Page 1

ETP-5E & ETP-10E

ECO-TECH® PLUS

ELECTRIC CONVECTION STEAMER

PARTS AND SERVICE MANUAL

EFFECTIVE NOVEMBER 1, 2016

The Company reserves the right to make substitution in the event that items specied are not available.

ERRORS: Descriptive and/or typographic errors are subject to correction.

44 Lakeside Avenue, Burlington, Vermont 05401 USA Telephone: (802) 658-6600 Fax: (802) 860-3732

Superseding All Previous Parts Lists.

MARKET FORGE INDUSTRIES

www.mi.com

P/N 14-0283 Rev B (10/16)

Page 2

TABLE OF CONTENTS

GENERAL TROUBLSHOOTING GUIDE .................................................3

ELECTRICAL FAULT ISOLATION GUIDE ................................................5

TROUBLESHOOTING ..................................................................6

ADJUSTMENTS .......................................................................7

WIRING DIAGRAMS ...................................................................8

ILLUSTRATED PARTS LIST

STEAMER EXPLODED VIEW ......................................................... 14

COMPONENT PANEL ................................................................ 19

CABINET ASSEMBLY ................................................................ 20

ALTERNATE FILTER SYSTEM ........................................................ 23

NOVEMBER 1, 2016 2 ETP-5E & ETP-10E

Page 3

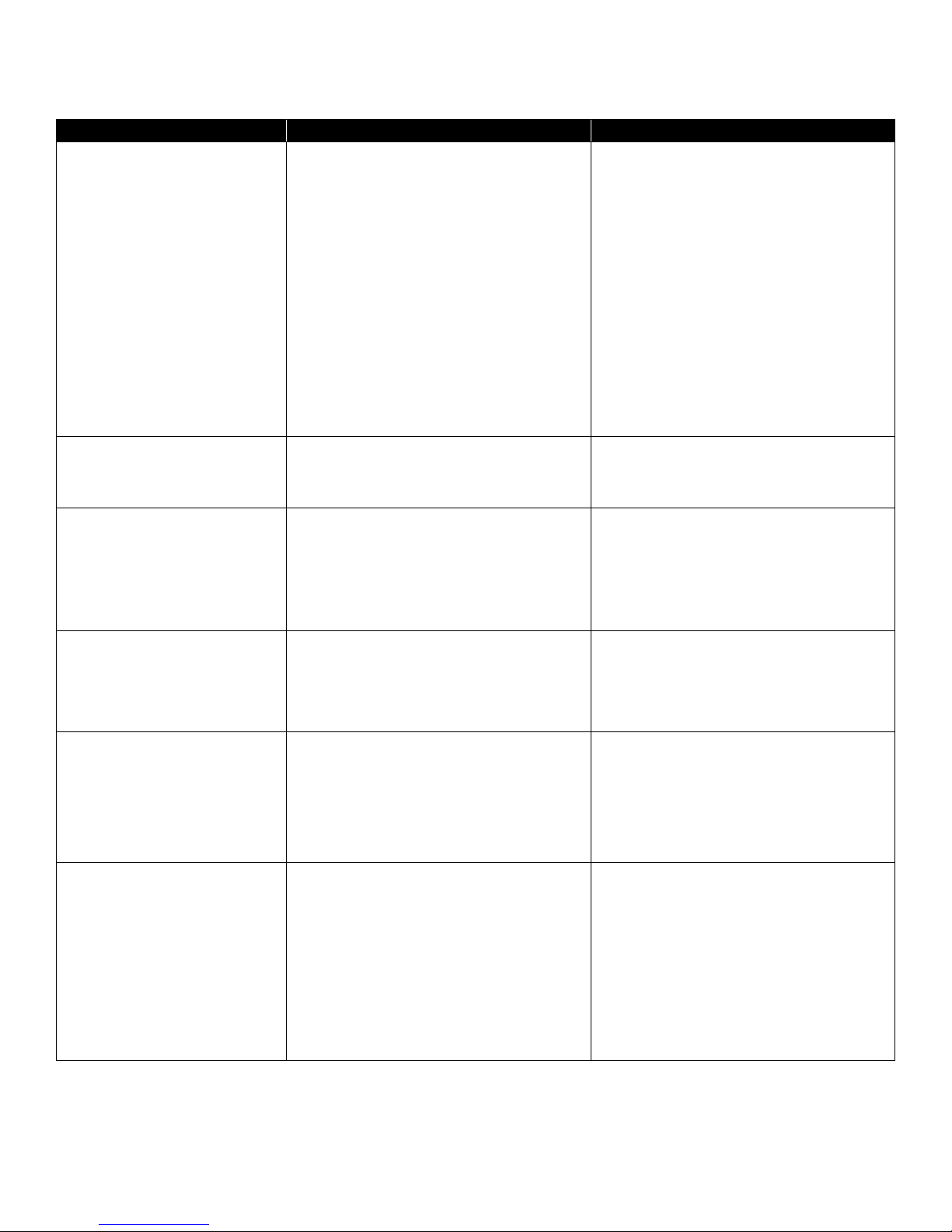

GENERAL TROUBLSHOOTING GUIDE

PROBLEM PROBABLE CAUSE REMEDY

Cooking indicator light fails to

light with Timer set.

Steam fails to enter cooking

compartment with cooking indicator light on.

Steam enters compartment

continuously without the cooking or ready light on.

a. Main power circuit breaker tripped.

b. Door interlock switch contacts not

closed.

c. Door interlock switch faulty.

d. Indicator light burned out.

e. Faulty timer contacts.

f. Faulty wiring.

a. Faulty wiring. a. Inspect condition of wire and tight-

a. Standby thermostat not set cor-

rectly.

b. Faulty thermostatic switch.

c. HOLD set on timer.

a. Locate external circuit breaker for

incoming power and place in ON

position.

b. Shut cooker door to close switch

contacts. Check alignment of door

with switch

c. Replace switch.

d. Replace light.

e. Replace timer.

f. Inspect condition of wire and tight-

ness of all connections. Correct as

needed.

ness of all connections. Correct as

needed.

a. Adjust the thermostat lower.

b. Replace thermostat.

c. Rotate timer knob to ‘OFF’ position.

Timer dial not turning. a. Faulty timer motor.

b. Faulty wiring.

Buzzer fails to sound at end of

timer setting.

Steam ows continuously

from drain line with cooker in

operation.

a. Timer contacts faulty.

b. Buzzer faulty.

c. Faulty wiring.

a. Cold water not connected.

b. Faulty cooling valve.

c. Faulty wiring.

d. Faulty or misadjusted operating.

a. Replace timer.

b. Inspect condition of wire and tight-

ness of all connections. Correct as

needed.

a. Replace timer.

b. Replace buzzer.

c. Inspect condition of wire and tight-

ness of all connections. Correct as

needed.

a. Turn on external shutoff valve.

b. Replace cooling valve.

c. Inspect condition of wire and tight-

ness of all connections. Correct as

needed.

d. Inspect operation of pressure switch

and setting and operation of time

delay relay.

Page 4

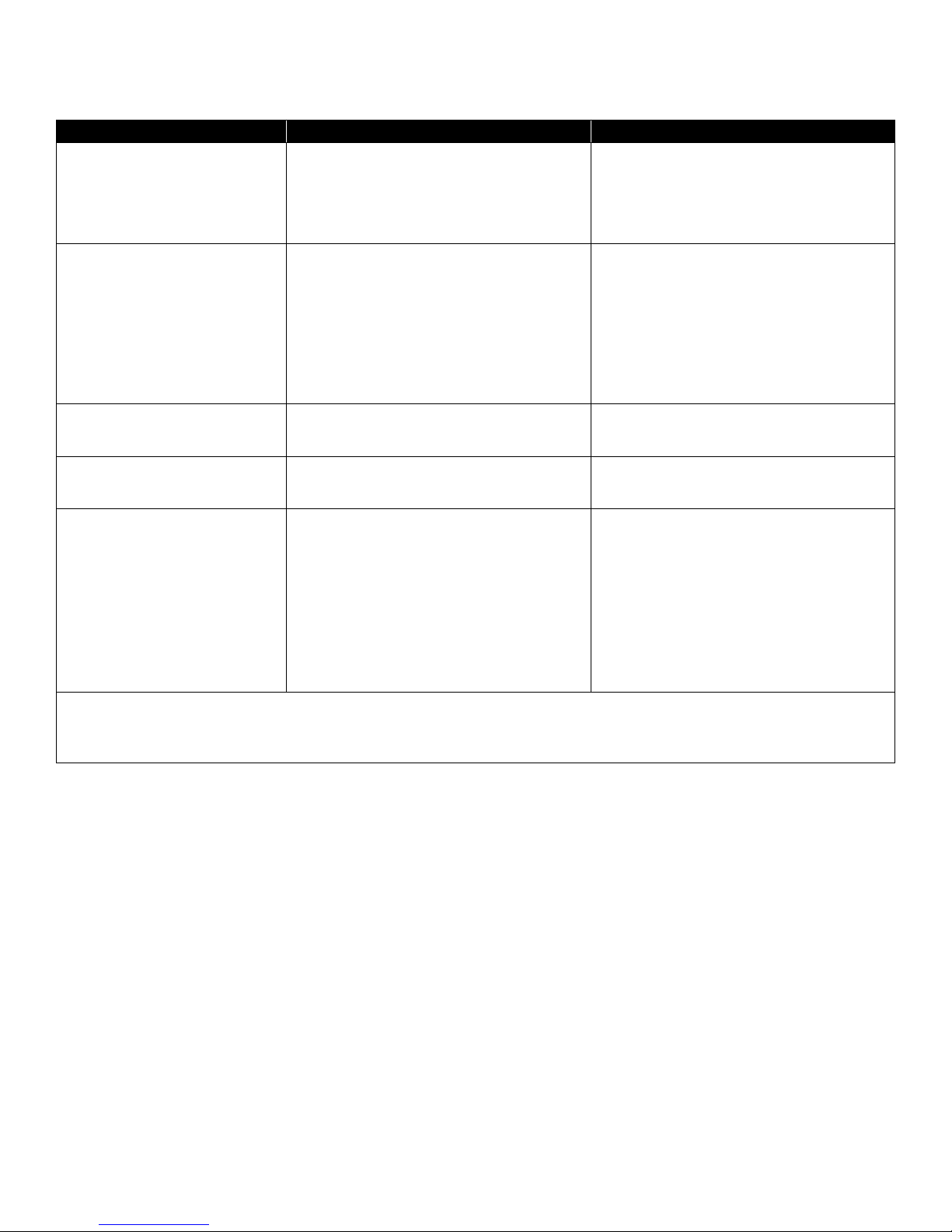

GENERAL TROUBLSHOOTING GUIDE

PROBLEM PROBABLE CAUSE REMEDY

Door leaks. a. Damaged door gasket.

b. Clogged compartment drain or

plumbing.

Water ows into cooking compartment.

Water accumulates in compartment.

Water ows into drain during

shutdown.

Water not being supplied to

Generator.

a. Level control has failed.

b. Water has very high resistance.

(i.e. low mineral content or Reverse

Osmosis Water).

c. Scale build-up on probe.

d. Water ll solenoid valve.

a. Plugged compartment drain. a. Remove screen and clean drain

a. Cooling valve does not close. a. Check valve for foreign material or

a. Water supply off.

b. Supply water pressure too low.

c. Defective water solenoid valve.

a. Check gasket for cuts and replace if

necessary.

b. Remove screen and clean drain line

or plumbing.

a. Replace.

b. Replace level control with high sen-

sitivity control.

c. Clean all probes in steam generator.

d. Plugged, defective, clean or re-

place.

line.

damage.

a. Check incoming water valve is on.

b. Call supply agency.

c. Replace or clean.

d. Level Probe shorted.

e. Defective water level control.

f. Drain valve is open.

NOTE: THESE PROBLEMS ARE AN INDICATION OF SEVERE WATER CONDITIONS WHICH SHOULD BE CORRECTED IMMEDIATELY TO AVOID DAMAGE TO THE COMPONENTS AND PERFORMANCE OF THE STEAMER.

CALL YOUR SERVICE AGENCY FOR ASSISTANCE.

d. Check and correct.

e. Replace.

f. Check valve, clean or replace.

Page 5

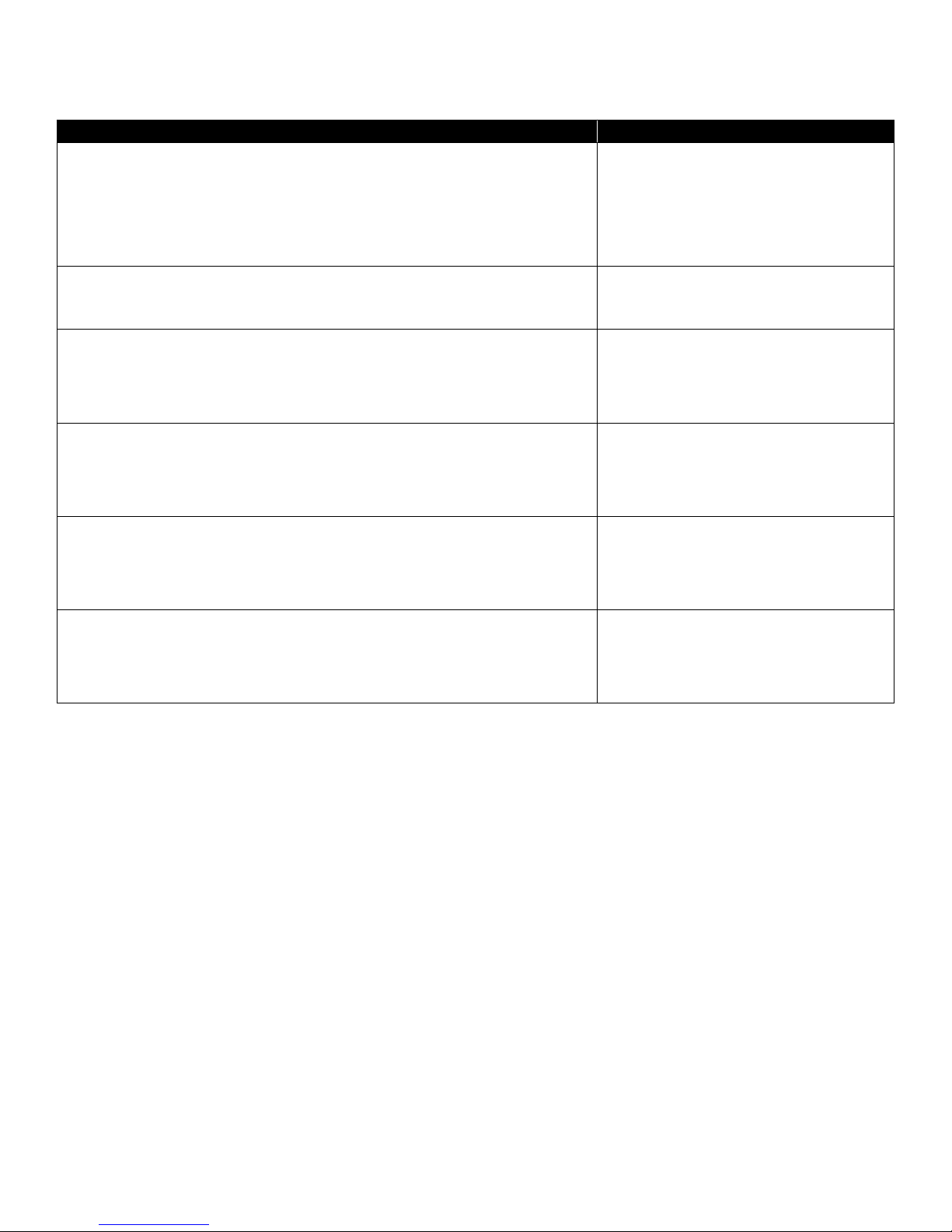

ELECTRICAL FAULT ISOLATION GUIDE

FAILURE FAULT LOCATION

1. WILL NOT OPERATE IN EITHER HOLD OR 60-MINUTE TIMER POSITIONS.

2. OPERATING IN HOLD POSITION BUT NOT IN 60-MINUTE TIMER

POSITION.

3. OPERATES IN 60-MINUTE TIMER POSITION BUT NOT IN HOLD POSITION.

4. WITH COOK INDICATOR LIGHT ON AND STEAM ENTERING THE

CAVITY, TIMER DIAL FAILS TO TURN.

5. BUZZER FAILS TO SOUND AT END OF 60-MINUTE TIMER MODE. a. 60-Minute timer contacts

a. Incoming power

b. Timer

c. Door interlock switch

d. Wiring

a. 60-Minute timer

b. Wiring

a. Timer

b. Wiring

c. Hold thermostat.

a. Hold position set on timer.

b. Timer motor

c. Wiring

b. Buzzer

c. Wiring

6. STEAM FLOWS CONTINUOUSLY FROM BOILER DRAIN LINE. a. Cooling valve needs replacing

b. Wiring

c. Thermostat faulty.

Page 6

TROUBLESHOOTING

TIMER MOTOR

A defective timer motor will cause continuous operation in

the TIME mode, with the timer dial failing to return to the

“0 - Minute” position.

To conrm timer motor condition, proceed as follows:

1. Carefully check motor wire leads and tighten loose

connections.

2. Turn on power to the steamer.

3. Set timer dial (any setting beyond “0 - Minute”). If

operation is correct, the motor will turn the dial toward

“0 - Minute”. If the motor fails to operate, it is defective and the entire timer must be replaced.

4. Shut off power to the cooker

DOOR INTERLOCK SWITCH

Malfunction of the cooker door interlock switch prevents

indicator lights from turning on and steam generator from

operating when the timer dial is set. If steam does not enter the compartment and the cooking indicator light fails

to turn on with the door latch securely engaged, the fault

may be in the door interlock switch. Proceed as follows:

1. Turn off power to the cooker.

2. Disconnect wires to the door switch terminals.

3. Connect an ohmmeter between the terminals of the

switch. The switch is marked “C” for common, ‘NC’

for normally closed and “NO” for normally open.

4. Actuate the switch by closing the cooking compartment door. If a zero reading cannot be obtained between the C and NO terminals, the switch is defective

and must be replaced.

INDICATOR LIGHTS

If the cooker compartment functions correctly, with the

single exception that the indicator light fails to light during

operation, the fault is a defective indicator light. A “burned

out” or defective light is veried by using an AC volt-meter

at the leads, with input power on the selector switch in the

correct position for that timer, the timer set, and the door

latches closed. If 240 volts is present, the fault is in the indicator light and requires replacement. If 240 volts is not

present, the fault is in the wiring or control components

(selector switch, timer or door switch).

BUZZER

If the buzzer does not sound at the termination of the

operator-selected timer setting (timer dial returned to “0

- Minute” position), the fault may be a defective buzzer.

Buzzer operation is veried using an AC volt-meter at

buzzer coil connections with input power on and selector switch and coinciding timer dial set at the “0 - Minute”

position. If voltage is 240 volts, the fault is in the buzzer,

which must be replaced. If 240 volts is not present, the

fault is in the wiring or control components (timer or selector switch).

WIRING

Using an ohmmeter, wiring continuity between the con-

nections shown on the wiring diagram is readily veried.

This is best done in stages, removing only those wires

required for each continuity check. As each lead is replaced, it should be checked for evidence of corrosion,

and cleaned if necessary. All leads must be tightly attached so as to provide a good electrical connection.

5. Remove the ohmmeter and replace the leads on

switch terminals.

Page 7

ADJUSTMENTS

WARNING

At least twice a year, have an authorized

service person clean and adjust the unit for

maximum performance.

ADJUSTMENT FOR HIGH ALTITUDE LOCATIONS

The steamer has been factory set so that when it is ON,

and during the READY phase, it will maintain water temperature in the steam generator tank at approximately

200°F (93°C) (just below water boiling point). However,

for high altitude locations, an authorized service agency

must adjust the steamer to achieve this temperature.

CAUTION

Shut off main electrical power to unit.

DOOR GASKET REPLACEMENT

The cooking compartment door gaskets are made of a

silicone-type rubber material that is very durable but subject to wear during normal operation. Should the gasket

leak replace it.

1. Open the cooking compartment door.

EXTERIOR PANEL REMOVAL

WARNING

To prevent hazard in servicing the cooker, be

certain the cold water shut-off valve is closed,

and the electrical disconnect circuit breaker

for the Cooker unit is OFF before removing

side panels.

Access to all internal plumbing and electrical assemblies

is from the right side. The right-side panel is removed by

removing the bottom screws from panel.

2. Remove the four screws on the outside of the door

frame, and remove the door panel assembly.

3. Remove the six screws from the gasket plate in the

door panel assembly.

4. Remove the gasket plate and the door gasket from

door panel.

5. Install the new door gasket to the door panel. Replace the gasket plate and six screws.

6. Reassemble the door panel assembly in the door

frame using the four screws.

7. Gasket replacement is now complete.

Door may be difcult to close until gasket has compressed

to conform to opening. Leaving door closed overnight will

compress gasket.

Page 8

WIRING DIAGRAMS

3E-10067R8

Page 9

WIRING DIAGRAMS

Page 10

WIRING DIAGRAMS

Page 11

WIRING DIAGRAMS

Page 12

WIRING DIAGRAMS

Page 13

WIRING DIAGRAMS

Page 14

STEAMER EXPLODED VIEW

NOVEMBER 1, 2016 14 ETP-5E & ETP-10E

Page 15

STEAMER EXPLODED VIEW

ITEM PART NO. DESCRIPTION ETP-5E ETP-10E

1 97-6334 Compartment Strainer 1 2

2 97-6177 Perforated Trough 1 1

3 97-6175 Pan Rack 2 4

4 97-6269 Hinge Rod 2

5 97-6191 Door Switch 1 2

97-6301 Switch Actuator 1 2

97-6429 Switch Actuator 1 2

6 97-6178 Striker 1 2

7 97-6580 Control Panel Decal, ETP-10E 1

8 97-6270 Pilot Light, Green, 250V 1 2

9 97-6271 Pilot Light, Red, 250V 1 2

10 98-6046 Knob 1 2

11 97-6272 Switch, On/Delime 1 2

12 08-7521 Temperature Indicator 1 2

12A 91-6491 Grommet 1 2

13 97-6227 Outer Door Shell 1 2

14 97-6432 Door Handle Assembly 1 2

15 97-6232 Latch Assembly 1 2

16 97-6236 Spacer, Upper 1 2

17 97-6261 Bushing 4 8

18 97-6230 Door Panel 1 2

19 97-6228 Door Gasket 1 2

20 97-6229 Gasket Retaining Plate 1 2

21 97-6233 Gasket Panel Screws 6 12

22 Right Side Panel 1

23 See Component Panel page

** 24 97-5864 Fuse Holder (208 - 240V) 1 2

98-6187 Fuse Holder (380 - 600V) 1 2

97-5864 Fuse Holder (220/380V, 240/415V) 1 1

** 25 97-6186 Fuse (208 - 240V) 1 2

98-6188 Fuse (380 - 600V) 1 2

97-6186 Fuse, (220/380V, 240/465V) 1 1

26 97-5052 Grounding Lug 1 1

27 97-6481 Hose Clamp 10 20

28 97-6434 Upper Tubing, Silicone, 5/8" ID x 13/16" OD x 30 Lg 1

* NOT SHOWN ** SELECT AS REQUIRED

NOVEMBER 1, 2016 15 ETP-5E & ETP-10E

Page 16

STEAMER EXPLODED VIEW

ITEM PART NO. DESCRIPTION ETP-5E ETP-10E

97-6584 Lower Tubing, Silicone, 5/8" ID x 13/16" OD x 12 Lg 1

** 29 97-6436 Brass Elbow, 5/8" C x 3/4" MPT 2

30 97-6283 Blowdown Solenoid Valve 1 2

97-6210 Blowdown Solenoid Valve 1 2

31 97-6326 Brass Connector, 1/2" C x 3/4" MPT 1 2

32 97-6583 Upper Tubing, Silicone, 5/8" ID x 13/16" OD x 32 Lg 1

97-6582 Lower Tubing, Silicone, 5/8" ID x 13/16" OD x 11 Lg 1

33 97-6443 Hose Clamp 2 4

34 97-6444 Drain Hose 1 2

35 97-6445 Drain Tube Assembly 1 2

36 97-6440 Brass Tee, 3/8" C 1

37 97-6188 Brass Elbow, 3/8" C x 1/8" MPT 2

38 97-6308 Solenoid Valve 3

97-6282 Solenoid Valve 3

39 97-6344 Brass Connector, 3/8" C x 1/8" MPT 3

40 97-6327 Brass Tee, 3/8" C x 1/8" MPT x 3/8"C 1

41 97-6226 Bulk Head Union, 3/8" NPT 1

42 97-6306 Transformer, 230 - 120V 1 2

43 See Component Panel page

97-6987 Dial 2

44 97-6278 High Limit Safety Thermostat 1 2

45 97-5619 Thermostat Fitting, 3/8" C x 3/8" MPT 1 2

46 97-6585 Hex Nut, 1/4 - 20 UNC 1 8

** 47 97-6309 Element Assembly, 10 kW, 208V 1 2

97-6310 Element Assembly, 10 kW, 220V (220V, 380V Units) 1 2

97-6311 Element Assembly, 10 kW, 240V (240V, 415V Units) 1 2

97-6312 Element Assembly, 10 kW, 277V (480V Units) 1 2

97-6313 Element Assembly, 10 kW, 347V (600V Units) 1 2

48 97-6319 Element Gasket 1 2

** 49 10-6962 Terminal Block, White 3 3

97-6586 Terminal Block Rail, 3" 1 1

10-6962 Terminal Block (380/220V, 415/240) 4 4

Rail 3.75L

** 50 98-6186 Terminal Block End, White 1 1

51 97-6587 Brass Hose Barb, 5/8" x ½" NPT 2

* NOT SHOWN ** SELECT AS REQUIRED

NOVEMBER 1, 2016 16 ETP-5E & ETP-10E

Page 17

STEAMER EXPLODED VIEW

ITEM PART NO. DESCRIPTION ETP-5E ETP-10E

97-6422 Brass Hose Barb, 5/8" x ½" NPT 2

52 See Component Panel page

** 53 See Component Panel page

See Component Panel page

54 See Component Panel page

55 See Component Panel page

See Component Panel page

56 97-6420 Brass Street Elbow, 3/8" FPT x 1/4" MPT 4

57 97-6588 Brass Hose Barb, 5/8" x 3/8" MPT 6

58 97-6589 Right Hand Hose Silicone Blue, 5/8" ID x .955" OD x 10 Lg 2

59 97-6590 Left Hand Hose Silicone Blue, 5/8" ID x .955" OD x 9.5 Lg 2

** 60 08-6621 240V, Timer 1 2

** 61 97-6424 Hose, Upper, 5/8" ID x 21" Long 1

97-6425 Hose, Lower, 5/8" ID x 37" 1

62 97-6351 Pressure Switch Tube 1 2

63 97-6591 Connector, 3/8"C x 1/8" FPT 2

64 97-6346 Brass Elbow, 3/8" C x 3/8" MPT 2

65 97-6347 Pressure Switch, Safety 5 PSI 1 2

66 97-6592 Brass Extruded Tee, 3/8" 2

67 97-6593 Brass Close Nipple, 3/8" 2

68 91-7765 Delime Elbow Assembly 1 2

91-7765 Clean Port Plug 1 2

08-7511 “O” Ring 2

69 97-6321 Generator Tank 1 2

97-6322 Tank Cover

97-6323 Tank Gasket 1 2

70 97-6594 Hex Head Bolt, 5/16 - 18 UNC x 1" Long 4

71 97-6324 Probe - Low Level Cut-Off 1 2

72 97-6325 Probe - Low Level 1 2

73 97-6326 Probe, High Level 1 2

74 97-6595 Pressure Switch Bracket 1 2

75 See Component Panel page

76 97-6446 Tubing, Silicone, 1/4" ID x 8" Long 2

77 97-6596 Brass Hose Barb, 1/4" x 1/8" MPT 4

97-6447 Brass Hose Barb, 1/4" x 1/8" MPT 2

* NOT SHOWN ** SELECT AS REQUIRED

NOVEMBER 1, 2016 17 ETP-5E & ETP-10E

Page 18

STEAMER EXPLODED VIEW

ITEM PART NO. DESCRIPTION ETP-5E ETP-10E

78 08-5015 Check Valve 1 2

79 97-6597 Tubing, Silicone, 1/4" ID x 2" Long 2

97-6449 Tubing, Silicone, 1/4" ID x 2" Long 1

80 97-6598 Brass Extruded Tee, 1/8" FPT 2

81 97-6452 Brass Bushing, NPT, 1/4" to 1/8" 2

82 97-6453 Brass Bushing, NPT, ½" to 1/4" 2

83 97-6454 Brass Locknut, ½" NPT 2

84 10-4586 Sealing Nut, ½" NPT 2

85 97-6599 Top Panel 1

86 97-6600 Time Delay Relay, Operating, 30 Seconds 1 2

* 87 See Component Panel page

* 90 08-6588 Hold Thermostat, 175°F 1 2

** * 91 See Component Panel page

See Component Panel page

See Component Panel page

92 Truss, HD Screw #10-32 UNF x 1/2 2 2

93 12 Amp Power Relay, DPDT 220V 1 1

* NOT SHOWN ** SELECT AS REQUIRED

NOVEMBER 1, 2016 18 ETP-5E & ETP-10E

Page 19

COMPONENT PANEL

1

5

2

6

7

3

8

4

9

10

2

ITEM PART NO. DESCRIPTION QTY

1 97-5613 TRANSFORMER - 480V-240V 100VA 1

97-5616 TRANSFORMER - 380-415V-240V 100VA 1

98-6191 TRANSFORMER - 600V-240V 100VA 1

2 97-9080 RELAY - DPDT 240V 3

3 97-5945 BUZZER - 240V 1

4 97-6276 WATER LEVEL BOARD - 240V - 10K Ohm 1

97-6277 WATER LEVEL BOARD - 240V - 1M Ohm 1

5 08-6502 WC PRESSURE SWITCH 1

6 92-0189 RELAY 1

7 97-6600 TIME DELAY RELAY - 240V - OPERATING 1

8 97-5610 CONTACTOR - 240V 1

9 97-5048 THERMOSTAT, PREHEAT 1

10 97-6581 TIME DELAY RELAY - 240V - COOLING 1

NOVEMBER 1, 2016 19 ETP-5E & ETP-10E

Page 20

CABINET ASSEMBLY

NOVEMBER 1, 2016 20 ETP-5E & ETP-10E

Page 21

CABINET ASSEMBLY

ITEM PART NO. DESCRIPTION ETP-5E ETP-10E

** 1 97-6537 Hinge Rod 1

97-6473 Hinge Rod 1

** 2 97-6538 Cabinet Door Assembly 1

97-6539 Cabinet Door Assembly 1

3 ~NPN~ Flat Washer 1 1

4 98-3784 Tempering Tank 1 1

5 97-6421 Brass Hose Barb, 5/8" x 3/8" MPT 5 7

6 97-6476 Brass Extruded, 90° Street Elbow, 3/8" 4 6

7 ~NPN~ Brass Square Head, 3/8" 2

8 08-5023 Float Switch 1 1

9 97-6477 Hex Nipple, 3/4" MPT x 1/2" MPT 1 1

10 97-5946 Drain Valve, Tank 1 1

11 97-6436 Brass Elbow, 90°, 5/8" C x 3/4 MPT 1 1

12 97-6422 Hose Clamp, 5/8 - 1-1/4" 6 6

** 13 97-6439 Hose, 5/8" I.D. x 16" Long 1

97-6480 Hose, 5/8" I.D. x 14" Long 1

13A 97-6480 Hose, 5/8" I.D. x 14" Long 2 2

14 08-6514 Tank Thermostat, 130°F 1 1

15 97-6482 Brass Bushing, 1/2" MPT to 3/8" FPT 1 1

16 97-6483 Brass Elbow, 90°, 5/8" C x 1/2" FPT 1 1

17 97-6346 Brass Elbow, 90°, 3/8" C x 3/8" MPT 1 1

18 97-6484 Vent 1 1

** 19 97-6415 Bullet Leg, Optional 2 2

* 97-6406 Swivel Caster, 5", c/w Brake, Optional 2 2

** 20 97-6486 Adjustable Flanged Foot 2 2

* 97-6561 Swivel Caster, 5", Optional 2 2

21 97-6487 Pan Slot Head Screws, #6-32 UNC x 3/8" Long 4 4

22 97-6488 Spring Lock Washer, #6 4 4

23 97-6489 Magnetic Catch 1 1

24 97-6490 Magnetic Catch Plate 1 1

25 97-6540 Manifold Assembly with Check Valve and Tee Fitting 1 1

26 97-6541 Elbow, 3/8" C to 3/8" MPT, Nylon 1 1

27 97-6542 Bushing, 3/4" to 3/8", Nylon 2 2

28 97-6543 Bushing, 3/4" to 1/2", Nylon 1 1

29 97-6544 Nipple, 1/2" NPT, Nylon 2 2

NOVEMBER 1, 2016 21 ETP-5E & ETP-10E

Page 22

CABINET ASSEMBLY

ITEM PART NO. DESCRIPTION ETP-5E ETP-10E

30 97-6545 Reducing Elbow, 3/4" to 1/2", Brass 1 1

31 97-6546 Nipple, 3/4" NPT, Nylon 2 2

32 08-8053 Check Valve, Nylon 1 1

33 97-6547 Connector, 3/8" C to 3/8" MPT, Nylon 1 1

34 97-6548 Tubing, 3/8" O.D., x 18" Long, Nylon 1

34A ~NPN~ Tubing, 3/8" O.D. x 30" Long, Nylon 1 1

35 97-6549 Sleeve, 3/8", Brass 2 2

36 97-6550 Connector, 3/8" C to 3/8" Nylon 1 1

37 ~NPN~ Tubing, 3/8" O.D. x 8" Long, Copper 1 1

38 08-8020 Filter, Large (* See Item 42). 1 1

39 08-8008 Filter, Small, Scale Inhibitor(* See Item 42) 1 1

41 97-6411 Drain Collector 1 1

42 08-8052 * Kit, Filter Replacement Cartridges 1 1

NOVEMBER 1, 2016 22 ETP-5E & ETP-10E

Page 23

ALTERNATE FILTER SYSTEM

ITEM PART NO. DESCRIPTION

1 08-8020 CUNO HF-40 Filter Cartridge (One Included in Kit 08-8052)

2 08-8008 CUNO HF8-S Filter Cartridge (One Included in Kit 08-8052)

4 08-8055 CUNO Filter Head, VH3 – NPT without Gauge Port

5 98-4378 Mounting Plate, CUNO Filter Assy

6 98-4379 Retainer Bracket, CUNO Filter Assy

7 08-8057 Tee, CUNO SF-18-S, Scale Feeder

8 08-8059 CUNO Pressure Gauge

9 97-6542 Reducing Nipple, Nylon, 3/4 x 3/8 NPT

10 97-6543 Reducing Nipple, Nylon, 3/4 x 1/2 NPT

11 08-8052 CUNO Filter Cartridge Kit (Includes HF-40 and HF8-S)

NOVEMBER 1, 2016 23 ETP-5E & ETP-10E

Loading...

Loading...