Marley 935, 958, 945, 968, 978 Instructions Manual

Dear Owner,

Congratulations! Thank you for purchasing this new heater manufactured by a division of Marley Engineered

Products. You have made a wise investment selecting the highest quality product in the heating industry.

Please carefully r ead and follow the installation and maintenance dir ections shown in this manual. You should

enjoy years of efficient heating comfort with this product from Marley Engineered Products... the industry’s

leader in design, manufacturing, quality and service.

... The Employees of

Marley Engineered Products

Installation & Maintenance Instructions

WARNING

!

Read carefully - These instructions are written to help

you prevent difficulties that might arise during installation

of heaters. Studying the instructions first may save you

considerable time and money later. Observe the following procedures and cut your installation time to a minimum.

TO REDUCE RISK OF FIRE AND ELECTRIC SHOCK:

1. Disconnect all power coming to the heater at main

service panel before wiring or servicing.

Note: More than one disconnect may be required.

2. All wiring must be in accordance with national and

local electric codes and the heater must be grounded.

3. Verify the power supply voltage coming to heater

matches the ratings printed on the heater nameplate

before energizing.

4. This heater is hot when in use. To avoid burns, do

not let bare skin touch hot surfaces.

5. Do not insert or allow foreign objects to enter any

ventilation or exhaust opening as this may cause

electric shock, fire, or damage to heater.

6. Do not block air intakes or exhaust in any manner.

Keep combustible materials at least 24” (610 mm)

away from heater. Keep drapes at least 6” (153 mm)

above top of front discharge grille. Do not use

drapes above top discharge units. Do not install

behind doors, furniture, towel rack, or boxes.

7. A heater has hot and arcing (sparking) parts inside.

Do not use in areas where gasoline, paint, or flammable

liquids are used or stored.

8. Use this heater only as described in this manual. Any

other use not recommended by the manufacturer

may cause fire, electric shock, or injury.

9. This heater is not approved for use in corrosive

atmospheres such as marine, green house, or chemical storage areas.

10.

FOR DUCT CONNECTED HEATERS, Do not

exceed 0.2” wg. external static pressure and do not

mount heater on end panels.

11. Do not use

OPTIONAL 0-100% OUTSIDE AIR

DAMPER with bottom air inlet.

SAVE THESE INSTRUCTION SHEETS

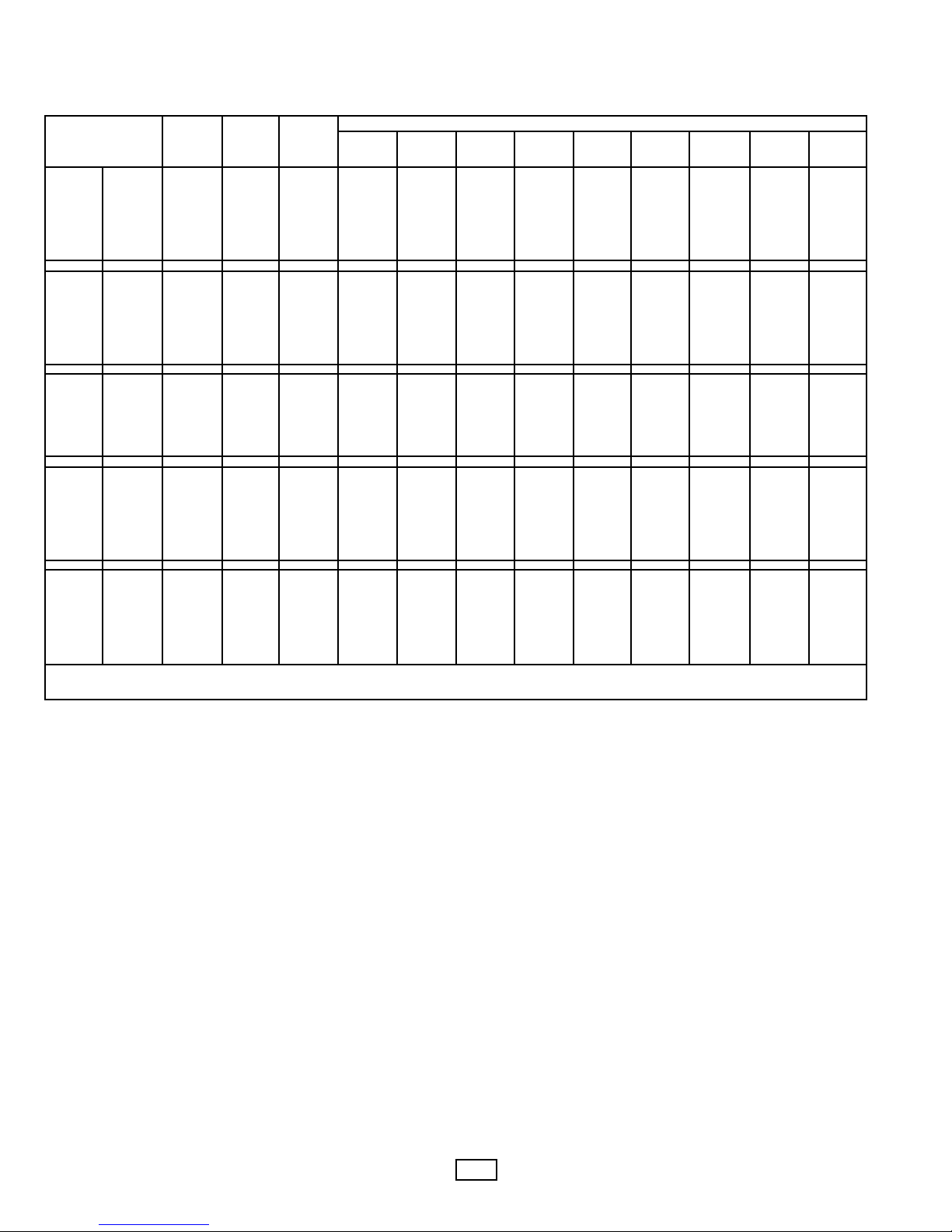

900 Series

Cabinet Unit Heaters

Model B

1

KW

2

3

4

5

6

7

8

4

6

8

10

12

14

16

6

8

10

12

14

16

6

9

12

15

18

21

24

8

12

16

20

24

28

32

BTU/hr

6,826

10,239

13,652

17,065

20,478

23,891

27,304

13,652

20,478

27,304

34,130

40,956

47,785

54,608

20,478

27,304

34,103

40,956

47,782

54,608

20,478

30,717

40,956

51,195

61,434

71,673

81,912

27,304

40,956

54,608

68,260

81,912

95,564

109,216

Series

935

945

958

968

978

Cabinet

Length

(in)

35

45

58

68

78

CFM*

250

500

750

750

1,000

208

1 ph

60 Hz

10

15

20

25

30

34

39

20

30

40

48

59†

68†

78†

30

40

48

59†

68†

78†

31

45

60

74

88

n/a

n/a

41

60†

79†

n/a

n/a

n/a

n/a

208

3 ph

60 Hz

6

9

12

15

17

20

23

12

18

23

29

34

40

46

18

23

29

34

40

46

19

27

35

44

52†

60†

69†

24

36

47

58†

69†

80†

91†

240

1 ph

60 Hz

9

13

17

22

26

30

34

18

26

34

43

51†

59†

68†

26

34

43

51†

59†

68†

27

39

52†

64†

77†

89†

n/a

36

52†

69†

86†

n/a

n/a

n/a

240

3 ph

60 Hz

6

8

10

13

15

18

20

11

16

20

25

30

35

40

16

20

25

30

35

40

16

24

31

38

45

52†

60†

21

31

41

50†

60†

70†

79†

277

1 ph

60 Hz

8

12

15

19

22

26

30

16

23

30

37

44

52†

59†

23

30

37

44

52†

59†

24

34

45

56†

67†

78†

n/a

31

46

60†

74†

n/a

n/a

n/a

347

1 ph

60 Hz

7

9

12

15

18

21

24

13

18

24

30

36

41

47

18

24

30

36

41

47

19

28

36

45

n/a

n/a

n/a

25

37

48

n/a

n/a

n/a

n/a

380

3 ph

60 Hz

4

5

7

8

10

11

13

7

10

13

16

19

22

25

10

13

16

19

22

25

11

16

20

25

29

34

38

14

20

27

33

39

45

n/a

480

3 ph

60 Hz

3

4

6

7

8

9

10

6

8

11

13

16

18

20

8

11

13

16

18

20

9

13

16

20

24

27

31

12

17

21

26

31

36

41

600

3 ph

60 Hz

3

4

5

6

7

7

8

5

7

9

11

13

15

17

7

9

11

13

15

17

8

11

13

16

19

22

25

10

14

18

21

15

29

33

HEATING

CAPACITY

† - CIRCUIT BREAKERS or FUSED DISCONNECT required

* - Value shown for HIGHSPEED on two speed units

Specifications

Total Line Amperage (includes motor amps)

2

3

General Information

900 Series Cabinet Unit Heaters are designed and UL & cUL

Listed to be applied as Standard Free Air heaters with both

louvered intake and louvered discharge panels for recess or

surface installation: a) on the floor, with front inlet and up flow

air movement in the up flow, down flow, left or right direction or

b) on the ceiling, or Ducted (0.2” wg external static pressure)

flange for direct connection of field supplied ductwork to the

inlet, discharge, or both inlet and discharge. Ducted heaters

can be installed for recess or surface installation: a) on the

floor, with front inlet and up flow air movement, b) on the wall,

with air movement in the up flow or down flow direction or c)

on the ceiling.

See Figure 1 for Mounting Clearances.

Note:

Keep all furniture or any other blocking material at least

24” (610mm) away from front of heater.

When draperies are used, hang them so that when in use they

are at least 6” (153mm) above the top of front discharge

heater.

Do not use draperies with top discharge heaters.

See Figure 2 for Mounting Dimensions

See Figure 3 for Duct Collar Dimensions and Installation

Details.

FLOOR MOUNTING

1.

Heaters with front inlet and up flow air movement

may be mounted directly on any floor surface including carpeting. Where wall to wall carpeting is

installed after heater installation the carpeting can be

run up to the front and around the heater body. See

Figure 1 for mounting clearances.

2. Heaters can be mounted on either end with air movement

left or right directly on any floor surface including carpeting.

See Figure 1 for mounting clearances.

3. If optional kick plate is not used, proceed to “HEATER

INSTALLATION” section.

INSTALLATION OF OPTIONAL 900 SERIES BASE

KIT

1. If desired, the heaters may be mounted off the floor with

optional kick plate panel.

2. Align panel on bottom of heater (Inlet side only.)

3. There should be a 1” (25mm) space from the panel to the

front and sides of the heater.

4. Match drill .140” (3.55 mm) diameter holes in the bottom of

the heater and secure with screws provided.

5. Proceed to “HEATER INSTALLATION” section.

WALL OR CEILING RECESS MOUNTING

1. Create on opening in the wall 26-5/8” (676mm) high by the

width of the heater plus 1/4” (6.4mm).

Example: If the heater

was 68 inches long, the opening should measure

26-5/8” high x 68-1/4” long).

2. The depth of the recess will vary with the desired amount

of heater recess.

3. Proceed to “HEATER INSTALLATION” section.

INSTALLATION OF OPTIONAL

900 SERIES RECESS TRIM KIT

1. Determine depth of heater recess.

2. Align recess trim frame so that the trim frame front edge

will touch wall when heater is installed.

3. Match drill .140” (3.55mm) diameter holes in all four sides of

the heater and secure trim frame with screws provided.

4. Proceed to “HEATER INSTALLATION” section.

HEATER INSTALLATION

1. Rough-in electrical wiring. See Figure 2 for knockout locations.

2. Remove the proper knockout in the heater or punch the

proper size hole in the bottom or right side of the heater as

shown in Figure 2.

3. Remove the front cover by rotating the lock(s) counterclockwise (ccw).

4. Remove Top (Discharge) Louver Panel by removing 2

screws (one on each end) that attach the louver panel to

the end panels.

5. Refer to Figure 3 for location of mounting holes.

6. Mark and drill holes for heater attachment in wall or ceiling.

7. Install heater in opening and tighten screws (field supplied)

to insecure tight fit of the heater against the mounting surface.

NOTE: Tightening the heater against an irregular wall

will cause distortion of the back panel of the heater. If

this is the case, shims should be used behind the back

panel to keep it straight.

8. Reinstall the Top (Discharge) Louver Panel by sliding the

panel into the heater. Position the panel tabs of the louver

panel to rest on the top of the lip of the heater back.

Position the louver panel top even with the top of the end

panels. Tap the louver panel at the top front (both sides) to

seat the panel. Reinstall 2 screws (one on each side) that

attach louver panel to the end panels.

9. WIRING - See wiring section.

10.After wiring is complete, insure that the control box cover is

closed and fastened and that the filter is installed.

11.Adjust the thermostat to the desired set point.

12.Adjust the heat selector to the heat and fan speed desired.

13.Replace front cover and secure by turning the locks clockwise (cw) until tight. Replace plug buttons provided.

14.Leave the heater running a few hours before making any

further change in thermostat setting.

CAUTION

TO PREVENT HEATER FROM FALLING AND CAUSING

PERSONAL INJURY, EACH FASTENER, AS APPLIED,

SHOULD HAVE THE HOLDING POWER OF AT LEAST 100

POUNDS (45 kg).

!

DUCTED APPLICA TIONS

1. See Figure 3 for duct flange size and location.

2. Duct collars have been factory located (Bottom inlet, Front

inlet, Top discharge, Front discharge) as ordered.

3. To change duct collar location:

A. Heater duct panels are supplied with a duct collar attached

to one surface and a blank-off plate attached to the other

surface. The location of the duct collar and the blank-off

plate can reversed.

B. Remove screws holding blank-off plate and remove blank-

off plate.

C. Remove screws holding duct collar and remove duct collar.

D. Position duct collar to location desired, align screws holes,

insert and tighten screws to secure duct collar to duct

panel.

E. Position blank-off plate to location desired, align screw

holes, insert and tighten screws blank-off plate to duct

panel.

4. Position field ductwork to outside of heater duct flange.

5. Mark and drill starting holes in duct and flange.

6. Install and tighten screws (field supplied) to provide a

secure seal.

OPTIONAL

0-100% OUTSIDE AIR DAMPER

1. Flange brackets for the rear mounted duct collar are packaged unassembled in the heater carton.

2. See Figure 2 for location of damper opening.

3. Position the top flange bracket with the flange at the top of

the damper opening and holes in the flange align with

holes in the cabinet back.

4. Attach flange to cabinet with screws provided.

5. Position and attach remaining three (3) flange brackets

around damper opening.

6. Position field ductwork to outside of flange brackets.

7. Mark and drill starting holes in duct and flange.

8. Install and tighten screws (field supplied) to provide a

secure seal.

OPERATION OF OPTIONAL

0-100% OUTSIDE AIR DAMPER

1. Controls, consisting of an “OPEN-CLOSED” switch and 0100% positioning potentiometer, are located on the control

panel door.

2. Place switch in OPEN position.

3. Adjust potentiometer to percentage of outside air desired.

4. The damper will remain open to the position selected until;

the “OPEN-CLOSED” switch is moved to the closed position, the “ON-OFF switch (if installed) is turned off, the

night set back relay (if installed) is in the night position, or if

there is a power failure.

TO REDUCE RISK OF FIRE AND ELECTRICAL

SHOCK:

DO NOT EXCEED 0.2” WG EXTERNAL STATIC

PRESSURE. DO NOT MOUNT HEATER ON END PANEL

(LEFT OR RIGHT AIR FLOW).

WARNING

!

TO REDUCE RISK OF FIRE AND ELECTRICAL

SHOCK: DO NOT USE 0-100% OUTSIDE AIR DAMPER

OPTION WITH BOTTOM AIR INLET. USE ONLY FRONT AIR

INLET WITH 0-100% OUTSIDE AIR DAMPER OPTION.

WARNING

!

4

Loading...

Loading...