Page 1

ST-5G

GAS COUNTERTOP CONVECTION STEAMER

INSTALLATION - OPERATION - MAINTENANCE

44 Lakeside Avenue, Burlington, Vermont 05401 USA

Telephone: (802) 658-6600 Fax: (802)864-0183

www.mi.com PN 14-0265 Rev A (7/14)

© 2014 - Market Forge Industries Inc.

Page 2

Your Service Agency’s Address:

Model

Serial number

Oven installed by

Installation checked by

Page 3

IMPORTANT

TABLE OF CONTENTS

WARNING: Improper installation, adjustment, alternation,

service or maintenance can

cause property damage, injury or death. Read the installation, operation and maintenance instructions thoroughly

before installing or servicing

this equipment.

INSTRUCTIONS TO BE FOLLOWED IN THE EVENT THE

USER SMELLS GAS MUST BE

POSTED IN A PROMINENT LOCATION. This information may

be obtained by contacting your

local gas supplier.

FOR YOUR SAFETY

Do not store or use gasoline or

other ammable vapors or liquids in the vicinity of this or any

other appliance.

INSTALLATION

Introduction .............................................................. 2

Service Connections ..................................................... 3

Location and Installation .................................................. 4

Utility Connections ....................................................... 5

Performance Check .................................................. 6

OPERATION

Control Panel ............................................................ 7

Steamer Operation ....................................................... 8

Steam Cooking .......................................................... 9

Suggested Steam Times ................................................. 10

MAINTENANCE

Cleaning & Deliming ...................................................... 1

The information contained in this

manual is important for the proper installation, use, and maintenance of this oven. Adherence

to these procedures and instructions will result in satisfactory

baking results and long, trouble free service. Please read

this manual carefully and retain

it for future reference.

ERRORS: Descriptive, typographic or pictorial errors are

subject to correction. Specications are subject to change

without notice.

Page 4

Introduction

DESCRIPTION

The ST-5G is a gas red countertop pressureless cooker.

The cooking compartment is equipped with a three-piece

door with inner gasket plate isolated from the exterior surface. Door latch operates by action for positive sealing on

inner door. Operation controls are displayed on a frontmounted panel and included timer with indicator lights for

selection of constant steam or selectable timed cooking.

The unit is equipped with a gas red, stainless steel generator operating at 0 PSI and rated at 45,000 BTU.

BASIC FUNCTIONING

The cooker becomes operational when it is set to constant steam, or the timer is set at the desired cooking time

and the compartment door is closed.

At the end of the set interval, timer contact switch to shut

off the cooking operation and sound a signal buzzer. The

buzzer is silences by returning the timer dial to the OFF

position. In the constant steam mode, cooking operation

will be continuous.

Steam emitted from the compartment along with liquid

cooking drainage is directed through a drain screen inside

the compartment into the cooker drain line to the generator drain box. A cold water condenser in the rear of the

cooking chamber helps to condense the steam prior to

discharge into the drain.

The steamer freely vents itself by the negative pressure

created by the condensate water drainage. This negative

pressure prevents steam leakage around the door gasket

and helps draw steam though the cooking compartment.

Steam leakage at the door may indicate a plugged or improperly installed drain screen.

SERVICE

Should repairs be required, a network of Authorized

Agencies is available to assist with prompt service. A

current Directory of Authorized Service Agencies may be

obtained by contacting:

Market Forge Industries, Inc.

44 Lakeside Avenue, Burlington, VT 05401 USA

Tel: (802) 658-6600 • Fax: (802) 864-0183

www.mi.com

The Model and Serial Numbers must be referenced

when corresponding with Market Forge. The data plate

containing the serial number is located on the top front of

the steamer (body panel).

CAUTION

Must read before installation

INSTALLATION CODES AND STANDARDS:

Gas installation to conform local codes, or in absence

of local codes, with the National Fuel Gas Codes - ANSI

ZZ223.1/NFPA 54. In Canada installation to be in accordance with the Natural Gas and Propane installation

code, CSA B149.1 and/or local codes.

• The unit and its individual shut off valve must be disconnected from the gas supply piping system during

any pressure testing of that system at pressures in

excess of 1/2 PSI.

• The unit must be isolates from the gas supply system by closing its individual manual shut off valve

during any pressure testing of the gas supply piping

system at test pressures equal to or less then 1/2

PSI.

Electrical Grounding must be provided in accordance with

local codes, or in the absence of local codes, with the

National Electric Code ANSI/NFPA 70. In Canada, installation must be in accordance with the Canadian Electrical

Code CSA C22.2.

WARNING

Electrical Grounding Instructions:

Units come equipped with a three prong

(grounding) plug for your protection against

shock hazard and should be plugged directly

into a properly grounded three prong receptacle. DO NOT cut or remove the ground prong

from this plug (120 volt units only).

NOTE: WIRING DIAGRAM FOR THIS UNIT IS LOCAT-

ED ON THE RIGHT HAND SIDE PANEL OF THE

COOKER CABINET.

MECHANICAL CONNECTIONS:

The pressureless cooker is interconnected at the factory

to the steam boiler. All electrical and plumbing connections are located on the rear panel of the cabinet.

INSTALLATION

2

Page 5

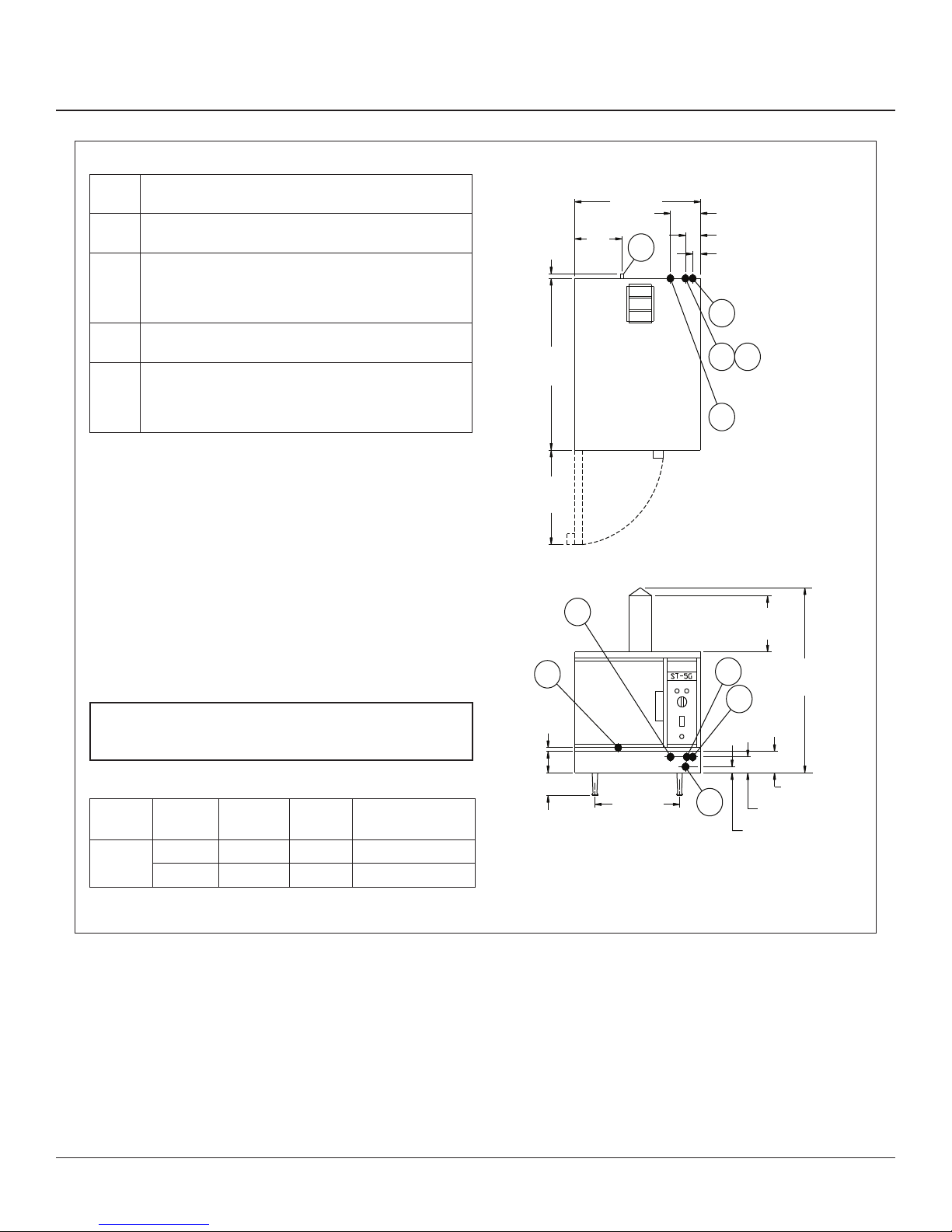

SERVICE CONNECTIONS

G Gas Connection - 3/4” (19mm) IPD O.D. supply line

required.

GW Generator Water - 3/8” (10mm) O.D. tubing at 25-50 PSI

(1.8-3.5kg/cm2)

E Electrical Connection - Unless otherwise specified, field

wire electrical connection to be 120 Volts, 60 Hz and 1pH

with grounding wire. Furnished with 6’ cord and 3 prong

plug. Maximum Amps 2.0.

CW Condensing Water - 3/8” (10mm) O.D. tubing at 25-50

PSI (1.8-3.5kg/cm2)

D Drain - 1” (25mm) IPS O.D. piped to open floor drain.

DO NOT MAKE SOLID CONNECTION TO THE FLOOR.

24” length before open air gap opening. NO BENDS OR

ELBOWS.

WATER QUALITY STATEMENT

Water quality is a major factor affecting the performance of your

appliance. If you are unsure of water quality, consult your local water

treatment specialist and have the water analyzed. Your water supply

must be within these general guidelines:

Total Dissolved Solids

Total Alkalinity

Silica

Chlorine

pH Factor

Water which fails to meet these standards should be treated by

installation of water conditioner.

FAILURE OR MALFUNCTION OF THIS APPLIANCE DUE

TO POOR WATER QUALITY IS NOT COVERED UNDER

WARRANTY.

1.12

[29]

32

[813]

16.75

[425]

D

1

[25]

E

9

[299]

24 [610]

D

Service Connections

5.25 [133]

3 [76]

1.75 [44]

CW

G

GW

E

12

[305]

GW

CW

40.38

[1026]

GAS REQUIREMENTS

MODEL FUEL BUT/HR. kW/HR.

ST-5G

Natural 45,000 13.2 Min. 4” (120mm)

Propane 45,000 13.2 Min. 11” (279mm)

WATER COLUMN

PRESSURE

Figure 1

3

4 [102] MIN.

16 [406] G

DIMENSIONS ARE IN INCHES [MM]

5 [127]

4 [102]

1.75 [44]

INSTALLATION

Page 6

Location and Installation

The location of installation must be under an exhaust

hood, which will remove water vapor emitted when the

cooker door is opened, and exhaust fumes. Level the

unit in nal location by turning adjustable feet. Using the

cabinet top as a reference, obtain level adjustment from

left-to-right and front-to-back.

Exhaust Fans and Canopies

Canopies are set over ranges, ovens, kettles, etc., for

ventilation purposes. It is recommended that a canopy

extend 6” past appliance and be located 6’ - 6” from the

oor. Filters should be installed at an angle of 45O or

more with the horizontal. This position prevents dripping

of grease and facilitates collecting the run-off grease in

adrippan, usually installed with the lter. A strong exhaust

fan tends to create a vacuum in the room and may interfere with burner performance or may extinguish pilot

ames. Makeup air openings approximately equal to the

fan area will relieve such vacuum. In case of unsatisfactory performance on any appliance; check with the exhaust

fan in the “OFF” position.

Wall Exhaust Fans

The exhaust fan should be installed at least two feet

above the vent opening at the top of the unit.

INSTALLATION

WARNING

These procedures must be followed by quali-

ed personnel or warranty will be voided. An

open gap oor drain is required immediately

below the appliance drain.

To Install:

1. Uncrate carefully. Report any hidden freight damage

to the freight company immediately.

2. Set the unit in place. Be certain to maintain the minimum clearances from combustibles and non-combustibles.

3. Level appliance using spirit level. Should anged ad-

justable feet be provided, anchor to oor using proper

anchoring devices.

4. Seal bolts and anged feet with Silastic or other

equivalent compound.

5. Be certain to leave adequate clearances for cleaning,

maintenance and service.

CLEARANCES

Adequate clearance must be provided in aisle and at the

side and back. Adequate clearances for air openings into

the combustion chamber must be provided, as well as for

serviceability for use on noncombustible oors. Minimum

clearance from combustible and noncombustible construction, 3” on left side, 8” on right side and 6” from back.

INSTALLATION

4

Page 7

Utility Connections

GAS CONNECTION

1. The serial and rating plate on the unit indicates the

type of gas your unit is equipped to burn. DO NOT

CONNECT to any other gas types than the type spec-

ied.

2. A 3/4” NPT line is provided at rear for the connection.

Each compartment is equipped with an internal press

regulator which is set at 3.5” WC manifold pressure

for natural gas and 10” WC for propane gas. Use 1/8”

pipe tap n the burner manifold for checking pressure.

An adequate gas supply is imperative. Undersized or low

pressure lines will restrict the volume of gas required for

satisfactory performance. A stead supply of pressure, between 6” WC and 14” WC, for natural gas and between

11” WC and 14” WC for propane gas is recommended.

With all units operating simultaneously the manifold pressure on all units should not show any appreciable drop.

Fluctuations of more that 25% on natural gas and 10% on

propane gas will create problems, affecting burner operation. Contact you local gas company for correct supply

line sizes.

Purge the supply line to clean out any dust, dirt or other

foreign matter before connecting the line to the unit. Use

pipe joint compound which is suitable for use with propane on all threaded connections. A manual gas shut-off

valve for each compartment is supplied with the unit.

Test pipe connections thoroughly for gas leaks.

All the connections must be checked for leaks, after the

unit has been put in operation. Use soapy water only for

testing on all gases. Never use an open ame to check

for gas leaks.

PLUMBING CONNECTION

WARNING

PLUMBING CONNECTIONS MUST COMPLY WITH

APPLICABLE SANITARY, SAFETY AND PLUMBING

CODES.

Two water lines are provided, one for each compartment. Connect water supply line to the 3/8” copper tube

in at the rear of the steamer. The 3/8” copper tube supplies water to both the generator tank and condense live

steam enter the drain line.

DRAIN CONNECTION

The drain connection must be 1” IPS vertically down,

preferably with one elbow only, and maximum length of 6

feet, piped to an open air gap type drain.

ELECTRICAL CONNECTION

WARNING

DO NOT CONNECT THE UNIT TO THE ELECTRICAL SUPPLY UNIT AFTER GAS CONNECTION HAS BEEN MADE.

120 VAC / 60 Hz / 1pH: Units with this rating are factory

supplied with a three-wire cord and three-prong plug

which ts any standard 120V, three-prong receptacle. A

separate 15 amp supply is needed for each unit.

Figure 2

CAUTION

PVC or CPVC are not acceptable materials for

drains.

In order to avoid any back pressure in the

steamer, DO NOT connect solidly to any drain

connection.

5

INSTALLATION

Page 8

Utility Connections

COLD WATER CONDENSER

The steamer is equipped with a cold water condenser in

the rear of the cooking chamber which helps to condense

the steam prior to discharge into drain.

The steamer freely vents itself by the negative pressure

created by the condensate water drainage. This negative

pressure prevents steam leakage around the door gasket

and helps draw the steam through the cooking compartment. Steam leakage at the door may indicate a plugged

or improper installed drain.

WATER CONDITIONING

It is important that the water supply connected to this

steamer be softened to no more than 2.0 grains of hardness and have a pH of 6 to 7.5. This degree of hardness

can be easily obtained with the use of a properly maintained water softener. The use of a water meter eill determine the water consumption and when the water softener

needs regeneration or recharging. Failure to comply with

these water condition standards may void the warranty.

Untreated water contains scale producing minerals which

can precipitate onto the surface in the boiler. Due to the

temperatures in the boiler, the minerals can bake onto the

surface and components. This can result in early component failure and reduced product life.

Water level probes become coated with scale. Scale will

bridge across the probe insulator from the metal extension which senses the water level in the boiler shell. Once

this scale becomes wet, the water level control is unable

to maintain the proper water level in the boiler. STRAINERS and FILTERS will NOT remove minerals from the

water.

PERFORMANCE CHECK

Once the steamer is installed and all mechanical connections have been made, thoroughly test the steamer before

operation.

1. Check that proper water, drain, electrical and gas

connections have been made.

2. Turn main power switch ON. After approximately 19

minutes the READY light should come on, indicating

that the water temperature is 205°F (97°C).

3. Check that IGNITION light comes on and cycles ON

and OFF.

4. When the READY light comes on, set timer to the

5 MINUTE position. With door open, observe that

no steam is entering the compartment and that the

COOKING light is OFF.

5. Close the compartment door. The COOKING light

should now be ON and steam should be heard entering the compartment after about 45 seconds.

6. Ensure that water from cold water condenser is owing through the drain line.

7. Open compartment door and observe that steam supply to chamber is cut off. READY light should come

ON again as COOKING light goes OFF.

8. Close compartment door and let cooking cycle nish. When the timer returns to 0 position, a buzzer will

sound signaling the end of the cooking cycle. Buzzer

must be manually turned off by setting the timer to its

OFF position.

INSTALLATION

6

Page 9

Control Panel

1. IGNITION LIGHT - When lit, indicates burners have

been ignited and are heating the generator tank.

2. READY - PILOT LIGHT: When lit, indicates

steam chamber has reached 205oF (97oC) and is

ready for the cooking cycle.

3. COOKING PILOT LIGHT - When lit, indicates that

cooking cycle is in progress.

4. TIMER - Set the cooking timer (0 to 60 minutes) Steam cooking will begin when the door is closed.

The cooking cycle will be interrupted if the door is

open during the cooking cycle; resume cooking by

closing the door.

5. MAIN POWER SWITCH:

ON - The boiler will automatically ll and begin heating to the pre-set temperature. Red

OFF: - The boiler will drain. No lights.

DELIME GENERTOR LIGHT (IF EQUIPPED) - Indicates that lime scale deposits have accumulated in

the steam generator and that a DELIME procedure

should be performed at the next convenient opportunity.

6. BUZZER - Signals end of cooking period (not shown).

Figure 3

7

OPERATION

Page 10

Steamer Operation

WARNING

The steamer and its parts are hot. Use care

when operating, cleaning or servicing the

steamer. The cooking compartment contains

line steam. Stay clear when opening door.

Your steamer has been factory set when ON to maintain

water temperature during the READY pH at approximately 205°F (97°C) just below water boiling point.

WARNING

IN THE EVENT OF MAIN POWER BURNER

IGNITION FAILURE, A 5 MINUTE PURGE

PERIOD MUST BE OBSERVED PRIOR TO

RE-ESTABLISHING IGNITION SOURCE. IF SO

EQUIPPED, SOME UNITS WILL AUTOMATICALLY RE-ATTEMPT IGNITION.

WARNING

IN THE EVENT THE USER SMELLS GAS

SHALL BE POSTED IN A PROMINENT LOCATION. THIS INFORMATION SHALL BE OBTAINED BY CONSULTING THE LOCAL GAS

SUPPLIER.

LIGHTING

1. Ensure power, gas and water supply is on.

2. Turn POWER switch ON.

3. Generator tank will begin lling with water.

COOKING

Before loading the cooker, be sure the compartment is hot

(Refer to preheating instructions above).

1. Slide pans of food into cooking compartment pan

supports.

2. Close cooking compartment door.

3. Set timer cooking time.

4. Set timer to the required cooking time (Refer to cook-

ing guidelines).

a. Constant Steam - For continuous cooking.

b. 60 Minute Timer - For timed cooking.

5. Turn off buzzer when cooking cycle is complete, by

turning the timer dial to the “off “ position.

6. Open door slightly at rst letting most of the steam

out of the compartment and then fully open the door.

7. Unload by sliding pans of food from pan supports.

SHUTDOWN

NOTE: The cooking compartments are operated indepen-

dently of each other. Each has its own gas, water

supply and generator tank.

STAND BY

1. Set timer to OFF position and leave door slightly

open.

4. Once water level has been reached, the IGNITION

light should come on and remain on until READY light

comes on.

5. Steamer is now ready for use.

PREHEATING

Before each initial operation of cooking and at any other

time when the cooking compartment is cold a 1 minute

preheating period is required. To preheat the cooker put

steam source into operation and proceed as follows:

1. Close cooking compartment door.

2. Set 60 minute timer dial to “1 minute” setting.

3. Turn off buzzer, which sounds to indicate cooking is

complete, by setting the timer dial to the “off ” position.

OPERATION

COMPLETE SHUTDOWN

1. Set timer to OFF and turn POWER switch to OFF.

Generator will drain automatically.

2. Turn water supply OFF.

3. Turn gas supply OFF.

4. Disconnect power supply.

8

Page 11

Steam Cooking

Your steamer efciently cooks vegetables or other foods

for immediate serving. Steam cooking should be carefully timed and controlled. Keep hot food holding time to

a minimum to produce the most appetizing results. Prepare small batches, cook only enough to start serving,

then cook additional amounts to meet demand. Separate

frozen foods into smelled pieces to allow more efcient

cooking.

Use a pan cover for pre-cooked frozen dishes that cannot

be cooked in the covered containers in which they are

packed if they require more than 15 minutes of cooking

time. When cover is used approximately one-third additional cooking time is necessary.

Cooking frozen foods depends on amount of defrosting

is required. If time permits, allow frozen foods to partially

thaw overnight in the refrigerator. This will reduce their

cooking time.

PREPARATION

Prepare vegetables, fruits, meats, seafood and poultry normally by cleaning, separating, cutting, removing

stems, etc. Cook root vegetables in a perforated pan un-

less juices are being saved. Liquids can be collected in a

solid 12” x 20” pan placed under a perforated pan. Perforated pans are used for frankfurters, wieners and simulate items when juices do not need to be preserved. Solid

pans are good for cooking puddings, rice and hot breakfast cereals. Vegetables and fruits are cooked in solid

pans in their own juices. Meats and poultry are cooked in

solid pans to preserve their own juices to to retain broth.

Canned foods can be heated in their opened cans placed

in the pans or the contents may be poured into solid pans.

PANS

The steamer compartment is designed to accept combinations of the pan of 12” x 20” (solid or perforated) as

shown in the table below:

DEPTH OF PAN NUMBER OF PANS

1” 10

2.5” 5

4” 3

6” 2

FACTS ON PARADE

1. Frozen vegetables should always be cooked in perforated 12” x 20” x 2.5” pan. 7.5lbs. (34kg) maximum

per pan.

2. Frozen entrees should be underlined with a perforated pan for best results. If they are defrosted before

hand, the heating time will be decreased.

3. Fresh foods may also be cooked in this unit. When

the stock is not to be retained should be cooked in

perforated 12” x 20” x 2.5” pans for the most nutritious

results.

4. There is a safety micro-switch on the door which

shuts off the steam each time the door is opened if

the unit is in the cooking cycle.

5. Total cooking time will vary depending on the load,

even though the timer setting is the same.

6. All foods, except cakes and pastry, can be coked in a

steam cooking unit.

7. Steam cooked meals have greater nutritional value

since they retain most of their vitamins and minerals.

8. Because foods are cooked faster by the higher temperatures of steam cooking, they can be prepared

closer to serving time, insuring maximum freshness.

9. Steam cooked foods have a higher percent yield

more portions per dollar spent.

10. Food may be served from the same pan in which it

is steam cooked, thus reducing food breakage since

there is no extra handling of transferring of food from

cooking pans to serving pans. It also reduces pot

washing tasks.

11. Some important advantages of steam coking are labor saving, reduced operating costs, space saving

and the lifting of heavy stock pots is eliminated.

12. Rice and spaghetti products, it thoroughly wet at the

start of the cooking process are very easily prepared.

13. Food such as potatoes, poultry, seafood and some

meats may be blanched in the steam cooker, thus reducing the total cooking time and grease absorption.

14. The steam cooker will loosen foods on pans making

washing easier.

15. Solid pans are recommended when liquid is to be re-

tained and perforated pand when the liquid is not to

be retained.

16. Eggs may be cooked out of the shell if they are to be

chopped which eliminates peeling after steaming.

17. The steam cooker can be opened during the cooking

period to add or remove items.

18. Steam cooking information including recommended

pan size and type, weight per pan, cooking times and

pan yields are given on the next few pages of this

bulletin.

9

OPERATION

Page 12

Suggested Steam Times

HEIGHT OF

WEIGHT

ITEM

VEGETABLES

Beans, Snap Green or

Waxed

Beets, 2” Diameter 7.5 lbs. (3.5kg) 2.5” (65mm) 1-3 40-50

Broccoli 1/2-3/4”, Stalks 6 lbs. (2.7kg) 2.5” (65mm) 1-3 14-18

Carrots, Sliced 9 lbs. (4kg) 2.5” (65mm) 1-3 18-21

Cauliower, Trimmed,

1.5”-2”

Corn on Cob, Husked 1 doz. 2.5” (65mm) 1-3 10-15 12

Cabbage 1/4-1/6 of Head,

Cored

Onions, 2” Diameter 6 lbs. (2.7kg) 2.5” (65mm) 1-3 20-25

Peas, Shelled 5 lbs. (2.25kg) 2.5” (65mm) 1-3 5-6

Potatoes, French Fry Cut 10 lbs. (4.5kg) 2.5” (65mm) 1-3 18-21

Potatoes, Regular Cut, 3” 10 lbs. (4.5kg) 2.5” (65mm) 1-3 35-40

Spinach, Cleaned Cut 3 lbs. (1.4kg) 2.5” (65mm) 1-3 3-5

Squash, Summer, Sliced

1” Thick

Squash, Winter, Peeled 9 lbs. (4kg) 2.5” (65mm) 1-3 10-15

Turnip, Diced 5 lbs. (2.25kg) 2.5” (65mm) 1-3 28-32

FROZEN VEGETABLES

Asparagus, Spears 7.5 lbs. (3.4kg) 2.5” (65mm) 1-3 12-15

Beans, Green, Regular 6 lbs. (2.7kg) 2.5” (65mm) 1-3 10-15

Beans, Green, French Cut 6 lbs. (2.7kg) 2.5” (65mm) 1-3 5-7

Beans, Lima

Broccoli

PER PAN

6 lbs. (2.7kg) 2.5” (65mm) 1-3 18-22

6 lbs. (2.7kg) 2.5” (65mm) 1-3 12-16

5 lbs. (2.25kg) 2.5” (65mm) 1-3 14-18

7 lbs. (3.2kg) 2.5” (65mm) 1-3 7-10

7.5 lbs. (3.4kg) 2.5” (65mm) 1-3 12-15

6 lbs. (2.7kg) 2.5” (65mm) 1-3 4-6

12” x 20”

PERFORATED

NUMBER

OF PANS

TIMER

SETTINGS

IN MINUTES

COOKED

SERVINGS

PER PAN

25-30

30 oz. 85g

30-35

3 oz. 85g

25-30

3 o. 85g

45-40

3 oz. 85g

30-35

3 oz. 85g

15-20

4 oz. 115g

25-30

4 oz. 115g

25-30

3 oz. 85g

50

3 oz. 85g

50

3 oz. 85g

10-12

3.75 oz. 105g

30-35

3 oz. 85g

25-30

3 oz. 85g

20-25

4 oz. 115g

30

3 oz. 85g

25

3 oz. 85g

25

3 oz. 85g

30

3 oz. 85g

25

3 oz. 85g

OPERATION

10

Page 13

Suggested Steam Times

HEIGHT OF

WEIGHT

ITEM

Brussel, Sprouts

Carrots

Cauliower

Corn-Cut

Mixed Vegetables 7.5 lbs. (3.4kg) 2.5” (65mm) 1-3 8-12

Peas, Loose 7.5 lbs. (3.4kg) 2.5” (65mm) 1-3 3-5

Spinach 9 lbs. (4kg) 2.5” (65mm) 1-3

Squash 12 lbs. (5.4kg) 2.5” (65mm) 1-3

FROZEN PREPARED ENTREES

Lobster Tails, 6-8 oz. 7-8 lbs. (3.2-3.6kg) 2.5” (65mm) 1-3 15-25

Shrimp, C.D.P. 16-20 lbs. (7-9kg) 2.5” (65mm) 1-3 8-11

Shrimp, Raw 16-20 lbs. (7-9kg) 2.5” (65mm) 1-3 11-15

Bulk Pack, Frozen

Bulk Pack, Defrosted

CANNED VEGETABLES

Vegetables, Canned 7 lbs. (3.2kg) 2.5” (65mm) 1-3 5-10

PER PAN

7.5 lbs. (3.4kg) 2.5” (65mm) 1-3 10-15

6 lbs. (2.7kg) 2.5” (65mm) 1-3 10-15

7.5 lbs. (3.4kg) 2.5” (65mm) 1-3 7-12

7.5 lbs. (3.4kg) 2.5” (65mm) 1-3 8-12

3.5-4 lbs

(1.6-1.8kg)

3.5-4 lbs.

(1.6-1.8kg)

12” x 20”

PERFORATED

2.5” (65mm) 1-3 11-15

2.5” (65mm) 1-3 25-35

NUMBER

OF PANS

TIMER

SETTINGS

IN MINUTES

Must be

defrosted

Must be

defrosted

COOKED

SERVINGS

PER PAN

30

3 oz. 85g

25

3 oz. 85g

25

3 oz. 85g

30

3 oz. 85g

30

3 oz. 85g

30

3 oz. 85g

30

4 oz. 115g

50

3 oz. 85g

15

6 oz. 170g

75

3 oz. 85g

50

3 oz. 85g

10

6 oz. 170g

10

6 oz. 170g

25-30

3 oz. 85g

MISCELLANEOUS

Eggs, in Shell 3 doz. 2.5” (65mm) 1-3 9-11

Eggs, out of Shell 4 doz. 2.5” (65mm) 1-3 6-8

Rice 4 lbs. (1.8kg) 2.5” (65mm) 1-2 18-22

Spaghetti 3 lbs. (1.4kg) 4” (102mm) 1-2 18-22

11

36

1 Egg Each

48

1 Egg Each

60-65

3 oz. 85g

40-45

4 oz. 115g

OPERATION

Page 14

Suggested Steam Times

HEIGHT OF

WEIGHT

ITEM

MEAT-POULTRY-FISH

Chicken, Cut up 8 lbs. (3.64kg) 2.5” (65mm) 1-3 20-30

Chicken, 4 lbs., Whole 3 Each 4” (102mm) 1-3 45-50

Fowl, 5 lbs. or more,

Whole

Fish, Fillets 3 lbs. (1.4kg) 2.5” (65mm) 1-3 10-15

Frankfort 5 lbs. (2.3kg) 2.5” (65mm) 1-3 3-5

Hamburgers, 3 oz. 5 lbs. (2.3kg) 2.5” (65mm) 1-3 18-22

Meatballs, 1 oz. * 6 lbs. (2.7kg) 2.5” (65mm) 1-3 20-25

Meatloaf * 15 lbs. (6.8kg) 2.5” (65mm) 1-3 40-50

Pork Chops, 4 oz., Loin

Bone

Sausage, 1.5 oz. 6 lbs. (2.7kg) 2.5” (65mm) 1-3 18-21

Turkey, on Carcass 20-22 lbs. (9-10kg) 2.5” (65mm) 1 2-2.5 Hours

* Raw weight for meatballs and meatloaf includes hamburger and extenders and yiels 2 oz. protein plus extenders or 3 oz.

total portion.

PER PAN

2 Each 4” (102mm) 1-3 50-60

6 lbs. (2.7kg) 2.5” (65mm) 1-3 25-30

12” x 20”

PERFORATED

NUMBER

OF PANS

TIMER

SETTINGS

IN MINUTES

COOKED

SERVINGS

PER PAN

15-20

2 oz. 55g

25-30

2 oz. 55g

20-25

2 oz. 55g

12-15

2 oz. 55g

35-40

2 oz. 55g

20-25

2 oz. 55g

20-25

2 oz. 55g

50-60

2 oz. 55g

24

2 oz. 55g

18-20

2 oz. 55g

50-65

2 oz. 55g

OPERATION

12

Page 15

NOTICE

As a safety precaution, disconnect the power

supply during cleaning or servicing.

CLEANING DAILY

Cleaning at the end of each day, or between cooking cycles if necessary:

1. Turn main POWER switch OFF.

2. Remove pans and racks from compartment and was

in sink.

3. Wash compartment interior with clean water.

4. Use warm soapy water with a cloth or sponge to clean

exposed bead of door gasket, rinse with warm clear

water and wipe with a dry cloth. Do not apply food oils

or petroleum solvents or lubricants directly to the door

gasket or surfaces which touch the door gasket.

5. Remove drain screens from inside compartment

drains. Using a plastic bottle brush and mild detergent, clean inside the drain opening ensuring there is

no food residue or blockage. Clean the drain screen

and replace in its original position.

6. Leave door slightly open when steamer is not in use.

CAUTION

DO NOT USE CLEANING AGENTS THAT ARE

CORROSIVE!

NOTE: Contact the factory, the factory representative or

local service company to preform maintenance

and repairs should the unit malfunction. Refer to

warranty terms and conditions.

WEEKLY CLEANING

1. Clean exterior with a damp cloth and polish with a soft

dry cloth.

2. Use a non-abrasive cleaner to remove discolorations.

3. Clean around burner air mixer and orice if lint has

accumulated. Side cover must be removed to clean

this area.

Cleaning & Deliming

MONTHLY CLEANING

1. Clean around burner air mixers, louvered panels if

grease or lint has accumulated.

NOTE: Following daily and period maintenance proce-

dures will enhance long-life for your equipment.

Climatic conditions, such as salt air may require

more thorough and frequent cleaning, otherwise

the life of the equipment could be adversely affected.

NOTE: Use of cleaning agents that contain chloride, ac-

ids or salts which are corrosive may cause pitting

and corrosion when used over a period of time;

this will reduce the life of the unit. Should pitting or

corrosion occur, this is not covered by warranty.

Follow the recommend cleaning instructions. Use

a mild detergent, warm water and rinse thoroughly.

WARNING

NEVER SPRAY WATER INTO ELECTRIC CONTROLS!

STAINLESS STEEL

To remove normal dirt, grease or product residue from

stainless steel, use ordinary soap and water (with or without detergent) applied with a sponge or cloth. Dry thoroughly with a clean cloth. Never use vinegar or any corrosive cleaner.

To remove grease and food splatters or condensed va-

pors that have baked on the equipment, apply cleanser

to a damp cloth or sponge and rub cleanser on the metal

in the direction of the polishing lines on the metal. Rubbing cleanser as gently as possible in the direction of the

polished lines will not mar the nish of the stainless steel.

NEVER RUB WITH A CIRCULAR MOTION.

Soil and burnt deposits which do not respond to the above

procedure can usually be removed by rubbing the surface with SCOTCH - BRITE scouring pads or STAINLESS

scouring pads. DO NOT USE ORDINARY STEEL WOOL

as any particles left on the surface will rust and further

spoil the appearance of the nish. NEVER USE A WIRE

BRUSH, STEEL SCOURING PADS (EXCEPT STAINLESS), SCRAPPER, FILE OR OTHER STEEL TOOLS.

Surfaces which are marred collect dirt more rapidly and

become more difcult to clean. Marring also increases

the possibility of corrosive attack. Renishing may then

be required.

13

MAINTENANCE

Page 16

Cleaning & Deliming

TO REMOVE HEAT TINT:

Darkened areas sometimes appear on the stainless steel

surface where the area has been subjected to excessive

heat. These darkened areas are caused by thickening of

the protective surface of the stainless steel and are not

harmful. Heat tint can normally be removed by the foregoing, but tint which does not respond to this procedure calls

for a vigorous scouring in the direction of the polish lines

using SCOTCH - BRITE scouring pads or a STAINLESS

scouring pad in combination with a powdered cleanser.

Heat tint action may be lessened by not applying or by

reducing heat to equipment during slack periods.

REMOVAL OF SCALE DEPOSITS

It is recommended that your steamer be delimed once a

month, or more often if necessary.

Should your steamer develop a heavy build-up of lime

scale deposits, use the CLR TREATMENT KIT available

from your authorized servicer.

Before beginning deliming procedures, ensure that the

water is not overowing into the cooking compartment.

DELIMING PROCEDURE:

For Units Equipped with the Feature:

WARNING

READ THE FOLLOWING IN INSTRUCTIONS ON THE

CLR BOTTLE. USE PLASTIC OR RUBBER GLOVES

TO AVOID SKIN CONTACT. IF CLR COMES IN CONTACT WITH SKIN, RINSE WITH CLEAN WATER.

2. Drain steam generator by setting POWER switch to

OFF, set cooking timer to 0.

3. Turn POWER switch to DELIME.

4. Unscrew brass deliming plug on right side of steamer.

5. Insert hose in hole of port.

6. Pour 20 ounces of solution into generator slowly to

avoid spillage.

7. Remove hose. Screw deliming plug back so it seals

tightly.

8. Turn POWER switch on. NOTE: If there is no deliming

plug on the side of the steamer, check with your local

service agency for proper deliming instructions.

9. Allow steamer to remain in ready cycle for 1/2 hour,

then turn POWER switch OFF and allow generator

to drain.

10. Flush cycle. Turn POWER switch to ON. When

READY light comes on, switch POWER to OFF. Re-

peat this step until generator is completely ushed

and drained.

11. Clean exterior and interior. (Refer to STAINLESS

STEEL Section above for cleaning instructions). After

the unit is clean leave compartment door open when

not in use.

12. Steamer is now ready for use or turn off for overnight

shutdown.

MAINTENANCE

14

Loading...

Loading...