TECHNICAL NOTICE V1.0

INDUSTRIAL REFRIGERATION UNITS

Identification

Version Date Comments

1.0 01.2009 First Edition

Correspondence

All correspondence regarding our products must provide the serial

number.

The serial number is located on the identification tablet fixed on the refrigeration unit.

LEISTUNGSAUFNAHME

Copyright ©

The reproduction, even partially, of this document is forbidden. No part may be copied in any form, and it may not

be used, edited nor transmitted by any electronic means (photocopy, photography, magnetic supports or other recording processes), without the written authorization of Marksa SA. All rights and particularly reproduction, translation, edition, distribution and also industrial property and recording are reserved.

Marksa SA

Industrial refrigeration units

39, avenue du Technicum

CH-2400 Le Locle

Tél.: +41 32 933 55 55

Fax: +41 32 931 15 65

Page 2 / 100 Technical Notice V1.0 / 01.09

Table of contents

1 Introduction .................................................................................................................... 9

1.1 Foreword............................................................................................................................................ 9

1.1 Typographical conventions.............................................................................................................. 10

1.1.1 Description ....................................................................................................................... 10

1.1.2 Command......................................................................................................................... 10

1.1.3 Procedure......................................................................................................................... 10

1.1.4 Procedure result ............................................................................................................... 10

1.1.5 Cross reference................................................................................................................ 11

1.1.6 List of items ...................................................................................................................... 11

1.1.7 Troubleshooting................................................................................................................ 11

1.1.8 Warning ............................................................................................................................ 12

1.1.9 Recommendation and Note.............................................................................................. 12

2 Generalities ..................................................................................................................15

2.1 Appropriate usage .......................................................................................................................... 15

2.2 Safety and usage warnings ............................................................................................................. 15

2.2.1 Importance of the safety instructions................................................................................ 15

2.2.2 Safety ............................................................................................................................... 15

2.2.3 Graphic symbols............................................................................................................... 16

2.3 Operation ......................................................................................................................................... 17

2.3.1 Basic schematic ............................................................................................................... 17

2.3.2 Principles of operation...................................................................................................... 18

2.3.3 Separated tank and refrigeration units ............................................................................. 19

2.4 Models and available options .......................................................................................................... 20

3 Model CSW 50/65/80 .................................................................................................... 21

3.1 Description....................................................................................................................................... 21

3.1.1 Overall view...................................................................................................................... 21

3.1.2 Technical specifications ...................................................................................................23

3.2 Handling .......................................................................................................................................... 25

3.3 Installation ....................................................................................................................................... 25

3.3.1 Hydraulic connections ......................................................................................................25

3.3.2 Electrical connections....................................................................................................... 25

3.3.3 Filling the reservoir ........................................................................................................... 25

3.4 Commissioning ................................................................................................................................ 26

4 Model CSW 100/150 ..................................................................................................... 27

4.1 Description....................................................................................................................................... 27

4.1.1 Overall view...................................................................................................................... 27

4.1.2 Technical specifications ...................................................................................................28

4.2 Handling .......................................................................................................................................... 30

4.3 Installation ....................................................................................................................................... 30

4.3.1 Hydraulic connections ......................................................................................................30

4.3.2 Electrical connections....................................................................................................... 30

4.3.3 Filling the reservoir ........................................................................................................... 30

4.4 Commissioning ................................................................................................................................ 31

4.5 Specific tuning ................................................................................................................................. 31

4.5.1 Draining the reservoir ....................................................................................................... 31

Technical Notice V1.0 / 01.09 Page 3 / 100

Table of contents

5 Model CSW 200/300 .....................................................................................................33

5.1 Description....................................................................................................................................... 33

5.1.1 Overall view...................................................................................................................... 33

5.1.2 Technical specifications.................................................................................................... 34

5.2 Handling........................................................................................................................................... 36

5.3 Installation........................................................................................................................................ 36

5.3.1 Hydraulic connections ......................................................................................................36

5.3.2 Electrical connections....................................................................................................... 36

5.3.3 Filling the reservoir ........................................................................................................... 36

5.4 Commissioning ................................................................................................................................ 37

5.5 Specific tuning ................................................................................................................................. 37

5.5.1 Draining the reservoir ....................................................................................................... 37

6 Model CSW 400 ............................................................................................................39

6.1 Description....................................................................................................................................... 39

6.1.1 Overall view...................................................................................................................... 39

6.1.2 Technical specifications.................................................................................................... 40

6.2 Handling........................................................................................................................................... 42

6.3 Installation........................................................................................................................................ 42

6.3.1 Hydraulic connections ......................................................................................................42

6.3.2 Electrical connections....................................................................................................... 42

6.3.3 Filling the reservoir ........................................................................................................... 42

6.4 Commissioning ................................................................................................................................ 43

6.5 Specific tuning ................................................................................................................................. 43

6.5.1 Draining the reservoir ....................................................................................................... 43

7 Model CSW 600/800 .....................................................................................................45

7.1 Description....................................................................................................................................... 45

7.1.1 Overall view...................................................................................................................... 45

7.1.2 Technical specifications.................................................................................................... 47

7.2 Handling........................................................................................................................................... 49

7.3 Installation........................................................................................................................................ 49

7.3.1 Hydraulic connections ......................................................................................................49

7.3.2 Electrical connections....................................................................................................... 49

7.3.3 Filling the reservoir ........................................................................................................... 49

7.4 Commissioning ................................................................................................................................ 50

7.5 Specific tuning ................................................................................................................................. 50

7.5.1 Draining the reservoir ....................................................................................................... 50

7.6 Close the drainage tap once the reservoir is empty. ....................................................................... 50

8 Model CSW 900/1000/1300/1700 .................................................................................51

8.1 Description....................................................................................................................................... 51

8.1.1 Overall view...................................................................................................................... 51

8.1.2 Technical specifications.................................................................................................... 53

8.2 Handling........................................................................................................................................... 55

8.3 Installation........................................................................................................................................ 55

8.3.1 Hydraulic connections ......................................................................................................55

8.3.2 Electrical connections....................................................................................................... 55

8.3.3 Filling the reservoir ........................................................................................................... 55

8.4 Commissioning ................................................................................................................................ 56

8.5 Specific tuning ................................................................................................................................. 56

8.5.1 Draining the reservoir ....................................................................................................... 56

Page 4 / 100 Technical Notice V1.0 / 01.09

Table of contents

9 Model CSW 2000/2400 ................................................................................................. 57

9.1 Description....................................................................................................................................... 57

9.1.1 Overall view...................................................................................................................... 57

9.1.2 Technical specifications ...................................................................................................59

9.2 Handling .......................................................................................................................................... 61

9.3 Installation ....................................................................................................................................... 61

9.3.1 Hydraulic connections ......................................................................................................61

9.3.2 Electrical connections....................................................................................................... 61

9.3.3 Filling the reservoir ........................................................................................................... 61

9.4 Commissioning ................................................................................................................................ 62

9.5 Specific tuning ................................................................................................................................. 62

9.5.1 Draining the reservoir ....................................................................................................... 62

9.6 Close the drainage tap once the reservoir is empty. ....................................................................... 62

10 Model CSW 3000/3500/4700 ........................................................................................ 63

10.1 Description....................................................................................................................................... 63

10.1.1 Overall view ...................................................................................................................... 63

10.1.2 Technical specifications ................................................................................................... 65

10.2 Handling .......................................................................................................................................... 67

10.3 Installation ....................................................................................................................................... 67

10.3.1 Hydraulic connections ...................................................................................................... 67

10.3.2 Electrical connections....................................................................................................... 67

10.3.3 Filling the reservoir ........................................................................................................... 67

10.4 Commissioning ................................................................................................................................ 68

10.5 Specific tuning ................................................................................................................................. 68

10.5.1 Draining the reservoir ....................................................................................................... 68

10.6 Close the drainage tap once the reservoir is empty. ....................................................................... 68

11 Tuning and maintenance............................................................................................. 69

11.1 Control settings................................................................................................................................ 69

11.1.1 Thermostat ....................................................................................................................... 69

11.2 Maintenance .................................................................................................................................... 71

11.2.1 Periodic maintenance ....................................................................................................... 71

11.2.2 Safety ............................................................................................................................... 71

11.2.3 Maintenance table ............................................................................................................ 71

11.2.4 Weekly maintenance ........................................................................................................71

11.2.5 Monthly maintenance .......................................................................................................71

11.2.6 Annual maintenance......................................................................................................... 72

Technical Notice V1.0 / 01.09 Page 5 / 100

Table of contents

12 Options..........................................................................................................................73

12.1 List of the options............................................................................................................................. 73

12.2 Air filter (A)....................................................................................................................................... 75

12.2.1 Description of the option................................................................................................... 75

12.2.2 Maintenance ..................................................................................................................... 75

12.2.3 Breakdowns...................................................................................................................... 75

12.3 By-pass (J)....................................................................................................................................... 76

12.3.1 Description of the option................................................................................................... 76

12.3.2 Maintenance ..................................................................................................................... 76

12.3.3 Breakdowns...................................................................................................................... 76

12.4 Distributor (D) .................................................................................................................................. 77

12.4.1 Description of the option................................................................................................... 77

12.4.2 Maintenance ..................................................................................................................... 77

12.4.3 Breakdowns...................................................................................................................... 77

12.5 400V power supply (E) .................................................................................................................... 77

12.5.1 Description of the option................................................................................................... 77

12.5.2 Maintenance ..................................................................................................................... 77

12.5.3 Breakdowns...................................................................................................................... 77

12.6 Water-flow controller (F) .................................................................................................................. 78

12.6.1 Description of the option................................................................................................... 78

12.6.2 Maintenance ..................................................................................................................... 78

12.6.3 Breakdowns...................................................................................................................... 78

12.7 Hot gas bypass (G).......................................................................................................................... 79

12.7.1 Description of the option................................................................................................... 79

12.7.2 Thermostat ....................................................................................................................... 80

12.7.3 Maintenance ..................................................................................................................... 81

12.7.4 Breakdowns..................................................................................................................... 81

12.8 Pre-heating kit (H)............................................................................................................................ 82

12.8.1 Description of the option................................................................................................... 82

12.8.2 Maintenance ..................................................................................................................... 82

12.8.3 Breakdowns...................................................................................................................... 82

12.9 Thermal insulation (I) ....................................................................................................................... 83

12.9.1 Description of the option................................................................................................... 83

12.9.2 Maintenance ..................................................................................................................... 83

12.9.3 Breakdowns...................................................................................................................... 83

12.10 Differential thermostat (L) ................................................................................................................ 83

12.10.1 Description of the option................................................................................................... 83

12.10.2 Maintenance ..................................................................................................................... 83

12.10.3 Breakdowns...................................................................................................................... 83

12.11 Chassis sur roulettes (M)................................................................................................................. 83

12.11.1 Description of the option................................................................................................... 83

12.11.2 Maintenance ..................................................................................................................... 83

12.11.3 Breakdowns...................................................................................................................... 83

12.12 Contrôle de niveau (N)..................................................................................................................... 84

12.12.1 Description of the option................................................................................................... 84

12.12.2 Maintenance ..................................................................................................................... 84

12.12.3 Breakdowns...................................................................................................................... 84

12.13 Circuit d’eau sous pression (P)........................................................................................................ 85

12.13.1 Description of the option................................................................................................... 85

12.13.2 Maintenance ..................................................................................................................... 85

12.13.3 Breakdowns..............................................................................................................

12.14 Reinforced pump (R) ....................................................................................................................... 86

12.14.1 Description of the option................................................................................................... 86

12.14.2 Maintenance ..................................................................................................................... 86

12.14.3 Breakdowns...................................................................................................................... 86

12.15 LP/HP safety pressure controllers (S) ............................................................................................. 87

........ 85

Page 6 / 100 Technical Notice V1.0 / 01.09

Table of contents

12.15.1 Description of the option................................................................................................... 87

12.15.2 Maintenance ..................................................................................................................... 87

12.15.3 Breakdowns...................................................................................................................... 88

12.16 Timer (T) .......................................................................................................................................... 88

12.16.1 Description of the option................................................................................................... 88

12.16.2 Maintenance ..................................................................................................................... 88

12.16.3 Breakdowns...................................................................................................................... 88

12.17 Electric valve and solenoid (W) ....................................................................................................... 88

12.17.1 Description of the option................................................................................................... 88

12.17.2 Maintenance ..................................................................................................................... 88

12.17.3 Breakdowns...................................................................................................................... 88

12.18 High temperature alarm (Y) ............................................................................................................. 89

12.18.1 Description of the option................................................................................................... 89

12.18.2 Maintenance ..................................................................................................................... 89

12.18.3 Breakdowns...................................................................................................................... 89

13 Breakdowns.................................................................................................................. 91

13.1 Warnings.......................................................................................................................................... 91

13.2 Checks............................................................................................................................................. 91

13.2.1 Pressure checks ............................................................................................................... 91

13.3 Breakdowns..................................................................................................................................... 92

13.3.1 Le groupe ne fonctionne pas ............................................................................................ 92

14 Appendix....................................................................................................................... 95

14.1 Compliance...................................................................................................................................... 95

14.1.1 Directives.......................................................................................................................... 95

14.1.2 Identification plate ........................................................................................................... 95

14.2 Disposal of the product.................................................................................................................... 96

14.2.1 General remarks............................................................................................................... 96

14.2.2 Preparation....................................................................................................................... 96

14.3 Maintenance sheet ......................................................................................................................... 97

14.4 Technical data sheet........................................................................................................................ 98

14.5 Compliance documents ................................................................................................................... 99

Technical Notice V1.0 / 01.09 Page 7 / 100

Table of contents

Page 8 / 100 Technical Notice V1.0 / 01.09

Chapter contents

This chapter contains basic information on the structure and the specifications of the document, and on

the documentation.

1.1 Foreword

This manual is intended for all users of a Marksa refrigeration unit. It contains all the information necessary for installation, commissioning, periodic maintenance and repair.

This manual was compiled by the Marksa SA company with the same care as your refrigeration unit and

is therefore an inseparable component. If you have any questions or do not completely understand any

point, please contact your retailer immediately or contact us directly.

Introduction 1

Technical Notice V1.0 / 01.09 Page 9 / 100

1 Introduction

1.1 Typographical conventions

The following styles are used in this manual.

1.1.1 Description

This style, use in conjunction with illustration numbers, is preceded with the corresponding numbers:

Example:

(1) First element

(2) Second element

(3) Etc...

1.1.2 Command

Any software command, button, function key, window, icon, option, tab, checkbox, selection box, article,

menu, tool bar, field and section used in this document is represented by a bold italic font.

Example:

The Exit command allows to quit the software.

1.1.3 Procedure

Each procedure step to be carried out step-by-step by the user is preceded by a letter.

Example

A. Open the drawer.

B. Put the microplate into position as shown.

C. Close the drawer.

1.1.4 Procedure result

A procedure result is shown by the following symbol .

Example

A. Click on the Parameters button.

The parameter window is displayed.

Page 10 / 100 Technical Notice V1.0 / 01.09

1.1.5 Cross reference

This style is used to helps the user find complementary information linked to the current subject.

Example:

See section “4.2.4 Sensor Board Positioning” on page 47.

1.1.6 List of items

This style is used in order to display a list of elements.

Example:

•item 1;

•item 2;

•item 3.

1.1.7 Troubleshooting

The complete description of the error message, the explanation and the remedy appear as follows:

Problem

- Explanation, possible cause

Introduction 1

✔ Remedy

Technical Notice V1.0 / 01.09 Page 11 / 100

1 Introduction

1.1.8 Warning

Depending on the importance of the warning and the associated risks, three warning styles are defined.

The safety aspects are used in accordance with the requirements contained in the following norms:

• ANSI Z535.4;

• ISO 3864, ISO 3864-1:2002, and ISO3864-2:2004.

1.1.8.1 Danger

Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

The main risk is shown in capitals under the symbol WARNING .The mention of a risk does not exclude

anyway the presence of subsidiary risks.

Example

ELECTROCUTION

Never touch unisolated electrical wire. A contact with conductors may cause an electrocution.

1.1.8.2 Warning

Used to indicate a potentially hazardous situation which, if not avoided, could result in death or serious

injury.

Example

Always disconnect the power supply cable before working inside the device. A contact with live

conductors may cause an electrocution.

1.1.8.3 Caution

Used to indicate a potentially hazardous situation which, if not avoided, may result in minor or moderate

injury.

Example

If the mirror is broken, do not handle it with unprotected hands because of risks of cut.

The use of the sign CAUTION without triangle means there is a risk of minor damage, but no possible

injury.

Example

The use of other cleaning agents or hard objects may damage the ID-Pipetor EP-5. Do not use

others cleaning agents or products prior to consult Marksa SA and to receive the agreement.

1.1.9 Recommendation and Note

When additional information is necessary and its non-respect conduct to minor inconveniences, recommendations and notes are presented.

1.1.9.1 Recommendation

Used to designate a preferred procedure or a recommended usage. Marksa SA declines any responsibility in case of non-respected recommendations.

Page 12 / 100 Technical Notice V1.0 / 01.09

Example

For more information, contact either your DiaMed AG representative or the manufacturer directly.

1.1.9.2 Note

Used to give a general or purely informative remark.

Example

The housing reassembly must follow the reverse order of the disassembly.

Introduction 1

Technical Notice V1.0 / 01.09 Page 13 / 100

1 Introduction

Page 14 / 100 Technical Notice V1.0 / 01.09

Chapter contents

This chapter contains generic information applicable to all refrigeration unit models. In particular, it

contains instructions concerning safety as well as practical and theoretical information.

2.1 Appropriate usage

The refrigeration unit is intended to be used to maintain the ambient temperature of a machine tool. It

can be only be used by trained and authorised personnel.

The instructions contained in this user manual must be carefully respected, specifically those concerning

safety.

2.2 Safety and usage warnings

2.2.1 Importance of the safety instructions

The safety and protection instructions appearing in this manual must be respected to avoid injury, damage to property and environmental pollution. In the same manner, the legal conditions, accident prevention and environmental protection measures, as well as the technical regulations for guaranteeing

safe and suitable working conditions applicable in your country and on the specific installation site of the

refrigeration unit must be respected.

Generalities 2

The use of the refrigeration unit in any other manner than described in this manual may void the

guarantee.

2.2.2 Safety

Leave free space of at least 0.5m in front of the intake and 1m in front of the exhaust fan.

As the cooling process is reliant on the circulation of air, sufficient space on each side and above

the refrigeration unit must be planned to ensure that the exhaust fan does not repeatedly recycle

the same air.

The maximum allowable ambient temperature is 38°C for the intake.

The minimum acceptable ambient temperature is 5°C. Below this limit, the operation of your refrigeration unit will be disrupted.

Technical Notice V1.0 / 01.09 Page 15 / 100

2 Generalities

2.2.3 Graphic symbols

The following symbols may be present on your refrigeration unit:

Symbol Description

Table 2-1: Symbols

Risk of electrocution

Risk of burns

Page 16 / 100 Technical Notice V1.0 / 01.09

2.3 Operation

TH

BP - HP

(7)(6)(4)(3)(2)(1)

(8) (9) (10) (11) (12) (14)(13)

(5)

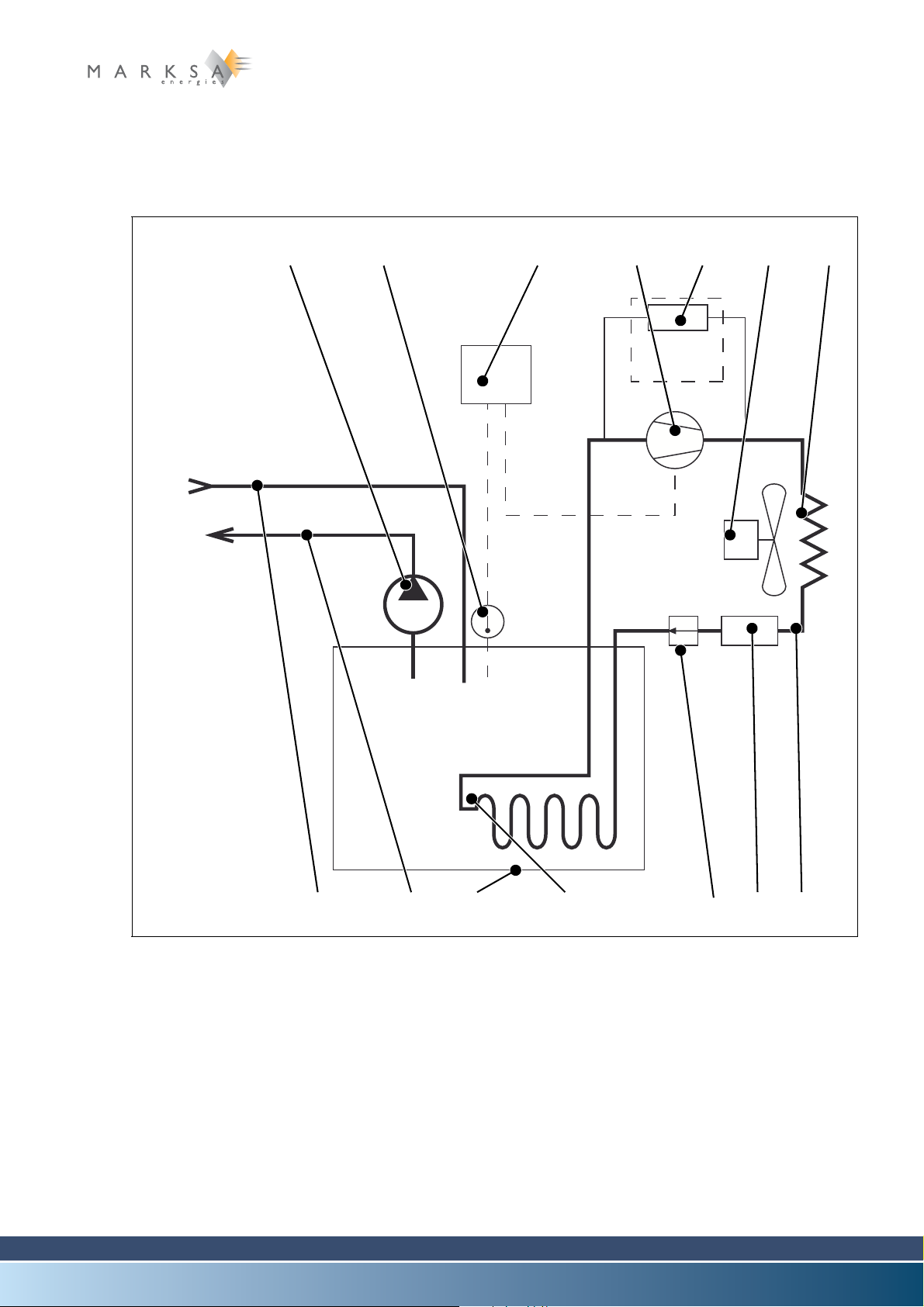

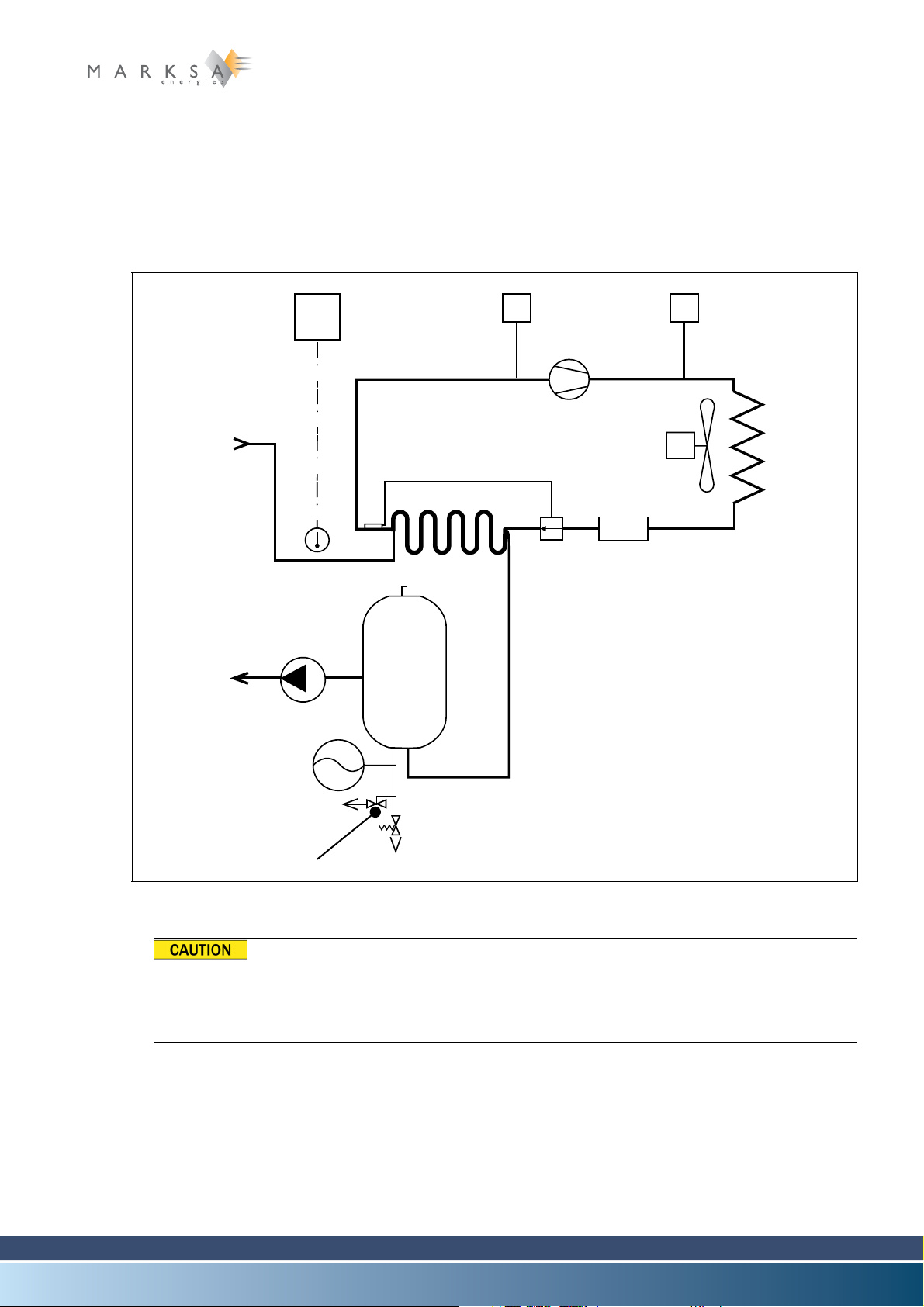

2.3.1 Basic schematic

2.3.1.1 Direct cooling of the tank

Generalities 2

Fig. 2-1 : Basic schematic

Technical Notice V1.0 / 01.09 Page 17 / 100

2 Generalities

2.3.1.2 Legend

(1) Pump

(2) Temperature probe

(3) Thermostat

(4) Compressor

(5) Safety pressure controller (an option on the CSW100)

(6) Exhaust fan

(7) Condenser

(8) Temperate water inlet

(9) Cold water outlet

(10) Reservoir

(11) Evaporator

(12) Pressure regulator

(13) Dehumidifier

(14) Cooling circuit

2.3.2 Principles of operation

The whole range of water chillers supply chilled water (9) continuously at a constant temperature.

The chilling is accomplished in the following manner: An HFC refrigerant of either R134A (tetrafluoroethane) or R407C types is compressed (4) then chilled in a condenser (7).

A pressure regulator (12) causes a drop in pressure which leads to a drop in temperature. The drop in

temperature is transmitted to the water contained in the reservoir (19) through a heat exchanger (11).

The cold water leaves the reservoir (9) to chill the end use equipment and then returns back to the reservoir (8).

Page 18 / 100 Technical Notice V1.0 / 01.09

2.3.3 Separated tank and refrigeration units

TH

HPBP

(7)(6)(4)(3)(2)(1)

(8) (9) (10) (11) (12) (14)(13)

(5)

For refrigeration units of greater capacity, the refrigerant liquid returned is stored in a reservoir (10) then

pumped (1) and chilled (11) before being returned back to the cooling circuit (8)..

Generalities 2

Fig. 2-2 : Basic schematic

Technical Notice V1.0 / 01.09 Page 19 / 100

2 Generalities

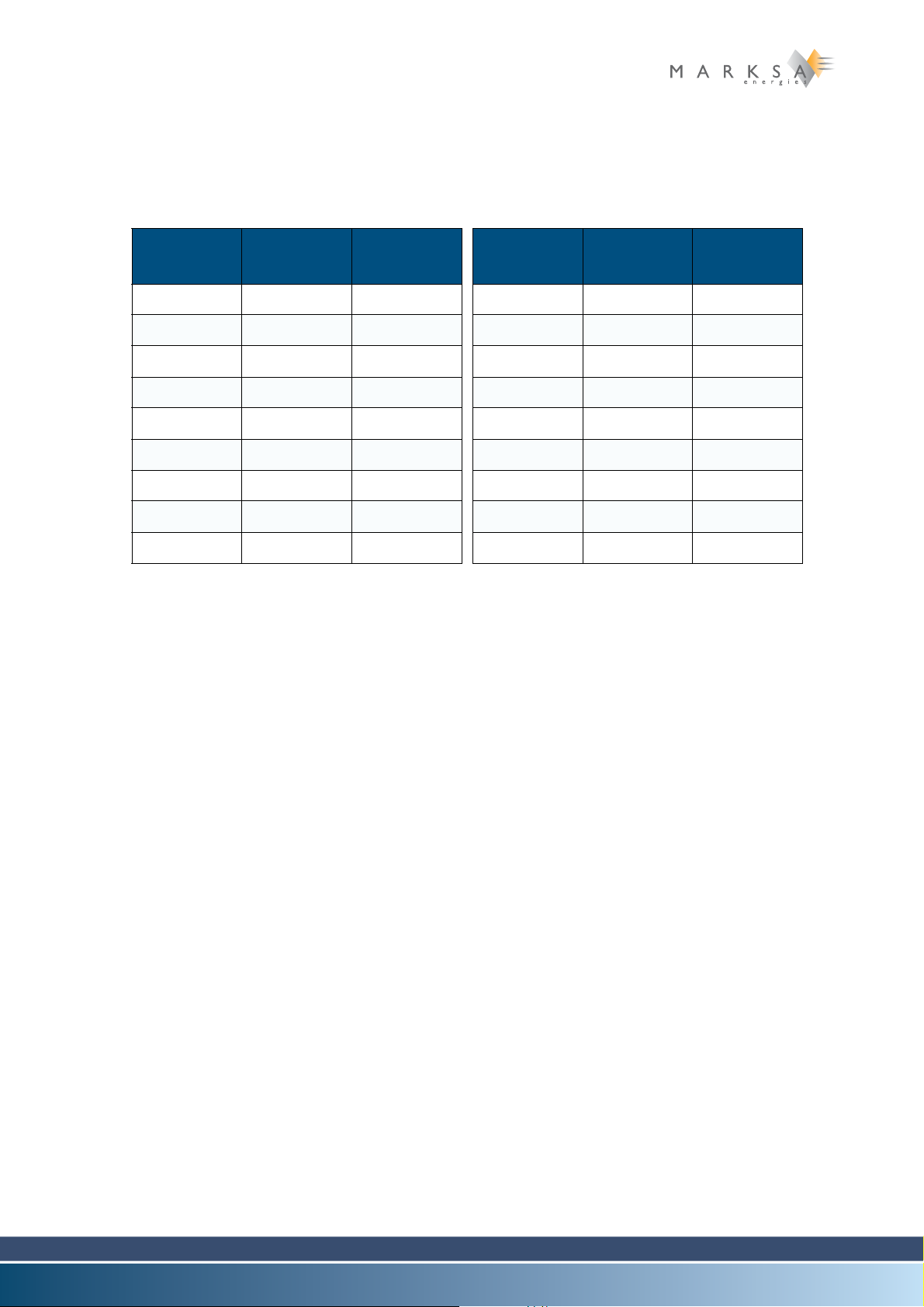

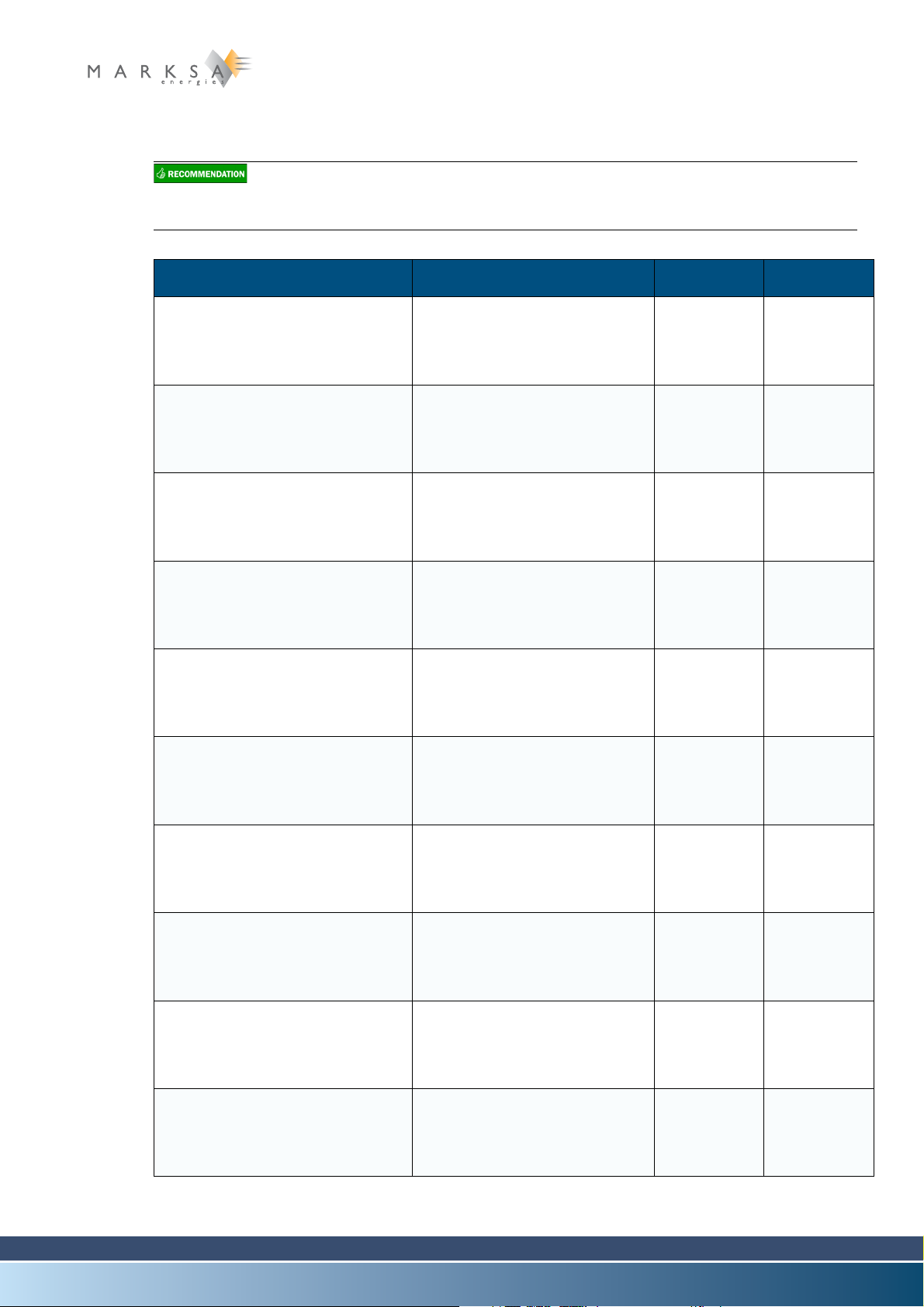

2.4 Models and available options

The CSW range of industrial water chillers covers several models, classified according to their capacities

and available options.

The following models are currently available:

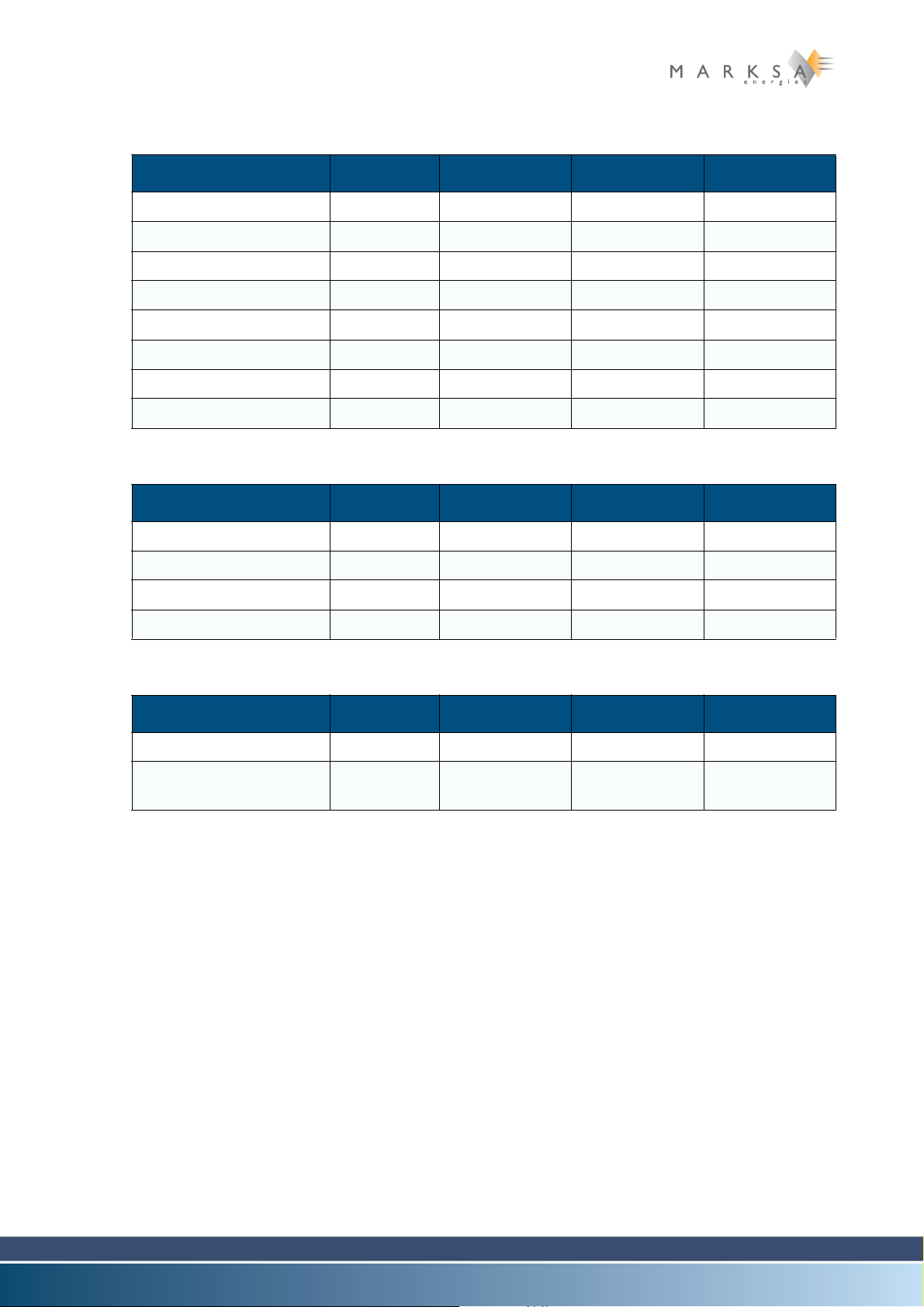

Model Capacity

CSW 50 0.5 kW 134A CSW 800 7.8 kW 407C

CSW 65 0.65 kW 134A CSW 900 9.3 kW 407C

CSW 80 0.8 kW 134A CSW 1000 9.7 kW 407C

CSW 100 1 kW 134A CSW 1300 12 kW 407C

CSW 150 1.5 kW 134A CSW 1700 16.4kW 407C

CSW 200 3 kW 134A CSW 2000 20 kW 407C

CSW 300 3 kW 134A CSW 2400 24 kW 407C

CSW 400 4 kW 407C CSW 3000 30 kW 407C

CSW 600 6 kW 407C CSW 3500 35 kW 407C

Table 2-2: List of models

Various options are available.

Refrigerant

gas

Model Capacity

See section “12.1 List of the options” on page 73.

The options are referenced as initials in the product name, just after the reference to its class.

Refrigerant

gas

Example

CSW 100 NRV

With:

N : Water-level control

R : Reinforced pump

V : Visual water-level indicator

Page 20 / 100 Technical Notice V1.0 / 01.09

Chapter contents

(1)

(2)

(3)

This chapter contains information specific to the CSW 50, CSW 65 and CSW 80 models. It covers all

topics associated with installation, commissioning, tuning and maintenance of these models.

For reasons of clarity, only the CSW 80 model is described in the current chapter. However, all

of the explanations apply in a similar fashion to the CSW 50 and CSW 65 models.

3.1 Description

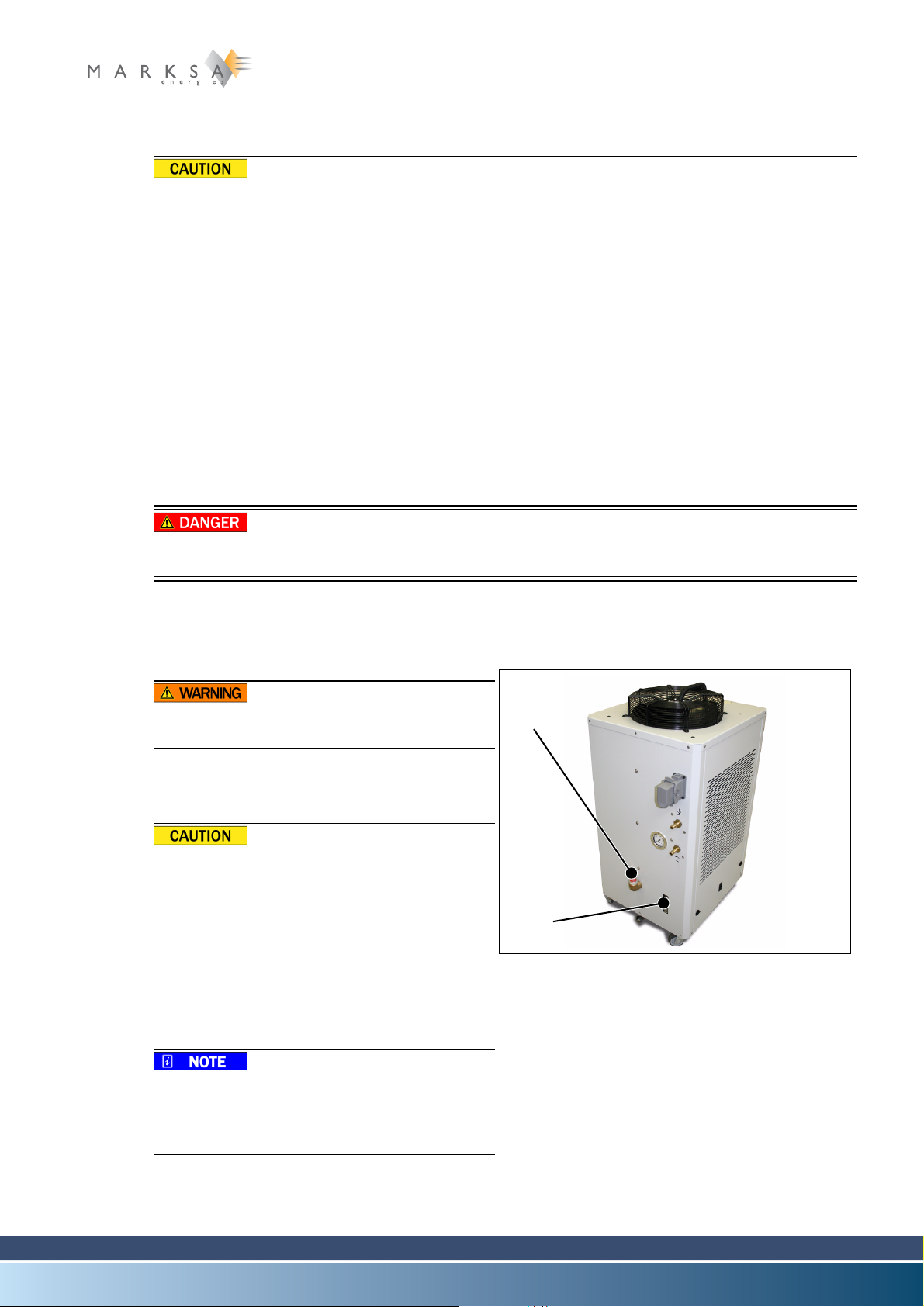

3.1.1 Overall view

Model CSW 50/65/80 3

Fig. 3-1 : CSW 80 type chiller (front view)

(1) Running pilot lamp

(2) Main power switch

(3) Thermostat display

Technical Notice V1.0 / 01.09 Page 21 / 100

3 Model CSW 50/65/80

(4)

(5)

(7)

(8)

(6)

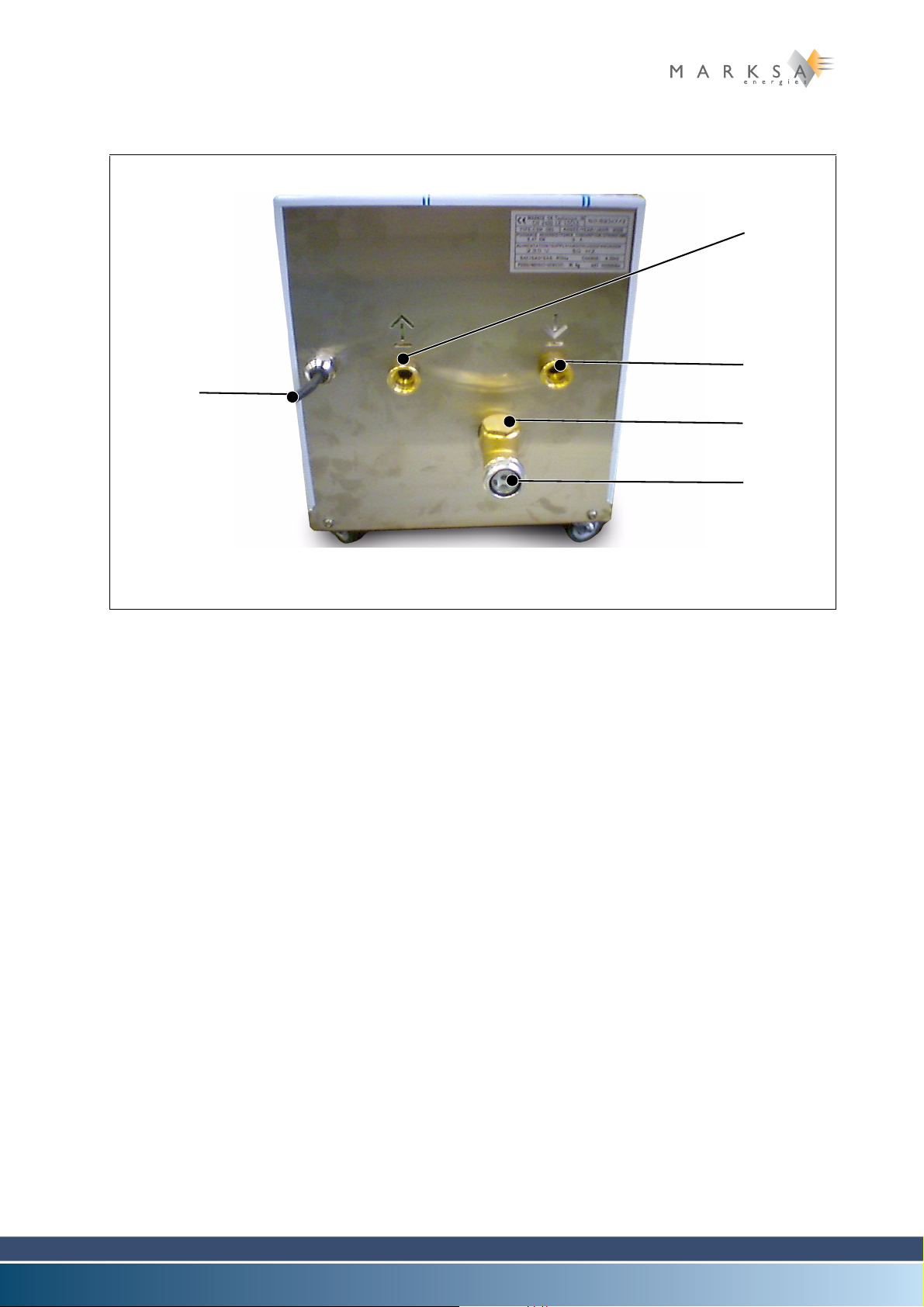

Fig. 3-2 : CSW 80 type chiller (rear view)

(4) Cooling liquid outlet

(5) Cooling liquid return inlet

(6) Refilling port

(7) Visual water-level indicator

(8) Electric power connector

Page 22 / 100 Technical Notice V1.0 / 01.09

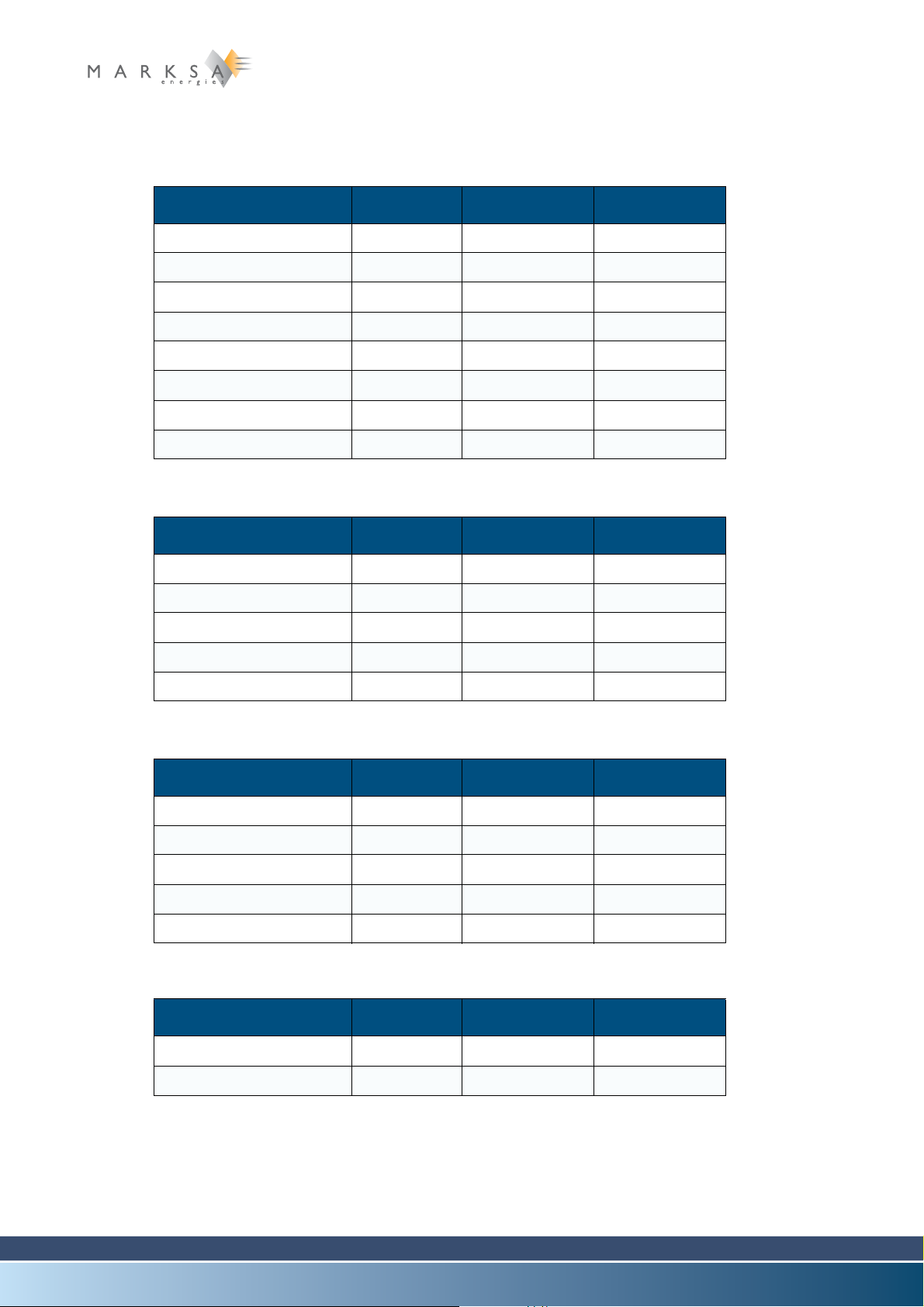

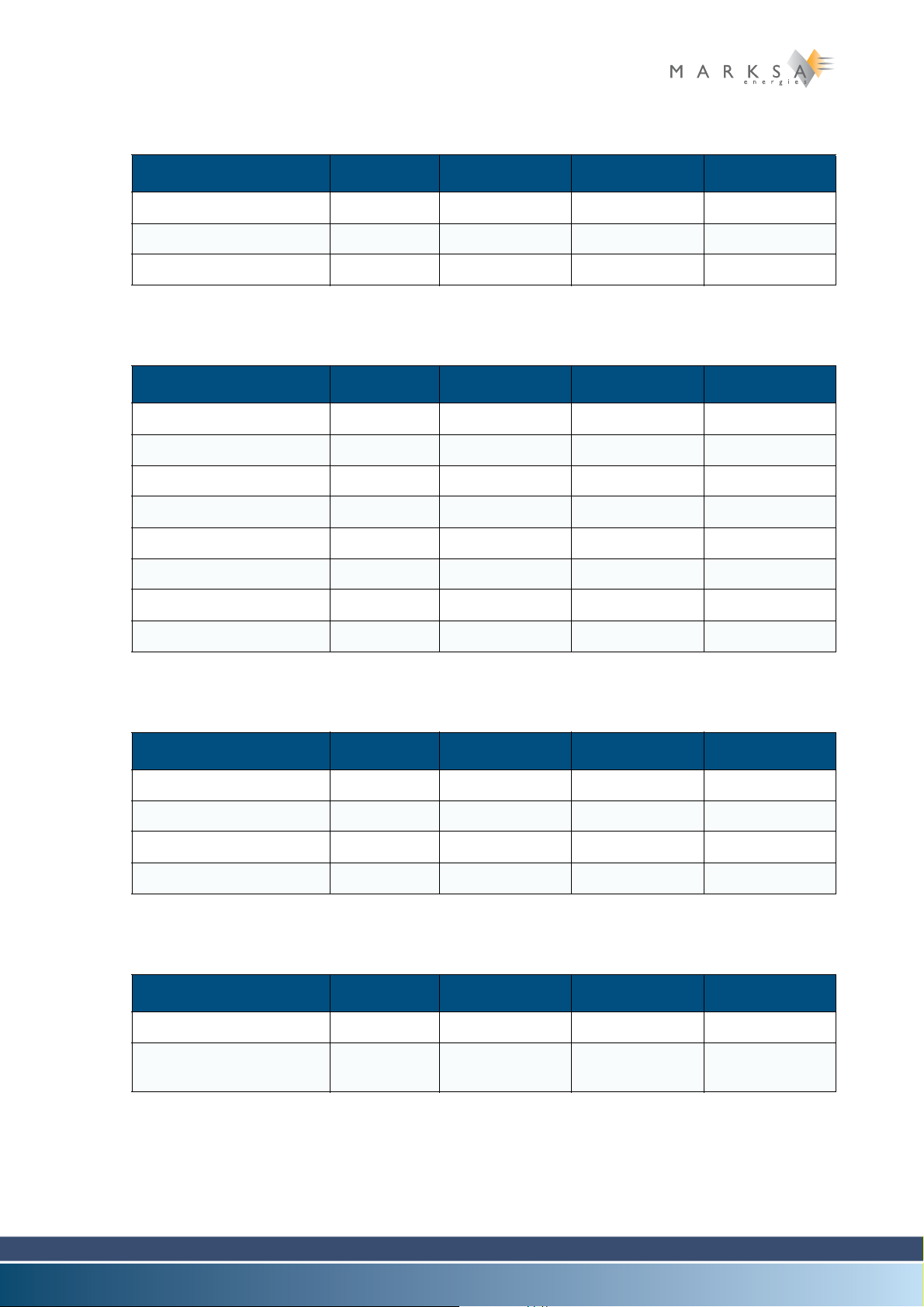

3.1.2 Technical specifications

3.1.2.1 Standard operating parameters

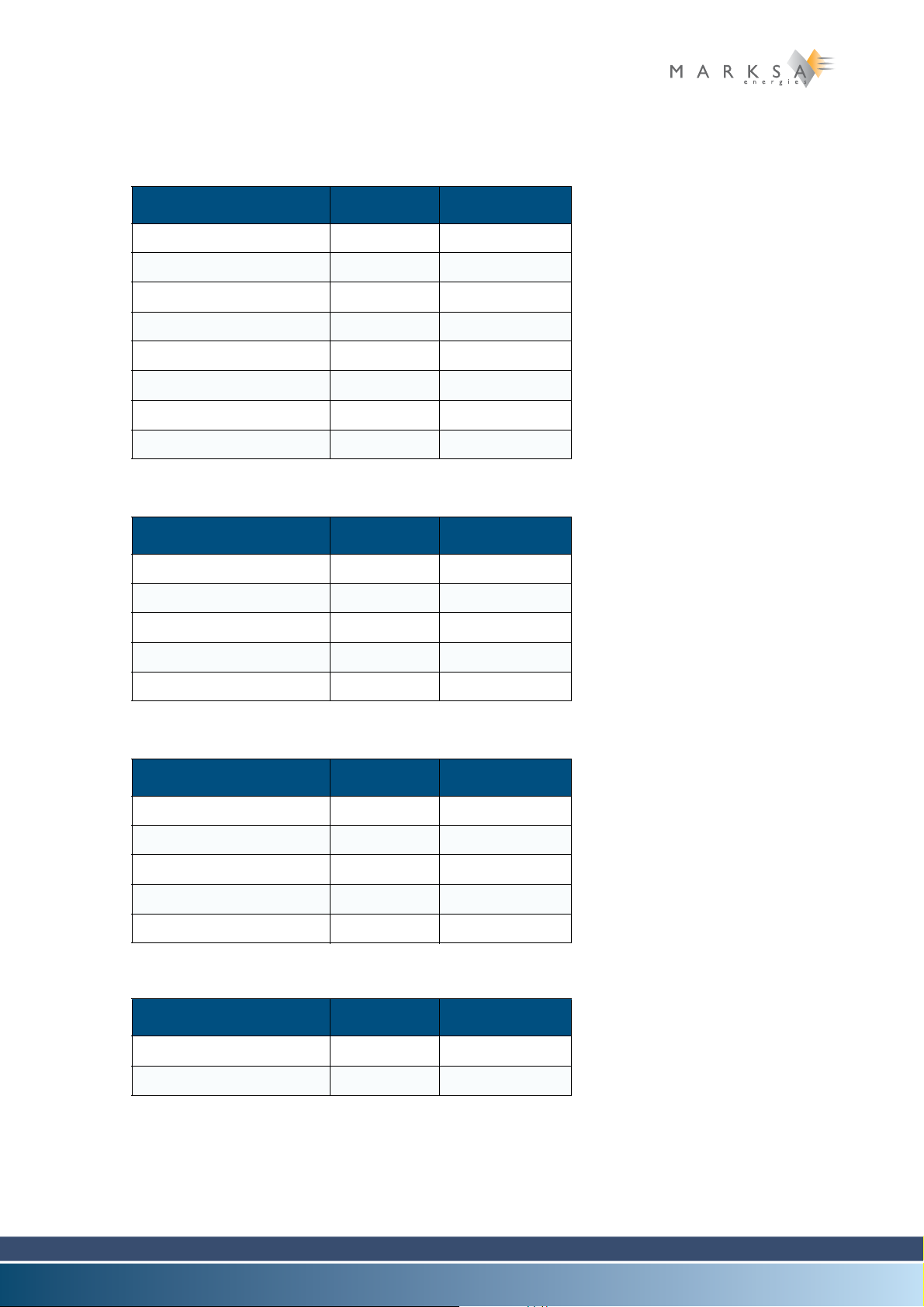

Description Units CSW 50 CSW 65/80

Refrigerant Type R134A R134A

Refrigerating capacity kW 0.5 0.8

Power consumption kW 0.23 0.41

Heat load kW 0.75 1.2

Inlet temperature °C 22 22

Outlet temperature °C 20 20

Flow rate l/min 8 8

Maximum input temperature °C 38 38

3.1.2.2 Electrical data

Model CSW 50/65/80 3

Description Units CSW 50 CSW 65/80

Power input kW 0.4 0.6

Maximum amperage A 2.5 3

Start-up amperage A 7 10

Line fuse A T 10 10

Power supply V x ph x Hz 230 x 1 x 50 230 x 1 x 50

3.1.2.3 Air condenser

Description Units CSW 50 CSW 65/80

Flow rate m3/h 245 580

Exhaust fan diameter mm 200 254

Power input W 5 16

Ampere rating A 0.2 0.58

Power supply V x ph x Hz 230 x 1 x 50 230 x 1 x 50

Evaporator

Description Units CSW 50 CSW 65/80

Composition COPPER COPPER

Flow rate l/min 8 8

Technical Notice V1.0 / 01.09 Page 23 / 100

3 Model CSW 50/65/80

Hydraulic circuit

Description Units CSW 50 CSW 65/80

Flow rate l/min 8 8

Total p r e s sure bar 0.4 0.4

Power input kW 0.16 0.16

Amperage A 0.70 0.70

Rotation t/min 2900 2900

Power supply V x ph x Hz 230 x 1 x 50 230 x 1 x 50

Stainless steel reservoir l 7 7

Inlet/outlet couplings 3/4’’ 3/4’’

Dimensions

Description Units CSW 50 CSW 65/80

Width mm 305 305

Height mm 320 320

Depth mm 560 560

Weight kg 35 35

Other characteristics

Description Units CSW 50 CSW 65/80

Standard colour Stainless steel Stainless steel

Sound rating

dB(A)

49 49

ISO 3741 – Lp

Page 24 / 100 Technical Notice V1.0 / 01.09

3.2 Handling

Fig. 3-3 : Filler cap

(1)

(2)

The unit must be transported flat and must not sustain any shocks.

3.3 Installation

The unit is normally installed close to the machine being cooled, as indicated on these installation plans.

During the installation, allow for a free space of about 0.5m around the refrigeration unit. This distance

must be 1m in front of the exhaust fan. With these precautions, both ventilation and maintenance access

will be made easier.

3.3.1 Hydraulic connections

Except where specifications state otherwise, the connections between the refrigeration unit and the machine being cooled can be made with pipes with a cross-section diameter at least equal to that indicated

in the technical characteristics.

See section “3.1.2 Technical specifications” on page 23.

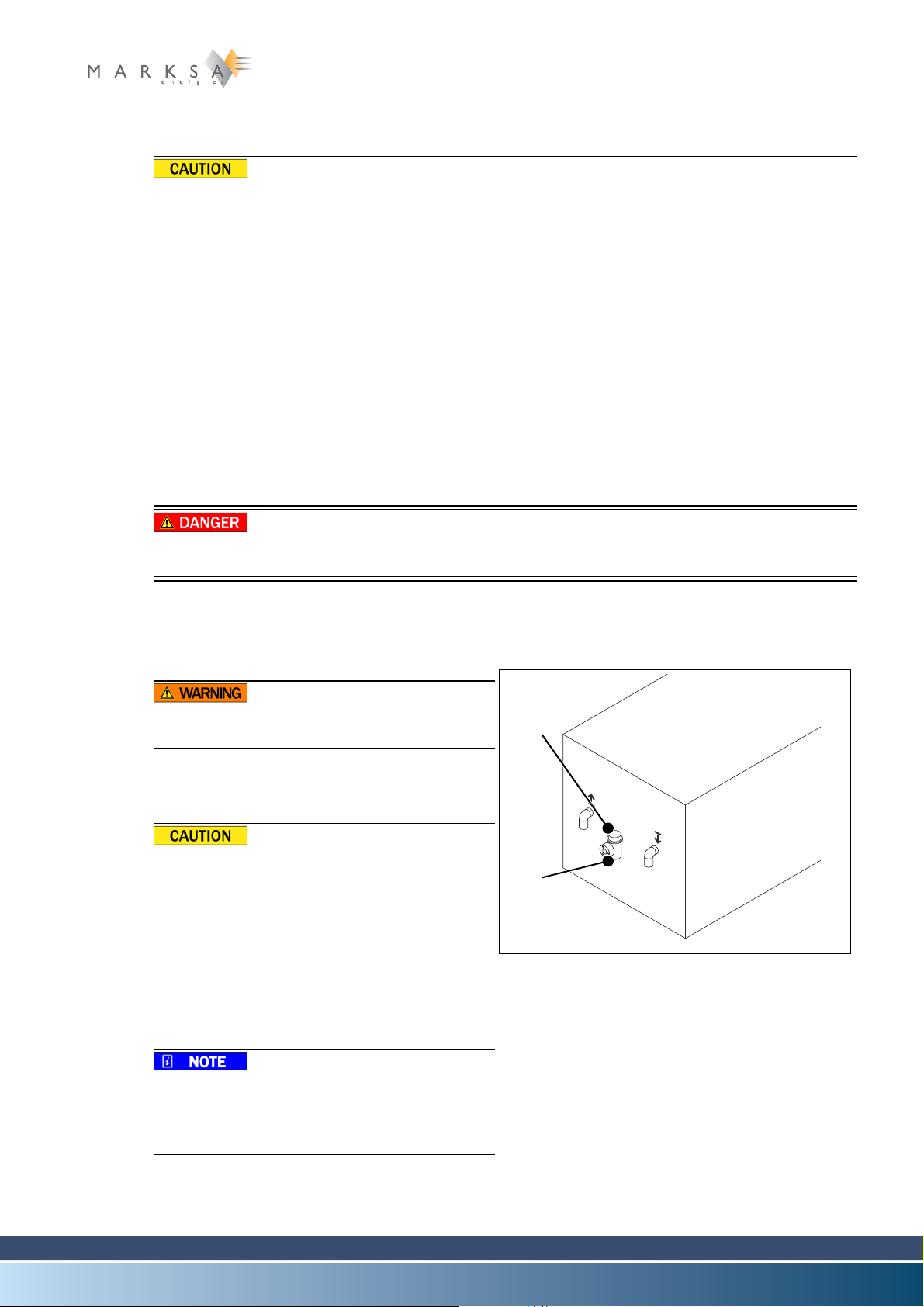

3.3.2 Electrical connections

Model CSW 50/65/80 3

ELECTROCUTION

The machine cabinet must be disconnected from power while connecting the cables.

Power cable .............................................installed with a 3m length

3.3.3 Filling the reservoir

The liquids used are not suitable for human

consumption.

A. Prepare a mixture of water and 30% ethylene gly-

col.

Do not use anti-freeze intended for motor vehicles.

Marksa recommends ANTIFROGEN N antifreeze.

B. Unscrew the cap (1).

C. Fill the reservoir to somewhere between the mini-

mum and maximum levels of the indicator (2).

D. Screw the cap back on.

(or according to customer specifications)

A certain volume of the fluid is used to fill the

machine's circuit. Pay attention to the level

when starting up the machine and top up as

necessary.

Technical Notice V1.0 / 01.09 Page 25 / 100

3 Model CSW 50/65/80

Fig. 3-4 : Engaging

(1)

3.4 Commissioning

The unit has been checked, tuned and tested in

our workshops.

A. Make the hydraulic and electrical connections.

B. Fill the reservoir with liquid.

C. Start up the machine (1).

D. Check the rotation direction of the pump and the

exhaust fan.

Page 26 / 100 Technical Notice V1.0 / 01.09

Chapter contents

(1) (2) (3) (4) (5) (6)

This chapter contains information specific to the CSW 100 and CSW 150 models. It covers all topics associated with installation, commissioning, tuning and maintenance of these models.

For reasons of clarity, only the CSW 100 model is described in the current chapter. However, all

of the explanations apply in a similar fashion to the CSW 150 model.

4.1 Description

4.1.1 Overall view

Model CSW 100/150 4

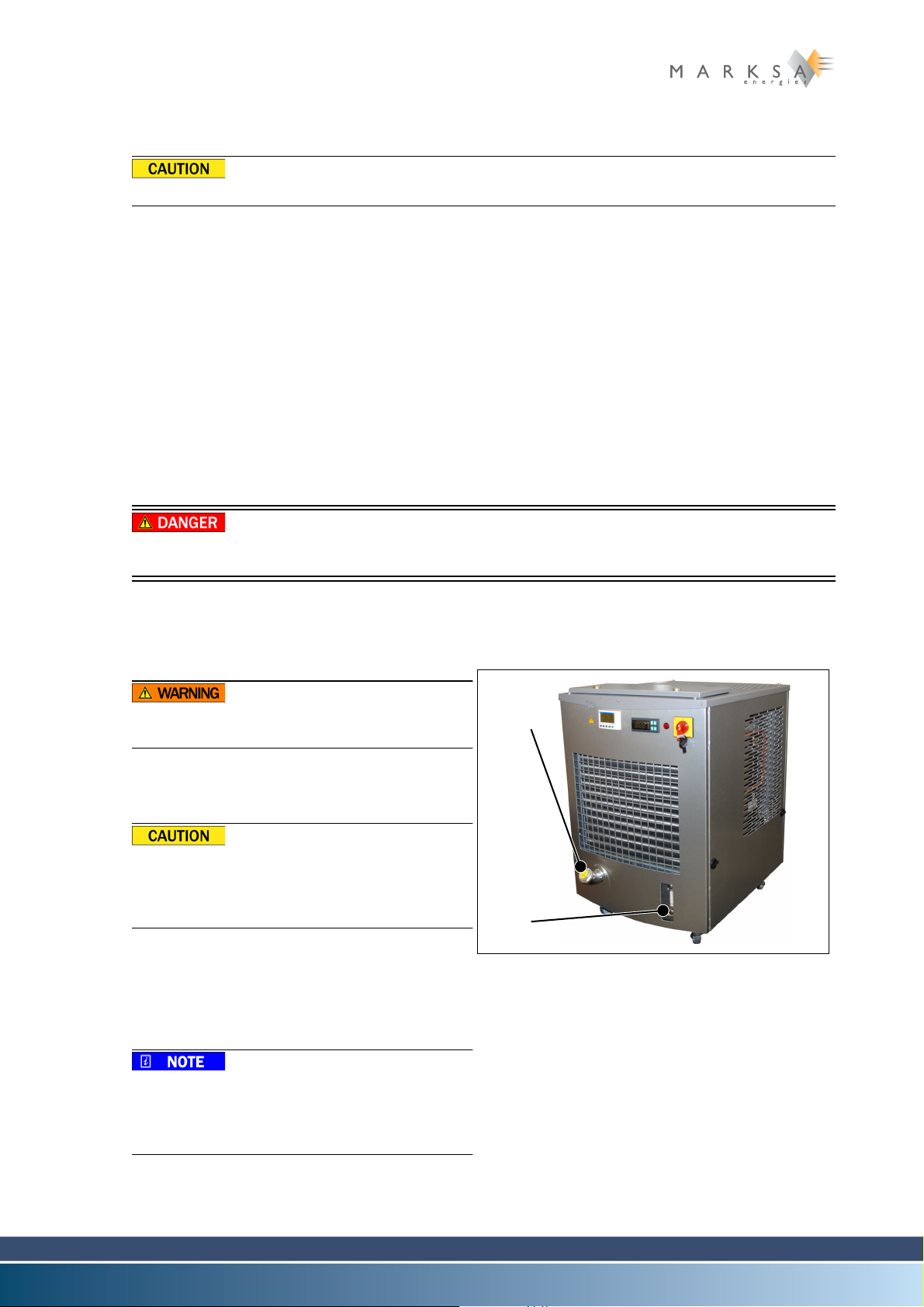

Fig. 4-1 : CSW 100 type chiller

(1) Lifting ring

(2) Breakdown indicator lamp (red)

(3) Water-level indicator lamp (orange, optional)

(4) Thermostat display

(5) Purge button

(6) Main power switch

Technical Notice V1.0 / 01.09 Page 27 / 100

4 Model CSW 100/150

4.1.2 Technical specifications

4.1.2.1 Standard operating parameters

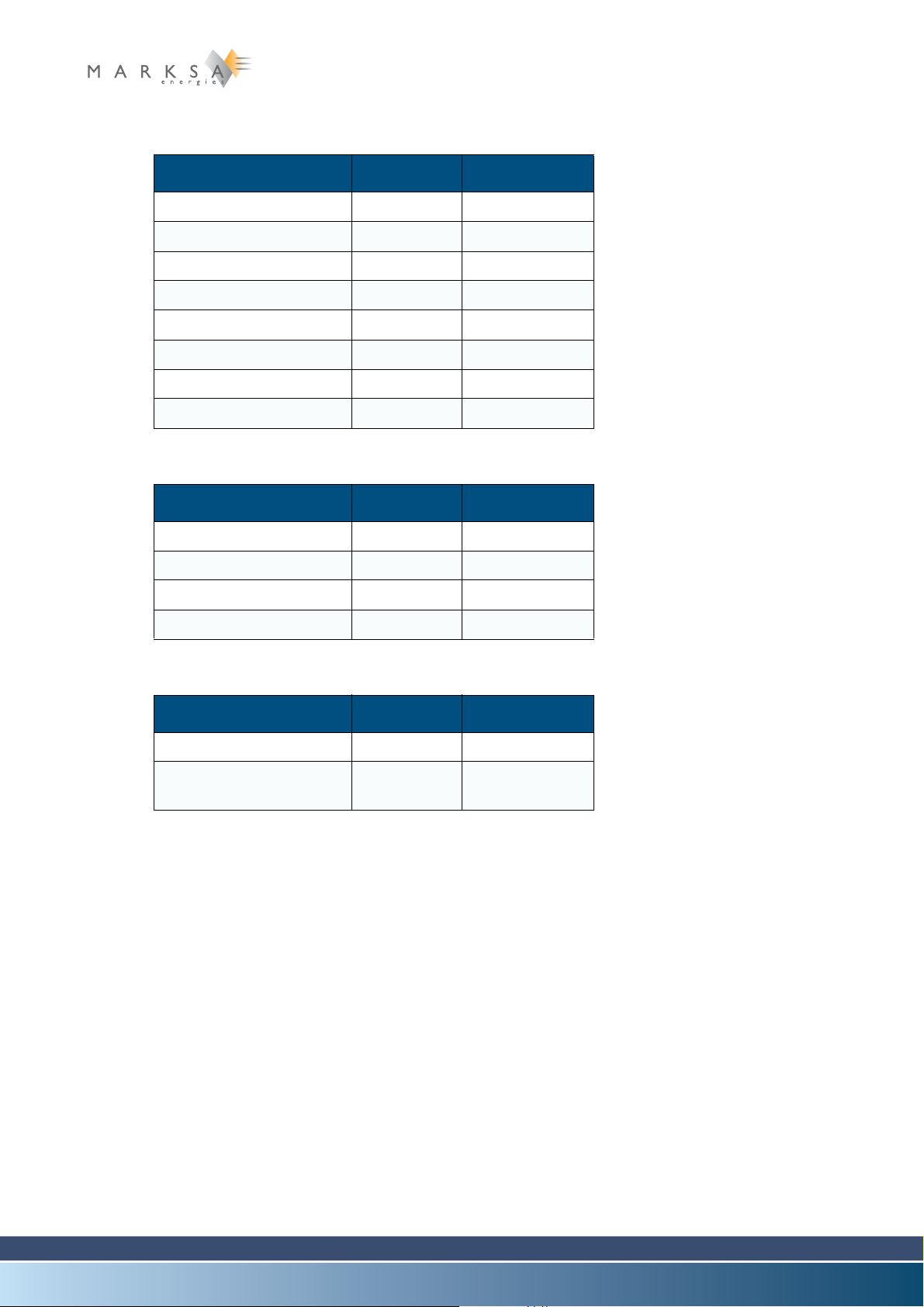

Description Units CSW 100 CSW 150

Refrigerant Type R134A R134A

Refrigerating capacity kW 1.20 1.50

Power consumption kW 0.53 0.53

Heat load kW 1.73 1.73

Inlet temperature °C 22 22

Outlet temperature °C 20 20

Flow rate l/min 8 8

Maximum input temperature °C 38 38

4.1.2.2 Electrical data

Description Units CSW 100 CSW 150

Power input kW 0.8 1.0

Maximum amperage A 6.5 6.5

Start-up amperage A 16 21

Line fuse A T 10 10

Power supply V x ph x Hz 230 x 1 x 50 230 x 1 x 50

4.1.2.3 Air condenser

Description Units CSW 100 CSW 150

Flow rate m3/h 580 580

Exhaust fan diameter mm 254 254

Power input W 16 16

Ampere rating A 0.58 0.58

Power supply V x ph x Hz 230 x 1 x 50 230 x 1 x 50

Evaporator

Description Units CSW 100 CSW 150

Composition COPPER COPPER

Flow rate l/min 8 8

Page 28 / 100 Technical Notice V1.0 / 01.09

Model CSW 100/150 4

Hydraulic circuit

Description Units CSW 100 CSW 150

Flow rate l/min 8 8

Total pressure bar 0.4 0.4

Power input kW 0.16 0.16

Amperage A 0.70 0.70

Rotation t/min 2900 2900

Power supply V x ph x Hz 230 x 1 x 50 230 x 1 x 50

Stainless steel reservoir l 8 8

Inlet/outlet couplings 3/4’’ 3/4’’

Dimensions

Description Units CSW 100 CSW 150

Width mm 370 370

Height mm 385 385

Depth mm 600 600

Weight kg 51 51

Other characteristics

Description Units CSW 100 CSW 150

Standard colour Stainless steel Stainless steel

Sound rating

dB(A)

49 49

ISO 3741 – Lp

Technical Notice V1.0 / 01.09 Page 29 / 100

4 Model CSW 100/150

Fig. 4-2 : Filler cap

(1)

(2)

4.2 Handling

The unit must be transported flat and must not sustain any shocks.

4.3 Installation

The unit is normally installed close to the machine being cooled, as indicated on these installation plans.

During the installation, allow for a free space of about 0.5m around the refrigeration unit. This distance

must be 1m in front of the exhaust fan. With these precautions, both ventilation and maintenance access

will be made easier.

4.3.1 Hydraulic connections

Except where specifications state otherwise, the connections between the refrigeration unit and the machine being cooled can be made with pipes with a cross-section diameter at least equal to that indicated

in the technical characteristics.

See section “4.1.2 Technical specifications” on page 28.

4.3.2 Electrical connections

ELECTROCUTION

The machine cabinet must be disconnected from power while connecting the cables.

Power cable ............................................ installed with a 3m length

4.3.3 Filling the reservoir

The liquids used are not suitable for human

consumption.

A. Prepare a mixture of water and 30% ethylene gly-

col.

Do not use anti-freeze intended for motor vehicles.

Marksa recommends ANTIFROGEN N antifreeze.

B. Unscrew the cap (1).

C. Fill the reservoir to somewhere between the mini-

mum and maximum levels of the indicator (2).

D. Screw the cap back on.

(or according to customer specifications)

Page 30 / 100 Technical Notice V1.0 / 01.09

A certain volume of the fluid is used to fill the

machine's circuit. Pay attention to the level

when starting up the machine and top up as

necessary.

4.4 Commissioning

Fig. 4-3 : Engaging

(1) (2)

The unit has been checked, tuned and tested in

our workshops.

A. Make the hydraulic and electrical connections.

B. Fill the reservoir with liquid.

C. Start up the machine (1).

D. Check the rotation direction of the pump and the

exhaust fan.

Model CSW 100/150 4

4.5 Specific tuning

4.5.1 Draining the reservoir

A. Disconnect the outlet pipe.

B. Put the output pipe into an empty container.

C. Press the push button (2) on the front of the unit.

D. Release the button when the pump emits air.

Technical Notice V1.0 / 01.09 Page 31 / 100

4 Model CSW 100/150

Page 32 / 100 Technical Notice V1.0 / 01.09

Chapter contents

(1) (2) (3) (4)

(5) (6)

This chapter contains information specific to the CSW 200 and CSW 300 models. It covers all topics associated with installation, commissioning, tuning and maintenance of these models.

For reasons of clarity, only the CSW 200 model is described in the current chapter. However, all

of the explanations apply in a similar fashion to the CSW 300 model.

5.1 Description

5.1.1 Overall view

Model CSW 200/300 5

Fig. 5-1 : CSW 200 type chiller

(1) Programmable controller display (optional)

(2) Thermostat display

(3) Breakdown indicator lamp (red)

(4) Main power switch

(5) Refilling port

(6) Visual water-level indicator

Technical Notice V1.0 / 01.09 Page 33 / 100

5 Model CSW 200/300

5.1.2 Technical specifications

5.1.2.1 Standard operating parameters

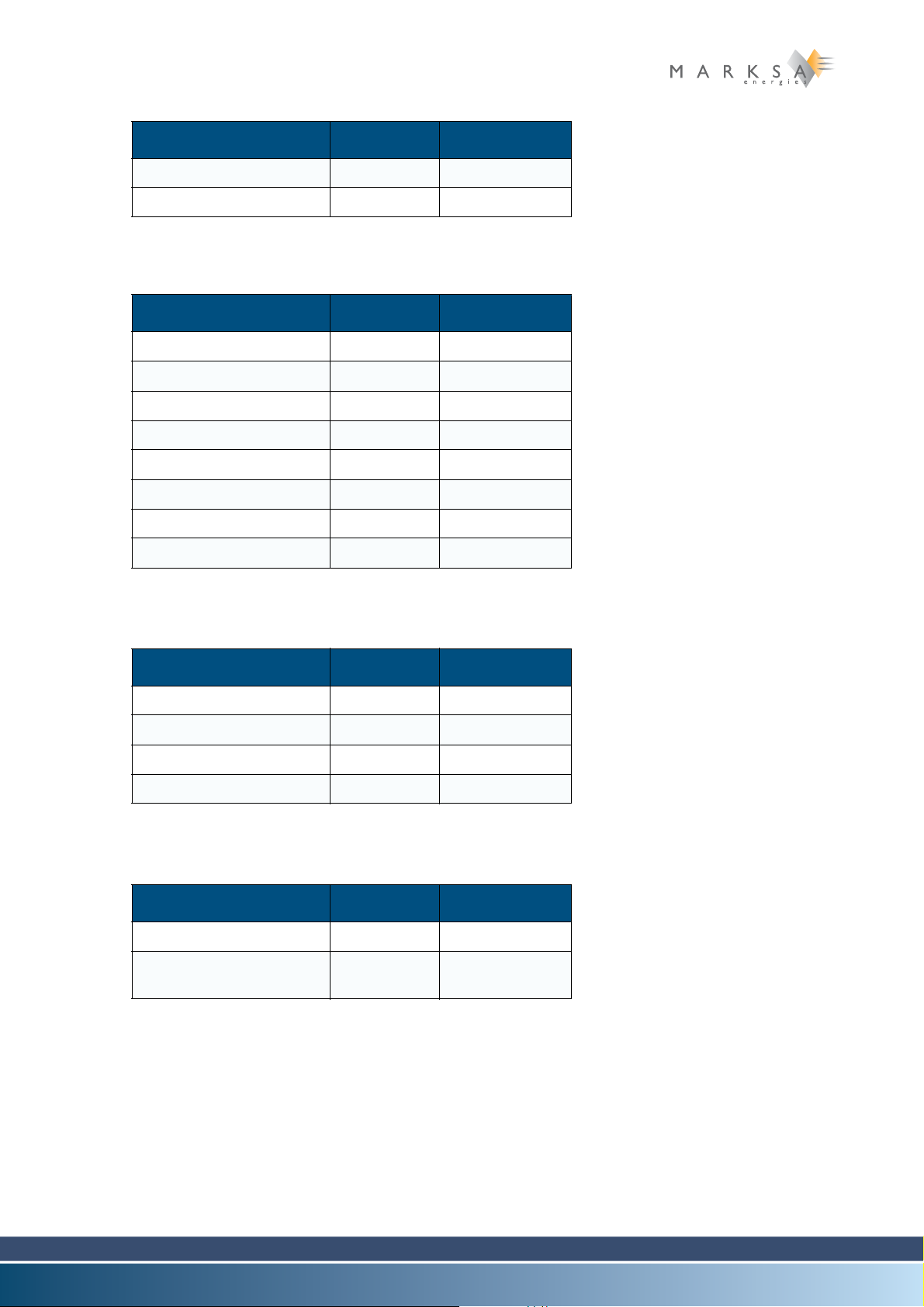

Description Units CSW 200/300 CSW200E/300E

Refrigerant Type R134A R134A

Refrigerating capacity W 3000 3000

Power consumption W 1355 1355

Heat load W 4355 4355

Inlet temperature °C 25 25

Outlet temperature °C 20 20

Flow rate l/min 8 10

Maximum input temperature °C 38 38

5.1.2.2 Electrical data

Description Units CSW 200/300 CSW200E/300E

Power input kW 1.70 1.70

Maximum amperage A 9 3.25

Start-up amperage A 36 15

Line fuse A T 10 6

Power supply V x ph x Hz 230 x 1 x 50 400 x 3 x 50

5.1.2.3 Air condenser

Description Units CSW 200/300 CSW200E/300E

Flow rate m3/h 700 800

Exhaust fan diameter mm 275 275

Power input W 25 25

Ampere rating A 0.75 0.49

Power supply V x ph x Hz 230 x 1 x 50 400 x 3 x 50

Evaporator

Description Units CSW 200/300 CSW200E/300E

Composition COPPER COPPER

Flow rate l/min 8 10

Page 34 / 100 Technical Notice V1.0 / 01.09

Model CSW 200/300 5

Hydraulic circui

Description Units CSW 200/300 CSW200E/300E

Flow rate l/min 8 10

Total pressure bar 0.40 0.50

Power input kW 0.16 0.25

Amperage A 0.70 0.80

Rotation t/min 2900 2900

Power supply V x ph x Hz 230 x 1 x 50 400 x 3 x 50

Stainless steel reservoir l 21 21

Dimensions

Description Units CSW 200/300 CSW200E/300E

Width mm 435 435

Height mm 580 580

Depth mm 525 525

Weight kg 78 78

Other characteristics

Description Units CSW 200/300 CSW200E/300E

Inlet/outlet couplings mm 13 13

Standard colour Stainless steel Stainless steel

Sound rating

dB(A)

52 52

ISO 3741 – Lp

Technical Notice V1.0 / 01.09 Page 35 / 100

5 Model CSW 200/300

Fig. 5-2 : Filler cap

(1)

(2)

5.2 Handling

The unit must be transported flat and must not sustain any shocks.

5.3 Installation

The unit is normally installed close to the machine being cooled, as indicated on these installation plans.

During the installation, allow for a free space of about 0.5m around the refrigeration unit. This distance

must be 1m in front of the exhaust fan. With these precautions, both ventilation and maintenance access

will be made easier.

5.3.1 Hydraulic connections

Except where specifications state otherwise, the connections between the refrigeration unit and the machine being cooled can be made with pipes with a cross-section diameter at least equal to that indicated

in the technical characteristics.

See section “5.1.2 Technical specifications” on page 34.

5.3.2 Electrical connections

ELECTROCUTION

The machine cabinet must be disconnected from power while connecting the cables.

Power cable ............................................ installed with a 3m length (or according to customer specifica-

5.3.3 Filling the reservoir

The liquids used are not suitable for human

consumption.

A. Prepare a mixture of water and 30% ethylene gly-

col.

Do not use anti-freeze intended for motor vehicles.

Marksa recommends ANTIFROGEN N antifreeze.

B. Unscrew the cap (1).

C. Fill the reservoir to somewhere between the mini-

mum and maximum levels of the indicator (2).

D. Screw the cap back on.

tions)

Page 36 / 100 Technical Notice V1.0 / 01.09

A certain volume of the fluid is used to fill the

machine's circuit. Pay attention to the level

when starting up the machine and top up as

necessary.

5.4 Commissioning

Fig. 5-3 : Engaging

(1)

(2)

Fig. 5-4 : Emptying cap

(2)

The unit has been checked, tuned and tested in

our workshops.

A. Make the hydraulic and electrical connections.

B. Fill the reservoir with liquid.

C. Start up the machine (1).

D. Check the rotation direction of the pump and the

exhaust fan.

Model CSW 200/300 5

5.5 Specific tuning

5.5.1 Draining the reservoir

A. Put a container under the tap (2) or the drainage

plug located under the chiller.

B. Open the drainage tap.

C. Close the drainage tap once the reservoir is emp-

ty.

Technical Notice V1.0 / 01.09 Page 37 / 100

5 Model CSW 200/300

Page 38 / 100 Technical Notice V1.0 / 01.09

Chapter contents

(1) (2) (3) (4)

(5)

(6)

This chapter contains information specific to the CSW 400 model. It covers all topics associated with installation, commissioning, tuning and maintenance of these models.

6.1 Description

6.1.1 Overall view

Model CSW 400 6

Abb. 6-1 : CSW 400 type chiller

(1) Programmable controller display (optional)

(2) Thermostat display

(3) Breakdown indicator lamp (red)

(4) Main power switch

(5) Refilling port

(6) Visual water-level indicator

Technical Notice V1.0 / 01.09 Seite 39 / 100

6 Model CSW 400

6.1.2 Technical specifications

6.1.2.1 Standard operating parameters

Description Units CSW 400

Refrigerant Typ R134A

Refrigerating capacity kW 4000

Power consumption kW 1200

Heat load kW 5200

Inlet temperature °C 24

Outlet temperature °C 20

Flow rate l/min 15

Maximum input temperature °C 38

6.1.2.2 Electrical data

Description Units CSW 400

Power input kW 2.5

Maximum amperage A 7.5

Start-up amperage A 25

Line fuse A T 10

Power supply V x ph x Hz 400 x 3 x 50

6.1.2.3 Air condenser

Description Units CSW 400

Flow rate m3/h 1100

Exhaust fan diameter mm 300

Power input W 140

Ampere rating A 0.6

Power supply V x ph x Hz 230 x 1 x 50

Evaporator

Description Units CSW 400

Composition COPPER

Flow rate l/min 15

Seite 40 / 100 Technical Notice V1.0 / 01.09

Hydraulic circui

Description Units CSW 400

Flow rate l/min 15

Total pressure bar 2.5

Power input kW 0.37

Amperage A 1.80

Rotation t/min 2900

Power supply V x ph x Hz 400 x 3 x 50

Stainless steel reservoir l 35

Inlet/outlet couplings 3/4’’

Dimensions

Description Units CSW 400

Model CSW 400 6

Width mm 620

Height mm 1000

Depth mm 620

Weight kg 160

Other characteristics

Description Units CSW 400

Standard colour RAL RAL 7035

Sound rating

dB(A) 55

ISO 3741 – Lp

Technical Notice V1.0 / 01.09 Seite 41 / 100

6 Model CSW 400

Abb. 6-2 : Filler cap

(1)

(2)

6.2 Handling

The unit must be transported flat and must not sustain any shocks.

6.3 Installation

The unit is normally installed close to the machine being cooled, as indicated on these installation plans.

During the installation, allow for a free space of about 0.5m around the refrigeration unit. This distance

must be 1m in front of the exhaust fan. With these precautions, both ventilation and maintenance access

will be made easier.

6.3.1 Hydraulic connections

Except where specifications state otherwise, the connections between the refrigeration unit and the machine being cooled can be made with pipes with a cross-section diameter at least equal to that indicated

in the technical characteristics.

See section “6.1.2 Technical specifications” on page 40.

6.3.2 Electrical connections

ELECTROCUTION

The machine cabinet must be disconnected from power while connecting the cables.

Power cable ............................................ installed with a 3m length (or according to customer specifica-

6.3.3 Filling the reservoir

The liquids used are not suitable for human

consumption.

A. Prepare a mixture of water and 30% ethylene gly-

col.

Do not use anti-freeze intended for motor vehicles.

Marksa recommends ANTIFROGEN N antifreeze.

B. Unscrew the cap (1).

C. Fill the reservoir to somewhere between the mini-

mum and maximum levels of the indicator (2).

D. Screw the cap back on.

tions)

Seite 42 / 100 Technical Notice V1.0 / 01.09

A certain volume of the fluid is used to fill the

machine's circuit. Pay attention to the level

when starting up the machine and top up as

necessary.

6.4 Commissioning

Abb. 6-3 : Engaging

(1)

Abb. 6-4 : Emptying cap

(2)

The unit has been checked, tuned and tested in

our workshops.

A. Make the hydraulic and electrical connections.

B. Fill the reservoir with liquid.

C. Start up the machine (1).

D. Check the rotation direction of the pump and the

exhaust fan.

Model CSW 400 6

6.5 Specific tuning

6.5.1 Draining the reservoir

A. Put a container under the tap (2) or the drainage

plug located under the chiller.

B. Open the drainage tap.

C. Close the drainage tap once the reservoir is emp-

ty.

Technical Notice V1.0 / 01.09 Seite 43 / 100

6 Model CSW 400

Seite 44 / 100 Technical Notice V1.0 / 01.09

Chapter contents

(1) (2) (3) (4)

This chapter contains information specific to the CSW 600 and CSW 800 models. It covers all topics associated with installation, commissioning, tuning and maintenance of these models.

For reasons of clarity, only the CSW 800 model is described in the current chapter. However, all

of the explanations apply in a similar fashion to the CSW 600 model.

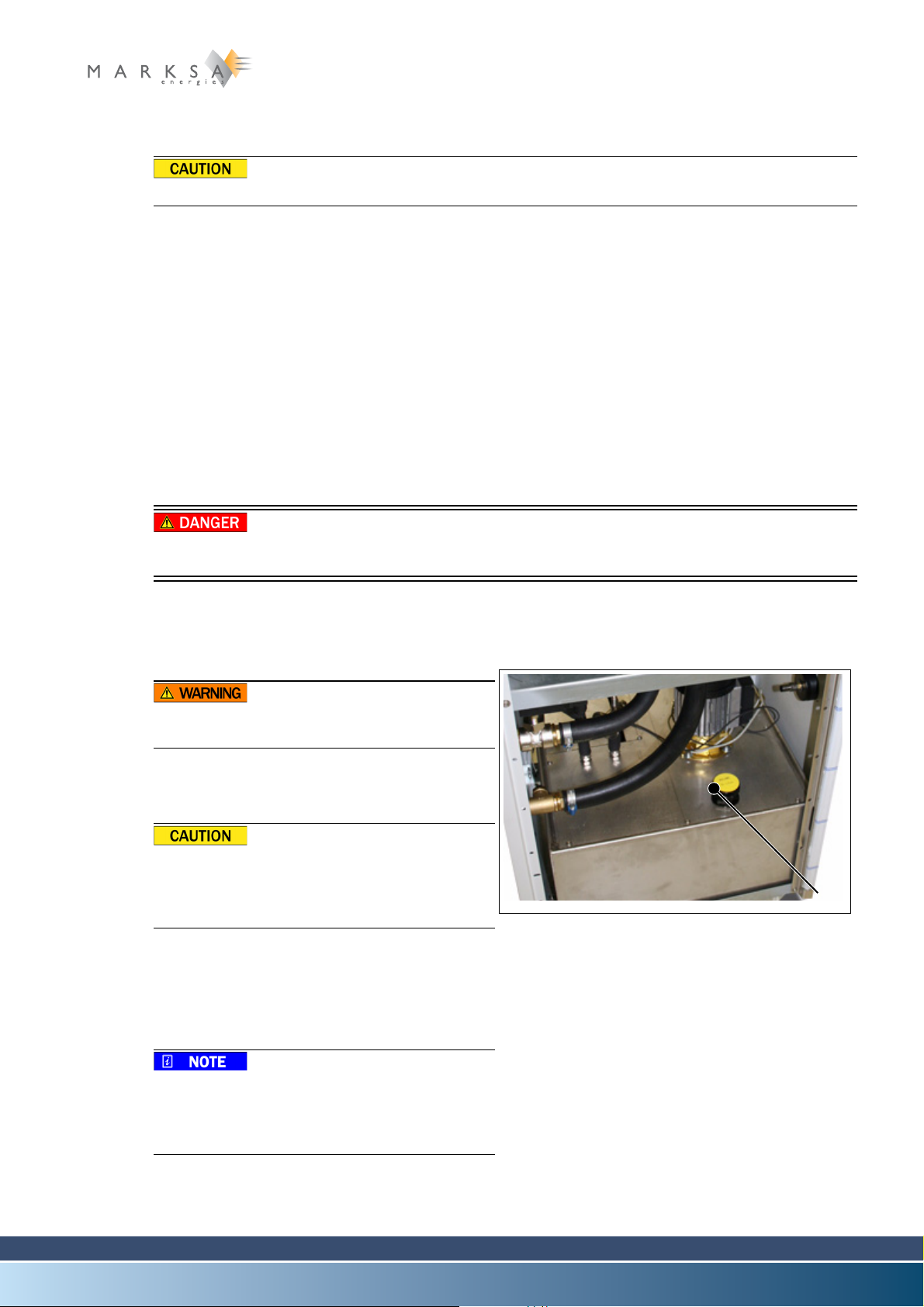

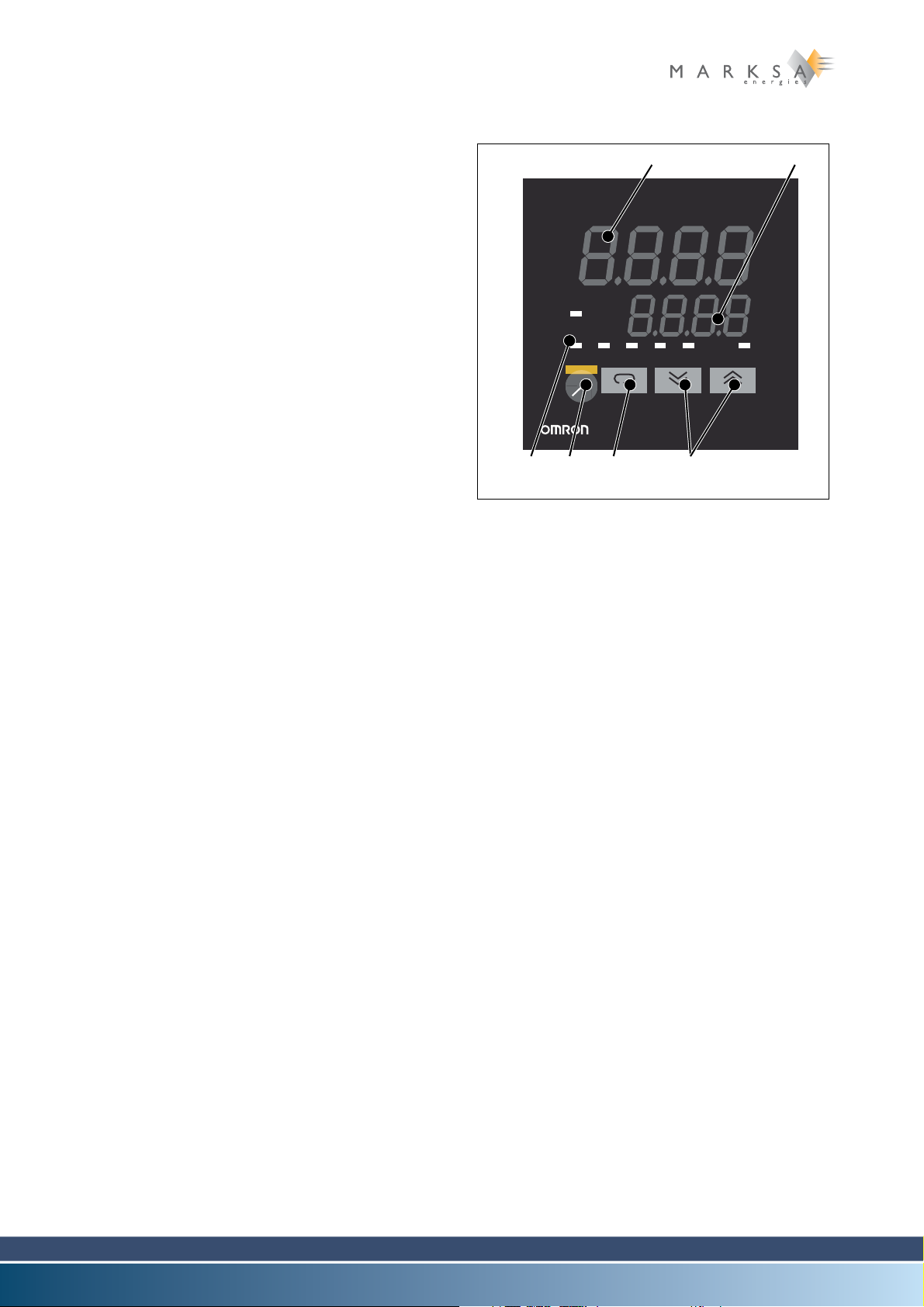

11.1 Description

11.1.1 Overall view

Model CSW 600/800 11

Fig. 11-1 : CSW 800 type chiller (front view)

(1) Programmable controller display (optional, visible after opening the door)

(2) Thermostat display

(3) Breakdown indicator lamp (red)

(4) Main power switch

Technical Notice V1.0 / 01.09 Page 69 / 100

11 Model CSW 600/800

(5) (7)(6)

(10)

(9)

(11)

(8)

Fig. 11-2 : CSW 800 type chiller (rear view)

(5) Output circuit pressure gauge (on request)

(6) Electric power connector (on request)

(7) Cooling liquid return inlet

(8) Cooling liquid outlet

(9) Refilling port

(10) Drainage tap

(11) Visual water-level indicator

Page 70 / 100 Technical Notice V1.0 / 01.09

11.1.2 Technical specifications

11.1.2.1 Standard operating parameters

Description Units CSW 600/800

Refrigerant Type R407C

Refrigerating capacity kW 7900

Power consumption kW 1500

Heat load kW 7500

Inlet temperature °C 25

Outlet temperature °C 20

Flow rate l/min 20

Maximum input temperature °C 38

Table 11-1:

11.1.2.2 Electrical data

Model CSW 600/800 11

Description Units CSW 600/800

Power input kW 3

Maximum amperage A 9,5

Start-up amperage A 30

Line fuse A T 10

Power supply V x ph x Hz 400 x 3 x 50

Table 11-2:

11.1.2.3 Air condenser

Description Units CSW 600/800

Flow rate m3/h 1585

Exhaust fan diameter mm 350

Power input W 135

Ampere rating A 0,32

Power supply V x ph x Hz 400 x 3 x 50

Table 11-3:

Evaporator

Description Units CSW 600/800

Composition COPPER

Table 11-4:

Technical Notice V1.0 / 01.09 Page 71 / 100

11 Model CSW 600/800

Description Units CSW 600/800

Flow rate l/min 20

Charge loss bar 0,2

Table 11-4:

Hydraulic circui

Description Units CSW 600/800

Flow rate l/min 20

Total p r e s sure bar 1,5

Power input kW 0,37

Amperage A 1,8

Rotation t/min 2900

Power supply V x ph x Hz 400 x 3 x50

Stainless steel reservoir l 55

Inlet/outlet couplings 3/4 ‘’

Table 11-5:

Dimensions

Description Units CSW 600/800

Width mm 550

Height mm 900

Depth mm 600

Weight kg 11 2

Table 11-6:

Other characteristics

Description Units CSW 600/800

Standard colour RAL 7035

Sound rating

dB(A) 50

ISO 3741 – Lp

Table 11-7:

Page 72 / 100 Technical Notice V1.0 / 01.09

11.2 Handling

Fig. 11-3 : Filler cap

(1)

(2)

The unit must be transported flat and must not sustain any shocks.

11.3 Installation

The unit is normally installed close to the machine being cooled, as indicated on these installation plans.

During the installation, allow for a free space of about 0.5m around the refrigeration unit. This distance

must be 1m in front of the exhaust fan. With these precautions, both ventilation and maintenance access

will be made easier.

11.3.1 Hydraulic connections

Except where specifications state otherwise, the connections between the refrigeration unit and the machine being cooled can be made with pipes with a cross-section diameter at least equal to that indicated

in the technical characteristics.

See section “7.1.2 Technical specifications” on page 71.

11.3.2 Electrical connections

Model CSW 600/800 11

ELECTROCUTION

The machine cabinet must be disconnected from power while connecting the cables.

Power cable .............................................installed with a 3m length (or according to customer specifica-

tions)

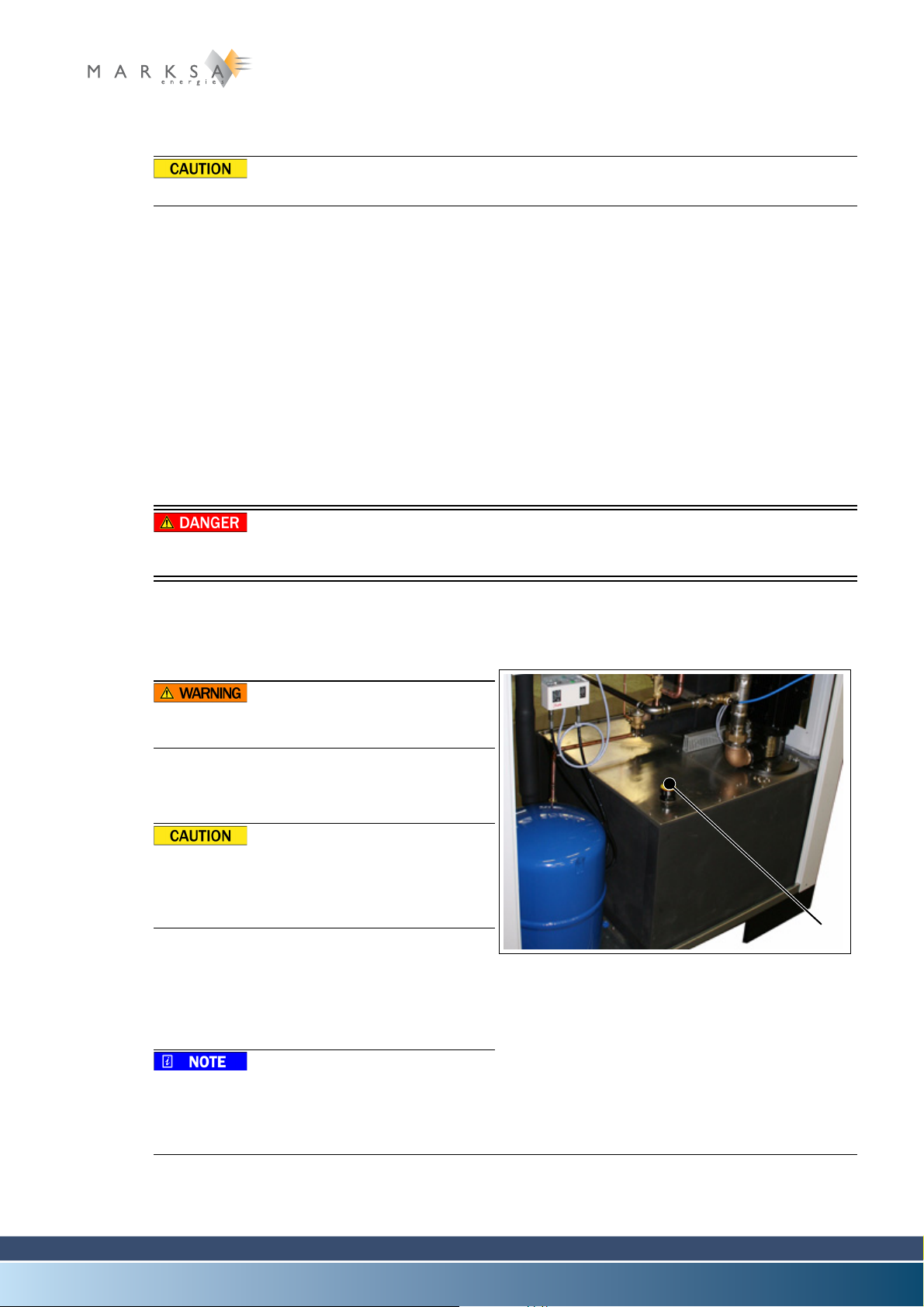

11.3.3 Filling the reservoir

The liquids used are not suitable for human

consumption.

A. Prepare a mixture of water and 30% ethylene gly-

col.

Do not use anti-freeze intended for motor vehicles.

Marksa recommends ANTIFROGEN N antifreeze.

B. Unscrew the cap (1).

C. Fill the reservoir to somewhere between the mini-

mum and maximum levels of the indicator (2).

D. Screw the cap back on.

A certain volume of the fluid is used to fill the

machine's circuit. Pay attention to the level

when starting up the machine and top up as

necessary.

Technical Notice V1.0 / 01.09 Page 73 / 100

11 Model CSW 600/800

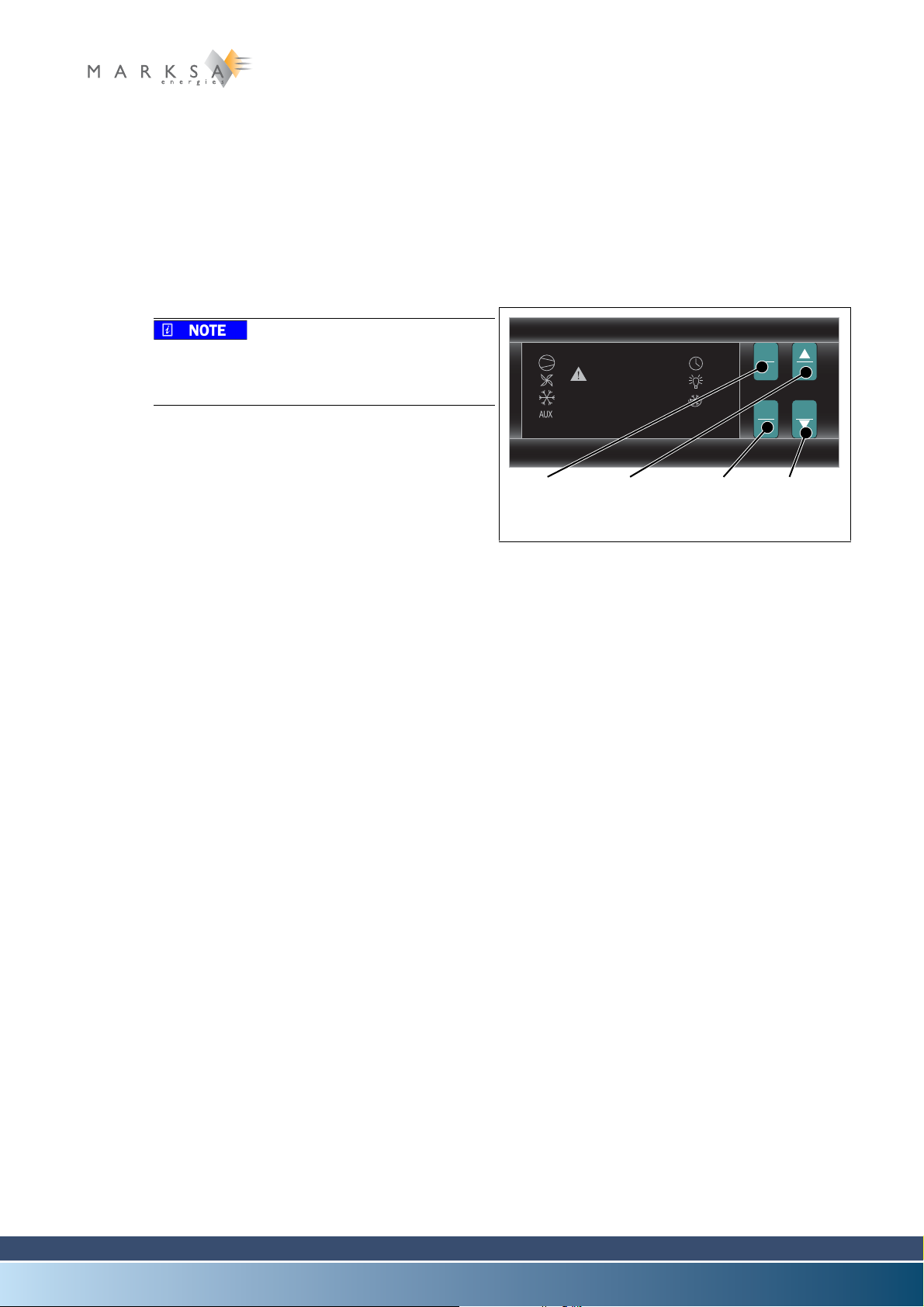

Fig. 11-4 : Engaging

(1)

Fig. 11-5 : Emptying cap

(2)

11.4 Commissioning

The unit has been checked, tuned and tested in

our workshops.

A. Make the hydraulic and electrical connections.

B. Fill the reservoir with liquid.

C. Start up the machine (1).

D. Check the rotation direction of the pump and the

exhaust fan.

11.5 Specific tuning

11.5.1 Draining the reservoir

A. Put a container under the tap (2) or the drainage

plug located under the chiller.

B. Open the drainage tap.

11.6 Close the drainage tap once the reservoir is empty.

Page 74 / 100 Technical Notice V1.0 / 01.09

Chapter contents

(1) (2)

(3)

(4)

This chapter contains information specific to the CSW 900, CSW 1000, CSW 1300 et CSW 1700models.

It covers all topics associated with installation, commissioning, tuning and maintenance of these models.

For reasons of clarity, only the CSW 1000 model is described in the current chapter. However, all

of the explanations apply in a similar fashion to the CSW 900, CSW 1300 et CSW 1700 models.

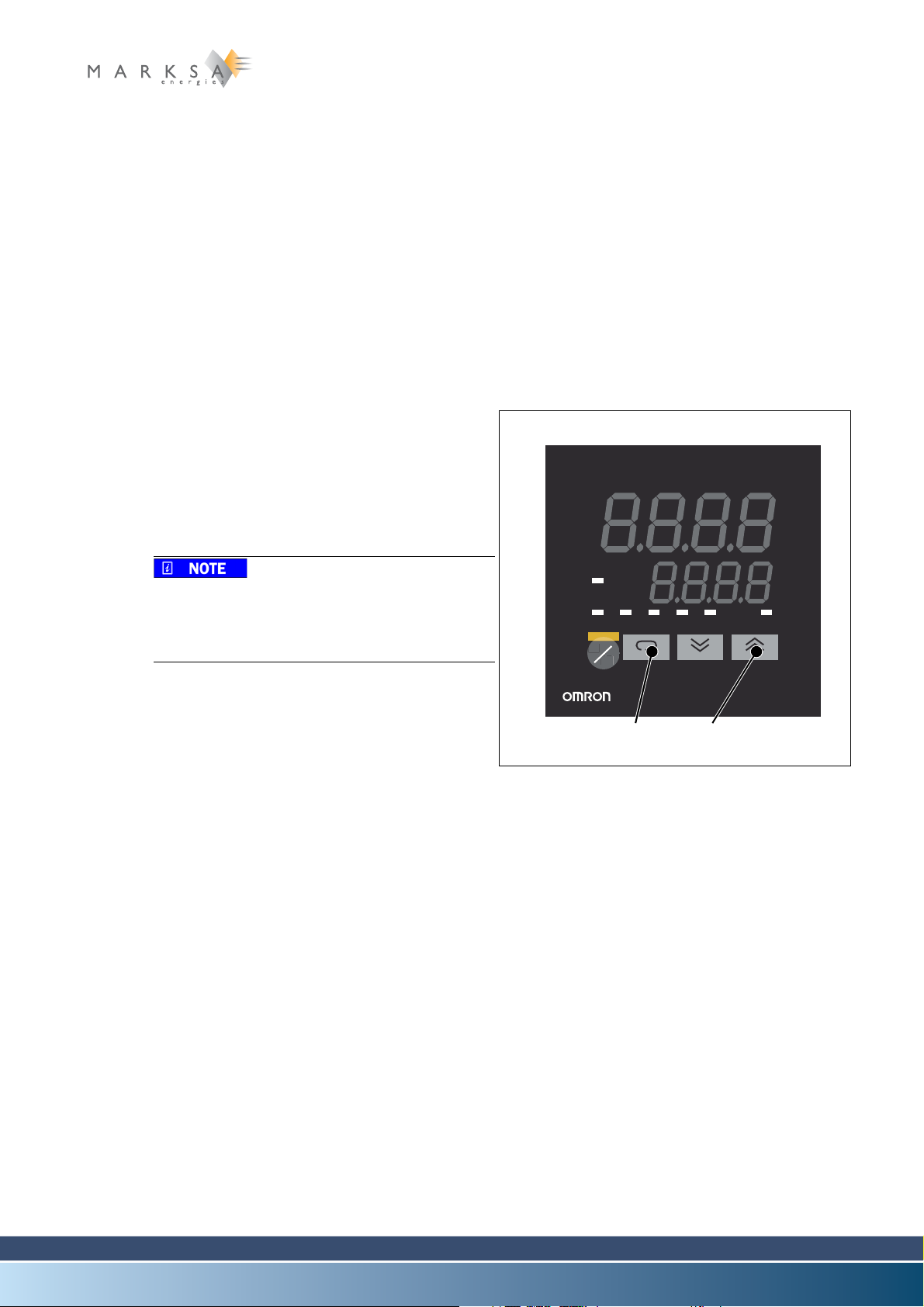

11.1 Description

11.1.1 Overall view

Model CSW 900/1000/1300/1700 11

Fig. 11-1 : CSW 1000 type chiller (front view)

(1) Programmable controller display (optional, visible after opening the door)

(2) Thermostat display

(3) Breakdown indicator lamp (red)

(4) Main power switch

Technical Notice V1.0 / 01.09 Page 69 / 100

11 Model CSW 900/1000/1300/1700

(5)

(8)

(6)

(7)

(9)

Fig. 11-2 : CSW 1000 type chiller (rear view)

(5) Electric power connector

(6) Cooling liquid return inlet

(7) Cooling liquid outlet

(8) Visual water-level indicator

(9) Drainage tap

Page 70 / 100 Technical Notice V1.0 / 01.09

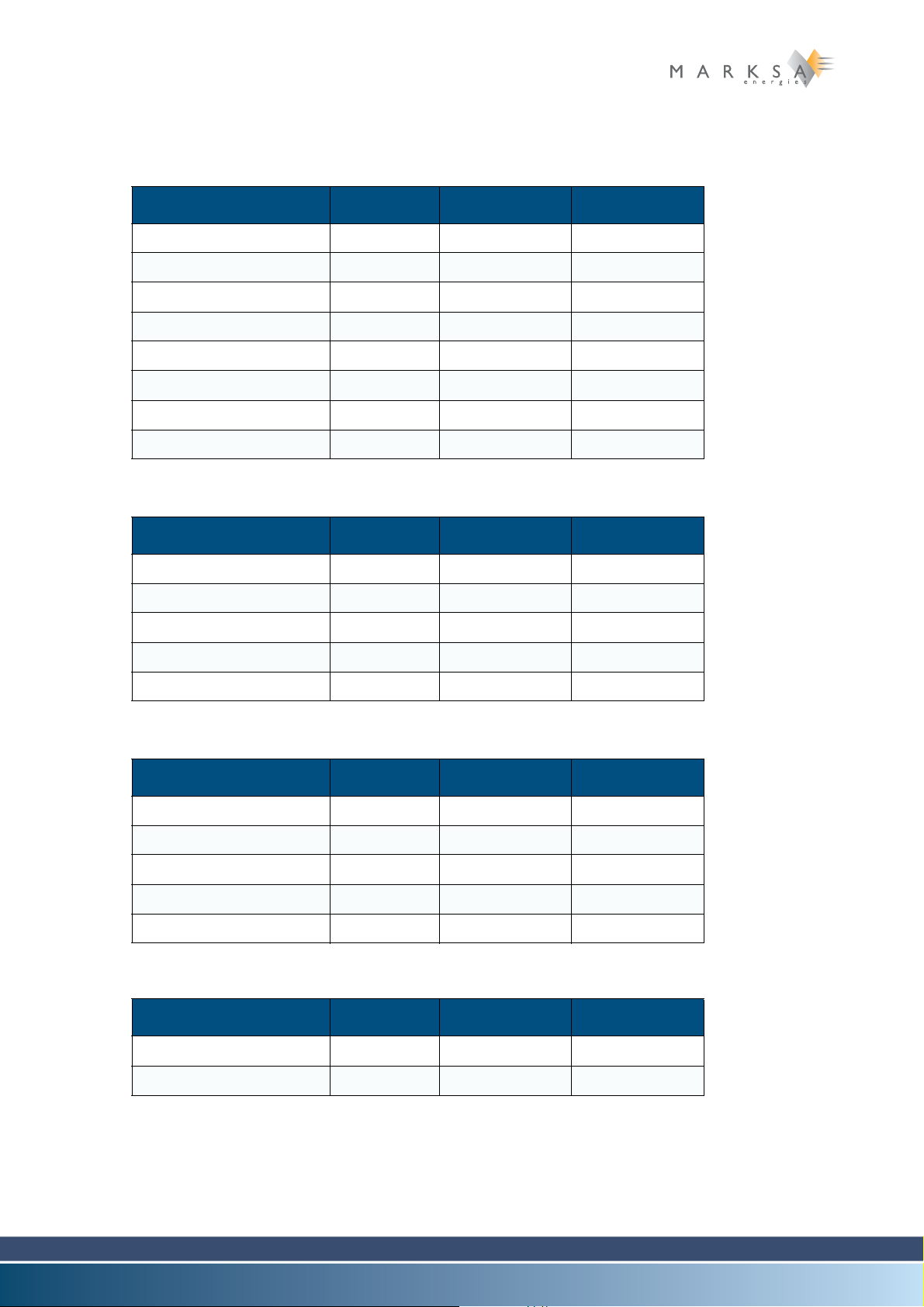

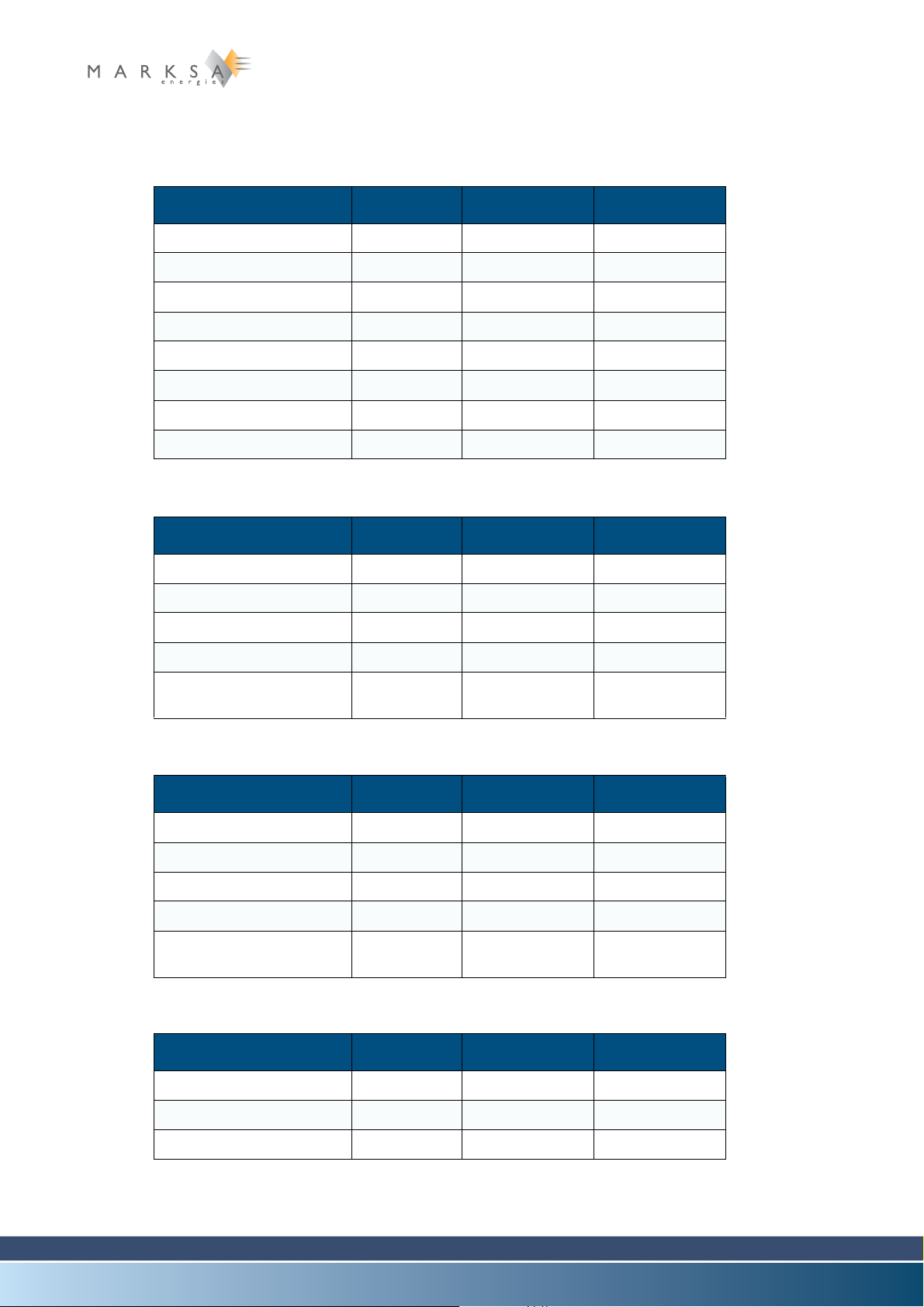

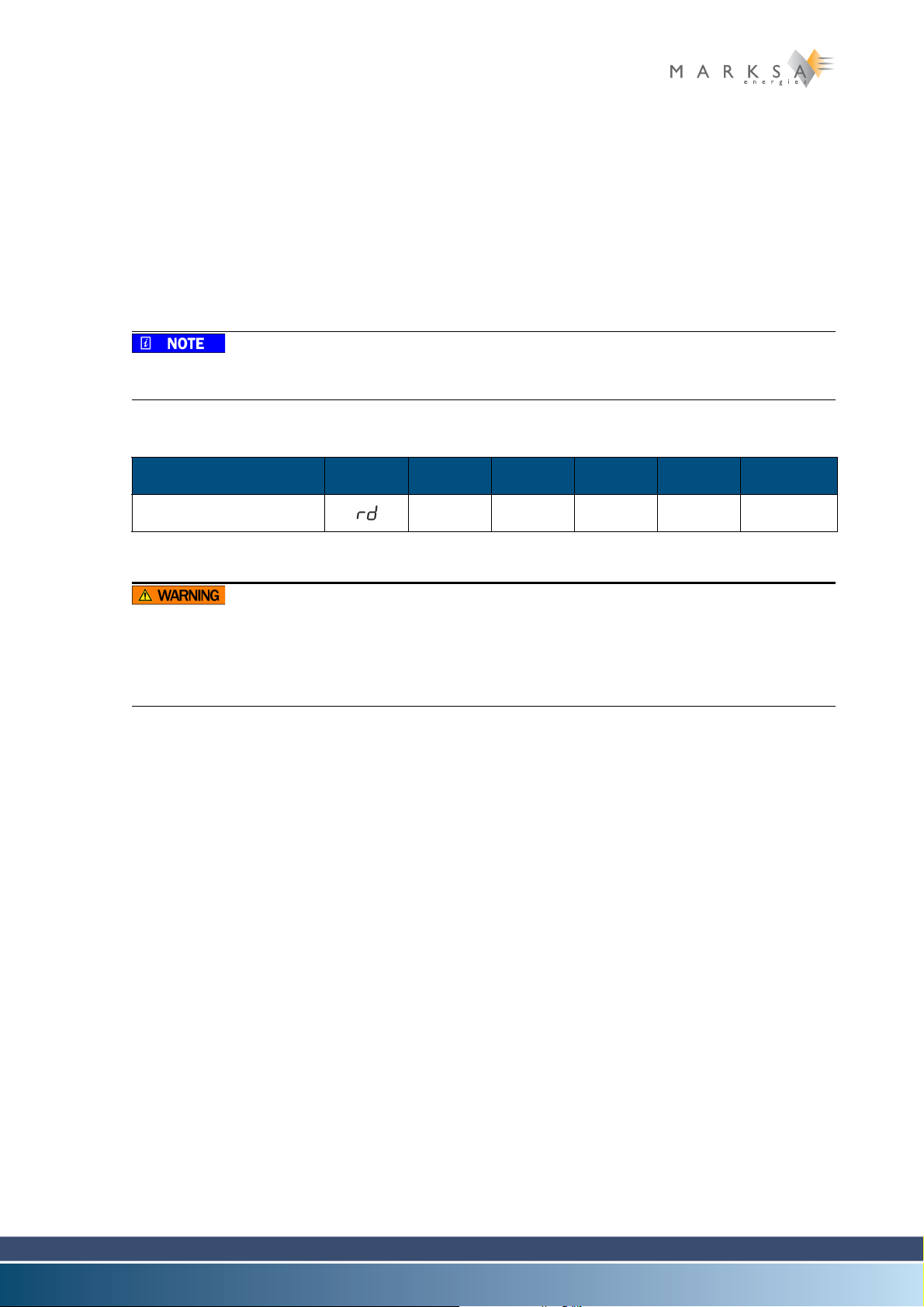

11.1.2 Technical specifications

11.1.2.1 Standard operating parameters

Description Units CSW 900/1000 CSW 1300 CSW 1700

Refrigerant Type R407C R407C R407C

Refrigerating capacity kW 9.7 12 16,4

Power consumption kW 2.2 3.5 4.5

Heat load kW 11,9 15,5 20.9

Inlet temperature °C 27 25 27

Outlet temperature °C 20 20 20

Flow rate l/min 20 35 35

Model CSW 900/1000/1300/1700 11

Maximum input temper-

ature

Table 11-1:

11.1.2.2 Electrical data

Description Units CSW 900/1000 CSW 1300 CSW1700

Power input kW 4 4.5 5.5

Maximum amperage A 12 13 16

Start-up amperage A 40 45 50

Line fuse A T 16 16 20

Power supply V x ph x Hz 400 x 3 x 50 400 x 3 x 50 400 x 3 x 50

Table 11-2:

11.1.2.3 Air condenser

Description Units CSW 900/1000 CSW 1300 CSW 1700

Flow rate m3/h 3350 3350 3350

°C 38 38 38

Exhaust fan diameter mm 420 420 420

Power input W 270 270 300

Ampere rating A 0.65 0.65 0.7

Power supply V x ph x Hz 400 x 3 x 50 400 x 3 x 50 400 x 3 x 50

Table 11-3:

Technical Notice V1.0 / 01.09 Page 71 / 100

11 Model CSW 900/1000/1300/1700

Evaporator

Description Units CSW 900/1000 CSW 1300 CSW 1700

Composition AISI 316 AISI 316 AISI 316

Flow rate l/min 20 40 40

Charge loss bar 0,2 0,25 0,25

Table 11-4:

Hydraulic circui

Description Units CSW 900/1000 CSW 1300 CSW 1700

Flow rate l/min 20 35 35

Total pressure bar 2 2,5 2,5

Power input kW 0,37 0,37 0,37

Amperage A 1,8 1,8 1,8

Rotation t/min 2900 2900 2900

Power supply V x ph x Hz 400 x 3 x 50 400 x 3 x 50 400 x 3 x 50

Stainless steel reservoir l 60 60 145

Inlet/outlet couplings 1 “ 1 “ 1 “

Table 11-5:

Dimensions

Description Units CSW 900/1000 CSW 1300 CSW 1700

Width mm 700 700 700

Height mm 1300 1300 1300

Depth mm 850 850 850

Weight kg 230 245 275

Table 11-6:

Other characteristics

Description Units CSW 900/1000 CSW 1300 CSW 1700

Standard colour RAL 7035 7035 7035

Sound rating

ISO 3741 – Lp

Table 11-7:

Page 72 / 100 Technical Notice V1.0 / 01.09

dB(A) 65 65 65

11.2 Handling

Fig. 11-3 : Filler cap

(1)

The unit must be transported flat and must not sustain any shocks.

11.3 Installation

The unit is normally installed close to the machine being cooled, as indicated on these installation plans.

During the installation, allow for a free space of about 0.5m around the refrigeration unit. This distance

must be 1m in front of the exhaust fan. With these precautions, both ventilation and maintenance access

will be made easier.

11.3.1 Hydraulic connections

Except where specifications state otherwise, the connections between the refrigeration unit and the machine being cooled can be made with pipes with a cross-section diameter at least equal to that indicated

in the technical characteristics.

See section “8.1.2 Technical specifications” on page 71.

11.3.2 Electrical connections

Model CSW 900/1000/1300/1700 11

ELECTROCUTION

The machine cabinet must be disconnected from power while connecting the cables.

Power cable .............................................installed with a 3m length (or according to customer specifica-

tions)

11.3.3 Filling the reservoir

The liquids used are not suitable for human

consumption.

A. Prepare a mixture of water and 30% ethylene gly-

col.

Do not use anti-freeze intended for motor vehicles.

Marksa recommends ANTIFROGEN N antifreeze.

B. Unscrew the cap (1).

C. Fill the reservoir to somewhere between the mini-

mum and maximum levels of the indicator (2).

D. Screw the cap back on.

A certain volume of the fluid is used to fill the

machine's circuit. Pay attention to the level

when starting up the machine and top up as

necessary.

Technical Notice V1.0 / 01.09 Page 73 / 100

11 Model CSW 900/1000/1300/1700

Fig. 11-4 : Engaging

(1)

Fig. 11-5 : Emptying cap

(2)

11.4 Commissioning

The unit has been checked, tuned and tested in

our workshops.

A. Make the hydraulic and electrical connections.

B. Fill the reservoir with liquid.

C. Start up the machine (1).

D. Check the rotation direction of the pump and the

exhaust fan.

11.5 Specific tuning

11.5.1 Draining the reservoir

A. Put a container under the tap (2) or the drainage

plug located under the chiller.

B. Open the drainage tap.

C. Close the drainage tap once the reservoir is emp-

ty.

Page 74 / 100 Technical Notice V1.0 / 01.09

Chapter contents

(2) (3) (4)(1)

This chapter contains information specific to the CSW 2000 and CSW 2400 models. It covers all topics

associated with installation, commissioning, tuning and maintenance of these models.

For reasons of clarity, only the CSW 2000 model is described in the current chapter. However, all

of the explanations apply in a similar fashion to the CSW 2400 model.

11.1 Description

11.1.1 Overall view

Model CSW 2000/2400 11

Fig. 11-1 : CSW 2000 type chiller (front view)

(1) Programmable controller display (optional, visible after opening the door)

(2) Thermostat display

(3) Breakdown indicator lamp (red)

(4) Main power switch

Technical Notice V1.0 / 01.09 Page 69 / 100

11 Model CSW 2000/2400

(5)

(6)

(7)

(8)

(9)

Fig. 11-2 : CSW 2000 type chiller (rear view)

(5) Electric power connector (optional)

(6) Output circuit pressure gauge

(7) Cooling liquid outlet

(8) Cooling liquid return inlet

(9) Drainage tap

Page 70 / 100 Technical Notice V1.0 / 01.09

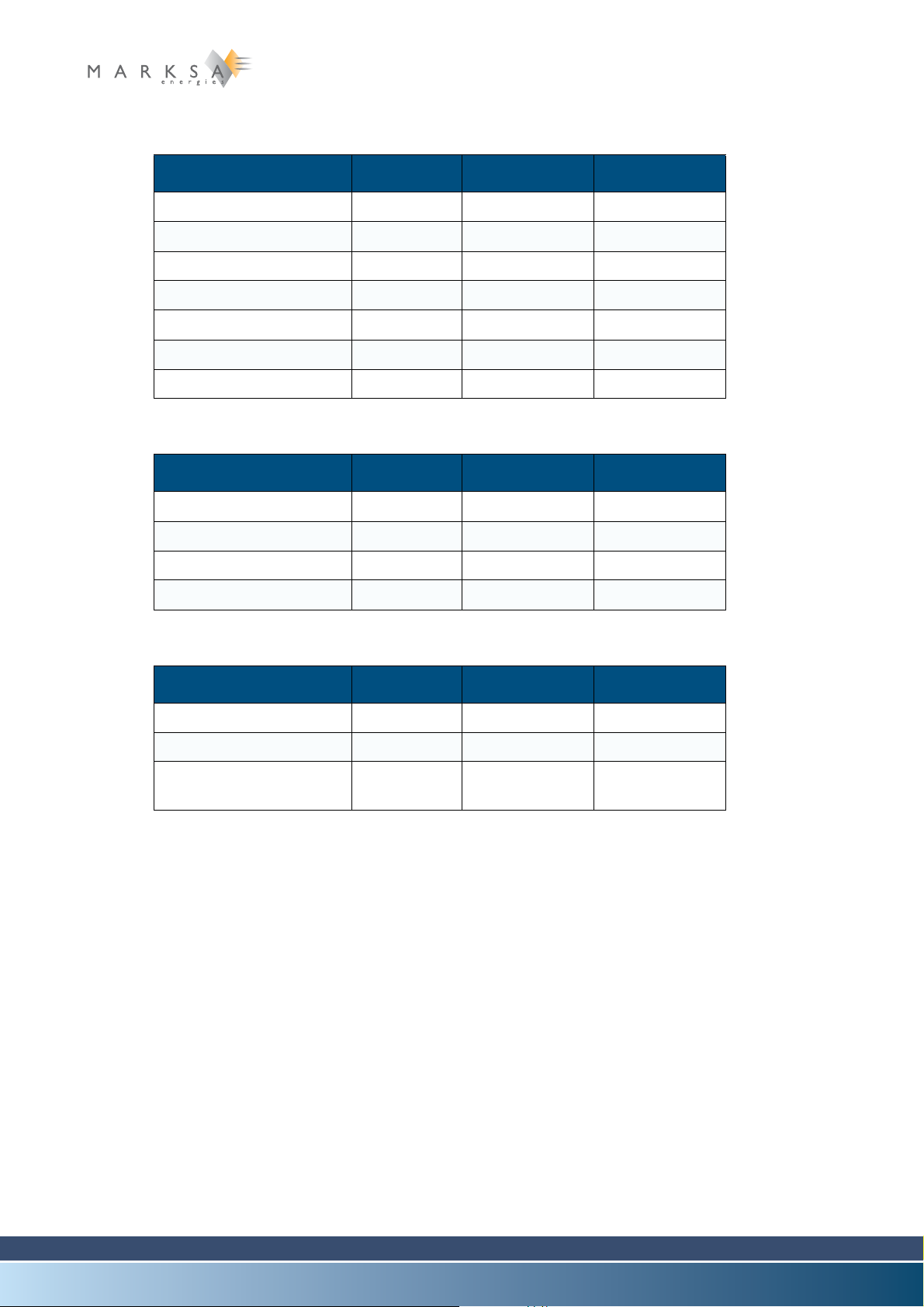

11.1.2 Technical specifications

11.1.2.1 Standard operating parameters

Description Units CSW 2000 CSW 2400

Refrigerant Type R407C R407C

Refrigerating capacity kW 20,0 24,0

Power consumption kW 6,7 7,4

Heat load kW 26,7 31,4

Inlet temperature °C 27 28

Outlet temperature °C 20 20

Flow rate l/min 40 40

Maximum input temperature °C 42 42

11.1.2.2 Electrical data

Model CSW 2000/2400 11

Description Units CSW 2000 CSW 2400

Power input kW 8,0 9,0

Maximum amperage A 16 18

Start-up amperage A 50 60

Line fuse A T 20 20

Power supply V x ph x Hz 400 x 3 x 50

11.1.2.3 Air condenser

Description Units CSW 2000 CSW 2400

Flow rate m3/h 8600 8600

Exhaust fan diameter mm 500 500

Power input W 500 500

Ampere rating A 1,2 1,2

Power supply V x ph x Hz 400 x 3 x 50 400 x 3 x 50

Evaporator

Description Units CSW 2000 CSW 2400

Composition AISI316 AISI316

Flow rate l/min 40 40

Charge loss bar 0,2 0,2

Technical Notice V1.0 / 01.09 Page 71 / 100

11 Model CSW 2000/2400

Hydraulic circui

Description Units CSW 2000 CSW 2400

Flow rate l/min 40 40

Total p r e s sure bar 2 2

Power input kW 0,37 0,37

Amperage A 1,2 1,2

Rotation t/min 2900 2900

Power supply V x ph x Hz 400 x 3 x 50 400 x 3 x 50

Stainless steel reservoir l 145 145

Inlet/outlet couplings 1’’ 1’’

Dimensions

Description Units CSW 2000 CSW 2400

Width mm 700 700

Height mm 1300 1300

Depth mm 1240 1240

Weight kg 305 32

Other characteristics

Description Units CSW 2000 CSW 2400

Standard colour RAL 7035 SFS 7055

Sound rating

dB(A) 71 71

ISO 3741 – Lp

Page 72 / 100 Technical Notice V1.0 / 01.09

11.2 Handling

Fig. 11-3 : Filler cap

(1)

The unit must be transported flat and must not sustain any shocks.

11.3 Installation

The unit is normally installed close to the machine being cooled, as indicated on these installation plans.

During the installation, allow for a free space of about 0.5m around the refrigeration unit. This distance

must be 1m in front of the exhaust fan. With these precautions, both ventilation and maintenance access

will be made easier.

11.3.1 Hydraulic connections