Page 1

Type CSL

Commercial Sill Height

Commercial

Sill Height Convection Heaters

(Type CSL)

Convectors

Installation, Operation & Maintenance Instructions

IMPORTANT INSTRUCTIONS

General

This heater is designed to provide years of efficient, trouble free operation as a primary or supplemental heat source for comfort

heating in residential (Model CSLAS, 250 watt max only) and commercial applications. Installation or use of this product in any

manner not described within this manual will void the warranty and could result in injury, damage to property, or permanent damage

to heater.

WARNING

WHEN USING ELECTRICAL APPLIANCES, BASIC PRECAUTIONS SHOULD ALWAYS BE FOLLOWED TO REDUCE

THE RISK OF FIRE, ELECTRIC SHOCK, AND INJURY TO

PERSONS, INCLUDING THE FOLLOWING:

1. Read all instructions before installing or using the heater.

2. A heater has hot and arcing or sparking parts inside. Do not

use in areas where gasoline or flammable liquids are used

or stored. Do not use in corrosive environment or any area

where explosive materials are used or stored.

3. This heater is hot when in use. To avoid burns, do not let

bare skin touch hot surfaces. Keep combustible materials,

such as furniture, pillows, bedding, papers, clothes, and cur-

RECEIVING

Material when shipped was in good order and Marley

Engineered Products holds clear bill of lading, therefore any

concealed damage must be reported at once to the carrier for

inspection and settlement.

SAVE THESE INSTRUCTIONS

!

tains away from heater.

4. To prevent a possible fire, do not block air intakes or

exhaust in any manner.

5. Do not insert or allow foreign objects to enter any ventilation

or exhaust opening as this may cause an electric shock, fire,

or damage the heater.

6. Serious injury or death could result from electric shock.

Make sure electrical power supply circuit coming to heater

is disconnected at main disconnect or service panel before

installing or servicing this heater.

7. This heater is not for residential or household use, except

model CSLAS @ 250 watts per foot.

Note:

It is advisable to store cartons in a central area to be

drawn upon as needed per room requirements. If called for on

order, the cartons will have been tagged with proper room

number.

Page 2

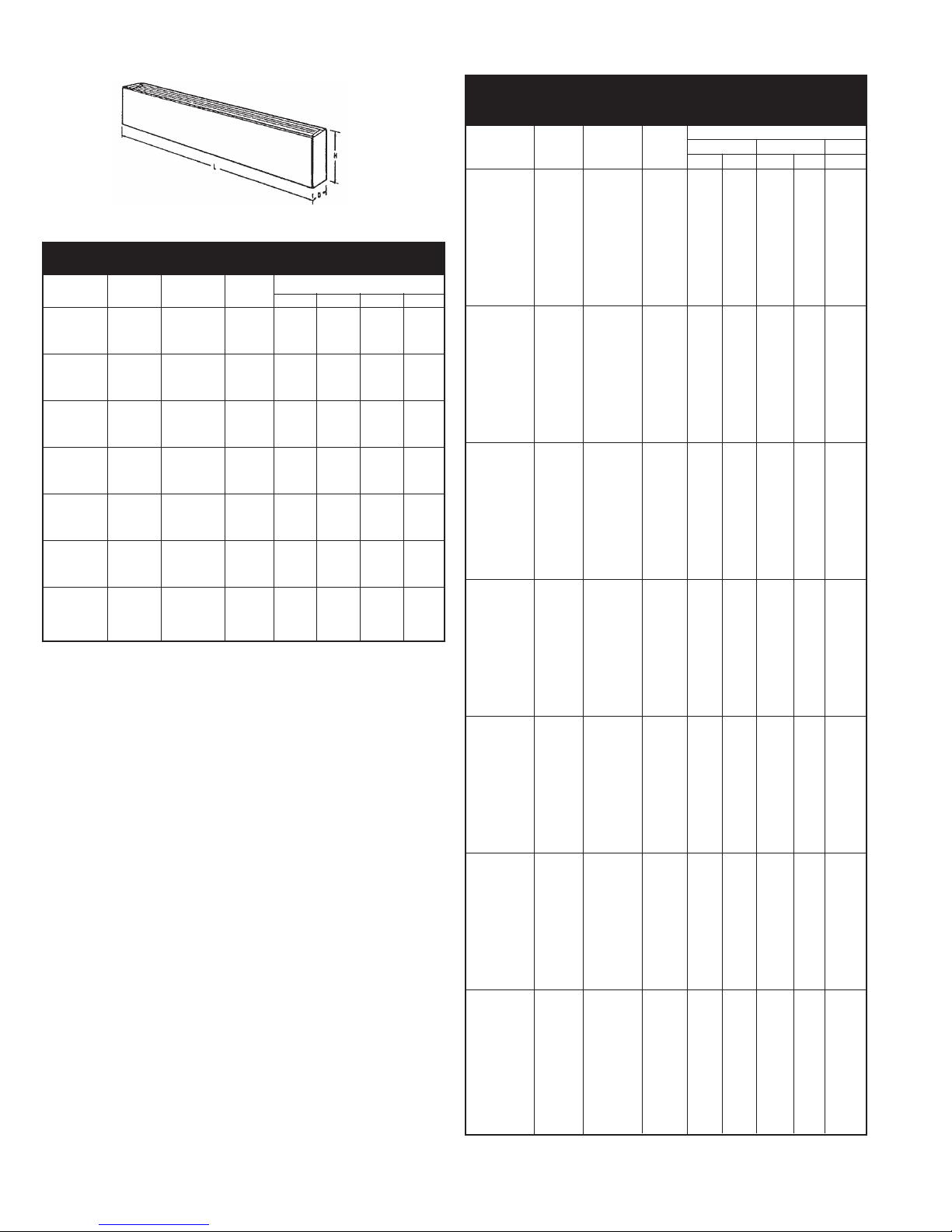

SPECIFICATIONS

Type CSL

Figure 1

Table A

Model CSLAS (H=5 1/2”; D=3”)

Catalog Length Total Amperage

Number* “L” Watts/Ft. Watts 120V 208V 240V 277V

-2125 125 250 2.4 1.2 1.0 0.9

-2188 28” 188 375 3.1 1.8 1.6 1.4

-2250 250 500 4.2 2.4 2.1 1.8

-3125 125 375 3.1 1.8 1.6 1.4

-3188 3’ 188 564 4.7 2.7 2.4 2.0

-3250 250 750 6.2 3.6 3.1 2.7

-4125 125 500 4.2 2.4 2.1 1.8

-4188 4 188 750 6.2 3.6 3.1 2.7

-4250 250 1000 8.3 4.8 4.2 3.6

-5125 125 625 5.2 3.0 2.6 2.2

-5188 5 188 940 7.8 4.5 3.9 3.4

-5250 250 1250 10.4 6.0 5.2 4.5

-6125 125 750 6.2 3.6 3.1 2.7

-6188 6 188 1125 9.4 5.4 4.7 4.1

-6250 250 1500 12.5 7.2 6.2 5.4

-8125 125 1000 - 4.8 4.2 3.6

-8188 8’ 188 1500 - 7.2 6.2 5.4

-8250 250 2000 - 9.6 8.3 7.2

-10125 125 1250 - 6.0 5.2 4.5

-10188 10’ 188 1875 - 9.0 7.8 6.7

-10250 250 2500 - 12.0 10.4 9.0

Clearance Chart

For safe and efficient operation, maintain at least the following

Minimum clearances at all times:

Bottom of heater to finished floor

Watts/Ft Heater Length Bottom Inlet Front Inlet

125, 188 and 250 1-3/4” (44 mm) 0” (0 mm)

376 500, 625, and 750 3” (76 mm) 0” (0 mm)

Top of heater to bottom of Drapes above heater:

Minimum 12 inches (305 mm)

Important Note:

vinyl blinds) may become damaged by the heated air from the

heater and should not be installed above the heater.

Front of heater to full length drapes in front of heater:

Minimum between bottom of drapes and floor - 2 1/2 inches

(64 mm)

Minimum between top of drapes and ceiling - 1/2 inches

(13 mm)

Minimum between front of heater and nearest fold of drape 2 inches

Top of heater to bottom of window sill:

Minimum 12 inches (305 mm)

Certain fabrics and vinyl materials ( such as

Table A (continued)

Model CSLAM (H=7”; D=5”)

Model CSLAL (H=14”; D=5”)

Amperage

Catalog Length Total 208V 240V 277V

Number** “L” Watts/Ft Watts 1Ø 3Ø 1Ø 3Ø 1Ø

-2125 125 250 1.2 - 1.0 - 0.9

-2188 188 375 1.8 - 1.6 - 1.4

-2250 250 500 2.4 - 2.1 - 1.8

-2375 28” 375 750 3.6 - 3.1 - 2.7

-2500 500 1000 4.8 - 4.2 - 3.6

-2564 564 1125 5.4 3.1 4.7 2.7 4.0

-2625 625 1250 6.0 3.5 5.2 3.0 4.5

-2750 750 1500 7.2 4.2 6.2 3.6 5.4

-3125 125 375 1.8 - 1.6 - 1.4

-3188 188 564 2.7 - 2.4 - 2.0

-3250 250 750 3.6 - 3.1 - 2.7

-3375 3’ 375 1125 5.4 - 4.7 - 4.0

-3500 500 1500 7.2 - 6.2 - 5.4

-3564 564 1690 8.1 4.7 7.4 4.3 6.1

-3625 625 1875 9.0 5.2 7.8 4.5 6.7

-3750 750 2250 11.0 6.5 9.4 5.4 8.1

-4125 125 500 2.4 - 2.1 - 1.8

-4188 188 750 3.6 - 3.1 - 2.7

-4250 250 1000 4.8 - 4.2 - 3.6

-4375 4’ 375 1500 7.2 - 6.2 - 5.4

-4500 500 2000 9.6 - 8.3 - 7.2

-4564 564 2250 10.8 6.2 9.4 5.4 8.0

-4625 625 2500 12.0 6.9 10.4 6.0 9.0

-4750 750 3000 14.4 8.3 12.5 7.2 10.8

-5125 125 625 3.0 - 2.6 - 2.2

-5188 188 940 4.5 - 3.9 - 3.4

-5250 250 1250 6.0 - 5.2 - 4.5

-5375 5’ 375 1875 9.0 - 7.8 - 6.7

-5500 500 2500 12.0 - 10.4 - 9.0

-5564 564 2820 13.5 7.8 11.8 6.8 10.2

-5625 625 3125 15.0 8.7 13.0 7.5 11.3

-5750 750 3750 18.0 10.4 15.6 9.0 13.5

-6125 125 750 3.6 - 3.1 - 2.7

-6188 188 1125 5.4 - 4.7 - 4.0

-6250 250 1500 7.2 - 6.2 - 5.4

-6375 6’ 375 2250 10.8 - 9.4 - 8.1

-6500 500 3000 14.4 - 12.5 - 10.8

-6564 564 3380 16.2 9.4 14.1 8.1 12.2

-6625 625 3750 18.0 10.4 15.6 9.0 13.5

-6750 750 4500 21.6 12.5 18.7 10.8 16.2

-8125 125 1000 4.8 - 4.2 - 3.6

-8188 188 1500 7.2 - 6.2 - 5.4

-8250 250 2000 9.6 - 8.3 - 7.2

-8375 8’ 375 3000 14.4 - 12.5 - 10.8

-8500 500 4000 19.2 - 16.7 - 14.4

-8564 564 4500 21.6 12.5 18.7 10.8 16.2

-8625 625 5000 24.0 13.9 20.8 12.0 18.0

-8750 750 6000 28.6 16.5 15.0 14.4 21.6

-10125 125 1250 6.0 - 5.2 - 4.5

-10188 188 1875 9.0 - 7.8 - 6.7

-10250 250 2500 12.0 - 10.4 - 9.0

-10375 10’ 375 3750 18.0 - 15.6 - 13.5

-10500 500 5000 24.0 - 20.8 - 18.0

-10564 564 5640 27.2 15.7 23.5 13.6 20.4

-10625 625 6250 30.0 17.3 26.0 15.0 22.6

-10750 750 7500 36.0 20.8 31.3 18.1 27.0

2

Page 3

INSTALLATION INSTRUCTIONS

TO REDUCE THE RISK OF FIRE AND ELECTRIC SHOCK

OR INJURY TO PERSONS, OBSERVE THE FOLLOWING:

1. Before installing this heater, remove and discard shipping

pads located within heater. Check to make sure heater is

not damaged.

2. Serious injury or death could result from electric shock.

Make sure electrical power supply circuit coming to heater

is disconnected at main disconnect or service panel

before installing this heater.

3. Wiring procedures and connections must be in accordance with the National Electrical Code (NEC) and local

codes. Refer to Wiring Diagram on heater and Figure 9.

Make sure all electrical connections are tight to prevent

possible overheating. Use Copper Supply Wire Only.

4. Verify the electrical power supply voltage matches the

voltage rating as printed on the heater nameplate.

CAUTION

the nameplate voltage as this will damage the heater and

could cause a fire.

5. Do not install the heater against combustible low-density

6. Do not install heater below an electrical convenience

CAUTION

trical cords (including telephone and computer cables),

drapes, and other furnishings away from heater. For efficient

and safe operation, we recommend maintaining a minimum of

6 inches (152 mm) clearance above and in front of the heater

at all times.

7. To reduce the risk of fire, do not store or use gasoline or

8. Do not install heater upside down or in any position other

9. Do not recess heater in wall or install heater inside any

10. When mounting heater, use care to secure heater to

11. Do not remove or bypass the safety limit control (thermal

12. The factory installed wires inside wireway are used to

13. Heaters that are not installed end to end must have end

- Never connect a heater to a voltage greater than

cellulose fiberboard surfaces, against or below vinyl wall

coverings, or below any materials that may be damaged

by heat such as vinyl or plastic blinds, curtains, etc. If

heater is intended to be installed against vinyl wall coverings, Stand Off Kits, Cat. No. SO1 or SO2, must be used.

See instructions supplied with kits.

receptacle (outlet).

– Heater operates at high temperatures. Keep elec-

other flammable vapors or liquids in the vicinity of the

heater.

than as shown in this manual. Caution label with word

“TOP” must be at the top when heater is installed.

type enclosure as this will cause heater to overheat and

could create a hazard.

building structure and avoid damaging internal heater

components.

protector) as this could allow heater to become a fire hazard – see heater wiring diagram supplied with heater.

connect the built-in controls. Limit the maximum current

to no more than 45 total amps. Refer to instructions and

current capacity rating as provided with the accessory.

caps installed to cover exposed ends of heater.

14. All field wiring brought in to heater must be rated minimum 75°C.

15 Do not allow objects to be placed on top of heater as they

may be damaged or create a fire hazard.

16. Before energizing, make sure that heater is completely

assembled with grille, front cover, end caps and any

accessories installed.

Rough-in Wiring

1. Run branch circuit of proper voltage and wire size to location

of left or right junction box as indicated on heater wiring diagram. Basic heaters are prewired and can be connected to

branch circuit at either end. Heaters with controls are

prewired for connection to branch circuit at one end only

(refer to heater wiring diagram), however, heater can be

wired from opposite end by running wire through heater wireway.

2. If it is necessary to run wires through the heater wireway,

use Table B to size the field installed wiring.

3. The factory installed wires in the heater wireway can be

loaded up to 45 amps. Refer to Table C for maximum length

of heater run when the heaters are connected in parallel.

Thermostat

Transformer relay

05A units: 22 amps @ 120-240 VAC

07A-14A Units: 25 AMPS @ 120-240 VAC

Power relay

Disconnect switch

Table B. Sizing Field Installed Wiring

Copper Maximum no.

wire size of wires Up to 3 4 to 6 7 thru 9

75º C in wireway Conductors Conductors Conductors

No. 12 AWG 9 11.5 amps 9.3 amps 8.1 amps

No. 10 AWG 8 17.4 amps 14.0 amps 12.1 amps

No. 8 AWG 4 24.0 amps 21.0 amps –

Table C. Maximum Length of Heater Run

(CSLAS-1Ø)

Watts/Ft. of Maximum allowable length of heater run (feet)

the heaters 120 Volts 208 Volts 240 Volts 277 Volts

125 33 58 67 77

188 22 38 44 51

250 16 29 33 38

Note:

For mix of watt densities, calculate amp draw. Do not

exceed values indicated in step 3 above.

Table D. Maximum Length of Heater Run

(CSLAM and CSLAL)

Watts/Ft.

of Heaters

125 74 - 86 - 99

188 49 - 57 - 66

250 37 - 43 - 49

376 24 - 28 - 33

500 18 - 21 - 24

564 16 27 19 32 22

625 15 24 17 29 20

750 12 20 14 24 16

1 Ph 3 Ph 1 Ph 3 Ph 1 Ph

3

24 amps @ 120-240 VAC

22 amps @ 277 VAC

Pilot duty– 125 VAC (all voltages)

19 amps @ 277 VAC

22 AMPS @ 277 VAC

25 amps @ 120-277 VAC- see wiring diagram on heater

20 amps @ 120-277 VAC

Maximum allowable current

Max. allowable length of heater run in feet (meters)

208V 240V 277V

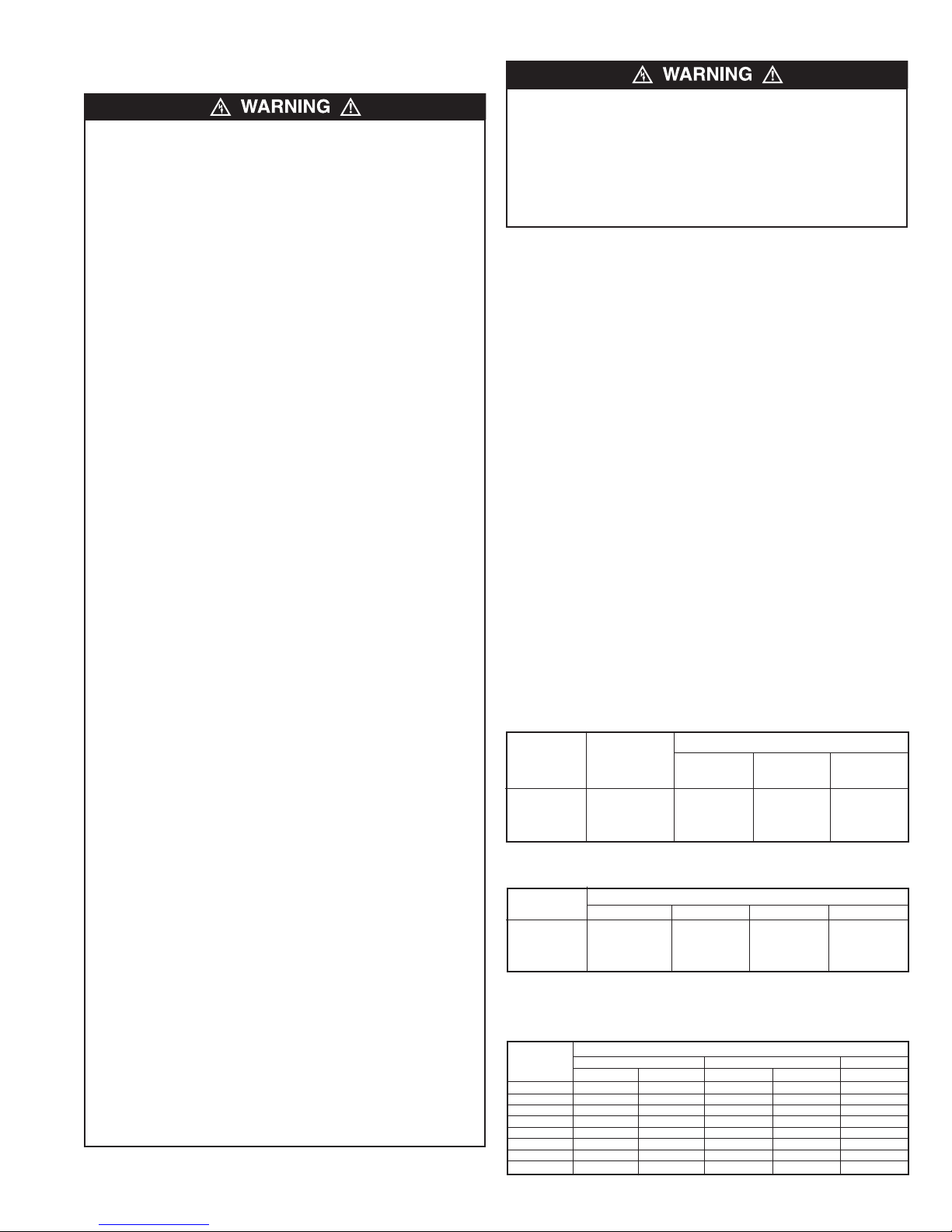

Page 4

4. Standard 75ºC wiring must be used in junction boxes, wire-

HEATER

HEATERS

BUTTED

TOGETHER

HEATER

FILLER

SECTION

HEATER

INSIDE

CORNER

HEATER

OUTSIDE

CORNER

HEATER

END

CAP

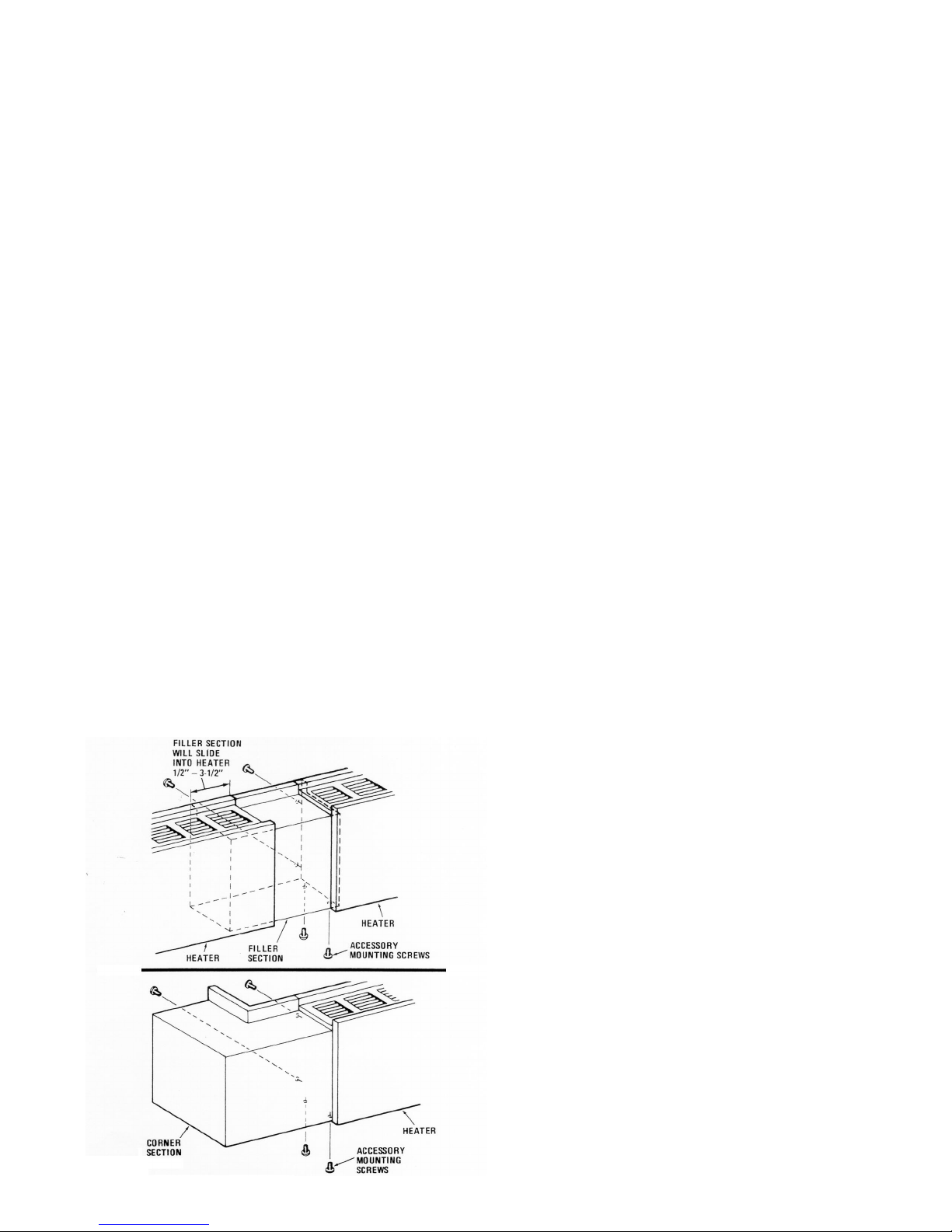

TYPICAL INSTALLATION

SPLICE PLATE

KIT

SPLICE PLATE

KIT

ways, blank sections, filler sections, and corner sections.

Room Layout

Refer to heating plans for exact room arrangements of heaters

(with or without thermostat and/or relays and/or switches and

accessories.)

Check the heater section dimensions and the additional wall

length required for telescoping accessories (Figure 2) before

starting wall-to-wall type installation. Be certain all heaters and

accessories needed are at hand and are of correct finish.

10

N

N

N

N

/4”

3

2-15/16”

-1/4”

1

1-7/16”

ACK PANEL

B

1-1/8” & 7/8” DIA.

CONCENTRIC K.O.’s

1-7/16”

/8” & 1-1/8” DIA.

7

CONCENTRIC K.O.’s

ACK PANEL

B

B

A

1-15/16”

-1/4”

1

2-1/2”

3/4”

1-3/8” & 1-3/4” DIA.

ONCENTRIC K.O.’s

C

1-9/16”

10

7

3

Figure 2

Typical Installation

See page 8 for N dimensions

2

4

1

8

N

5

6

N

9

Installation of Single Unit

Note:

For ease of installation, it is important that the sequence

of operations indicated below be followed in order.

1. Remove front cover by removing mounting screws (Figure

3).

2. Remove appropriate electrical knockout from either junction

box. See Figure 4 for location of knockouts.

1-3/8” & 1-1/8” DIA.

ONCENTRIC K.O.’s

C

BOTTOM VIEW

1-3/8” & 1-3/4” DIA.

ONCENTRIC K.O.’s

C

BOTTOM VIEW

CSLAM CSLAL

A

B

4”

N/A

5”

5”

Figure 4

3. Install end caps (must be purchased separately) on both

ends of the heater housing. Refer to Figure 5 for details of

end cap installation.

4. If filler section is desired to terminate the heater, install the

filler section in the end of the heater and extend to desired

length. Mark the mounting hole locations, remove the filler

section and drill the required mounting holes. Install the filler

section in the heater and the end cap on the filler section as

shown in Figure 3.

Note:

If a thermostat and/or disconnect switch are installed in

the heater left junction box, it may be necessary to cut away a

portion of the filler section to allow access to these controls

(Figure 3).

5 Position heater housing on wall to check for evenness of

wall. Do not draw the heater against an uneven wall surface.

If an uneven wall is encountered, use shims to keep the

heater housing straight.

6. Run proper size branch circuit to the junction box through the

selected knockout.

Figure 3

HOUSING

MOUNTING

SCREWS

END

CAP

ACCESSORY

MOUNTING

END CAP

HOLES

Figure 5

4

Page 5

7. Drill the required size mounting holes in the back of the

heater housing and install the housing on the wall using

screws, bolts or anchors (by installer) to suit the wall construction.

Note:

Predrilled 1/4” diameter mounting holes are provided in

each junction box. Additional mounting holes will have to be

drilled in the housing to support the weight of long length

heaters (6’ and longer). Do not drill any additional holes in the

junction boxes.

8. Tighten mounting screws and back off 1/4 to 3/4 turn to

allow for expansion and contraction of the heater.

9. Following the wiring diagram secured to the heater, make

electrical connections. Ground the heater using the ground

screws provided (Figure 3).

10. Replace front cover and secure with mounting screws. (See

Figure 3).

Installation of Multiple Wall to Wall Units

Note:

For ease of installation, it is important that the sequence

of operations indicated below be followed in order.

1. Remove all the front covers from the heaters by removing

mounting screws (Figure 3).

2. Refer to wiring diagram for power supply entry and remove

appropriate electrical knockout (Figure 4) from the heater in

which power supply connections are to be made. The power

supply may be brought in to the end of only one heater and

the remaining heaters may be connected in parallel using the

wireway. Use Table B to size the field installed wiring in the

wireway.

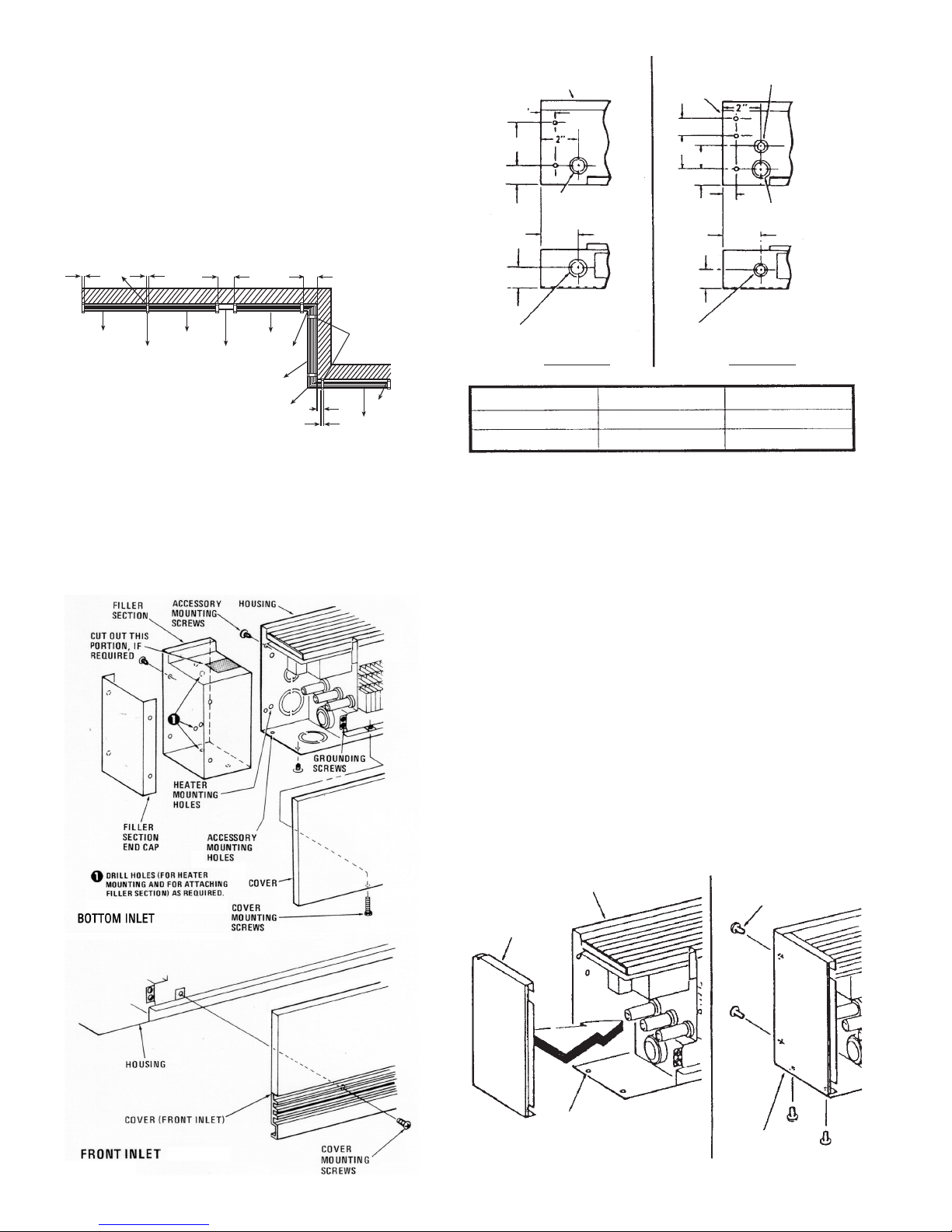

3. If conduit cover (must be purchased separately) is desired,

cut off the appropriate length and install to the wall.

4. If required by plan, install filler section (1), (Figure 1) to either

heater (2) or (3) by means of four #6 screws supplied with

filler section. (Refer to Figure 6.) Discard filler section end

cap in this application.

Note:

Heaters may butt against each other, thus eliminating the

filler piece, if so desired.

Note:

If a heater has a disconnect switch and / or thermostat

and is to have a filler section or a corner section at the left end,

the section must be mounted to the heater since the thermostat

or disconnect switch will prevent the section from telescoping

into the heater.

5 If the wall run has inside or outside corners, install corner (4

and 5) to the heater (2 and 9) by means of four #6 screws

supplied with corner section. (Refer to Figure 6).

6. Install end caps (6) on the outer end of the last heater(7) and

(9) using four #6 screws supplied with end caps. (Refer to

Figure 5 for details of end cap installation.)

7. Drill the required size mounting holes in all the heater housings.

Note:

Predrilled 1/4” diameter mounting holes are provided in

each junction box. These holes may be used only when no slipin accessory is to be installed in that end of the heater ( such as

when heater(3 and 7) are butted together as shown in Figure 2).

Additional mounting holes will have to be drilled in the housing

to support the weight of long-length heaters (6’ and longer). Do

not drill any additional holes in junction boxes.

8. Check for evenness of wall. Do not draw the heaters

against an uneven wall surface. If an uneven wall is

encountered, use shims to keep the heater housing

straight.

9. Run proper size branch circuit to the junction box through

the selected knockout.

10. Mount the heater (2, Figure 2) on the wall using screws,

bolts or anchors (by installer) to suit the wall construction.

11. Telescope the heater housing (3) over the filler section (1)

by the desire amount and mount the housing to the wall.

12. Telescope the heater housing (8) over the corner section

(4) by the desired amount and mount the housing to the

wall.

13. Mount the remaining heaters as described above, making

sure that the heaters with end caps are installed at the end

of the run.

14. Blank sections, if any are installed in the same manner as

the heaters.

Note:

75ºC field wiring may be run through the blank sections,

filler sections and corner sections.

15. Control sections, if any, are installed in the same manner

as heaters. Refer to wiring diagram on control sections for

connecting the wiring to the heaters

Figure 6

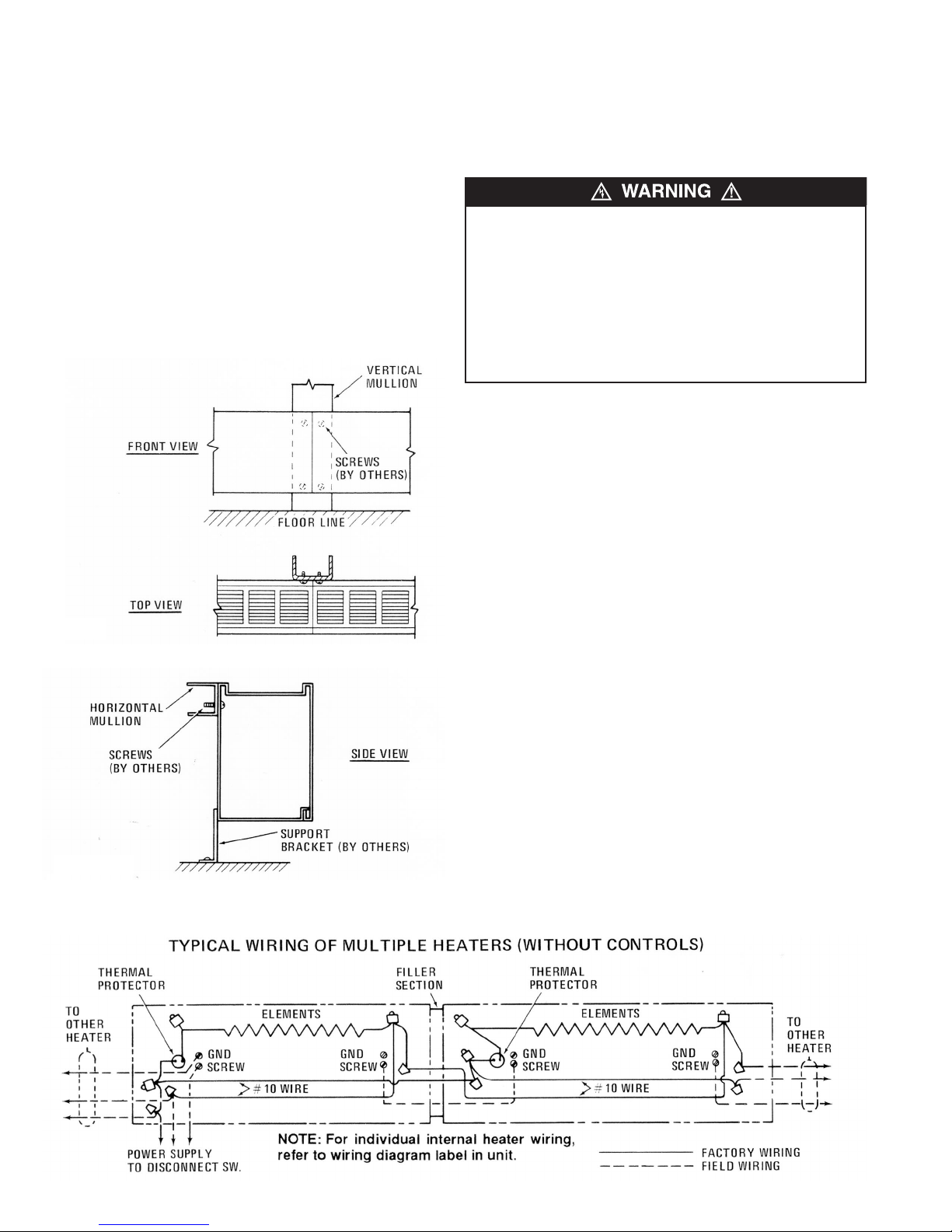

Installation of Mullion to Mullion Units

The back of the heater housing contains no mounting holes

(other than those at the ends) and therefore is ideal for installation in front of glass curtain walls. The housing back presents

an attractive appearance when viewed from the outside through

the glass wall.

Installation procedures are similar to those for wall-to-wall installation (Step Six) except for the following differences.

1. Attach the housing to the mullion using the mounting holes

provided in the junction boxes as shown in Figure 7.

2. On horizontal mullion installation, install support brackets as

shown in Figure 8.

5

Page 6

OPERATION INSTRUCTIONS

1. This heater must be properly installed before it is used.

2. If the heater is equipped with a built-in thermostat, adjust the

shaft to the mid-range and let the heater run for a few hours.

If the room temperature is too hot, rotate the shaft counterclockwise; if too cool, rotate the shaft clockwise until a comfortable temperature is obtained. Let room temperature stabilize after each setting change. The heater will automatically cycle around this set point on the thermostat.

Note:

If a thermostat or disconnect switch is provided in the

heater, these components are accessible through the grille

openings at the left or right end of the heater.

Figure 7

MAINTENANCE INSTRUCTIONS

For efficient and safe operation and to extend the life of the

heaters, they should be cleaned and inspected for damage at

least annually (preferably at the beginning fo the heater season)

or more often in dirty environments. Other than cleaning, your

heaters require no other preventative maintenance.

1. Serious injury or death could result from electric shock.

Make sure electrical power supply circuit(s) coming to

heater is/are disconnected at main disconnect or service

panel before servicing this heater. Allow heater to cool

before cleaning to prevent a possible burn.

Note:

More than one power source may enter heater. Be

sure all power is disconnected to heater before cleaning or

servicing.

2. Use care when cleaning element fins to avoiding damaging

fins. Note also that fins are sharp and may cause cuts so

avoid contact.

1. The user can perform periodic cleaning of the outer cabinet.

All other servicing is to be done by qualified service personnel.

2. Heater cabinet may be cleaned using a damp cloth to

remove dust that may have accumulated on surfaces. Do not

use harsh cleaners or waxes on surfaces since these could

damage the finish or discolor in use.

3. A vacuum cleaner and/or compressed air may be used to

remove dust and lint that may have accumulated inside

heater around element fins. If heater must be disassembled

for cleaning, use care when cleaning element fins to avoid

damaging fins.

4. After cleaning and servicing, always reassemble replacing

any hardware removed, restore power and check to make

sure the heaters are operating properly.

Important Note:

the heaters including one or more over-temperature limit controls (Thermal Protector) - see Wiring Diagram on heater for

specific controls provided. These safety controls are provided to

cycle the heater off to maintain safe temperatures in the event of

a blockage or other abnormal condition. DO NOT remove or

bypass these important safety controls as they are provided to

limit the temperatures and prevent a possible fire in the event

the heater is subjected to an overheating condition. If it is determined that the heater is cycling off on the safety controls during

normal use, discontinue using the heater until it can be

inspected and repaired by a qualified service personnel.

There are built-in safety devices provided within

Figure 8

Figure 9 - Wiring Diagram

6

Page 7

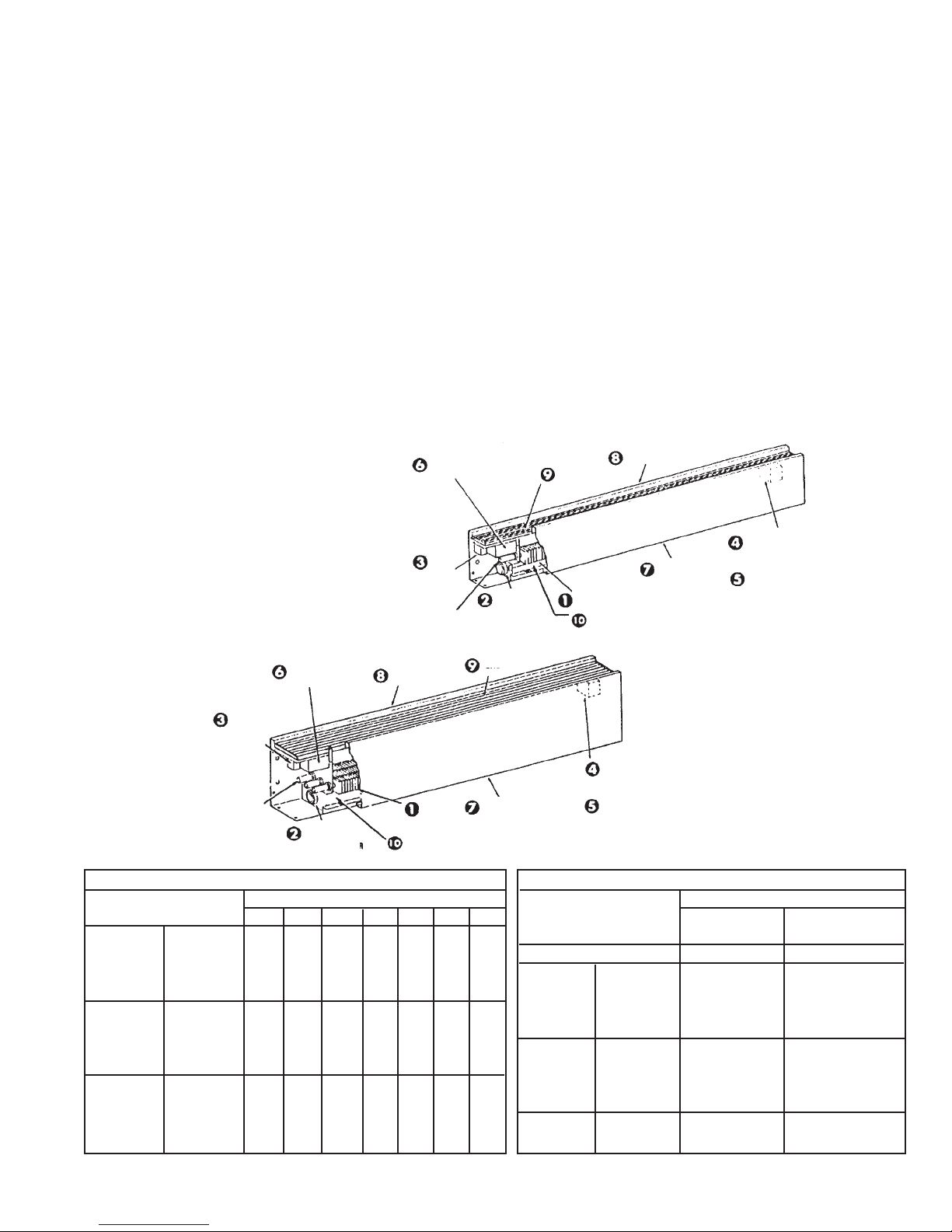

RENEWAL PARTS

IDENTIFICATION:

CSLAS, CSLAM, CSLAL

THERMOSTAT

(OPTIONAL)

DISCONNECT

SWITCH

(OPTIONAL)

ELEMENT BUSHING

1213-2000-001

OVERLOAD

PROTECTOR

GRILLE

HEATING

ELEMENT

WIREWAY COVER

BACK PANEL

FRONT

COVER

TRANSFORMER

RELAY

(OPTIONAL)

POWER RELAY

(OPTIONAL)

BACK PANEL

FRONT COVER

1402-0315-VAR (OSH07A)

1402-0314-VAR (OSH14A)

DISCONNECT

SWITCH

(OPTIONAL)

ELEMENT BUSHING

1213-2000-001

THERMOSTAT

(OPTIONAL)

OVERLOAD

PROTECTOR

4502-0007-VAR

GRILLE

HEATING

ELEMENT

WIREWAY COVER

6405-0053-VAR

Heater Element (Part No. Prefix 1802-2001)

Description Heater Length

28” 3’ 4’ 5’ 6’ 8’ 10’

125 W/ft. 120 Volts 085 087 089 091 093 – –

per 208 Volts 086 088 090 092 094 095 096

Element 240 Volts 048 054 060 066 072 077 081

277 Volts 049 055 061 067 073 078 082

188 W/ft. 120 Volts 005 011 017 023 029 – –

per 208 Volts 002 008 014 020 026 032 036

Element 240 Volts 001 007 013 019 025 031 035

277 Volts 000 006 012 018 024 030 034

250 W/ft. 120 Volts 004 010 016 022 028 ––

per 208 Volts 003 009 015 021 027 033 037

Element 240 Volts 002 008 014 020 026 032 036

277 Volts 001 007 013 019 025 031 035

TRANSFORMER

RELAY

(OPTIONAL)

POWER RELAY

(OPTIONAL)

Built-in Controls (Optional)

Description Part Number

CSLAM & CSLAS UNITS

CSLAL UNITS

Disconnect Switch 5216-0124-000 5216-0124-000

Transformer 120 Volts R13700002B001 410043001

Relay 208 Volts R13700002B002 410043002

240 Volts R13700002B003 410043003

277 Volts R13700002B004 410043004

Power 24 Volts 5018-2006-000 5018-2006-000

Relay 120 Volts 5018-2006-001 5018-2006-001

208/240 Volts 5018-2006-002 5018-2006-002

277 Volts 5018-2006-003 5018-2006-003

Thermostat 1 Pole 5813-0024-000 5813-0024-000

2 Pole 5813-0023-000 5813-0023-000

7

Page 8

Renewal Parts Identification: Optional Controls: CSLAMBCS, CSLALBCS

Description Part Number

Mercury relay, 1 pole 30 amps, 24 Volt coil 5018-7050-001

Mercury relay, 1 pole 60 amps, 24 Volt coil 5018-7049-001

Mercury relay, 1 pole 30 amps, 120 Volt coil 5018-7050-002

Mercury relay, 1 pole 60 amps, 120 Volt coil 5018-7049-002

Mercury relay, 1 pole 30 amps, 208 Volt coil 5018-7050-003

Mercury relay, 1 pole 60 amps, 208 Volt coil 5018-7049-003

Mercury relay, 1 pole 30 amps, 240 Volt coil 5018-7050-004

Mercury relay, 1 pole 60 amps, 240 Volt coil 5018-7049-004

Mercury relay, 1 pole 30 amps, 277 Volt coil 5018-7050-005

Mercury relay, 1 pole 60 amps, 277 Volt coil 5018-7050-005

Circuit breaker, 2 pole 30 amps 1226-7009-013

Circuit breaker, 2 pole 60 amps 1226-7009-010

Circuit breaker, 3 pole 30 amps 1226-7009-005

Circuit breaker, 3 pole 60 amps 1226-7009-002

24V Transformer, 120 Volt primary 5814-7017-007

24V Transformer, 208 Volt primary 5814-7017-002

24V Transformer, 240 Volt primary 5814-7017-007

24V Transformer, 277 Volt primary 5814-7017-001

Disconnect Switch 5216-0124-000

Thermostat, 1 pole 5813-0024-000

Thermostat, 2 stage 5813-0023-000

Pneumatic Control 5216-7027-001

All products manufactured by Marley Engineered Products are warranted against defects in workmanship and materials for one year from date of installation, except

LIMITED WARRANTY

heating elements which are warranted against defects in workmanship and materials for five years from date of installation. This warranty does not apply to damage from

accident, misuse, or alteration; nor where the connected voltage is more than 5% above the nameplate voltage; nor to equipment improperly installed or wired or

maintained in violation of the product’s installation instructions. All claims for warranty work must be accompanied by proof of the date of installation.

The customer shall be responsible for all costs incurred in the removal or reinstallation of products, including labor costs, and shipping costs incurred to return products

to Marley Engineered Products Service Center. Within the limitations of this warranty, inoperative units should be returned to the nearest Marley authorized service center or the Marley Engineered Products Service Center, and we will repair or replace, at our option, at no charge to you with return freight paid by Marley. It is agreed that

such repair or replacement is the exclusive remedy available from Marley Engineered Products.

THE ABOVE WARRANTIES ARE IN LIEU OF ALL OTHER WARRANTIES EXPRESSED OR IMPLIED, AND ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE WHICH EXCEED THE AFORESAID EXPRESSED WARRANTIES ARE HEREBY DISCLAIMED AND EXCLUDED FROM

THIS AGREEMENT. MARLEY ENGINEERED PRODUCTS SHALL NOT BE LIABLE FOR CONSEQUENTIAL DAMAGES ARISING WITH RESPECT TO THE

PRODUCT, WHETHER BASED UPON NEGLIGENCE, TORT, STRICT LIABILITY, OR CONTRACT.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above exclusion or limitation may not apply to you. This warranty gives

you specific legal rights, and you may also have other rights which vary from state to state.

For the address of your nearest authorized service center, contact Marley Engineered Products in Bennettsville, SC, at 1-800-642-4328. Merchandise returned to the factory must be accompanied by a return authorization and service identification tag, both available from Marley Engineered Products. When requesting return authorization,

include all catalog numbers shown on the products.

HOW TO OBTAIN WARRANTY SERVICE AND

WARRANTY PARTS PLUS GENERAL INFORMATION

1. Warranty Service or Parts

2. Purchase Replacement Parts

3. General Product Information

Note:

When obtaining service always have the following:

1. Model number of the product

2. Date of manufacture

3. Part number or description

1-800-642-4328

1-800-654-3545

www.marleymep.com

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

Part No. 5200-2210-002

ECR 38636

12/10

Page 9

Convectores

Calefactores

comerciales a nivel

de convección comerciales a nivel de zócalo

(Tipo CSL)

de zócalo

Tipo CSL

Instrucciones de instalación, operación y mantenimiento

INSTRUCCIONES IMPORTANTES

Información general

Este calefactor está diseñado para proporcionar muchos años de funcionamiento eficiente y sin problemas como fuente de calor

principal o complementaria para calefacción ambiental, en aplicaciones residenciales (modelo CSLAS, 250 watts por pie máx. únicamente) y comerciales. La instalación o uso de este producto de cualquier manera no descrita en este manual anulará la garantía,

y podría provocar lesiones, daños materiales o daño permanente al calefactor.

ADVERTENCIA

AL UTILIZAR ARTEFACTOS ELÉCTRICOS, PARA REDUCIR

EL RIESGO DE INCENDIO, CHOQUE ELÉCTRICO Y

LESIONES PERSONALES DEBEN OBSERVARSE SIEMPRE

ALGUNAS PRECAUCIONES BÁSICAS, COMO LAS SIGUIENTES:

1. Lea todas las instrucciones antes de instalar o utilizar el

calefactor.

2. Un calefactor tiene en su interior piezas calientes, y piezas

en donde se producen arcos o chispas. No lo utilice en

áreas en las que se utilice o almacene gasolina o líquidos

inflamables. No lo utilice en entornos corrosivos ni en

ningún lugar en el que se utilicen o almacenen materiales

explosivos.

3. Cuando está en funcionamiento, el calefactor está muy

caliente. Para evitar quemaduras, no deje que su piel haga

contacto directo con las superficies calientes. Mantenga

RECEPCIÓN

Cuando el material se envió estaba en buenas condiciones, y

Marley Engineered Products cuenta con un conocimiento de

embarque limpio (sin objeciones), por lo que todo daño oculto

debe informarse enseguida al transportista para su inspección y

resolución.

!

lejos del calefactor los materiales combustibles como muebles, almohadas, ropas de cama, papeles, ropas y cortinas.

4. Para evitar un posible incendio, no bloquee de ningún modo

las entradas o la descarga de aire.

5. No inserte ni permita que entren objetos extraños en ninguna abertura de ventilación o de descarga, porque esto

puede ser causa de choque eléctrico, incendio o daño al

calefactor.

6. Un choque eléctrico podría producir lesiones graves o la

muerte. Asegúrese de que el circuito de alimentación eléctrica del calefactor esté desconectado en el tablero de servicio o desconectador principal, antes de instalar o prestar

servicio a este calefactor.

7. Este calefactor no es para uso residencial o doméstico,

excepto el modelo CSLAS con 820 watts por metro / 250

watts por pie.

Nota:

es aconsejable almacenar las cajas en un área central,

para enviar las unidades a las habitaciones a medida que lo

requieran. Si las cajas constituyen un pedido, estarán etiquetadas con el número correcto de la habitación.

GUARDE ESTAS INSTRUCCIONES

Page 10

ESPECIFICACIONES

Typo CSL

Figura 1

Tabla A

Modelo CSLAS (H = 5 1/2"; D = 3”)”)

Número de Longitud Watts Corriente, A

catálogo* “L” Watts/pie . totales 120 V 208 V 240 V 277 V

-2125 125 250 2.4 1.2 1.0 0.9

-2188 28” 188 375 3.1 1.8 1.6 1.4

-2250 250 500 4.2 2.4 2.1 1.8

-3125 125 375 3.1 1.8 1.6 1.4

-3188 3’ 188 564 4.7 2.7 2.4 2.0

-3250 250 750 6.2 3.6 3.1 2.7

-4125 125 500 4.2 2.4 2.1 1.8

-4188 4 188 750 6.2 3.6 3.1 2.7

-4250 250 1000 8.3 4.8 4.2 3.6

-5125 125 625 5.2 3.0 2.6 2.2

-5188 5 188 940 7.8 4.5 3.9 3.4

-5250 250 1250 10.4 6.0 5.2 4.5

-6125 125 750 6.2 3.6 3.1 2.7

-6188 6 188 1125 9.4 5.4 4.7 4.1

-6250 250 1500 12.5 7.2 6.2 5.4

-8125 125 1000 - 4.8 4.2 3.6

-8188 8’ 188 1500 - 7.2 6.2 5.4

-8250 250 2000 - 9.6 8.3 7.2

-10125 125 1250 - 6.0 5.2 4.5

-10188 10’ 188 1875 - 9.0 7.8 6.7

-10250 250 2500 - 12.0 10.4 9.0

Cuadro de espacios libres

Para garantizar un funcionamiento seguro y eficiente mantenga

como mínimo, en todo momento, los espacios libres que se indican

a continuación:

Del fondo del calefactor al piso terminado

Watts/pie de longitud

de los calefactores Enrada inferior Entrada frontal

125, 188 y 250 44 mm (1-3/4”) 0 mm (0”)

376 500, 625, y 750 76 mm (3”) 0 mm (0”)

Del extremo superior del calefactor al extremo inferior de los

cortinados situados arriba del calefactor:

Mínimo: 305 mm (12 pulgadas)

Nota importante:

sianas vinílicas) pueden sufrir daños por el aire caliente proveniente del

calefactor, y no deben instalarse sobre el mismo.

Del frente del calefactor a cortinados largos situados frente a él:

Mínimo entre el borde inferior de los cortinados y el piso: 64 mm

(21/2 pulgadas)

Mïnimo entre el borde superior de los cortinados y el cielorraso:

13 mm (1/2 pulgada)

Mïnimo entre el frente del calefactor y el pliegue más cercano del

cortinado: 51 mm (2 pulgadas)

Del extremo superior del calefactor al extremo inferior del

alféizar de una ventana:

Mínimo: 305 mm (12 pulgadas)

algunas telas y materiales vinílicos (como las per-

Tabla A (continuación)

Modelo CSLAM (H = 7”; D = 5”)

Modelo CSLAL (H = 14”; D = 5”)

Corriente, A

Número de Longitud Watts 208 V 240 V 277 V

catálogo** “L” Watts/pie totales 1Ø 3Ø 1Ø 3Ø 1Ø

-2125 125 250 1.2 - 1.0 - 0.9

-2188 188 375 1.8 - 1.6 - 1.4

-2250 250 500 2.4 - 2.1 - 1.8

-2375 28” 375 750 3.6 - 3.1 - 2.7

-2500 500 1000 4.8 - 4.2 - 3.6

-2564 564 1125 5.4 3.1 4.7 2.7 4.0

-2625 625 1250 6.0 3.5 5.2 3.0 4.5

-2750 750 1500 7.2 4.2 6.2 3.6 5.4

-3125 125 375 1.8 - 1.6 - 1.4

-3188 188 564 2.7 - 2.4 - 2.0

-3250 250 750 3.6 - 3.1 - 2.7

-3375 3’ 375 1125 5.4 - 4.7 - 4.0

-3500 500 1500 7.2 - 6.2 - 5.4

-3564 564 1690 8.1 4.7 7.4 4.3 6.1

-3625 625 1875 9.0 5.2 7.8 4.5 6.7

-3750 750 2250 11.0 6.5 9.4 5.4 8.1

-4125 125 500 2.4 - 2.1 - 1.8

-4188 188 750 3.6 - 3.1 - 2.7

-4250 250 1000 4.8 - 4.2 - 3.6

-4375 4’ 375 1500 7.2 - 6.2 - 5.4

-4500 500 2000 9.6 - 8.3 - 7.2

-4564 564 2250 10.8 6.2 9.4 5.4 8.0

-4625 625 2500 12.0 6.9 10.4 6.0 9.0

-4750 750 3000 14.4 8.3 12.5 7.2 10.8

-5125 125 625 3.0 - 2.6 - 2.2

-5188 188 940 4.5 - 3.9 - 3.4

-5250 250 1250 6.0 - 5.2 - 4.5

-5375 5’ 375 1875 9.0 - 7.8 - 6.7

-5500 500 2500 12.0 - 10.4 - 9.0

-5564 564 2820 13.5 7.8 11.8 6.8 10.2

-5625 625 3125 15.0 8.7 13.0 7.5 11.3

-5750 750 3750 18.0 10.4 15.6 9.0 13.5

-6125 125 750 3.6 - 3.1 - 2.7

-6188 188 1125 5.4 - 4.7 - 4.0

-6250 250 1500 7.2 - 6.2 - 5.4

-6375 6’ 375 2250 10.8 - 9.4 - 8.1

-6500 500 3000 14.4 - 12.5 - 10.8

-6564 564 3380 16.2 9.4 14.1 8.1 12.2

-6625 625 3750 18.0 10.4 15.6 9.0 13.5

-6750 750 4500 21.6 12.5 18.7 10.8 16.2

-8125 125 1000 4.8 - 4.2 - 3.6

-8188 188 1500 7.2 - 6.2 - 5.4

-8250 250 2000 9.6 - 8.3 - 7.2

-8375 8’ 375 3000 14.4 - 12.5 - 10.8

-8500 500 4000 19.2 - 16.7 - 14.4

-8564 564 4500 21.6 12.5 18.7 10.8 16.2

-8625 625 5000 24.0 13.9 20.8 12.0 18.0

-8750 750 6000 28.6 16.5 15.0 14.4 21.6

-10125 125 1250 6.0 - 5.2 - 4.5

-10188 188 1875 9.0 - 7.8 - 6.7

-10250 250 2500 12.0 - 10.4 - 9.0

-10375 10’ 375 3750 18.0 - 15.6 - 13.5

-10500 500 5000 24.0 - 20.8 - 18.0

-10564 564 5640 27.2 15.7 23.5 13.6 20.4

-10625 625 6250 30.0 17.3 26.0 15.0 22.6

-10750 750 7500 36.0 20.8 31.3 18.1 27.0

INSTRUCCIONES DE INSTALACIÓN

10

Page 11

PARA REDUCIR EL PELIGRO DE INCENDIO, CHOQUE ELÉCTRICO O DAÑO A LAS PERSONAS, OBSERVE LO SIGUIENTE::

1. Antes de instalar este calefactor, extraiga y deseche las almohadillas de embalaje que están dentro del mismo. Revise el calefactor para asegurarse de que no esté dañado.

2. Un choque eléctrico podría producir lesiones graves o la muerte.

Asegúrese de que el circuito de alimentación eléctrica del calefactor esté desconectado en el tablero de servicio o desconectador principal, antes de instalar este calefactor.

3. Los procedimientos de cableado y las conexiones deben estar

de acuerdo con el Código Eléctrico Nacional (NEC) de los EE.

UU. y los códigos locales. Consulte el Diagrama de conexionado

que está en el calefactor y en la Figura 9. Asegúrese de que

todas las conexiones eléctricas estén firmes, para evitar posibles

sobrecalentamientos. Utilice cables de alimentación de cobre

únicamente.

4. Verifique que la tensión de alimentación eléctrica coincida con la

tensión nominal que está impresa en la placa de características

del calefactor.

PRECAUCIÓN:

no conecte nunca un calefactor a una tensión mayor

que la nominal que se indica en la placa de características, ya

que esto dañará el calefactor y podría originar un incendio.

5. No instale el calefactor contra superficies de tableros combustibles de fibra de celulosa de baja densidad, contra o debajo

de revestimientos de pared vinílicos, ni debajo de ningún material que pueda dañarse por el calor, como cortinas o persianas

vinílicas o plásticas, etc.Si el calefactor se va a instalar contra

revestimientos de pared vinílicos deben utilizarse los Juegos de

soporte separador, Nº de catálogo SO1 o SO2. Vea las instrucciones que se proporcionan con los juegos.

6. No instale el calefactor debajo de un tomacorriente eléctrico.

PRECAUCIÓN:

el calefactor funciona a altas temperaturas.

Mantenga los cordones eléctricos (incluidos los cables de teléfono y de computadora), cortinados y otros elementos del mobiliario, alejados del calefactor. Para garantizar un funcionamiento

eficiente y seguro, recomendamos mantener en todo momento

un espacio libre de 152 mm (6 pulgadas) como mínimo por encima y frente al calefactor.

7. Para reducir el riesgo de incendio, no almacene ni use gasolina

u otros vapores y líquidos inflamables en las cercanías del calefactor.

8. No instale el calefactor en posición invertida ni en cualquier otra

posición diferente de la que se muestra en esta hoja de instrucciones. La etiqueta de precaución con la palabra ‘ARRIBA’

(‘TOP’) debe quedar en la parte superior cuando se instale el

calefactor.

9. No instale el calefactor embutido en la pared ni dentro de gabinetes de ningún tipo, ya que esto hará que se sobrecaliente, lo

que podría crear un riesgo.

10. Al montar el calefactor, tenga cuidado al sujetarlo a la estructura

del edificio y evite dañar sus componentes internos.

11. No retire ni puentee el control de límite de seguridad (protector

térmico), ya que esto podría crear en el calefactor un riesgo de

incendio; vea el diagrama de conexionado del calefactor, que se

suministra con él.

12. Los cables instalados en fábrica dentro del canal de cables se

utilizan para conectar los controles incorporados. Limite la corriente máxima a no más de 45 amperes en total. Consulte las

instrucciones y los valores nominales de capacidad de corriente

que se suministran con el accesorio.

13. Los calefactores que no están instalados extremo a extremo

deben tener tapas extremas instaladas, para cubrir los extremos

expuestos de cada calefactor.

14. Todo el conexionado del sitio que llega al calefactor debe ser

apto para 75 ºC como mínimo.

15. No permita la colocación de objetos sobre el calefactor, ya que

pueden dañarse o crear un riesgo de incendio.

16. Antes de energizarlo, asegúrese de que el calefactor esté completamente montado, con la rejilla, la cubierta frontal, las tapas

extremas y los accesorios que se hubieran instalado.

Cableado de instalación

1. Realice el tendido de un circuito de derivación, de la tensión y calibre de cables adecuado, hasta la ubicación de la caja de conexiones izquierda o derecha, como se indica en el diagrama de conexionado del calefactor. Los calefactores básicos están precableados y

pueden conectarse al circuito de derivación por cualquiera de sus

extremos. Los calefactores con controles están precableados para

su conexión al circuito de derivación por uno solo de sus extremos

(consulte el diagrama de conexionado del calefactor); sin embargo,

el calefactor puede cablearse a partir del extremo opuesto si se

tiende el cable a través del canal de cables del calefactor.

2. Si fuera necesario tender cables por el canal de cables del calefactor, utilice la Tabla B para dimensionar el conexionado instalado en

el sitio.

3. Los cables instalados en fábrica en el canal de cables del calefactor

pueden cargarse hasta 45 A. Para conocer la longitud máxima del

tramo de calefactores cuando se los conecta en paralelo, consulte la

Tabla C.

Termostato

24 A @ 120-240 V CA

22 A @ 277 V CA

Servicio auxiliar – 125 V CA

(todas las tensiones)

Relé con transformador

Unidades 05A: 22 A @ 120-240 V CA

19 A @ 277 V CA

Unidades 07A-14A: 25 A @ 120-240 V CA

22 A @ 277 V CA

Relé de potencia

Interruptor de desconexión

25 A @ 120-277 V CA; vea el diagrama de

conexionado en el calefactor

20 A @ 120-277 V CA

Tabla B. Dimensionamiento del conexionado

instalado en el sitio

Calibre de Cantidad máx.

cable de de cables Hasta 3 4 a 6 7 a 9

cobre, 75 ºC en el canal conductores conductores conductores

No. 12 AWG 9 11.5 amperes 9.3 amperes 8.1 amperes

No. 10 AWG 8 17.4 amperes 14.0 amperes 12.1 amperes

No. 8 AWG 4 24.0 amperes 21.0 amperes –

Corriente máxima admisible

Tabla C. Longitud máxima del tramo de calefactores (CSLAS,

monofásico)

Watts/pie de los

calefactores 120 volts 208 volts 240 volts 277 volts

125 33 58 67 77

188 22 38 44 51

250 16 29 33 38

Nota:

para casos de mezcla de densidades de potencia, calcule el consumo de

corriente. No supere los valores indicados en el paso 3 anterior.

Longitud máxima admisible del tramo de calefactores (pies

)

Tabla D. Longitud máxima del tramo de calefactores

(CSLAM y CSLAL)

Watts/pie

de los

calefactores

125 74 - 86 - 99

188 49 - 57 - 66

250 37 - 43 - 49

376 24 - 28 - 33

500 18 - 21 - 24

564 16 27 19 32 22

625 15 24 17 29 20

750 12 20 14 24 16

Longitud máxima admisible del tramo de calefactores en pies (metros)

208 V 240 V 277 V

1 Monof. 3 Trif. 1 Monof. 3 Trif. 1 Monof.

11

Page 12

4. Deben utilizarse cables estándar de 75 ºC en cajas de conexiones,

H

EATER

H

EATERS

BUTTED

TOGETHER

H

EATER

F

ILLER

S

ECTION

H

EATER

I

NSIDE

C

ORNER

H

EATER

OUTSIDE

CORNER

HEATER

E

ND

CAP

TYPICAL INSTALLATION

S

PLICE PLATE

KIT

S

PLICE PLATE

KIT

canales de cables, secciones vacías, secciones de relleno y secciones de esquina.

Disposición en la habitación

Para ver los arreglos exactos de los calefactores en la habitación, vea

los planos de calefacción (con o sin termostato y/o relés y/o interruptores y accesorios).

Antes de comenzar una instalación del tipo de pared a pared identifique

las dimensiones de la sección de calefactores y la longitud de pared

adicional requeridas para los accesorios de extensión (Figura 2).

Asegúrese de que todos los calefactores y accesorios necesarios estén

a mano y tengan el acabado correcto.

10

JUEGO DE PLACAS DE

N

UNIÓN

N

N

N

ANEL POSTERIOR

P

/4”

3

2-15/16”

-1/4”

1

CONCÉNTRICOS DE 29 mm

(1-1/8”) Y 22 mm (7/8”) DE DIÁM.

1-7/16”

1-7/16”

PREPUNZONADOS

PREPUNZONADOS

CONCÉNTRICOS DE 22 mm (7/8”) Y

29 mm (1-1/8”) DE DIÁM.

ANEL POSTERIOR

P

B

A

1-15/16”

-1/4”

1

CONCÉNTRICOS DE 35 mm (1-3/8”)

1-9/16”

-1/2”

2

3/4”

PREPUNZONADOS

Y 44.5 mm (1-3/4”) DE DIÁM.

10

JUEGO DE PLACAS DE

N

CALEFACTOR

9

UNIÓN

CAPUCHON

D’EXTRÉMITÉ

6

CALEFACTOR

7

CALEFAC-

TORES JUNTA-

DOS A TOPE

CALEFACTOR

Figura 2

Instalación típica

Vea las dimensiones N

en la página 8

3

SECCIÓN DE

RELLENO

1

CALEFACTOR

2

ANGLE

RENTRANT

CALEFACTOR

8

ANGLE

SORTANT

5

4

N

Instalación de una sola unidad

Nota:

para facilitar la instalación es importante seguir en orden la

secuencia de operaciones que se indica a continuación.

1. Retire la cubierta frontal; para ello quite los tornillos de montaje

(Figura 3).

2. Extraiga el prepunzonado eléctrico apropiado de una de las cajas

de conexiones. Vea las ubicaciones de los prepunzonados en la

Figura 4.

SECCIÓN DE

RELLENO

RECORTE ESTA

PORCIÓN SI FUERA

NECESARIO

TAPA EXTREMA DE LA

SECCIÓN DE RELLENO

TORNILLOS DE

MONTAJE PARA

ACCESORIOS

AGUJEROS DE

MONTAJE DEL

CALEFACTOR

AGUJEROS DE MONTAJE

PARA ACCESORIOS

GABINETE

TORNILLOS DE

PUESTA A TIERRA

PREPUNZONADOS CONCÉN-

TRICOS DE 35 mm (1-3/8”) Y 29

mm (1-1/8”) DE DIÁM.

VISTA INFERIOR

PREPUNZONADOS

CONCÉNTRICOS DE 35 mm (1-3/8”)

Y 44.5 mm (1-3/4”) DE DIÁM.

VISTA INFERIOR

CSLAM CSLAL

A

B

4”

N/D

5”

5”

Figura 4

3. Instale las tapas extremas (deben comprarse por separado) en

ambos extremos del gabinete del calefactor. Para ver los detalles de

la instalación de las tapas extremas consulte la Figura 5.

4. Si se desea una sección de relleno como terminación del calefactor,

instale la sección de relleno en el extremo del calefactor y extiéndala hasta la longitud deseada. Marque las ubicaciones de los agujeros de montaje, retire la sección de relleno y perfore los agujeros

de montaje requeridos. Instale la sección de relleno en el calefactor

y la tapa extrema en la sección de relleno, como se muestra en la

Figura 3.

Nota:

si se instala un termostato y/o un interruptor de desconexión en la

caja de conexiones izquierda del calefactor, puede que sea necesario

recortar una porción de la sección de relleno para permitir el acceso a

estos controles (Figura 3).

5 Coloque el gabinete del calefactor en la pared para verificar la uni-

formidad de la misma. No lleve el calefactor contra una superficie de

pared que sea irregular. Si se encuentra una pared irregular, utilice

suplementos para mantener recto el gabinete del calefactor.

6. Realice el tendido de un circuito de derivación del calibre

adecuado hasta la caja de conexiones, a través del prepunzonado

seleccionado.

CUBIERTA

TORNILLOS DE

MONTAJE DE

LA CUBIERTA

TORNILLOS DE MONTAJE

DE LA CUBIERTA

PERFORE AGUJEROS (PARA EL MONTAJE

DEL CALEFACTOR Y PARA INSTALAR LA SECCIÓN DE RELLENO) SEGÚN SEA NECESARIO.

ENTRADA INFERIOR

ENTRADA FRONTAL

Figura 3

GABINETE

CUBIERTA (ENTRADA FRONTAL)

GABINETE

TORNILLOS

DE MONTAJE

TAPA

EXTREMA

AGUJEROS DE

MONTAJE PARA

ACCESORIOS

TAPA

EXTREMA

Figura 5

12

Page 13

7. Perfore los agujeros de montaje del tamaño necesario en el dorso

del gabinete del calefactor e instale el gabinete en la pared mediante tornillos, pernos o anclajes (a suministrar por el instalador) que

sean adecuados para la construcción de la pared.

Nota:

en cada caja de conexiones se proporcionan agujeros de montaje

pre-perforados de 6.4 mm (1/4”) de diámetro. Se deberán perforar

agujeros de montaje adicionales en el gabinete para sostener el peso

de los calefactores más largos (de 1.83 m / 6 pies o mayores). No

perfore agujeros adicionales en las cajas de conexiones.

8. Apriete los tornillos de montaje y luego retroceda de ¼ a ¾ de

vuelta para permitir la expansión y contracción del calefactor.

9. Haga las conexiones eléctricas de acuerdo con el diagrama de

conexionado que está sujeto al calefactor. Conecte el calefactor a

tierra mediante los tornillos de puesta a tierra provistos (Figura 3).

10. Vuelva a colocar la cubierta frontal y sujétela con los tornillos de

montaje (vea la Figura 3).

Instalación de unidades múltiples de pared a pared

Nota:

para facilitar la instalación es importante seguir en orden la

secuencia de operaciones que se indica a continuación.

1. Retire todas las cubiertas frontales de los calefactores; para ello

quite los tornillos de montaje (Figura 3).

2. Consulte el diagrama de conexionado para ver cómo es la entrada

de la alimentación eléctrica, y extraiga el prepunzonado eléctrico

apropiado (Figura 4) del calefactor en el que va a hacer las conexiones de alimentación eléctrica. La conexión de alimentación eléctrica puede llevarse sólo hasta el extremo de un calefactor, y los calefactores restantes pueden conectarse en paralelo mediante el canal

de cables. Para dimensionar el conexionado instalado en el sitio en

el canal de cables, utilice la Tabla B.

3. Si se desea colocar la cubierta del canal (debe comprarse por sepa-

rado), corte la longitud apropiada e instálela contra la pared.

4. Si el plano lo requiere, sujete la sección de relleno (1) (Figura 1) a

uno de los calefactores (2) o (3) mediante 4 tornillos Nº 6 suministrados con la sección de relleno (consulte la Figura 6). Deseche la

tapa extrema de la sección de relleno en esta aplicación.

Nota:

si se desea, los calefactores pueden juntarse a tope entre sí, con

lo que se elimina la pieza de relleno.

LA SECCIÓN DE RELLENO

SE DESLIZA DENTRO DEL

CALEFACTOR DE 13 mm

(1/2”) A 88.9 mm (3-1/2”)

Nota:

si un calefactor tiene un interruptor de desconexión y/o un termostato, y va a tener una sección de relleno o una sección de esquina

en el extremo izquierdo, la sección debe montarse en el calefactor,

dado que el termostato o el interruptor de desconexión impedirán que la

sección se extienda hasta el calefactor.

5 Si el tramo de pared tiene esquinas interiores o exteriores, instale la

esquina (4 y 5) en el calefactor (2 y 9) mediante 4 tornillos Nº 6

suministrados con la sección de la esquina (consulte la Figura 6).

6. Instale las tapas extremas (6) en el extremo exterior del último

calefactor (7 y 9) mediante 4 tornillos Nº 6 suministrados con las

tapas extremas (para ver los detalles de la instalación de las tapas

extremas consulte la Figura 5).

7. Perfore los agujeros de montaje del tamaño requerido en todos los

gabinetes de los calefactores.

Nota:

en cada caja de conexiones se proporcionan agujeros de montaje

pre-perforados de 6.4 mm (1/4”) de diámetro. Estos agujeros pueden

utilizarse únicamente cuando no se vaya a instalar ningún accesorio

deslizante en ese extremo del calefactor, como cuando se juntan

calefactores a tope (3 y 7) según se muestra en la Figura 2. Se deberán

perforar agujeros de montaje adicionales en el gabinete para sostener el

peso de los calefactores más largos (de 1.83 m / 6 pies o mayores). No

perfore agujeros adicionales en las cajas de conexiones.

8. Verifique la uniformidad de la pared. No lleve los calefactores con-

tra una superficie de pared que sea irregular. Si se encuentra una

pared irregular, utilice suplementos para mantener recto el gabinete del calefactor.

9. Realice el tendido de un circuito de derivación del calibre adecua-

do hasta la caja de conexiones, a través del prepunzonado seleccionado.

10. Monte el calefactor (2, Figura 2) contra la pared mediante tornillos,

pernos o anclajes (a suministrar por el instalador) que sean adecuados para la construcción de la pared.

11. Extienda el gabinete del calefactor (3) sobre la sección de relleno

(1) en la cantidad deseada, y monte el gabinete en la pared.

12. Extienda el gabinete del calefactor (8) sobre la sección de esquina

(4) en la cantidad deseada, y monte el gabinete en la pared.

13. Monte los calefactores restantes como se describió antes;

asegúrese de que los calefactores con tapas extremas se instalen

en el extremo del tramo.

14. Las secciones vacías, si las hay, se instalan del mismo modo que

los calefactores.

Nota:

los cables de 75 ºC del conexionado del sitio puede tenderse a

través de las secciones vacías, secciones de relleno y secciones de

esquina.

15. Las secciones de control, si las hay, se instalan del mismo modo

que los calefactores. Para la conexión del cableado que va a los

calefactores, consulte el diagrama de conexionado de las secciones de control.

SECCIÓN DE

RELLENO

SECCIÓN DE

ESQUINA

CALEFACTOR

Figura 6

CALEFACTOR

TORNILLOS DE MONTAJE

PARA ACCESORIOS

CALEFACTOR

TORNILLOS DE MONTAJE

PARA ACCESORIOS

Instalación de unidades de montante a montante

El dorso del gabinete del calefactor no contiene agujeros de montaje

(además de los que están en los extremos), y por lo tanto es ideal para

la instalación frente a paredes de cortina de vidrio. El dorso del gabinete

presenta un aspecto atractivo cuando se lo ve desde el exterior a través

de la pared de vidrio. Los procedimientos de instalación son similares a

los de la instalación de pared a pared (paso 6), excepto por las

siguientes diferencias.

Installation procedures are similar to those for wall-to-wall installation

(Step Six) except for the following differences.

1. Sujete el gabinete al montante por medio de los agujeros de monta-

je provistos en las cajas de conexiones, como se muestra en la

Figura 7.

2. En instalaciones en montantes horizontales, instale escuadras de

soporte como se muestra en la Figura 8.

13

Page 14

INSTRUCCIONES DE OPERACIÓN

1. Este calefactor debe instalarse correctamente antes de usarlo.

2. Si el calefactor está equipado con un termostato incorporado, ajuste

el eje del mismo en una posición intermedia y deje que el calefactor

funcione durante unas horas. Si la temperatura de la habitación es

demasiado alta haga girar el eje en sentido antihorario, y si es

demasiado baja hágalo girar en sentido horario, hasta obtener una

temperatura confortable. Deje que la temperatura de la habitación

se estabilice después de cada nuevo ajuste. El calefactor hará ciclos

automáticos alrededor de este valor de ajuste del termostato.

Nota: si se proporciona un termostato o un interruptor de desconexión

en el calefactor, estos componentes son accesibles a través de las

aberturas de la rejilla que están en los extremos izquierdo y derecho del

calefactor.

MONTANTE

VERTICAL

VISTA FRONTAL

TORNILLOS (A

SUMINISTRAR

POR TERCEROS)

LÍNEA DEL PISO

VISTA SUPERIOR

Figura 7

MONTANTE

HORIZONTAL

Figura 8

TORNILLOS (A

SUMINISTRAR

POR TERCEROS)

ESCUADRA DE SOPORTE (A

SUMINISTRAR POR TERCEROS)

VISTA LATERAL

INSTRUCCIONES DE MANTENIMIENTO

Para garantizar un funcionamiento eficiente y seguro y para extender la

vida útil de los calefactores, estos deben limpiarse e inspeccionarse

para ver si presentan daños una vez al año como mínimo (preferiblemente el comienzo de la temporada de uso del calefactor), o más a

menudo en entornos muy cargados de suciedad. Sus calefactores no

requieren ningún otro mantenimiento preventivo que la limpieza.

1. Un choque eléctrico podría producir lesiones graves o la muerte.

Asegúrese de que el (los) circuito(s) de alimentación eléctrica del

calefactor esté(n) desconectado(s) en el tablero de servicio o

desconectador principal, antes de prestar servicio a este calefactor. Deje enfriar el calefactor antes de limpiarlo, para prevenir una

posible quemadura.

Nota:

puede ingresar al calefactor más de una fuente de alimentación. Asegúrese de que toda la alimentación eléctrica esté

desconectada antes de la limpieza o el servicio.

2. Tenga cuidado al limpiar las aletas de los elementos calefactores,

para evitar dañarlas. Note también que las aletas son aguzadas y

pueden causar cortes; por eso, evite el contacto.

1. El usuario puede realizar una limpieza periódica del gabinete exterior. Los demás servicios deben estar a cargo de personal de servicio

calificado.

2. El gabinete del calefactor puede limpiarse con un paño húmedo

para eliminar el polvo que pueda haberse acumulado en las superficies. No utilice limpiadores o ceras agresivas en las superficies, ya

que podrían dañar el acabado o alterar el color durante el uso.

3. Para eliminar el polvo y la pelusa que se podrían haber acumulado

dentro del calefactor y alrededor de las aletas de los elementos

calefactores, puede utilizarse una aspiradora y/o aire comprimido. Si

se debe desmontar el calefactor para la limpieza, tenga cuidado al

limpiar las aletas del elemento calefactor para evitar dañarlas.

4. Después de la limpieza y del servicio, vuelva a montar la unidad

cuidando de colocar todos los accesorios de montaje que se

quitaron, restablezca la alimentación eléctrica, y haga una revisión

para asegurarse de que los calefactores estén funcionando correctamente.

Nota importante:

suministran dentro de los calefactores, incluidos uno o más controles de

límite de sobretemperatura (protector térmico). Vea en el Diagrama de

conexionado del calefactor los controles específicos provistos. Estos

controles de seguridad se proporcionan para apagar el calefactor, si

fuera necesario, a fin de mantener temperaturas seguras en caso de un

bloqueo u otra condición anormal. NO puentee ni retire estos importantes controles de seguridad, ya que se suministran para limitar las

temperaturas y evitar un posible incendio en caso de que el calefactor

esté sometido a una condición de sobrecalentamiento. Si se determina

que el calefactor está haciendo ciclos de apagado por medio de los controles de seguridad en el uso normal, descontinúe el uso del calefactor

hasta que pueda ser inspeccionado y reparado por personal de servicio

calificado.

existen dispositivos de seguridad incorporados que se

Figura 9 - Diagrama de conexionado

CONEXIONADO TÍPICO DE CALEFACTORES MÚLTIPLES (SIN CONTROLES)

PROTECTOR

TÉRMICO

A OTRO

CALEFACTOR

ALIMENTACIÓN ELÉCTRICA AL INTERRUPTOR DE

DESCONEXIÓN

ELEMENTOS CALEFACTORES

TORNILLO DE

PUESTA A TIERRA

CABLE Nº 10 CABLE Nº 10

NOTA : para ver el conexionado interno individual del

calefactor, consulte la etiqueta del diagrama de conexionado de la unidad.

TORNILLO DE

PUESTA A TIERRA

SECCIÓN DE

RELLENO

14

PROTECTOR

TÉRMICO

ELEMENTOS CALEFACTORES

TORNILLO DE

PUESTA A TIERRA

TORNILLO DE

PUESTA A TIERRA

A OTRO

CALEFACTOR

CONEXIONADO DE FÁBRICA

CONEXIONADO DEL SITIO

Page 15

IDENTIFICACIÓN DE

PIEZAS PARA

RENOVACIÓN:

CSLAS, CSLAM, CSLAL

TERMOSTATO

(OPCIONAL)

INTERRUPTOR DE

DESCONEXIÓN

(OPCIONAL)

MANGUITO AIS-

LANTE DEL ELEMEN-

TO CALEFACTOR

1213-2000-001

PROTECTOR DE

SOBRECARGA

4502-0007-VAR

TERMOSTATO

(OPCIONAL)

INTERRUPTOR DE

DESCONEXIÓN

(OPCIONAL)

MANGUITO AISLANTE DEL

ELEMENTO CALEFACTOR

1213-2000-001

REJILLA

ELEMENTO

CALEFAC-

TOR

WIREWAY COVER

6405-0053-VAR

REJILLA

PROTECTOR

DE SOBRE-

CARGA

PANEL

POSTERIOR

CUBIERTA

FRONTAL

1402-0315-VAR (OSH07A)

1402-0314-VAR (OSH14A)

ANEL

P

OSTERIOR

P

ELEMENTO

CALEFACTOR

CUBIERTA DEL

CANAL DE CABLES

RELÉ CON

TRANSFORMADOR

(OPCIONAL)

RELÉ DE POTENCIA

(OPCIONAL)

CUBIERTA

FRONTAL

RELÉ CON

TRANSFORMADOR

(OPCIONAL)

RELÉ DE POTENCIA

(OPCIONAL)

Elemento calefactor (prefijo del Nº de parte: 1802-2001)

Descripción Longitud del calefactor

28” 3’ 4’ 5’ 6’ 8’ 10’

125 W/pie 120 volts 085 087 089 091 093 – –

por 208 volts 086 088 090 092 094 095 096

elemento 240 volts 048 054 060 066 072 077 081

277 volts 049 055 061 067 073 078 082

188 W/pie. 120 volts 005 011 017 023 029 – –

por 208 volts 002 008 014 020 026 032 036

elemento 240 volts 001 007 013 019 025 031 035

277 volts 000 006 012 018 024 030 034

250 W/pie. 120 volts 004 010 016 022 028 ––

por 208 volts 003 009 015 021 027 033 037

elemento 240 volts 002 008 014 020 026 032 036

277 volts 001 007 013 019 025 031 035

Controles incorporados (opcionales)

Descripción Número de parte

UNIDADES UNIDADES CSLAS

CSLAM y CSLAL

Interruptor de desconexión 5216-0124-000 5216-0124-000

Relé con 120 volts R13700002B001 410043001

transformador: 208 volts R13700002B002 410043002

240 volts R13700002B003 410043003

277 volts R13700002B004 410043004

Relé de 24 volts 5018-2006-000 5018-2006-000

potencia 120 volts 5018-2006-001 5018-2006-001

208/240 volts 5018-2006-002 5018-2006-002

277 volts 5018-2006-003 5018-2006-003

Termostato 1 Polo 5813-0024-000 5813-0024-000

2 Polos 5813-0023-000 5813-0023-000

15

Page 16

Identificación de piezas para renovación: Controles opcionales - CSLAMBCS, CSLALBCS

Descripción Número de parte

Relé de mercurio, 1 polo, 30 A, bobina de 24 volts 5018-7050-001

Relé de mercurio, 1 polo, 60 A, bobina de 24 volts 5018-7049-001

Relé de mercurio, 1 polo, 30 A, bobina de 120 volts 5018-7050-002

Relé de mercurio, 1 polo, 60 A, bobina de 120 volts 5018-7049-002

Relé de mercurio, 1 polo, 30 A, bobina de 208 volts 5018-7050-003

Relé de mercurio, 1 polo, 60 A, bobina de 208 volts 5018-7049-003

Relé de mercurio, 1 polo, 30 A, bobina de 240 volts 5018-7050-004

Relé de mercurio, 1 polo, 60 A, bobina de 240 volts 5018-7049-004

Relé de mercurio, 1 polo, 30 A, bobina de 277 volts 5018-7050-005

Relé de mercurio, 1 polo, 60 A, bobina de 277 volts 5018-7050-005

Interruptor automático, 2 polos, 30 A 1226-7009-013

Interruptor automático, 2 polos, 60 A 1226-7009-010

Interruptor automático, 3 polos, 30 A 1226-7009-005

Interruptor automático, 3 polos, 60 A 1226-7009-002

Transformador 24 V, primario 120 V 5814-7017-007

Transformador 24 V, primario 208 V 5814-7017-002

Transformador 24 V, primario 240 V 5814-7017-007

Transformador 24 V, primario 277 V 5814-7017-001

Interruptor de desconexión 5216-0124-000

Termostato, 1 polo 5813-0024-000

Termostato, 2 etapas 5813-0023-000

Control neumático 5216-7027-001

Todos los productos fabricados por Marley Engineered Products están garantizados contra defectos de fabricación y de materiales por 1 año desde la fecha de

GARANTÍA LIMITADA

instalación,

instalación.

nominal -indicada en la placa de características- en más de 5 %, ni a equipos que hayan sido instalados o cableados incorrectamente, o mantenidos en forma

que no cumpla lo indicado en las instrucciones de instalación del producto. Todo reclamo por trabajos en garantía debe acompañarse con una prueba de la fecha

de instalación.

El cliente será responsable de todos los costos incurridos en el retiro o reinstalación de productos, incluyendo los costos de mano de obra y los costos de envío

incurridos para regresar productos a un Centro de Servicio de Marley Engineered Products. Dentro de las limitaciones de esta garantía, las unidades que no

funcionan deben regresarse al centro de servicio autorizado Marley más cercano, o al Centro de Servicio de Marley Engineered Products, y nosotros lo

repararemos o reemplazaremos, a nuestra opción, sin cargo para usted, con el flete de retorno pagado por Marley. Se acuerda que tal reparación o reemplazo

es el único recurso que Marley Engineered Products pone a su disposición.

LAS GARANTÍAS EXPUESTAS MÁS ARRIBA TOMAN EL LUGAR DE TODA OTRA GARANTÍA, EXPRESA O IMPLÍCITA, Y POR LA PRESENTE SE

DECLINA Y EXCLUYE DE ESTE ACUERDO TODA GARANTÍA IMPLÍCITA DE COMERCIABILIDAD Y ADECUACIÓN A UN PROPÓSITO PARTICULAR QUE

EXCEDA LAS GARANTÍAS EXPRESAS ANTEDICHAS. MARLEY ENGINEERED PRODUCTS NO SE HARÁ RESPONSABLE POR DAÑOS CONSIGUIENTES

QUE SE PRODUZCAN CON RESPECTO AL PRODUCTO, EN BASE YA SEA A NEGLIGENCIA, AGRAVIO, RESPONSABILIDAD ESTRICTA, O CONTRATO.

Algunos estados o jurisdicciones no permiten la exclusión o limitación de daños incidentales o consiguientes, de modo que la exclusión o limitación expresada

más arriba puede no aplicarse a su caso. Esta garantía le da derechos legales específicos, y usted puede tener también otros derechos, que varían de un estado o jurisdicción a otro.

Para obtener la dirección de su centro de servicio autorizado más cercano comuníquese con Marley Engineered Products en Bennettsville, SC, Estados Unidos,

llamando al 1-800-642-4328. Toda mercadería regresada a la fábrica debe ser acompañada por una autorización de retorno y una etiqueta de identificación de

servicio, disponibles ambas en Marley Engineered Products. Cuando solicite la autorización de retorno, incluya todos los números de catálogo mostrados en los

productos.

CÓMO OBTENER SERVICIO EN GARANTÍA, PIEZAS DE

REPUESTO E INFORMACIÓN GENERAL

1. Servicio o repuestos en garantía

2. Compra de repuestos

3. Información general sobre productos

Nota:

1. Número de modelo del producto

2. Fecha de fabricación

3. Número de parte o descripción

excepto los elementos calefactores los cuales están garantizados contra defectos en manufactura y materiales durante cinco años a partir de la fecha de

Esta garantía no se aplica a daños debidos a accidente, mal uso o alteración, ni a los casos en que la tensión eléctrica conectada supere a la tensión

1-800-642-4328

1-800-654-3545

www.marleymep.com

cuando solicite servicio, siempre dé la información que sigue:

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

Número de parte 5200-2210-002

ECR 38636

12/10

Page 17

Convecteurs

Convecteurs

commerciaux à hauteur

commerciaux à hauteur d’appui de fenêtre (Type

CSL)

d’appui de fenêtre

(Type CSL)

Instructions d’installation, d’utilisation et d’entretien

INSTRUCTIONS IMPORTANTES

GÉNERALITÉS

Ce radiateur est conçu pour fournir des années de fonctionnement sans souci comme source de chaleur principale ou auxiliaire,

pour du chauffage de confort dans des applications résidentielles (Modèle CSLAS de 250 maximum seulement) et commerciales.

L’installation ou l’utilisation de ce produit d’une quelconque manière non décrite ici annulera la garantie et pourrait entraîner des

blessures, des dégâts matériels ou des dommages permanents sur le radiateur.

AVERTISSEMENT

LORS DE L’UTILISATION D’APPAREILS ÉLECTRIQUES,

DES PRÉCAUTIONS DE BASE DOIVENT TOUJOURS ÊTRE

SUIVIES AFIN DE RÉDUIRE LE RISQUE DE DÉPART D'INCENDIE, DE COMMOTION ÉLECTRIQUE ET DE

BLESSURES AUX PERSONNES, INCLUANT CELLES QUI

SUIVENT :

1. Lisez toutes les instructions avant d’installer ou d’utiliser le

radiateur.

2. Un radiateur comporte à l’intérieur des parties chaudes, et

pouvant produire un arc ou des étincelles électriques. Ne

l’utilisez pas dans des zones où de l’essence ou des liquides inflammables sont utilisés. Ne l’utilisez pas non plus

en environnement corrosif, ou dans toute zone où des

matières explosives sont utilisées ou entreposées.

3. Ce radiateur est chaud quand il est en fonctionnement. Pour

éviter des brûlures, ne laissez pas de peau nue toucher ses

surfaces chaudes. Maintenez les matières combustibles,

RÉCEPTION

Le matériel au moment où il a été expédié était en bon état et

Marley Engineered Products garde un reçu pour l’embarquement clair, de ce fait tout dommage caché doit être signalé

immédiatement au transporteur pour inspection et traitement.

!

comme les meubles, les oreillers et la literie, les papiers, les

habits et les rideaux, à distance du radiateur.

4. Pour éviter un possible départ d’incendie, n'obstruez en

aucune façon les admissions et les échappements d’air.

5. N’insérez pas d’objets étrangers, et ne permettez pas qu’il

en entre, dans toute ouverture d’admission ou d’évacuation,

car cela peut causer une commotion électrique ou un départ

d’incendie, ou endommager le radiateur.

6. Une blessure sérieuse voire mortelle peut résulter d’une

commotion électrique. Assurez-vous que le circuit du

secteur d’alimentation électrique arrivant au radiateur est

bien débranché en amont à l’interrupteur général ou au panneau de service avant d’intervenir pour installer ou dépanner ce radiateur.

7. Ce radiateur n’est pour une utilisation résidentielle ou

domestique, sauf le modèle CSLAS de 250 watts par pied.

Remarque:

endroit central pour être utilisés selon les besoins. S’ils sont

demandés en séquence, les cartons devront être étiquetés avec

le numéro de pièce adéquat.

Il est conseillé de garder les cartons dans un

CONSERVEZ CES INSTRUCTIONS

Page 18

SPÉCIFICATIONS

Type CSL

Figure 1

Tableau A

Modèle CSLAS (H=5-1/2”; D=3”)”)

N° du longueur Total en Ampérage

catalogue* “L” Watts/pied Watts 120 V 208 V 240 V 277 V

-2125 125 250 2,4 1,2 1,0 0,9

-2188 28” 188 375 3,1 1,8 1,6 1,4

-2250 250 500 4,2 2,4 2,1 1,8

-3125 125 375 3,1 1,8 1,6 1,4

-3188 3’ 188 564 4,7 2,7 2,4 2,0

-3250 250 750 6,2 3,6 3,1 2,7

-4125 125 500 4,2 2,4 2,1 1,8

-4188 4 188 750 6,2 3,6 3,1 2,7

-4250 250 1000 8,3 4,8 4,2 3,6

-5125 125 625 5,2 3,0 2,6 2,2

-5188 5 188 940 7,8 4,5 3,9 3,4

-5250 250 1250 10,4 6,0 5,2 4,5

-6125 125 750 6,2 3,6 3,1 2,7

-6188 6 188 1125 9,4 5,4 4,7 4,1

-6250 250 1500 12,5 7,2 6,2 5,4

-8125 125 1000 - 4,8 4,2 3,6

-8188 8’ 188 1500 - 7,2 6,2 5,4

-8250 250 2000 - 9,6 8,3 7,2

-10125 125 1250 - 6,0 5,2 4,5

-10188 10’ 188 1875 - 9,0 7,8 6,7

-10250 250 2500 - 12,0 10,4 9,0

Tableau d’écartements

Pour un fonctionnement sûr et efficace, maintenez au moins les écartements suivants en permanence :

Bas du radiateur jusqu’à la finition de sol :

Longueur du radiateur Entrée par Entrée pour

watts/pied le bas frontale

125, 188 et 250 1-3/4” (44 mm) 0” (0 mm)

376 500, 625, et 750 3” (76 mm) 0” (0 mm)

Dessus du radiateur au bas des rideaux surmontant

le radiateur :

Distance minimale de 12 pouces (305 mm)

Remarque importante :

des stores en vinyle) peuvent être endommagés par l’air réchauffé

venant du radiateur, et ne doivent être installés au-dessus de lui.

De l’avant du radiateur aux rideaux sur toute la longueur

devant lui :

Distance minimale entre le bas des rideaux et le sol – 2-½ pouces

(64 mm)

Distance minimale entre le haut des rideaux et le plafond – 1/2

pouce (13 mm)

Distance minimale entre l’avant du radiateur et le pli le plus proche

des rideaux – 2 pouces (51 mm)

Dessus du radiateur au bas de l’appui de fenêtre :

Distance minimale de 12 pouces (305 mm)

Certains tissus et matériaux en vinyle (comme

Tableau A (suite)

Modèle CSLAM (H=7” ; D=5”)

Modèle CSLAL (H=7” ; D=5”)

Ampérage

N° du

catalogue* “L” Watts/pied Watts

-2125 125 250 1,2 - 1,0 - 0,9

-2188 188 375 1,8 - 1,6 - 1,4

-2250 250 500 2,4 - 2,1 - 1,8

-2375 28” 375 750 3,6 - 3,1 - 2,7

-2500 500 1000 4,8 - 4,2 - 3,6

-2564 564 1125 5,4 3,1 4,7 2,7 4,0

-2625 625 1250 6,0 3,5 5,2 3,0 4,5

-2750 750 1500 7,2 4,2 6,2 3,6 5,4

-3125 125 375 1,8 - 1,6 - 1,4

-3188 188 564 2,7 - 2,4 - 2,0

-3250 250 750 3,6 - 3,1 - 2,7

-3375 3’ 375 1125 5,4 - 4,7 - 4,0

-3500 500 1500 7,2 - 6,2 - 5,4

-3564 564 1690 8,1 4,7 7,4 4,3 6,1

-3625 625 1875 9,0 5,2 7,8 4,5 6,7

-3750 750 2250 11,0 6,5 9,4 5,4 8,1

-4125 125 500 2,4 - 2,1 - 1,8

-4188 188 750 3,6 - 3,1 - 2,7

-4250 250 1000 4,8 - 4,2 - 3,6

-4375 4’ 375 1500 7,2 - 6,2 - 5,4

-4500 500 2000 9,6 - 8,3 - 7,2

-4564 564 2250 10,8 6,2 9,4 5,4 8,0

-4625 625 2500 12,0 6,9 10,4 6,0 9,0

-4750 750 3000 14,4 8,3 12,5 7,2 10,8

-5125 125 625 3,0 - 2,6 - 2,2

-5188 188 940 4,5 - 3,9 - 3,4

-5250 250 1250 6,0 - 5,2 - 4,5

-5375 5’ 375 1875 9,0 - 7,8 - 6,7

-5500 500 2500 12,0 - 10,4 - 9,0

-5564 564 2820 13,5 7,8 11,8 6,8 10,2

-5625 625 3125 15,0 8,7 13,0 7,5 11,3

-5750 750 3750 18,0 10,4 15,6 9,0 13,5

-6125 125 750 3,6 - 3,1 - 2,7

-6188 188 1125 5,4 - 4,7 - 4,0

-6250 250 1500 7,2 - 6,2 - 5,4

-6375 6’ 375 2250 10,8 - 9,4 - 8,1

-6500 500 3000 14,4 - 12,5 - 10,8

-6564 564 3380 16,2 9,4 14,1 8,1 12,2

-6625 625 3750 18,0 10,4 15,6 9,0 13,5

-6750 750 4500 21,6 12,5 18,7 10,8 16,2

-8125 125 1000 4,8 - 4,2 - 3,6

-8188 188 1500 7,2 - 6,2 - 5,4

-8250 250 2000 9,6 - 8,3 - 7,2

-8375 8’ 375 3000 14,4 - 12,5 - 10,8

-8500 500 4000 19,2 - 16,7 - 14,4

-8564 564 4500 21,6 12,5 18,7 10,8 16,2

-8625 625 5000 24,0 13,9 20,8 12,0 18,0

-8750 750 6000 28,6 16,5 15,0 14,4 21,6

-10125 125 1250 6,0 - 5,2 - 4,5

-10188 188 1875 9,0 - 7,8 - 6,7

-10250 250 2500 12,0 - 10,4 - 9,0

-10375 10’ 375 3750 18,0 - 15,6 - 13,5

-10500 500 5000 24,0 - 20,8 - 18,0

-10564 564 5640 27,2 15,7 23,5 13,6 20,4

-10625 625 6250 30,0 17,3 26,0 15,0 22,6

-10750 750 7500 36,0 20,8 31,3 18,1 27,0

longueur