Page 1

Revision 3-1975

MODEL A &

MODEL A I

STEAM COOKERS

Manual & Automatic

PARTS and SERVICE

MANUAL

Market Forge

Everett Ma. 01249 Tel. 387-4100

Facsimile #617-387-4456

5099

Page 2

TABLE OF CONTENTS

5100

Subject Code No. Page

HOW TO USE THIS MANUAL ................................……………………………………………. 5101 3

BASIC OPERATING INSTRUCTIONS ......................………………………………………..... 5101 3

ILLUSTRATION AND PARTS LIST - AUTOMATIC A-1 COOKER ...………………………... 5102 4

ILLUSTRATION AND PARTS LIST-MANUAL A-1 COOKER ...…………………………….... 5103 5

ILLUSTRATION AND PARTS LIST-AUTOMATIC A COOKER ..……………………………... 5104 6

ILLUSTRATION AND PARTS LIST-MANUAL A COOKER .......………………………………. 5108 7

MODEL A-1 DOOR ASSEMBLY ................. .............. …………………………………………. 5106 8

MODEL A DOOR ASSEMBLY ................................……………………………………………. 5107 9

WATTS PRESSURE REDUCING VALVE-A-1 COOKER .........……………………………….. 5010 10

STRONG PRESSURE REDUCING VALVE-A COOKER ........………………………………… 5108 11

STEAM MANIFOLD AND VALVE ASSEMBLY. .............…………………………………...... . 5109 12

SERVICING THE STEAM SUPPLY VALVE ..................……………………………………..... 5110 13

STEAM PRESSURE GAUGE ASSEMBLY .....................………………………………………. 5110 13

CONTROL BOX ASSEMBLY ...............................……………………………………………... 5111 14

SUGGESTED STEAM CONNECTIONS ...................………………………………………...... 5112 15

WIRING DIAGRAM ......................................…………………………………………………….. 5113 16

SCHEMATIC DIAGRAM ..............................…………………………………………………...... 5114 17

Page 3

YOUR "SET IT AND FORGET IT" MARK-FORE

Same as Automatic.

MODEL "A" AND "A-1" STEAM COOKERS are the

ultimate in steam cooking advancement and were

developed through extensive research and

engineering skills to satisfy an urgent demand for an

easy-to-operate, easy-to-service steam cooker.

Independently controlled cooking compartments

constitute a remarkable and superior feature.

Each compartment can be used alone, or all three

can be employed simultaneously because each has

its own timing, steam control and signal devices.

The careful factory workmanship of Market Forge

craftsmen in developing this newest scientific

triumph in steam cooking equipment is your

guarantee of efficient, dependable performances.

HOW TO USE THIS MANUAL

This manual contains maintenance and service instructions for Model "A" and "A-1" automatic and

manually operated steam cookers. The exploded

view drawings of components are aids to the

identification, disassembly and assembly of parts.

The parts listings provide information necessary for

ordering replacement parts (proper part names and

part numbers). When requesting parts or service,

always furnish the model and serial number of your

machine. The serial number is located on the left

side under the bezzel on the con-trol panel. A

listing of Factory Aut horized Service Agencies who

maintain Market Forge equipment will be supplied

without charge upon request.

ORDERING REPAIR PARTS

Many repair parts on the Model "A1" steam

cooker are not interchangeable with parts on

the "A" cooker. It is necessary, therefore, to

furnish the following information when ordering

repair parts.

1. Quantity, part number and description of

part.

2. Model and Serial number for which the part

is required.

3. Please specify how you wish merchandise

shipped. If this information is not furnished

we will ship the best and most economical

way.

NOTE- All part orders received before 2:00

P.M. are shipped the same day the order is

received.

BASIC OPERATING INSTRUCTIONS FOR

AUTOMATIC

1. Check to be sure the steam pressure gauge

regis-ters between 4 and 5 pounds.

2. Place pans of food into the cook ing

compartment to be used.

3. Close and latch the door.

4. Turn the door wheel clockwise to seal the

cooking compartment.

WARNING: Do not permit steam to leak.

Set the door tight enough to make a firm

seal. Steam leakage will cause undue

wear to the gasket.

5. Turn timer pointer clockwise to the 60 minute

mark, and then to the desired cooking time.

6. Pull the-operating handle out and allow it to

lock in this position. The pilot light will signify

this cooking compartment is in operation. At

the end of the cooking cycle the AUTOMATIC

controls will release the operating handle,

shutting off the steam supply and exhausting

the steam from the cooking com-partment.

The pilot light will be turned off and the

buzzer will signify that cooking has been

terminated.

7. Press the buzzer release knob to silence the

buzzer.

FOR MANUALLY OPERATED

1 through 5

6. Set timer. When bell rings, lift handle and

push in to shut off cooker.

5101

Page 4

Page 5

Manifold Compartment A-1 Cooker Automatic * Indicates Interchangeable Parts A1 & Old 'A'

comp.)

5102

Cooker

Master Illustration Parts List

ITEM PART NO. DESCRIPTION

1 10-2445* 1" O.D. x 3/8 St. St. Washer

2 10-2328 * 1/4" x 20" Elastic Stop Nut

3 10-2652 * Gasket

4 10-3343* Lock nut

5 10-2988* Rd. Hd. Rivet

6 10-2427 1/2" I.D. Plated washer

7 10-2777 3/8" O.D. x 1 1/2" long spring

8 90-8331 Latch Handle Ass'y.

9 10-2328 Stop Nut

10 10-2755 * Spring-Operating Arm

11 10-2331 No. 6-32 Hex Nut (Cad. PI.)

12 90-9212 Operating Handle Ass'y.

13 90-9215 Control Handle

14 10-1881 No. 10-32 x 3/8 Fl. Hd. Screw

15 10-1967 Shoulder Screw for linkage

16 90-8926 Signal light term ass'y.

17 90-9214 Shaft Reset Button

18 90-8537* Valve Actuating Arm

19 10-2756* Synchronizer Spring

20 10-2515* No. 6 Lock Washer

21 90-7189 Timer Knob

22 10-4748* Pressure Gauge

23 90-8963 Copper Tubing 3/16" O.D. x 18"

24 90-9219 Bezel (2 comp.)

25 10-6238 Identification Name plate

26 10-1654 Drive Pin

27 90-8549* Shield Ass'y. Manifold

28 90-9188 Side Panel-St. St. (2 comp.)

29 10-1740 No. 8-32 x 3/4" Truss Head Screw

30 10-2124* 3/8-16 x 1 1/8 Hex Hd. Screw

31 10-2503* 3/8" Lock washer (cad. PI.)

32 10-1059 3/4" Std. 90° street elbow

33 10-3761 Nipple 3/4" IPS 71/4" Ig.

34 10-6156 Steam Trap

35 10-6157 Adapter Sub—ass'y.

36 10-5514* Timer

37 90-8144 Comb. Steam & Exhaust Header (2 comp.)

10-4370 Brass Nut

10-4371 Brass Sleeve (Female)

90-9220 Bezel (3 comp.)

90-7537 Bezel (4 comp.) Pol. Only

90-9199 Side Panel-St. St. (3 comp.)

90-9203 Side Panel-St. St. (4 comp.)

90-9189 Side Panel—Enamel (2 comp.)

90-9200 Side Panel—Enamel (3 comp.)

90-8145 Comb. Steam & Exhaust Header (3 comp.)

90-8146 Comb. Steam & Exhaust Header (4 comp.)

ITEM PART NO. DESCRIPTION

38 90-8534* Pivot Arm

39 10-4742* Safety Valve 3/4" 8 Ibs. chrome

40 10-1053 Elbow 3/4" IPS, 90°

41 10-5164* Junction Box Cover

42 90-9195 Insulator-Buzzer

43 10-6682 Buzzer

44 10-5997* Solenoid

45 90-8905 Push Rod-Solenoid

46 10-2160 No. 10-32 x 3/8 Philips Truss Hd. Scr. (Cadm. PI.)

47 10-2505* No. 10 Lock washer (Cadm. PI.)

48 10-1717 No. 8-32 x 3/8 Rd. Hd. Screw

49 10-2151 No. 6- 32 x 2 1/4 Ig. Rd. Hd. Mach. Screw

50 10-5613* Micro Switch (Solenoid)

51 10-5511* Micro Switch (Buzzer)

52 90-9223 Spacer

53 10-2428 Flat Washer

54 90-9226 Name plate Panel—Auto 2 comp.

55 10-4619* Replacement element for Steam Trap painted cap

56 10-4559* 1/2" Steam trap complete painted (obs)

57 10-2154 No. 10 Ty. "B" Pan Hd. Screw 1/2" Ig. (Cad. PI.)

58 10-1975 No. 4-40 x 7/16 Flat Hd.Scr.

59 10-1949 No. 6 Ty. "A" Pan Hd. Screw 3/8 Ig. (Cad. PI.)

60 10-5614* Junction Box

61 10-5680 Air Adapter

62 10-5972 Fuse Holder Buss H.K.P.

63 10-5973 Fuse Buss M.D.L. 8/10 amp. Slow

64 10-1703 No. 2 Drive Screw

65 90-9237 Top Cover Ass'y. - St. St. (2,3&4 Comp.

66 90-9186 Bottom Enclosure- St. St.

67 90-9184 Back Side Enclosure - St. St. (2 Comp.)

10-4741* Safety Valve 3/4" 8 Ibs. brass

10-2652 Gasket

90-9229 Name plate Panel—Auto 3 comp.

90-8308 Name plate Panel—Auto 4 comp

10-5625* Replacement element for Steam Trap chrome cap

90-4003* 1/2" Steam Trap complete chrome (obs)

90-9238 Top Cover Ass'y. Enamel (2 & 3 Comp.)

90-9187 Bottom Enclosure - Enamel

90-9231 Back Side Enclosure - St. St. (3 comp.)

90-9896 Back Side End. Ass'y. - St. St. (4 comp.)

90-9185 Back Side End. - Enamel (2 comp.)

90-9232

Back Side Enclosure - Enamel (3

Page 6

Page 7

* INDICATES INTERCHANGEABLE

PART A1 & A COOKER - MANUAL CONTROLS

Hex.

Hd. Cap Screw

Screw

header

(2

comp.)

header

(3

comp.)

header

(4

comp.)

Painted cap.

Chrome cap.

painted (obs)

chrome (obs)

40x7/16"

Flat Hd. Scw.

Hd. Screw

St. St.

(2,3.

&4 comp.)

Enamel

(2

&3 comp.)

Ty "B" Pan Hd.

Screw

1/2"

Lg. (Cad. PI.)

St. St.

(2,3, &4

comp.)

Enamel

(2 & 3

comp.)

Ty. "A" Pan Hd. Screw

3/8 Lg. (cad p(.)

St. St.

(2

comp.)

St. St.

St. St.

(4

comp.)

Enamel

(2

comp.)

Enamel

(3

comp.)

Manifold Compartment A-1 Cooker Manually Operated

Master Illustration Parts List

ITEM PART NO. DESCRIPTION

1 102445* 1" O.D. x 3/8 St. St. washer

2 102328* 1/4" x 20 Elastic stop nut

3 10-2652* Gasket

4 103343* Lock nut

5 10-2988* Rd. Hd. Rivet

6 10-2427 1/2" I.D. plated washer

7 10-2777

8 90-8331 Latch Handle Ass'y.

9 10-2328 Stop nut

10 10-2755* Spring Operating Arm

11 90-9212 Operating Handle Ass'y.

12 10-1967* Shoulder Screw for linkage

13 90-8534* Pivot Arm

14 10-1881 No. 10-32 x 3/8 fl. hd. screw

15 90-9215 Control Handle

16 90-8537* Valve Actuating Arm

17 10-2756* Synchronizer Spring

18 10-6307 Timer Knob

19 10-5520* Timer

20 10-4748* Pressure Gauge

21 90-9219 Bezel (2 comp.)

90-9220 Bezel (3 comp.)

90-7537 Bezel (4 comp.) Pol. Only

22 106238 Identification name plate

23 10-1703 No. 2 Drive Screw

24 90-8549* Shield Ass'y. Manifold

25 10-2124*

26 10-2503* 3/8" Lock Washer (cad. p .)

27 10-1740

28 90-8144

29 90-9188 Side Panel-St. St. (2 comp.)

30 10-6156 Steam Trap

31 10-6157 Adapter Sub—Ass'y.

32 90-8963 Copper Tubing 3/16" O.D. x 18"

90-8145

90-8146

90-9199 Side Panel-St. St. (3 comp.)

90-9203 Side Panel-St. St. (4 comp,)

90-9189 Side Panel-Enamel (2 comp.)

90-9200 Side Panel-Enamel (3 comp.)

10-4370 Brass Nut

3/8" O.D. x 1 1/2" long

3/8" - 16 x 1 1/8"

No. 8 - 32 x 3/4 Truss Hd

Comb. steam & exhaust

Comb. steam & exhaust

Comb. steam & exhaust

ITEM PART NO. DESCRIPTION

10-4371 Brass Sleeve (Female)

33 10-3761 Nipple 3/4" IPS 7 1/4" Ig.

34 10-1053 Elbow 3/4" IPS 90°

35 10-4741* Safety Valve 3/4" 8 Ibs. brass

10-4742* Safety Valve 3/4" 8 Ibs. chrome

36 10-1059 3/4" Std. 90°Street Elbow

37 105846 Name plate Panel (2 comp.)

10-5847 Name plate Panel (3 comp.)

90-8312 Name plate Panel (4 comp.)

38 10-4619*

39 10-4559*

40 10-1975

41 10-2505 Lock Washer

42 10-2160

43 909237

44 10-2154

45 90-9186

46 10-1949

47 90-9184

10-5625*

90-4003*

909238

90-9187

90-9231

90-9896

90-9185

90-9232

Replacement element for Steam Trap

Replacement element for Steam Trap

1/2" Steam trap complete

1/2" Steam trap complete

No. 4-

No. 10-32 x 3/8 Phil Truss

Top Cover Ass'y. Top Cover Ass'y. No. 10 Bottom Enclosure Bottom Enclosure —

No. 6

Back Side Enclosure Back Side Enclosure -

(3 comp.)

Back Side End. Ass'y. -

Back Side Enclosure Back Side Enclosure -

5103

Page 8

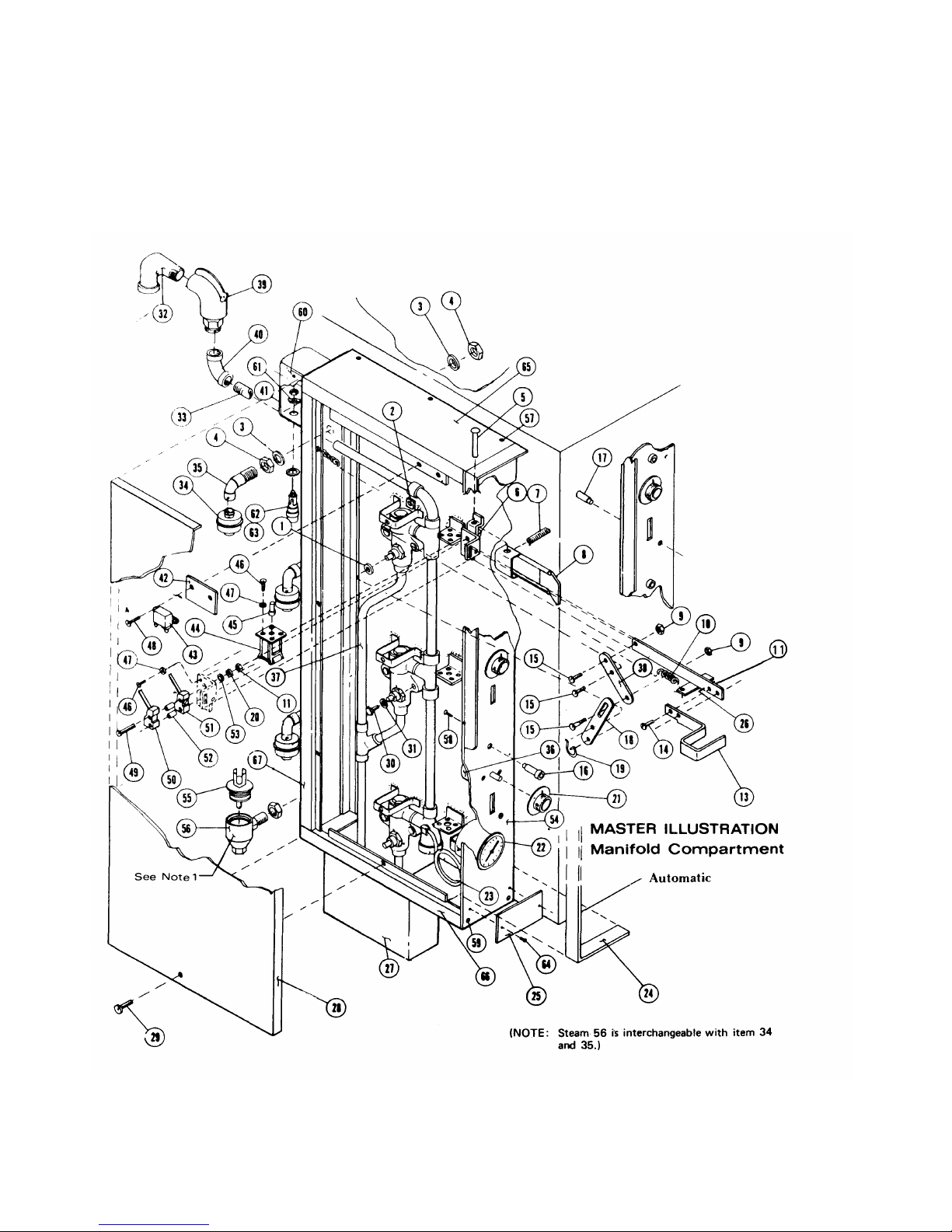

MASTER ILLUSTRATION

Manifold Compartment

Automatically Operated

Page 9

Manifold Compartment A Cooker Automatically Operated

5

3343*

Lock nut Nickel Plated

exhaust header

Rd hd mach screw cad

(OBSOLETE)

Master Illustration Parts List

* INDICATES INTERCHANGEABLE

PARTS A1 & 'A' COOKER

Item Part No. Description

1 10-2445* 1" OD x 3/8 St. St. Washer

2 10-2328* 1/4-20 Elastic stop nut

3 10-2652* 7/8 x 1 x 1/16 Composition Gasket

4 10-1910 3/16" Tube x 1/8" Taper pipe thread

10-

1/2"

7 90-8387 1/2" I.D. plated washer

8 10-2757 3/8" O.D. x 1" long Spring

9 90-8546 Shaft for reset button

10 90-8545 Bracket for reset button

11 90-8524 Latch handle assembly

12 90-8550 Operating Arm Assembly

13 90-8547 Left Bracket

14 10-1975 4-40-1/2 Flat hd. screw

15 10-2505* 10/32 x 1/16" Lock washer

16 10-2339 10/32 St. St. hex nut

17 10-2755* Spring for Operating Arm

18 90-8531 Spring Bracket

19 10-1908 1/8" x 1 1/ 4" drive pin

20 90-8669 Operating Handle

21 10-1922 8/32 x 1/2 Oval hd. screw cad. pl.

22 90-8534* Pivot Arm

23 10-1852 10/24 x 3/4 Rd. Hd. mach. screw

24 90-8537* Valve actuating arm

25 90-8533 Shoulder Screw for Linkage

90-8573 Side Enclosure St. St. 2 comp.

26

90-8575 Side Enclosure St. St. 3 comp.

90-8577 Side Enclosure St. St. 4 comp.

90-8574 Side Enclosure Painted 2 comp.

90-8576 Side Enclosure Painted 3 comp.

90-8578 Side Enclosure Painted 4 comp.

27 10-2756* Valve Synchronizer Spring

28 10-1845 8/32 x 1/4 St. St. self tapping screw

29 10-5514* 0-60 minute electric timer

30 10-5499 115V Pilot Light

31 10-4713 Timer knob

32 10-4748* 0-30# Pressure Gauge

90-8683 Bezel 2A 33

90-8684 Bezel 3A

34 10-2339 #10 Hex nut St. St.

Item Part No. Description

90-8549* Manifold Shield St. St. 35

90-8541 Manifold Shield Painted

36

90-8434 Side Panel St. St. 2 comp .

90-8435 Side Panel St. St. 3 comp.

90-8436 Side Panel St. St. 4 comp.

90-8430 Side Panel Painted 2 comp.

90-8431 Side Panel Painted 3 comp.

90-8432 Side Panel Painted 4 comp.

37 10-4563 Buzzer

38 10-1888 #10 Cad plated lock washer

39 10-5613* Solenoid Micro switch

40 90-4159 Insulator

41 10-2337 6/32 St. St. hex nut

42 10-2503* 3/8" Lock washer cad. pl.

43 10-2124* 3/8" - 16 x 1 1/8" hex hd. cap screw

44

90-8498 Comb steam &

90-8496 Comb steam & exhaust header -

90-8604 Comb steam & exhaust header -

45 10-5511* Buzzer micro switch

46 10-5997* 115V solenoid

47 10-1701 1/4 - 20 x 3/8

48 10-2508 1/4 x 3/32 x 1/16 St. St. lock washer

49 90-8542 Push rod for Solenoid

50 10-2515* #6 x 3/6 x 1/32 lock washer cad pl

51 10-1760 10/32 x 1/2" St. St. mach screw

52 90-4399 Spring clip

53 90-8739 Panel clip

54

10-4559* 1/2" steam trap complete brass

90-4003* 1/2" steam trap complete chrome

55 10-1921 Retaining screw - side enclosure

56

104619* Replacement element for steam trap

10-5625* Replacement element for steam trap

57 10-5614 Junction box

10-4742* 3/4 - 8# Safety valve chrome 58

10-4741* 3/4 - 8# Safety valve brass

10-3455 3/4" B. I. elbow 59

90-7304 3/4" chrome elbow

60 10-5164* Junction box (Cover)

5104

Page 10

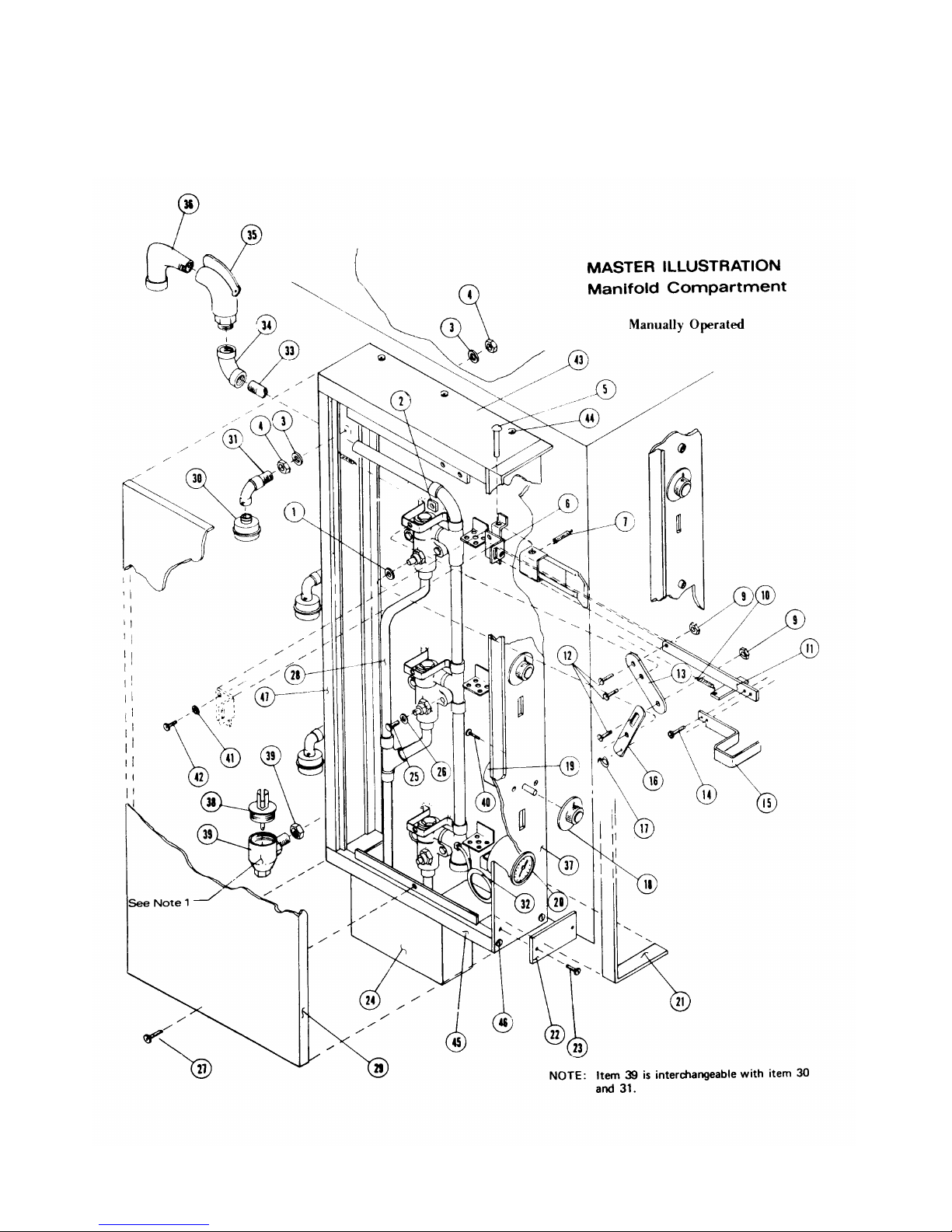

MASTER ILLUSTRATION

Manifold Compartment

Manually Operated

Page 11

Manifold Compartment A Cooker Manually Operated

Fitting

17

26

Comp.

Comp.

Painted Cap.

Chrome Cap.

36

(OBSOLETE)

Master Illustration Parts List

* INDICATES INTERCHANGEABLE PARTS

A-1'& 'A' COOKER

Item Part No. Description

1 10-2445* 1"O.D.x 3/8" St. St. Washer

2 10-2328* 1/4-20 Elastic Stop Nut

3 10-2652* 7/8x1 x 1/16 Composition Gasket

4 10-1910

5 10-3343* 1/2" Lock nut Nickel Plated

6 10-2988* 1/2" x 3 1/2" Rd.Hd. Rivet

7 90-8387 1/2" I.D. Plated Washer

8 10-2757 3/8" O.D. x 1" Long Spring

9 90-8524 Latch Handle Assembly

10 90-8550 Operating Arm Assembly

11 10-2755* Spring for Operating Arm

12 90-8669 Operating Handle

13 10-1922 8/32 x 1/2 Oval Hd. Screw Cad. PI.

14 90-8534* Pivot Arm

15 90-8537* Valve Actuating Arm

16 10-1967* Shoulder Screw for Linkage

90-8573 Side Enclosure St. St. 2 Comp.

18 10-2756* Valve Synchronizer Spring

19 10-1845 8/32 x 1/4 St. St. Self Tapping Screw

20 10-5220* 0 - 60 Minute Mechanical Timer

21 10-4713 Timer Knob

22 10-4748* 0 - 30# Pressure Gauge

23 90-8683 Bezel 2A

24 10-2339 #10 Hex Nut St. St.

90-8575 Side Enclosure St. St. 3 Comp.

90-8577 Side Enclosure St. St. 4 Comp.

90-8574 Side Enclosure Painted 2 Comp.

90-8576 Side Enclosure Painted 3 Comp.

90-8578 Side Enclosure Painted 4 Comp.

90-8684 Bezel 3A

3/16" Tube x 1/8" Taper Pipe Thread w/

Item Part No. Description

25 90-8549* Manifold Shield St. St.

27 10-2503* 3/8" Lock washer Cad. PI.

28 10-2124* 3/8"-16x1 1/8" Hex. Hd. Cap Screw

29

30 90-8739 Panel Clip

31 10-4559* 1/2" Steam Trap Complete Brass (obs)

32 10-1921 Retaining Screw - Side Enclosure

33 10-4619* Replacement Element for Steam Trap

34 10-4742* 3/4" - 8# Safety Valve Chrome

35 10-3455 3/4" B. 1. Elbow

90-8541 Manifold Shield Painted

90-8434 Side Panel St. St. 2 Comp.

90-8435 Side Panel St. St. 3 Comp.

90-8436 Side Panel St. St. 4 Comp.

90-8430 Side Panel Painted 2 Comp.

90-8431 Side Panel Painted 3 Comp.

90-8432 Side Panel Painted 4 Comp.

90-8498

90-8496

90-8604

90-4003* 1 /2" Steam Trap Complete Chrome

10-5625* Replacement Element for Steam Trap

10-4741* 3/4" - 8# Safety Valve Brass

90-7304 3/4 "Chrome Elbow

10-0435 Name Plate 2A

10-0434 Name Plate 3A

90-8583 Name Plate 4 A Upper

90-8588 Name Plate 4A Lower

Comb. Steam Supply & Exhaust Header 2

Comp.

Comb Steam Supply & Exhaust Header 3

Comb Steam Supply & Exhaust Header 4

5105

Page 12

MODEL A-1 DOOR ASSEMBLY.

11/32

I.D. x

3/4

O.D. Flat

Washer St. St.

1/16

Thk. x

1"

O.D. Flat

Washer

ITEM PART NO. DESCRIPTION

1 90-8310 Model A-1 Hand Grip

2 10-1945 Gasket Screws

3 90-8311 Model A-1 Gasket Plate

4 10-0433 Model A-1 Door Gasket

5 90-8514 Model A-1 Inner Door

6 10-2135 5/16-18 x 3/4 Hex. Hd. Bolt

7 10-2426

8 10-1909 5/16" Thredseal

9 90-8114 Spring Door Release

10 10-3079 (Pivot Bearing Interchangeable)

11 10-2427

12 90-8111 Hinge — Polished upper and lower

90-8316 Hinge — Enameled upper and lower

90-8147 Inner Door Ass'y (Items 1-5)

ITEM PART NO. DESCRIPTION

13 10-1981 Pivot Hinge

14 90-8113 Handwheel — Polished Solid

90-8328 Handwheel -Spoked (Enamel)

15 90-8126 Outer Door Ass'y.— Polished

90-8320 Outer Door Ass'y.— Enameled

16 10-2423 Thrust Washer

17 10-3080 Door Bushing

18 10-1696 Roll Pin

19 90-8124 Strong Back

20 10-2012 Cap Screw

21 10-1973 Support Stud Ass'y.

22 10-2302 Hex. Nut 3/8-16

23 90-8317 (Bushing for spoke wheel only)

24 10-2013 Hex. Jam Nut 3/8-16

5106

Page 13

5107

Item Part No. Description

1 90-8518 Model A Gasket Plate Handle

2 10-1704 Gasket Screws

3 90-8517 Model A Gasket Plate

4 10-0433 Model A Door Gasket

5 90-8514 Model A Inner Door

6 90-8504 Model A Outer Door

7 10-2124 3/8" Hex Head Cap Screw x

1-1/8" long St. St.

8 10-2426 11/32 I.D. x 3/4'

O.D. Flat Washer

St. St.

90-8519 Inner Hinge Bracket - Top -

Polished

9

10-0427 Inner Hinge Bracket - Top -

Painted

10 10-1909 5/16" Thread seal

11 90-8523 Spring Door Release

12 10-4121 Retaining Ring

13 90-8879 Door Hinge Pin

90-8677 Outer Hinge Bracket - Polished 14

10-0474 Outer Hinge Bracket - Painted

90-8520 Inner Hinge Bracket - Bottom -

Polished

15

10-0426 Inner Hinge Bracket - Bottom -

Painted

16 90-8559 Handwheel stainless steel

90-

8560 Handwheel painted

17 90-8680 Outer Shell Assembly painted

90-8507 Outer Shell Assembly St. St.

18 10-1690 Roll Pin

19 10-2423 Thrust Washer

20 90-8511 Door Bushing

21 90-8480 Door Latch

22 10-2426

11/32" I.D. x 3/4" O.D. Flat Washer

St. St.

23 10-1907 1/4-

20 x 5/8" long Hex Head Screw

cad. plated

24 90-8513 Strong Back

25 10-2071 3/8-

16 x 2 1/2" long Hex Head cap

Screw

26 10-1839 Inner Door Support Pin

Page 14

Assembly

ITEM NO. PART NO. DESCRIPTION

1 10-1083 Adjusting Spring

2 10-1082 Diaphragm

3 10-1075 Diaphragm Gasket

4 10-1076

Diaphragm Button & Stem

5 10-1077 Strainer

6 10-1078 Bottom Plug Gasket

7 10-1079 Bottom Spring

8 10-1080 Seat

9 10-1081 Disc Assembly

10 10-1033 3/4" Complete Valve-Painted

11 10-1034 3/4" Complete Valve-Chrome

12 10-0893 Valve Stem Guide

WATTS PRESSURE REDUCING VALVES - 3/4"

To provide adequate steam pressure regulation, your

unit may be equipped with a Wat ts steam pressure reducing valve. The 3/4" Watts pressure reducing valve is

designed to operate from a 7 to 50 P.S.I, source of

steam pressure and reduce this to 5 P.S.I, for delivery to

your cooker. Installation must be made from your source

of steam supply, through the pressure reducing valve,

and into the manifold input part of the steam cooker.

WARNING: Before final connection is made, blow

down your steam line to remove all dirt, scale,

packing and compound which may have

accumulated during the installation of piping to the

cooker.

OPERATION OF WATTS 3/4" REDUCING VALVE

Steam enters the valve at the inlet port and passes upward through the seat (8) into the discharge side of the

valve. As pressure in the discharge side increases, it

forces the diaphragm (2) upward, overcoming the tension

of the adjusting spring (1) and closing valve. As the

pressure drops, the adjusting spring forces the

diaphragm down, reopening the valve. Where demand

and initial pressures are fairly constant, the valve opens

to the proper position and maintains the desired re duced

pressure.

ADJUSTING WATTS 3/4" REDUCING VALVE

1. Release the adjusting screw lock nut and loosen the

adjusting screw enough to release all tension on adjusting spring (1).

2. Turn steam on slowly. Then turn adjusting screw

clockwise just enough to allow the valve to open

slightly. Allow cooker to operate in this manor

several minutes.

3. Turn adjusting screw down slowly, at intervals,

until reduced pressure reaches the desired Point.

(5 P.S.I.)

4. Tighten adjusting screw lock nut.

5. If chattering noise should occur turn adjusting screw

located in bottom half of valve body, clockwise or

counter-clockwise, until chattering stops.

INSPECTION - MAINTENANCE

Reports of unsatisfactory regulation of the pressure

reducing valve is usually due to dirt, pipe compound,

etc., blocking the internal strainer, or gumming up the

seat and disc assembly. To clean the strainer, seat,

and disc assembly remove the bottom plug (6) and

remove strainer screen (5), bottom spring (7) and disc

assy. (9) Clean the lower part of the valve. This can be

accom plished without removing the valve from the line

or unbolting the cover. If cleaning the strainer and disc

assy. does not correct fault, the disc assy. and seat

should be replaced. Also the top cover should be removed and the diaphragm button stem assembly

should be removed and cleaned.

REPAIRS

The following item should be cleaned or replaced

should the value fail to operate properly.

1. Both the disc assembly (9) and strainer (5) are removed by removing the bottom plug (11) and bottom

spring (7). Upon cleaning or replacing these items,

be sure that the disc assembly (9) is seated properly

on the stem assembly (4) otherwise the stem

assembly will be bent restricting its mov ement and

the regulation of steam through the valve.

2. Should there be a restriction in the diaphragm button

and stem assembly (4) it will cause a drop in steam

flow or large fluctuations in steam pressure. It is

then necessary to replace diaphragm but ton and

stem assembly (4), valve stem guide (12) and

diaphragm gasket (3) as well as those items in step

1.

Upon completion of the above and removal of any

loose scale, which may be found in the valve, the valve

should be reassembled; and upon installation, function

properly.

5010

Page 15

STRONG PRESSURE REDUCING VALVE

Item Description

Part No

2 Adjusting Spring Cap

10-4825

3

Spring Washer

10-4826

4 Adjusting Spring, Green

15

Ib 10-

4827

5 Cover

104828

6 Upper Stem Guide

104829

7

Upper Diaphragm Block

10-4830

8 Cover Gasket

10-4831

9 Diaphragm (with gasket)

10478

2 10 Body (with seat insert)

10-4832

11

Lower Diaphragm Plate

10-3833

13 Strainer Screen

10-4783

14 Disc (pressed on stem)

10-4835

TYPE "K"— 3/4 INCH

(OBSOLETE)

3/4" PRESSURE REDUCING VALVE Parts List

1 Adjusting Screw 104824

12 Seat Insert 10-4834

15 Bottom Plug 10-4836

ADJUSTING TYPE K REDUCING VALVES

1. Release the adjusting screw lock nut and loosen

adjusting screw (1) enough to release all tension

on adjusting spring (4).

The 3/4" Strong Pressure Reducing Valve, Type K is

designed to operate from a 20 to 100 P.S.I, source of

steam and reduce this to 5 P.S.I, for delivery to your

steam cooker.

With the introduction of a pressure reducing valve to

your input line, it is recommended that a pressure gauge

be also installed on the supply side so that the actual

steam input pressure may be constantly record-ed. The

selection of a pressure gauge must be made to operate

within the range of pressure experienced from your

source of supply. The reduced pressure may con-stantly

be read on the steam cooker pressure gauge.

WARNING: Before final installation connection is made,

blow down your steam line to remove all

dirt, scale, packing, and compound which

may have accumulated within the new

piping.

OPERATION OF TYPE K REDUCING VALVES

Steam enters inlet port and passes upward through seat

(12) into discharge side of valve. As pressure in

discharge side increases, diaphragm (9) is forced

upward overcoming tension of adjusting spring (4) and

closing valve. As pressure drops, adjusting spring (4)

forces diaphragm (9) down, reopening valve.

2. Turn steam on slowly. Then turn adjusting screw (1)

down just enough to allow the valve to open slightly.

Allow cooker to operate in this manner several

minutes.

3. Turn adjusting screw (1) down slowly, at intervals

until reduced pressure reaches the desired point.

4. Tighten adjusting screw lock nut.

INSPECTION - MAINTENANCE - REPAIRS

Reports of unsatisfactory regulation of the pressure

reducing valve is usually due to dirt, pipe compound,

etc., blocking the internal strainer or gumming up the

internal mechanism. To clean the strainer, unscrew

bottom plug (16) and remove strainer screen (13).

Clean the lower part of the valve. This can be accomplished without removing the valve from the line or

unbolting the cover. If cleaning the strainer does not

correct fault, remove the valve from the line and disassemble. After thoroughly cleaning, the seat insert

(12) and disc (14) should be ground together, using a

very fine abrasive or compound. The seat insert and

disc are of the ball type and must be "wobbled" when

lapping. Avoid excessive lapping as this will cause

ridges to form and make tight seating impossible.

5108

Page 16

THE STEAM MANIFOLD AND VALVE ASSEMBLY

The steam manifold and valve assembly provides a means of

steam input and exhaust control for each cooking compartment.

Though complete removal of the manifold and valve assembly

will be necessary to replace a complete valve, each may be

serviced in its position by following these service instructions.

TO DISASSEMBLE VALVE

1. Shut off the steam supply to the cooker.

2. Unfasten the pivot arm at points A and B.

3. Unfasten the valve synchronizer spring at point C

remove to free valve actuating arm and spacer.

4. Remove the pivot stud to allow more working room.

5. Remove valve cap (6) and valve bonnet (1).

6. Pull out valve synchronizer (3).

7. Lift out valve synchronizer lever and ball

assembly (5).

8. Insert a pencil in the hole of valve synchronizer

ball (4) and lift out through the front portal.

TO ASSEMBLE VALVE

1. Slip valve synchronizer ball (4) into the valve with

the hole facing the front portal.

2. Drop valve synchronizer lever and ball assembly (5)

in from the top opening of the valve with cut out on

the lever facing ball (4).

3. Manipulate valve synchronizer (3) in position (large

prong in ball - smaller prong in lever).

4. Screw on valve bonnet (1) and valve cap (6).

5. Place the spacer over the shaft of the valve

synchronizer.

6. Place the valve actuating arm over the shaft of

the valve synchronizer with the bushing facing

the valve.

7. Fit the valve synchronizer spring into the hole in the

shaft of the valve synchronizer and secure it in

place with the screw and the flex-loc nut.

8. Secure the pivot stud into the wall and assemble

the pivot arm fastening at point A and then at point

B.

5109

ITEM PART NO. DESCRIPTION

1 10-3774 Valve Synchronizer Bearing &

Seal

2 10-1133 0 Ring 1/4 I.D. x 3/8" O.D. x 1/16"

thick

3 90-4153 Valve Synchronizer

4 90-0483 Exhaust Valve Ball

5 90-2419 Valve Synchronizer Lever &

Supply Ball Assembly

6 10-0410 Valve Bonnet

7 90-2442 Supply Valve Seat

8 10-2696 Valve Body Gasket

9 90-2443 Exhaust Valve Seat

10 90-2434 Supply & Exhaust Valve - comp.

Page 17

TO SERVICE SUPPLY VALVE AGAINST LEAKS

Remove the interference of the pivot arm by detaching

it at the actuating arm junction and from the pivot stud.

Remove the pivot stud and proceed as follows:

1. Remove existing valve cap (6). (It is not necessary to remove the valve.)

2. Replace valve cap (6) with the seating tool after

having retarded the bolt to a point where it will not

prematurely strike the ball in the valve.

3. After the seating tool-is well secured, screw down

the bolt to make contact with the ball assembly and

apply pressure to force the ball to "make" a new

seat.

4. Remove the seating tool and replace it with

original valve cap(6). (We recommend an

application of "Rectorseal" to threads to make a

secure fit.)

5. Repeat the above process if the first attempt

does not stop the valve from leaking.

'(Seating tool may be obtained from the factory.)

THE STEAM PRESSURE GAUGE ASSEMBLY

To remove the complete steam pressure gauge

assembly, it will first be necessary to remove the side

panel. The steam pressure gauge may then be

detached by removing item (2) and then removing the

two nuts which hold the pressure gauge bracket in

place. The guage is then removed from the front of

cooker. To reassemble, reverse the above procedure.

ITEM PART NO. DESCRIPTION

1 90-8693 3/16 "0. D. Tubing (Model A-1)

15-7054 3/16 " 0. D. Tubing (Model A)

2 10-4370 Brass Nut for Compression Fitting

3 10-4371

Brass Sleeve for 3/16 "

Compression Fitting

4 10-4748 0-30 No. Pressure Gauge

5 10-3360

1/8 "IPS Male x 3/ 16 O.D. Tube

Elbow

5110

Page 18

THE CONTROL BOX ASSEMBLY

The control box assembly is a device which

converts an electrical impulse into a mechanical

action. The mechanical action, stemming from the

sudden release of a spring loaded system of

levers, shuts off the steam supply, exhausts the

steam from the cooking chamber, switches off a

pilot light, and sets off a buzzer. This action is

preset manually, with the simple action of setting

the timer to the cooking timer required and pulling

out the operating handle into the "on" position.

The illustrations of "on" and "off" positions will

serve to familiarize you with the proper

relationship of the inner parts of the control box

assembly.

HOW IT WORKS

When in "off" position; the valve will be closed restricting the steam from passing into the cooking

compartment, the pilot light will be off, the buzzer

inactive and the solenoid de-energized.

When the timer is set for the required cooking time

and the operating handle is pulled to the "on"

position; the valve will be opened to allow steam

into the cooking compartment, the pilot light will

light up, signifying that cooking is taking place, the

buzzer and solenoid will still be de-energized.

When the cycle on the timer clock has been

completed, a flow of current will energize the solenoid

forcing the solenoid push rod to lift and disengage the

operating handle. The operating handle now freed

from the bumper and stop bar will spring back to the

"off" position. The innermost micro-switch, released

from the pressure of the pin of the operating handle

will break the circuit to the solenoid, and the pilot light

and the solenoid both will become inactive. The

nearer solenoid having been pushed into a locked

position under the buzzer lock will remain in contact

operating the buzzer until released by pushing the

buzzer release knob by hand.

TROUBLE -TEST AND REMEDIES

If the operating handle will not lock in the "on"

position:

Check first that timer has been set. Check that

the stop bar is properly secured.

Check that solenoid and bracket is pos itioned

properly.

If the operating handle fails to retract to "off" position:

Check the valve synchronizer spring for

looseness. Check all linkage for binding or

loosened parts.

Check switch on timer for continuity.

Check micro switch for bent arm.

Check for blown fuse and then for defective

wiring or defective solenoid.

5111

Page 19

Valve

5

Ib. -

enamel

SUGGESTED STEAM CONNECTIONS

The illustration shows a recommended system of installation

which provides: a pressure gauge to measure the pressure

input at the source of supply, a globe valve for emergency

shut-off, a ball-float trap to prevent dirt and water from

entering the cooking units, and a pres sure regulating valve to

reduce and regulate steam pres sures for delivery.

..... NOTES .....

ITEM PART NO. DESCRIPTION

1 10-2821 3/4" Globe Valve

2 10-5336 Ball Float Trap

3 10-1033

10-1034

3/4" Pressure Reducing

3/4" Pressure Reducing

Valve 5 Ib. - chrome

5112

Page 20

Wiring Diagram

A-1 Cooker (Automatic) 2,3

&4 Compartment 120 Volt, 60

Hz 240 Volt, 50 Hz Drawing

No. 90-9240

NOTES:

1. Wiring for 2 compartment as shown. For 3 & 4

compartment similar except for no. req'd. of

Timers, Switches, Solenoids, Lights &

Connectors.

2. On 3 & 4 compartment wiring use Marr Conn.

#10-5172 when connecting more than 3 wires.

DIAGRAM NOTES:

1. Dw'g. No. B-90-9217 or B-90-8727 Guide

Bracket & Micro Switch Ass'y. made up as a

sub-ass'y. with leads 90-8915, 90-8916, 908917, & 90-8918.

2. Use B-90-9217 on A-1 Cooker. Use B-908727 on 'A' Cooker.

5113

Page 21

Schematic Diagram

A-1 Cooker (Automatic) 2,3 &

4 Compartment 120 V., 60

Hz 240 V., 50 Hz Drawinq

No. B-90-9240

SCHEMATIC NOTE:

End of Cooking Cycle Timer at zero, Control Arm in

unlocked position. Light, Solenoid & Buzzer deenergized. (Buzzer silenced by reset button on

switch.)

5114

Loading...

Loading...