Market Forge Industries STM-ED, STM-EDX Owner's Manual

OWNER’S MANUAL

ELECTRIC STERILMATIC STERILIZER

ELECTRIC STERILMATIC STERILIZER

DIGITAL VERSION

DOMESTIC MODEL: □ STM-ED

EXPORT MODEL:

INSTALLATION

•

OPERATION

•

MAINTENANCE

•

TROUBLE-SHOOTING

•

PARTS & SERVICE

•

WARRANTY

•

□ STM-EDX

FORM NO.:

03/14 REV. A

H-2117

Sterilizers.com - Your Sterilizer Expert

Telephone: (617) 387-4100, (866) 698-3188

Distribution – Maintenance - Guaranteed

Alfa Medical - 10 Bond St Great Neck NY 11021

1-800-762-1586 - info@Sterilizers.com

35 Garvey Street, Everett, MA 02149

Fax: (617) 387-4456, (800) 227-2659

custserv@m i.com, www.m i.com

TABLE OF CONTENTS

INTRODUCTION

Product Description ..........................................................i

Service Contacts ..............................................................i

SECTION 1 INSTALLATION INSTRUCTIONS

Service & Technical Information Contact ..........................1

Operating Environmental Conditions ................................1

Intended Use - Sterilization Cycle ....................................1

Installation ........................................................................1

Electrical ...........................................................................1

Outside Venting ................................................................1

Water-Cooled Exhaust Condenser ...................................1

Tray Supports ...................................................................1

Bafe Installation ..............................................................1

Operation Check...............................................................1

Cold Water Condenser .....................................................2

Service Connections.........................................................3

Electrical Requirements....................................................3

Dimensions .......................................................................3

Instructions for Installing Pan Supports & Bafes.............4

Electrical Supply Connections ..........................................4

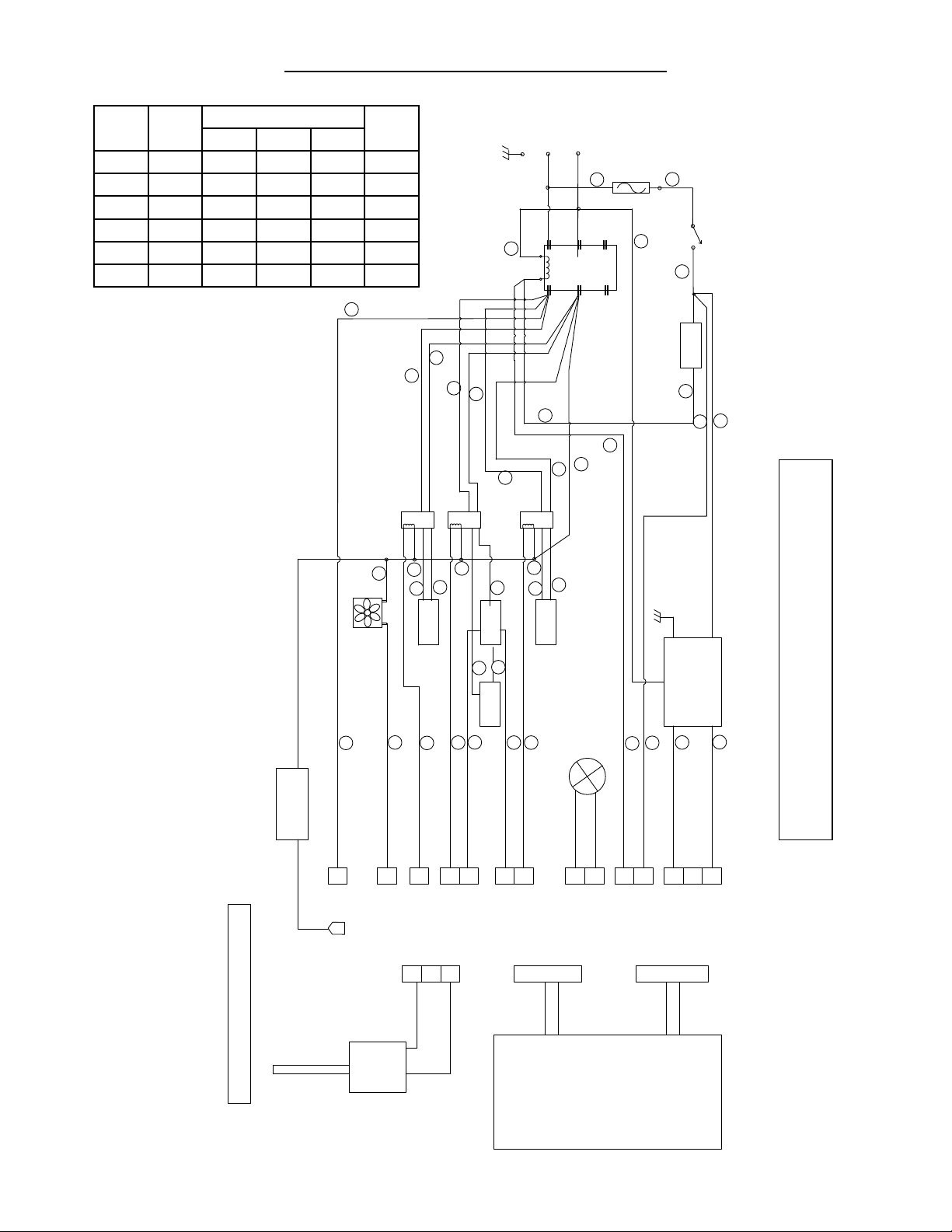

Wiring Diagram - 1 Phase ................................................5

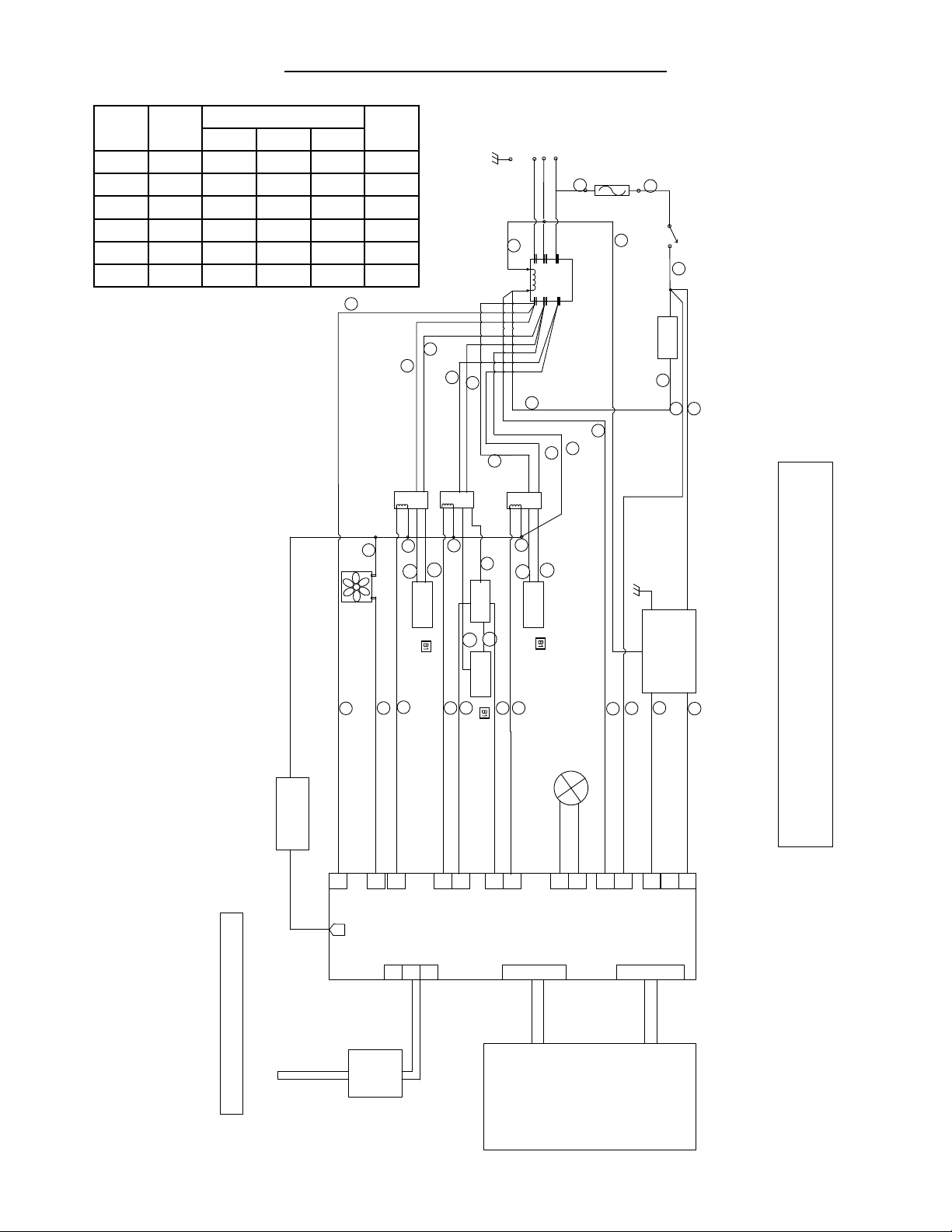

Wiring Diagram - 3 Phase ................................................6

Typical Circuit Connection for STM-ED ............................7

SECTION 2 WATER CONDITIONS

Water Conditions ..............................................................9

SECTION 3 OPERATING INSTRUCTIONS

General Operating Instructions.........................................10

Load Sterilizer...................................................................10

Close Door........................................................................10

Determine Correct Sterilization Times ..............................10

Sterilization Guide ............................................................10

Minimum Sterilization Times Table ...................................11

SECTION 4 MAINTENANCE

Daily Cleaning Procedure .................................................18

SECTION 5 FIELD SERVICE INSTRUCTIONS & ASSEMBLY

Sterilmatic Open Stand.....................................................19

Sterilmatic Open Stand with Condenser...........................19

Parts List for Condenser with Optional Stand...................19

Door Adjustment ...............................................................19

Door Assembly .................................................................20

The Door Gasket ..............................................................20

Door Lift Spring.................................................................20

To Remove the Door Assembly ........................................20

The Fulcrum & Drain Assembly ........................................21

Roller Assembly ................................................................21

Cast-In Heating Elements.................................................22

Low Water Cut-Off Manual Reset .....................................22

Saftey Valve ......................................................................22

The Flue ...........................................................................22

Echaust Solenoid Valve ....................................................22

SECTION 6 ILLUSTRATED PARTS LIST

Vent Piping .......................................................................23

Electrical Components......................................................24

Sterilizer Assembly ...........................................................25

Pan Supports & Bafe ......................................................26

Door Handle Assembly .....................................................27

SECTION 7 TROUBLE-SHOOTING

Trouble Shooting Guide ....................................................29

SECTION 8 APPENDIX

Error Codes ......................................................................30

SECTION 9 WARRANTY INFORMATION

Sterilizer Warranty ............................................................31

Sterilizer Warranty Resistration ........................................32

CONTROL PANEL

Detailed Operating Instructions ........................................12

Controller Overview ..........................................................13

Set Up...............................................................................13

Manual Programing ..........................................................13

Setting Units .....................................................................13

Setting Temperature .........................................................13

Setting Time......................................................................14

Setting Vent Mode ............................................................14

Stopping the Unit ..............................................................14

Description of Cycles ........................................................14

Keys ......................................................................15

Preset

Programing Preset Keys...................................................15

Using Preset Keys ............................................................15

Printing Data Logger.........................................................15

Print Key ...........................................................................16

Printing Previously Run Cycles ........................................16

Printer Paper Cutting ........................................................16

Printer paper Changing ....................................................16

Low Water Reset ..............................................................17

Steps to Reset the Unit.....................................................17

Recommended Steps but not Required ...........................17

INTRODUCTION

A. Product Description:

The Market Forge Sterilmatic Sterilizer with Digital Controller (model STM-ED) is a compact, automatic, low cost

steam pressure sterilizer (autoclave).

The sterilizing cylinder is a 3/16” (4.8mm) thick wall, welded aluminum. The exterior is made of polished stainless

steel. Interior dimensions of 16” (406mm) diameter and 26” (660mm) long with a cubic content of 5,220 cubic

inches (0.085 cubic meters) and has a door opening of 13-1/2” (343mm) wide and 11” (279mm) high. The steril-

izing compartment has a pan capacity of:

□ (3) 12” x 20” x 2 ½” (305mm x 508mm x 64mm) or,

□ (2) 12” x 20” x 4” (305mm x 508mm x 102mm) or,

□ (1) 12” x 20” x 6” (305mm x 508mm x 152mm)

The sterilizer door is a self-sealing type that cannot be opened until the steam pressure is completely exhausted

from the chamber. The door is 12 gauge stainless steel and removable for cleaning without tools. The door gas-

ket is one-piece molded, also replaceable without tools or cement.

The sterilizing cycle is fully automatic with the time, temperature and venting controlled by the microprocessor

based, digital controller.

The sterilizing temperature can be set anywhere in a range from 225°F (107°C) and 250°F (121°C). There is an

on-board data logger/printer. The data logger records the time, temperature and pressure for each sterilization

cycle. This data can be stored for future printing or printed out following each cycle.

B. Service Contacts:

Should repairs be required, a network of authorized agencies is available to assist with prompt service. A current

Directory of Authorized Service Agencies may be obtained by contacting:

Market Forge Industries, Inc.

Sterilizers.com - Alfa Medical - 10 Bond St Great Neck NY 11021

1-800-762-1586 - info@Sterilizers.com

To nd an Authorized Service Agent in your area, go to:

Everett, Massachusetts 02149-4403

Outside MA Fax: (800) 227-2659

Parts / Price / Service Telephone: (888) 259-7076

http://www.mi.com/company/service

35 Garvey Street

Telephone: (617) 387-4100

Toll Free: (866) 698-3188

Fax: (617) 387-4458

Email: custserv@mi.com

Web Site: www.mi.com

i

SECTION 1 INSTALLATION INSTRUCTIONS

AUTOMATIC STERILMATIC STEAM

PRESSURE STERILIZER

MODELS: STM-ED, & STM-EDX

SERVICE & TECHNICAL INFORMATION CONTACT

NOTE: This unit should be serviced by qualied

service personnel only.

Your Sterilmatic Sterilizer has been developed to

answer the need for a compact, automatic, low-cost

steam pressure sterilizer. The following instructions

cover installation. Should service be required, it is

readily available by contacting our authorized ser-

vice agency located nearest to you. The name of

your local service company can be obtained by con-

tacting the Service Department at Market Forge.,

Tel (617) 387-4100 or e-mail custserv@mi.com, or

go to: http://www.mi.com/company/service to nd

an authorized service agent in your area.

OPERATING ENVIRONMENTAL CONDITIONS

This unit is designed for commercial use and to be

safe at least under the following conditions:

For indoor use only.

•

For use at altitudes up to 6500ft (2000m)

•

For use at temperatures from 41

•

o

F (5oC) to 104oF

(40oC).

Maximum relative humidity 80% for temperatures

•

up to 88oF (31oC) decreasing linearly to 50% rela-

tive humidity at 104

Main supply voltage uctuations not to exceed ±

•

o

F (40oC).

10% of nominal voltage.

Transient overvoltages according to Installation

•

Categories II (in accordance with IEC 664).

Pollution Degree 2 (in accordance with IEC 664).

•

INTENDED USE - STERILIZATION CYCLE

This unit is intended to be operated intermittently.

After a pre-heat cycle, the longest period of sterilization (heating) should be a maximum of 60 min-

utes. The digital timer allows up to 99 minutes, but

it should be kept at no more than 60 minutes. After

each use the unit should be opened for removal

and reloading of product. The water level should

be checked after each use and relled when nec-

essary.

INSTALLATION

Set sterilizer on counter, using the 6” (152mm) legs

provided or assemble the optional stainless steel stand

with under-shelf. If your Sterilmatic includes a watercooled exhaust condenser, we recommend the use

of the Sterilmatic stand, part number 95-6060. First,

level unit in place, then adjust rear legs to pitch the unit

forward 1/4” (6mm) to insure positive drainage of the

cylinder.

ELECTRICAL

Connect to proper electrical supply box and disconnect

switch as shown on one of the following schematic diagrams - 208 or 240 volts, single or three phase. Con-

nection is made from the rear of the unit, through the

conduit to the terminal box located at the front of the

unit. See installation specications on page 5.

OUTSIDE VENTING

Connect 1/2” (13mm) nominal tubing exhaust to out-

side vent connection located on top of unit, within the

control housing. IMPORTANT: Exhaust line must be

vented to the outside to eliminate the exhausted steam

and the accompanying noise from entering the room.

Use 1/2” (13mm) copper tubing or suitable alternate.

The overall height and length of the line should not rise

more then 4 feet (1.2 meters) above the unit and exceed 15 feet (4.5 meters) with a minimum of bends.

The line should slope downward after leaving the steril-

izer in order to insure condensate drainage.

WATER-COOLED EXHAUST CONDENSER

If outside venting is not possible, an optional watercooled condenser is available for connection to an

open drain. If required order part no. 95-0436 kit.

TRAY SUPPORTS

Install side tray supports. Tray supports are attached

by means of key-hole clearance slots which are slipped

over studs located on the sides of the Sterilmatic cham-

ber.

BAFFLE INSTALLATION

To insure maximum drying of packs, a bafe is supplied

with your Sterilmatic. Place perforated splash bafe in

bottom of the sterilizing chamber. Install small bafe

with no perforation at the rear of the upper tray support

channel.

NOTE: The perforated bafe is not to be used as a

shelf to place media or other items. It is intended to

eliminate splashing.

OPERATION CHECK

To check for proper operation of unit:

Close drain valve by turning handle clockwise.

1.

WARNING: DO NOT OPEN DRAIN VALVE WHILE

UNIT IS OPERATING. PREMATURE OPENING

MAY RESULT IN SCALDING OF OPERATOR.

Fill chamber with 4 to 5 quarts (3.8 to 4.7 liters) of

2.

ordinary tap water. DO NOT USE DISTILLED OR

1

SECTION 1 INSTALLATION INSTRUCTIONS

DEIONIZED WATER.

Close chamber door.

3.

Set exhaust selector to INSTRUMENTS AND

4.

PACKS (fast exhaust) or LIQUIDS (slow exhaust).

Set timer to 15 minutes. Cycle will go to completion

5.

automatically.

NOTE: Sterilizing cycle timer will not start until steril-

izing set point temperature is obtained.

AMPS PER WIRE *STERILIZER

Phase 3 Phase 1 Phase

Volts 208 240 208 240

Amps 26 30 45 52

208V

240V

(197-219)

or

(220-240)

NOTES:

Unit must be grounded and all wiring to comply with local

1.

codes.

Pipe to open drain. Do not make solid connection to sewer.

2.

Condensing unit to bt installed. Requires a front to back pitch,

3.

shown in the illustration below (see A).

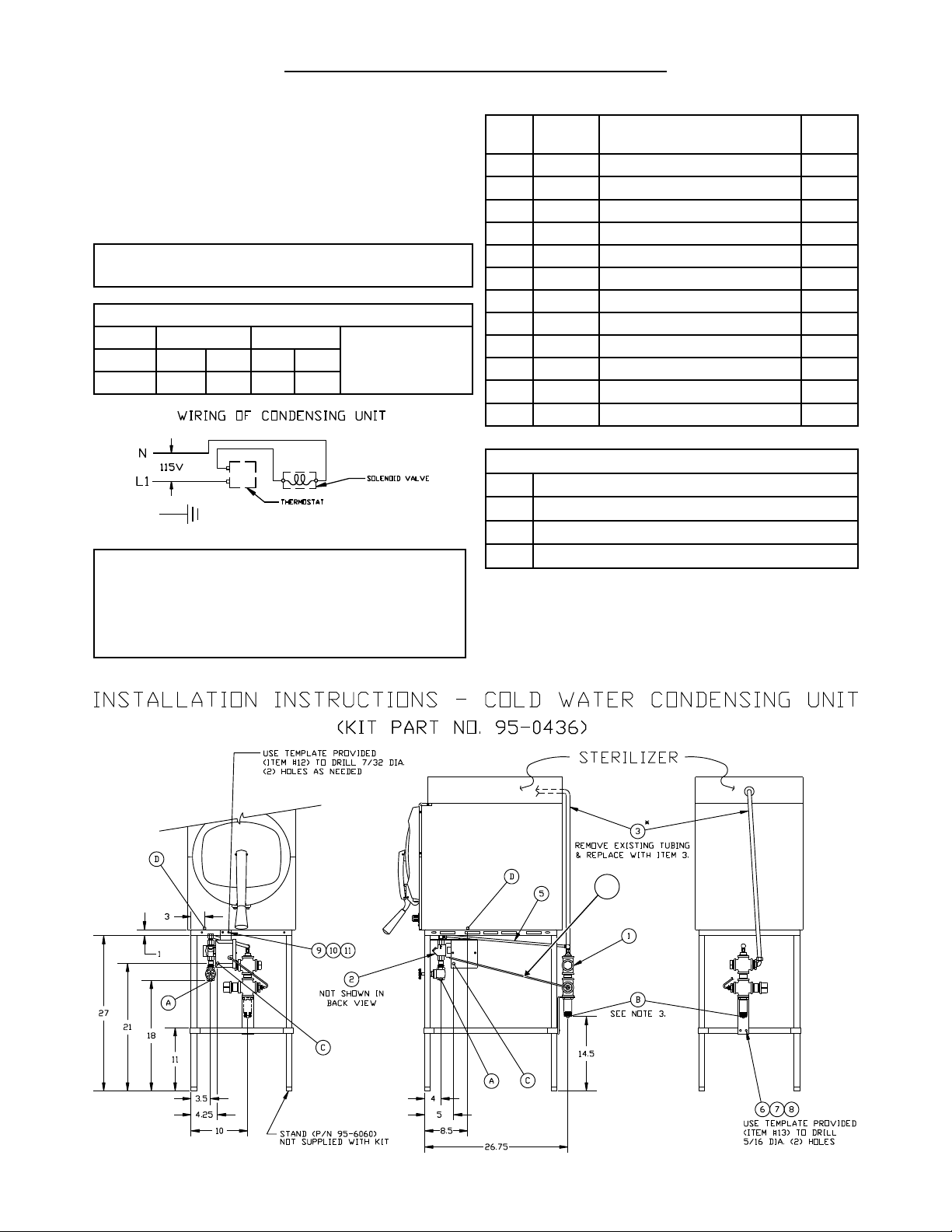

COLD WATER CONDENSER

PART

ITEM

1 95-2119 Steam condensing unit 1

2 95-2219 Thermostat

3 95-0086 Exhaust line 1

5 15-7057 Copper tubing 3/8

6 10-1775 Rd. Hd. Mach. Screw, 1/4-20 2

7 10-2500 Lockwasher, 1/4 2

8 10-2308 Hex Nut, 1/4-20 2

9 10-1812 Rd. Hd. Mach. Screw, 10-32 2

10 10-2505 Lockwasher, 10 2

11 10-2340 Hex Nut, 10-32 2

12 95-4009 Front

13 95-4010 Back Template (11” Lg) 1

A

B

C

D

NO. DESCRIPTION

Box Assy. 1

OD

Template (7” Lg) 1

SERVICE CONNECTIONS REQUIRED

1/2” IPS Cold Water Connection

1” IPS Drain Connection (See Note 3)

115V Elec. Connection 7/8 Ø knockout (cond. unit)

Electrical Connection

QTY.

22.25”

A

2

SECTION 1 INSTALLATION INSTRUCTIONS

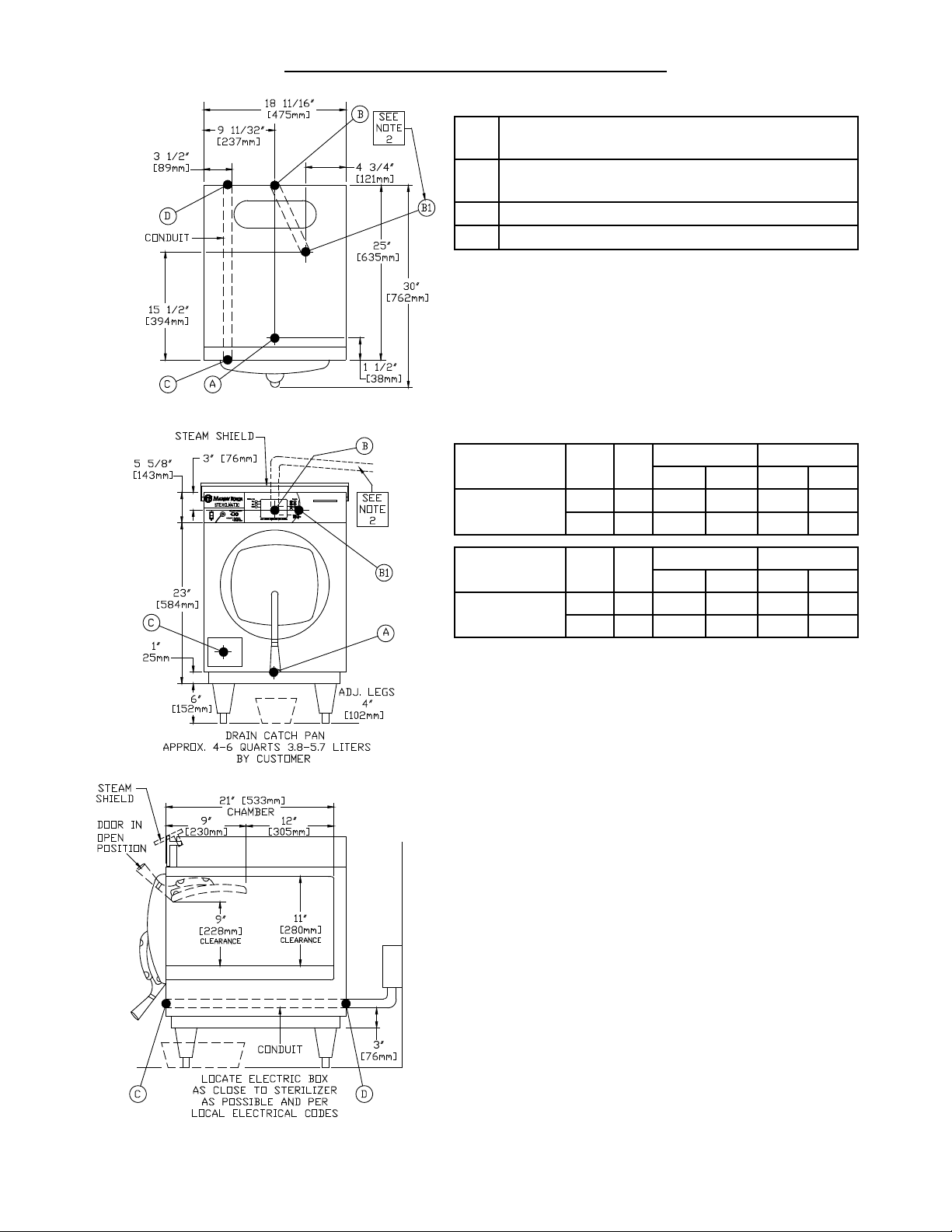

REQUIRED CONNECTIONS:

A Drain - 1/2” (13mm) FPT of 5/8” (16mm) OD

copper (see note 1)

B Steam Exhaust Connection - 3/8” (10mm) IPS

(see note 2)

C Electrical Connection - (*see table below)

D Power Supply

ELECTRICAL REQUIREMENTS: Unit will be rated at

12kW at 236V and will be equipped for operation at:

□ 208-240V, 3 Wire, 1 Phase, 60 Hz

□ 208-240V, 4 Wire, 3 Phase, 60 Hz

□ 220V, 1 Phase, 50 Hz

□ 220V, 3 Phase, 50 Hz

AMP/PHASE

DOMESTIC

MODEL

STM-ED

kW Hz

9.3 60 45A - 26A -

12.4 60 - 52A - 30A

Single Phase

208V 240V 208V 240V

Three Phase

EXPORT

MODEL

STM-EDX

•

UNIT MUST BE GROUNDED

•

MAIN SUPPLY VOLTAGE FLUCTUATIONS ARE NOT TO

EXCEED ± 10% NOMINAL SUPPLY VOLTAGE

kW Hz

10.4 50 48A - 16A -

12.4 50 - 52A - 18A

Single Phase

220V 240V

Three Phase

220/380V 240/415V

NOTES:

An air break must be provided if a unit drain line is run.

1.

Vent exhaust to atmosphere. B1 is actual connection,

2.

but must exit casing at B.

IMPORTANT: Exhaust line must be vented to the outside to eliminate the exhaust steam and the accompanying noise from entering the room. Use 1/2” (13mm)

copper tubing or suitable alternate. The overall height

and length of the line should not rise more then 4’ (1.2

meters) above the unit and exceed 15’ (4.5 meters) with

a minimum of bends. The line should slope downward

after leaving the sterilizer in order to ensure condensate

drainage.

IMPORTANT: Failure to comply with this outline will af-

fect the sterilization process.

When an exhaust condenser is supplied; the following

services must be provided: 1/2” (13mm) IPS cold water:

1” (25mm) IPS waste: 115V electrical line.

3

SECTION 1 INSTALLATION INSTRUCTIONS

INSTRUCTIONS FOR INSTALLING PAN SUPPORTS AND BAFFLES

Locate the mounting studs on the inside of the chamber. There are two rack mounting studs on each side

1.

(see Fig. 1).

Taking one pan support and positioning rack so that the pan stop is facing the rear of the unit and the wires

2.

are facing toward the center of the unit. The pan stop is a piece of sheet metal welded to the rack with a 65° bend.

Begin to hang the pan support by placing the rear key-way slot onto the rear mounting stud and slide the rack

3.

until the slot sits on the mounting stud. When this is done correctly the front mounting stud will be in position

to place the front key-way slot. Slide the rack down into its correct position (see Fig 2).

After installing one pan support rack correctly, you can install the upper bafe. Position the bafe so that the

4.

45° bend is facing up towards the front of the unit (see Fig. 3). Slide the mounting tab onto the at bend on

the pan stop bracket. The bafe should now stay in place by itself, but in a tilted state (see Fig. 4).

Position the second pan support rack into the cavity and slide the other mounting tab onto the rack at bend

5.

while the pan support rack is not on the mounting studs. Hang the pan support by placing the rear key-way

slot onto the rear mounting stud and slide the rack until the slot sits on the mounting stud. When this is done

correctly the front mounting stud will be in position to place the front key-way slot. Slide the rack down into

its correct position.

Place the Perforated Water Bafe so that it sits on the bottom of the inside of the sterilizer chamber (see Fig. 5).

6.

CAUTION: Do not cover the holes in the Perforated Water Bafe by using it as a shelf. This will result in a

7.

disrupted ow of steam.

THE ELECTRIC SUPPLY CONNECTIONS FOR STM-ED: Connect to proper electrical supply as indicated on

nameplate on top of unit. The power supply cord is brought in from the rear of the unit, through the conduit and

the connection is made at the terminal box located at the front of the unit.

THE ELECTRIC SUPPLY CONNECTIONS FOR STM-EDX: Connect to proper electrical supply as indicated on

nameplate on top of unit. Connection is made from the rear of the unit, through the conduit to the terminal box

located at the front of the unit. All control circuits are 220 volts.

In order to accomplish this, a current-carrying grounded neutral must be provided.

Thus, a three phase system must be 4-wires. Most electrical codes require, and we recommend, that a separate

switch be located within sight of the sterilizer.

4

SECTION 1 INSTALLATION INSTRUCTIONS

SSR

3+

-

1

CONTROL

BOARD

2

1

2

1

2

4

9

8

3

7

2

1

P4

P13

PRINTER

1

2

J4

POWER

J3

J21

J21

J21

J21

J21

J5

J14

J1

J13

T1

POWER

LOW WATER LED

P21

P5

T1

THERMISTOR

PROBE

EXHAUST

VALVE

4

2

1

+

-

L

G

POWER

SUPPLY

5 VDC

K1

2

3

5

4

24

7

8

9

6

26

23

K3

LOW WATER

CUTTOFF

13

13

13

13

27

L1

L2

L1

L2

L1

L2

POWER

31

29

1.5 A

FUSE

1

5

20

N

28

22

L2 (2A)

L1 (1A)

L1

L2

L3

T2

T3

23

16

14

21

25

RS232

RS232

13

18

15

4

MK

22

HEATER 2

17

HEATER 1

T1

T2

K2 T1

T2

19

HEATER 3

T1

T2

25

11

10

12

WIRE YEL 22 GA

WIRE BRN 22 GA

WIRE RED 22 GA

WIRE RED 22 GA

WIRE RED 22 GA

WIRE BLU 18 GA

WIRE BLU 22 GA

WIRE RED 18 GA

WIRE BLK 22 GA

WIRE ORG 22 GA

WIRE ORG 22 GA

WIRE ORG 18 GA

WIRE ORG 22 GA

WIRE ORG 18 GA

WIRE RED 18 GA

WIRE BLK 18 GA

WIRE ORG 18 GA

WIRE RED 18 GA

30

WIRE BLU 18 GA

WIRE ORG 22 GA

WIRE ORG 22 GA

WIRE BLK 16 GA

WIRE RED 16 GA

WIRE WHT 16 GA

WIRE RED 16 GA

WIRE WHT 16 GA

WIRE BLK 16 GA

WIRE RED 18 GA

WIRE ORG 22 GA

WIRE ORG 22 GA

DIGITAL STERILMATIC MODEL STM-ED - 1 PHASE WIRING DIAGRAM

DRAWING No. 95-6311 Revision A - Date 10/25/13

DRAWING No. 95-6311 Revision A

Volts Phase

AMPs Per Line Wire

L1 L2 L3

kW

208 1 45 45 -- 9.3

208 3 26 26 26 9.3

220 1 48 48 -- 10.4

220 3 28 28 28 10.4

240 1 52 52 -- 12.4

240 3 30 30 30 12.4

5

SECTION 1 INSTALLATION INSTRUCTIONS

SSR

3+

-

1

CONTROL

BOARD

2

1

2

1

2

4

9

8

3

7

2

1

P4

P13

PRINTER

1

2

J4

POWER

J3

J21

J21

J21

J21

J21

J5

J14

J1

J13

C

C

T1

POWER

LOW WATER LED

P21

P5

T1

THERMISTOR

PROBE

EXHAUST

VALVE

4

2

1

+

-

L

G

POWER

SUPPLY

5 VDC

K1

2

3

5

4

24

7

8

9

6

26

23

LOW WATER

CUTTOFF

13

13

13

13

27

L1

L2

L1

L2

POWER

31

29

2.0 A

FUSE

1

5

20

N

1

22

L3 (3A)

L2 (2A)

L1 (1A)

30

L1L2L3

T2

T3

23

16

14

21

25

RS232

RS232

13

18

15

4

MK

22

WIRE RED 18 GA

WIRE BLK 22 GA

WIRE ORG 22 GA

WIRE YEL 22 GA

WIRE BRN 22 GA

WIRE RED 22 GA

WIRE RED 22 GA

WIRE ORG 22 GA

WIRE ORG 22 GA

WIRE BLK 16 GA

WIRE ORG 18 GA

WIRE ORG 22 GA

WIRE RED 22 GA

WIRE BLU 18 GA

WIRE BLU 22 GA

WIRE RED 16 GA

WIRE WHT 16 GA

WIRE RED 16 GA

WIRE BLK 16 GA

WIRE ORG 18 GA

WIRE BLU 18 GA

WIRE ORG 22 GA

WIRE RED 18 GA

WIRE ORG 18 GA

WIRE BLK 18 GA

WIRE RED 18 GA

WIRE WHT 16 GA

WIRE ORG 18 GA

WIRE RED 18 GA

WIRE ORG 22 GA

FAN

K3

L1

L2

HEATER 1

T1

T2

K2

T1

T2

HEATER 3

T1

T2

25

11

10

12

HEATER 2

17

19

DIGITAL STERILMATIC MODEL STM-ED - 3 PHASE WIRING DIAGRAM

DRAWING No. 95-6312 Revision A - Date 10/25/13

DRAWING No. 95-6312 Revision A

Volts Phase

AMPs Per Line Wire

L1 L2 L3

kW

208 1 45 45 -- 9.3

208 3 26 26 26 9.3

220 1 48 48 -- 10.4

220 3 28 28 28 10.4

240 1 52 52 -- 12.4

240 3 30 30 30 12.4

6

SECTION 1 INSTALLATION INSTRUCTIONS

15

240 Volt, 3 Phase

240

240

16

23

13

25

14

18

21

40A

40A

40A

L

1

L2

L3

ELECTRICAL SOURCE UNIT WIRING

FUSE AND

DISCONNECTED MEANS

TYPICAL CIRCUIT CONNECTION FOR STM-ED STERILIZER

240

15

208 Volt, 3 Phase

208

208

16

23

13

25

14

18

21

40A

40A

40A

L

1

L2

L3

208

15

240 Volt, 1 Phase

240

21

16

23

18

25

14

13

60A

60A

L

1

L2

15

208 Volt, 1 Phase

208

21

16

23

18

25

14

13

50A

50A

L

1

L2

7

SECTION 1 INSTALLATION INSTRUCTIONS

1

4- Wire, 3 Phase

Delta (480/240V)

4- Wire, Wye Connected

380/220V, 3 Phase

240

240

8

2

12

19

25

7

5

20A

20A

20A

L

2

L1

N

N

L

3

480

ELECTRICAL SOURCE UNIT WIRING

FUSE AND

DISCONNECTED MEANS

TYPICAL CIRCUIT CONNECTION FOR STM-EDX STERILIZER -EXPORT-

480

415

415

20A

20A

20A

L

1

L2

L3

240

1

8

2

12

19

25

7

5

4- Wire, Wye Connected

415/240V, 3 Phase

N

380

380

20A

20A

20A

L

1

L2

L3

220

1

8

2

12

19

25

7

5

This page intentionally left blank.

8

Loading...

Loading...