Page 1

8

Page 2

Page 3

INTRODUCTION

The Market Forge Direct Connected Steam Jacketed Kettle is a steam operated pressure vessel

designed for cooking. It consists of a welded satin finish of stainless steel (type 304) kettle with

double wall construction, forming a surrounding chamber around the kettle into which steam is

introduced as a source of heat for cooking. Steam input plumbing is equipped with a manual control

valve.

Unit is mounted on stainless steel tubular tri-legs. Each leg is fitted with a four hole adjustable

flange foot for securing the kettle to the floor.

Unit is also equipped with a tangent draw-off valve with heat resistant handle for the removal of

kettle contents and a condensate return assembly that permits removal of excessive condensate. A

two piece, hinged lid covers the kettle opening.

Operation is by direct steam at a minimum of 5 PSI (0.4kg/cm2) and a maximum of 55 PSI

(3.9kg/cm

2

).

1

Page 4

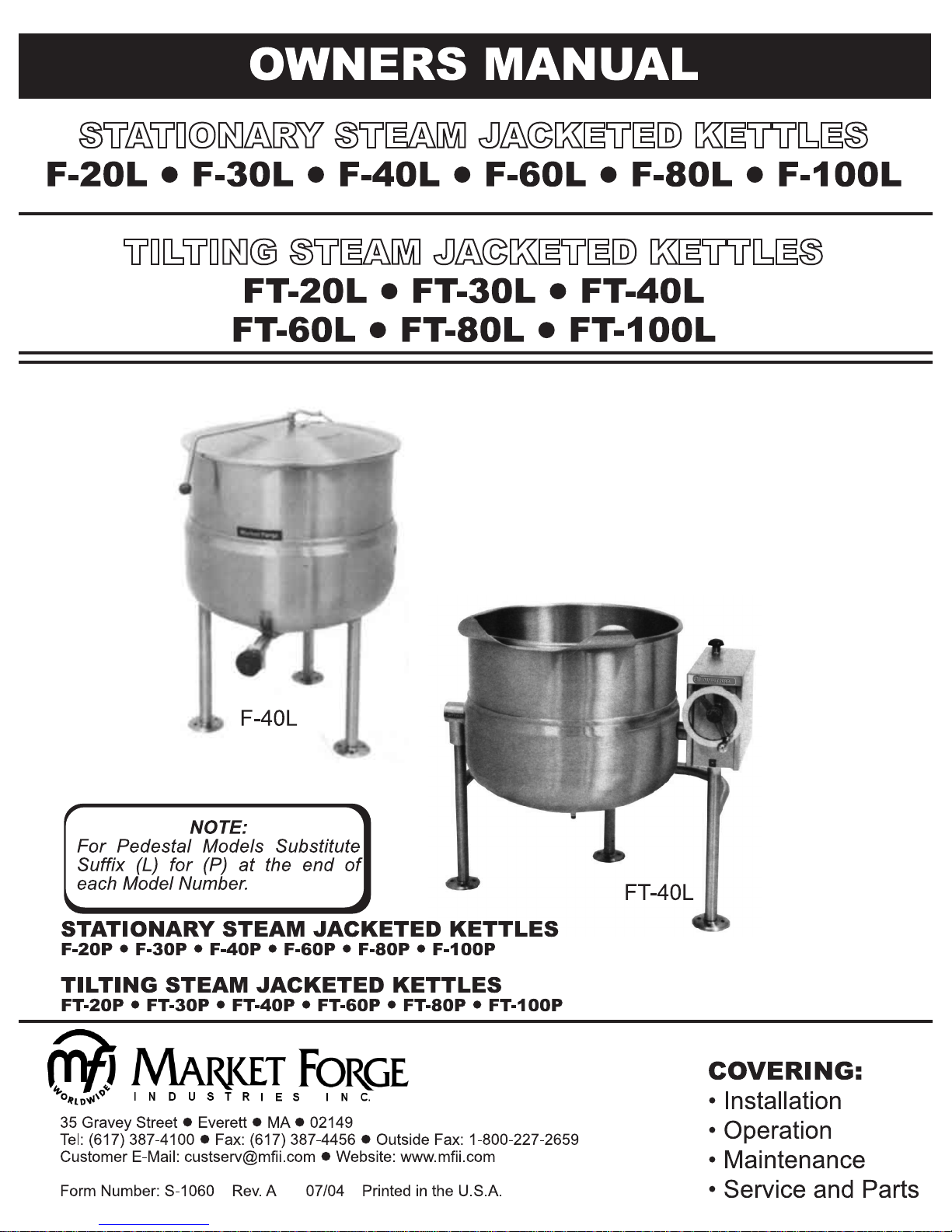

F-20L l F-30L l F-40L l F-60L l F-80L l F-100L

STATIONARY TRI-LEG

D

MODELS: m F-20L m F-30L

DESCRIPTION:

Will be a Market Forge direct connected stationary tri-leg

steam jacketed kettle model:

m F-20L20 Gallon (76 liter) Capacity

m F-30L30 Gallon (114 liter) Capacity

m F-40L40 Gallon (152 liter) Capacity

m F-60L60 Gallon (227 liter) Capacity

m F-80L80 Gallon (303 liter) Capacity

m F-100L100 Gallon (380 liter) Capacity

DIRECT STEAM KETTLE

m F-40L m F-60L

m F-80L m F-100L

JOB NAME: __________________________

ITEM NO.: ___________________________

NO. REQUIRED: ______________________

STEAM FLOW REQUIREMENTS:

34 lbs. (15.5 kg) steam per hour or 1 BHP per 20 gallons

(76 liters) of kettle capacity.

m FT- 20L ............................... ..............................

m FT- 30L ............................... ..............................

m FT- 40L ............................... .............................

m FT- 60L ............................... .............................

m FT- 80L ............................... .............................

m FT- 100L ............................. ..............................

BHP/Hour

1.0

1.5

2.0

3.0

4.0

5.0

(lbs) Steam/Hour

34.5

52.0

69.0

103.5

138.0

172.5

11/04

Spec No. S-2117I

Kettle will be constructed of welded satin finish stainless

steel, type 304. A double wall kettle interior will form a

steam jacket around the lower 2/3 of the kettle. The kettle

bottom will be of elliptical design for superior heat

circulation.

Tri-leg mounting frame of stainless steel pipe will conceal

the steam piping. Each leg will be fitted with a four-hole

adjustable flange foot for securing to the floor.

A sealed stainless steel tilting mechanism will permit the

kettle to tilt forward a full 90

tilting mechanism will be self-locking for positive stop

action. Steam control valve will be mounted on control box.

Unit will include as standard a Steam Control Kit (CKT-1).

OPERATION WILL BE BY:

Direct steam at 15–50 PSI (1.0–3.5 kg/cm2). 1/3 BHP

required per kettle. Over 50 PSI (3.5 kg/cm

reducing valve is required.

o

for complete emptying. The

2

), a pressure

The manufacturer reserves the right to modify materials and specifications without notice

Printed in U.S.A.

OPTIONAL AT EXTRA COST:

m One-piece lift-off stainless steel cover.

m One-piece counterbalanced hinged stainless steel

cover.

m Double pantry faucet with swing spout and mounting

bracket.

m Single pantry faucet with swing spout and mounting

bracket.

m Triple bracket assembly.

m 1 1/2" (38mm) draw-off valve with strainer.

m 2" (50mm) draw-off valve with strainer.

m 3" (76mm) draw-off valve with strainer.

m Steam trap and strainer.

m Steam trap assembly * includes:

* Steam control valve (steam inlet globe valve).

* Steam trap.

* Line strainer.

m Check valve.

m Graduated measuring stick.

m Wall models (consult factory).

m Type 316 stainless steel liner (for high acid content).

An Employee Owned Company

FOOD SERVICE EQUIPMENT

Stationary Tri-leg Kettle

2

Page 5

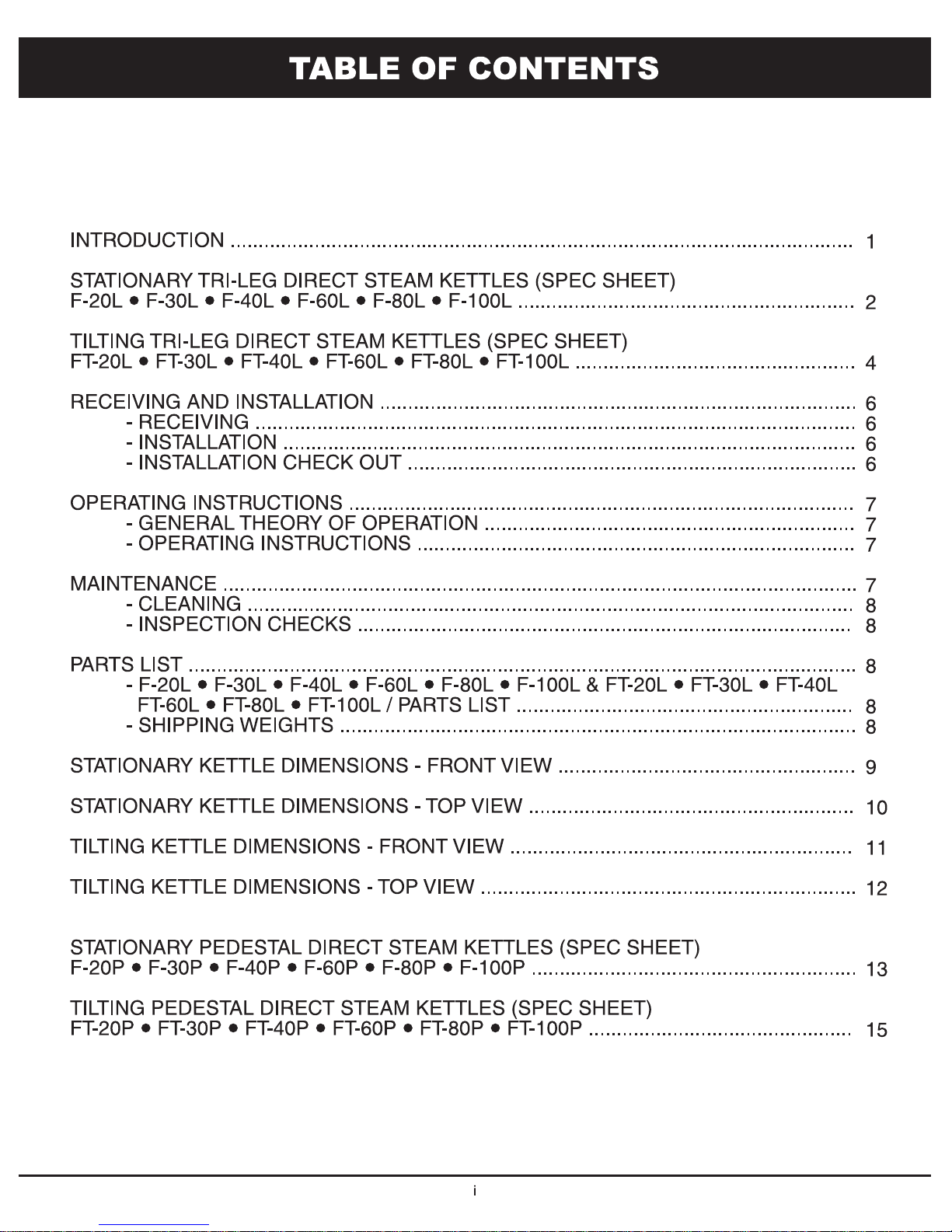

F-20L l F-30L l F-40L l F-60L l F-80L l F-100L

F-80L

80 Gallon inches 33 28 42.5 34.75

303 liter mm 838 711 1030 118 5

F-20L

F-30L

F-40L

F-60L

D

STATIONARY TRI-LEG

DETAILS & DIMENSION

DIRECT STEAM KETTLE

MODEL CAPACITY A B C D E F G H J K L

F-100L

20 Gallon inches 21 18 37 22.75 16.875 12 16.5 41 17.5 16.375

76 liter mm 533 457 940 578 429 305 419 1041 445 416

30 Gallon inches 24 20 37 25.75 14.875 12.75 16.5 42.5 20.5 14.375

114 liter mm 610 508 940 654 378 324 419 1080 521 365

40 Gallon inches 26 22.5 37 27.75 12.375 13.25 17 45 22.5 11.875

152 liter mm 660 572 940 705 314 337 432 1143 572 302

60 Gallon inches 29.5 26 42.5 31.25 12.375 13.75 19 48.5 25.75 11.875

227 liter mm 749 660 1030 794 314

80 Gallon inches 33 28 42.5 45.75 14.5 20.5 52

303 liter mm 838 711 1030 863 368 521 1334

80 Gallon inches 35.5 30 44.25 37.25 15.25 22 31.75 31.75 11.875

303 liter mm 802 762 1130 946 387 559 806 806 302

Direct Steam

S

**CR

12.375

314

12.375

314

Steam Supply - 3/4" (19mm) IPS at 15-35 PSI (1.0-2.5 kg/cm2).

Condensate Return - 1/2" (13mm) IPS.

349 483 1232 654 302

29.25

SERVICE CONNECTIONS

11.875

743

302

59.5

1151

62.5

1588

63.5

1613

71

1803

77

1956

83

2108

** Optional at extra cost.

Spec No. S-2117I

11/04

Stationary Tri-leg Kettle

*It is our policy to build equipment which is design certified by U.L., A.S.M.E., N.S.F. and C.S.A. However, a continuing program of product improvement makes it necessary

FOOD SERVICE EQUIPMENT

to submit new models to the agencies as they are developed and consequently not all models bear the appropriate agency labels at all times.

Printed in U.S.A.

An Employee Owned Company

3

Page 6

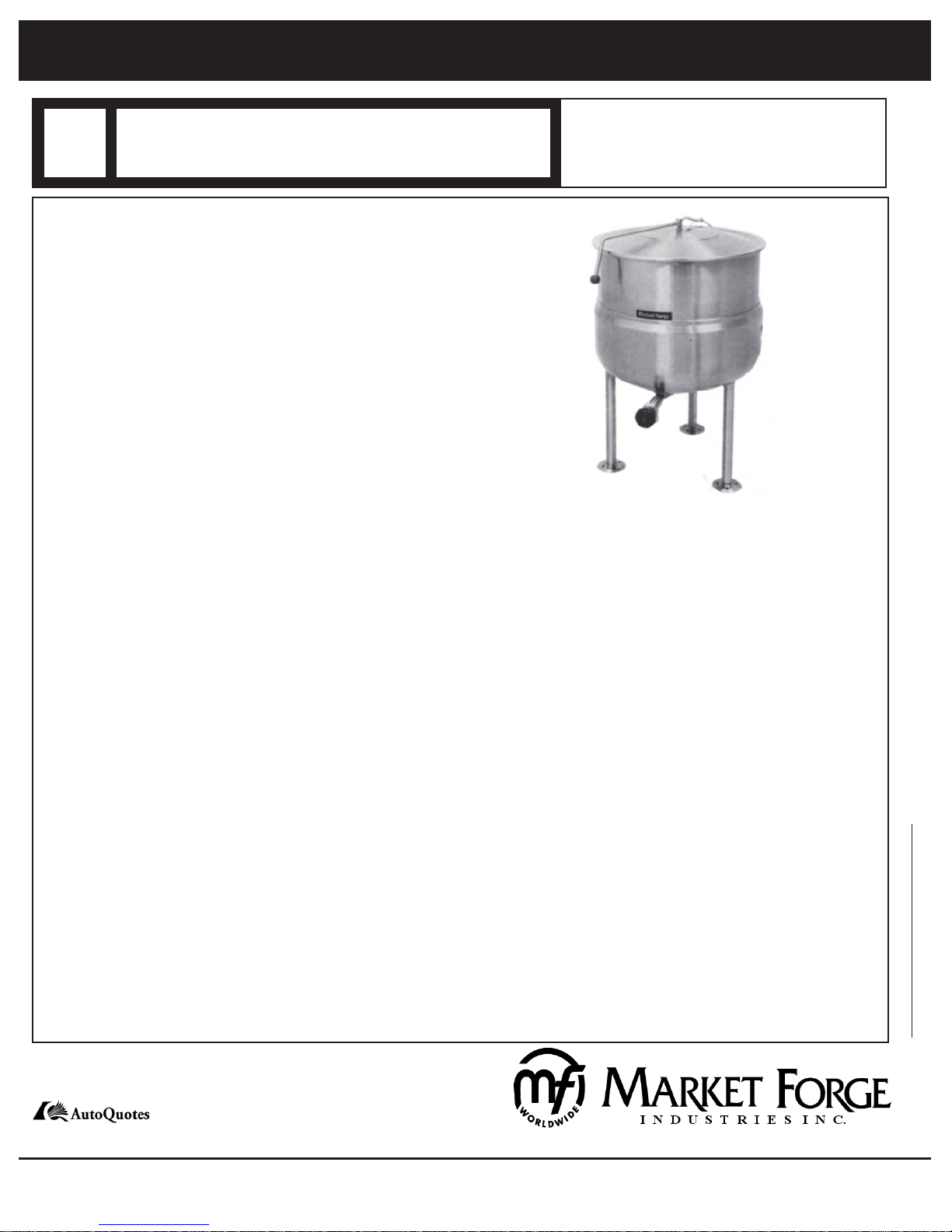

FT-20L l FT-30L l FT-40L l FT-60L l FT-80L l FT-100L

TILTING TRI-LEG

D

MODELS: m FT- 20L m FT-60L

m FT-30L m FT-80L

m FT-40L m FT-100L

DESCRIPTION: Will be a Market Forge Direct Steam

Connected Tilting Tri-leg Steam Jacketed Kettle.

m FT- 20L20 Gallon (76 liter) Capacity

m FT- 30L30 Gallon (114 liter) Capacity

m FT- 40L40 Gallon (152 liter) Capacity

m FT- 60L60 Gallon (227 liter) Capacity

m FT- 80L80 Gallon (303 liter) Capacity

m FT- 100L100 Gallon (380 liter) Capacity

Kettle will be constructed of welded satin finish stainless

steel, type 304. A double wall kettle interior will form a

steam jacket around the lower 2/3 of the kettle. The kettle

bottom will be of elliptical design for superior heat

circulation.

Tri-leg mounting frame of stainless steel pipe will conceal

the steam piping. Each leg will be fitted with a four-hole

adjustable flange foot for securing to the floor.

DIRECT STEAM KETTLE

JOB NAME: __________________________

ITEM NO.: ___________________________

NO. REQUIRED: ______________________

11/04

Spec No. S-2116I

A sealed stainless steel tilting mechanism will permit the

kettle to tilt forward a full 90

tilting mechanism will be self-locking for positive stop

action. Steam control valve will be mounted on control box.

Unit will include as standard a Steam Control Kit (CKT-1).

OPERATION WILL BE BY:

Direct steam at 15-35 PSI (1.0-2.5 kg/cm2).

m Over 35 PSI (2.5 kg/cm2), a pressure reducing valve

is required.

STEAM FLOW REQUIREMENTS:

34 lbs. (15.5 kg) steam per hour or 1 BHP per 20 gallons

(76 liters) of kettle capacity.

m FT- 20L ............................... ..............................

m FT- 30L ............................... ..............................

m FT- 40L ............................... .............................

m FT- 60L ............................... .............................

m FT- 80L ............................... .............................

m FT- 100L ............................. .............................

o

for complete emptying. The

BHP/Hour

1.0

1.5

2.0

3.0

4.0

5.0

The manufacturer reserves the right to modify materials and specifications without notice

(lbs) Steam/Hour

34.5

52.0

69.0

103.5

138.0

172.5

OPTIONAL AT EXTRA COST:

m One-piece lift-off stainless steel cover.

m One-piece counterbalanced hinged stainless steel

cover.

m Double pantry faucet with swing spout and mounting

bracket.

m Single pantry faucet with swing spout and mounting

bracket.

m Triple bracket assembly.

m 1 1/2" (38mm) draw-off valve with strainer.

m 2" (50mm) draw-off valve with strainer.

m 3" (76mm) draw-off valve with strainer.

m Steam trap and strainer.

m Steam trap assembly * includes:

* Steam control valve (steam inlet globe valve).

* Steam trap.

* Line strainer.

m Check valve.

m Graduated measuring stick.

m Wall models (consult factory).

m Type 316 stainless steel liner (for high acid content).

FOOD SERVICE EQUIPMENT

Tilting Tri-leg Kettle

Printed in U.S.A.

An Employee Owned Company

4

Page 7

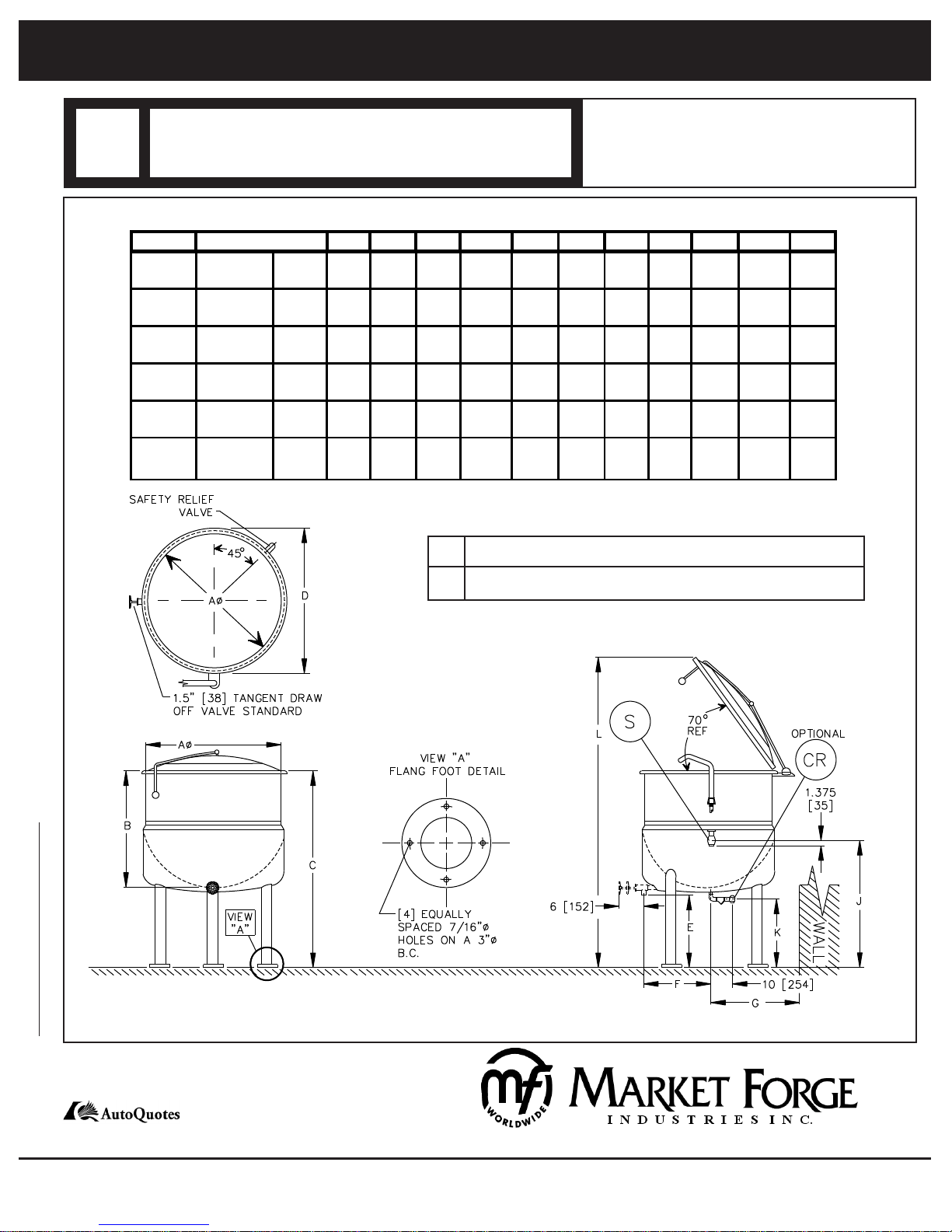

FT-20L l FT-30L l FT-40L l FT-60L l FT-80L l FT-100L

FT-80L

80 Gallon inches 33 28 42.5 46.75

303 liter mm 838 711 1030 118 1 5

FT-20L

FT-30L

FT-40L

FT-60L

TILTING TRI-LEG

D

MODEL CAPACITY A B C D E F G H J K L M

FT-100L

DIRECT STEAM KETTLE

20 Gallon inches 21 18 37 34.5 28.5 22 28.5 41 15.25 12 16.875 59.5

76 liter mm 533 457 940 885 724 559 724 1041 387 305 440 1512

30 Gallon inches 24 20 37 37.75 31.5 20.75 30 42.5 13.25 12.5 14.875 62.5

114 liter mm 610 508 940 960 800 527 762 1080 337 317 390 1588

40 Gallon inches 26 22.5 37 39.75 33.5 20.25 32 45 10.75 13 12.375 64

152 liter mm 660 572 940 1010 850 514 813 1143 273 330 314 1626

60 Gallon inches 29.5 26 42.5 43.25 37 18.75 35.75 48.5 10.25 13.75 12.375 71.5

227 liter mm 749 660 1030 1100 940 476 910 1232 260 350 314 1816

80 Gallon inches 33 28 42.5 45.75 40.5 20 40 52

303 liter mm 838 711 1030 1185 1030 508 1016 1334

80 Gallon inches 35.5 30 44.5 48.5 42.25 22 42 55 8.5 15.5 12.375 83

303 liter mm 802 762 1130 1232 1073 559 1066 1397 217 390 314 2108

SERVICE CONNECTIONS

Direct Steam

Steam Supply - 3/4" (19mm) IPS at 15-35 PSI (1.0-2.5 kg/cm2).

S

Condensate Return - 1/2" (13mm) IPS.

**CR

DETAILS & DIMENSION

9.75

14.5 12.375 76

248

368 314 1930

** Optional at extra cost.

Spec No. S-2116I

11/04

Tilting Tri-leg Kettle

*It is our policy to build equipment which is design certified by U.L., A.S.M.E., N.S.F. and C.S.A. However, a continuing program of product improvement makes it necessary

FOOD SERVICE EQUIPMENT

to submit new models to the agencies as they are developed and consequently not all models bear the appropriate agency labels at all times.

Printed in U.S.A.

An Employee Owned Company

5

Page 8

RECEIVING AND INSTALLATION

RECEIVING:

The kettle is shipped strapped and bolted to a skid and covered by a carton which is nailed to the skid. The

packing materials must be carefully removed prior to installation. Inspect each unit. If any damage has

been incurred during shipment, report same within two days to both the carrier and Market Forge Ind., Inc.

INSTALLATION:

1. Select a location to provided drange directly below the draw-off valve.

2. Mark hole location through flange adjustable feet.

3. On marked hole locations, drill holes and insert expansion shields to accommodate 5/16" size lag bolts,

4 bolts per foot. (see fig. 1 detail - leg flange diagram).

4. Level unit in proposed location by turning adjustable flange feet.

5. Bolt down unit and seal with Silastic or other equivalent

sealing compound.

NOTE: Sealant must be applied not only to bolt heads, but also

around flange feet making contact with the floor surface.

fig. 1

This aplication fulfills NSF Requirements.

6. Connect steam line to kettle. Ensure that line is clean and checked

for foreign matter and that a steam control valve strainer is fairly convenient to kettle.

7. Connect kettle condensate return line to drain.

WARNING:

If incoming steam pressure is greater than kettle maximum operating pressure, then a pressure reducing

valve MUST be installed in the steam line.

A steam line pressure gauge is also recommended to determine the actual amount of steam entering

the kettle.

NOTE: If large amounts of water accumulate in steam line, install one or more ball float traps in the line to

eliminate water.

(4) Equally Spaced 7/16"E

Holes on a 3"E B.C.

INSTALLATION CHECK OUT:

1. Fill kettle part way with water.

2. Turn steam supply valve on slowly.

3. Pull safety vavle lever. Observe that steam escapes freely.

Stay clear of exhaust from valve outlet when checking safety valve.

4. Observe that water comes to a boil in the kettle. Allow approximately 2 to 5 minutes per gallon of water.

5. Close steam supply valve.

WARNING:

6

Page 9

OPERATING INSTRUCTIONS

GENERAL THEORY OF OPERATION:

The Market Forge Series (F-20L, F-30L, F-40L, F-60L F-80L and F-100L) and (FT-20L, FT-30L, FT-40L,

FT-60L FT-80L and FT-100L) kettles are tri-leg mounted, stainless steel jacketed kettles. The inner liner is

jacketed by an outer shell which creates a space between the two walls and cooking is achieved by allowing

steam flow within this space.

The steam flowing in the space between the shells condenses on the cooler inner shell wall and releases

heat through the wall to the food in the kettle. The condensate drains to the kettle bottom and is released

through a steam trap without any loss or variation on steam pressure. The amount of steam allowed to flow

the jacket controls that kettle heat.

OPERATING INSTRUCTIONS:

1. Ensure that steam supply to kettle is operating.

2. Ensure that draw-off valve is tightly closed.

3. Place perforated strainer in kettle if liquid is to be drained.

4. Fill kettle with product to desired level.

5. Turn steam control valve on (counterclockwise) to full open position.

6. When product has reached desired temperature, regulate heat as needed by turning valve clockwise.

7. When product is cooked, close steam control valve and remove product from kettle immediately to prevent

overcooking.

8. Clean kettle immediately. If unable to thoroughly clean kettle immediately, fil kettle wit warm water and mild

detergent. Allow kettle to soak until thorough cleaning can be completed.

MAINTENANCE

CLEANING:

As with cleaning fod soil from any clockware, an important part of kettle cleaning is to prevent foods from

drying on. For ths reason, cleaning should be completed immediately after food is removed from kettle. If

unable to thoroughly clean kettle immediately, fil kettle wit warm water and mild detergent. Allow kettle to

soak until thorough cleaning can be completed.

1. Wash kettle and cover with mild detergent and lukewarm water, using a nylon brush. If food is stuck to

surface use a little heat to loosen the food.

CAUTION:

NEVER scrape the inside of the kettle with metal tools, steel scouring pads or abrasive cleaners. Scratches

will result in damage and inappropriate appearance to the kettle and make it harder to clean and maintain ina

sanitary condition.

2. Drain kettle and remove disc in draw-off valve. Rinse and dry.

3. Disassemble and clean draw-off valve as follows:

a. Turn the handle counterclockwise.

c. Remove valve carefully.

e. Rinse and dry.

b. Loosen hex nut on end of handle by turning it

counterclockwise.

d. Wash draw-off area thoroughly using nylon brush.

f. Reassemble by reversing these steps.

7

Page 10

MAINTENANCE

INSPECTION CHECKS:

1. Check safety valve daily. With steam supply valve open, pull safety valve control lever. Observe that steam

escapes.

WARNING:

Do not stand infront of the valve outlet when checking safety valve.

2. Inspect operating valve occasionally to ensure that the packings and valve seats are in proper condition.

3. Check and clean line strainer in steam trap assembly as required.

PARTS LIST

ITEM

1

2

4

5

6

N/A

8

N/A

N/A

N/A

7

PART NO.

97-5008

10-4928

97-5063

08-0008

95-5051

97-5052

97-5053

97-5054

97-5055

SPECIFY CAPACITY

97-5131

97-5132

97-5028

97-5133

97-5134

SPECIFY CAPACITY

97-5029

97-5030

97-5031

97-5105

97-5106

97-5113

97-5032

DESCRIPTION

KNOB, HANDLE

VALVE, DRAW-OFF

l

1.5"

l

2"

l

3"

COVER HINGED: l 20 GALLON - (1) PIECE (F OR FT-20L)

l

30 GALLON - (1) PIECE (F OR FT-30L)

l

40 GALLON - (1) PIECE (F OR FT-40L)

l

60 GALLON - (1) PIECE (F OR FT-60L)

l

80 GALLON - (1) PIECE (F OR FT-80L)

l

100 GALLON - (1) PIECE (F OR FT-100L)

l

20 GALLON - (2) PIECE (F OR FT-20L)

l

30 GALLON - (2) PIECE (F OR FT-30L)

l

40 GALLON - (2) PIECE (F OR FT-40L)

l

60 GALLON - (2) PIECE (F OR FT-60L)

l

80 GALLON - (2) PIECE (F OR FT-80L)

l

100 GALLON - (2) PIECE (F OR FT-100L)

RETURN, CONDENSATE (STEAM TRAP ASSEMBLY - ERWEL)

VALVE, STEAM CONTROL (DAHL)

BRUSH, NYLON (NOT SHOWN)

STRAINER, PERFORATED

l

1.5"

l

2"

l

3"

FOOT, FLANGE

SHIPPING WEIGHTS

MODEL:

F-20L

F-30L

F-40L

F-60L

F-80L

F-100L

FT-20L

FT-30L

FT-40L

FT-60L

FT-80L

FT-100L

LBS.:

225

245

270

295

320

345

255

275

300

315

325

350

8

Page 11

PARTS LIST

STATIONARY KETTLE DIMENSIONS - FRONT VIEW

F-20L - 59.5 [1151]

F-30L - 62.5 [1588]

F-40L - 63.5 [1613]

F-60L - 71 [1803]

F-80L - 77 [1956]

F-100L - 83 [2108]

F-20L - 18 [457]

F-30L - 20 [508]

F-40L - 22.5 [572]

F-60L - 26 [660]

F-80L - 28 [711]

F-100L - 30 [762]

F-20L - 21 [533]

F-30L - 24 [610]

F-40L - 26 [660]

F-60L - 29.5 [749]

F-80L - 33 [838]

F-100L - 35.5 [802]

F-20L - 37 [940]

F-30L - 37 [940]

F-40L - 37 [940]

F-60L - 42.5 [1030]

F-80L - 42.5 [1030]

F-100L - 42.5 [1030]

F-20L - 21.25 [540]

F-30L - 21.25 [540]

F-40L - 21.25 [540]

F-60L - 23.25 [590]

F-80L - 24.5 [622]

F-100L - 25.5 [648]

F-20L - 16.375 [416]

F-30L - 14.375 [365]

F-40L - 11.875 [302]

F-60L - 11.875 [302]

F-80L - 11.875 [302]

F-100L - 11.875 [302]

F-20L - 17.5 [445]

F-30L - 20.5 [521]

F-40L - 22.5 [572]

F-60L - 25.75 [654]

F-80L - 29.25 [743]

F-100L - 31.75 [806]

F-20L - 16.875 [429]

F-30L - 14.875 [378]

F-40L - 12.375 [314]

F-60L - 12.375 [314]

F-80L - 12.375 [314]

F-100L - 12.375 [314]

fig. 2 (F) FRONT

9

Page 12

PARTS LIST

STATIONARY KETTLE DIMENSIONS - TOP VIEW

WALL

F-20L - 16.5 [419]

F-30L - 16.5 [419]

F-40L - 17 [432]

F-60L - 19 [483]

F-80L - 20.5 [521]

F-100L - 22 [559]

F-20L - 22.75 [578]

F-30L - 25.75 [654]

F-40L - 27.75 [705]

F-60L - 31.25 [794]

F-80L - 45.75 [863]

F-100L - 37.25 [946]

F-20L - 5.75 [146]

F-30L - 6.5 [165]

F-40L - 6.875 [175]

F-60L - 7.75 [197]

F-80L - 8.5 [216]

F-100L - 9.25 [235]

F-20L - 9.75 [248]

F-30L - 11 [279]

F-40L - 11.75 [298]

F-60L - 13.25 [337]

F-80L - 14.75 [375]

F-100L - 15.75 [400]

F-20L - 12 [305]

F-30L - 12.75 [324]

F-40L - 13.25 [337]

F-60L - 13.75 [349]

F-80L - 14.5 [368]

F-100L - 15.25 [387]

8 [203]

MAX.

fig. 3 (F) TOP

10

Page 13

PARTS LIST

TILTING KETTLE DIMENSIONS - FRONT VIEW

F-20L - 59.5 [1512]

F-30L - 62.5 [1588]

F-40L - 64 [1626]

F-60L - 71.5 [1816]

F-80L - 76 [1930]

F-100L - 83 [2108]

F-20L - 28.5 [724]

F-30L - 31.5 [800]

F-40L - 33.5 [850]

F-60L - 37 [940]

F-80L - 40.5 [1030]

F-100L - 42.25 [1073]

F-20L - 18 [457]

F-30L - 20 [508]

F-40L - 22.5 [572]

F-60L - 26 [660]

F-80L - 28 [711]

F-100L - 30 [762]

F-20L - 37 [940]

F-30L - 37 [940]

F-40L - 37 [940]

F-60L - 42.5 [1030]

F-80L - 42.5 [1030]

F-100L - 44.5 [1130]

F-20L - 34.5 [885]

F-30L - 37.75 [960]

F-40L - 39.75 [1010]

F-60L - 43.25 [1100]

F-80L - 45.75 [1185]

F-100L - 48.5 [1232]

fig. 3 (FT) FRONT

11

Page 14

PARTS LIST

TILTING KETTLE DIMENSIONS - TOP VIEW

F-20L - 28.5 [724]

F-30L - 30 [762]

F-40L - 32 [813]

F-60L - 35.75 [910]

F-80L - 40 [1016]

F-100L - 42 [1066]

fig. 3 (FT) TOP

12

Page 15

Page 16

MODEL CAPACITY A B C D E F G H J K L M

FT-20P 20 Gallon inches 21 18 37 22.75 17 11.75 15.5 18.75 26 13.5 59.5 17.25

76 liter mm 533 457 940 578 432 298 394 476 660 419 1511 438

FT-30P 30 Gallon inches 24 20 37 25.75 15 12.5 16.5 16.75 25.5 14.5 62.5 17.25

114 liter mm 610 508 940 654 381 318 419 424 948 368 1588 438

FT-40P 40 Gallon inches 26 22.5 37 27.75 12.5 13 17.5 14.25 24 12 63.5 17.25

152 liter mm 660 571 940 704 318 330 445 362 610 305 1613 438

FT-60P 60 Gallon inches 30 25.5 40.5 31.25 12.5 13.5 19.5 14 24.75 12 71 17.25

227 liter mm 762 648 1029 794 318 343 495 356 629 305 1803 438

FT-80P 80 Gallon inches 33 28 42.5 34.75 12.5 15.25 21 14 25 12 77 19.25

303 liter mm 838 711 1080 883 318 362 533 356 635 305 1956 489

FT-100P 100 Gallon inches 36 30 44.5 37.25 12.5 15 22.5 14 26.75 12 83 19.25

380 liter mm 914 762 1130 946 318 381 572 356 679 305 2108 489

14

Page 17

An Employee Owned Company

Page 18

MODEL CAPACITY A B C D E F G H J K L M N

20 Gallon inches 21 18 37 33.75. 15 20 13.5 41 15.25 20.5 59.5 17.25 11.25

76 liter mm 533 457 940 857 381 508 343 1041 387 521 1511 438 286

30 Gallon inches 24 20 37 36.75 16.25 21.75 14 43 13.25 20 62.5 17.25 11.75

114 liter mm 610 508 940 933 413 553 356 1092 337 508 1587 438 298

40 Gallon inches 26 22.5 37 38.75 17.25 22.75 15.5 45 10.75 18.5 63.5 17.25 13.25

152 liter mm 660 572 940 984 438 578 394 1143 273 470 1613 438 337

60 Gallon inches 29.5 26 42.5 42.5 19 24.5 17.5 48 10.25 19.25 71.5 17.25 16

227 liter mm 749 660 1030 1073 483 622 445 1219 260 489 1816 438 406

80 Gallon inches 33 28 42.5 45.75 20.625 26 19 52 9.75 20.5 76 19.25 16.75

303 liter mm 838 711 1030 1162 524 660 1483 1067 248 521 1930 489 425

FT-80P

FT-20P

FT-30P

FT-40P

FT-60P

16

Loading...

Loading...