Page 1

SERVICE & PARTS MANUAL

Models:

2500 HE

2700 HE

2592 HE

High Efficiency Gas Convection Oven

2792 HE

MARKET FORGE industries Inc

Employee Owned Company

World Headquarters: 35 Garvey Street, Everett, MA 02149

Tel. (617) 387-4100, Fax 800-227-2659 (U.S. Except MA) or (617) 387-4456 (In MA)

Form No. S-2207 6/94 Printed in U.S.A.

Page 2

TABLE OF CONTENTS

Paragraph Page Paragraph Page

SECTION 1 INTRODUCTION

11 Description 1-1 51 General 5-1

12 Basic Functioning 1-1 52 Trouble-Shooting Guide 5-1

13 Service 1-1 53 Electrical Fault Isolation 5-3

SECTION 2 INSTALLATION

21 Receiving 2-1 541 Incoming Power 5-3

22 Assembly 2-1 542 Electrical Inspection 5-3

221 Oven on 7" (178mm} Stand 2-1 543 Direct Spark Ignition System 5-3

222 Oven on Modular Base 2-1 544 Thermostatic Control 5-5

223 Oven on 28" (711mm} Open Stand 2-1 545 Solenoid Gas Valve 5-5

224 Stack Oven on 7" (178mm} Stand 2-1 546 Wiring 5-5

23 Gas Connection 2-3 547 Buzzer Relay 5-5

231 Placement 2-3

232 Materials 2-3 SECTION 6 MAINTENANCE

233 Connection 2-3 61 General 6-1

234 Gas Leak Test 2-3 62 Preventive Maintenance 6-1

24 Electrical Connection 2-3 63 Adjustment Procedures 6-1

25 Ventilation 2-5 631 Oven Door Adjustments 6-1

251 Flue Deflector Installation 2-5 632 Thermostat Calibration 6-2

26 Installation Check-Out 2-5 64 Repair and Replacement 6-2

261 Initial Control Settings 2-5 641 Control Panel Removal 6-2

262 Oven Check-Out 2-5 642 Right Side Panel Removal 6-3

263 Shut -Down Procedure 2-6 643 Fan Blade Removal 6-3

SECTION 3 OPERATION

31 Operating Controls and Indicators 3-1 646 Gas Valve Removal 6-4

32 Operating Procedures 3-1 647 Thermostat Removal 6-4

321 Preheating 3-1 648 Ignition Control Board Removal 6-4

322 Cooking 3-1 65 Adjustments and Operational

SECTION 4 PRINCIPLES OF OPERATION

41 General 4-1 652 Regulator Adjustment 6-4

42 Combustion/Vent Circuits 4-1

43 Electrical Circuits 4-2 SECTION 7 ILLUSTRATED PARTS LISTS

431 Control Circuit Components 4-2 71 General 7-1

SECTION 5 TROUBLE -SHOOTING

54 Electrical Trouble-Shooting

Procedures 5-3

644 Burner Pan Removal 6-3

645 Electrode Removal 6-4

Checks of Burner Components 6-4

651 Gas Burners 6-4

72 Ordering Information 7-1

73 Index of Illustrated Parts Lists 7-1

Page 3

LIST OF ILLUSTRATIONS

Figure

Page

SECTION 1 INTRODUCTION

1-1 High Efficiency Gas Convection Oven

SECTION 2 INSTALLATION

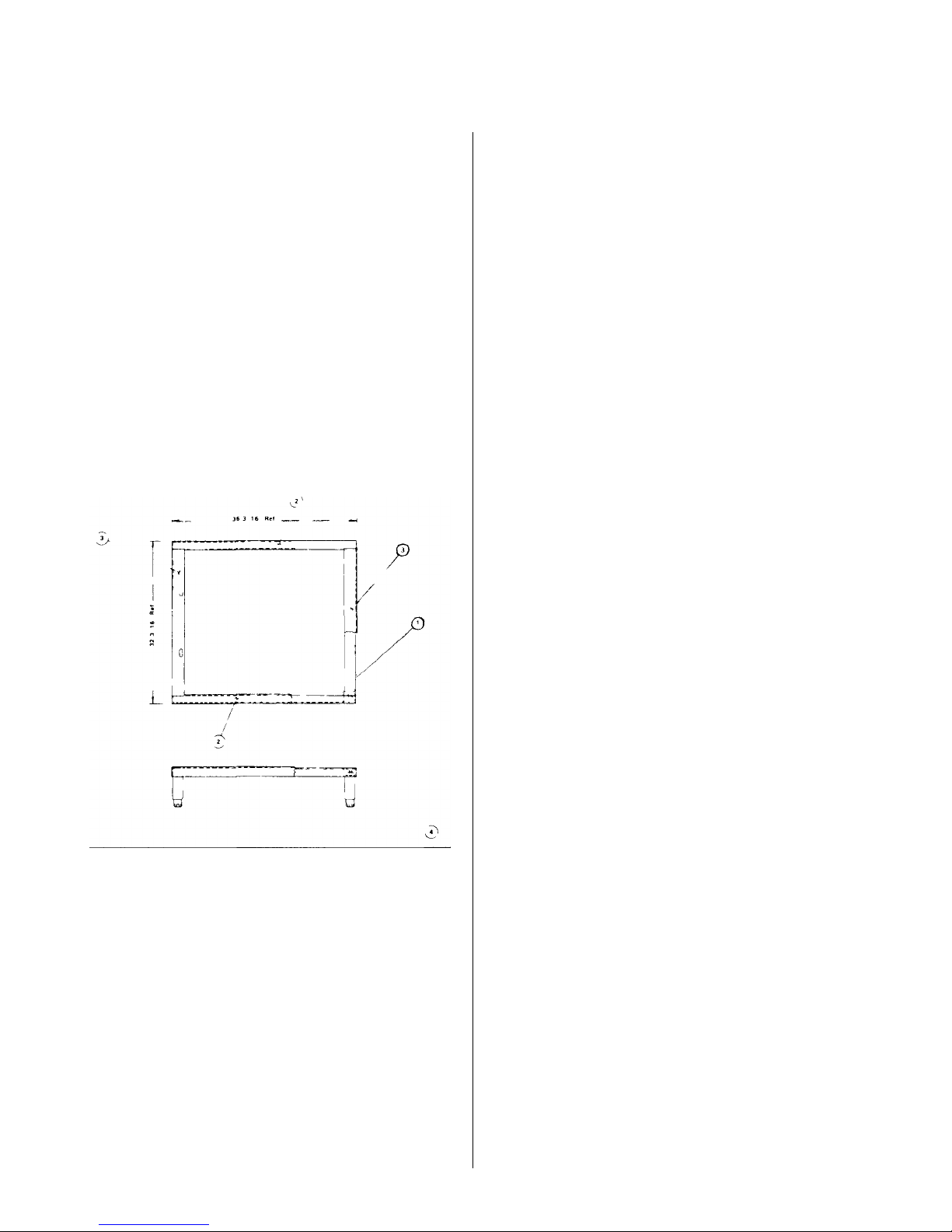

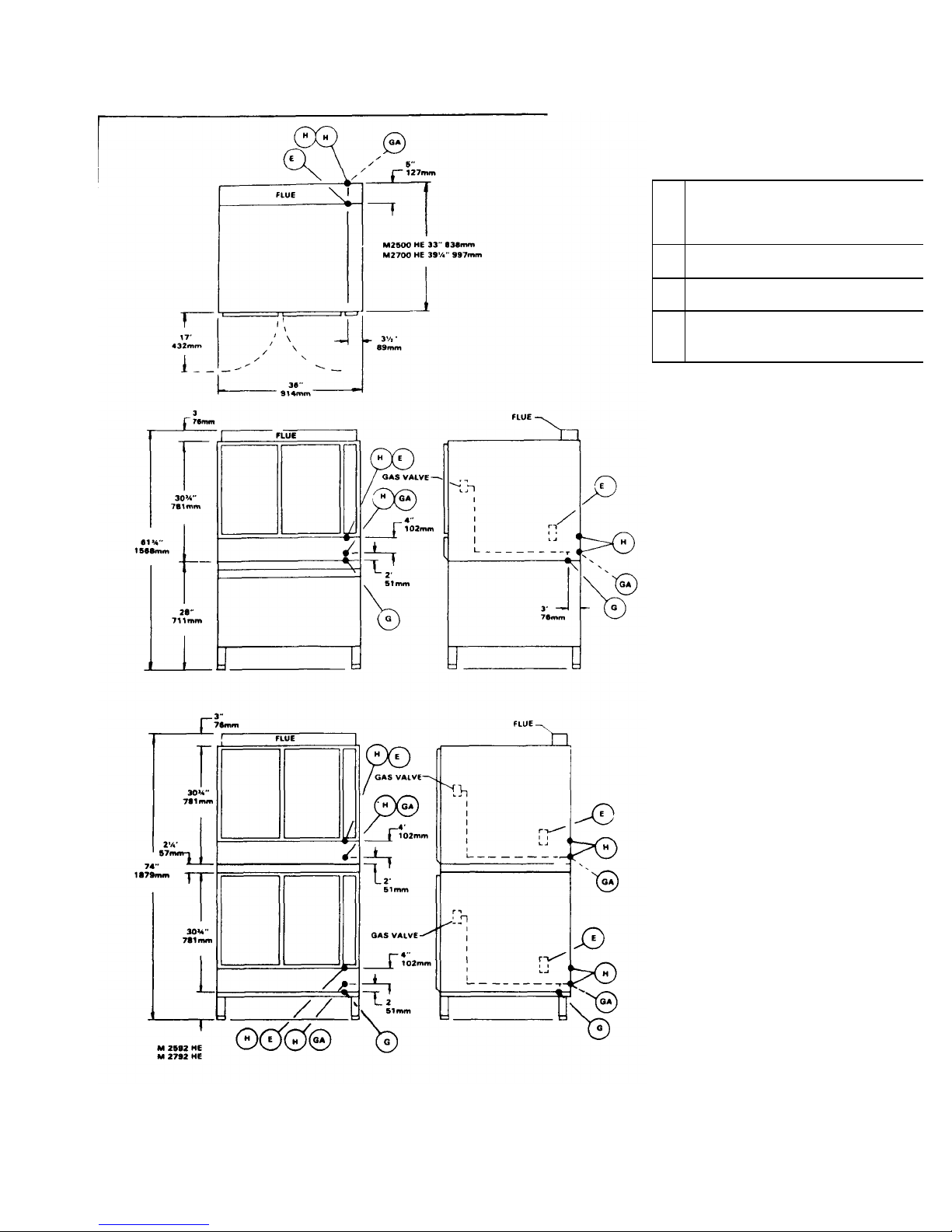

2-1 7" Stand 2-1

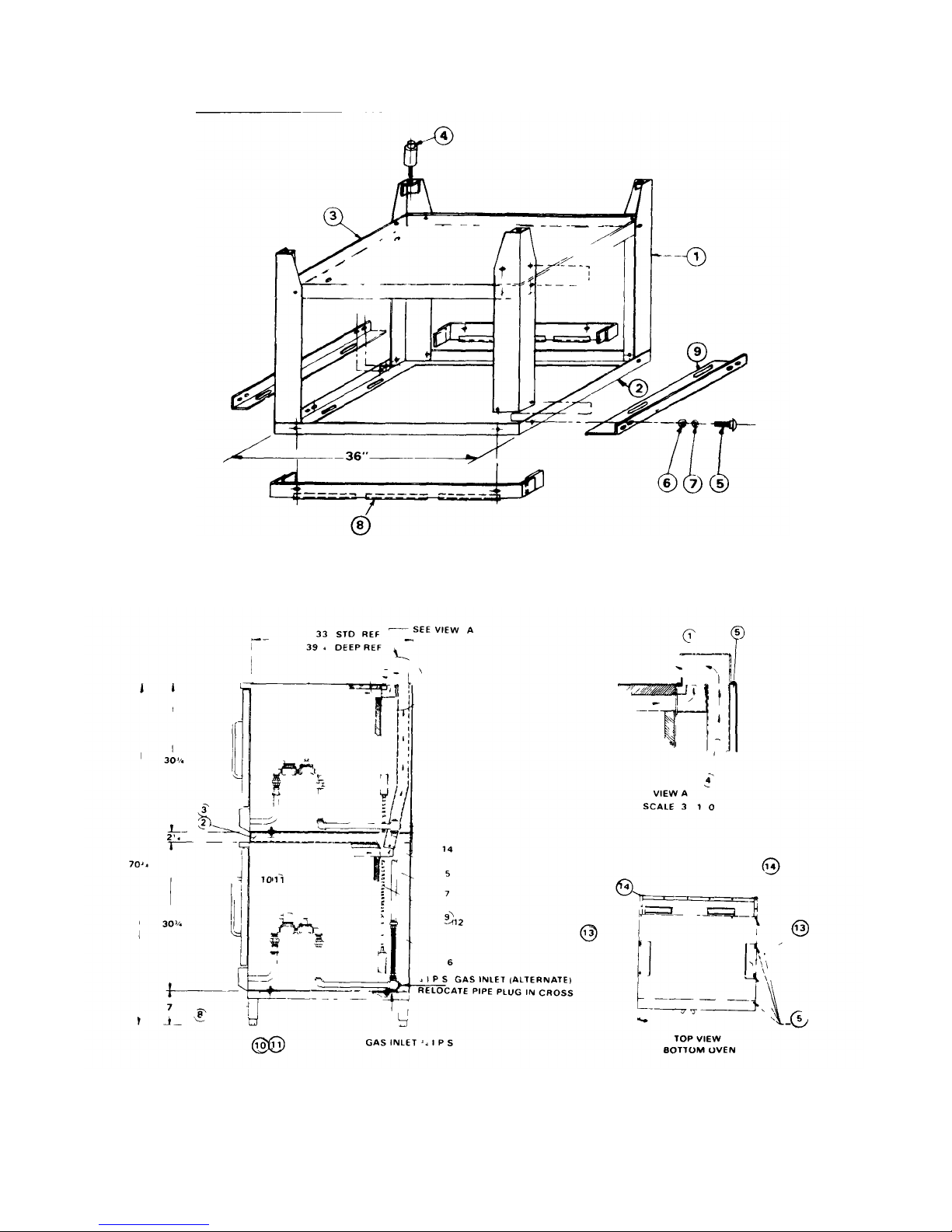

2-2 28" Stand 2-2

2-3 Stacked Ovens 2-2

2-4 Service Connections 2-4

SECTION 3 OPERATION

3-1 Control Panel 3-2

SECTION 4 PRINCIPLES OF OPERATION

4-1 Cutaway Oven 4-1

4-2 Schematic Control Circuits 4-2

1-2

LIST OF TABLES

Figure

SECTION 5 TROUBLE -SHOOTING

5-1 Wiring Diagram 5-3

5-2 Flame Current Meter Placement 5-4

SECTION 6 MAINTENANCE

6 1 Blower Guard 6-1

6-2 Wheel Puller Kit 6-3

6-3 Air Shutter Adjustment 6-5

SECTION 7 ILLUSTRATED PARTS LISTS

7-1 Frame & Cabinet Assembly 7-2

7-2 Manifold & Burner Pan Assembly 7-4

7-3 Door Assembly 7-6

7-4 Control Panel Assembly 7-8

7-5 Ignition Control Board Assembly 7-10

Page

Table Page Table

SECTION 3 OPERATION SECTION 5 TROUBLE-SHOOTING

3-1 Control Panel Components 3-3 5-1 General Trouble-Shooting Guide 5-1

5-2 Electrical Fault Isolation Guide 5-2

Page

Page 4

SECTION 1 INTRODUCTION

This service and parts manual contains general information, installation, operation, principles of operation, trouble-

shooting, and maintenance information for the Market Forge High Efficiency Gas Convection Oven Also included

are parts lists, in which each replaceable part is identified and shown in an accompanying exploded view

1.1 DESCRIPTION

The Market Forge Model HE Gas Convection

Oven is a gas fired, pilotless, direct-spark-igni-tion

system convection oven The unit is designed to

operate from a natural, propane, or butane gas

supply when equipped with appropriate gas orifices

It consists of a heavily insulated cooking

compartment fitted with a convector fan and heated

by a gas burner system designed to achieve optimal

efficiency from the fuel burned All oven controls are

located on a recessed panel on the right front of the

oven as seen from the front

The major assemblies of the HE oven are the

stainless steel or baked enamel finish cabinet

enclosure, solid doors, stainless steel cooking

compartment with nine shelf supports, convector

fan, pressure regulator and gas valve manifold

assembly, burner box assembly consisting of gas

burners, orifices, and direct spark ignition elec trode

The control panel assembly includes the thermostat,

electronic ignition control board, 60-minute and 5hour mechanical timers, red indicator light, ON-OFF

power switch, warning buzzer, and ignition and

motor reset switches

The unit is available in a variety of mounting

configurations 7" (178mm) counter stand, 28"

(711mm) modular base, open stand on legs with

shelf and optional storage rack, or stacked on top of

another HE oven with the bottom unit on 6" (152mm)

stainless steel legs

1.2 BASIC FUNCTIONING

The HE oven becomes operational when the

power switch is placed in the ON position, doors are

closed, and thermostat set Electronic ignition

activates, energizing the burner electrodes and

opening the gas valve (The fan operates continuously

with power on and doors closed, regardless of

thermostat setting ) Gas passes through the regulator

and valve to the burners, where it is ignited by the

sparking of the elec trodes The resulting flame heats a

flame baffle plate mounted under the cooking

chamber, which in turn heats the chamber The fan

circulates air uniformly through the chamber When the

chamber reaches the preset temperature, the

thermostat contacts open and the gas valve closes

When the temperature drops enough to close the

contacts, the ignition system reactivates Any number

of such cycles might occur during the cooking time If

for any reason the burners fail to ignite, the system

automatically closes the gas valve Should the burners

go out prematurely, the system will automatically activate the ignition electrodes, and if flame is not

established the system will shut down and close the

gas valve

1.3 SERVICE

Required service, both preventive and corrective,

is explained in Section 6 Should repairs be required, a

network of authorized agencies is

Page 5

available to assist with prompt service. A current directory

of Authorized Service Agencies may be obtained by

contacting:

Product Service Department

Market Forge

35 Garvey Street

Everett, Massachusetts 02149

Telephone (617) 387-4100

Product Service Department

Market Forge Canada Ltd.

1375 Aimco Blvd., Unit 5

Mississauga, Ontario, Canada L4W 1B5

Telephone (416) 621-9252

The model and serial numbers must be referenced when

corresponding with Market Forge. The data plate with serial

number is located on the center of the bottom front trim

ledge.

Figure 1-1. High Efficiency Gas Convection Oven on Optional Stand

Page 6

SECTION 2 INSTALLATION

2.1 RECEIVING

The oven is shipped bolted to a skid and cov ered by

a carton which is nailed to the skid, these must be

carefully removed prior to installation DO NOT AT ANY

TIME LAY THE OVEN ON ITS TOP, SIDE, OR FRONT

TO DO SO MAY DAMAGE THE EQUIPMENT AND

INVALIDATE THE WARRANTY

2.2 ASSEMBLY

Set-up and assembly procedures for the various oven

configurations are described in the following paragraphs

2.2.1 Oven on 7" (178mm) Stand

1. Screw legs (Figure 2-1, #4) into top frame assembly

(1)

2. Place into position front and rearchannel assembly

(2) and side angles (3) These items are loose parts

and are tied together with mounting of oven to stand

3. For single oven, mount oven to stand using four

3/8-16 x 3/4 Ig hex head cap screws and four 3/8

plain washers provided

4. For stacked oven, proceed to paragraph 2 2 4

5. For single oven, proceed to subsection 2 3

2.2.2 Oven on Modular Base

1. Screw adjustable feet into cabinet base

2. Mount oven to base using four 3/8- 16 x 3/4 Ig

hex head cap screws and four % plain washers

provided

3. Proceed to subsection 2 3

2.2.3 Oven on 28" (711mm) Open Stand

1. Place top frame (Figure 2-2, #2) upside down on

a clean smooth surface

2. Place into position front and rear angle as semblies (8) (stainless only) and legs (1)

3. Align holes in legs, frame, and angle assemblies

Secure using carriage bolts, lockwash-ers, and

nuts provided (5,6,7)

4. Align holes in shelf (3) with leg holes and secure

using hardware (5,6,7)

5. Screw adjustable feet (4) into stand legs

6. Install four clips for oven rack support inside top

frame using hardware (5,6,7) optional

7. Place stand in upright position Install rack

support, if supplied, inserting ends through holes

in clips and shelf

8. Mount oven to stand using four ¾-16 x 3/4 Ig

hex head cap screws and four 3/8 plain washers

provided

9. Proceed to subsection 2. 3

Figure 2-1. 7" (178mm) Stand

2.2.4 Stack ovens on 7" (178mm) stand

See 2.2.1 for stand assembly and proceed as

Follows:

1. Remove rear panels from both ovens by

removing 14 Phillips head screws from each

rear panel.

Page 7

Figure 2-2 28" (711mmi Open Stand (Inverted for Assembly)

Figure 2-3 Stacked Ovens

Page 8

2. Tilt ovens onto left sides as seen from front to

access bottoms DO NOT AT ANY TIME LAY THE

OVENS DOWN ON TOPS, RIGHT SIDES, OR

FRONTS. TO DO SO MAY DAMAGE THE

EQUIPMENT AND INVALIDATE THE WARRANTY

3. Install 7" (178mm} stand to bottom oven using

hardware (Figure 2-3, #10, 11). Either oven may

serve as bottom oven. Stand is 32" (813} front to

back. When used with deep ovens, overhang may

be either front or back, as desired. (Recommended

overhang is in back )

4. Stand bottom oven upright, onto stand.

5. Install top retaining brackets (13) on top of bottom

oven by removing two screws from top panel, left

and right, as shown, and replacing through holes in

brackets.

6. Install spacer assembly (2 or 3) on bottom of top

oven using hardware (10, 11).

7. Stack top oven on bottom oven.

8. Attach long flue assemblies (4) to top and bottom

ovens. See Figure 2-3, view "A".

NOTE

If stacked ovens are adjacent to moisture producing

equipment (such as kettles or steam cookers) it is

necessary to seal the seam between the stacked ovens

and the moisture producing equipment to prevent

condensation from entering the control section of the

bottom oven Silicone synthetic rubber is recommended

for a sealant

rear wall if adjoining wall is combustible Allow 6" (152mm}

clearance on right from another gas fired heat generating

piece of equipment, unless the equipment is another Market

Forge High Efficiency Oven, in which case no spacinq is

needed.

2.3.2 Materials

Use new pipe 3/4" (19mm} IP S properly reamed, free from

chips, and threaded to the proper length. If pipe dope is

used, apply a moderate amount, leaving two end threads

bare If Teflon tape is used, apply one and one-half turns,

leave ing the two end threads bare

2.3.3 Connection

Connect the gas line into the oven bottom at the right rear as

seen from the front, or alternate connection right rear back.

See Figure 2-4 For stacked ovens, connect gas pipe lines

between ovens using 3/4" (19mm} I.P.S. flexible connector

(Figure 2-3, #6) and 3/4" (19mm} I.P.S. x 20 1/4 tg nipple

(7). Install 3/4" (19mm} external gas supply shut -off valve

(furnished with unit) in an easily accessible location.

NOTE:

MANIFOLD PRESSURE MUST BE 4.0" (102mm} WATER

COLUMN FOR NATURAL GAS OVENS AND 10.0"

(254mm} FOR LP GAS OVENS SUPPLY PRESSURE

MUST BE AT LEAST 6.0" (152mm} FOR NATURAL GAS

AND 100" (254mm} FOR LP GAS. INSTALL PIPE PLUG IN

SIDE OF PIPE NOT BEING USED TO FEED GAS TO UNIT

2.3 GAS CONNECTION

This oven is factory adjusted for a gas consumption

rate of 60,000 BTU/hour. Read the nameplate on the

lower front access panel If this plate is marked for a

different gas than that being supplied, notify your dealer

immediately. DO NOT CONNECT GAS LINES Only a

qualified service technician should make the installation.

Installation must conform with the National Fuel Gas

Code ANSI Z223 1-1974, or CSAB1491 installation

codes, where applicable.

2.3.1 Placement

Allow 2" (51mm} clearance from side wall and

2.3.4 Gas Leak Test

Perform a gas leak test of all newly made joints, as well as

those leading to the main gas control valve. Check for leaks

using soap solution. DO NOT USE FLAME.

2.4 ELECTRICAL CONNECTION

Where applicable, installation must conform with

National Electrical Code ANSI C1-1975 or Canadian

Electrical Code C22 1, and/or local codes.

Page 9

SERVICE CONNECTIONS

Hz.

1/2" 13mm conduit connection or equivalent

amps per oven Use wire suitable for at

Alternate

2.

Access to electrical junction box

GAS OPERATED

E

Electrical connection — 120 volt AC. 60

10

least 90°C

G 3/4" 19mm I.P.S Gas Connection Inlet,

Standard

GA 3/4" 19mm I.P.S Gas Connection Inlet,

H 1 3/4" 44mm dia. access holes for

1. Alternate gas supply connection GA

Page 10

1. Connect the power supply wires to the junction

box at the right back of the oven Use wire

suitable for at least 90°C Ensure that hot wire

connects to terminal L1 and neutral wire to L2

2. For stacked ovens, connect power supply to

bottom oven junction box Install flexible conduit

assembly (Figure 2-3, #9 or 12) between top

and bottom junction boxes

3. Ground unit using ground lug in supply box

4. Replace rear panel(s)

5. For stacked ovens, add back retainer clips

(Figure 2-3, #14) to back of both units using

existing screws

2.5 VENTILATION

Proper ventilation is highly important for good

oven operation The use of a mechanical exhaust

system is ideal A properly designed unit will extend

approximately 4" to 6" (102-152mm) beyond all

sides of the oven unit In such instances the oven will

be equipped with a flue deflector, which is shipped

separate from the oven in the stand carton If the flue

outlet is to be connected directly to a chimney, then

a down draft diverter should be employed AT NO

TIME SHOULD A DAMPER BE INSTALLED IN THE

EXHAUST SYSTEM OF THIS OVEN

2.5.1 Flue Deflector Installation

To install deflector, remove back row of screws from

oven top panel Add flue deflector with open side

facing front, and replace screws For stacked ovens,

see Figure 2-3, view "A"

2.6 INSTALLATION CHECK-OUT

After the oven is completely assembled and

properly located with gas and electrical supplies

connected, the unit should be given a thorough

check-out before being put into operation Check-out

procedures for the oven are given in subsection 2 6

2 If the unit fails to perform as described, consult the

trouble shooting guides in section 5 for corrective

action

Before making this check-out, the operator must

be thoroughly familiar with the operating procedures

in Section 3, and with the function of

each control described in Table 3 1 Reference Figure

3-1 for identification of controls

2.6.1 Initial Control Settings

Power switch and thermostat dial are in OFF

position

2.6.2 Oven Check-Out

A final check of the controls and connections

should be made as follows

1. Make sure that the blower guard is properly

mounted See Figure 6-1

2. With a level on the oven shelves make sure that

the oven is level both front and back left and right

To adjust, turn feet in stand legs NOTE Be sure

wire shelf supports are in, not on, brackets

3. Make sure that gas and electrical supplies are

available to the unit

4. Set thermostat dial at 350°F

5. Place power switch in the ON position with doors

open

6. Close doors Indicator light should come on, fan

should come on and rotate clockwise (seen from

front) NOTE Buzzer may sound for an instant

a) If fan does not start, or starts and immediately

stops, press MOTOR RESET

b) If buzzer sounds, press IGNITION RESET

7. If fan still does not work or buzzer sounds again,

see Tables 5-1 and 5-2 for troubleshooting and

electrical fault isolation

8. Indicator light will remain on while oven is heating,

and go out when preset temperature is reached

During the heat -up period, some slight smoke or

fumes may result due to oil or grease on metal

surfaces This should cease after five minutes

9. During initial burner operation, observe flame

angle of each burner through the louvers on the

lower front panel If flames are not vertical, burners

may not be positioned properly, see subsection

6.4.4

10. After this check is completed, turn thermostat dial

and power switch to OFF position

Page 11

2.6.3 Shut-Down Procedure

1. For daily shut -down, place thermostat dial

and power switch in OFF position.

2. For extended shut-down, place thermostat dial and

power switch in OFF position. Close external gas

supply shut -off valve. Leave doors ajar.

Page 12

SECTION 3 OPERATION

3.1 OPERATING CONTROLS AND

INDICATORS

All the controls required to operate the oven are

listed in Table 3-1 with a short functional description

of each. Figure 3-1 shows the physical location of

each control and indicator.

3.2 OPERATING PROCEDURES

Before attempting to use the oven for cook ing,

be sure that proper gas and electrical connections

have been made, gas supply valve is open, and fan

guard properly mounted.

3.2.1 Preheating

1. Arrange shelf positions according to the item to

be cooked. Refer to Test Kitchen Bulletin #41

for correct positioning.

2. Place power switch in the ON position. Close

doors. Fan should come on and rotate clockwise. If not, depress the MOTOR RESET but ton. If fan still does not operate, consult Table 5-

1.

3. Set thermostat dial to desired temperature.

Indicator light should come on. Burners should

ignite. If not, buzzer will sound. Depress the

IGNITION RESET button. If burners still do not

ignite, consult Table 5-1.

4. Preheat to temperature and allow to cycle once

(indicator light on, off, on) to obtain

even temperature throughout oven Total time:

approximately 15 minutes

3.2.2 Cooking

The oven is ready for cooking use when the

indicator light goes off. The load should be adjacent to

the oven, so that doors will be open as short a time as

possible during loading.

1. Load oven. If using oven for long term roasting of

meats, fish, or poultry, place about a quart of

water in the oven in a suitable container or under

a trivet in the same pan as the food.

2. Close doors and set timer for desired cooking

time.

NOTE: Timer is for convenience only and does not

control oven operation. Bell will ring at end of

preset interval.

3. Unload oven and proceed as follows:

a) If oven is to be turned off, place thermostat

dial and power switch in the OFF position.

b) If oven temperature is to be lowered, set

thermostat to desired temperature. Close right

door and leave left door open. Fan will

continue to run. When light comes on, oven is

at lower temperature. Close left door. When

light goes off, oven is ready to use.

4. Place thermostat dial and power switch in OFF

position for daily shut -down. For extended shutdown, place dial and switch in OFF position,

close gas supply valve, and leave doors ajar.

3-1

Page 13

HIGH EFFICIENCY CONVECTION OVEN

3-2

Page 14

TABLE 3-1

FIGURE 3-1 REF. DESCRIPTION FUNCTION

1 Thermostat Dial

2 60-Minute Timer

Regulates oven temperature by controlling burner operation. When

set, activates gas valve and ignition system.

Mechanical timer to aid operator in timing cooking cycle. Does not

control oven operation.

3 5-Hour Timer Same as 60-Minute Timer

4 Power Switch

5 Indicator Light

Controls power to control circuits and convector fan. Must be in ON

position for oven to operate

Indicates when lit that burners are operating Cycles on and off with

thermostat control.

Resets direct spark ignition system. If burners do not ignite after 3.3

6 Ignition Reset

seconds of ignition sparking, system locks out, closing gas valve.

Buzzer will sound. Press to reset system.

7 Motor Reset Circuit breaker protecting fan motor and control circuits. Press to reset.

3-3

Page 15

SECTION 4 PRINCIPLES OF OPERATION

4.1 GENERAL

The HE gas fired convection oven employs a carefully

designed ventilation combustion system which achieves

optimal control of combustion products. A convector fan

distributes heat uniformly throughout the oven interior The

gas burners are ignited by a pilotless, direct spark ignition

system. Cooking temperature is maintained by a thermostat

mounted on the control panel. Manual 60-minute and 5 hour

timers assist the operator but do not control oven operation

4.2 COMBUSTION/VENT CIRCUITS

With electrical power applied, gas supply

valve open, and the power switch on, electrical control

circuits are activated to energize the burner electrodes

Gas passes through the regulator and valve to the burner

orifices. Primary air enters the burner tubes through

shutter openings and mixes with the gas, which is ignited

by the ignition electrodes. The flame heats a baffle plate

mounted under the cooking chamber. Heat passes to the

oven interior by radiant and convection transfer from the

baffle plate. Combustion products are directed via internal

flues around the sides of the cooking chamber, where

additional heating is achieved, and into the flue deflector

at the top.

Figure 4-1 Cutaway Oven

4-1

Page 16

4.3 ELECTRICAL CIRCUITS

120 volt a-c power is supplied to the fan motor,

indicator light, and ignition control board, which in turn

controls power to the burner electrodes. IGNITION RESET

switch, and gas valve solenoid Input power is connected at

the junction box mounted (behind an access cover) at the

lower right rear of the oven.

4.3.1 Control Circuit Components

The control circuit is shown in the simplified schematic

drawing Figure 4-2. A brief description of major electrical

control circuit components is included in the following

paragraphs.

4.3.1.1 Door Interlock Switch

The interlock switch is a single pole, two-position

micro-switch with normally open contacts. The switch lever

is operated by an actuating

Figure 4-2 Simplified Schematic — Controls in OFF position

bar built into the door jamb of the right side door When the

door is open, the bar remains retracted with the switch

contacts in the normally open position. When the door is

closed, the door pushes the actuating bar against the switch

lever to close the contacts. Connected into the circuit for the

fan and ignition system, the door switch interrupts fan

operation and deactivates the ignition system when the door

is opened

4.3.1.2 Thermostat Control

The thermostat is a bulb and capillary type system,

manually adjustable from 200-475°F (94-246°C).The oven is

put into an automatic heating cycle with the setting of the

thermostat to any of its calibrated temperature settings.

Expansion and contraction of gas with in the capillary/bellows system in response to temperature change

opens and closes the thermostat contacts, energizing and

de-energizing the ignition control system

4.3.1.3 Direct Spark Ignition System

The direct spark ignition system consists of the

electrodes, ignition control board, and associated wiring. On

a call for heat, input power is applied to the control board.

Sparking is then initiated and the gas valve is energized.

Sparking continues with the gas valve powered for a "trial

for ignition" period of 3.3 seconds. If flame has not been

established by the end of the trial period, the system will

lock out, the gas valve will close, the reset function will trip

out, and a warning buzzer will sound. Reset action is manually accomplished by pressing IGNITION RESET switch In

normal operation, as soon as flame is established and

proven by the flame sensing circuitry, sparking will cease

immediately and the system will remain "on", monitoring the

flame until the end of the duty cycle. Should flame -out occur

during the duty cycle, the system will reactivate the spark to

provide for reignition.

The flame will either be reestablished or the system will

lock out in the normal manner. Should lock-out occur, the

system is reactivated by the IGNITION RESET switch

located on the control panel.

4-2

Page 17

SECTION 5 TROUBLE-SHOOTING

PROBLEM

a) Power to oven is off.

Locate external circuit breaker for power and place

a) External gas supply shut

-

off Open valve

5.1 GENERAL

The information in this section is intended to

assist both the operator and service personnel in

described in Section 3. If the problem cannot be

readily corrected, the operator should contact the

nearest Market Forge Service Agency for assistance

locating the general source of problems which may

occur with the High Efficiency Convection Oven.

Before following any of the procedures given in this

section, the operator should be thoroughly familiar

with the operating instruc tions and the function of all

5.2 TROUBLE-SHOOTING GUIDE

A general trouble-shooting guide for use by

service personnel is given in Table 5-1

controls which are

TABLE 5-1 GENERAL TROUBLE-SHOOTING

GUIDE

Probable Cause Remedy

1. CONVECTOR FAN FAILS TO OPERATE.

in ON position

b) Control circuit breaker open. Press MOTOR RESET

c) Right oven door open. Close door

d) ON-OFF switch off Place in ON position

e) Faulty circuit breaker, power Test each component and connecting wiring. Re

switch, door switch, fan motor, or place as required

wiring.

2. GAS BURNERS FAIL TO IGNITE (BUZZER SOUNDS)

closed.

b) Ignition circuit locked out Press IGNITION RESET

c) Gas solenoid valve fails in closed Replace valve.

position.

d) Faulty control board. Replace control board. See subsection 6.4.8.

e) Faulty electrode unit Replace electrode unit See subsection 6. 4.5.

f) Damaged or loose wire. Trace all wiring from control board to controls.

ly connected and located at least 1/2" (13mm} from

5- 1 S 2207

Check to see that all wiring is secured, and that the

high and low voltage leads to electrode are proper-

ground.

Page 18

TABLE 5-1 (cont )

3. INDICATOR LIGHT FAILS TO LIGHT WITH THERMOSTAT SET, FAN OPERATING

a) Indicator light burned out Replace light

b) Thermostat contacts faulty Replace thermostat

c) faulty wiring Check wiring from door switch to thermostat and light

4. ERRATIC OVEN TEMPERATURE

a) faulty thermostat operation

5.3 ELECTRICAL FAULT ISOLATION

Correction of an electrical failure first requires

isolation of the fault to a single circuit or component. In

most cases the nature of the failure and its effect upon

Recalibrate or replace as required See subsection 6.3.2

(neutral lead to wire #11) Make sure the unit is

properly grounded to the ground lug in the Junc tion

box If 120 vo lts are present, the fault lies in the

electrical circuits of the oven

the operation of the oven will be sufficient to isolate it

to one or more circuit elements Table 5-2 is provided

as a guide for isolating electrical faults.

5.4 ELECTRICAL TROUBLE-SHOOTING

PROCEDURES

Before performing the trouble-shooting pro-

cedures in this section the serviceman must be

familiar with the function of all controls as described in

Section 3 and with the Principles of Operation

described in Section 4.

Electrical trouble-shooting procedures which

follow require access to components and terminals of

the operating controls and ignition control board

Electrical controls are reached by removing the control

panel as described in paragraph 6.4.1 Wiring and

terminal locations are shown in Figure 5-1. Figure 4-2

shows the circuit schematically

5.4.2 Electrical Inspection

The first step in any electrical trouble-shooting

procedure is a thorough inspection of all wiring

connections To access the electrical components,

remove control panel as described in subsection 6.4.1

WARNING

Before removing the control panel or checking

connections or wiring, make sure incoming

power is shut off When power is supplied, all

exposed terminals carry 120 volts

Check all connections by hand to ensure that all

connection points are tightly secured Use a

screwdriver to tighten if necessary Inspect all quickdisconnect terminals for evidence of corrosion

Terminals in this condition should be replaced

5.4.1 Incoming Power

Before trouble-shooting any of the electrical parts

or assemblies, make sure power is being supplied to

the junction box (Figure 7-1, #11). With power

connected to the oven, an a-c voltmeter is used to

measure 120 volts across terminals to lines coded L1

(hot lead to wi re #1) and L2

5.4.3 Direct Spark Ignition System

The ignition control board and associated

components are the main electrical control for

operation of the HE oven If it is determined that the

electrical controls (solenoid valve, RESET switches,

electrode, etc ,) are not damaged and

5-2

Page 19

TROUBLESHOOTING

1.

Will not operate when thermostat is set.

a. Incoming power

Figure

5-1.

Wiring Diagram

the interconnecting wiring is complete and not

TABLE 5-2

ELECTRICAL FAULT ISOLATION GUIDE

FAILURE FAULT LOCATION

2. Intermittent operation of burners

b. Door switch

c. Faulty thermostat

d. Wiring

e. Ignition system control board

f. Ignition electrode

g. Gas valve solenoid

a. Damaged control system. Refer to paragraph

3. Indicator light off (system operating) a. Indicator light

4. System fails to operate upon pressing RESET a. RESET switch

switch

5. Convector fan fails to operate a. Circuit breaker

b. Thermostat malfunction

b. Wiring

b. Wiring

b. On-Off switch

c. Door switch

d. Fan motor

damaged, the trouble is due to a malfunction of the

components on the ignition control board.

Components on the control board are not replaceable

and a damaged control board must be replaced as a

functional unit. The following paragraphs outline

possible problems and symptoms that may be

encountered during the normal use of the oven.

CAUTION

IF A CONTROL BOARD IS REPLACED, BE SURE

THAT THE HIGH VOLTAGE LEAD OF THE

ELECTRODE IS CONNECTED TO TERMINAL E1

AND THE LOW VOLTAGE LEAD IS CONNECTED

TO TERMINAL E2 OF THE CONTROL BOARD.

5-3

Page 20

5.4.3.1 Improper Polarity

If a spark is present and the gas valve opens but the system

shuts down after the trial period, check the 120 volt a c input

voltage at terminals A (L1) ,and L2 of the control board for

proper polarity Terminal A should be the hot side and L2

neutral with respect to ground.

5.4.3.2 Damaged Grounding

If a spark is present and gas valve opens but the

system shuts down after the trial period, check to make sure

the system is properly grounded to the burner and the

burner itself is properly grounded Proper grounding is

essential for the proof of flame safety device. If the system

is not grounded to the burner, it cannot determine the

presence of flame and will lock out A restart will initiate the

trial for ignition period, but the system will continue to go into

'lock out' if it is not properly grounded, and the thermal reset

will trip. Wait one minute before pushing the IGNITION

RESET button. Check all power and ground terminals to

make sure good contact is made. Clean any corrosion that

might interfere with good electrical contact.

5.4.3.3 Malfunction Due To High Voltage

During the trial for ignition, if the spark is intermittent

and the valve may (or may not) open, check the spark gap

on the electrodes and system wiring as follows:

1. Remove the electrode from the burner and check to see

that the gap is 1/8" ± 1/32". If not, replace electrode.

2. Check the ceramic housing and lead wires for cracks or

breaks.

3. Check terminals E1 and E2 for inadvertent grounding.

They should be at least 1/2" from metal objects which

can cause arcing to ground. If the electrode or lead

wires are faulty replace with new components.

5.4.3.4 Malfunction Of Gas Valve

If the board is receiving proper power and sparking

occurs during the trial for ignition period but the valve does

not open, check the valve for an open coil or other

malfunction. Be sure

Figure 52 Placement of Flume Current Meter

voltage rating of the valve is 120 volts a-c. Use a voltage

tester or voltmeter at terminals B and V2 of the ignition control

board. Voltage should be 120V

5.4.3.5 Erratic Operation

If the system operates properly for a while but randomly

shuts down during the duty cycle, or won't operate during

'cold' starts, check the flame proving circuit with a d-c

microamp meter Refer to Figure 5-2 and proceed as follows:

1. Locate ignition control board (Figure 7-5, 2) 2 Remove low

voltage wire from terminal E2 and connect one lead of

microamp meter to push-on connector attached to lead

wire.

3. Connect second lead of meter to terminal E2 on ignition

control board.

4. Energize control board and read current on microamp

meter. Typical flame current is 2 to 20 microamperes.

If low or marginal flame current is present, it is tripping the

thermal reset switch. If this is the case, relocate the electrodes

or flame sensor into the flame to increase the flame current. If

the ignitor is switched off and on several times in succession,

the thermal reset switch will trip, and it will have to be reset. If

ignition is not achieved after the first two or three attempts,

check to ensure that the other components in the system are

functioning correctly.

Page 21

5.4.4 Thermostatic Control

5.4.4.1 Thermostat Contacts

Defective contacts will result in failure of the

oven to operate properly. If the ignition system fails

to operate when the thermostat knob is set to the

desired temperature, the fault may be the

thermostat switch contacts or thermostat wiring.

When this occurs, remove the control panel

(subsection 6.4.1) and proceed as follows.

1. Turn off power to the oven at external (main)

circuit breaker

2. Disconnect all wires (8,9,18) from thermostat

terminals (See Figure 5-1)

3. Connect an ohmmeter between the terminals

4. Rotate the thermostat knob to the maximum

setting With the oven cool, a zero ohm reading

should be obtained on the ohmmeter. If zero

reading cannot be obtained, contacts are

defective and the thermostat must be replaced.

5. Remove ohmmeter and replace all leads on

terminals as shown in Figure 5-1

5.4.4.2 Thermostat Capillary

A defective or punctured capillary/bellows

system may cause continuous operation of the

burners. If continuous operation occurs and

recalibration of the thermostat as explained in

subsection 6.3.2 fails to correct the problem, the

entire thermostat control must be replaced

If voltage of 120 volts is present, the valve is defective

and must be replaced as a unit If 120 volts is not

present and all wiring connections are tight, the

ignition control board is defective and must be

replaced

5.4.6 Wiring

All the electrical components of the HE oven (ON-

OFF switch, door switch, thermostat control, gas

solenoid valve, RESET switches, ignition control

board, and indicator light) are connected to each other

by wiring shown in Figure 5-1. If all of the electrical

components are operating correctly (and the incoming

power has been checked) but the unit fails to operate,

the fault lies in the wiring.

Figure 5-1 is a wiring diagram which shows all

terminals and interconnections within the electrical

circuits All numbered terminals are identified and all

leads number coded as shown Connections can be

easily removed Figure 4-2 shows the same

information schematically and is an aid in isolating

circuits for testing

Using an ohmmeter, wiring continuity between the

connections shown on the wiring diagram (Figure 5-1)

is readily verified. This is best done in stages,

removing only those wires required for eac h continuity

check. As each lead is replaced, it should be checked

for evidence of corrosion and cleaned if necessary. All

leads must be tightly attached to provide a good elec trical connection.

5.4.5 Solenoid Gas Valve

When the solenoid gas valve fails to operate,

the fault may be a defective valve or control board.

An a-c voltmeter is used to check the voltage at the

coil wire terminals with the oven operating.

5.4.7 Buzzer Relay

A defective relay will cause continuous sounding

of the buzzer when the thermostat is set If the buzzer

is sounding but the burners are operating properly, the

relay is defective and must be replaced.

5-5 S2207

Page 22

SECTION 6 MAINTENANCE

6.1 GENERAL

This section contains both preventive and

corrective maintenance information. Preventive

maintenance may be performed by maintenance

personnel at the establishment in which the oven is

installed. It is recommended that user personnel

never attempt to make repairs without the assistance

of an authorized service agency. Assistance in

service methods or a current directory of authorized

Service Agencies may be obtained from Market Forge

(See subsection 1.3).

6.2 PREVENTIVE MAINTENANCE

A good preventive maintenance program in the

form of daily cleaning procedures is outlined in the

following steps

1. Remove oven shelves and wash in mild detergent

and water. Rinse and dry.

2. Remove left and right hand shelf supports by

lifting up and out toward center of oven Wash,

rinse, and dry.

3. Remove fan guard (Figure 6 1) by lifting up and

out Wash, rinse, and dry.

4. Wash interior sides, bottom, and top with mild

detergent and water. A stainless steel cleaner

(not polish) should be used for the interior Rinse

and dry.

5. Replace fan guard, shelf supports, and shelves.

6. Wash both sides of doors, using a stainless steel

cleaner Rinse and dry.

6.3 ADJUSTMENT PROCEDURES

6.3.1 Oven Door Adjustments

Access to adjustable parts is obtained by first

removing upper door trim strips.

Figure 6 1 Blower Guard

6.3.1.1 Door Catch Adjustment

Remove upper and lower trim strips and proceed

as follows

1. Loosen door catch assembly mounting screws (Fig

7-3, #4) at top and bottom of door frame.

2. Move door catch assembly (7) in or out as required

to hold door firmly against oven front. Do not

leave any gaps or space between roller on door

catch assembly and dimple on door trim.

3. Tighten the screws (4) and replace trim.

6- 1 S 2207

Page 23

6.3.1.2 Door Switch Adjustment

1. Remove upper oven trim strip by removing four

screws (Fig 7-3, #1 & 2) left and right

2. Loosen the two hex nuts on the end of the

switch retaining screws Move the switch to the

left or the right as required, and retighten the

hex nuts Use care when retightening to avoid

damaging the switch

3. Open and close door several times to check

switch adjustment Repeat step 2 as required to

obtain proper operation

4. Replace trim and panel

6.3.1.3 Oven Door Horizontal Adjustment

To adjust the doors horizontally (either left to

right or front to back)

1. Remove top front trim (Figure 7-3) by remov ing

screws (1 & 2, left and right)

2. Loosen four hex nuts (15, two at top and two [not

shown] at bottom) on both doors

3. Reposition both doors using the following as a

guide

4. Close both doors

5. Set doors square with top angle and control

panel The gap between the doors (actually the

raised embossment on the edges) should be

approximately 1/32" (1mm} It is import ant that

this gap be maintained the full height of the

doors

6. Open left door Check that inside surface of door

trim hits against raised edge of oven liner at

point 'A', top and bottom Tighten four hex nuts

(15)

7. Repeat the same (#6) for right door Recheck for

squareness and 1 /32" (1mm} gap Readjust if

necessary

8. Replace trim

6.3.1.4 Oven Door Vertical Adjustment

To adjust the doors vertically

1. Loosen the two hex nuts (Figure 7-3, 9)

2. Back off top door pivot pin (8)

3. Reposition door by turning bottom door pivot pin

(8) Turn pin clockwise (up) or counter-clockwise

(down) as required Top of doors should be level

with each other and equally

spaced between top and bottom trim.

4. Retighten the two hex nuts

HIGH EFFICIENCY CONVECTION OVEN

6.3.2 Thermostat Calibration

If the oven components are operating but the unit

is not cooking properly, the thermostat may need

calibration To calibrate, proceed as fol lows

1. Attach a thermocouple lead to the bulb of the

thermostat and close oven doors

2. Place power switch in the ON position

3. Set thermostat dial at 400°F and carefully remove

the switch control knob

4. Allow the unit to heat until the indicator light has

gone out twice

5. Note the temperature reading on the thermocouple

a) If the temperature reading is off 50° or more,

the thermostat must be replaced

b) If the reading is off less than 50°F, adjust the

thermostat setting using a fine blade screwdriver

in the stem of the thermostat

6. With the oven temperature set at 400°F, the

cycling should retain a peak of 420°F and a low of

380°F after two stabilizing cycles A good

indication of proper calibration is the temperature

at which the burners ignite and shut off It should

be:

Cut off 400-405°F

Cut in 380-385°F

7. After completing calibration, apply Duco cement

or equivalent to the adjusting screw of the

thermostat and replace the knob

6.4 REPAIR AND REPLACEMENT

Section 7 of this manual contains a listing of all

replaceable parts and associated exploded views of

the model HE gas convection oven In most cases

disassembly procedures are obvious from the

exploded views. Disassembly and as sembly

instructions follow for procedures which are not

readily apparent

6.4.1 Control Panel Removal

1. Remove four screws from control panel (Figure 7-

4). All controls on the panel are serviceable from

the front.

6-2 S2207

Page 24

MAINTENANCE

2. Remove panel carefully to avoid damaging connections

WARNING

Controls carry 120 volts Be sure that ex ternal circuit

breaker is shut off before removing panel to avoid

accidental shock or short circuit

6.4.2 Right Side Panel Removal

1. Remove four screws from rear of right side panel

3. Remove six screws from control panel

4. Remove right side panel to gain access to gas valve

and regulator Gas valve and regulator may also be

accessed by removing control panel only

WARNING

Controls carry 120 volts Be sure that external circuit

breaker is shut off before removing panel to avoid

accidental shock or short circuit

6.4.3 Fan Disassembly and Repair

6.4.3.1 Fan Blade Removal

Removal of the fan requires use of a wheel puller kit

(part #99-3334) supplied by Market Forge Wheel puller kit

components are shown in Figure 6-2 To remove fan blade,

proceed as follows

1. Remove fan guard (Fig 7-1,18)

2. Remove Allen head set screws which secure fan to

motor shaft

3. Install wheel puller over hub of fan using Allen head

cap screws

4. Gradually tighten hex bolt on wheel puller until fan

slides off motor shaft

5. Remove wheel puller from fan blade and reinstall

replacement fan on motor shaft as required

6.4.3.2 Fan Motor Removal

Motor removal is completed from inside the oven.

With external circuit breaker shut off, proceed as follows

1. Remove fan guard (Fig 7-1, 18).

Figure 6 2 Wheel Puller Kit Components

2. Remove four nuts (17) and clips (16) from motor

assembly

3. Pull motor forward, carefully disconnect electrical wiring,

and slide motor off screws

4. Install replacement motor assembly as re quired

6.4.4 Burner Pan Removal

1. Remove control panel (See subsection 6.4.1 )

2. Break union below gas valve (Figure 7-2, 35)

3. Remove bottom front louvered panel

4. Disconnect the high voltage lead and the low voltage

lead from their connections at the ignition electrode (25)

and slide the wires out from their respective guides

along the front of the burner pan

5. Remove the two screws (16) that retain man ifold shield

assembly (17) Remove assembly by tipping it forward

and down

6. Remove end seals (10) from burner pan assembly by

removing screws (18) and prying channels out.

7. Remove manifold retaining bolt (11) and washer(7).

8. Remove screws from front of burner pan assembly (6).

Slide assembly out.

6.4.4.1 Burner Removal

1. Remove burner pan (See subsection 6.4.4).

2. Pop off retaining clip and slide burner tube (Fig 7-2, 4)

out from manifold.

6-3 S 2207

Page 25

6.4.4.2 Flame Baffle Assembly Removal

1. Remove burner pan assembly (see subsec tion 6.

4.4) to access flame baffle assembly (Fig 7-2 26.)

2. Remove two screws (32) from flame baffle front

support clips (31) left and right. Remove clips and

allow flame baffle to tip down into burner cavity.

3. Slide baffle forward and off rear support

channel.

6.4.5 Electrode Removal

1. Remove bottom front louvered panel (Fig 7-3

#34).

2. Disconnect high voltage lead and low voltage lead

by removing retaining nuts, washers, and

terminals.

3. Remove two retaining screws (Fig 7-2, #12) from

electrode mounting plate Slide out electrode (25).

6.4.6 Gas Valve Removal

1. Remove right side panel (see subsection 6.4.2).

2. Break two unions (Fig 7-2, #35) connecting gas

valve and regulator to manifold. Remove valve

and regulator assembly.

3. Unscrew gas valve from close nipple (34) and

elbow (33).

6.4.7 Thermostat Removal

1. Remove six screws from top panel (Fig 7-1,5) on

right side of ove n.

2. Remove four screws from rear panel (7).

3. Remove four screws from control panel (13).

4. Remove right side panel (9).

5. Remove five screws that secure perforated

capillary tube guard to oven liner.

6. Slide thermostat bulb out from clips and through

hole in side of oven.

7. Slide entire assembly out front of oven through the

control area.

8. Install replacement thermostat as required.

6.4.8 Ignition Control Board Removal

To access ignition control board, remove control

panel See subsection 6.4.1.

HIGH EFFICIENCY CONVECTION ION OVEN

1. Disconnect high and low voltage electrodes and

wires to reset switch, gas valve, and terminal strip

2. Remove screws, nuts, lockwashers, and spacers

from board. Remove control board.

6.5 ADJUSTMENTS AND OPERATIONAL CHECKS

OF BURNER COMPONENTS

During normal use or when parts are replaced,

certain adjustments must be made to gas burners,

pressure regulator, and electrode assembly.

Procedures are outlined in the following paragraphs.

6.5.1 Gas Burners

The burners and fixed orifices are sized at the

factory for natural gas operation. The burner air

shutters should be adjusted at the proper opening to

produce a blue flame without yellow tipping. To adjust

air shutters, see Fig 6-3 Refer to Fig 6-3 indexes for

correct orifices to be used with cert ain gases.

6.5.2 Regulator Adjustment

Regulator (Fig 7 2, 2) is factory set at 4" (102mm}

and adjustable from 3 5 6" water column gas pressure

for natural gas, factory set at 10" {254mm) and

adjustable from 6115" for propane or butane gas.

Check input by attaching manometer to downstream

pressure tapping of manifold (behind front louver, right

side) by removing plug fitting with burners off. To

adjust, proceed as follows.

1. Remove right side panel (see subsection 6.4.2).

2. With the main burner operating, remove pressure

regulator cover screw.

3. Turn the valve adjusting screw (located under the

cover) clockwise to increase, or counter clockwise

to decrease the gas flow. Do not exceed the input

rating on the unit nameplate.

4. To ensure proper adjustment , cycle main burners

on and off several times by means of the

thermostat switch.

6-4 S 2207

Page 26

MAINTENANCE

Figure 6-3. Air Shutter Adjustment

6-5

Page 27

SECTION 7 ILLUSTRATED PARTS LISTS

7-2 Gas Burner and Manifold Assembly

7-5 7-3

Door Assembly

7-7 7-4

Control Panel Assembly

7-8

7.1 GENERAL

This section contains a complete listing of all

replaceable parts of the High Efficiency gas convection oven. For the purposes of part identification,

the unit is broken down into functional assemblies,

and each assembly is shown in an exploded view

which is keyed to the accompany ing parts list. Each

parts list contains the figure index number, the

Market Forge part number, and an abbreviated

description.

7.3 INDEX OF ILLUSTRATED PARTS LISTS

Figure

7-1 Cabinet and Frame Assembly 7-3

7.2 ORDERING INFORMATION

Orders for repair parts should be directed to the

nearest authorized parts distributor. For a current Market

Forge Authorized Parts Distributor List contact:

Customer Service Department

Market Forge

35 Garvey Street

Everett, Massachusetts 02149

Telephone: (617) 387-4100

Customer Service Department

Market Forge Canada, Ltd.

1375 Aimco Blvd., Unit 5

Mississauga, Ontario, Canada L4W 1B5

Telephone: (416) 621-9252

Page

7-5 Ignition Control Board Assembly 7-10

7-1 S-2207

Page 28

Figure 7-1. Frame and Cabinet Assembly

Page 29

ILLUSTRATED PARTS LIST 7-3

INDEX NO.

PART NO.

DESCRIPTION

1 99-3932

Motor Ass'y

- 60

Hz 115/230V

INSULATION

*19 10-8212

Bottom Rear Insulation (Maronite)

*Denotes Items Not Shown

FIG. 7-1

2 99-1925 Clip

3 10-1295 Rack Support - Standard

3a 10-1296 Rack Support - Deep

4 99-1579 L/H Panel Ass'y - Standard - Enamel

4a 99-1578 L/H Panel Ass'y - Deep - Enamel

5 99-4431 Top Panel - Standard - Enamel

5a 99-4429 Top Panel - Deep - Enamel

5b 99-4435 Top Panel - Standard - Stainless Steel

5c 99-4434 Top Panel - Deep - Stainless Steel

6 99-4137 Flue Deflector - Enamel

6a 99-4138 Flue Deflector - Stainless Steel

7 99-1572 Rear Panel - Enamel

7a 99-3386 Rear Panel - Stainless Steel

8 10-6870 Transformer (Export only) 100V

9 99-1576 R/H Panel Ass'y - Standard - Enamel

10 99-4507 Connector Box (Export only)

11 10-5291 Terminal Box

12 99-4368 Base Ass'y

13 99-4819 Control Panel Plate

14 10-6415 Control Panel Bezel

15 10-5453 Blower Wheel

16 99-0951 Clip

17 10-2335 Hex Nut 5/16-18

18 10-5957 Fan Guard

*20 09-5413 Rear Insulation

*21 10-8219 Lt. Side Insulation (Model 2500)

*22 10-8220 Rt. Side Insulation (Model 2500)

*23 09-5415 Lt. Side Insulation, Top (Model 2500)

*24 09-5418 Rt. Side Insulation, Top (Model 2500)

*25 10-8216 Lt. Side Insulation, Top (Model 2700)

*26 10-8218 Rt. Side Insulation (Model 2700)

*27 09-5414 Lt. Side Insulation, Top (Model 2700)

*28 09-5417 Rt. Side Insulation, Top (Model 2700)

S-2207

Page 30

HIGH EFFICIENCY CONVECTION OVEN

Figure 7-2. Gas Burner and Manifold Assembly

7-4

Page 31

ILLUSTRATED PARTS LIST 7-5

FIG.

7-2 PART NO.

DESCRIPTION

1 10-7694

Gas Valve

- Magnetic Solenoid

2 09-1150 Pressure Regulator - Natural

2a 09-1151 Pressure Regulator - Propane

3 99-4424 Cross & Bracket Ass'y

4 10-3258 Gas Burner

5 99-3968 Manifold Ass'y

6 99-4349 Burner Pan Ass'y (Standard)

6a 99-4366 Burner Pan Ass'y (Deep)

7 10-2400 Washer 1/4" Plain

8 10-2330 Hex Nut 8-32

9 10-2518 Lockwasher #8

10 99-4355 End Seal—Manifold Shield Ass'y

11 10-1804 Hex Hd. Screw 1/4" - 20 x 5/8" Ig.

12 10-1722 Screw Mach. Rd. Hd. #6-32 x 3/8" Ig.

13 10-2347 Speednut

14 10-1956 Phill. Truss Hd. Scr. Type "A" #8-32

15 99-4358 Support Clip—Electrode Wires

16 10-1954 Phill. Rd. Hd. Mach. Scr. #8-32 x 1 5/8"

17 99-4351 Manifold Shield Ass'y

18 10-1735 Phill. Rd. Hd. Sheet Scr. 3/8" Ig.

19 10-1735 Phill. Rd. Hd. Sheet Scr. 3/8" Ig.

20 99-4356 Bottom Seal—Manifold Shield Ass'y

21 10-1855 Pan Hd. Scr. Type "F" 8-32 x 3/8" Ig.

22 10-3366 Burner Orifice #49 (.078) Natural Gas

23 10-3367 Burner Orifice #56 (.465) Propane

24 10-8226 Burner Orifice #57 (.043) Butane

25 10-8090 Ignition Electrode

26 99-3925 Flame Baffle Ass'y (Standard)

26a 99-3927 Flame Baffle Ass'y (Deep)

27 10-1954 Pan Hd. Mach. Scr. #8-32 x 3/8"

28 10-2330 Washer #8

29 10-2408 Hex Nut #8-32

30 99-3564 Support Bracket

31 99-4362 Front Support Clips - Flame Baffle

32 10-1761 Truss Hd. Mach. Scr. #8 - 32 x 3/8"

33 10-2811 Street Elbow 90° M.I. 1/2

34 10-2810 Close Nipple B.I. 1/2

35 10-3332 Union M.I. 1/2

36 10-2876 Reducing Coupling M.I. 3/4-1/2

37 99-4359 Retaining Clip—Electrode Wires

38 99-4585 Gas Burner With Electrode Bracket

39 10-8136 High Voltage Wire

S-2207

Page 32

HIGH EFFICIENCY CONVECTION OVEN

Figure

7-3.

Door Assembly

7-6

Page 33

ILLUSTRATED PARTS LIST 7- 7

FIG. 7-3

PART NO.

DESCRIPTION

1 10-1717

Rd Hd Mach Scr

#8 - 32 x

3/8

2 10-1956 Phil Truss Hd Type 'A' #8 x 3/8

3 10-2341 Washer - Thin #10

4 10-1759 Rd Hd Mach Scr #10 - 32 x 3/8 Ig.

5 10-2509 Lock Washer #10

6 10-2432 Washer - Med #10

7 99-3362 Assembly - Spring Door Catch - (single roller)

7a 99-4785 Assembly - Spring Door Catch - (double roller)

8 99-3279 Pivot Pin - Door

9 10-2552 Hex Nut - 3/8" - 24

10 99-3557 Support Brk't

11 10-1761 #8 - 32 Truss Hd Mach Scr x 3/8 Ig.

12 10-2330 Hex Nut #8 - 32

13 10-2518 Lock Washer #8

14 99-3559 Bushing

15 10-2340 Hex Nut #10-32

16 10-2509 Lock Washer #10

17 99-3562 Trip Lever Ass'y

18 10-2432 Washer - Med #10

19 99-1251 Insulation Shield

20 10-6859 Door Micro-Switch (Not Shown)

21 99-3511 Door Pivot Pin Support

22 10-2523 Ext Tooth L Washer 1/4 x 3/4 O.D. x .035

23 10-1997 Flat Head Machine Screw

24 10-1997 Flat Head Machine Screw

25 10-2337 Hex Nut

26 10-1895 Lock Washer

27 10-1996 #8 - 32 Ft Hd Mach Scr #6 - 32 x 1/2" Ig.

28 99-3237 Head Shield Ass'y Rt Frt

29 99-3283 Front Frame Ass'y

30 99-3378 Hinge Ass'y - Locking Truck

31 10-1990 Button Socket Hd Scr w/Lok #10-24 x 1 - 3/4 Ig.

32 99-3534 Door Assembly - Stainless Steel

33 10-0657 Door Handle

34 99-4399 Louver

35 10-2432 Washer

36 10-1760 Screw

37 99-4361 Spacer

38 99-4396 Louver

S-2207

Page 34

HIGH EFFICIENCY CONVECTION OVEN

7-8

Figure 7-4 Control Panel Assembly

Page 35

ILLUSTRATED PARTS LIST 7-9

4

FIG. 7-

INDEX NO.

PART NO. DESCRIPTION

1 99-4209 Control Panel Assembly—Complete

(excluding thermostat)

2 10-6307 Knob

2a 09-5270 Knob, For (60) Mm. Timer

2b 09-5259 Knob, For (5) Hour Timer

3 99-5301 Nameplate—Bottom Section

3a 08-5916 Overlay For (2) Speed Switch

(must be ordered together with 99-5301)

4 10-6415 Bezel

5 10-4714 Thermostat

6 10-5520 60 Minute Timer

7 10-5553 5 Hour Timer

8 10-5016 Indicator Light

9 10-6264 On - Off Switch

10 09-8015 Reset Switch (supplied with Circuit Breaker Board)

11 10-6266 Motor Reset Switch—12 Amp

S-2207

Page 36

7-10

HIGH EFFICIENCY CONVECTION OVEN

Figure

7-5.

Ignition Control Board Assembly

Page 37

ITEM NO.

1 95-4465

Bracket for Control Board

&

Buzzer

ILLUSTRATED PARTS LIST

7-11

FIG. 7-5

PART NO. DESCRIPTION

2 10-8258 Ignition Control Board

3 10-6512 Socket

3a 10-9175 Socket*

4a 10-9174 Mini-relay*

5 10-6682 Buzzer 120V

6 10-1717 Screw, Rd. Hd. Mach. #8 - 32 x 3/8" Ig.

7 10-2420 Washer, Plain #6

8 10-2330 Hex Nut #8 - 32

9 10-1747 Screw, Rd. Hd. Mach. #8 - 32 x 5/8" Ig.

10 10-1849 Screw, Rd. Hd. Mach. #6 - 32 x 1/2" Ig.

11 10-2420 Washer, Plain #6

12 10-2337 Hex Nut #6 - 32

* Must be purchased together.

S-2207

Loading...

Loading...