Page 1

Description

CDF500 Series

Ceiling Mounted

Marley downflow ceiling mounted heaters are designed for

recessed or surface applications. Surface mounted heaters

extend only six inches into the room. Recessed mounted

eaters recess only seven inches into the ceiling. Mounts

h

easily into 2 X 2 foot ceiling grids.

Fan Forced Heaters

Installation, Operation & Maintenance Instructions

Specifications

Model Kw

CDF552SE 5/3.8/2.5 17.2/13.0/8.5 240 1-3 20.8/15.8/10.4 283 (133.5) 45

CDF547SE 4/3/2 13.7/10.2/6.8 277 1 14.5/10.8/7.2 283 (133.5) 51

CDF548SE 4/3/2 13.7/10.2/6.8 208 1-3 19.2/14.4/9.6 283 (133.5) 51

CDF557SE 5/3.8/2.5 17.2/13.0/8.5 277 1 18.1/13.7/9.0 283 (133.5) 45

CDF558SE 5/3.8/2.5 17.2/13.0/8.5 208 1-3 24.0/18.2/12.0 283 (133.5) 45

Model Kw

CDF552RE 5/3.8/2.5 17.2/13.0/8.5 240 1-3 20.8/15.8/10.4 283 (133.5) 45

CDF547RE 4/3/2 13.7/10.2/6.8 277 1 14.5/10.8/7.2 283 (133.5) 51

CDF548RE 4/3/2 13.7/10.2/6.8 208 1-3 19.2/14.4/9.6 283 (133.5) 51

CDF557RE 5/3.8/2.5 17.2/13.0/8.5 277 1 18.1/13.7/9.0 283 (133.5) 45

CDF558RE 5/3.8/2.5 17.2/13.0/8.5 208 1-3 24.0/18.2/12.0 283 (133.5) 45

(1) Factory wired for highest wattage, field convertible to lower wattages.

(2) Factory wired 1Ø, field convertible to 3Ø.

(3) On dual phase units, maximum amp draw is listed.

(4) Temperature difference at highest rated wattage.

1

1

BTU/Hr. (000) Volts Phase

BTU/Hr. (000) Volts Phase

Surface Mounted

Recessed Mounted

2

2

Amps

Amps

3

3

CFM (dm3/s) °F

CFM (dm3/s) °F

4

4

CAUTION - TO REDUCE RISK OF FIRE AND ELECTRIC

SHOCK OR INJURY TO PERSONS, OBSERVE THE

FOLLOWING:

1. To prevent electrical shock, disconnect all power coming to

heater at main service panel before wiring or servicing.

2. All wiring must be in accordance with the National and Local

Electrical Codes and the heater must be grounded as a precaution against possible electric shock.

3. Verify the power supply voltage coming to heater matches

the ratings printed on the heater nameplate before energizing.

4. This heater is intended for ceiling installation ONLY. Do not

install the heater closer than 12” (305 mm) to any wall for

4000W models and 24” (609 mm) to any wall for 5000W

models.

5. Do not insert or allow foreign objects to enter any ventilation

or exhaust opening as this may cause an electric shock, fire,

or damage to the heater.

SAVE THESE INSTRUCTIONS

WARNING

6. To prevent a possible fire, do not block air intakes or

exhaust in any manner. Keep combustible materials, such

as crates, drapes, etc., away from heater.

7. A heater has hot and arcing (sparking) parts inside. Do not

use it in areas where gasoline, paint, or flammable liquids

are used or stored.

8. This heater is not approved for use in corrosive atmospheres such as marine, green house, or chemical storage

areas.

9. The heater enclosure must be securely mounted to ceiling

or framing capable of supporting the heater (45 lbs/20.4 kg).

Failure to do so could allow heater to fall.

10. Do not operate heater without outlet grilles installed. When

installing grilles with louver guides, make sure guides drop

into position so they cannot slide out during use.

!

Page 2

IMPORTANT SAFETY INFORMATION

FAILURE TO INSTALL THE FOUR MOUNTING NUTS TO

SECURE HEATER TO MOUNTING FRAME COULD RESULT

IN THE HEATER FALLING (SEE FIGURE 2).

FAILURE TO INSTALL THE FOUR SCREWS COULD ALLOW

THE SURFACE ENCLOSURE TO FALL (SEE FIGURE 2).

IMPORTANT NOTICE: This heater is wired so the fan will come

n with no delay when energized as the thermostat is calling for

o

heat. When the thermostat is satisfied, the fan must continue to

run until the heater has cooled to a safe temperature. If an

external thermostat or controls are to be used, DO NOT wire

heater so thermostat shuts power to fan. The heater will be

damaged and the warranty will be voided. Thermostat must be

connected as shown on wiring diagram (Figure 13, page 7) for

correct operation.

NOTE: Field wiring must be #10 AWG min. rated 90°C min. Max

run length 125’ at 208V/5 kW. Wiring Compart-ment Volume:

3

252 in

(4130 cm3).

INSTALLATION

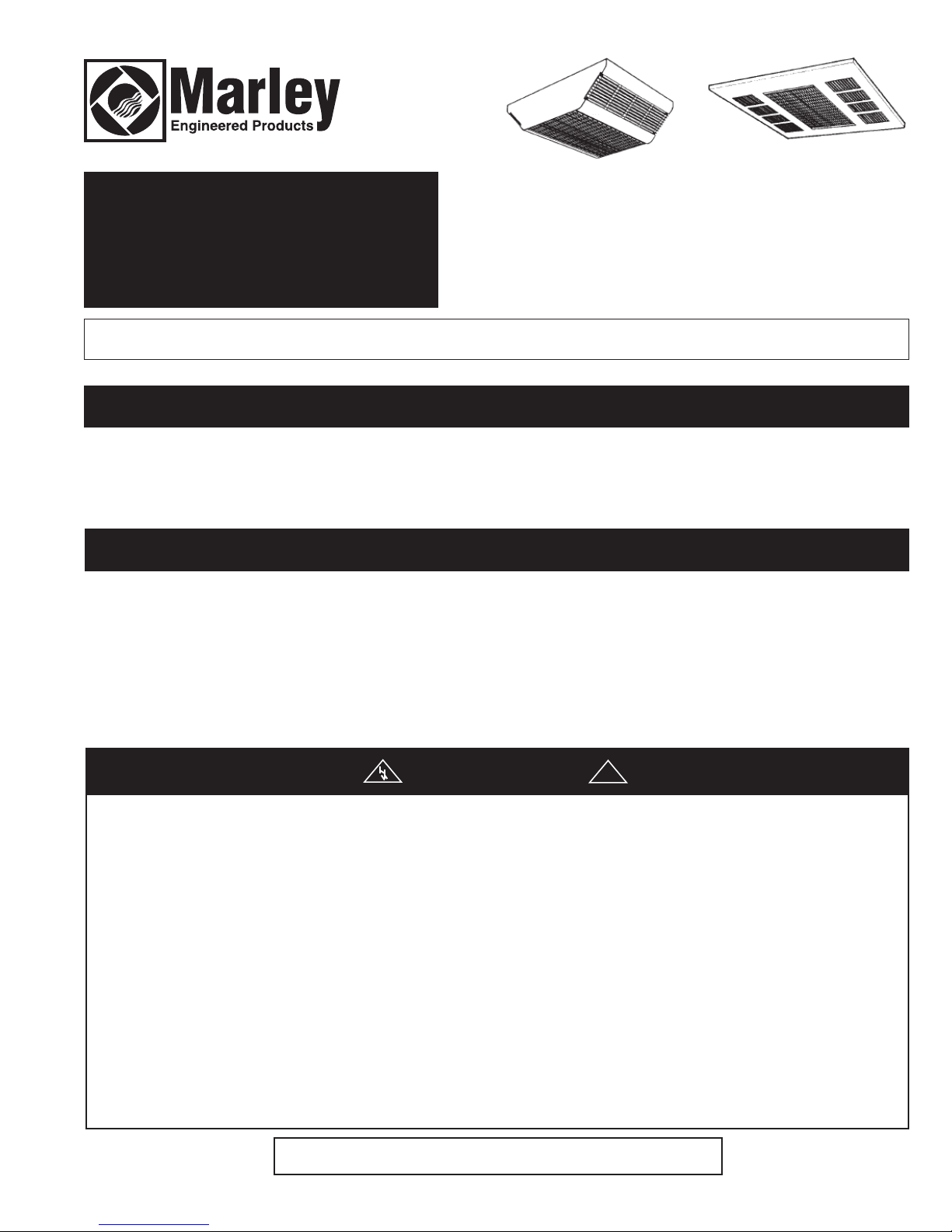

Installation of Surface Mounted Heaters

(See Figures 1 and 2)

1. Determine the desired location of the heater. See Warning

No. 4, page 1 for minimum mounting clearances.

2. Remove Surface Mounted Heater assembly from carton.

Heater assembly includes (1) surface mounting plate,

(1) heater, (1) surface mount enclosure and (1) set of

discharge grilles, Figure 2, page 3.

3. Remove Surface Mount Enclosure from assembly. Remove

four (4) nuts from studs so heater can be removed from surface mounting plate. Do not discard nuts since these will be

used in Step 11 to mount heater back on to surface plate.

4. Remove one of the knockouts and install a cable or conduit

connector.

7/8”(22.2 mm) & 11/8”

(28.6 mm) Nested

Knockout

Screw (2)

Optional

Disconnect

Switch

(CDFDS)

7/8”

(22.2 mm)

Knockout

FFiigguurree 11

5. Install the optional disconnect switch CDFDS (if required) as

shown in Figure 1. Refer to accessory installation manual for

proper wiring.

6. Run the power supply cable through the connector, leaving

about 8” (203 mm) of wire inside the surface mounting plate.

(Power supply cable must be #10 AWG min. rated 90°C minimum. Maximum run length 125' at 208V/5kW.)

1/2”(12.7 mm)

Knockout

Surface

Mounting

Plate

1/2” (12.7 mm) Knockout

Cable or Conduit

Connector

Surface

Mounting Plate

7. Position the surface mounting plate against the ceiling and

secure with bolts or screws (Figure 2). See Warning No. 9,

age 1. Connect the ground wire to the green ground screw

p

on the surface mounting plate.

8. Install optional controls (if required) into the heater section in

accordance with the Instruction Sheet packaged with the

control.

. To wire the heater, thermostat, reduce wattage or convert

9

from single to three-phase voltage, refer to “Field Conversion

for Lower Wattage Rating” or “Conversion for 3ø Installation”

on page 7 and wiring diagrams, Figure 13, page 7.

TO REDUCE THE RISK OF FIRE OR PERMANENT DAMAGE

TO THE HEATER, THERMOSTAT MUST BE WIRED AS

SHOWN IN WIRING DIAGRAM. DO NOT CONNECT THERMOSTAT IN MAIN POWER LINES BECAUSE IT WILL

DEFEAT THE FAN DELAY FUNCTION.

10. Position the heater section over the studs on the surface

mounting plate (Figure 2).

NOTE: The end of the heater section with the terminal block

must be positioned at the end of the surface mounting plate

where the supply wiring enters.

11. Push the heater section onto the studs and securely tighten

four (4) nuts (removed from step 3) on the studs to secure the

heater section to the surface mounting plate (Figure 2).

FAILURE TO INSTALL THE FOUR MOUNTING NUTS COULD

RESULT IN THE HEATER FALLING (SEE FIGURE 2).

NOTE: Insure that the “thumb pin” in each end of the discharge

grille opening is pulled outward to allow the body of the thumb

pins to fit into the holes in the heater section (Figure 2).

12. Position the surface mounting enclosure over heater sec-

tion/surface mounting plate, making sure that the thumb

pins are in the holes in the heater section.

13. With the surface enclosure seated firmly against the heater

section, depress the “thumb pins”. This will cause the

thumb pins to expand and will temporarily hold the surface

enclosure in place.

NOTE: The thumb pins are an aid to help position and hold the

surface mounting enclosure during installation. Additional support (step 14) is required. See Warning.

FAILURE TO INSTALL THE FOUR SCREWS COULD ALLOW

THE SURFACE WRAPPER TO FALL (SEE FIGURE 2).

14. Install and securely tighten four screws (supplied) to secure

the surface mounting enclosure to the heater section

(Figure 2).

15. Install discharge air grilles. (Refer to “Installation of

Discharge Air Grilles”, page 6.)

2

Page 3

Grounding Screw

Screws

or Bolts

(Not Supplied)

Nut (4)

2” (305 mm) Min. 4 kW

1

4” (609 mm) Min. 5 kW

2

Surface Mounting

Plate

Power Supply

Cable

12” (305 mm) Min. 4 kW

24” (609 mm) Min. 5 kW

Thumb Pin

Hole (2)

Heater Section

Surface Mounting Enclosure

Stud (4)

able or

C

onduit

C

onnector

C

Screw (2)

Screw (3)

1/2” (12.7 mm) Knockout

7/8” & 11/8” (22.2 mm

& 28.5 mm) Knockout

Optional

Disconnect

Switch

(CDFDS)

7/8” & 11/8” (22.2 mm &

28.5 mm) Nested Knockout

Side

Panel

1/2” (12.7 mm) Knockout

Grounding

Screw

Stud (4)

Thumb Pin Hole

(2)

Screw (4)

FFiigguurree 22

Insure that “Thumb Pin” is pulled out before positioning

the surface mounting enclosure on the heater section.

Depress “Thumb Pin” after surface enclosure is sealed

firmly against the heater section.

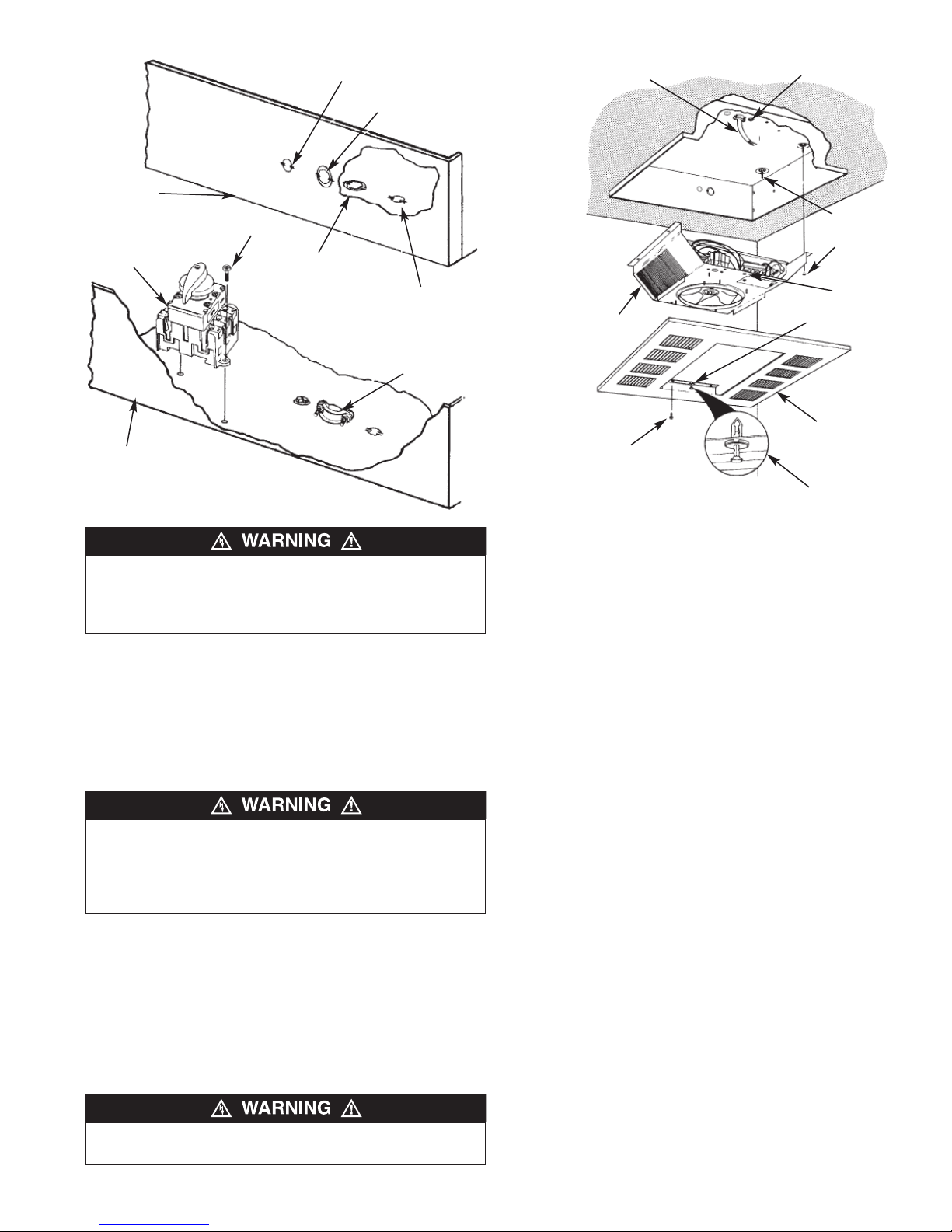

Installation of Recess Mounted Heaters in T-Bar

Ceiling (See Figures 3 and 4)

The recess mounted heater will mount in any standard 2’ x 2’

(609 mm x 609 mm) T-Bar (drop) ceiling. See Warning No. 4 for

minimum mounting clearance and Warning No. 9, page 1.

1. Remove Recess Mounted Heater assembly from carton.

Heater assembly includes (1) recess mounting box, (1)

heater, (1) recess mount face plate and (1) set of discharge

grilles, Figure 3.

2. Remove recess mount box from assembly. Remove four (4)

nuts from studs so heater can be removed from recess

mounting box. Do not discard nuts since these will be used

in Step 9 to mount heater section back on to the recess

mounting box.

3. Remove three screws and the side of the recess mounting

box to allow for easier wiring (Figure 3).

4. Remove one of the knockouts and install a cable or conduit

connector (Figure 3).

5. Install the optional disconnect switch CDFDS (if required as

shown in Figure 3). Refer to accessory instal lation manual

for proper wiring.

6. Install optional controls (if required) into the heater section in

accordance with the Instruction Sheet packaged with the

control.

7. To wire the heater, thermostat, reduce wattage or convert

from single to three-phase voltage, refer to “Field Conversion

for Lower Wattage Rating” or “Conversion for 3ø Installation”

on page 7 and wiring diagrams, Figure 13, page 7.

Recess Mounting Box

Heater Section

Recess Face Plate

Screw (4)

FFiigguurree 33

Heater

Wall

12” (305 mm) Min. 4 kW

24” (609 mm) Min. 5 kW

FFiigguurree 44

3

Thumb Pin Hole (2)

Nut (4)

Thumb

Pin (2)

Insure that “Thumb Pin” is

pulled out before positioning

the face plate on the heater

section. Depress “Thumb Pin”

after face plate is sealed firmly

against the heater section.

T-Bar Grid

Power Supply

Cable

Wall

12” (305 mm) Min. 4 kW

24” (609 mm) Min. 5 kW

Page 4

TO REDUCE THE RISK OF FIRE OR PERMANENT DAMAGE

TO THE HEATER, THERMOSTAT MUST BE WIRED AS

SHOWN IN WIRING DIAGRAM. DO NOT CONNECT THERMOSTAT IN MAIN POWER LINES BECAUSE IT WILL

DEFEAT THE FAN DELAY FUNCTION.

8. Position the heater section over the studs in the recess

ounting box (Figure 3).

m

NOTE: The end of the heater section with the terminal block

ust be posi tioned at the end of the recess mounting box where

m

the supply wiring enters.

9. Push the heater section onto the studs and securely tighten

the four (4) nuts (removed from step 3) on the studs to

secure the heater section to the recess mounting plate

(Figure 3).

16. Connect the ground wire to the green ground screw on the

recess mounting box.

17. After wiring is complete, replace and secure the side of the

recess mount ing box previously removed in Step 3.

18. Install discharge air grilles. Refer to “Installation of

Discharge Air Grilles”, page 6.

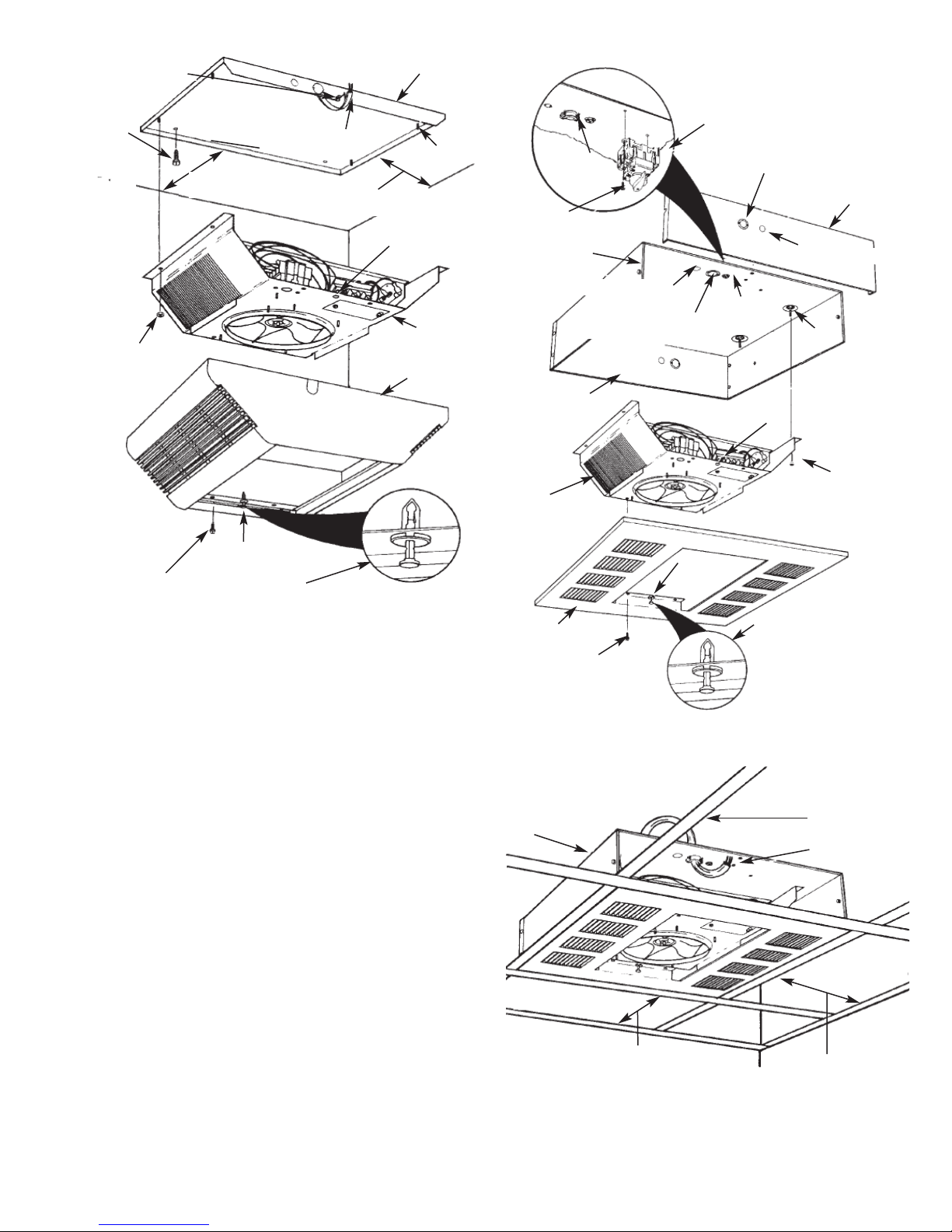

Installation of Recess Mounted Heaters in Permanent

Ceiling (See Figures 5, 6, 7 and 8)

1. Determine the desired location of the heater. See Warning

No. 4 for minimum mounting clearance and Warning No. 9,

page 1.

1

2. Cut a 22

ceiling for the recess mounting box (Figure 5).

. Remove Recess Mounted Heater assembly from carton.

3

Heater assembly includes (1) recess mounting box, (1)

heater, (1) recess mount face plate and (1) set of discharge

grilles.

⁄4” x 221⁄4” (565 mm x 565 mm) mounting hole in the

FAILURE TO INSTALL THE FOUR MOUNTING NUTS COULD

RESULT IN THE HEATER FALLING (SEE FIGURE 3).

NOTE: Insure that the “thumb pin” in each end of the discharge

grille opening is pulled outward to allow the body of the thumb

pins to fit into the holes in the heater section (Figure 3).

FAILURE TO INSTALL THE FOUR SCREWS COULD ALLOW

THE SURFACE WRAPPER TO FALL (SEE FIGURE 3).

10. Position the recess face plate over the heater

section/recess mounting box, making sure that the thumb

pins are in the holes in the heater section.

11. With the recess face plate seated firmly against the heater

section, depress the “thumb pins”. This will cause the

thumb pins to expand and will temporarily hold the recess

face plate in place.

NOTE: The thumb pins are an aid to help position and hold the

recess face plate during installation. Additional support (Step 12)

is required.

FAILURE TO INSTALL THE FOUR SCREWS COULD ALLOW

THE SURFACE WRAPPER TO FALL (SEE FIGURE 3).

12. Install and securely tighten four screws (supplied) to secure

the recess face plate to the heater section (Figure 3).

13. Determine the desired location of the heater.

14. Position the heater in the T-bar grid (Figure 4) and secure

as required.

THE HEATER ENCLOSURE MUST BE SECURELY MOUNTED TO CEILING OR FRAMING CAPABLE OF SUPPORTING

THE HEATER (45 LBS/20.4 KG). FAILURE TO DO SO COULD

ALLOW HEATER TO FALL.

1

2

2

/4”

565 mm)

221/4”

(565 mm)

12” (305 mm) Min. 4 kW

24” (609 mm) Min. 5 kW

Wall

8’ (2438 mm) to Floor Min.

14’ (4267 mm) to Floor Max.

(

12”

(305 mm)

Min. 4 kW

Wall

24”

(609 mm)

Min. 5 kW

FFiigguurree 55

4. Remove recess mount box from assembly. Remove four (4)

nuts from studs so heater can be removed from recess

mounting box. Do not discard nuts since these will be used

in Step 13 to mount heater section back on to the recess

mounting box.

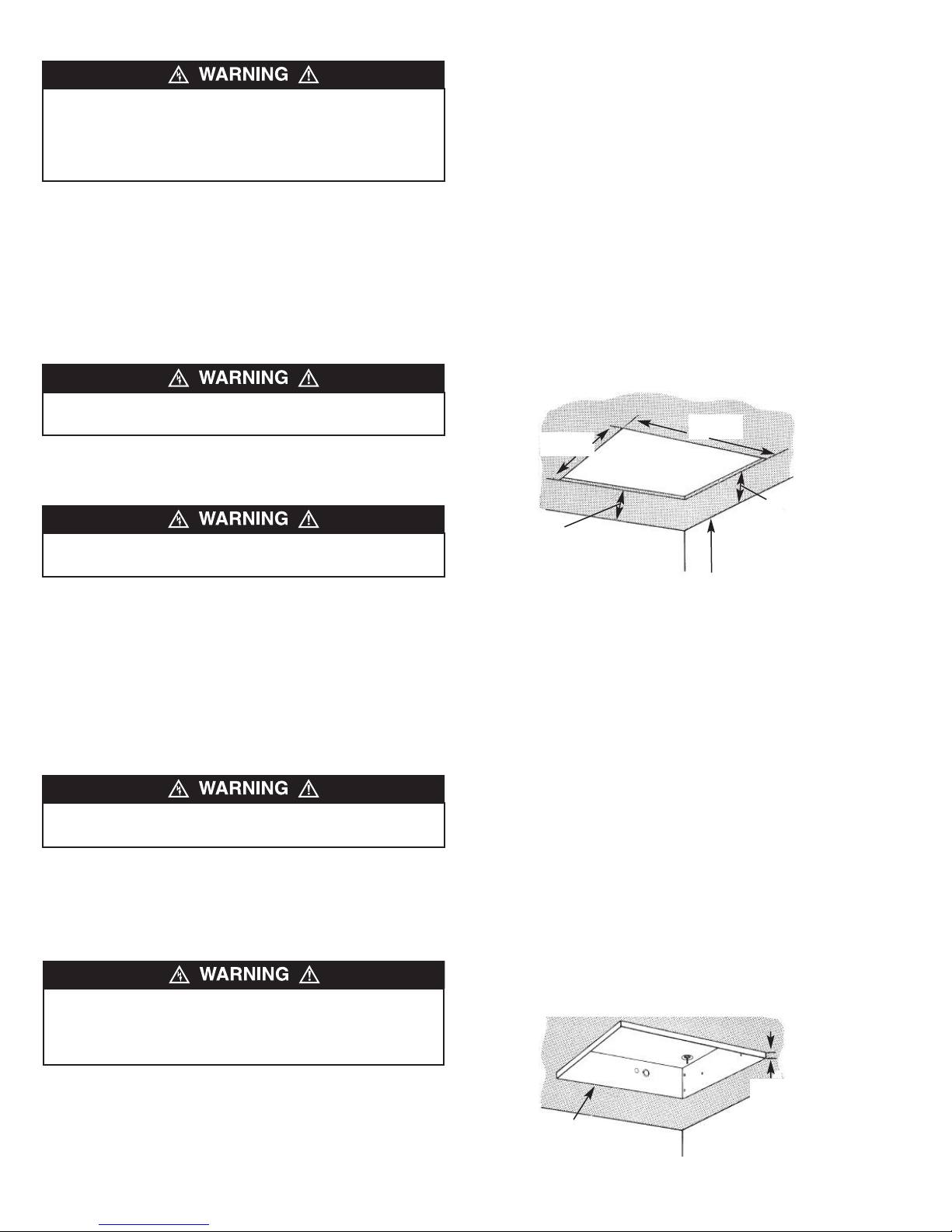

5. Remove one of the knockouts and install a cable or conduit

connector (Figure 7).

6. Install the optional disconnect switch (if required) as shown

in Figure 7.

7. Run the power supply cable through the connector, leaving

about 8” (203 mm) of wire inside the recess mounting box.

(Power supply cable must be #10 AWG min. rated 90°C

minimum.)

8. Place the recess mounting box in the ceiling opening and

align the marks on the sides of the mounting box with the

bottom of the finished ceiling (Figure 6). This will position the

edge of the mounting box 3/8” (9.5 mm) below the ceiling

and will allow the recess face plate to lay flat against the

ceiling.

9. Secure the recess mounting box to the building structure

using a mini mum of four fasteners (not supplied).

15. Run the power supply cable through the connector, leaving

about 8” (203 mm) of wire inside the recess mounting box.

(Power supply cable must be #10 AWG min. rated

90°C minimum.)

FFiigguurree 66

4

Recess Mounting

Box

3/8”

(9.5 mm)

Wall

Wall

Page 5

1/2” (12.2 mm) Knockout

1

7/8” & 1

/8”

(22.2 & 28.5 mm)

Nested Knockout

Recess

Mounting

Box

Optional

Disconnect

Switch (CDFDS)

Recess

Mounting

Box

Screw (2)

7/8” & 11/8”

(22.2 & 28.5 mm)

Nested Knockout

1/2” (12.2 mm)

Knockout

Cable or

Conduit

Connector

FFiigguurree 77

THE HEATER ENCLOSURE MUST BE SECURELY MOUNTED TO CEILING OR FRAMING CAPABLE OF SUPPORTING

THE HEATER (45 LBS/20.4 KG). FAILURE TO DO SO COULD

ALLOW HEATER TO FALL.

10. Install optional controls (if required) into the heater section

in accordance with the Instruction Sheet packaged with the

control.

11. To wire the heater, thermostat, reduce wattage or convert

from single to three-phase voltage, refer to “Field

Conversion for Lower Wattage Rating” or “Conversion for

3ø Installation” on page 7 and wiring diagrams, Figure 13,

page 7.

TO REDUCE THE RISK OF FIRE OR PERMANENT DAMAGE

TO THE HEATER, THERMOSTAT MUST BE WIRED AS

SHOWN IN WIRING DIAGRAM. DO NOT CONNECT THERMOSTAT IN MAIN POWER LINES BECAUSE IT WILL

DEFEAT THE FAN DELAY FUNCTION.

12. Position the heater section over the studs in the recess

mounting box (Figure 8).

Note: The end of the heater section with the terminal block must

be posi tioned at the end of the recess mounting box where the

supply wiring enters.

13. Push the heater section onto the studs and securely tighten

the four (4) nuts (removed from step 4) on the studs to

secure the heater section to the recess mounting box

(Figure 8).

FAILURE TO INSTALL THE FOUR MOUNTING NUTS COULD

RESULT IN THE HEATER FALLING (SEE FIGURE 8).

rounding

G

crew

S

Stud (4)

Nut (4)

Thumb

Pin Hole

Thumb Pin

Recess Face

Plate

FFiigguurree 88

Heater

Section

Screw (4)

Power Supply

Cable

Insure that “Thumb Pin” is pulled out

before positioning the face plate on

the heater section. Depress “Thumb

Pin” after face plate is sealed firmly

against the heater section.

14. Connect the ground wire to the green ground screw on the

recess mounting box.

15. Position the recess face plate over the heater

section/recess mounting box, making sure that the thumb

pins are in the holes in the heater section.

16. With the recess face plate seated firmly against the heater

section, depress the “thumb pins”. This will cause the

thumb pins to expand and will temporarily hold the recess

face plate in place.

Note: The thumb pins are an aid to help position and hold the

recess face plate during installation. Additional support (Step 17)

is required. See Warning, page 2.

17. Install and securely tighten four screws (supplied) to secure

the recess face plate to the heater section (Figure 8).

18. Install discharge air grilles. (Refer to “Installation of

Discharge Air Grilles.”)

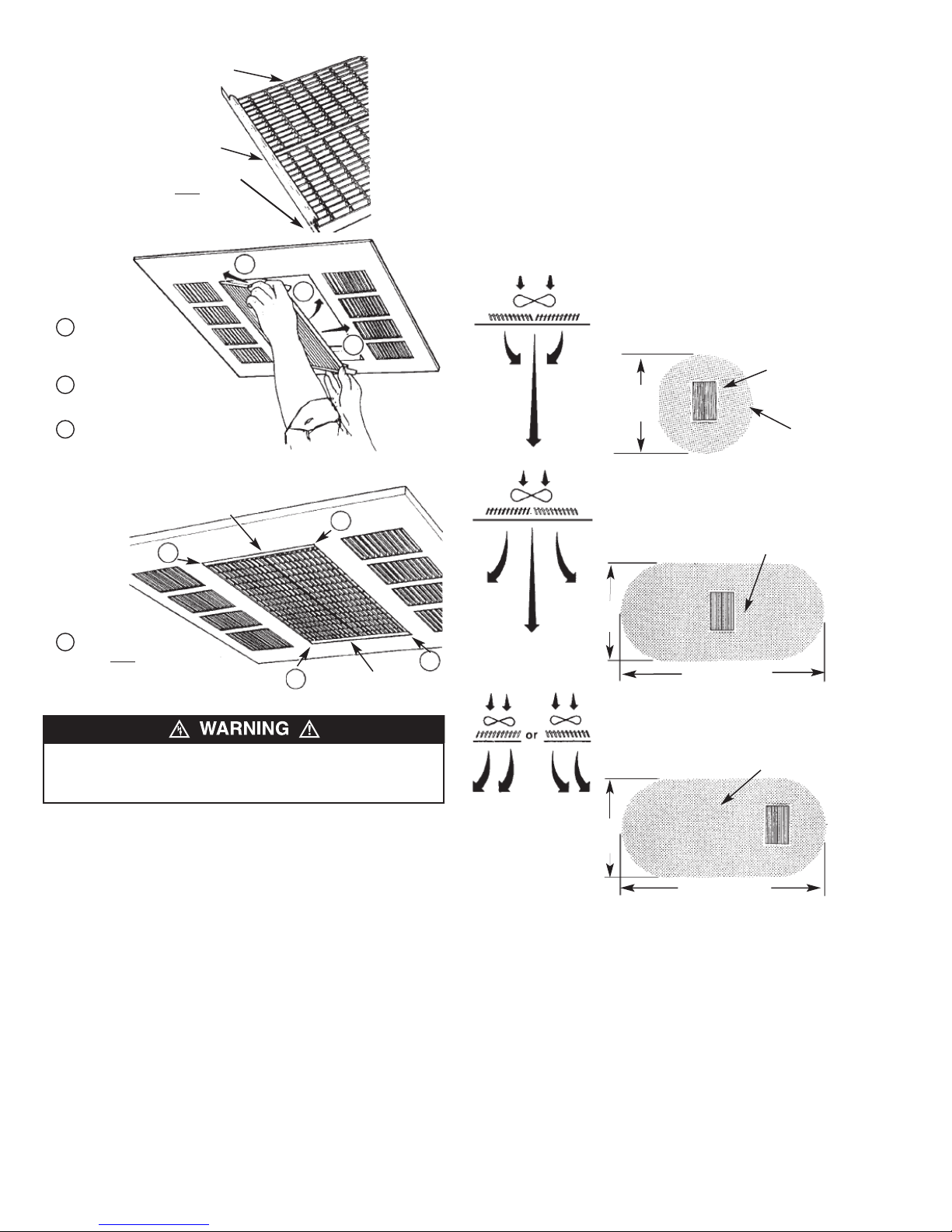

Installation of Discharge Air Grilles

(See Figures 9, 10 and 11)

1. Refer to “Adjustable Discharge Grilles Custom Air Flow

Patterns”, page 6 of this instruction sheet to determine

desired air flow direction.

2. Place the two discharge grilles onto a flat surface in the

desired configura tion with tabs on each end of grilles

upward.

3. Fit the two louver guides over the two discharge grilles as

shown in Figure 9.

4. While holding the assembly together with both hands, fit one

side of assembly into the opening of the enclosure, and slide

this side inward while fitting the opposite side into the enclosure. (See Figure 10.) Slide the assembly into position so

that the bottom portion of each guide locks into the opening.

5

Page 6

9

FFiigguurree 9

Slide grille assembly

1

into opening far enough

to clear louver ends.

2

Push grille assembly up

into opening.

3

Slide grille assembly

into position in opening.

FFiigguurree 1100

Discharge Grille (2)

Louver Guides

Tabs on Discharge

Grilles Must

Upward

Louver Guide

Face

Adjustable Discharge Grilles Custom Air Flow

Patterns (Figure 12)

1. The discharge air pattern is deter mined by the arrangement

of the discharge grilles.

2. Care must be taken when selecting location of heater. Refer

to “Installation of Discharge Air Grilles”, page 5.

Note: The discharge grill area is rectang ular; the discharge

grilles can only be installed parallel to the intake louvers.

DDiisscchhaarrggee AAiirr

1

2

3

1

GGrriillllee AArrrraannggeemmeenntt

NARROW AIR PATTERN for high ceiling applications

(11’ (3352 mm) to 14’ (4267 mm)), concentrates the

heated air to ensure full penetration to the floor level.

8’

(2438 mm)

WIDE AIR PATTERN for standard ceiling applications

(8’ (2438 mm) to 10’ (3048 mm)), disperses the air to

give a gentle, less pronounced pattern while circulating all the air from floor to ceiling.

CCuussttoomm AAiirr

FFllooww PPaatttteerrnn

Heater Discharge

Grilles

Air Pattern on Floor

1

Bottom of each louver

1

guide Must

position in opening.

lock in

1

Louver Guide

FFiigguurree 1111

TO PREVENT THE DISCHARGE GRILLE GUIDES FROM

FALLING, THE GUIDES MUST BE FITTED (LOCKED) IN

POSITION AS SHOWN IN FIGURE 12.

1

FFiigguurree 1122

Air Pattern on Floor

8’

(2438 mm)

24’ (7315 mm)

ASYMMETRICAL AIR PATTERN directs heated air in a

specific direction, allowing the heater to be located

where space allows with the heated air delivered to

where it is required.

Air Pattern on Floor

10’

(3048 mm)

17’ (5181 mm)

6

Page 7

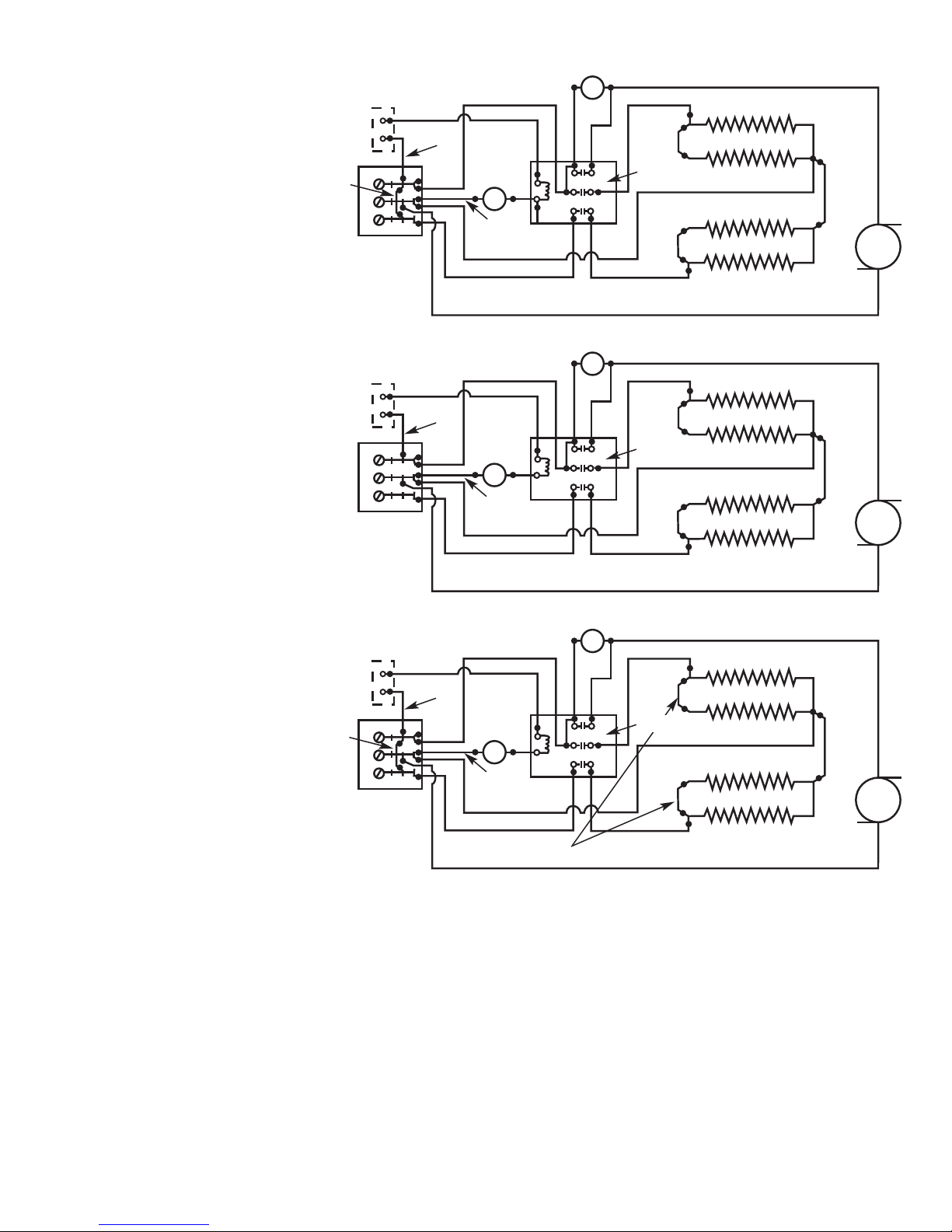

Wiring Diagrams

Standard Wiring Diagram

(Factory Wired)

Optional Field Installed Wall

Thermostat SPST or Internal CDFT

Thermostat Accessory

White

Blue

Power

Block

Blue

Black

White

High

Limit

Black

Black

Blk

Fan Delay

Yellow

L1

L2

L3

Black

Black

Yellow

T1

2

T

T3

Red

Contactor

Red

Element 1

Black

Element 2

Black

Fan

Wiring

Conversion

for 3Ø

Installation

Wiring

Conversion

to Lower

Wattage

(1Ø)

Optional Field Installed Wall

Thermostat SPST or Internal CDFT

Thermostat Accessory

White

Power

Block

Optional Field Installed Wall

Thermostat SPST or Internal CDFT

Thermostat Accessory

White

Blue

Power

Block

Blue

Blue

Black

White

High

Limit

Black

Black

Black

White

High

Limit

Black

Black

Blk

Blk

Fan Delay

Yellow

1

L

L2

3

L

Fan Delay

Yellow

L1

L2

L3

Black

Black

Black

Element 1

Black

Element 2

Element 1

Black

Element 2

Black

Fan

Black

Fan

Yellow

1

T

2

T

3

T

Yellow

T1

T2

T3

Red

Contactor

Red

Black

Red

Contactor

Red

FFiigguurree 1133 –– EElleeccttrriiccaall WWiirriinngg

OPERATION

1. Set the thermostat (internal or remote) to highest setting.

This will energize the heating elements and the fan causing

air to flow from the center of the heater.

2. After the operational check, set the thermostat to obtain the

desired comfort level.

Note: Heater contains a fan delay on shut down.

– The fan energizes immediately when the thermostat turns on

the elements.

– Fan will operate for a short time after the heating elements

are turned off (approx. 1 minute).

Remove One (1) Red Jumper to Obtain 3/4 Nameplate Wattage

Field Conversion for Lower Wattage Rating

(Figure 13)

To convert the heater to a lower watt-age rating, completely

remove one (1) red jumper wire from one heating element for

25% wattage reduction. Completely remove two (2) red jumper

wires for a 50% wattage reduction. Discard the jumper(s). Be

sure the remaining wires are securely connected.

Conversion for 3Ø Installation

Heater is factory wired for connection to 1Ø only. To convert to

3Ø, remove and discard blue jumper wire between L1 & L3.

(Figure 13).

7

Page 8

MAINTENANCE

TO PREVENT ELECTRICAL SHOCK, DISCONNECT ALL

POWER TO HEATER AT MAIN SERVICE PANEL BEFORE

SERVICING.

1. Once each year the heater should be cleaned to remove

ust and foreign material which has collected during the

d

heating season.

2. Turn off all electrical power at the circuit breaker or fuse box

to discon nect the electrical power to heater.

3. Remove dust and other foreign material with a vacuum

leaner nozzle or dust cloth.

c

4. Turn on the main line switch to restore power to the heater.

IMPORTANT INFORMATION

NAMEPLATE

MODEL NO. 557 DATE CODE: 1195

CEILING HEATER FAN DECK

BÀTI DU VENTILATEUR, APPAREIL DE PLAFOND

OLTS WATTS AMPS

V

277VAC 5000 18.1

OR SUPPLY CONNECTIONS USE NO. 10AWG

F

OR LARGER WIRES SUITABLE FOR 90°C MIN.

UTILISER UN CÁBLE D´ALIMENTATION D´AU MOINS

NO. 10AWG CONVENANT À UNE TEMPERATURE

´AU MOINS 90°C.

D

774G LISTED

AIR HEATER

Figure 14

8

Page 9

SURFACE

1

7

MOUNTING

ENCLOSURE,

2

6

8

RECESS

4

3

FFiigguurree 1155 –– RReeppaaiirr PPaarrttss IIlllluussttrraattiioonn ffoorr CCeeiilliinngg MMoouunntteedd FFaann FFoorrcceedd HHeeaatteerrss

8

7

MOUNTING

ENCLOSURE,

Repair Parts List for Ceiling Mounted Fan Forced Heaters

Ref. Part Number for Models:

No. Description CDF552SE CDF547SE CDF548SE CDF557SE CDF558SE Qty.

1 Element 302012813 302012803 302012801 302012814 302012812 2

2 Fan Delay 1414-2039-000 1414-2039-000 1414-2039-000 1414-2039-000 1414-2039-000 1

3 Fan Blade 1210-2000-000 1210-2000-000 1210-2000-000 1210-2000-000 1210-2000-000 1

4 Motor 3900-2011-000 3900-2011-001 3900-2011-000 3900-2011-001 3900-2011-000 1

5 High Limit 4520-0011-000 4520-0011-000 4520-0011-000 4520-0011-000 4520-0011-000 1

6 Contactor 5018-0004-102 5018-0004-103 5018-0004-102 5018-0004-103 5018-0004-102 1

7 Outlet Grille 2501-2020-001 2501-2020-001 2501-2020-001 2501-2020-001 2501-2020-001 2

8 Louver Guides 1215-2059-001 1215-2059-001 1215-2059-001 1215-2059-001 1215-2059-001 2

(Surface)

Ref. Part Number for Models:

No. Description CDF552RE CDF547RE CDF548RE CDF557RE CDF558RE Qty.

1 Element 302012813 302012803 302012801 302012814 302012812 2

2 Fan Delay 1414-2039-000 1414-2039-000 1414-2039-000 1414-2039-000 1414-2039-000 1

3 Fan Blade 1210-2000-000 1210-2000-000 1210-2000-000 1210-2000-000 1210-2000-000 1

4 Motor 3900-2011-000 3900-2011-001 3900-2011-000 3900-2011-001 3900-2011-000 1

5 High Limit 4520-0011-000 4520-0011-000 4520-0011-000 4520-0011-000 4520-0011-000 1

6 Contactor 5018-0004-102 5018-0004-103 5018-0004-102 5018-0004-103 5018-0004-102 1

7 Outlet Grille 2501-2020-001 2501-2020-001 2501-2020-001 2501-2020-001 2501-2020-001 2

8 Louver Guides 1215-2059-000 1215-2059-000 1215-2059-000 1215-2059-000 1215-2059-000 2

(Recessed)

9

Page 10

All products manufactured by Marley Engineered Products are warranted against defects in workmanship and materials for one year from date of installation, except

LIMITED WARRANTY

heating elements which are warranted against defects in workmanship and materials for five years from date of installation. This warranty does not apply to damage from

accident, misuse, or alteration; nor where the connected voltage is more than 5% above the nameplate voltage; nor to equipment improperly installed or wired or

maintained in violation of the product’s installation instructions. All claims for warranty work must be accompanied by proof of the date of installation.

The customer shall be responsible for all costs incurred in the removal or reinstallation of products, including labor costs, and shipping costs incurred to return products

to Marley Engineered Products Service Center. Within the limitations of this warranty, inoperative units should be returned to the nearest Marley authorized service center or the Marley Engineered Products Service Center, and we will repair or replace, at our option, at no charge to you with return freight paid by Marley. It is agreed that

such repair or replacement is the exclusive remedy available from Marley Engineered Products.

THE ABOVE WARRANTIES ARE IN LIEU OF ALL OTHER WARRANTIES EXPRESSED OR IMPLIED, AND ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE WHICH EXCEED THE AFORESAID EXPRESSED WARRANTIES ARE HEREBY DISCLAIMED AND EXCLUDED FROM

THIS AGREEMENT. MARLEY ENGINEERED PRODUCTS SHALL NOT BE LIABLE FOR CONSEQUENTIAL DAMAGES ARISING WITH RESPECT TO THE

PRODUCT, WHETHER BASED UPON NEGLIGENCE, TORT, STRICT LIABILITY, OR CONTRACT.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above exclusion or limitation may not apply to you. This warranty gives

you specific legal rights, and you may also have other rights which vary from state to state.

For the address of your nearest authorized service center, contact Marley Engineered Products in Bennettsville, SC, at 1-800-642-4328. Merchandise returned to the factory must be accompanied by a return authorization and service identification tag, both available from Marley Engineered Products. When requesting return authorization,

include all catalog numbers shown on the products.

HOW TO OBTAIN WARRANTY SERVICE AND

WARRANTY PARTS PLUS GENERAL INFORMATION

1. Warranty Service or Parts 1-800-642-4328

2. Purchase Replacement Parts 1-800-654-3545

3. General Product Information www.marleymep.com

Note: When obtaining service always have the following:

1. Model number of the product

2. Date of manufacture

3. Part number or description

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

Part No. 5200-11039-000

ECR 38415

08/09

Page 11

Descripción

Series CDF500

Calentadores de Tiro

Forzado por Ventilador

para Montaje en Cielo Raso

Los calentadores de flujo descendente para montaje en cielo

raso Dayton están diseñados para aplicaciones empotradas o

en superficie. Los calentadores montados en superficie se

extienden sólo 15.2 cm hacia dentro de la habitación. Los calentadores de montaje empotrado se empotran sólo 17.8 cm dentro

del cielo raso. Se monta fácilmente en las cuadrículas de cielo

raso de 609 mm x 609 mm (2 pies x 2 pies).

Instrucciones de instalación, operación y mantenimiento

Especificaciones

Modelo Kw

CDF552SE 5/3.8/2.5 17.2/13.0/8.5 240 1-3 20.8/15.8/10.4 283 (133.5) 45

CDF547SE 4/3/2 13.7/10.2/6.8 277 1 14.5/10.8/7.2 283 (133.5) 51

CDF548SE 4/3/2 13.7/10.2/6.8 208 1-3 19.2/14.4/9.6 283 (133.5) 51

CDF557SE 5/3.8/2.5 17.2/13.0/8.5 277 1 18.1/13.7/9.0 283 (133.5) 45

CDF558SE 5/3.8/2.5 17.2/13.0/8.5 208 1-3 24.0/18.2/12.0 283 (133.5) 45

Modelo Kw

CDF552RE 5/3.8/2.5 17.2/13.0/8.5 240 1-3 20.8/15.8/10.4 283 (133.5) 45

CDF547RE 4/3/2 13.7/10.2/6.8 277 1 14.5/10.8/7.2 283 (133.5) 51

CDF548RE 4/3/2 13.7/10.2/6.8 208 1-3 19.2/14.4/9.6 283 (133.5) 51

CDF557RE 5/3.8/2.5 17.2/13.0/8.5 277 1 18.1/13.7/9.0 283 (133.5) 45

CDF558RE 5/3.8/2.5 17.2/13.0/8.5 208 1-3 24.0/18.2/12.0 283 (133.5) 45

(1) Cableado en la fábrica para el mayor vataje, se puede convertir a vatajes más bajos en el campo.

(2) Cableado en la fábrica para 1Ø, puede convertirse a 3Ø en el campo.

(3) En las unidades de doble fase, se indica el consumo de corriente máximo.

(4) Diferencia de temperatura a la mayor capacidad de vataje.

1

1

BTU/Hr. (000) Voltios Fase

BTU/Hr. (000) Voltios Fase

Montaje en Superficie

Montaje Empotrado

2

2

Amperios

Amperios

3

3

PCM (dm3/s) °F

PCM (dm3/s) °F

4

4

ATENCIÓN: PARA REDUCIR EL PELIGRO DE INCENDIO Y

CHOQUE ELÉCTRICO O DAÑOS PERSONALES, OBSERVE

LO SIGUIENTE:

1. Para evitar el riesgo de choque eléctrico, desconecte toda

la alimentación eléctrica suministrada para el calentador en

el panel principal de servicio antes de intentar hacer

cualquier trabajo de cableado o mantenimiento.

2. Todo el cableado deberá cumplir con los códigos eléctricos

nacionales y loca-les, y el calentador debe conectarse a

tierra como una medida de precaución contra un posible

choque eléctrico.

3. Verifique que el voltaje de alimenta-ción suministrado al

calentador coin-cida con los valores de capacidad impresos

en la placa de identificación del calentador antes de energizarlo.

4. Este calentador está diseñado SOLO para instalación en

cielos rasos. No instale el calentador a menos de

305 mm (12 pulg.) de cualquier pared para los modelos

4kW y 609 mm (24 pulg.) de cualquier pared para los

modelos 5kW.

5. No inserte ni permita que objetos extraños entren en ningu-

CONSERVE ESTAS INSTRUCCIONES

ADVERTENCIA

na abertura de ventilación o escape, ya que esto podría

causar un choque eléctrico, incendio o daños al calentador.

6. Para evitar un posible incendio, no bloquee de ninguna

manera las entradas o salidas de aire. Mantenga los

materiales combustibles, como las cajas de madera,

cortinas, etc. lejos del calentador.

7. Los calentadores tienen en su inte-rior piezas calientes y

productoras de arcos eléctricos (chispas eléctricas). No

utilice el calentador en las áreas donde se utilice o

almacene gasolina, pintura o líquidos inflamables.

8. Este calentador no está aprobado para uso en atmósferas

corrosivas, como por ejemplo, de mar, inver-naderos o

áreas de almacenamiento de productos químicos.

9. La cubierta del calentador debe montarse fijamente en un

cielo raso o entramado que pueda soportar el peso del

calentador (20.4 kg/45 lb.). El calentador se puede caer si

no se cumple con lo anterior.

10. No utilice el calentador si la rejilla de la salida no está instalada. Cuando instale rejillas con guías de rejilla, asegúrese

que las guías queden fijas en posición para que no puedan

deslizarse y soltarse durante el uso de la unidad.

!

Page 12

IMPORTANTE INFORMACION DE SEGURIDAD

EL CALENTADOR SE PUEDE CAER SI NO SE INSTALAN LAS

CUATRO TUERCAS DE MONTAJE PARA FIJAR EL CALENTADOR EN EL BASTIDOR DE MONTAJE (VEA LA FIGURA 2).

LA CUBIERTA PARA SUPERFICIES SE PUEDE CAER SI NO

SE INSTALAN LOS CUATRO TORNILLOS (VEA LA FIGURA 2).

AVISO IMPORTANTE: Este calentador está cableado para que

el ventilador se active sin ningún retardo cuando está energizado

el termostato está pidiendo calor. Cuando el termostato está

y

satisfecho, el ventilador debe seguir funcionando hasta que el

calentador se enfríe y alcance una temperatura no peligrosa. Si

van a utilizarse un termostato externo o controles externos, NO

conecte el calentador de manera que el termostato corte la alimentación eléctrica para el ventilador. El calentador se dañará y

la garantía será anulada. El termostato debe conectarse como se

muestra en el diagrama de cableado (Figura 13, página 17) para

que la unidad funcione correctamente.

AVISO: El cableado de campo deberá ser de tamaño No. 10

AWG como mínimo, con capacidad de 90°C como mínimo.

Máxima longitud de cable de 38 m (125 pies) a 208V/5 kW.

Volumen del compartimiento de cableado: 4130 cm

3

(252 pulg.3).

INSTALACIÓN

Instalación de los Calentadores de Montaje en

Superficie (vea las Figuras 1 y 2)

1. Determine el lugar deseado para el calentador. Consulte la

Advertencia No. 4 en la página 11 para ver los espacios

libres mínimos de montaje.

2. Extraiga de la caja el conjunto del Calentador de Montaje en

Superficie. El conjunto del calentador incluye (1) placa de

montaje en superficie, (1) calentador, (1) cubierta de montaje

en superficie y (1) juego de rejillas de descarga.

3. Extraiga del conjunto la Cubierta de Montaje en Superficie.

Extraiga cuatro (4) tuercas de los pasadores de manera que el

calentador pueda retirarse de la placa de montaje en superficie.

No deseche las tuercas ya que se utilizarán en el Paso 11 para

montar nuevamente el calentador en la placa de superficie.

4. Destape uno de los agujeros ciegos e instale un conector de

cable o conducto.

5. Instale el interruptor de desconexión opcional CDFDS (si es

necesario) como se muestra en la Figura 1. Consulte el

manual de instalación del accesorio para ver cómo se

conecta correctamente éste.

Agujero ciego encajado de

22.2 mm (7/8 pulg.) y

28.6 mm (1

Interrup-tor de

des-conexión

opcional

(CDFDS)

1

/8pulg.)

Tornillo (2)

FFiigguurraa 22

Agujero

ciego de

22.2 mm

(7/8 pulg.)

Agujero ciego de

12.7 mm (1/2 pulg.)

Placa de montaje

en superficie

Agujero ciego de

12.7 mm (1/2 pulg.)

Conector de cable o conducto

Placa de montaje

en superficie

6. Pase el cable de suministro eléctrico a través del conector y

deje aproximadamente 203 mm (8 pulg.) de conductor

entro de la placa de montaje en superficie. (El cable de

d

suministro eléctrico debe ser de tamaño No. 10 AWG como

mínimo, con capacidad de 90°C como mínimo. Máxima

longitud de cable de 38 m [125 pies] a 208V/5 kW.)

7. Coloque la placa de montaje en superficie contra el cielo raso y

fíjela con pernos o tornillos (Figura 2). Consulte la Advertencia

No. 9, en la página 1. Conecte el conductor de tierra al tornillo

verde de conexión a tierra en la placa de montaje en superficie.

8. Instale los controles opcionales (si son necesarios) en la

sección del calentador de acuerdo con la Hoja de

Instrucciones suministrada con el control.

9. Para conectar el calentador, reducir el vataje o convertir de

voltaje monofásico a trifásico, consulte “Conversión en el

campo para una menor capacidad de vatios” o “Conversión

para una instalación trifásica” en la página 17 y en los

diagramas de cableado, Figura 13, página 17.

PARA REDUCIR EL RIESGO DE INCENDIO O DE DAÑO

PERMANENTE AL CALEFACTOR, EL TERMOSTATO DEBE

CABLEARSE COMO SE INDICA EN EL DIAGRAMA DE

CONEXIONADO. NO CONECTE EL TERMOSTATO A LAS

LÍNEAS DE ALIMENTACIÓN PRINCIPAL, PORQUE ESTO

ANULARÁ LA FUNCIÓN DE RETARDO DE VENTILADOR.

10. Coloque la sección del calentador sobre los pasadores de

la placa de montaje en superficie (Figura 2).

AVISO: El extremo de la sección del calentador con el bloque de

terminales debe situarse en el extremo de la placa de montaje

en superficies por donde entra el cable de suministro eléctrico.

11. Presione la sección del calentador sobre los pasadores y

apriete bien las cuatro (4) tuercas (extraídas en el paso 3)

en los pasadores para asegurar la sección del calentador

en la placa de montaje en superficie (Figura 2).

EL CALENTADOR SE PUEDE CAER SI NO SE INSTALAN

LAS CUATRO TUERCAS DE MONTAJE (VEA LA FIGURA 2).

AVISO: Asegúrese que la “espiga de pulgar” en cada extremo

de la aber-tura de la rejilla de descarga no esté totalmente insertada, para permitir que los cuerpos de las espigas de pulgar

quepan en los orificios en la sección del calentador (Figura 2).

12. Coloque la cubierta de montaje en superficie sobre la

sección del calentador y la placa de montaje en superficie,

asegurándose que las espigas de pulgar estén insertadas

en los orificios en la sección del calentador.

13. Con la cubierta para superficies asentada firmemente contra la

sección del calentador, oprima e inserte las “espigas de pulgar”.

Esto causará que se expandan las espigas de pulgar y retendrá

temporalmente en posición la cubierta para superficies.

AVISO: Las espigas de pulgar facilitan la colocación y sujeción

de la cubierta de montaje en superficie durante la instalación.

Será necesario utilizar sujetadores adicionales (paso 14).

Consulte la Advertencia en la página 12.

LA ENVOLTURA PARA SUPERFICIE SE PUEDE CAER SI NO

SE INSTALAN LOS CUATRO TORNILLOS (VEA LA FIGURA 2).

12

Page 13

Tornillos o

pernos (no

suministrados)

Tuerca (4)

Tornillo de conexión

a tierra

05 mm (12 pulg.) mín. 4 kW

3

09 mm (24 pulg.) mín. 5 kW

6

Placa de montaje

en superficie

Cable de suministro

eléctrico

305 mm (12 pulg.) mín. 4 kW

609 mm (24 pulg.) mín. 5 kW

Agujero para espiga

de pulgar (2)

Sección del calentador

Cubierta de montaje en superficie

Pasador (4)

onector

C

e cable

d

conducto

o

Tornillo (2)

Tornillo (3)

Agujero ciego de

12.7 mm (1/2 pulg.)

Agujero ciego de 22.2 mm y

28.5 mm (7/8 pulg. y 1

Tornillo de conexión a tierra

Caja de montaje

empotrado

Interruptor de

desconexión

opcional (CDFDS)

1

/8pulg.)

Agujero ciego encajado

de 22.2 mm y 28.5 mm

(7/8 pulg. y 1

Agujero para

espiga de pulgar (2)

1

/8pulg.)

Agujero ciego de

12.7 mm (1/2 pulg.)

Panel lateral

Pasador

(4)

Tuerca (4)

Tornillo (4)

Agujero para espiga

de pulgar (2)

Asegúrese que la “Espiga de pulgar” no esté totalmente insertada

antes de colocar la cubierta de montaje en superficie sobre la

sección del calentador. Oprima e inserte la “Espiga de pulgar”

después de que la cubierta para superficies esté firmemente

FFiigguurraa 22

sellada contra la sección del calentador.

14. Instale y apriete firmemente cuatro tornillos (suministrados)

para fijar la cubierta de montaje en superficie en la sección

del calentador (Figura 2).

15. Instale las rejillas del aire de des-carga. (Consulte

“Instalación de las rejillas del aire de descarga”, en la

página 16).

Instalacion de los Calentadores de Montaje

Empotrado en Cielos Rasos de Barras T

(vea las Figuras 3 y 4)

El calentador de montaje empotrado puede montarse en

cualquier cielo raso (falso o colgante) de barras T estándar de

609 mm x 609 mm (2 pies x 2 pies).

Consulte la Advertencia No. 4 para los espacios libres mínimos

de montaje y la Advertencia No. 9, en la página 11.

1. Extraiga de la caja el conjunto del Calentador de Montaje

Empotrado. El conjunto del calentador incluye (1) caja de

montaje empotrado, (1) calentador, (1) placa frontal de

montaje empotrado y (1) juego de rejillas de descarga.

2. Extraiga del conjunto la caja de montaje empotrado. Extraiga

cuatro (4) tuercas de los pasadores de manera que el calentador

pueda retirarse de la caja de montaje empotrado. No deseche las

tuercas ya que se utilizarán en el Paso 9 para montar nuevamente

la sección del calentador en la caja de montaje empotrado.

3. Extraiga tres tornillos y retire un lado de la caja de montaje

empotrado para facilitar las conexiones eléctricas (Figura 3).

Sección del calentador

Placa frontal empotrada

Tornillo (4)

FFiigguurraa 33

Calentador

Pared

305 mm (12 pulg.) mín. 4 kW

609 mm (24 pulg.) mín. 5 kW

FFiigguurraa 44

Espiga de

pulgar (2)

Asegúrese que la “Espiga de

pulgar” no esté totalmente

insertada antes de colocar la

placa frontal sobre la sección

del calentador. Oprima e

inserte la “Espiga de pulgar”

después de que la placa frontal

esté firmemente sellada contra

la sección del calentador.

Cuadrícula de barras T

Cable de suministro

eléctrico

Pared

305 mm (12 pulg.) mín. 4 kW

609 mm (24 pulg.) mín. 5 kW

13

Page 14

4. Destape uno de los agujeros ciegos e instale un conector de

cable o conducto (Figura 3).

5. Instale el interruptor de desconexión opcional CDFDS (si es

necesario, según como se muestra en la Figura 3). Consulte

el manual de instalación del accesorio para conectar éste

correctamente.

6. Instale los controles opcionales (si son necesarios) en la

ección del calentador de acuerdo con la Hoja de

s

Instrucciones suministrada con el control.

7. Para conectar el calentador, termóstato, reducir el vataje o

convertir de voltaje monofásico a trifásico, consulte

“Conversión en el campo para una menor capacidad de

vatios” o “Conversión para una instalación trifásica” en la

página 17 y en los diagramas de cableado, Figura 13

PARA REDUCIR EL RIESGO DE INCENDIO O DE DAÑO

PERMANENTE AL CALEFACTOR, EL TERMOSTATO DEBE

CABLEARSE COMO SE INDICA EN EL DIAGRAMA DE

CONEXIONADO. NO CONECTE EL TERMOSTATO A LAS

LÍNEAS DE ALIMENTACIÓN PRINCIPAL, PORQUE ESTO

ANULARÁ LA FUNCIÓN DE RETARDO DE VENTILADOR.

8. Coloque la sección del calentador sobre los pasadores en la

caja de montaje empotrado (Figura 3).

AVISO: El extremo de la sección del calentador con el bloque

de terminales debe situarse en el extremo de la caja de montaje

empotrado por donde entra el cable de suministro eléctrico.

9. Presione la sección del calentador sobre los pasadores y

apriete bien las cuatro (4) tuercas (extraídas en el paso 3)

en los pasadores para asegurar la sección del calentador

en la placa de montaje empotrado (Figura 3).

EL CALENTADOR SE PUEDE CAER SI NO SE INSTALAN

LAS CUATRO TUERCAS DE MONTAJE (VEA LA FIGURA 3).

AVISO: Asegúrese que la “espiga de pulgar” en cada extremo

de la aber-tura de la rejilla de descarga no esté totalmente insertada, para permitir que los cuerpos de las espigas de pulgar

quepan en los orificios en la sección del calentador (Figura 3).

12. Instale y apriete firmemente cuatro tornillos (suministrados)

para fijar la placa frontal empotrada en la sección del calen-

ador (Figura 3).

t

13. Determine el lugar deseado para el calentador.

14. Coloque el calentador en la cuadrícula de barras T (Figura

4) y sujételo según sea necesario.

LA CUBIERTA DEL CALENTADOR DEBE MONTARSE FIJAMENTE EN UN CIELO RASO O ENTRAMADO QUE PUEDA

SOPORTAR EL PESO DEL CALENTADOR (20.4 KG/45 LB.).

EL CALENTADOR SE PUEDE CAER SI NO SE CUMPLE

CON LO ANTERIOR.

15. Pase el cable de suministro eléctrico a través del conector y

deje aproximadamente 203 mm (8 pulg.) de conductor dentro

de la caja de montaje empotrado. (El cable de suministro

eléctrico debe ser de tamaño No. 10 AWG como mínimo, con

capacidad de 90°C como mínimo.)

16. Conecte el conductor de tierra al tornillo verde de conexión

a tierra en la caja de montaje empotrado.

17. Después de hacer las conexiones, reinstale y fije el lado de

la caja de montaje empotrado extraído previamente en el

Paso 3.

18. Instale las rejillas del aire de descarga. Consulte

“Instalación de las rejillas del aire de descarga”, en la

página 16.

Instalacion de los Calentadores de Montaje

Empotrado en Cielos Rasos Permanentes

(vea las Figuras 5, 6, 7 y 8)

1. Determine el lugar deseado para el calentador. Consulte la

Advertencia No. 4 para los espacios libres mínimos de

montaje y la Advertencia No. 9, en la página 1.

1

2. Corte una abertura de montaje de 565 mm x 565 mm (22

pulg. x 221⁄4pulg.) en el cielo raso para la caja de montaje

empotrado (Figura 5).

3. Extraiga de la caja el conjunto del Calentador de Montaje

Empotrado. El conjunto del calentador incluye (1) caja de

montaje empotrado, (1) calentador, (1) placa frontal de montaje

empotrado y (1) juego de rejillas de descarga.

⁄

4

LA ENVOLTURA PARA SUPERFICIE SE PUEDE CAER SI NO

SE INSTALAN LOS CUATRO TORNILLOS (VEA LA FIGURA 3).

10. Coloque la placa frontal empotrada sobre la sección del

calentador y la caja de montaje empotrado, asegurándose

de que las espigas de pulgar estén insertadas en los orificios en la sección del calentador.

11. Con la placa frontal empotrada asentada firmemente contra la

sección del calentador, oprima e inserte las “espigas de pulgar”.

Esto causará que se expandan las espigas de pulgar y retendrá

temporalmente en posición la placa frontal empotrada.

AVISO: Las espigas de pulgar facilitan la colocación y sujeción

de la placa frontal empotrada durante la instalación. Será necesario utilizar sujetadores adicionales (Paso 12).

LA ENVOLTURA PARA SUPERFICIE SE PUEDE CAER SI NO

SE INSTALAN LOS CUATRO TORNILLOS (VEA LA FIGURA 3).

565 mm

(221/4pulg.)

305 mm (12 pulg.) mín. 4 kW

609 mm (24 pulg.) mín. 5 kW

FFiigguurraa 55

Caja de montaje empotrado

FFiigguurraa 55

14

565 mm

(221/4pulg.)

305 mm (12 pulg.) mín. 4 kW

609 mm (24 pulg.) mín. 5 kW

Pared

Mín. de 8 pies (2438 mm) desde el piso

Máx. de 14 pies (4267 mm) desde el piso

Pared

Pared

9.5 mm

(3/8 pulg.)

Pared

Page 15

Agujero ciego de 12.2 mm (1/2 pulg.)

Agujero ciego encajado

Caja de

montaje

empotrado

Interruptor de

desconexión

opcional (CDFDS)

Caja de montaje

empotrado

de 22.2 y 28.5 mm

(7/8 pulg. y 1

Tornillo (2)

Agujero ciego encajado de

22.2 y 28.5 mm

(7/8 pulg. y 11/8pulg.)

1

/8pulg.)

Agujero ciego de

12.2 mm

(1/2 pulg.)

Conector

de cable

o conducto

FFiigguurraa 77

4. Extraiga del conjunto la caja de montaje empotrado. Extraiga

cuatro (4) tuercas de los pasadores de manera que el

calentador pueda retirarse de la caja de montaje empotrado.

No deseche las tuercas ya que se utilizarán en el Paso 13 para

montar nuevamente la sección del calentador en la caja de

montaje empotrado.

5. Destape uno de los agujeros ciegos e instale un conector de

cable o conducto (Figura 7).

6. Instale el interruptor de desconexión opcional (si es

necesario) como se muestra en la Figura 7.

7. Pase el cable de suministro eléctrico a través del conector y

deje aproximadamente 203 mm (8 pulg.) de conductor dentro de la caja de montaje empotrado. (El cable de suministro

eléctrico debe ser de tamaño No. 10 AWG como mínimo,

con capacidad de 90°C como mínimo.)

8. Coloque la caja de montaje empotrado en la abertura en el cielo

raso y alinee las marcas en los lados de la caja de montaje con

la parte inferior del cielo raso acabado (Figura 6). Esto situará el

borde de la caja de montaje a 9.5 mm (3/8 pulg.) por debajo del

cielo raso y permitirá que la placa frontal empotrada descanse

plana sobre el cielo raso.

9. Fije la caja de montaje empotrado en la estructura del edificio usando un mínimo de cuatro sujetadores (no suministrados).

ornillo de

Tuerca (4)

T

onexión a

c

ierra

t

able de

C

uministro

s

léctrico

e

Agujero para

espiga de

pulgar

Placa frontal

empotrada

FFiigguurraa 88

Tornillo (4)

Pasador (4)

Agujero para

espiga de pulgar

Espiga de pulgar

Asegúrese que la “Espiga de

pulgar” no esté totalmente

insertada antes de colocar la

placa frontal sobre la sección

del calentador. Oprima e

inserte la “Espiga de pulgar”

después de que la placa frontal

esté firmemente sellada contra

la sección del calentador.

vatios” o “Conversión para una instalación trifásica” en la

página 17 y en los diagramas de cableado, Figura 13, página 17.

PARA REDUCIR EL RIESGO DE INCENDIO O DE DAÑO

PERMANENTE AL CALEFACTOR, EL TERMOSTATO DEBE

CABLEARSE COMO SE INDICA EN EL DIAGRAMA DE

CONEXIONADO. NO CONECTE EL TERMOSTATO A LAS

LÍNEAS DE ALIMENTACIÓN PRINCIPAL, PORQUE ESTO

ANULARÁ LA FUNCIÓN DE RETARDO DE VENTILADOR.

12. Coloque la sección del calentador sobre los pasadores en

la caja de montaje empotrado (Figura 8).

AVISO: El extremo de la sección del calentador con el bloque

de terminales debe situarse en el extremo de la caja de montaje

empotrado por donde entra el cable de suministro eléctrico.

13. Presione la sección del calentador sobre los pasadores y

apriete bien las cuatro (4) tuercas (extraídas en el paso 4)

en los pasadores para asegurar la sección del calentador

en la caja de montaje empotrado (Figura 9).

EL CALENTADOR SE PUEDE CAER SI NO SE INSTALAN

LAS CUATRO TUERCAS DE MONTAJE (VEA LA FIGURA 8).

LA CUBIERTA DEL CALENTADOR DEBE MONTARSE FIJAMENTE

EN UN CIELO RASO O ENTRAMADO QUE PUEDA SOPORTAR EL

PESO DEL CALENTADOR (20.4 KG/45 LB.). EL CALENTADOR SE

PUEDE CAER SI NO SE CUMPLE CON LO ANTERIOR.

10. Instale los controles opcionales (si son necesarios) en la sección del calentador de acuerdo con la Hoja de Instrucciones

suministrada con el control.

11. Para conectar el calentador, termóstato, reducir el vataje o

convertir de voltaje monofásico a trifásico, consulte

“Conversión en el campo para una menor capacidad de

14. Conecte el conductor de tierra al tornillo verde de conexión

a tierra en la caja de montaje empotrado.

15. Coloque la placa frontal empotrada sobre la sección del

calentador y la caja de montaje empotrado, asegurándose

de que las espigas de pulgar estén insertadas en los orificios en la sección del calentador.

16. Con la placa frontal empotrada asentada firmemente contra

la sección del calentador, oprima e inserte las “espigas de pulgar”. Esto causará que se expandan las espigas de pulgar y

retendrá temporalmente en posición la placa frontal empotrada.

15

Page 16

Rejilla de descarga (2)

Guías de rejilla

Las pestañas de las rejillas

de descarga deben

orientadas hacia arriba

Figura 9

Deslice e inserte el conjunto de la

1

rejilla en la abertura hasta que

pase los extremos de la rejilla.

Empuje el conjunto de la rejilla

2

hacia arriba e insértelo en la

abertura.

Deslice el conjunto de la rejilla a

3

su posición en la abertura.

Figura 10

Guía de rejilla

1

estar

1

Disposición de las rejillas

del aire de descarga

PATRON DE AIRE ESTRECHO: para aplicaciones

de cielos rasos altos (3352 mm [11 pies] a 4267

mm [14 pies]), concentra el aire calentado para

garantizar una penetración total hasta el nivel

del piso.

2438 mm (8

pies)

PATRON DE AIRE AMPLIO: para aplicaciones de

2

3

2438 mm (8

pies)

1

3048 mm (10

pies)

cielos rasos estándar (2438 mm [8 pies] a 3048

mm [10 pies]), dispersa el aire para brindar un

patrón más suave, menos pronunciado, a la vez que

se circula todo el aire desde el piso hasta el cielo

raso.

7315 mm (24 pies)

PATRON DE AIRE ASIMETRICO: dirige el aire

calentado en una cierta dirección, lo cual permite

situar el calentador donde hay suficiente espacio y

el aire calentado es entregado donde se necesita.

Patrón personalizado

de flujo del aire

Rejillas de descarga

del calentador

Patrón de aire en

el piso

Patrón de aire

en el piso

Patrón de aire

en el piso

La parte inferior de cada

1

guía de rejilla debe quedar fija

en posición en la abertura.

1

Figura 11

Guía de rejilla

AVISO: Las espigas de pulgar facilitan la colocación y sujeción

de la placa frontal empotrada durante la instalación. Será necesario utilizar sujetadores adicionales (Paso 17). Consulte la

Advertencia en la página 2.

17. Instale y apriete firmemente cuatro tornillos (suministrados)

para fijar la placa frontal empotrada en la sección del calentador (Figura 8).

18. Instale las rejillas del aire de descarga. (Consulte

“Instalación de las rejillas del aire de descarga”).

Instalacion de las Rejillas del Aire de Descarga

(vea las Figuras 9, 10 y 11)

1. Consulte “Patrones personalizados de flujo del aire de las

rejillas de descarga ajustables”, en la página 16 de esta hoja

de instrucciones para determinar la dirección deseada de

flujo del aire.

2. Coloque las dos rejillas de descarga sobre una superficie

plana usando la configuración con las pestañas en cada

extremo de las rejillas orientadas hacia arriba.

3. Encaje las dos guías de rejilla sobre las dos rejillas de

descarga como se muestra en la Figura 9.

FFiigguurraa 1122

4. Mientras sujeta junto el conjunto con las dos manos, inserte

1

un lado del conjunto en la abertura de la cubierta, y deslice

5181 mm (17 pies)

ese lado hacia adentro mientras encaja el lado opuesto en la

cubierta (vea la Figura 10). Deslice el conjunto en posición

de manera que la porción inferior de cada guía quede firmemente fijada en la abertura.

PARA IMPEDIR QUE LAS GUÍAS DE LAS REJILLAS DE DESCARGA

SE CAIGAN, ÉSTAS DEBEN ENCAJARSE (FIJARSE) EN POSICIÓN

COMO SE MUESTRA EN LA FIGURA 12.

Patrones Personalizados de Flujo del Aire de las

Rejillas de Descarga Ajustables

1. El patrón del aire de descarga es determinado por la disposición de las rejillas de descarga.

2. Se debe tener cuidado al seleccionar la ubicación del calentador. Consulte “Instalación de las rejillas del aire de

descarga”.

AVISO: El área de la rejilla de descarga es rectangular; las rejillas de descarga sólo pueden instalarse paralelas a las rejillas

de admisión.

16

Page 17

iagramas de Cableado

D

Diagrama de cableado estándar

(Cableado en fábrica)

Termóstato unipolar opcional de la

instalación del campo o termóstato

interno 2YU46 auxiliar

Blanco

Azul

Bloque de alimentación

Azul

Negro

Blanco

Límite

alto

Negro

Negro

Retardo del ventilador

L3

Negro

Negro

Negro

Amarillo

Amarillo

T1

L1

L2

2

T

T3

Rojo

Contacto

Rojo

Elemento 1

Negro

Elemento 2

Negro

Ventilador

Conversión del cableado

para instalación trifásica

Conversión del cableado

para un menor vataje

(monofásico)

Termóstato unipolar opcional

de la instalación del campo o

termóstato interno 2YU46 auxiliar

Blanco

Bloque de alimentación

Termóstato unipolar opcional

de la instalación del campo o

termóstato interno 2YU46 auxiliar

Blanco

Azul

Bloque de alimentación

Límite

Azul

Azul

Negro

Blanco

alto

Negro

Negro

Negro

Blanco

Límite

alto

Negro

Negro

Negro

Negro

Retardo del

ventilador

Amarillo

Amarillo

T

1

L

L2

T

3

L

Retardo del

ventilador

Amarillo

Amarillo

T1

L1

L2

T2

L3

Negro

Negro

Negro

Elemento 1

Negro

Elemento 2

Elemento 1

Negro

Elemento 2

Negro

Ventilador

Negro

Ventilador

Rojo

1

2

Contacto

3

T

Rojo

Negro

Rojo

Contacto

T3

Rojo

FFiigguurraa 1133 –– DDiiaaggrraammaa ddee CCaabblleeaaddoo

OPERACIÓN

1. Ajuste el termostato (interior o remoto) a la temperatura más

alta. Esto energizará los elementos de calefacción y el ventilador y causará que el aire fluya desde el centro del calentador.

2. Después de verificar el funcionamiento, ajuste el termostato

para obtener el nivel de comodidad deseado.

AVISO: El calentador tiene un retardo de ventilador para cuando se apaga el calentador.

– El ventilador se energiza inmediatamente cuando el ter-

mostato enciende o activa los elementos.

– El ventilador funcionará durante un corto tiempo después de que se

apagan los elementos de calefacción (aproximadamente 1 minuto).

Retire un (1) puente rojo para obtener 3/4 del vataje indicado en la placa de identificación

Conversion en el Campo para una Menor Capacidad

de Vatios (Figura 13)

Para convertir el calentador para una menor capacidad de

vatios, retire totalmente un (1) conductor rojo de puente de uno

de los elementos de calefacción para reducir el vataje en

un 25%. Retire totalmente dos (2) conductores rojos de puente

para reducir el vataje en un 50%. Deseche el puente o los

puentes. Asegúrese que los conductores restantes estén firmemente conectados.

Conversion para una Instalacion Trifasica

El calentador viene cableado de fábrica sólo para conexión

monofásica. Para convertirlo a trifásico, retire y deseche el conductor azul de puente entre L1 y L3. (Vea la Figura 13).

17

Page 18

MANTENIMIENTO

PARA EVITAR EL RIESGO DE CHOQUE ELÉCTRICO,

DESCONECTE TODA LA ALIMENTACIÓN ELÉCTRICA PARA EL

CALENTADOR EN EL PANEL PRINCIPAL DE SERVICIO ANTES

DE HACER CUALQUIER TRABAJO DE MANTENIMIENTO.

1. Se recomienda limpiar el calentador una vez por año para

eliminar el polvo y todo material extraño que se haya

cumulado durante la temporada de uso de la calefacción.

a

2. Corte el suministro eléctrico en el cortacircuito o la caja de

usibles para desconectar la alimentación eléctrica para el

f

calentador.

3. Limpie el polvo y todo otro material extraño con la boquilla

de una aspiradora o un trapo para limpiar polvo.

4. Vuelva a conectar el suministro eléctrico en el interruptor

principal de la línea de suministro para restablecer la alimentación eléctrica para el calentador.

INFORMACIÓN IMPORTANTE

PLACA DE IDENTIFICACION

FFiigguurraa 1144

ODELO NO.

M

PLATAFORMA DE VENTILADOR DE CALENTADOR

DE CIELO RASO

VOLTIOS VATIOS AMPERIOS

77V CA 5000 18.1

2

PARA LAS CONEXIONES DE SUMINISTRO

ELECTRICO UTILICE CONDUCTORES NO.

0 AWG O DE MAYOR CALIBRE ADECUADOS

1

PARA NO MENOS DE 90°C.

557 C

ODIGO DE FECHA:

1195

CALENTADOR DE

AIRE CON CLASIFI-

CACION 774G

18

Page 19

1

7

CUBIERTA DE MONTAJE

EN SUPERFICIE,

2

6

4

5

Figura 17 – Ilustración de las Partes de Reparación para los Calentadores de Tiro Forzado por Ventilador para Montaje en Cielo Raso y

Juego de Junta de Ajuste Auxiliar 2YU47

3

8

CUBIERTA DE MONTAJE

8

7

EMPOTRADO,

Lista de Partes de Reparación para los Calentadores de Tiro Forzado por Ventilador para

Montaje en Cielo Raso

No. de Número de Parte para Modelos:

Ref. Descripción CDF552SE CDF547SE CDF548SE CDF557SE CDF558SE Cant.

1 Elemento 302012813 302012803 302012801 302012814 302012812 2

2 Retardo del 1414-2039-000 1414-2039-000 1414-2039-000 1414-2039-000 1414-2039-000 1

3 Aspas del 1210-2000-000 1210-2000-000 1210-2000-000 1210-2000-000 1210-2000-000 1

4 Motor 3900-2011-000 3900-2011-001 3900-2011-000 3900-2011-001 3900-2011-000 1

5 Límite alto 4520-0011-000 4520-0011-000 4520-0011-000 4520-0011-000 4520-0011-000 1

6 Contratista 5018-0004-102 5018-0004-103 5018-0004-102 5018-0004-103 5018-0004-102 1

7 Rejilla de salida 2501-2020-001 2501-2020-001 2501-2020-001 2501-2020-001 2501-2020-001 2

8 Guías de rejilla 1215-2059-001 1215-2059-001 1215-2059-001 1215-2059-001 1215-2059-001 2

No. de Número de Parte para Modelos:

Ref. Descripción CDF552RE CDF547RE CDF548RE CDF557RE CDF558RE Cant.

1 Elemento 302012813 302012803 302012801 302012814 302012812 2

2 Retardo del 1414-2039-000 1414-2039-000 1414-2039-000 1414-2039-000 1414-2039-000 1

3 Aspas del 1210-2000-000 1210-2000-000 1210-2000-000 1210-2000-000 1210-2000-000 1

4 Motor 3900-2011-000 3900-2011-001 3900-2011-000 3900-2011-001 3900-2011-000 1

5 Límite alto 4520-0011-000 4520-0011-000 4520-0011-000 4520-0011-000 4520-0011-000 1

6 Contratista 5018-0004-102 5018-0004-103 5018-0004-102 5018-0004-103 5018-0004-102 1

7 Rejilla de salida 2501-2020-001 2501-2020-001 2501-2020-001 2501-2020-001 2501-2020-001 2

8 Guías de rejilla 1215-2059-000 1215-2059-000 1215-2059-000 1215-2059-000 1215-2059-000 2

ventilador

ventilador

(En superficie)

ventilador

ventilador

(Empotradas)

19

Page 20

Todos los productos fabricados por Marley Engineered Products están garantizados contra defectos de fabricación y de materiales por 1 año desde la fecha de

GARANTÍA LIMITADA

instalación. Esta garantía no se aplica a daños debidos a accidente, mal uso o alteración, ni a los casos en que la tensión eléctrica conectada supere a la tensión nominal -indicada en la placa de características- en más de 5 %, ni a equipos que hayan sido instalados o cableados incorrectamente, o mantenidos en

forma que no cumpla lo indicado en las instrucciones de instalación del producto. Todo reclamo por trabajos en garantía debe acompañarse con una prueba de

la fecha de instalación.

El cliente será responsable de todos los costos incurridos en el retiro o reinstalación de productos, incluyendo los costos de mano de obra y los costos de envío

incurridos para regresar productos a un Centro de Servicio de Marley Engineered Products. Dentro de las limitaciones de esta garantía, las unidades que no

funcionan deben regresarse al centro de servicio autorizado Marley más cercano, o al Centro de Servicio de Marley Engineered Products, y nosotros lo

repararemos o reemplazaremos, a nuestra opción, sin cargo para usted, con el flete de retorno pagado por Marley. Se acuerda que tal reparación o reemplazo

es el único recurso que Marley Engineered Products pone a su disposición.

LAS GARANTÍAS EXPUESTAS MÁS ARRIBA TOMAN EL LUGAR DE TODA OTRA GARANTÍA, EXPRESA O IMPLÍCITA, Y POR LA PRESENTE SE

DECLINA Y EXCLUYE DE ESTE ACUERDO TODA GARANTÍA IMPLÍCITA DE COMERCIABILIDAD Y ADECUACIÓN A UN PROPÓSITO PARTICULAR QUE

EXCEDA LAS GARANTÍAS EXPRESAS ANTEDICHAS. MARLEY ENGINEERED PRODUCTS NO SE HARÁ RESPONSABLE POR DAÑOS CONSIGUIENTES

QUE SE PRODUZCAN CON RESPECTO AL PRODUCTO, EN BASE YA SEA A NEGLIGENCIA, AGRAVIO, RESPONSABILIDAD ESTRICTA, O CONTRATO.

Algunos estados o jurisdicciones no permiten la exclusión o limitación de daños incidentales o consiguientes, de modo que la exclusión o limitación expresada

más arriba puede no aplicarse a su caso. Esta garantía le da derechos legales específicos, y usted puede tener también otros derechos, que varían de un estado o jurisdicción a otro.

Para obtener la dirección de su centro de servicio autorizado más cercano comuníquese con Marley Engineered Products en Bennettsville, SC, Estados Unidos,

llamando al 1-800-642-4328. Toda mercadería regresada a la fábrica debe ser acompañada por una autorización de retorno y una etiqueta de identificación de

servicio, disponibles ambas en Marley Engineered Products. Cuando solicite la autorización de retorno, incluya todos los números de catálogo mostrados en los

productos.

CÓMO OBTENER SERVICIO EN GARANTÍA, PIEZAS DE

REPUESTO E INFORMACIÓN GENERAL

1. Servicio o repuestos en garantía 1-800-642-4328

2. Compra de repuestos 1-800-654-3545

3. Información general sobre productos www.marleymep.com

Nota: cuando solicite servicio, siempre dé la información que sigue:

1. Número de modelo del producto

2. Fecha de fabricación

3. Número de parte o descripción

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

Número de parte 5200-11039-000

ECR 38415

08/09

Page 21

Description

Séries CDF500

Radiateurs à air pulsé

installés au plafond

Les radiateurs à circulation descendante installés au plafond sont

conçus pour des applications encastrées ou en applique. Les radiateurs en applique dépassent de seulement 15,2 cm dans la pièce.

Les radiateurs encastrés s'enfoncent sur seulement 17,8 cm dans

le plafond. S'installe aisément dans des panneaux de 2 pi x 2 pi

des plafonds suspendus.

Instructions d'installation, d’utilisation et d'entretien

Spécifications

Modèle Kw

CDF552SE 5/3,8/2,5 17,2/13,0/8,5 240 1-3 20,8/15,8/10,4 283 (133,5) 45

CDF547SE 4/3/2 13,7/10,2/6,8 277 1 14,5/10,8/7,2 283 (133,5) 51

CDF548SE 4/3/2 13,7/10,2/6,8 208 1-3 19,2/14,4/9,6 283 (133,5) 51

CDF557SE 5/3,8/2,5 17,2/13,0/8,5 277 1 18,1/13,7/9,0 283 (133,5) 45

CDF558SE 5/3,8/2,5 17,2/13,0/8,5 208 1-3 24,0/18,2/12,0 283 (133,5) 45

Modèle Kw

CDF552RE 5/3,8/2,5 17,2/13,0/8,5 240 1-3 20,8/15,8/10,4 283 (133,5) 45

CDF547RE 4/3/2 13,7/10,2/6,8 277 1 14,5/10,8/7,2 283 (133,5) 51

CDF548RE 4/3/2 13,7/10,2/6,8 208 1-3 19,2/14,4/9,6 283 (133,5) 51

CDF557RE 5/3,8/2,5 17,2/13,0/8,5 277 1 18,1/13,7/9,0 283 (133,5) 45

CDF558RE 5/3,8/2,5 17,2/13,0/8,5 208 1-3 24,0/18,2/12,0 283 (133,5) 45

(1) Câblé en usine pour la plus grande puissance, convertible sur site à des puissances plus basses.

(2) Câblé à l'usine 1 Ø, peut être converti sur le site à 3 Ø.

(3) Sur les appareils à deux phases, l'appel maximum de l'ampérage figure dans la liste.

(4) Différence de température à la puissance la plus élevée.

1

1

BTU/h (000) Volts Phase

BTU/h (000) Volts Phase

En applique

Encastré

2

2

Ampères

Ampères

3

3

PCM (dm3/s) °F

PCM (dm3/s) °F

4

4

AVERTISSEMENT

ATTENTION – POUR RÉDUIRE LES RISQUES D’INCENDIE,

D’ÉLECTROCUTION ET D’AUTRES BLESSURES

OBSERVEZ LES CONSIGNES SUIVANTES :

1. Afin d'éviter un risque de décharge électrique, couper l'alimentation du radiateur au niveau du panneau de service

principal avant d'effectuer le câblage ou l'entretien.

2. Tout le câblage doit être conforme au Code national de

l'électricité et aux codes locaux; et le radiateur doit être mis

à la terre en guise de précaution contre les décharges électriques.

3. Avant de mettre sous tension, vérifier que la tension d'alimentation correspond aux valeurs nominales imprimées sur

la plaque signalétique.

4. Ce radiateur est destiné à être monté au plafond SEULEMENT. Ne pas installer le radiateur à moins de 305 mm (12

po) d'un mur quelconque pour les modèles 4kW et à moins

de 609 mm (24 po) pour les modèles 5kW.

5. Ne pas insérer ou laisser des corps étrangers pénétrer dans

toute ouverture de ventilation ou de sortie, car il pourrait en

résulter une décharge électrique, un incendie ou des dom-

CONSERVER CES INSTRUCTIONS

!

mages au radiateur.

6. Afin d'éviter la possibilité d'un incendie, ne pas bloquer les

entrées ou les sorties d'air d'une quelconque manière.

Garder les matériaux combustibles, comme les caisses, les

draperies, etc., loin du radiateur.

7. Un radiateur comprend des pièces chaudes et qui produisent un arc électrique ou forment des étincelles à l'intérieur. Ne pas utiliser dans des endroits où sont utilisés ou

entreposés de l'essence, de la peinture ou des liquides

inflammables.

8. Ce radiateur n'est pas approuvé pour une utilisation dans

des atmosphères corrosives, comme des zones marines,

des serres ou d'entreposage de produits chimiques.

9. L'enveloppe du radiateur doit être installée de façon sécuritaire au plafond ou dans un cadre pouvant supporter le radiateur (20,4 kg / 45 lb). Sinon le radiateur pourrait tomber.

10. Ne pas utiliser le radiateur sans avoir installé ses grilles de

sortie. Lors de l'installation des grilles avec guides de lame,

s'assurer que les guides tombent en position afin qu'ils ne

glissent pas durant l'utilisation.

Page 22

INFORMATIONS IMPORTANTES SUR LA SÉCURITÉ

NÉGLIGER D'INSTALLER LES QUATRE ÉCROUS DE MONTAGE POUR FIXER SOLIDEMENT LE CADRE DE MONTAGE POURRAIT ENTRAÎNER LA CHUTE DU RADIATEUR

(VOIR LA FIGURE 2).

NÉGLIGER D'INSTALLER LES QUATRE VIS POURRAIT

ENTRAÎNER LA CHUTE DE L'ENVE-LOPPE D'APPLIQUE

VOIR LA FIGURE 2).

(

AVIS IMPORTANT : Ce radiateur est câblé pour que le ventilateur s'active sans délai lorsqu'il est excité alors que le thermostat fait un appel de chaleur. Lorsque le thermostat est satisfait,

le ventilateur doit continuer à fonctionner jusqu'à ce que le radiateur ait refroidi à une température sécuritaire. Si un thermostat

externe ou des commandes sont utilisées, NE PAS câbler le

radia-teur pour que le thermostat coupe l'alimentation au ventilateur. Le radiateur sera endommagé et la garantie annulée. Pour

fonctionner correctement, le thermostat doit être raccordé

comme il est illustré sur le schéma de câblage (Figure 13,

page 27).

o

REMARQUE : Le câblage sur le site doit être n

10 AWG au

minimum avec caractéristique nominale minimale de 90 °C.

Longueur d'acheminement maximale de 38 m (125 pi) à 208 V/

5 kW. Volume du compartiment de câblage - 4130 cm

3

(252

po3).

INSTALLATION

Installation des radiateurs en applique

(voir les Figures 1 et 2)

1. Déterminer l'emplacement du radiateur. Voir l'avertissement

o

4, page 21, pour connaître les dégagements minima.

n

2. Retirer le radiateur en applique de l’emballage de carton. Le

radiateur inclut (1) plaque d’applique, (1) radiateur, (1)

enveloppe d’applique et (1) jeu de grilles.

3. Retirer l’enveloppe d’applique de l’ensemble. Enlever les

quatre (4) écrous des montants afin de pouvoir enlever le

radiateur de la plaque de montage en saillie. Ne pas jeter

les écrous car ils seront utilisés à l'étape 11 pour réinstaller

le radiateur sur la plaque en saillie.

4. Enlever une des alvéoles et installer un connecteur de câble

ou de conduit.

5. Installer le disjoncteur en option CDFDS (si exigé) comme

l'illustre la Figure 1. Consulter le manuel d'installation des

accessoires pour câbler correctement.

Alvéole défonçable emboîtée 22,2

mm et 28,6 mm

(7/8 po et 1

Alvéole défonçable

22,2 mm (7/8 po)

Disjoncteur en

option (CDFDS

1

/8po)

Vis (2)

FFiigguurree 11

Alvéole défonçable 12,7 mm (1/2 po)

Fil ou connecteur de conduit

Alvéole défonçable

12,7 mm (1/2 po)

Plaque de

montage

en applique

Plaque de montage

en applique

6. Acheminer le câble d'alimentation à travers le connecteur en

laissant environ 203 mm (8 po) à l'intérieur de la plaque

'applique. (Le câble d'alimentation doit être de no 10 AWG

d

au minimum avec caractéris-tique nominale minimale de 90

°C. Longueur d'acheminement maxi-male de 38 m (125 pi) à

208 V/5 kW.)

7. Placer la plaque d'applique contre le plafond et la fixer

solidement avec des boulons ou des vis (Figure 2). Voir