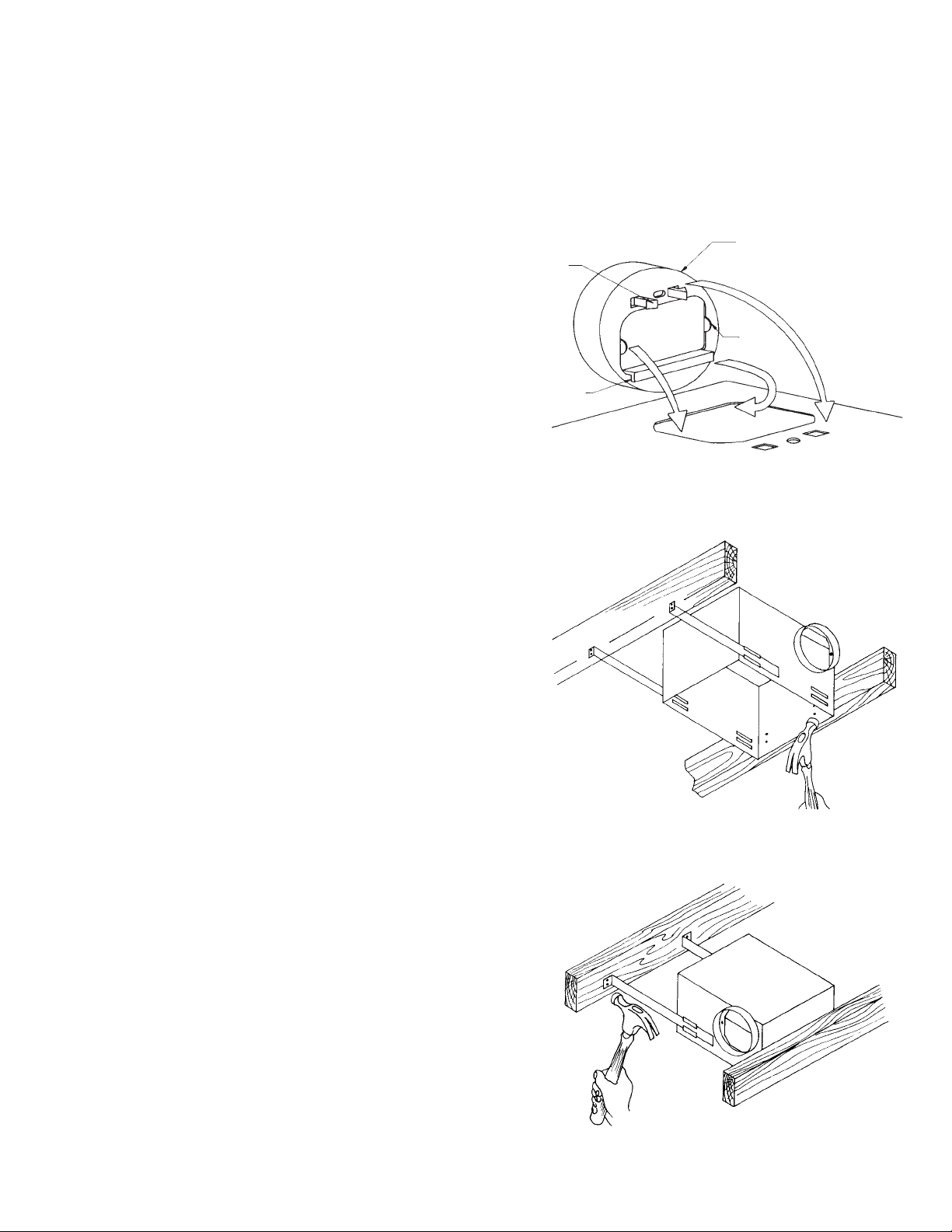

NEW HOME INSTALLATION

(MODELS: 7100, 7130, 7150, 8090, 8100, 7100L,

7150L, 7100H, 7100FLH, 7150H, 7150FLH, 7100FL, 7150FL, 8090L & 8100L)

1. Remove grille assembly from carton and set aside until needed. Remove reflector assembly from blower unit

(MODELS: 7100L, 7100FLH, 7150FLH, 7150L, 7100FL, 7150FL, 8090L & 8100L) by pulling plug from receptacle,

loosen mounting screws and remove through keyhole slot. Pull timer plug from recetpacle if applicable. See Fig. 9.

2. Loosen three screws securing blower unit to housing and slide it toward outlet box. Carefully lift and tilt blower unit

and remove from housing. Pull motor plug from receptacle. Pull humidity sensor plug from recetpacle if

applicable. See Figs. 8 & 9.

3. Remove outlet box cover by removing mounting screw. Retain cover and screw for reinstallation. Remove desired

knockout from housing.

4. If DUCT ADAPTER is already attached to housing, disregard Item #4. If not proceed as follows! Attach DUCT

ADAPTER to housing by first hooking mounting flange over edge of air discharge opening. Pivot duct adapter

insuring (2) aligning tabs are inside opening and align (2) locking tabs with small rectangular holes. Press tabs

firmly into holes to lock. See Fig. 3. Remove tape securing damper.

NOTE: The attachment of the duct adapter to the housing may be reinforced, if desired, by

installing a #8AB screw through the oblong hole in the duct adapter and the small round

hole in the housing.

5. Insert (4) mounting brackets with angles pointing away from housing. In approximate location between joist where

housing will be located, drive (2) nails (4D or 6D) 1” from bottom of joist, 11” apart leaving 1/4” of nail projecting.

Position one set of mounting brackets over nails and drop into place. Extend the remaining mounting brackets to

the adjacent joist and repeat nailing procedure. Finish driving nails and adjust housing between ceiling joist.

See Fig. 10.

6. Run 120V A C, 60 Hz power cables from wall switch/switches to appropriate knockout in housing. Use a BX or

Romex connector. (Refer to wiring diagram designated for the model being installed.) Connect cables from wall

switch/switches to receptacle wires using approved wire connectors. Connect ground wire to green screw or lead

in outlet box. Install outlet box cover and secure with screw provided.

7. Run four inch duct from discharge outlet to roof jack or wall cap. See Figs. 6 & 7.

IMPORTANT: Be sure nothing obstructs the discharge of the vent. Take precautions to insure that

insulation does not get into ductwork or fan discharge opening, and damper opens and closes freely.

8. Push humidity sensor plug into receptacle, if applicable. Push blower motor plug into receptacle and carefully

replace blower unit. Reverse procedure as noted. Tighten screws securely. See Figs. 8 & 9.

9. Insert timer plug into humidity sensor receptacle, if applicable. Insert lamp plug of reflector assembly into lamp

receptacle on the outlet box. Align keyhole slot on reflector

assembly bracket over screw on blower unit and slide into place. Insure that protrusion in bracket aligns with hole

in blower assembly and tighten screw. Install 100 watt (maximum) type A-19 bulb and a 7 1/2 watt candelabra base

C-7 bulb. (MODELS: 7100L, 7150L, 8090L & 8100L only.) On fluorescent models 7100FL, 7150FL, 7100FLH and

7150FLH install two of the following 13 watt quad-tube compact fluorescent lamps / 2 Pin:

Osram/Sylvania Panasonic Philips General Electric

CF13DD/841 FQ13E41.u/2 PL-C13W/41/USA F13DBX23T4/SPX41

10.Squeeze spring on plastic grille and insert into tabs located in housing. See Figs. 8 & 9. Press grille firmly into place.

Page 6

AIR DISCHARGE

OUTLET

OUTLET

BOX COVER

GRILLE

MOUNTING

TABS

BLOWER UNIT

GRILLE

12 1/2”

11 13/16”

7 5/8”

10”

11 1/2”

GRILLE

SPRING

BLOWER

MOUNTING

SCREWS

WIRE

CONNECTORS

HUMIDITY SENSOR

MODELS:

7100, 7130, 7150,

7100H, 7150H,

8090 & 8100

OUTLET

BOX COVER

GRILLE MOUNTING

TABS

BLOWER

UNIT

GRILLE

12 1/2”

12 1/2”

11 3/16”

7 5/8”

10”

GRILLE

SPRING

BLOWER

MOUNTING

SCREWS

REFLECTOR

MOUNTING

SCREW

REFLECTOR

ASSEMBLY

MODELS:

7100L, 7150L, 7100FLH,

7150FLH, 7100FL,

7150FL,

8090L & 8100L

FIG. 8

FIG. 9

MOUNTING

BRACKETS

MOUNTING

BRACKETS

WIRE

CONNECTOR

(PLUG)

WIRE

CONNECTOR

(PLUG)

TIMER

TIMER

HUMIDITY

SENSOR

AIR DISCHARGE

OUTLET

WIRE

CONNECTORS

Page 7

INSTALLATION IN EXISTING HOMES

(MODELS: 7100, 7130, 7150, 8090, 8100, 7100L, 7150L,

7100H, 7100FLH, 7150H, 7150FLH, 7100FL, 7150FL, 8090L & 8100L)

1. Carefully read all previous installation instructions and follow those applicable to your installation, including ducting

and wiring. (Figs. 6 & 7.)

2. Drill a small hole in the ceiling from below in proposed location, then locate this hole in the attic (or crawl space).

3. In attic, mark ceiling for cutout by using housing as a template. Using this line, make a cutout about 1/4” larger.

4. Place housing with mounting brackets installed into hole and rest mounting brackets on sheetrock. Extend and

nail all four ends of mounting brackets.

5. Perform steps 1 through 10 as for new construction.

REQUIREMENTS AND ADJUSTMENTS FOR HUMIDITY SENSING UNITS ONLY

The unit should be mounted on a flat ceiling surface that does not exceed twelve feet in height and is away from

a direct heat source such as a room or sauna heater.

Note: Open windows may affect the humidity level in the room and cause the unit not to operate properly.

Once the location is selected, refer to the previous figures for instruction on determining the proper hole size for

mounting the unit.

The unit is operated by a wall switch. Each time the switch is turned on, the unit will operate until the preset

time on the timer is expired. After time has expired, the unit will be in the automatic mode. At this point the operation of the unit is dependent upon the humidity level of the room. When the humidity level of the room is above the

set-point selected on the humidity sensor, the unit will run. It will operate until the humidity level of the room drops

below its set-point. For the unit to come on when it is on automatic mode, the set-point of the sensor must be below

the existing humidity level in the room. It takes some amount of time for the unit to stop when the moisture is

removed or decreased and it also takes some amount of time for the unit to come on when the moisture is

increased. This prevents short cycling of the motor or its coming on and off too fast.

The automatic mode can be bypassed by simply switching the unit off and back on again through its wall switch.

This will allow immediate operation of the unit for the pre-set amount of time on the timer. the timer is preset for

about 15 minutes from factory with an adjustment range of 18 seconds minimum to a maximum of thirty minutes.

To adjust the humidity and time settings follow the steps below:

–Disconnect power and remove the grille

–Refer to Figure 11 for location and orientation of components

–Timer knob can be adjusted with your fingers. Turn clockwise to increase pre-set time delay. Full clockwise position

will set it to thirty minutes. Full counter clockwise position will set it to 18 seconds minimum.

–The humidity sensor can also be adjusted with your fingers. Turn shaft to full clockwise position to start at minimum

(contacts close) and turn counterclockwise to increase set-point level. If you are turning the shaft counterclockwise

and you hear a click from the sensor switch, this means you are going higher than the existing relative humidity in

the room and the contact has opened.

–Replace the grille and turn the unit on to check its operation.

FIG. 10

FIG. 11

1”

11”

15

HUMIDITY

SENSOR

SHAFT

TIMER KNOB

Page 8

ACCESSORIES

MODEL DESCRIPTION

1011A One Hour Timer

1117A Wall cap with damper. Adaptable for 3” or 4” round duct.

AD1106 Roof Cap with damper. Will fit duct up to 7” round.

SPECIFICATIONS:

MODEL VOLTS DUCT CFM H.V.I. Certification (Sq. Ft.)

SIZE RA TING BATH KITCHEN OTHER

761 120 4” 70 65 N/A 85

763/768IC 120 4” 90 85 N/A 1 15

8090/8090L

765/770IC 120 4” 1 10 105 N/A 135

7100/7100L 120 4” 100 95 N/A 125

7100H/7100FLH

7100FL/8100

8100L

7130 120 4” 130 120 N/A 165

7150/7150L 120 4” 150 140 N/A 190

7150H/7150FLH,

7150FL

Part No. 5200-2500-003 ECR 35922

10/03

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

HOW TO OBTAIN WARRANTY SERVICE AND

WARRANTY PARTS PLUS GENERAL INFORMATION

1. Warranty Service or Parts 1-800-642-4328

2. Purchase Replacement Parts 1-800-654-3545

3. General Product Information www.marleymep.com

Note: When obtaining service always have the following:

1. Model number of the product

2. Date of manufacture

3. Part number or description

Page 9

LEA Y GUARDE ESTAS INSTRUCCIONES

VENTILADORES MODELOS

761, 763, 765, 7100, 7130, 7150, 8090 Y 8100

VENTILADORES MODELOS CON LUZ

768IC, 770IC, 7100L, 7150L, 7100FL, 7150FL, 8090L Y 8100L

VENTILADORES Y VENTILADORES CON LUZ CON SENSOR

DE HUMEDAD MODELOS 7100H, 7100FLH, 7150H Y 7150FLH

DESCRIPCION

Los modelos de VENTILADORES y VENTILADORES CON LUZ

incluídos en estas instrucciones están destinados a su empleo en

baños. Sin embargo, pueden usarse también en otras áreas en las

que se necesite ventilación. Estas unidades están aprobadas para su

instalación en el cielorraso sobre una bañera o compartimiento de

ducha, únicamente si están conectadas a un circuito de derivación

protegido por un Interruptor Diferencial / Interruptor de Falla a Tierra

(GFCI) inscripto en las listas de Underwriters Laboratories de los E. U.

de A. (U.L. listed). TODOS LOS MODELOS DE VENTILADORES

CON LUZ están inscriptos en las listas de Underwriters Laboratories

de los E. U. de A. (U.L. listed) como Tipo I. C. (Intrínsecamente

Protegidos) para su instalación en cielorrasos aislados.

DESEMBALAJE

Tenga cuidado en el desembalaje. Si hubiera componentes faltantes

o daños ocultos, comuníquese inmediatamente con su distribuidor o

con la empresa de transporte para tratar sobre estas discrepancias.

INSTRUCCIONES IMPORTANTES DE SEGURIDAD

ADVERTENCIA:

PARA REDUCIR EL PELIGRO DE INCENDIO,

CHOQUE ELECTRICO O DAÑO A LAS PERSONAS,

OBSERVE LO SIGUIENTE:

1. No use este ventilador con ningún dispositivo de Estado Sólido

(electrónico) para control de velocidad.

2. Use esta unidad exclusivamente en la forma prevista por el fabricante. Si tiene preguntas que hacer, comuníquese con el fabricante.

3. Antes de proceder a reparar o limpiar la unidad, corte la energía

eléctrica en el panel de servicio, y bloquee el panel para impedir

que pueda conectarse la energía eléctrica accidentalmente.

4. Los trabajos de instalación y de cableado eléctrico deben ser

realizados por personal calificado, de conformidad con todas las

reglamentaciones y normas aplicables, incluyendo la construcción clasificada como anti-incendio.

5. Para asegurar una adecuada combustión y una completa expulsión de gases a través de la chimenea en los equipos quemadores de combustible -impidiendo así que se produzcan corrientes de retorno- se necesita suficiente aire. Siga las guías del

fabricante del equipo de calefacción y las normas de seguridad

correspondientes, como las publicadas por la Asociación

Nacional de Protección contra Incendio (NFPA) y la Sociedad de

Ingenieros de Calefacción, Refrigeración y Aire Acondicionado

de los E. U. de A. (ASHRAE), y las autoridades locales de

reglamentación.

6. Al realizar cortes o perforaciones en paredes o cielorrasos,

asegúrese de no dañar cableado eléctrico u otras instalaciones

ocultas.

7. Los ventiladores entubados deben tener siempre una salida al

exterior.

8. Para instalar esta unidad sobre una bañera o ducha, debe estar

debidamente marcada como apropiada para esa aplicación.

Vea la etiqueta del producto.

9. NUNCAinstale un interruptor eléctrico de modo que se lo

pueda alcanzar desde una bañera o ducha.

10. ATENCION: ¡Sólo para usos normales en ventilación!

No lo use para expulsar materiales o vapores peligrosos o

explosivos.

11. No lo use en cocinas.

HERRAMIENT AS

La instalación de su ventilador Marley Engineered Products es fácil.

No se necesitan conocimientos técnicos especiales; sólo se requieren

unas pocas herramientas comunes:

Destornillador

Martillo

Sierra eléctrica portátil, Sierra de calador, o Sierra de vaivén

Taladro eléctrico con broca

Alicate (Pinza de cortar cable)

Pinza pelacables

Cable, tornillería y suministros eléctricos de uso general

Anteojos de seguridad

Regla y regla de trazar

Todas las herramientas manuales deben estar eléctricamente aisladas. Las herramientas eléctricas deben exhibir la Marca de Listado

de Underwriters Laboratories de los E. U. de A. (U.L. Listing Mark).

Page 10

TORNILLOS DE MONTAJE

DEL SOPLADOR

ALETAS DE MONTAJE

DE LA REJILLA

SOPORTE DE

MONTAJE DE LA

REJILLA

SALIDA DE DESCARGA

DE AIRE

SALIDA DE

DESCARGA

DE AIRE

SOPORTES

DE MONTAJE

SOPORTES

DE MONTAJE

CUBIERTADE

LA CAJADE

SALIDA

CUBIERTADE

LA CAJADE

SALIDA

TORNILLOS DE MONTAJE

DEL SOPLADOR

UNIDAD

SOPLADORA

UNIDAD SOPLADORA

CONJUNTO DEL

REFLECTOR

PIEZA ELASTICA

DE LA REJILLA

REJILLA

REJILLA

LENTE

292 MM (11

1

⁄2)

318 MM (12

1

⁄

2)

292 MM (11

1

⁄2)

318 MM (12 1⁄2)

MODELOS:

761, 763 AND 765

FIG. 1

MODELOS:

768IC AND 770IC

FIG. 2

270 MM (10 5⁄8)

191 mm (7

1

⁄2)

244 mm (9

5

⁄8)

TORNILLO DE

MONTAJE DEL

REFLECTOR

270 MM (10

5

⁄8)

124 mm

(4

7

⁄8)

244 MM (9

5

⁄8

)

Page 11

INSTALACION EN UNA CASA NUEVA

MODELOS 761, 763, 765, 768IC, Y 770IC

NOTA: Si se desea, antes de comenzar con el Paso 1 puede

retirarse del bastidor metálico el conjunto de la hélice plástica y el motor.

Simplemente, afloje los cuatro tornillos de montaje que sujetan la hélice

al bastidor, y deslícela hacia la caja de salida. Levante e incline cuidadosamente el conjunto de hélice, motor y rueda, y retírelo del bastidor.

(Vea las Figuras 1 y 2).

1. Desconecte el conector macho del conector hembra del motor.

Retire del bastidor la cubierta de la caja de salida y un prepunzonado adecuado.

2. Si el adaptador para conducto ya está fijado, no tenga en cuenta esta

nota. Fije el adaptador para conducto al bastidor, sujetando primero

la brida de montaje sobre el borde de la abertura de descarga de

aire. Haga girar el adaptador para conducto, asegurando que las dos

(2) aletas de alineación estén dentro de la abertura, y alinee las dos

(2) aletas de traba con los agujeros rectangulares pequeños. Para

trabar, presione firmemente hacia dentro de los agujeros. Vea la

Figura 3. Retire la cinta que sujeta la compuerta reguladora.

NOTA: La fijación del adaptador para conducto al bastidor puede

reforzarse, si se lo desea, instalando un tornillo Nº 8AB que pase por

el agujero oblongo del adaptador para conducto y por el pequeño

agujero redondo del bastidor.

3. Inserte los soportes de montaje con el ángulo apuntando hacia el

lado opuesto al bastidor. Posicione el bastidor en su ubicación en el

cielorraso. El bastidor está marcado con una línea a 9,5 mm (3/8”)

para pared seca, y a 19 mm (3/4”) para placas de yeso y yeso estándar. Sujételo firmemente a través de los agujeros de montaje provistos en el bastidor. (Figura 4). Tire de los soportes de montaje contra

la vigueta adyacente del cielorraso, y sujételos firmemente. (Figura

5).

4. Encamine los cables de 120 Volt CA, 60 Hz, desde el (los) interruptor(es) de pared hasta un prepunzonado adecuado del bastidor. Use

un conector BX o Romex. (Tome como referencia el diagrama de

conexionado indicado para el modelo que esté instalando). Conecte

los cables del (de los) interruptor(es) de pared a los cables del conector hembra, mediante conectores de cable aprobados. Conecte el

cable de tierra al tornillo o terminal verde de la caja de salida. Instale

la cubierta de la caja de salida, y sujétela por medio del tornillo provisto.

5. Tienda un conducto redondo de 10 cm (4”) de diámetro desde la salida de descarga de aire del ventilador hasta el casquete de pared o

de techo. Vea las Figuras 6 y 7.

IMPORTANTE:Asegúrese de que nada obstruya la descarga del ventilador. Tome precauciones para asegurar que la aislación no penetre en

el conducto o en la abertura de descarga del ventilador, y la valvula de

aire abre y cierra libremente.

6. En caso de que la unidad haya sido desmontada para su instalación,

vuelva a colocar cuidadosamente el conjunto de hélice plástica,

motor y rueda. Invierta el procedimiento indicado anteriormente.

Apriete los tornillos firmemente, y conecte el conector macho al

conector hembra del motor.

7. (SOLO PARAMODELOS 761, 763 Y 765)

Comprima las piezas elásticas de la rejilla, e insértelas en las aletas

ubicadas en el bastidor. Vea la Fig. 1. Presione firmemente la rejilla

hasta colocarla en su lugar.

8. (SOLO PARAMODELOS 768IC Y 770IC)

Centre el reflector en el centro de la rejilla. Conecte el conector

macho de la luz en su conector hembra. Centre el conjunto reflector/rejilla sobre el bastidor, e inserte el perno de montaje de 1”, pasando a través del agujero central del reflector, en el soporte metálico de

montaje ubicado en el conjunto de la hélice plástica y el motor.

Apriete el perno hasta que la rejilla quede firmemente atraída contra

el cielorraso. Vea la Figura 2.

9. Instale la lámpara. (Tipo A-19, máximo 100 watt).

10. Instale la lente de montaje rápido, insertando sus aletas dentro de las ranuras de la rejilla.

FIG. 3

FIG. 4

FIG. 5

ALETAS DE

TRABA

BRIDA DE

MONTAJE

ADAPTADOR PARA CONDUCTO

ALINEACION

Page 12

FIG. 6

FIG. 7

¡ATENCION!

ASEGURESE DE QUE TODO EL CONEXIONADO CUMPLA CON LAS REGLAMENTA-

CIONES ELECTRICAS LOCALES Y NACIONALES,

Y QUE EL BASTIDOR ESTE PUESTO A TIERRA ADECUADAMENTE.

CASQUETE DE TECHO

CASQUETE

DE PARED

CONDUCTO REDONDO

DE 10 CM (4”) DE

DIAMETRO

CONDUCTO REDONDO

DE 10 CM (4”) DE

DIAMETRO

TECHO

CAJA DE SALIDA

CONECTOR HEMBRA

DIAGRAMA DE CONEXIONADO

MODELOS 768IC, 770IC

LUZ

VERDE

BLANCO

BLANCO

BLANCO

VERDE

NEGRO

DIAGRAMA DE CONEXIONADO

MODELOS 7100H, 7150H

SENSOR

TEMPORIZADOR

SENSOR

NEGRO

BLANCO

BLANCO

BLANCO

DIAGRAMA DE CONEXIONADO

MODELOS 7100L, 7150L,

7100FL, 7150FL, 8090L Y 8100L

LUZ

LUZ NOCTURNA

BLUE

BROWN

BLANCO

BLANCO

BLANCO

BLANCO

NEGRO

DIAGRAMA DE CONEXIONADO

MODELOS 7100FLH, 7150FLH

LUZ

BALASTO

BALASTO

LUZ

LUZ NOCTURNA

BLU

BLU

MARRON

VENTILADOR

NEGRO

BLANCO

TORNILLO DE PUESTA A TIERRA

TIERRA

BLANCO

NEGRO

NEGRO

DIAGRAMA DE CONEXIONADO

MODELOS 761, 763, 765

7100, 7130, 7150, 8090

Y 8100

INTERR.

DE PARED

INTERR.

DE PARED

INTERR.

DE PARED

INTERR.

DE PARED

INTERR.

DE PARED

INTERR.

DE PARED

ALIMENTACION

ELECTRICA,

120 VOLT CA, 60 Hz

CAJA DE SALIDA

RECEPTACLE

VENTILADOR

TORNILLO DE PUESTA A TIERRA

TIERRA

BLANCO

NEGRO

NEGRO

NEGRO

ALIMENTACION ELECTRICA,

120 VOLT CA, 60 Hz

CAJA DE SALIDA

RECEPTACLE

VENTILADOR

TORNILLO DE PUESTA A TIERRA

TIERRA

BLANCO

NEGRO

NEGRO

NEGRO

NEGRO

ALIMENTACION ELECTRICA,

120 VOLT CA, 60 Hz

INTERR.

DE PARED

INTERR.

DE PARED

INTERR.

DE PARED

INTERR.

DE PARED

CAJA DE SALIDA

VENTILADOR

TEMPORIZADOR

TORNILLO DE PUESTA A TIERRA

TIERRA

BLANCO

NEGRO

NEGRO

ALIMENTACION

ELECTRICA,

120 VOLT CA, 60 Hz

CAJA DE SALIDA

CONECTOR HEMBRA

VENTILADOR

TORNILLO DE PUESTA A TIERRA

TIERRA

BLANCO

NEGRO

NEGRO

NEGRO

NEGRO

ALIMENTACION

ELECTRICA,

120 VOLT CA, 60 Hz

NEGRO

BLANCO

NEGRO

BLANCO

Page 13

INSTALACION EN CASAS EXISTENTES

(MODELOS: 761, 763, 765, 768IC, Y 770IC)

1. Vea la sección: “Instalación en una casa nueva”, y siga las instrucciones que sean aplicables.

2. Tome como referencia para el conexionado los diagramas de conexionado, y para el sistema de conductos las Figuras 6 y 7.

3. Determine la ubicación del ventilador, recordando que el bastidor debe instalarse cerca de una vigueta.

4. Perfore un pequeño agujero en el cielorraso en la ubicación propuesta, y luego localice este agujero en el ático.

5. En el ático, posicione el bastidor contra la vigueta del cielorraso y sobre el agujero que perforó antes. Usando el bastidor como plantilla, marque el cielorraso para el recorte. Haga el recorte en esta línea.

6. El resto de la instalación es igual a lo indicado antes en “Instalación en una casa nueva”, pasos 1 al 10. Las grietas entre el bastidor y

el cielorraso pueden rellenarse con yeso o calafatearse.

INSTALACION EN UNA CASA NUEVA

(MODELOS: 7100, 7130, 7150, 8090, 8100, 7100L,

7150L, 7100H, 7100FLH, 7150H, 7150FLH, 7100FL, 7150FL, 8090L Y 8100L)

1. Retire el conjunto de rejilla de la caja, y déjelo preparado para cuando lo necesite. Retire el conjunto del reflector de la unidad soplado-

ra (MODELOS: 7100L, 7100FLH, 7150FLH, 7150L, 7100FL, 7150FL, 8090LY8100L) separando el conector macho del conector hembra, aflojando los tornillos de montaje y quitándolos a través de la ranura tipo bocallave. Desconecte el conector macho del temporizador

del conector hembra, si fuera el caso. Vea la Figura 9.

2. Afloje los tres tornillos que sujetan la unidad sopladora al bastidor , y deslícela hacia la caja de salida. Levante e incline cuidadosamente

la unidad sopladora, y retírela del bastidor. Desconecte el conector macho del motor del conector hembra. Desconecte el conector

macho del sensor de humedad del conector hembra, si fuera el caso. Vea las Figuras 8 y 9.

3.. Retire la cubierta de la caja de salida quitando el tornillo de montaje. Conserve la cubierta y el tornillo para su reinstalación. Retire un

prepunzonado adecuado del bastidor.

4. Si el ADAPTADOR PARA CONDUCTO ya está fijado al bastidor, no tenga en cuenta el paso Nº 4. Si no lo está, proceda como sigue:

Fije el ADAPTADOR PARA CONDUCTO al bastidor, sujetando primero la brida de montaje sobre el borde de la abertura de descarga

de aire. Haga girar el adaptador para conducto, asegurando que las dos (2) aletas de alineación estén dentro de la abertura, y alinee

las dos (2) aletas de traba con los agujeros rectangulares pequeños. Para trabar, presione las aletas firmemente hacia dentro de los

agujeros. Vea la Figura 3. Retire la cinta que sujeta la compuerta reguladora.

NOTA: La fijación del adaptador para conducto al bastidor puede reforzarse, si se lo desea, instalando un tornillo Nº 8AB

que pase por el agujero oblongo del adaptador para conducto y por el pequeño agujero redondo del bastidor.

5. Inserte los cuatro (4) soportes de montaje con sus ángulos apuntando hacia el lado opuesto al bastidor . En un lugar ubicado entre vigue-

tas, cercano a aquél donde va a colocarse el bastidor, clave dos (2) clavos (4D o 6D) a 25 mm (1”) del fondo de la vigueta, y separados 280 mm (11”) entre sí, dejándolos sobresalir 6 mm (1/4”). Posicione un juego de soportes de montaje sobre los clavos, y déj elo caer

en su lugar. Extienda los soportes de montaje restantes hasta la vigueta adyacente, y repita el procedimiento de clavado. Después que

termine de clavar los clavos, ajuste el bastidor entre las viguetas del cielorraso. Vea la Figura 10.

6. Encamine los cables de la alimentación eléctrica de 120 Volt CA, 60 Hz, desde el (los) interruptor(es) de pared hasta un prepunzana-

do adecuado del bastidor. Use un conector BX o Romex. (Tome como referencia el diagrama de conexionado indicado para el modelo que esté instalando). Conecte los cables del (de los) interruptor(es) de pared a los cables del conector hembra, mediante conectores

de cable aprobados. Conecte el cable de tierra al tornillo o terminal verde de la caja de salida. Instale la cubierta de la caja de salida, y

sujétela por medio del tornillo provisto.

7. Tienda un conducto redondo de 10 cm (4") de diámetro desde la salida de descarga hasta casquete de techo o de pared.

Vea las Figuras 6 y 7.

IMPORTANTE: Asegúrese de que nada obstruya la descarga de ventilación. Tome precauciones para asegurar que la aislación no penetre en el sistema de conductos o en la abertura de descarga del ventilador, y que la compuerta reguladora

abra y cierre libremente.

8. Conecte el conector macho del sensor de humedad en el conector hembra, si fuera el caso. Conecte el conector macho del motor del

soplador en el conector hembra, y vuelva a colocar cuidadosamente la unidad sopladora. Invierta el procedimiento indicado anteriormente. Apriete los tornillos firmemente. Vea las Figuras 8 y 9.

9. Conecte el conector macho del temporizador en el conector hembra del sensor de humedad, si fuera el caso. Inserte el conector macho

del conjunto del reflector en el conector hembra de la lámpara, en la caja de salida. Alinee la ranura tipo bocallave, ubicada en el soporte

del conjunto del reflector, con el tornillo de la unidad sopladora, y deslícelo en su posición. Asegúrese de que la saliente del soporte

esté alineada con el agujero del conjunto del soplador, y apriete el tornillo. Instale una lámpara tipo A-19, de 100 watt como máximo, y

una lámpara C-7 de 7 1/2 watt, con base tipo candelero. (MODELOS: 7100L, 7150L, 8090L y 8100L únicamente). En los modelos fluorescentes 7100FL, 7150FL, 7100FLH y 7150FLH, instale dos lámparas fluorescentes compactas de tubo cuádruple (‘quad-tube’) de

13 watt, de dos terminales (‘2-pin’), de alguno de los tipos siguientes:

Osram/Sylvania Panasonic Philips General Electric

CF13DD/841 FQ13E41.u/2 PL-C13W/41/USA F13DBX23T4/SPX41

10. Comprima las piezas elásticas de la rejilla plástica, e insértelas en las aletas ubicadas en el bastidor. Vea las Figuras 8 y 9.

Presione firmemente la rejilla hasta colocarla en su lugar.

Page 14

SALIDA DE DESCARGA

DE AIRE

CUBIERTA

DE LA CAJADE

SALIDA

ALETAS DE MONTAJE

DE LA REJILLA

UNIDAD

SOPLADORA

REJILLA

318 MM (12 1/2”)

284 MM

(11 3/16”)

194 MM (7 5/8”)

254 MM (10”)

292 MM (11 1/2”)

PIEZA ELASTICA

DE LA REJILLA

TORNILLOS DE

MONTAJE DEL

SOPLADOR

CONECTORES

DE CABLE

SENSOR DE

HUMEDAD

MODELOS:

7100, 7130, 7150,

7100H, 7150H,

8090 Y 8100

CUBIERTA

DE LA CAJADE

SALIDA

ALETAS DE MONTAJE DE

LA REJILLA

UNIDAD

SOPLADORA

REJILLA

318 MM (12 1/2”)

318 MM (12 1/2”)

284 MM

(11 3/16”)

194 MM (7 5/8”)

254 MM (10”)

PIEZA ELASTICA

DE LA REJILLA

TORNILLOS DE MONTA-

JE DEL SOPLADOR

TORNILLO DE

MONTAJE DEL

REFLECTOR

CONJUNTO DEL

REFLECTOR

MODELOS:

7100L, 7150L, 7100FLH,

7150FLH, 7100FL, 7150FL,

8090L Y 8100L

FIG. 8

FIG. 9

SOPORTES DE

MONTAJE

SOPORTES

DE MONTAJE

CONECTOR DE

CABLE

(MACHO)

CONECTOR

DE CABLE

(MACHO)

TEMPORIZADOR

TEMPORIZADOR

SENSOR DE

HUMEDAD

SALIDA DE DESCARGA

DE AIRE

CONECTORES

DE CABLE

Page 15

INSTALACION EN CASAS EXISTENTES

(MODELOS: 7100, 7130, 7150, 8090, 8100, 7100L, 7150L,

7100H, 7100FLH, 7150H, 7150FLH, 7100FL, 7150FL, 8090L Y 8100L)

1. Lea cuidadosamente todas las instrucciones de instalación anteriores, y siga aquéllas que sean aplicables a su instalación,

incluyendo todo lo referente a conductos y conexionado. (Figs. 6 y 7).

2. Perfore un pequeño agujero en el cielorraso, desde abajo, en la ubicación propuesta, y luego localice este agujero en el ático

(o entrepiso).

3. En el ático, marque el recorte en el cielorraso usando el bastidor como plantilla. Usando esta línea, marque el recorte alrede-

dor de 6 mm (1/4”) mayor.

4. Coloque el bastidor, con los soportes de montaje instalados, en el agujero, y apoye los soportes de montaje en la placa de

yeso. Extienda y clave los cuatro extremos de los soportes de montaje.

5. Lleve a cabo los pasos 1 a 10, del mismo modo que para una construcción nueva.

REQUISITOS YAJUSTES (SOLO PARAUNIDADES CON SENSORES DE HUMEDAD)

La unidad debe montarse en un cielorraso de superficie plana, de una altura no mayor a 3,60 m (12 pies), y lejos de toda fuente

directa de calor, tal como un calefactor de ambiente o de sauna.

Nota: Las ventanas abiertas pueden afectar el nivel de humedad de la habitación, y hacer que la unidad no funcione correctamente..

Una vez seleccionada la ubicación, vea cómo determinar el tamaño adecuado de los agujeros para el montaje de la unidad, consultando las figuras anteriores.

La unidad es accionada por medio de un interruptor de pared. Cada vez que el interruptor se encienda, la unidad funcionará hasta

que se cumpla el tiempo predeterminado en el temporizador. Después de que este tiempo haya transcurrido, la unidad quedará funcionando en modo automático. En este punto, la operación de la unidad dependerá del nivel de humedad de la habitación. Cuando el nivel

de humedad de la habitación esté por arriba del valor prefijado que se seleccionó en el sensor de humedad, la unidad entrará en funcionamiento. El funcionamiento se mantendrá hasta que el nivel de humedad de la habitación caiga por debajo del valor prefijado. Para

que la unidad entre en funcionamiento cuando se encuentra en modo automático, el valor prefijado del sensor debe ser menor que el

nivel de humedad existente en la habitación. La detención de la unidad cuando la humedad desaparezca o disminuya lleva cierto tiempo,

así como también lleva cierto tiempo que la unidad entre en funcionamiento cuando la humedad aumente.Esto impide que el motor se

vea sometido a múltiples ciclos cortos, o que arranque o se detenga demasiado rápido.

El modo automático puede abandonarse en cualquier momento, apagando simplemente la unidad por medio del interruptor de

pared, y volviendo al encenderla. Esto habilitará inmediatamente el funcionamiento de la unidad durante el tiempo prefijado en el temporizador. El temporizador está preajustado en fábrica para un tiempo de alrededor de 15 minutos, con una gama de ajuste que va desde

un mínimo de 18 segundos hasta un máximo de 30 minutos.

Para ajustar los valores preajustados de humedad y de tiempo, siga los pasos que se indican a continuación:

–Desconecte la alimentación eléctrica, y retire la rejilla

–Vea la ubicación y orientación de componentes en la Figura 11

–La perilla del temporizador puede ajustarse con los dedos. Para aumentar el valor prefijado de retardo de tiempo, hágala girar en sentido

horario. La posición extrema a la que se llega girando en sentido horario corresponde a 30 minutos. La posición extrema a la que se

llega girando en sentido antihorario corresponde al mínimo de 18 segundos.

–El sensor de humedad puede ajustarse también con los dedos. Lleve el eje al máximo en sentido horario, para comenzar al mínimo

(contactos cerrados), y vaya girando en sentido antihorario para aumentar el valor preajustado del nivel de humedad. Si usted está

haciendo girar el eje en sentido antihorario, y oye un ‘clic’ proveniente del interruptor del sensor, esto significa que ha llegado a un nivel

mayor que la humedad relativa existente en la habitación, y que el contacto se ha abierto.

–Vuelva a colocar la rejilla, y encienda la unidad para verificar su funcionamiento.

FIG. 10

FIG. 11

25 mm (1”)

279 mm (11”)

15

EJE DEL

SENSOR DE

HUMEDAD

PERILLA DEL

TEMPORIZADOR

Page 16

ACCESORIOS

MODELO DESCRIPCION

1011A Temporizador de una hora

1117A Casquete para pared, con compuerta reguladora. Adaptable para

conductos redondos de 7,5 cm (3”) o 10 cm (4”) de diámetro.

AD1106 Casquete para techo, con compuerta reguladora. Se adapta a con-

ductos redondos de hasta 18 cm (7”).

ESPECIFICACIONES:

MODELO TENSION CERTIFICACIÓN H. V. I. (PIES CUADRADOS)

(VOLT) BAÑO COCINA OTROS

761 120 4” 70 65 N/A 85

763/768IC 120 4” 90 85 N/A 115

8090/8090L

765/770IC 120 4” 110 105 N/A 135

7100/7100L 120 4” 100 95 N/A 125

7100H/7100FLH

7100FL/8100

8100L

7130 120 4” 130 120 N/A 165

7150/7150L 120 4” 150 140 N/A 190

7150H/7150FLH,

7150FL

Número de parte 5200-2500-003 ECR 35922

10/03

470 Beauty Spot Rd. East

Bennettsville, SC 29512

Estados Unidos de América

DIAMETRO DEL

CONDUCTO

(PULGADAS)

CAUDAL

(PIES CUBICOS

POR MINUTO)

NOTAS:

1. H.V.I.: INSTITUTO DE VENTILACION DEL HOGAR (E. U. DE A.)

2. N/A: NO APLICABLE

COMO OBTENER SERVICIO Y PIEZAS BAJO GARANTIA MAS

INFORMACION GENERAL

1. Servicio o piezas bajo garantía 1-800-642-4328

2. Compra de piezas de repuesto 1-800-654-3545

3. Información general del producto www.marleymep.com

Nota: Cuando se solicite servicio tener siempre a mano lo siguiente:

1. Número de modelo del producto

2. Fecha de fabricación

3. Número de pieza o descripción

Page 17

LIRE ET CONSERVER CES INSTRUCTIONS

MODÈLES 761, 763, 765, 7100, 7130, 7150, 8090 ET 8100 DE VENTI-

LA TEURS

MODÈLES 7681C, 7701C, 7100L, 7150L, 7100FL, 7150FL, 8090L ET

8100L DE VENTILATEURS/ÉCLAIRAGES

MODÈLES 7100H, 7100FLH, 7150H ET 7150FLH DE VENTILA TEURS

ET VENTILA TEURS/ÉCLAIRAGES AVEC DÉTECTEUR D’HUMIDITÉ

DESCRIPTION

Les modèles de VENTILATEUR et VENTILATEUR/ÉCLAIRAGE

listés dans ces instructions sont prévus pour une utilisation dans des

salles de bains. Cependant ils peuvent aussi être utilisés dans d’autres

pièces où une ventilation est nécessaire. Ces unités sont approuvées

pour une installation dans le plafond au dessus d’une baignoire et cabine de douches uniquement s’ils sont branchés sur un circuit électrique protégé par un disjoncteur différentiel approuvé ULet listé GFCI.

Tous les modèles de VENTILA TEUR/ÉCLAIRAGE sont listés ULtype

IC (protection intrinsèque) pour une installation dans des plafonds

isothermes.

DÉBALLAGE

Déballez l’appareil soigneusement. S’il et a des composants manquants ou des dommages cachés, contactez immédiatement votre

concessionnaire ou le transporteur au sujet de ces découvertes.

INSTRUCTIONS DE SÉCURITÉ IMPORTANTES

AVERTISSEMENT

POUR RÉDUIRE LE RISQUE D’INCENDIE,

DE COMMOTION ÉLECTRIQUE OU DE BLESSURES COR-

PORELLES, SUIVEZ CES CONSIGNES :

1. N’utilisez pas ce ventilateur avec n’importe quel dispositif de

réglage de vitesse à semi-conducteurs.

2. N’utilisez cet appareillage que de la manière prévue par son fabricant. Si vous avez des questions contactez-le.

3. Avant d’intervenir sur cet appareillage ou de le nettoyer, coupez

l’arrivée d’alimentation au panneau distribution électrique et bloquez-la pour éviter que le secteur ne soit remis accidentellement.

4. Le travail d’installation et le câblage électrique doivent être effectués par une ou des personnes qualifiées en conformité avec

toutes les réglementations et normes applicables, et compris

celles pour la résistance au feu des constructions.

5. Il faut suffisamment d’air pour la bonne combustion et l’évacuation des gaz par la cheminée des équipements brûlant du mazout

pour éviter les problèmes de tirage. Suivez les instructions du fabricant de l’équipement de chauffage et les standards de sécurité

tels que ceux publiés par la NFPA(association nationale de protection contre l’incendie) et la ASHRAE (société des ingénieurs

américains en chauffage et climatisation), et par les autorités

locales.

6. Quand vous coupez ou percez dans une cloison ou un plafond,

n’endommagez pas le câblage électrique ou des conduites

cachées.

7. Les ventilateurs carénés doivent toujours mis à l’air libre vers

l’extérieur.

8. Si l’appareil est à monter au-dessus d’une douche ou d’une

baignoire, il doit être spécifié comme approprié pour cette application et alimenté par un circuit secteur muni d’un disjoncteur

différentiel. Consultez l’étiquette signalétique de l’appareil.

9. Ne placez JAMAIS un interrupteur qui puisse être atteint à partir

de la baignoire ou de la douche.

10. ATTENTION : Pour la ventilation générale seulement ! Ne

pas utiliser l’appareil pour évacuer des matières ou vapeurs

dangereuses ou explosives.

11. À ne pas utiliser pour des cuisines.

OUTILS

L’installation de votre ventilateur de Marley Engineered Products est

facile. Il n’et a pas besoin de connaissances particulières, il suffit de

juste quelques outils :

Tournevis

Marteau

Scie sauteuse ou à guichet

Perceuse électrique et foret

Pince coupante

Pince à dénuder

Serre-fils et accessoires électriques

Lunettes de sécurité

Règle

Tout l’outillage à main doit être isolé. Les outils électriques doivent

comporter le label UL.

Page 18

VIS DE MONTAGE DE

VENTILATEUR

TAQUETS DE

MONTAGE DE

GRILLE

SUPPORT DE

MONTAGE DE

GRILLE

BOUCHE

D’ÉVACUATION D’AIR

BOUCHE

D’ÉVACUATION

D’AIR

SUPPORTS

DE MONTAGE

SUPPORTS DE

MONTAGE

COUVERCLE

DE BOÎTIER

ÉLECTRIQUE

COUVERCLE

DE BOÎTIER

ÉLECTRIQUE

VIS DE MONTAGE DE

VENTILATEUR

UNITÉ DE VENTILATEUR

VENTILATEUR

ENSEMBLE DE

RÉFLECTEUR

RESSORT DE

GRILLE

GRILLE

GRILLE

VERRE DIFFUSEUR

292 MM (11

1

⁄2)

318 MM (12

1

⁄

2)

292 MM (11

1

⁄2)

318 MM (12 1⁄2)

MODÈLES :

761, 763 ET 765

SCHÉMA 1

MODÈLES :

768IC ET 770IC

SCHÉMA 2

270 MM (10 5⁄8)

191 mm (7

1

⁄2)

244 mm (9

5

⁄8)

BOULON DE

MONTAGE DE

RÉFLECTEUR

270 MM (10

5

⁄8)

124 mm

(4

7

⁄8)

244 MM (9

5

⁄8

)

Page 19

NOUVELLE INSTALLA TION DOMESTIQUE

MODÈLES 761, 763, 765, 768IC, ET 770IC

REMARQUE : L’ensemble d’enveloppe plastique et moteur peut

être enlevé du châssis métallique avant l’étape 1 si on le souhaite.

Desserrez simplement quatre vis de montage fixant l’enveloppe sur le

châssis et faites-la glisser vers la boîte électrique. Levez avec précautions et faites pivoter l’ensemble enveloppe, moteur et roue, pour les

enlever du châssis (voir les Schémas 1 et 2).

1. Tirez la fiche du moteur de la prise. Enlevez le couvercle du boîtier

électrique et dégagez le trou enfonçable voulu dans le châssis.

2. Si l’adaptateur de conduit est déjà attaché, ne tenez pas compte de

ce passage. Fixez l’adaptateur de conduite au châssis en

accrochant d’abord la cornière de montage sur le bord de l’ouverture de l’évacuation d’air. Faites pivoter l’adaptateur de conduite en

vous assurant que les deux taquets d’alignement dont à l’intérieur

de l’ouverture et alignez-les avec les petites fentes rectangulaires.

Appuyez fermement dans ces fentes pour verrouiller (voir le

Schéma 3). Enlevez la bande qui retient le clapet.

REMARQUE : La fixation de l’adaptateur de conduite sur le châssis

peut être renforcée si on le souhaite, en installant une vis calibre 8AB

dans le trou ovalisé de l’adaptateur de conduite et le petit trou rond

du châssis.

3. Insérez les équerres de montage avec l’angle pointant en dehors du

châssis. Positionnez le châssis dans le logement du plafond. Le

châssis est repéré pour montrer une ligne à 9,5 mm (3/8") pour de la

cloison sèche et à 19,0 mm (3/4") pour du placoplâtre. Fixez

soigneusement au travers des trous de montage fournis dans le

châssis (voir le Schéma 4). Tirez les équerres de montage contre la

solive adjacente du plafond et fixez solidement (voir Schéma 5).

4. 4. Tirez le câble d’alimentation en 120 V CA / 60 Hz depuis l’interrupteur mural jusqu’au trou défoncé approprié dans le châssis.

Utilisez un connecteur BX ou Romex (reportez-vous au schéma de

câblage correspondant au modèle que vous installez).Reliez les fils

venant de l’interrupteur mural à ceux de la prise en utilisant des serrefils approuvés. Branchez le fil de terre sur la vis verte ou sur le fil de

terre dans la boîte électrique. Remettez en place le couvercle de

boîte électrique et fixez-le avec la vis fournie.

5. Mettez en place une conduite ronde de 10 cm de diamètre (4")

depuis la bouche d’évacuation d’air jusqu'au chapeau de mur ou toit

(voir les Schémas 6 et 7).

IMPORTANT: Vérifiez bien que rien n’obstrue l’évacuation du

ventilateur. Prenez des précautions pour assurer que l’isolation n’entre pas dans les conduites ou la bouche d’évacuation du ventilateur,

et que le clapet ouvre et ferme librement.

6. Remettez en place soigneusement l’ensemble enveloppe plastique,

moteur et roue, si l’unité avait été démontée pour l’installation.

Procédez de la manière inverse au démontage. Serrez bien les vis et

enfoncez la prise du moteur dans sa prise.

7. (MODÈLES 761, 763 ET 765 UNIQUEMENT)

Pressez les ressorts sur la grille et insérez-la dans les taquets du

châssis (voir le Schéma 1). Enfoncez bien la grille en place.

8. (MODÈLES 7681C ET 7701C UNIQUEMENT)

Centrez le réflecteur au milieu de la grille. Enfoncez la fiche d’éclairage dans sa prise. Centrez l’ensemble réflecteur/grille sur le

châssis et engagez le boulon de montage de 2,5 cm (1") au travers

du trou central du réflecteur dans le support métallique de montage

situé sur l’ensemble d’enveloppe plastique et moteur. Serrez ce

boulon jusqu’à ce que la grille soit fermement tirée contre le plafond

(voir le Schéma 2).

9. Installez l’ampoule (type A-19, 100 watts maximum).

10. Installez le verre rentrant en engageant ses taquets dans les

fentes de la grille.

SCHÉMA 3

SCHÉMA 4

SCHÉMA 5

TAQUETS

DE VERROUILLAGE

CORNIÈRE DE

MONTAGE

ADAPTATEUR DE CONDUITE

ALIGNEMENT

Page 20

SCHÉMA 6

SCHÉMA 7

ATTENTION !

VÉRIFIEZ BIEN QUE TOUT LE CÂBLAGE EST EN CONFORMITÉ AVEC LES NORMES

ÉLECTRIQUES LOCALES ET NATIONALES ET QUE LE CHÂSSIS EST MIS À LA TERRE.

CHAPEAU DE TOIT

CHAPEAU

DE MUR

CONDUITE

CYLINDRIQUE

Ø 10 CM

CONDUITE

CYLINDRIQUE

Ø 10 CM

TOIT

BOÎTIER ÉLECTRIQUE

PRISE

SCHÉMA DE CÂBLAGE

MODÈLES 768IC, 770IC

ÉCLAIRAGE

VERT

BLANC

BLANC

BLANC

VERT

NOIR

SCHÉMA DE CÂBLAGE

MODÈLES 7100H, 7150H

DETECTEUR

DETECTEUR

MINUTERIE

NOIR

BLANC

BLANC

BLANC

SCHÉMA DE CÂBLAGE

MODÈLES 7100L, 7150L,

7100FL, 7150FL, 8090L ET

8100L

ÉCLAIRAGE

ECLAIRAGE NOCTURNA

BLEU

MARRON

BLANC

BLANC

BLANC

BLANC

NOIR

SCHÉMA DE CÂBLAGE

MODÈLES 7100FLH, 7150FLH

ÉCLAIRAGE

BALLAST

BALLAST

ÉCLAIRAGE

ECLAIRAGE NOCTURNA

BLEU

BLEU

MARRON

VENTILATEUR

NOIR

BLANC

VIS DE TERRE

TERRE

BLANC

NOIR

NOIR

SCHÉMA DE CÂBLAGE

MODÈLES 761, 763, 765

7100, 7130, 7150, 8090

ET 8100

INTERR.

MURAL

INTERR.

MURAL

INTERR.

MURAL

INTERR.

MURAL

INTERR.

MURAL

INTERR.

MURAL

SECTEUR

120 V CA 60 HZ

BOÎTIER ÉLECTRIQUE

PRISE

VENTILATEUR

VIS DE TERRE

TERRE

BLANC

NOIR

NOIR

NOIR

SECTEUR

120 V CA 60 HZ

BOÎTIER ÉLECTRIQUE

PRISE

VENTILATEUR

VIS DE TERRE

TERRE

BLANC

NOIR

NOIR

NOIR

NOIR

SECTEUR

120 V CA 60 HZ

INTERR.

MURAL

INTERR.

MURAL

INTERR.

MURAL

INTERR.

MURAL

BOÎTIER ÉLECTRIQUE

VENTILATEUR

MINUTERIE

VIS DE TERRE

TERRE

BLANC

NOIR

NOIR

SECTEUR

120 V CA 60 HZ

BOÎTIER ÉLECTRIQUE

PRISE

VENTILATEUR

VIS DE TERRE

TERRE

BLANC

NOIR

NOIR

NOIR

NOIR

SECTEUR

120 V CA 60 HZ

NOIR

BLANC

NOIR

BLANC

Page 21

ANCIENNE INSTALLA TION DOMESTIQUE

(MODÈLES : 761, 763, 765, 768IC, ET 770IC)

1. Passez en revue la section précédente « Nouvelle installation domestique » et suivez les instructions qui sont applicables.

2. Reportez-vous aux Schémas électriques pour le câblage et aux Schémas 6 et 7 pour la pose de conduite.

3. Déterminez l’emplacement pour le ventilateur, en vous souvenant que le châssis doit être installé contre une solive.

4. Percez un petit trou dans le plafond à l’emplacement voulu, puis allez repérer ce trou dans les combles.

5. Dans les combles positionnez le châssis contre la solive de plafond et par dessus le trou percé. En utilisant le contour du châssis comme

guide marquez le dessus du plafond dans les combles pour marquer la découpe. Découpez l’ouverture en suivant ce marquage.

6. La suite de l’installation est la même qu’aux étapes 1 à 10 de la section précédente « Nouvelle installation domestique ». Les intervalles

résiduels entre châssis et plafond peuvent être masqués au plâtre ou à l’enduit.

NOUVELLE INSTALLA TION DOMESTIQUE

(MODÈLES : 7100, 7130, 7150, 8090, 8100, 7100L,

7150L, 7100H, 7100FLH, 7150H, 7150FLH, 7100FL, 7150FL, 8090L ET 8100L)

1. Enlevez l’ensemble de grille du carton et mettez-le de côté jusqu’à ce qu’il soit à placer. Enlevez l’ensemble de déflecteur de l’unité de

ventilation (MODELES 7100L, 7100FLH, 7150FLH, 7150L, 7100FL, 7150FL, 8090L et 8100L) en enlevant la fiche de sa prise, en

desserrant les vis de montage et en l’enlevant par la fente en forme de trou de serrure. S’il y a lieu débranchez la fiche de la minuterie

de sa prise (voir le Schéma 9).

2. Desserrez les trois vis fixant le ventilateur au châssis et faites-le glisser vers la boîte électrique. Levez avec précautions et faites pivot-

er le ventilateur pour le sortir du châssis. Débranchez le moteur de sa prise. S’il y a lieu, débranchez la fiche du détecteur d’humidité de

sa prise (voir les Schémas 8 et 9).

3. Déposez le couvercle du boîtier électrique en enlevant sa vis de fixation. Gardez couvercle et vis pour une remise en place à la fin.

Ouvrez le trou enfonçable voulu dans le châssis.

4. Si l’adaptateur de conduit est déjà attaché, ne tenez pas compte de ce passage. Sinon procédez comme suit. Fixez l’ADAPTATEUR

DE CONDUITE au châssis en accrochant d’abord la cornière de montage sur le bord de l’ouverture de l’évacuation d’air. Faites pivoter l’adaptateur de conduite en vous assurant que les deux taquets d’alignement dont à l’intérieur de l’ouverture et alignez-les avec les

petites fentes rectangulaires. Appuyez fermement dans ces fentes pour verrouiller (voir le Schéma 3). Enlevez la bande qui retient le

clapet.

REMARQUE : La fixation de l’adaptateur de conduite sur le châssis peut être renforcée si on le souhaite, en installant une

vis calibre 8AB dans le trou ovalisé de l’adaptateur de conduite et le petit trou rond du châssis.

5. Insérez quatre équerres de montage avec l’angle pointant en dehors du châssis. Dans l’emplacement approximatif entre solives où le

châssis sera situé, plantez deux clous (4D ou 6D) de 2,5 cm (1") dans le dessous de solive, écartés de 27,94 cm (11") en laissa nt 6 mm

(1/4 ") de clou non enfoncé. Positionnez un jeu d’équerres sur les clous et mettez en place. Étendez les deux autres équerres de montage vers la solive adjacente et recommencez le clouage. Finissez d’enfoncer les clous et ajustez la position du châssis entre les solives

du plafond (voir le Schéma 10).

6. Tirez le câble d’alimentation en 120 V CA/ 60 Hz depuis l’interrupteur mural jusqu’au trou défoncé approprié dans le châssis. Utilisez

un connecteur BX ou Romex (reportez-vous au schéma de câblage correspondant au modèle que vous installez).Reliez les fils venant

de l’interrupteur mural à ceux de la prise en utilisant des serre-fils approuvés. Branchez le fil de terre sur la vis verte ou sur le fil de terre

dans le boîtier électrique. Remettez en place le couvercle de boîtier électrique et fixez-le avec la vis fournie.

7. Mettez en place une conduite ronde de 10 cm de diamètre (4") depuis la bouche d’évacuation d’air jusqu'au chapeau de mur

ou toit (voir les Schémas 6 et 7).

IMPORTANT : Vérifiez bien que rien n’obstrue l’évacuation du ventilateur. Prenez des précautions pour assurer que l’isolation n’entre pas dans les conduites ou la bouche d’évacuation du ventilateur.

8. S’il y a lieu mettez la fiche du détecteur d’humidité dans sa prise. Poussez le moteur de ventilateur dans le réceptacle et remettez avec

soin le ventilateur. Procédez en suivant la procédure inverse du démontage. Serrez bien les vis (voir les Schémas 8 et 9).

9. S’il y a lieur mettez la fiche de la minuterie dans sa prise. Insérez la fiche de lampe de l’ensemble réflecteur dans la prise de lampe du

boîtier électrique. Alignez la fente en trou de serrure du support de l’ensemble réflecteur sur la vis du ventilateur et glissez-le en place.

Assurez-vous que la saillie du support s’aligne avec le trou de l’ensemble de ventilateur, puis serrez la vis. Installez une ampoule de 100

watts (maximum) type A-19, et une ampoule de 7 1/2 watts à col candélabre type C-7 (MODELES 7100L, 8090Let 8100Lseulement).

Sur les modèles fluorescents 7100FL, 7150FL, 7100FLH et 7150FLH, installez deux des lampes fluorescentes de 13 watts tube quarte

à deux broches :

Osram/Sylvania Panasonic Philips General Electric

CF13DD/841 FQ13E41.u/2 PL-C13W/41/USA F13DBX23T4/SPX41

10. Pressez les ressorts sur la grille plastique et insérez-la dans les taquets du châssis (voir le Schémas 8 et 9). Enfoncez bien la

grille en place.

Page 22

BOUCHE D’ÉVACUATION D’AIR

COUVERCLE

DE BOÎTIER

ÉLECTRIQUE

TAQUETS DE MON-

TAGE DE GRILLE

VENTILATEUR

GRILLE

318 MM (12 1/2”)

284 MM

(11 3/16”)

194 MM (7 5/8”)

254 MM (10”)

292 MM (11 1/2”)

RESSORT DE

GRILLE

VIS DE FIXATION

DE VENTILATEUR

SERRE-FILS

DÉTECTEUR

D’HUMIDITÉ

MODÈLES :

7100, 7130, 7150,

7100H, 7150H,

8090 ET 8100

COUVERCLE

DE BOÎTIER

ÉLECTRIQUE

TAQUETS DE MONTAGE

DE GRILLE

VENTILATEUR

GRILLE

318 MM (12 1/2”)

318 MM (12 1/2”)

284 MM

(11 3/16”)

194 MM (7 5/8”)

254 MM (10”)

RESSORT DE

GRILLE

VIS DE FIXATION DE

VENTILATEUR

VIS DE FIXATION

DU RÉFLECTEUR

ENSEMBLE

RÉFLECTEUR

MODÈLES :

7100L, 7150L, 7100FLH,

7150FLH, 7100FL, 7150FL,

8090L ET 8100L

SCHÉMA 8

SCHÉMA 9

ÉQUERRES DE

MONTAGE

ÉQUERRES

DE MONTAGE

BOUCHON

SERRE-FILS

BOUCHON

SERRE-FILS

MINUTERIE

MINUTERIE

DÉTECTEUR

D’HUMIDITÉ

BOUCHE D’ÉVACUATION D’AIR

SERRE-FILS

Page 23

ANCIENNE INSTALLATION DOMESTIQUE

(MODÈLES : 7100, 7130, 7150, 8090, 8100, 7100L, 7150L,

7100H, 7100FLH, 7150H, 7150FLH, 7100FL, 7150FL, 8090L ET 8100L)

1. Passez en revue tous les instructions d’installation des section précédentes y compris pour conduite et câblages (Schémas 6

et 7).

2. Percez un petit trou par en dessous dans le plafond à l’emplacement voulu, puis allez repérer ce trou dans les combles ou le

grenier.

3. Dans les combles utilisez le contour du châssis comme guide et marquez le dessus du plafond pour marquer la découpe.

Découpez l’ouverture environ 6 mm plus largement que ce marquage.

4. Placez le châssis avec les 4 supports de montage dans l’ouverture et placez les supports dans la plaque de plâtre et les clover

en place.

5. La suite de l’installation est la même qu’aux étapes 1 à 10 de la section précédente pour construction nouvelle.

BESOINS ET RÉGLAGES, POUR UNITÉS AVEC DÉTECTEUR D’HUMIDITÉ SEULEMENT

L’unité doit être montée sur une surface de plafond plane qui n’est pas à plus de 3,65 m (12 pi.) de hauteur et à l’écart d’une source

directe de chaleur comme un chauffage de pièce ou sauna.

REMARQUE : Les fenêtres ouvertes peuvent affecter le taux d’humidité de la pièce et faire que l’unité ne fonctionne pas correctement.

Une fois l’emplacement choisi, reportez-vous aux illustrations précédentes de façon à déterminer la bonne taille pour la découpe

d’ouverture pour le montage de l’unité.

L’unité est activée par un interrupteur mural. Chaque fois que l’interrupteur est actionné, l’unité fonctionnera pour la durée définie à

l’avance pour la minuterie. Une fois passé ce délai, l’unité passe en mode automatique. Dans cet état son fonctionnement dépend du

niveau d’humidité dans la pièce. Si elle est au dessus du seuil défini pour le détecteur d’humidité, l’unité tourne. la ventilation reste active

jusqu’à ce que le taux d’humidité de la pièce retombe en dessous du seuil. Pour que le fonctionnement de l’unité soit déclenché en mode

automatique, le point de réglage du détecteur doit être inférieur au taux d’humidité régnant dans la pièce. L’unité met un certain temps

pour s’arrêter quand l’humidité est chassée ou est retombée, de même elle temporise un peu avant de redémarrer quand l’humidité

remonte en dépassant le seuil. Cela évite des commandes oscillantes du moteur ou des durées d’activité trop courtes.

Le mode automatique peut être contourné en coupant et en remettant l’unité sous tension au niveau de son interrupteur mural. Cela

provoque la mise en marche immédiate de la ventilation pour la durée déterminée à l’avance. Ce réglage en sortie d’usine est de 15 minutes, mais il est ajustable de 18 secondes au minimum à 30 minutes au maximum.

Pour régler le seuil d’humidité et la durée de minuterie suivez ces étapes :

–Débranchez l’alimentation et enlevez la grille.

–Reportez-vous au Schéma 11 pour l’emplacement et l’orientation des composants.

–Le bouton de minuterie peut être tourné avec les doigts. En le tournant dans le sens des aiguilles d’une montre vous augmentez le délai,

jusqu'au maximum de 30 minutes en butée. En le tournant dans le sens contraire des aiguilles d’une montre vous diminuez le délai,

jusqu'au minimum de 18 secondes en butée.

–Le détecteur d’humidité peut aussi être réglé avec les doigts. Tournez l’axe à fond dans le sens des aiguilles d’une montre pour démarrer

au minimum (contact fermé) et tournez-le dans le sens inverse pour augmenter le seuil de réglage. En le tournant progressivement vous

pouvez entendre le déclic du commutateur du détecteur, qui indique que vous venez de dépasser le taux d’humidité ambiante actuelle

de la pièce et que le contact s’est ouvert.

–Replacez la grille et remettez l’unité sous tension pour vérifier son bon fonctionnement.

SCHÉMA 10

SCHÉMA 11

25 mm (1”)

279 mm (11”)

15

AXE DU

DÉTECTEUR

D’HUMIDITÉ

BOUTON DE

MINUTERIE

Page 24

ACCESSOIRES

MODÈLE DESCRIPTION

1011A Minuterie une heure maximum

1117A Chapeau mural avec clapet. Adaptable aux conduites cylindriques

de 76 et 102 mm (3 et 4").

AD1106 Chapeau de toit avec clapet. Adaptable aux conduites cylindriques

de 178 mm (7")

SPÉCIFICATIONS

MODÈLE VOLTS CERTIFICATION H.V.I. (PIEDS CARRÉS)

S. BAINS CUISINE AUTRE

761 120 4” 70 65 NON DISPONIBLE 85

763/768IC 120 4” 90 85 NON DISPONIBLE 115

8090/8090L

765/770IC 120 4” 110 105 NON DISPONIBLE 135

7100/7100L 120 4” 100 95 NON DISPONIBLE 125

7100H/7100FLH

7100FL/8100

8100L

7130 120 4” 130 120 NON DISPONIBLE 165

7150/7150L 120 4” 150 140 NON DISPONIBLE 190

7150H/7150FLH,

7150FL

Document N° 5200-2500-003 ECR 35922

10/03

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

Ø

CONDUITE

SPÉCIFICATION

PI3/MIN

COMMENT OBTENIR UNE RÉPARATION OU DES PIÈCES SOUS

GARANTIE, AINSI QUE DES INFORMATIONS GÉNÉRALES

1. Réparation et pièces sous garantie 1-800-642-4328

2. Achat de pièces de rechange 1-800-654-3545

3. Informations générales sur les produits www.marleymep.com

Remarque : Pour demander une assistance technique, ayez toujours en main les

informations suivantes :

1. Numéro de modèle du produit

2. Date de fabrication

3. Numéro de pièce ou description

Loading...

Loading...