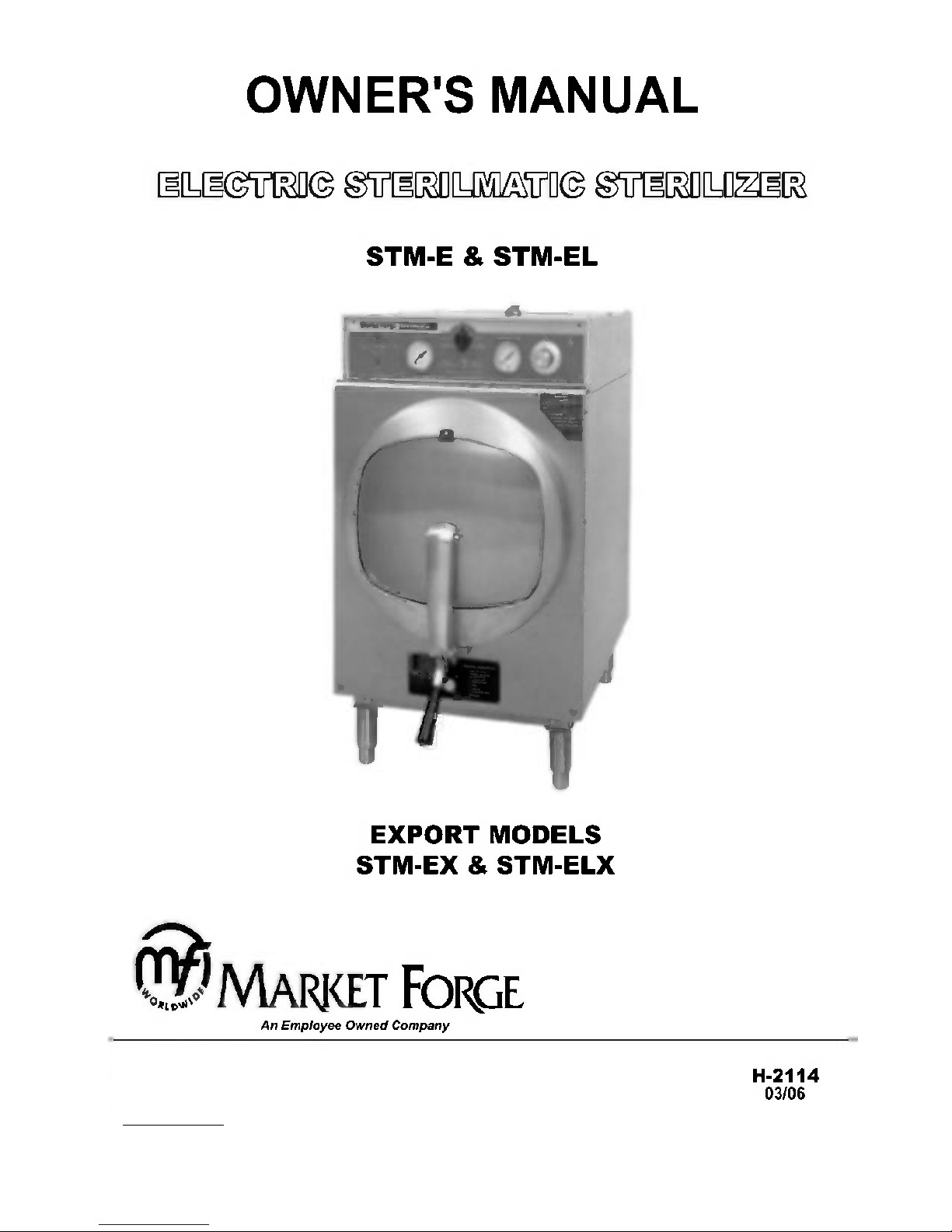

Market Forge Industries STM-EX, STM-ELX, STM-E, STM-EL Owner's Manual

Your Sterilizer Experts

Manufacturing – Distribution – Maintenance- Guaranteed!

Alfa Medical 1-800-762-1586

265 Post Ave 516-280-7822

Westbury, NY 11590 516-280-7832 fax

www.sterilizers.com

eMail@sterilizers.com

The attached manual is for your records.

Go to the below web site to look for parts

http://bit.ly/Market-Forge-Sterilmatic-Parts

35 Garvey Street

Everett, Massachusetts 02149

SECTION 1 INSTALLATION INSTRUCTIONS

TABLE OF CONTENTS

INSTALLATION ........................................................................................................................................................................... 2

ELECTRICAL .............................................................................................................................................................................. 2

OUTSIDE VENTING .................................................................................................................................................................... 2

WATER-COOLED EXHAUST CONDENSER .............................................................................................................................. 2

RECORDING THERMOMETER .................................................................................................................................................. 2

TRAY SUPPORTS ...................................................................................................................................................................... 3

BAFFLE INSTALLATION ............................................................................................................................................................ 3

OPERATION CHECK .................................................................................................................................................................. 3

INSTALLATION INSTRUCTIONS FOR COLD WATER CONDENSER ....................................................................................... 4

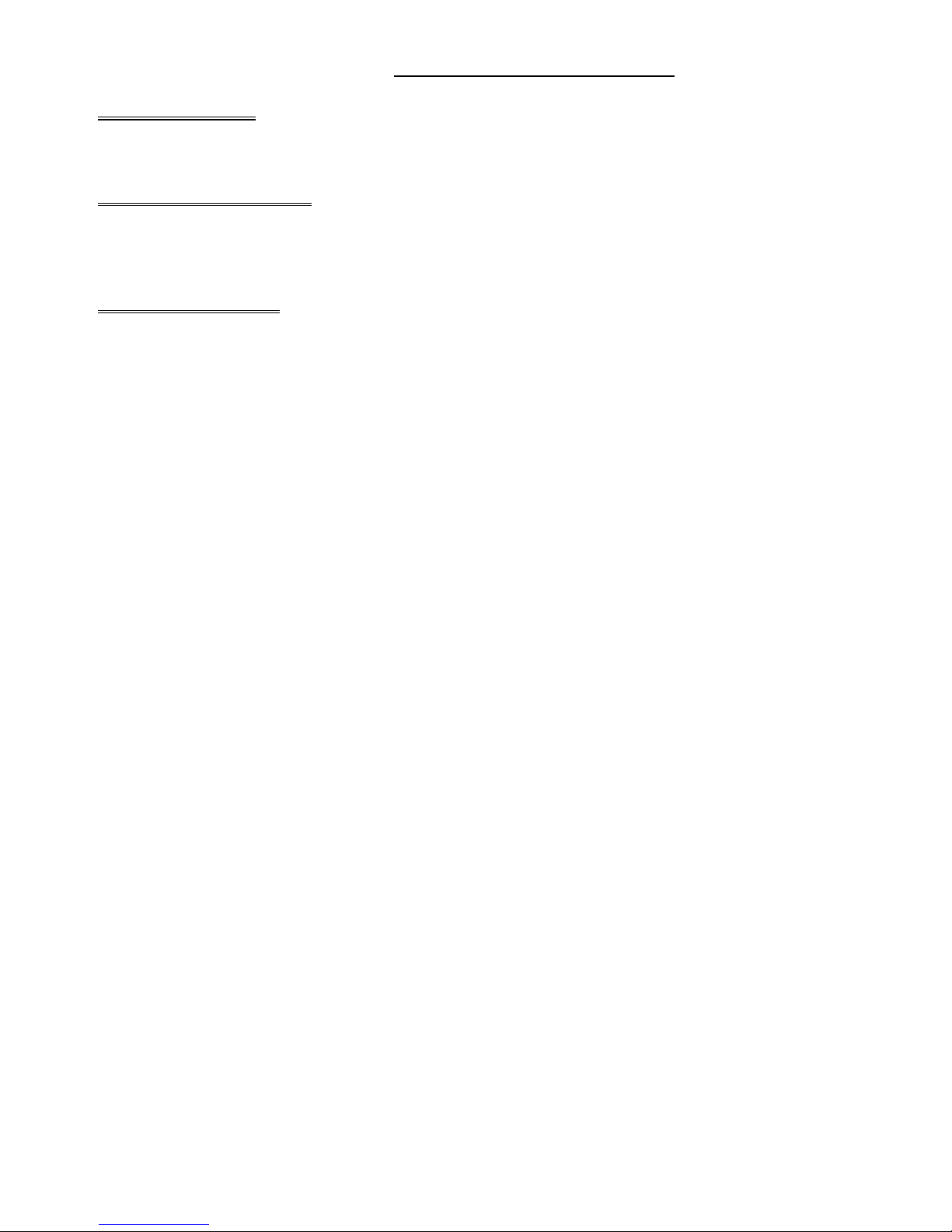

REQUIRED CONNECTIONS ...................................................................................................................................................... 5

INSTALLING PAN SUPPORTS AND BAFFLES ......................................................................................................................... 6

ELECTRICAL SUPPLY CONNECTIONS FOR STM-E AND STM-EL........................................................................................... 7

ELECTRICAL SUPPLY CONNECTIONS FOR STM-EX AND STM-ELX ..................................................................................... 7

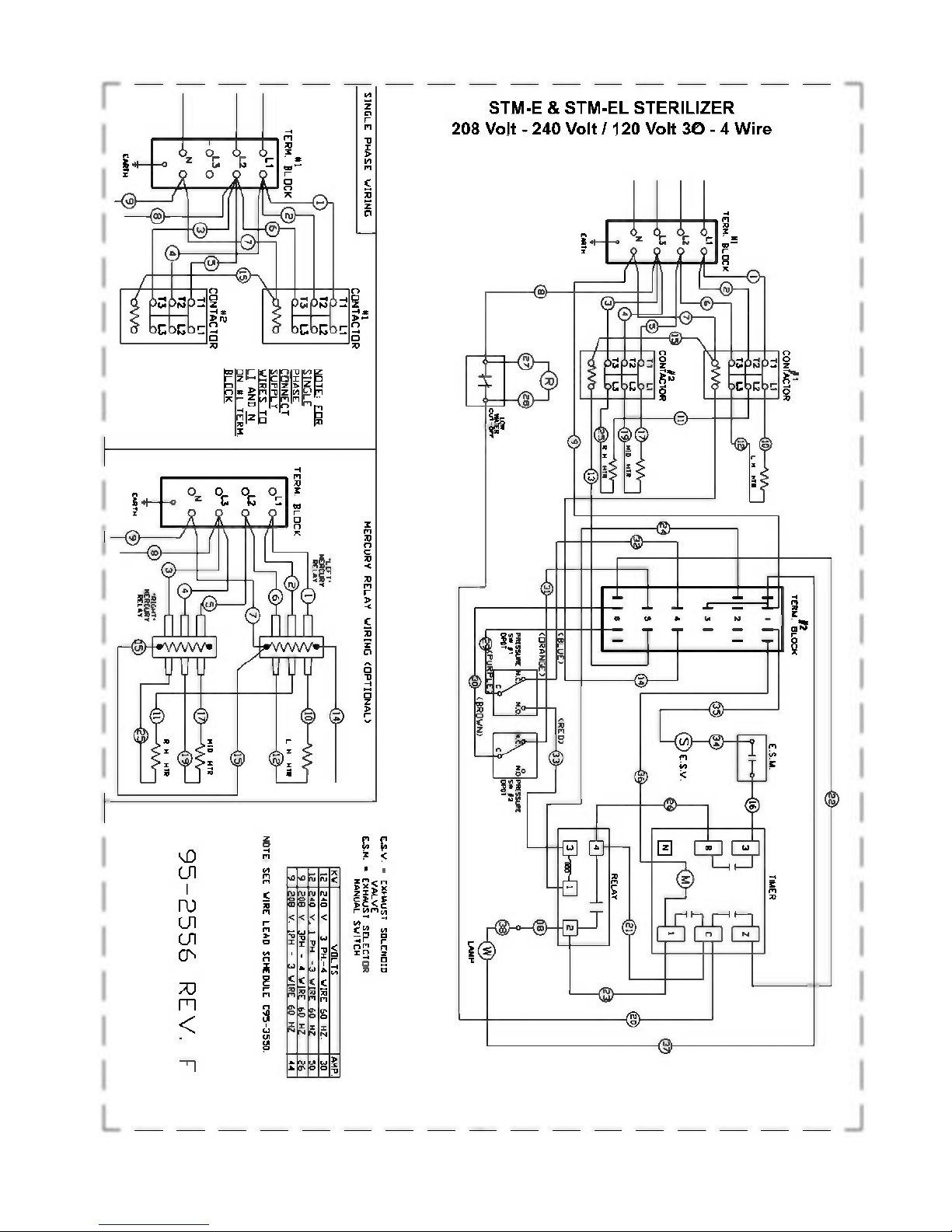

DOMESTIC WIRE DIAGRAM FOR STM-E AND STM-EL ........................................................................................................... 8

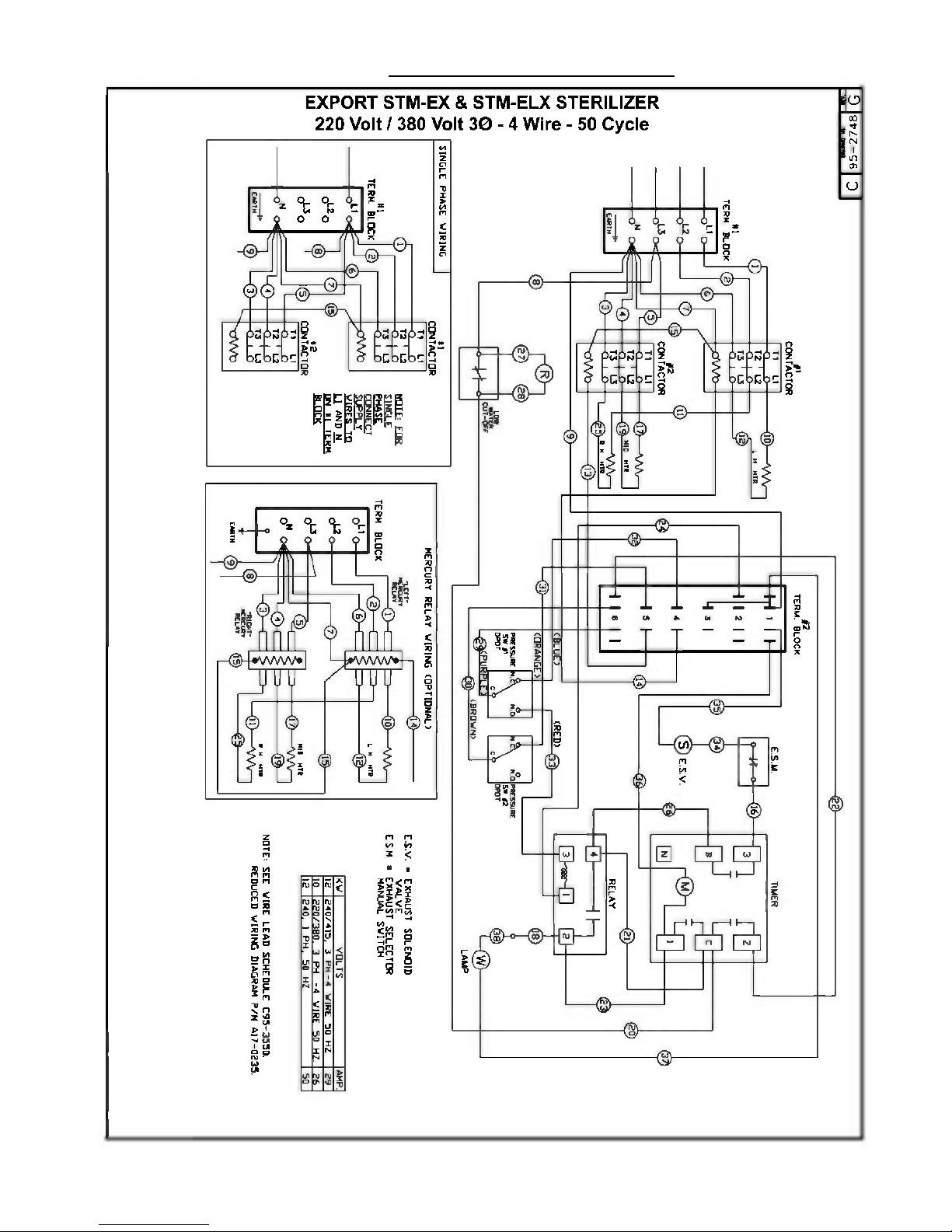

DOMESTIC WIRE DIAGRAM FOR STM-EX AND STM-ELX ...................................................................................................... 9

TYPICAL CIRCUIT CONNECTION FOR STM-E AND STM-EL ...................................................................................................10

TYPICAL CIRCUIT CONNECTION FOR STM-EX AND STM-ELX EXPORT ............................................................................... 11

INSTALLATION FOR OPTIONAL RECORDING THERMOMETER ............................................................................................. 12

TO REMOVE THE CHART .......................................................................................................................................................... 12

TO INSTALL NEW CHART .........................................................................................................................................................12

PEN ADJUSTMENT .................................................................................................................................................................... 12

REPLACEMENT PARTS FOR 24 HOUR THERMOMETER ........................................................................................................12

SECTION 2 WATER CONDITIONS ............................................................................................................................................ 13

SECTION 3 OPERATING INSTRUCTIONS

OPERATING INSTRUCTIONS ....................................................................................................................................................14

STERILIZATION GUIDE .............................................................................................................................................................15

MINIMUM STERILIZATION TIMES .............................................................................................................................................16

SECTION 4 DAILY CLEANING

DAILY CLEANING PROCEDURE ............................................................................................................................................... 16

SECTION 5 ASSEMBLY

STERILMATIC OPEN STAND .....................................................................................................................................................17

STERILMATIC OPEN STAND WITH CONDENSER ...................................................................................................................17

PARTS LIST FOR CONDENSER WITH OPTIONAL STAND ......................................................................................................17

STERILMATIC DOOR ASSEMBLY .............................................................................................................................................17

DOOR ADJUSTMENT .................................................................................................................................................................18

THE DOOR GASKET .................................................................................................................................................................. 18

DOOR LIFT SPRING ...................................................................................................................................................................18

TO REMOVE THE DOOR ASSEMBLY .......................................................................................................................................19

DOOR ASSEMBLY PARTS LIST ................................................................................................................................................19

THE FULCRUM AND DRAIN ASSEMBLY ..................................................................................................................................20

FULCRUM AND DRAIN PARTS LIST .........................................................................................................................................20

ROLLER ASSEMBLY ..................................................................................................................................................................21

DOMESTIC – THE PRESSURE ACTUATED TEMPERATURE CONTROL, STM-E AND STM-EL .............................................21

DOMESTIC – HOW IT WORKS .................................................................................................................................................. 21

DOMESTIC – ADJUSTING THE RANGE OR OPERATION, STM-E ...........................................................................................21

EXPORT - THE PRESSURE ACTUATED TEMPERATURE CONTROL, STM-EX AND STM-ELX .............................................22

EXPORT – HOW IT WORKS ...................................................................................................................................................... 22

EXPORT – CHECKING THE 100oC SETTING, STM-ELX ........................................................................................................... 22

EXPORT – ADJUSTING THE RANGE OF OPERATION, STM -ELX ...........................................................................................22

DOMESTIC – CHECKING THE 230oSETTING, STM-EL ........................................................................................................... 23

DOMESTIC – ADJUSTING THE RANGE OF OPERATION, STM-EL .........................................................................................23

CAST-IN THE HEATING ELEMENTS .........................................................................................................................................23

THE LOW WATER CUT-OFF (MANUAL RESET) ....................................................................................................................... 23

THE ELECTRIC CONTACTORS .................................................................................................................................................23

THE TIMER .................................................................................................................................................................................24

THE STEAM PRESSURE GAUGE ..............................................................................................................................................24

THE SAFETY VALVE ..................................................................................................................................................................24

THE FLUE ...................................................................................................................................................................................24

THE EXHAUST SOLENOID VALVE ............................................................................................................................................24

TO REPLACE A THERMOSTATIC ELEMENT ............................................................................................................................25

THE STEAM TRAP ..................................................................................................................................................................... 25

HOW IT WORKS ......................................................................................................................................................................... 25

SECTION 6 ILLUSTRATED PARTS

MASTER ILLUSTRATION AND PARTS, STM-E AND STM-EX .......................................................................................... 26 & 27

MASTER ILLUSTRATION AND PARTS, STM-El AND STM-ElX ......................................................................................... 28 & 29

CONTROL CONSOLE PARTS LIST FOR STM-E AND STM-EX ................................................................................................. 30

CONTROL CONSOLE PARTS LIST FOR STM-EL AND STM_ELX............................................................................................. 31

DOOR HANDLE PARTS LIST .....................................................................................................................................................32

SECTION 7 TROUBLE SHOOTING

STEAM TRAP TROUBLE-SHOOTING ........................................................................................................................................ 33

TROUBLE-SHOOTING GUIDE ................................................................................................................................................... 33

SECTION 8 WARRANTY INFORMATION ..................................................................................................................................34

1

SECTION 1 INSTALLATION INSTRUCTIONS

AUTOMATIC STERILMATIC STEAM PRESSURE STERILIZER

MODELS: STM-E, STM-EL, STM-EX & STM-ELX

Your Sterilmatic Sterilizer has been developed to answer the need for a compact, automatic,

low-cost steam pressure sterilizer. The following instructions cover installation. Should

service be required, it is readily available by contacting our authorized service agency

located nearest to you. The name of your local service company can be obtained from your

Market Forge Representative in your area or by contacting the Service Department at Market

Forge Co., 35 Garvey Street, Everett, MA 02149, Tel. (617) 387-4100.

INSTALLATION

Set sterilizer on counter, using the 4" (102mm) legs provided or assemble the an optional

stainless steel stand with under-shelf. If your Sterilmatic includes a water-cooled exhaust

condenser, we recommend the use of the Sterilmatic stand, part number 95-6060. First, level

unit in place, then adjust front legs to pitch the unit forward 1/4" (6mm) to insure positive

drainage of the cylinder.

ELECTRICAL

Connect to proper electrical supply box and disconnect switch as shown on one of the

following schematic diagrams-208 or 240 volts, single or three phase. Connection is located

behind the terminal box cover at the lower left side of unit. Whether the supply current is 208

volt or 240 volt, single or three phase, all control circuits are 120 volts. In order to accomplish

this connection, a current-carrying grounded neutral must be provided. Thus, a three phase

system must be 4-wires and a single phase system must be 3-wires. If a current-carrying

grounded neutral is not available from the power source, a separate 120 volt circuit must be

run. Most electrical codes require, and we recommend, that a separate disconnect switch be

located within sight of the sterilizer. When separate 120 volt control circuit must be run, this

must also be part of the disconnect box assembly.

OUTSIDE VENTING

Connect 1/2" (13mm) nominal tubing exhaust to outside vent connection located on the top

of the control housing. IMPORTANT: Exhaust line must be vented to the outside to eliminate

the exhausted steam and the accompanying noise from entering the room. Use 1/2" (13mm)

copper tubing or suitable alternate. Length of the line should not exceed 15 feet (4.5 meters)

and should have a minimum of bends. The line should slope downward after leaving the

sterilizer in order to insure condensate drainage.

WATER-COOLED EXHAUST CONDENSER

If outside venting is not possible, an optional water-cooled condenser is available for

connection to an open drain. If required order part number 95-0436 kit.

RECORDING THERMOMETER

If a recording thermometer is provided, refer to installation guide provided with recorder.

2

SECTION 1 INSTALLATION INSTRUCTIONS

TRAY SUPPORTS

Install side tray supports. Tray supports are attached by means of key-hole clearance slots

which are slipped over studs located on the sides of the Sterilmatic chamber.

BAFFLE INSTALLATION

To insure maximum drying of packs, a baffle is supplied with your STM-E Sterilmatic. Place

perforated splash baffle in bottom of the sterilizing chamber. Install small baffle with no

perforation at the rear of the upper tray support channel.

OPERATION CHECK

To check for proper operation of unit:

1. Close drain valve by turning handle clockwise.

WARNING:

DO NOT OPEN DRAIN VALVE WHILE UNIT IS OPERATING. PREMATURE OPENING

MAY RESULT IN SCALDING OF OPERATOR.

2. Fill chamber with 4 to 6 quarts (3.7 to 5.6 liters) of ordinary tap water. DO NOT USE

DISTILLED OR DIONIZED WATER.

3. Close chamber door.

4. Set exhaust selector to INSTRUMENTS AND PACKS (fast exhaust) or LIQUIDS (slow

exhaust).

5. Set timer to 15 minutes. Cycle will go to completion automatically.

NOTE: Cycle timer will not start until sterilizing temperature is obtained.

3

SECTION 1 INSTALLATION INSTRUCTIONS

5

SECTION 1 INSTALLATION INSTRUCTIONS

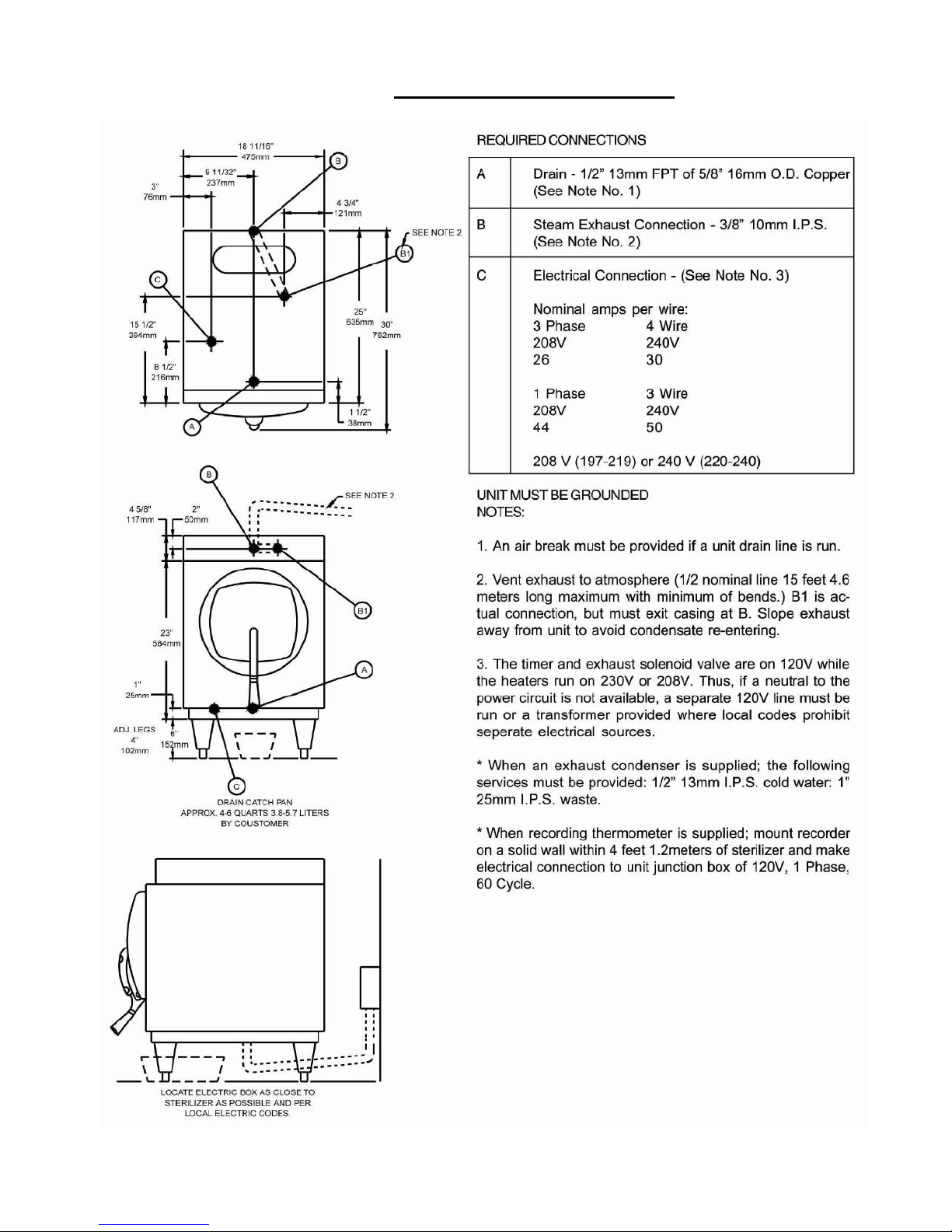

INSTRUCTIONS FOR INSTALLING PAN SUPPORTS AND BAFFLES

1. Locate the mounting studs on the inside of the chamber. There are two rack mounting studs on each side.

2. Taking one pan support and positioning rack so that the pan stop is facing the rear of the unit and the wires

are facing toward the center of the unit. The pan stop is a piece of sheet metal welded to the rack with a 65

bend.

3. Begin to hang the pan support by placing the rear key-way slot onto the rear mounting stud and slide the

rack until the slot sits on the mounting stud. When this is done correctly the front mounting stud will be in

position to place the front key-way slot. Slide the rack down into its correct position. See Fig. 1.

Fig. 1.

4. After installing one pan support rack correctly, you can install the baffle. Position the baffle so that the 45o

bend is facing up and towards the front of the unit. Slide the mounting tab onto the flat bend on the pan stop

bracket. The baffle should now stay in place by itself, but in a tilted state. See Fig. 2.

o

5. Position the second pan support rack into the cavity and slide the other mounting tab onto the rack flat bend

while the pan support rack is not on the mounting studs. Hang the pan support by placing the rear key-way

slot onto the rear mounting stud and slide the rack until the slot sits on the mounting stud. When this is done

correctly the front mounting stud will be in position to place the front key-way slot. Slide the rack down

into its correct position. See Fig. 3.

Fig. 2.

Fig. 3.

6

SECTION 1 INSTALLATION INSTRUCTIONS

THE ELECTRIC SUPPLY CONNECTIONS FOR STM-E AND STM-EL

Connect to proper electrical supply as indicated on nameplate on top of unit. Connection is

located behind the terminal box cover at the lower left side of unit. Whether the supply

current is 208 or 240 volt, single phase or three phase, all control circuits are 120 volts. In

order to accomplish this, a current-carrying grounded neutral must be provided.

Thus, a three phase system must be 4-wires and a single phase system must be 3-wires. If a currentcarrying grounded neutral is not available from the power source, a separate 120 volt circuit must be

run. Most electrical codes require, and we recommend, that a separate disconnect switch be located

within sight of the sterilizer. When a separate 120 volt control circuit must be run, this must also be

part of the disconnect box assembly.

THE ELECTRIC SUPPLY CONNECTIONS FOR STM-EX AND STM-ELX EXPORT

Connect to proper electrical supply as indicated on nameplate on top of unit. Connection is located

behind the terminal box cover at the lower left side of the unit. All control circuits are 220 volts.

In order to accomplish this, a current-carrying grounded neutral must be provided.

Thus, a three phase system must be 4-wires. Most electrical codes require, and we recommend, that

a separate switch be located within sight of the sterilizer.

7

SECTION 1 INSTALLATION INSTRUCTIONS

8

SECTION 1 INSTALLATION INSTRUCTIONS

9

Loading...

Loading...