Page 1

Marley H3 Fan

/

/

User Manual 92-1452

Page 2

FAN SERIAL NO.

FAN BLADE CLAMP FASTENER TIGHTENING INSTRUCTIONS

GENEROUSLY COAT CLAMP BOLT THREADS AND NUT

BEARING SURFACE WITH MARLEY THREAD LUBRICANT

SPX COOLING TECHNOLOGIES, INC. OVERLAND PARK, KS.

71-81-2 PW

TIGHTEN TO

FT LB TORQUE

55

96 H3 6 — XXXX

FAN SERIAL NO.

FAN BLADE CLAMP FASTENER TIGHTENING INSTRUCTIONS

GENEROUSLY COAT CLAMP BOLT THREADS AND NUT

BEARING SURFACE WITH MARLEY THREAD LUBRICANT

SPX COOLING TECHNOLOGIES, INC. OVERLAND PARK, KS.

71-81-2 PW

TIGHTEN TO

FT LB TORQUE

55

96 H3 6 — XXXX

Marley / H3 Fan

/

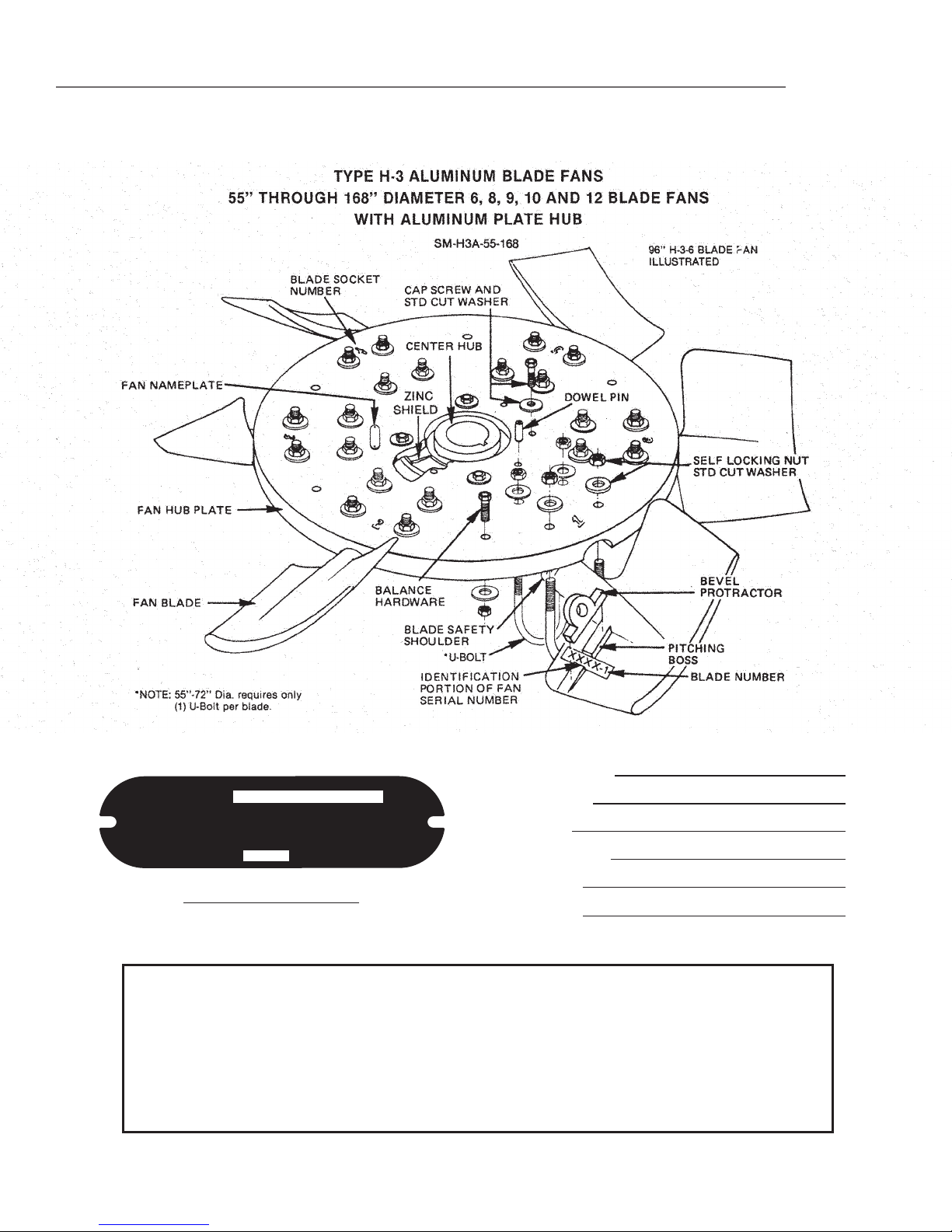

TYPICAL FAN NAMEPLATE

(NOTE: Refer to Table for Prescribed Torque)

IMPORTANT

A. Each fan is statically balanced at the factory as an assembly. The fan hub is identified with the complete serial number

and each blade socket is identified by number. Each fan blade is marked with the identification portion of the fan serial

number and a sequential number indicating position of the fan blade in the fan hub.

B. Check and, if necessary, retighten blade clamping hardware to prescribed torque prior to startup and subsequently at

6 month intervals.

C. When writing the Marley sales office or representative for repair or replacement parts, please refer to the tower order

number and fan serial number. CONTACT YOUR MARLEY SALES REPRESENTATIVE FOR ASSISTANCE ON ORDER

PLACEMENT.

Marley Order No.

Fan Diameter

Order No.

Order No.

Final Pitch Angle

Speed, rpm

Contract hp

Page 3

FAN ASSEMBLY

CHECKING LOAD AT MOTOR

Fan hubs are shipped from the Marley factory with center hub and zinc

shield assembled to the hub plate. If components of the hub assembly

are to be replaced in the field, refer to paragraphs 1,2 and 3 for reassembly instructions.

1. Position the protective zinc shield and the fan hub plate on the

center hub with the keyway and socket No. 1 lined up. One of the

bolt hole patterns will be aligned properly in only one position.

2. Drive the dowel pins flush into the four smaller holes to accurately

position the hub plate.

3. Apply a thread sealant/adhesive to the cap screws, install and

tighten. See Table 1 for correct center hub torque.

4. Make certain that the identification number on each blade cor-

responds to the identification number in the fan assembly serial

number on the nameplate.

5. U-bolt threads and bearing surface of self-locking nuts are lubri-

cated at the factory prior to shipment. Touch up all threads and

nut bearing surfaces with a generous coating of the lubricant

supplied with the fan.

6. Install blade marked No. 1 in hub socket No. 1. Install blade No. 2

in hub socket No. 2, and so on around the fan. Install blades with

pitching boss and fan direction arrow on air discharge side of fan.

7. Be certain that each blade is as far from the center of the fan

as the shoulder on the shank end of the blade will permit

after the locking nuts are tightened. This is necessary in order

to maintain proper balance.

8. Support blade tips in a horizontal plane when U-bolts are tight-

ened. Hold each blade at the proper pitch angle when tightening.

9. Total vertical tip track variation should not exceed tolerances specified in Table 1. Excessive tip track will cause dynamic imbalance.

SETTING FAN BLADE PITCH

1. The trial pitch angle is the calculated setting for design conditions

(water rate, heat load, air density and contract horsepower). Set

the bevel protractor at the trail pitch angle supplied and pitch all

the blades to the same angle. All blades must be pitched to the

same angle when each blade is pointing in the same direction in

the fan cylinder.

2. Progressively tighten the self-locking U-bolt nuts to specified

torque. Stainless steel fasteners are prone to galling. Be alert to

a sudden rise in nut turning resistance before parts are properly

clamped. This signifies galling. Remove nuts and U-bolt and

replace with new ones until satisfactory joint is made. See Table 1

for correct U-bolt torque.

3. Recheck the pitch of each blade, as the pitch might change while

tightening the nuts.

Table 1 - Specified Torque and Tip Track Variation

FAN DIA.

Center Hub

Torque

U-Bolt Torque

Vertical Tip

Track Variation

55”72”

40-50

ft/lbs

ft/lbs40ft/lbs55ft/lbs40ft/lbs70ft/lbs

(± 3⁄8”)

3

40

⁄4”

73”84”

40-50

ft/lbs

3

⁄4”

(± 3⁄8”)

85”96”

97”144”

40-50

ft/lbs40ft/lbs

3

⁄4”

(± 3⁄8”)1”(± 1⁄2”)

145”168”

100

ft/lbs

11⁄2”

(± 3⁄4”)

CAUTION: When checking and/or changing blade pitch or when cycling

fan in normal operation, do not exceed 30 sec./hr. total motor starting

time as motor may become overheated.

1. Operate the fan until motor and Geareducer have reached operation temperature. Take operating voltage and amperage measurements* for use in calculating motor hp by the following equation:

hp = x nameplate hp

actual volts x actual amps

nameplate volts x nameplate amps

2. The calculated horsepower should equal but not exceed the speci-

fied contract horsepower. Measurements used in above calculations must be made with hot water flowing through the tower.

Repitch blades as required to obtain contract horsepower. Reading

taken with no water or cold circulating water will result in an erroneous calculate horsepower. Degrees change in pitch required

to change motor load one hp: see Table 2.

Table 2 - Pitch vs. hp

No. of Blades: 6 8 9 10 12

Fan Dia. Pitch Change Per hp

60” 3 2.5

72” 2.5 2

84” 1 .8 .6

96” .8 .7 .6 .5

108” 1

120” .8

132” .6

144” .4

168”

A one degree change in pitch will vary the

power required by approximately 3 hp.

3. If blades are repitched, self-locking U-bolt nut must be retightened

to specified torque. See Table 1. Touch up U-bolt threads and nut

bearing surface with lubricant consisting of 50% petrolatum and

50% graphite by weight.

FAN REBALANCE

1. If the fan hub plate, center hub, or one or more blades are

replaced, the complete fan assembly may require rebalancing.

Other components can be replaced without significantly affecting

balance.

2. If rebalance is required, trail and error attachment of balance

weights at various locations on the hub may produce a satisfactory dynamic balance with the fan operating on the tower. If this

is not satisfactory, the fan assembly can be rebalanced as follows:

A.

Fan assembly should be mounted on a suitable mandrel matching the hub bore, and the mandrel placed on knife wheels or

level, parallel bars with the fan blades in a vertical plane. This

must be done in a draft free area.

B. Apply balance washers to hub, on same side as blade sockets,

until all tendency for fan to rotate is overcome. This is accomplished by allowing the fan assembly to rotate freely on

the knives until it comes to rest with the heaviest portion at

the bottom. Manually rotate the fan 90º so that the heaviest

portion is at either side of the fan centerline. Add weights to

the light side of the hub plate. Holes are provided in the plate

between each blade socket for attachment of weights.

C. If one or more blades are replaced, relocating some of the

blades in other sockets might simplify balance and result in

fewer balance weights being required.

FAN MAINTENANCE

A monthly inspection of the fan should be made to assure continued

trouble-free operation. Remove carefully and completely any accumulation of dirt or scale deposits, if balance is affected.

Page 4

7401 WEST 129 STREET | OVERLAND PARK, KANSAS 66213 UNITED STATES | 913 664 7400 | spxcooling@ct.spx.com | spxcooling.com

In the interest of technological progress, all products are subject to design and/or material change without notice.

©2009 SPX Cooling Technologies, Inc. | Printed in USA

Manual 92-1452

Loading...

Loading...