l

Material conforms to UL94 V-2 flammability ratings

l

6.4mm spacer height as standard

l

Variable spacer height options available

l

Product illustrated 127-505-04-55

l

Typically available ex stock

PCB MOUNTING LEDs - Ø 5mm

Ordering Information & Typical Technical Characteristics (Ta = 25°C)

Mean Time Between Failure up to = 100,000 Hours. Luminous intensity figures refer to the unmodified discrete LED.

FEATURES

SPECIFICATIONS

127 SERIES

PACK QUANTITY = 100 PIECES

PART NUMBER COLOUR LENS VOLTAGE CURRENT LUMINOUS WAVE OPERATING STORAGE

DC DC INTENSITY LENGTH TEMP TEMP

Vopr lopr lv@20mA λp Topr Tstg

127-505-04-54 Red Colour Diffused 2.0* 20 60 627 -40 ~ +85^ -40 ~ +85 Yes

127-511-04-54 Yellow Colour Diffused 2.1* 20 40 590 -40 ~ +85^ -40 ~ +85 Yes

127-514-04-54 Green Colour Diffused 2.2* 20 40 565 -40 ~ +85^ -40 ~ +85 Yes

127-530-04-54 Red/Green White Diffused 2.0/2.2* 20 30/25 627/565 -40 ~ +85^ -40 ~ +85 Yes

127-581-20-54 Red Colour Diffused 5 10 50 627 -40 ~ +70 -40 ~ +85 Yes

127-582-20-54 Yellow Colour Diffused 5 10 20 590 -40 ~ +70 -40 ~ +85 Yes

127-583-20-54 Green Colour Diffused 5 10 20 565 -40 ~ +70 -40 ~ +85 Yes

UNITS Vdc mA mcd nm

0

C

0

C

STANDARD INTENSITY

SAMPLES AVAILABLE

© MARL

INTERNATIONAL LTD 2007 : DS 074/07 Issue 2

Page 1 of 3

How to Order:

website: www.marl.co.uk•email: sales@marl.co.uk

•

•

Telephone +44 (0)1229 582430•Fax: +44 (0)1229 585155

The information contained in this datasheet does not constitute part of any order or contract and should not be regarded as a representation

relating to either products or service. Marl International reserve the right to alter without notice the specification or any conditions of supply

for products or service.

^ = Products must be derated according to the derating information. Each derating graph refers to specific LEDs.

* = Voltage DC for 20mA product is Vf@20mA, not Vopr

505 & 511

514

530

127 Series

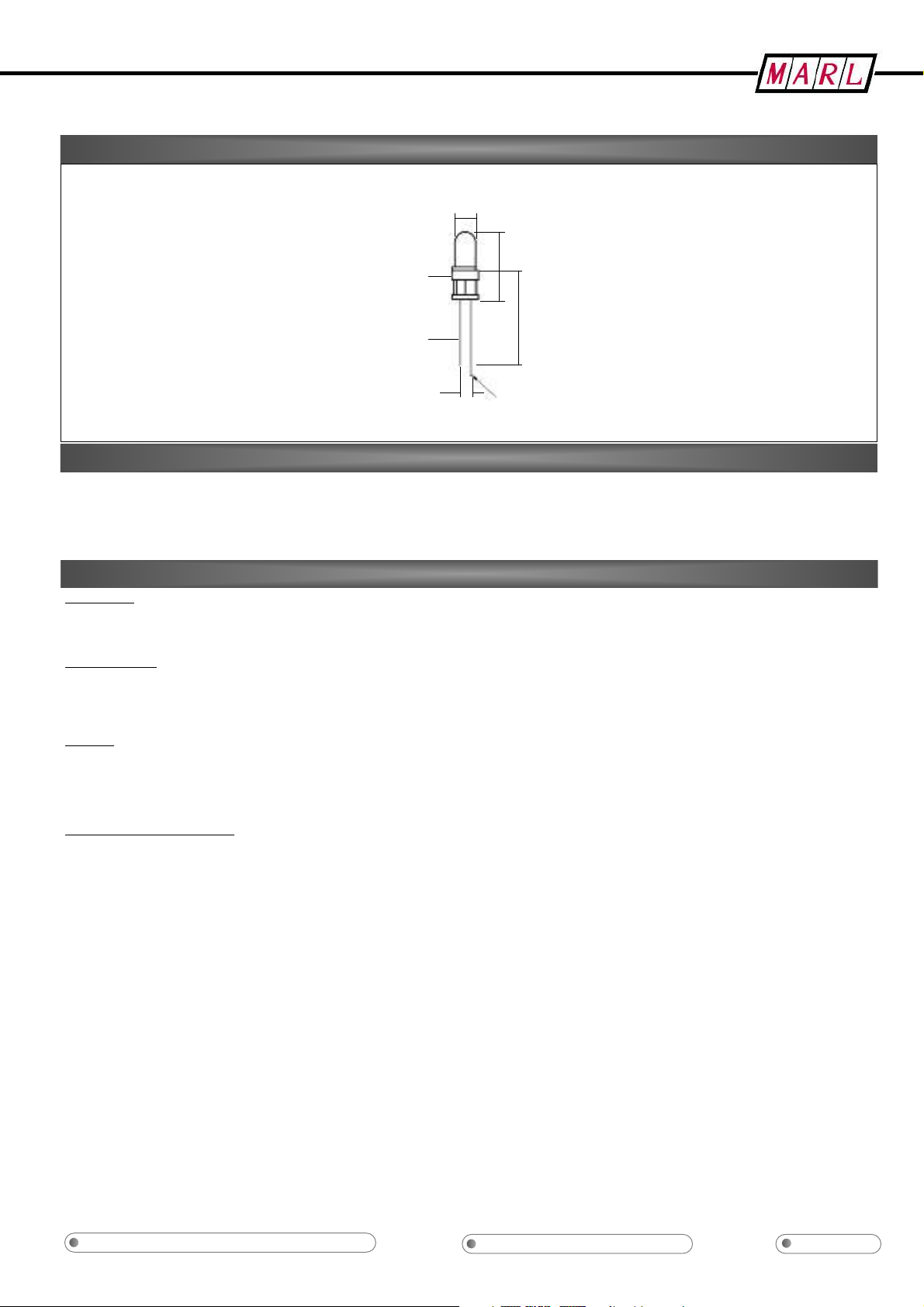

Dimensions in mm (Typical)

Not to scale

SAMPLES AVAILABLE

© MARL

INTERNATIONAL LTD 2007 : DS 074/07 Issue 2

Page 2 of 3

How to Order:

website: www.marl.co.uk•email: sales@marl.co.uk

•

•

Telephone +44 (0)1229 582430•Fax: +44 (0)1229 585155

The information contained in this datasheet does not constitute part of any order or contract and should not be regarded as a representation

relating to either products or service. Marl International reserve the right to alter without notice the specification or any conditions of supply

for products or service.

Housing Material

Polycarbonate

This material offers UL94 V-0 flame retardancy* and a high impact strength. This material has a melt point of 290-340°C and is suitable for use in

the majority of automatic soldering processes.

*Material test thickness 1.6mm

LEDs

LED Polarity

Anode identification is shown in the dimensional diagram. The long lead of a non-cropped unit can also be used to help identify the anode. For

the 2 pin Bi-colour units the standard colour configuration is red anode to the ‘+’ sign.

Reverse Polarity

This is offered on all PCB units, with the exception of the 125 series, if requested to help overcome the problem of systems with reverse polarity

connections. Multiple units can also be supplied in reverse polarity but not with mixed polarities. The 2 pin and 3 pin Bi-colours can be supplied in

reverse colour configuration.

Bi-colour

2 Pin Operation

To achieve the second colour for a 2 pin Bi-colour unit the supply must be reversed, standard colour configuration for these units is red anode to

the ‘+’ sign.

Electro-st

atic Discharge (ESD)

Build up of electrostatic discharge occurs in many situations involving people moving and handling products. The range of possible situations is

very diverse but voltage levels as high as several thousand volts can and do arise in many individual situations. When an operator charged up to

these levels handles a ‘static sensitive device’, there is a very probable likelihood that the device will be irreversibly damaged. It is essential that

precautions are taken at all stages during manufacture and assembly of these products. Although LEDs were never considered to be static

sensitive devices, changes in manufacturing technology and materials used to produce higher intensity products over a large range of the

wavelength spectrum have changed this. Marl has an approved system of ESD control from goods in, through production and into final packing

and despatch. We recommend all users of LED based products follow the guidelines of BS 100015.

Note: All luminous intensity figures refer to the unmodified discrete LED.

Anode

Ø4.8

Ø6.0

0.5Sq

2.54

8.7

6.4

24.0 MIN

ALSO AVAILABLE

SAMPLES AVAILABLE

© MARL

INTERNATIONAL LTD 2007 : DS 074/07 Issue 2

Page 3 of 3

How to Order:

website: www.marl.co.uk•email: sales@marl.co.uk

•

•

Telephone +44 (0)1229 582430•Fax: +44 (0)1229 585155

The information contained in this datasheet does not constitute part of any order or contract and should not be regarded as a representation

relating to either products or service. Marl International reserve the right to alter without notice the specification or any conditions of supply

for products or service.

PART NO. COLOUR VOLTAGE DC SPACER

(Vdc) Vopr HEIGHT (mm)

127-505-01-52 Red 2mA 9.5

127-505-04 Red 20mA 5

127-505-04-50 Red 20mA 9.5

127-505-04-55 Red 20mA 15.9

127-505-04-56 Red 20mA 19.1

127-511-01-52 Yellow 2mA 9.5

127-511-04-50 Yellow 20mA 9.5

127-511-04-55 Yellow 20mA 15.9

127-511-04-56 Yellow 20mA 19.1

127-514-01-52 Green 2mA 9.5

127-514-04-50 Green 20mA 9.5

127-514-04-51 Green 20mA 4.8

127-514-04-52 Green 20mA 6.4

127-514-04-55 Green 20mA 15.9

127-514-04-56 Green 20mA 19.1

127-523-01-51 Red 2mA 6.4

127-523-01-55 Red 2mA 19.1

127-524-01-69 Yellow 2mA 19.1

127-525-01-50 Green 2mA 6.4

127-525-01-62 Green 2mA 19.1

127-530-04-55 Red/Green Bi-colour 20mA 15.9

UNITS VDC

Part numbers also available in the 127 Series:

The products listed above illustrate all of the options available to order. These products may have custom modifications that alter

their operation beyond the generic information contained within this datasheet. Please contact sales for further information.

Loading...

Loading...