Page 1

INSTALLATION AND OPERATION MANUAL

Post in a prominent location, instructions to be followed in the event the user smells gas.

This information shall be obtained by consulting the local gas supplier.

MARKET FORGE INDUSTR IES, INC.

35 GARVEY STREET EVERETT, MA 02149-4403

TEL 6173874100 TELEX 94-94 1 4

FAX: 617 387 4450 OUTSIDE MA 800 227 2659

FORM NO. S-2465 REV B 12-9-96

PRINTED IN USA

Page 2

1. INTRODUCTION

1.1 To The Kitchen Manager 1.1

1.2 Description 1.1

1.3 Cooking Capacities 1.1

1.4 Basic Functioning 1.1

2. INSTALLATION.

2.1 Setting in Place 2.1

2.2 Service 2.1

2.3 Before Use 2.2

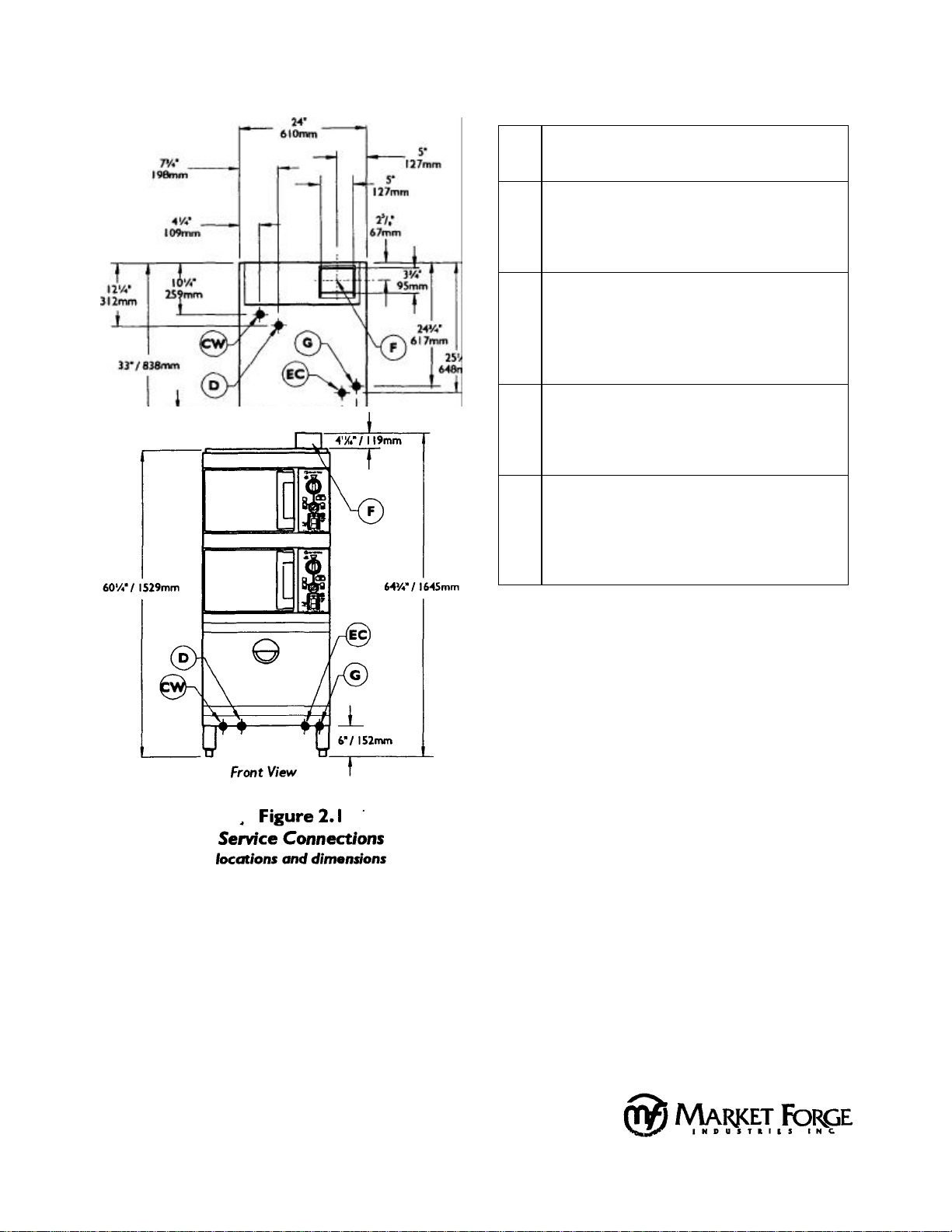

Figure 2. 1 - Service Connections

locations & dimensions 2.3

Table 2. 1 - Service Connections

specifications & details 2.3

2.4 Service Connections 2.3

2.4.1 Water Connections 2.4

2.4.2 Electrical Connections 2.4

2.4.3 Gas Connections 2.4

2.4.4 Initial Systems Inspection 2.4

2.3 Reversing the Doors 2.5

3. INITIAL SYSTEMS INSPECTION

3.1 General 3. 1

3.2 Warm-up 3.1

3.3 Steam Demand 3.1

3.4 STEAM Mode 3.2

3.5 STEAM & HOLD Mode 3.2

3.6 CONSTANT STEAM Mode 3.2

3.7 Steam Suppression System 3.2

3.8 Shut -Down 3.3

4. OPERATION

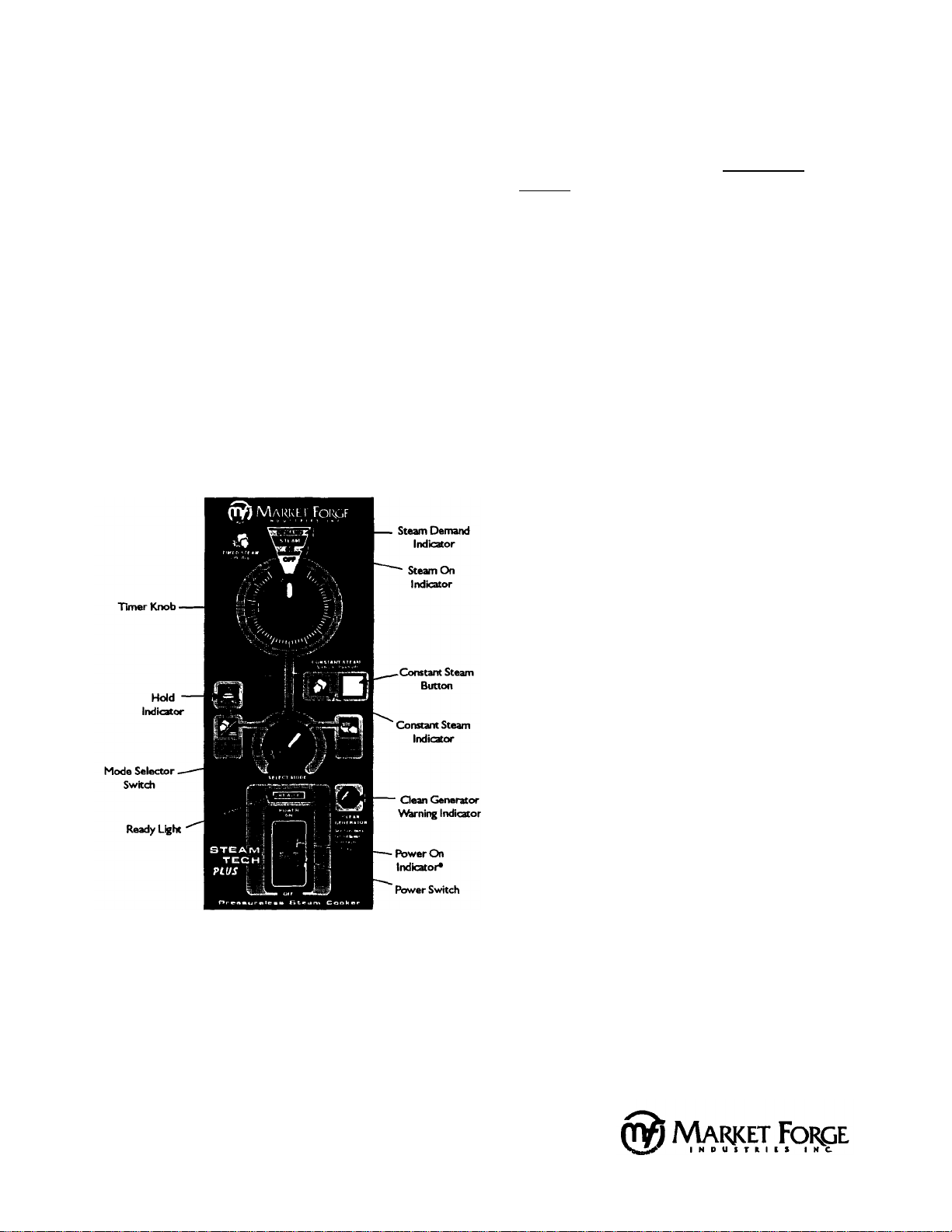

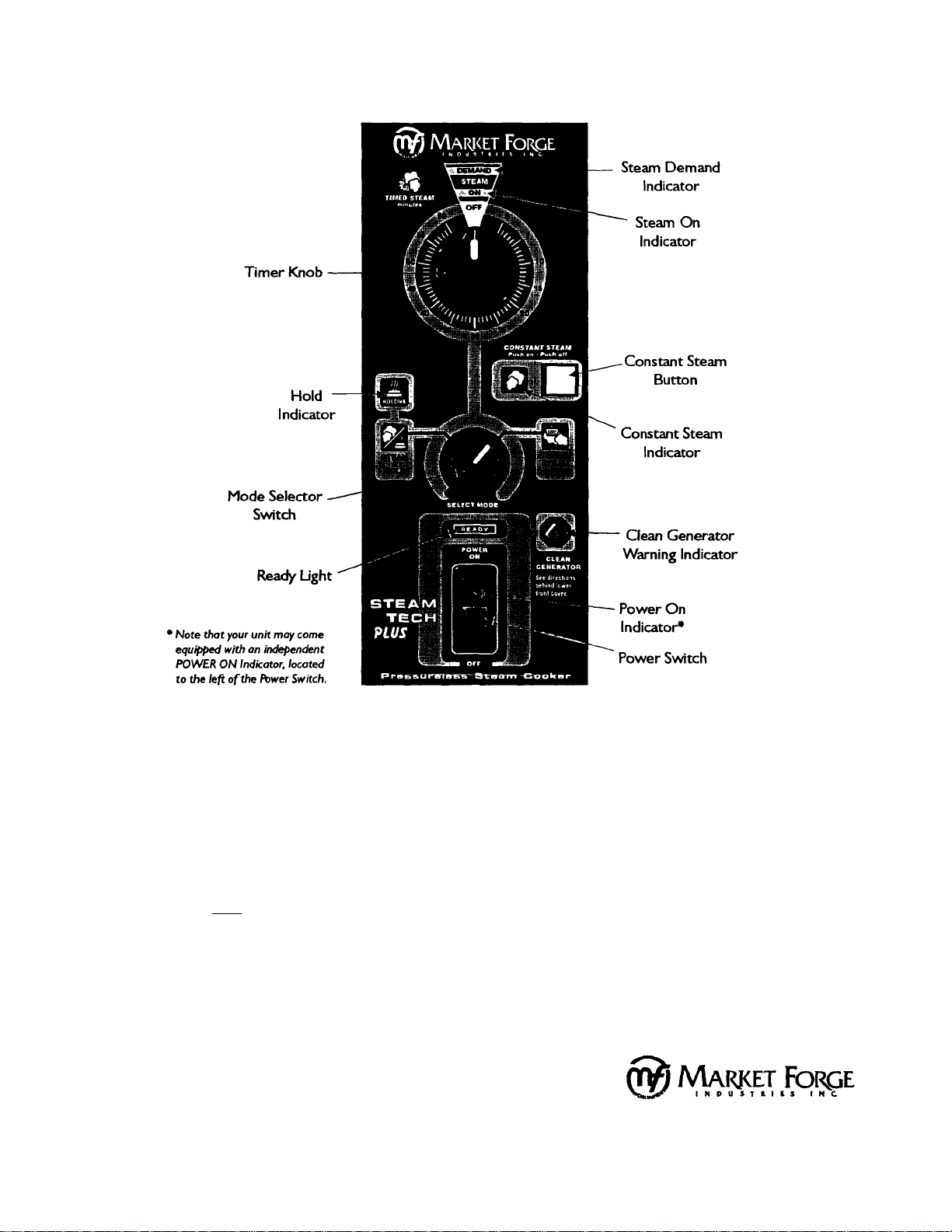

4.1 Controls and Indicators 4. 1

4.2 Operating Procedures 4. 1

4.2.1 Startup and Preheating 4. 1

4.2.2 Cooking 4.1

4.2.3 Shut Down 4.2

Figure 4. 1 - Control Panel 4.2

Table 4. 1 - Controls and Indicators 4.3

Figure 4.2 - Removal for Daily Cleaning 4.4

Table 4.2 - Removal for Daily Cleaning 4.4

4.3 Daily Cleaning 4.5

4.4 Prolonged Shut -Down & Cleaning 4.5

5. TROUBLESHOOTING

5.1 General 5. 1

Troubleshooting Table 5.1 -5.5

5.2 Water Level Control Board 5.6

6. MAINTENANCE

6.1 General 6. 1

6.2 Daily Cleaning 6. 1

6.3 Preventative Maintenance 6. 1

Figure 6. 1 - Assembly of Exterior Sheet

Metal Panels to Unit 6.2

Table 6. 1 - Assembly of Exterior Sheet

Metal Panels Parts List 6.2

6.4 Cleaning the Generator 6.3

6.4.1 Cleaning Instructions 6.3

6.5 Cleaning the Ventilation Ductwork 6.4

6.6 Electrical Box Service Access 6.4

Figure 6.2 - Electrical Panel 6.5

Table 6.2 - Electrical Panel Parts List 6.5

Principles of Operation Schematic 6.7

Wiring Diagram 6.8 - 6.9

6.7 Control Panel Service Access 6.10

Table 6.3 - Control Panel Parts List 6.10

Figure 6.3 - Control Panel Assembly 6. 11

6.8 Door Adjustment 6. 12

6.8.1 Door Alignment 6. 12

6.8.2 Door Latch Tension 6. 12

Figure 6.4 - Door Latch Assembly 6. 13

Table 6.4 - Door Latch Parts List 6. 13

6.8.3 Door Handle Tension 6. 13

Figure 6.5 - Door Assembly: 6.14

Table 6.5 - Door Assembly Parts List 6. 15

MARKET FORGE INDUSTR IES, INC

35 GARVEY STREET EVERETT, MA 02149

TEL 6173874100 TELEX 94-9414

FAX 6173874456 OUTSIDE MA 800 227 2659

Page 3

6.9 Door Gasket Replacement 6.15

Figure 6.6 - Upper Generator Assy 6.16

Table 6.6 - Upper Gen Parts List 6. 17

Figure 6.7 - Lower Generator Assy 6.18

Table 6.7 - Lower Gen Parts List 6.19

Figure 6.8 - Exhaust Duct Assy 6.20

Table 6.8 - Exhaust Duct Parts List 6.21

Figure 6.9 - Blower Box Assembly 6.21

Table 6.9 - Blower Box Parts List 6.21

6.10 Solenoid Fill Valve Screen Service 6.22

Table 6.10 - Tempering Tank Parts List 6.22

Figure 6.10 - Tempering Tank Assy 6.23

Figure 6. 11 -Gas Tubing Assy 6.24

Table 6. 1 I - Gas Tubing Parts List 6.5

Figure 6.12 - Chassis Assembly 6.26

Table 6. 12 - Chassis Assy Parts List 6.27

Table 6. 13 - Tubing Routing List 6.28

Figure 6. 13 - Tubing Routing 6.29

MARKET FORGE INDUSTRIES, INC

35 GARVEY STREET EVERETT, MA 02149

TEL 6173874100 TELEX 94-9414

FAX 6173874456 OUTSIDE MA 800 227 2659

Page 4

1. Introduction

1.1 TO THE KITCHEN MANAGER

1. Read this manual carefully and in its entirety. Contact

Market Forge Industries, Inc. for clarification if necessary.

2. Protect your kitchen personnel from scalding and other

serious injury by providing training programs to acquaint

all equipment operators with the correct and safe

methods of operation.

3. Operators must be made aware of the consequences

of misuse. Steam producing equipment, no matter who

the manufacturer, is inherently dangerous when misused.

The possibility of serious scalding always exists, the

careless and/or untrained operator will be injured.

4. This equipment must be maintained according to the

guidelines In this manual (see Section 6, "Maintenance").

Lack of maintenance will lead to a potentially hazardous

condition and possible liability. Operators should report

any equipment malfunction immediately and steps must

be taken to correct the problem before further use of the

equipment is allowed.

5. KEEP THIS MANUAL FOR DAILY REFERENCE.

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE CAN

CAUSE PROPERTY DAMAGE, INJURY OR DEATH.

READ THE INSTALLATION. OPERATION, AND

MAINTENANCE INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR SERVICING THIS

EQUIPMENT

MARKET FORGE INDUSTRIES, INC.

35 GARVEY STREET EVERETT, MA 02149

TEL: 017 387 4100 TELEX: 94-94 1 4

FAX: 6 1 7 387 4456 OUTSIDE MA 800 227 2659 1.1

1.2 DESCRIPTION

The Steam Tech Plus is a pressureless steam

cooker consisting of two independently controlled

cooking compartments in a single cabinet. Each

compartment has its own Independent control

panel, consisting of a power switch, mode select

switch, constant steam switch, timer (mechanical or

electronic), steam demand indicator, and indicator

lights for each of its functions. The Steam Tech

Plus is equipped with a steam suppression safety

system. These Features and functions will be

discussed in greater det ail in Sections 3.

1.3 COOKING CAPACITIES

Each cooking compartment will accept:

• Three 12" x 20" x 2 1/2 pans, or

• Three I/I gastronorm pans, 65mm deep.

The inside dimensions of the cooking compartment

are:

Width- 14 1/2 (368mm) Height -103/4" (273mm) Depth

- 23" (584mm)

1.4 BASIC FUNCTIONING

Each Steam Tech Plus cooking compartment has its

own independent steam generator. Each of its two

cooking compartments may be operated either

Independently or simultaneously. Each compartment

is equipped with identical controls. These controls

allow it to be used in the "TIMED STEAM" mode,

"CONSTANT STEAM" untimed mode. or the "STEAM

& HOLD" mode.

Page 5

1. Introduction

The Steam Tech Plus utilizes a unique STEAM

DEMAND feature. This feature allows the Steam Tech

Plus to operate at extremely high cooking efficiencies.

The Steam Demand system creates only the amount of

steam as will be absorbed by the food being cooked,

no more and no less. No excess steam is created,

therefore, nothing is lost down the drain.

To begin operation, the POWER switch is

pressed into the ON position, illuminating the power

light. This opens the water feed solenoid valves, to

both the steam generator and tempering tank. Once

the appropriate water level has been reached, the

burner is ignited. When the water temperature in the

steam generator has reached 193°F, the green READY

light, is illuminated, indicating that the unit is now ready

to make steam and all controls are functional.

A steaming mode is selected with the MODE

SELECT switch. After selecting a steaming mode, the

TIMER knob must be set to the desired cooking time to

activate the main burner and begin making steam.

In the STEAM mode, the unit will create steam

for the duration of time you have set. Once the timer

reaches the end of its cycle (0 minutes), the unit will

stop making steam, and the buzzer will sound. The

buzzer is silenced by returning the timer knob to the

OFF position. The generator will continue to idle at

193°F.

In the STEAM & HOLD mode, the unit will create

steam for the duration of time you have set. Once the

timer reaches the end of its cycle (0 minutes), the unit

will stop making steam and go into the HOLD mode,

illuminating the amber hold light. When in the HOLD

mode, the auxiliary thermostatically controlled electric

strip heater is activated. The strip heater is mounted

onto the outside of the cooking compartment and will

maintain a safe internal holding temperature. The unit

will now act as a holding cabinet until you call for steam

again. During this time, the generator will continue to

idle at 193°F.

The CONSTANT STEAM button overrides the

MODE SELECT switch and the TIMER. When the

button is depressed, the green constant steam light is

illuminated. In this mode, the generator will constantly

supply steam, as controlled by the Steam Demand

System, regardless of the MODE SELECT switch and

TIMER setting, until the CONSTANT STEAM button is

pressed again. While the CONSTANT STEAM button is

depressed, the TIMER may be used as an alarm only,

as it will have no effect on the creation of steam. To

exit the constant steam mode, the CONSTANT STEAM

button must be pressed again. This will cause the

green constant steam light to go off. The generator will

now idle at 193°F, ready to make steam.

All drainage is routed through the common

tempering tank, which regulates the drain water

temperature. This tank cools the drain water to 130°F

before discharging it down the main drain line.

NOTE: Read this manual carefully and in its

entirety. Contact Market Forge Industries, Inc. for

clarification if necessary

Product Service Department

Market Forge Industries, Inc.

35 Garvey Street

Everett, Massachusetts 02149

Telephone: (617) 387-4100

The model and serial numbers must be

referenced when corresponding with Market Forge.

The data plate containing the serial number is located

on the top of the unit.

NOTE: It is the owner/manager's responsibility to provide instruction to kitchen equipment

operators. The instruction must include the safe

operation of all equipment. Operators must report

malfunctioning equipment immediately so the

equipment can be taken out of service and

repaired.

MARKET FORGE INDUSTRIES, INC.

35 GARVEY STREET EVERETT, MA 02149 1.2

TEL: 017 387 4100 TELEX: 94-9414

PAX: 6 17 387 4456 OUTSIDE MA 800 227 2659

Page 6

2. Installation

2.1 SETTING IN PLACE

The assembled Steam Tech Plus Pressureless

Steam Cooker is shipped bolted to a skid, with the

cabinet feet shipped in a separate container. Steps

required for assembly are as follows:

I - Remove the four bolts which secure the unit to the

skid.

2- Install the feet into the threaded mounting

locations on the bottom of the unit.

3- Mount the left and right pan support racks on the

mounting brackets located inside each of the

cooking compartments.

NOTE: The racks wit h the metal baffling mount on

the right (steam inlet) side of the cooking

compartments.

4- A location must be selected under an exhaust

hood which will remove the products of gas

combustion, along with the small amounts of vapor

emitted from the cooker during normal operation.

5- Level the unit after it is placed in its final location.

This is accomplished by turning the bottom part of

the adjustable feet. Using the cabinet top as a

reference, obtain level adjust ment left-to-right and

front-to-back.

6- Remove all instructional materials from the

cooking compartments and leave both doors

slightly ajar.

MARKET FORGE INDUSTRIES , INC. 2.1

35 GARVEY STREET EVERETT, MA 02149

TEL: 61 7 387 4100 TELEX: 94-94 1 4

FAX: 6 1 7 387 4456 OUTSIDE MA 800 227 2659

2.2 SERVICE

corrective, is explained in Section 6 of this manual.

Should repairs be required, a network of aut horized

agencies is available to assist with prompt service. A

current Directory of Authorized Service Agencies may

be obtained by contacting:

referenced when corresponding with Market Forge.

The data plate containing the serial number is located

on the top of the unit.

of this manual, along with a schematic of the principles

of operation on page 6.7. For more in depth technical

information on the Steam Tech Plus, consult your

Market Forge Factory Authorized Service Agency

Representative. An electrical diagram is also posted on

the inside of the front cover panel of the unit, for your

convenience.

ment system, but are representative of both

systems, as the top and bottom cooking compartment systems are the same. The top system circuits

on the unit have an "A" designation following the wire

numbers, while the bottom system circuits have a "B"

designation following the wire numbers.

bility to provide instruction to kitchen equipment

operators. The instruction must include the safe

operation of all equipment. Operators must report

malfunctioning equipment immediately so the

equipment can be taken out of service and

repaired.

Required service, both preventative and

Product Service Department

Market Forge Industries, Inc. 35

Garvey Street

Everett, Massachusetts 02149

Telephone: (617) 387-4100

The model and serial numbers must be

An electrical diagram is located on pages 6.8 -6.9

These diagrams show only a single compart-

NOTE: It is the owner/manager's responsi -

Page 7

2. Installation

2.3 BEFORE USE

Before proceeding to Section 2.4, Service

Connections, be sure you have road and under-

stand the following statements.

•Keep this appliance free and dear from

combustibles.

• Do not obstruct the flow of combustion and

ventilation air.

•This installation, must conform with local codes,

or in the absence of local codes, with the

National Fuel Gas code, ANSI Z223.1, the

Natural Gas Installation Code. For installation

in Canada, this appliance is to be in accordance with the current Natural Gas Installation

Code CAN/CGA-B149.1, or the Propane Gas

Installation Code. CAN/CGA-B149.2 . and/ or

Local Codes as applicable, including:

•The generator and its individual shut off

valve must be disconnected from the gas

supply piping system during any pressure

testing of that system at test pressure in

excess of 1/2 psig (3.45 k/PA).

•The generator must be isolated from the gas

supply system by closing its individual

manual shut off valve during any pressure

testing of the gas supply piping system at

test pressures equal to or less than 1/2 psig

(3.45k/PA).

•This appliance, when installed, must be

electrically grounded in accordance with local

codes, or in the absence of local codes, with

the National Electric code, ANSI/NFPA70-

Latest Edit ion. For installation in Canada, all

electrical connections are to be made in

accordance with CSA C22. 1 Canadian

Electrical Code Part I and/or Local Codes.

•This product must be installed in a room with

adequate air supply.

•Do not place any objects on or directly against

the unit that will block air openings into the

combustion chamber.

•Minimum clearances from both combustible and

non combustible surfaces are 2" (51 mm) from

right side wall, 2" (51 mm) from left wall and 6"

(152mm) from rear wall. Suitable for installation

on combustible floors.

•This unit is serviceable almost entirely from the

front. Do not install in such a manner that a

service person cannot access the lower front

cover panel. Some of the componentry may be

more easily accessed by removing either of the

side panels and/or the back panel, as shown in

Figure 6.1, on page 6.2 of this manual. The

minimum suggested clearance for servicing this

unit from the left or right sides is 18". The

minimum suggested clearance for servicing this

unit from the rear is 12"

The steps for side panel removal are as

follows:

1. To remove either side panel, remove the

screw from the center of the bottom edge of

the panel.

2. Slide the side panel upwards until it stops.

3. Swing the bottom edge of the side panel out

away from the unit far enough (about 1.5

inches), so that it is free to slide down to the

floor.

4. This will allow the top edge of the side panel

to slide out from under the top cap of the unit.

To remove the back panel, remove the 8 screws

which attach it to the unit, as shown in Figure

6.1, on page 6.2 of this manual.

•There are no special lighting or shut down

procedures for the burners. Each burner is

controlled by the POWER, switch for that

generator.

• Keep this manual for daily referen ce.

MARKET FORGE INDUSTRIES, INC.

35 GARVEY STREET EVERETT, MA 02149 2.2

TEL: 617 387 4100 TELEX: 94-94 I 4

FAX: 617 387 4456 OUTSIDE MA 800 227 2659

Page 8

2. Installation

Table 2.1 Service

Connections

specifications and details

Gas Supply Connection-

G

1/2" NPT

Electrical Connection 120 VAC, 60hz, 1/2" conduit or equivalent.

Current draw for 120V control circuitry is 6.5

EC

Amps. Use wire suitable for at least 90°C.

Cold Water 1/2" NPT to cold water supply manifold. Cold

water supply line to have a maximum of 50 PSI

CW

(3.5 kg/cm2) and a minimum of 25 PSI (1.8

kg/cm2) water pressure.

Drain 1 1/2" 0. D. pipe coupled to 1 1/2" 0. D.

D

tempering tank drain. DO NOT MAKE SOLID

CONNECTION TO FLOOR DRAIN.

FluePlace unit so that the Flue is under an exhaust

F

hood to remove the products of gas combustion. DO NOT TOUCH FLUE! The Flue

reaches extremely high temperatures!

MARKET FORGE INDUSTRIES, INC.

35 GARVEY STREET EVERETT, MA 02149

TEL: 617 387 4100 TELEX: 94-9414 2.3

PAX: 6 I 7 387 4456 OUTSIDE MA 800 227 2659

1.4 SERVICE CONNECTIONS

All service connections are made at the bottom of

the unit, in the 6 inch high space between the floor and

the bottom of the cabinet. Please see Figure 2. 1 and

Table 2.1 for service connections, details and

dimensions.

NOTE:

If the equipment is to be installed where the

elevation exceeds 2,000 feet (609.6 meters) above

sea level, specify installation altitudes so that the

proper gas orifices can be provided.

Page 9

2. Installation

2.4.1 Water Connections

Before connecting water to this unit, have water

supply analyzed to make sure that hardness is no

greater than 2.0 grains per gallon and pH level is within

the range of 7.0 - 8.5. Water which fails to meet these

standards should be treated by the installation of a

water conditioner. EQUIPMENT FAILURE CAUSED

BY INADEQUATE WATER QUALITY IS NOT

COVERED UNDER WARRANTY.

CAUTION: PVC OR CPVC PIPING ARE NOT

ACCEPTABLE MATERIALS FOR USE IN DRAINS.

2.4.2 Electrical Connections

Connect cooker controls to 110/120 volt AC, 60

Hz, single phase branch circuit rated 15 amps capacity.

Wiring will conform to the requirements of national and

local electrical codes, (220 volts, 50Hz, single phase

for export units.

NOTE: ONLY A LICENSED ELECTRICIAN SHOULD

MAKE ELECTRICAL CONNECTIONS.

2.4.3 Gas Connections

Each of the generators are factory adjusted for a

gas input of 40,000 BTU/hr at the pressure indicated.

Please read the rating plate on the top of the unit. If

this plate is marked for a different gas than that

supplied, notify your dealer immediately. Install the

supplied external gas supply shut off valve at the gas

main inlet. This is located just under the bottom edge of

the lower front cover panel. Install so that the shut off

valve handle is clearly visible to the operator.

Use new iron or steel pipe complying with the

latest ANSI Standard for Wrought -Steel and Wroughtlron Pipe, B36, Properly threaded, reamed and free

from chips, oil, and dirt. If pipe dope is used, apply a

moderate amount leaving two end threads bare. Pipe

dope must be resistant to LP gas. Connect the gas line

into the bottom (inlet) side of the gas

MARKET FORGE INDUSTRIES, INC.

35 GARVEY STREET EVERETT. MA 02149 2.4

TEL: 61 7 387 4100 TELEX: 94-94 1 4

supply shut off valve. The supply pressure must be at

least I" (25mm) water column higher than the manifold

or regulator pressure for proper functioning of the

regulator. If it is not, check the supply pipe for blockage

or excessive pressure drop and make the necessary

corrections.

Perform a gas leak test of all newly -made joints,

as well as those leading to the main gas control valve.

Use a soap solution. DO NOT USE FLAME!

Natural gas units are equipped with a pressure

regulator factory adjusted to give 3.5" (89mm) water

column manifold pressure.

Propane gas units are equipped with a pressure

regulator factory adjusted to give 11" (279.5mm) water

column manifold pressure.

For conversion to either natural or propane

gas, 3 components must be changed. They are:

1. Gas orifices for each of the main burners.

2. Both complete pilot burners.

3. Springs inside each of the gas regulator

valves.

Consult the Market Forge for more detailed

information, instructions, and part numbers for

field conversion to either natural or propane gas.

NOTE: ONLY A LICENSED GAS FITTER SHOULD

MAKE GAS LINE CONNECTIONS.

2.4.4 Initial Systems Inspection

After the cooker is set in place, and all service

connections have been made, the cooker must be

given a final systems inspection prior to use. This is to

determine that all systems are functioning properly.

This procedure is described in full detail in Section 3,

"Initial Systems Inspection", of this manual. If all

systems perform as described in Section 3, the cooker

is ready for cooking use. If any of the systems are not

functioning as they should, consult Section 5,

"Troubleshooting" in this manual.

Page 10

2. Installation

2.5 REVERSING THE DOORS

The Steam Tech Plus Pressureless Steam

Cooker has cooking compartment doors which are

reversible, for your convenience. For Door Assembly

illustration and table, refer to pages 6.14 and 6.15.

9. Remove the two white hole plugs from the left

NOTE : This procedure is identical for both the

upper and lower cooking compartment doors.

1. Remove the left large side panel by removing the

screw from the center of the bottom edge of the

panel. Gripping one of the louvers, slide the

panel upwards until the bottom edge of the panel

is free to swing out slightly away from the unit.

Slide the panel down until its top edge is dear of

the top cap of the unit.

2. Open Cooking Compartment door.

3. Remove the two 5/16" bolts that attach the top

10. Rotate the door latch assembly 180°, and

install into the left door latch mounting holes.

NOTE : Each stud on the latch assembly should

have a plastic washer, a spring, a plastic washer

and a Nyloc type nut, as shown In Figure 6.5 on

page 6.14.

11. To adjust the tension of the door latch, tighten

hinge to the front of the unit.

4. Slide the door upwards, off the bottom hinge.

12. Replace large side panel by placing the panel

5. Remove the two 5/16" bolts that attach the bottom

hinge to the front of the unit.

NOTE: The top hinge is slightly larger than

the bottom hinge.

6. Remove the 4 black plastic hole plugs from the

front of the unit. Push the black hole plugs into

the now vacant left upper and lower hinge

13. Rotate the door 180° for mounting.

14. Slide the remaining (small) hinge into the top

mounting holes.

7. Reinstall the top (larger) hinge and bolts into the

15. Slide the door and hinge assembly down onto

right lower hinge mounting holes. Rotate the

hinge 180° for installation, so that the pin

which the door rides on is now facing up. The

hinge must be rotated because it will now

function as the bottom hinge. DO NOT

COMPLETELY TIGHTEN THE HINGE

MOUNTING BOLTS YET These will be used

later for adjusting the door.

MARKET FORGE INDUSTRIES, INC.

35 GARVEY STREET EVERETT, MA 02149 2.5

TEL: 617 387 4100 TELEX: 94-94 1 4

FAX: 0 1 7 387 4456 OUTSIDE MA 800 227 2659

16. Door Adjustment is covered in Section 6.8 on

8. Remove the door latch assembly from the

face of the unit. The 2 door latch mounting nuts

are located behind the face of the unit and must

be accessed by removing the large side panels.

door latch mounting holes, and insert them into

the right door latch mounting holes (where the

door latch assembly was originally mounted).

both nuts down until the springs are fully

compressed, then back each nut off 1/2 turn.

against the side of the unit. Be sure that the top

edge of the side panel slides under the top cap

of the unit. Slide the panel upwards until it stops.

Then, while pushing the panel in towards the

unit, slide it down into position. Replace screw.

door bearing.

the hinge which you have already mounted to

the front of the unit. Use the two 5/16" bolts to

mount the top hinge into the right upper hinge

mounting holes. DO NOT COMPLETELY

TIGHTEN THE HINGE MOUNTING BOLTS

YET. These are used later for door adjustment.

page 6. 12 of this manual.

Page 11

3.1 GENERAL

This section contains information for you to test

and familiarize yourself with the operation of the Steam

Tech Plus.

After the unit is completely assembled, all

packaging materials removed, and all service

connections are made, all systems must be given a

thorough check-out before being put into operation. Be

sure that the cooking compartments are empty, and all

pan support racks are in place. Confirm that all service

connections are on. Select a cooking compartment to

test. Close the cooking compartment door, and turn the

timer knob to the OFF position.

Figure 3. 1, below, illustrates the position of the

controls and Indicators for operation.

3. Initial Systems Inspection

NOTE: REPEAT STEPS IN SECTIONS 3.2

THROUGH 3.7 FOR BOTH THE UPPER AND

LOWER COOKING COMPARTMENTS TO INSURE

PROPER FUNCTIONING OF THE ENTIRE UNIT.

3.2 WARM-UP

Push the POWER switch Into the ON position.

The power light will come on immediately, along with

the fan motor. You will hear water entering the unit

through the solenoid valves, filling both the steam

generator and tempering tank.

Once the water levels in the steam generator

and tempering tank have reached the appropriate

level, the solenoid valves will close, and the burner

will Ignite. After a short time (approximately 5

minutes), the green READY light will come on,

indicating that the unit is ready to make steam.

3.3 STEAM DEMAND

Due to the unique nature of this design, it is

important to understand what the STEAM DEMAND

system does. The STEAM DEMAND syst em is the

means by which the Steam Tech Plus monitors and

creates steam. This system uses very sensitive sensors

to monitor the minute steam fluctuations inside the

cooking compartment. These fluctuations are an

indicator of how much steam energy the food inside the

cooking compartment is using. The sensor controls the

burner, Insuring that steam is created only as fast as it

will be accepted by the food inside the cooking

compartment, no more and no less.

This system can be monitored by observing the

red STEAM DEMAND indicator, located at the top of the

control panel. The STEAM DEMAND indicator will light

up red only when steam is called for, and will cycle on

and off throughout the cooking cycle.

Figure 3.1 Control Panel

• Note that your unit may come equipped with an independent POWER. ON

Indicator, located to the left of the Power Switch.

MARKET FORGE INDUSTRIES, INC.

35 GARVEY STREET EVERETT, MA 02149 3.1

TEL: 017 387 4100 TELEX: 94-94 1 4

FAX: 617 387 4456 OUTSIDE MA 800 227 2659

Page 12

3. Initial Systems Inspection

3.4 STEAM MODE

Turn the MODE SELECT switch to the STEAM

mode. Set the TIMER, knob to 10 minutes. Immediately, the STEAM ON window, located near the top of

the control panel, should light up green. At the same

time, the STEAM DEMAND window should light up red.

After a short time, the red STEAM DEMAND light will

begin to cycle on and off, while the green STEAM ON

light stays on continuously.

When the timer reaches 0 minutes, the buzzer

will sound, and both the STEAM ON and the STEAM

DEMAND lights will turn off. The buzzer is silenced by

returning the TIMER knob to the OFF position. The

green READY light will stay illuminated.

3.5 STEAM & HOLD MODE

Turn MODE SELECT switch to the STEAM &

HOLD mode. Set the TIMER knob to 10 minutes.

Immediately, the STEAM ON window, located near the

top of the control panel, should light up green. At the

same time, the STEAM DEMAND window should light

up red. After a short time, the red STEAM DEMAND

light will begin to cycle on and off, while the green

STEAM ON light stays on continuously.

When the timer reaches 0 minutes, the HOLD

window will light up amber. Both the STEAM ON and

the STEAM DEMAND lights will turn off. The green

READY light will stay Illuminated.

While the HOLD light is on, the cooking

compartment will function as a holding cabinet,

maintaining a safe food holding temperature of

approximately 160°F, indefinitely (as long as power is

supplied to the unit). Each of the cooking compartments has its own independent temperature gauge.

The cooking compartment temperature gauges are

mounted on the right hand side of the steam vent

hoods, directly above the control panel for each of the

cooking compartments.

3.6 CONSTANT STEAM MODE

The CONSTANT STEAM button overrides all

other cooking modes. When the CONSTANT STEAM

button is depressed, the CONSTANT STEAM window,

located next to the CONSTANT STEAM button, will

light up green. Immediately, the STEAM ON window,

located near the top of the control panel, should light up

green. At the same time, the STEAM DEMAND window

should light up red. After a short time, the red STEAM

DEMAND light will begin to cycle on and off, while the

green STEAM ON light remains illuminated

continuously.

NOTE : Even in the Constant Steam mode, the

generator will only create as much steam as will be

accepted by the food inside the cooking compartment.

No matter what mode has been selected, the red

STEAM DEMAND indicator will cycle on and off.

The generator will continuously make steam as

needed, until the CONSTANT STEAM button is

released (by pressing it again) and the green CONSTANT STEAM light goes off.

CAUTION: The timer is useful only as an alarm when in

the CONSTANT STEAM mode. The timer will count

down, but it will have no effect on the continuous

generation of steam, as it will be overridden by the

CONSTANT STEAM button.

3.7 STEAM SUPPRESSION

The proper operation of the Steam Suppression

system is evidenced by the lack of steam billowing out

of the cooking cavity when the door Is opened. While

the generator is creating steam, open the door to the

cooking compartment. As soon as the door is opened,

a solenoid valve will open, sending water to a spray

nozzle inside the steam generator. You should hear the

spray for approximately 3 to 4 seconds. At the same

time, both the STEAM ON and the STEAM DEMAND

lights will turn off. The green READY light will stay

illuminated.

MARKET FORCE INDUSTRIES, INC.

35 GARVEY STREET EVERETT, MA 02149 3.2

TEL: 617 387 4100 TELEX: 94-94 1 4

FAX: 6 17 387 4456 OUTSIDE MA 8OO 227 2659

Page 13

3. Initial Systems Inspection

Also, when the door is opened, any residual steam

will be drawn up into the steam vent hood. The steam

vent hoods are located above each cooking

compartment

When the door is closed, the STEAM ON and the

STEAM DEMAND windows will light up again. At the

same time, a bubbling sound may be heard, as the cool

air is evacuated from the cooking compartment and

replaced with fresh steam from the generator. The unit

will continue to cycle normally, as it was before the door

was opened.

NOTE: REPEAT STEPS IN SECTIONS 3.2

THROUGH SECTION 3.7 FOR BOTH THE UPPER AND

LOWER COOKING COMPARTMENTS TO INSURE

PROPER FUNCTIONING OF THE ENTIRE UNIT

BEFORE PROCEEDING TO THE NEXT PARAGRAPH,

(3 8 SHUTDOWN).

3.8 SHUTDOWN

No special procedure is necessary for shutting the

unit down. Simply press the POWER switch into the OFF

position. All indicator lights on the control panel will go out,

and the generator for that cooking compartment will drain.

The tempering tank will not drain until both POWER

switches are in the OFF position

CAUTION: When the unit is not in use, leave both

cooking compartment doors slightly ajar to extend the

life of the cooking compartment door gaskets.

Please note that the TIMER should be in the OFF

position and the CONSTANT STEAM button should be

disengaged upon restarting the unit to avoid any

unintentional generation of steam on startup.

NOTE: As a final test of the unit before use in

cooking food, both generators should be shut down,

allowing both the generators and tempering tank to

completely drain.

MARKET FORGE INDUSTRIES INC

35 QARVEYSTREET EVERETT. MA 02149

TEL 0173874100 TELEX 949414

FAX 6 1 7 387 4456 OUTSIDE MA 800 227 2659

Page 14

4. Operation

4.1 CONTROLS AND INDICATORS

The controls and indicators used to operate the Steam

Tech Plus pressureless steam cooker are listed and described

in Table 4.1, on page 4.3. Their locations are called out in

Figure 4.1, on page 4.2.

4.2 OPERATING PROCEDURES

1. Slide pans of food into the cooking compartment

pan support racks.

2. Firmly close the cooking compartment door.

3. Select a cooking cycle, either timed or untimed.

4. For timed cooking, set the MODE SELECT switch

to the desired cooking mode and set the TIMER,

to the desired cook time.

This section includes general instructions for daily

operation of the Steam Tech Plus pressureless steam

cooker. You should review Section 3.1 through

Section 3.8 of this manual if you are unfamiliar with the

functions of the Steam Tech Plus. If you require more

detailed technical information on the Steam Tech Plus'

various systems and their functions, please consult

your Market Forge Factory Authorized Service Agency

Representative.

4.2.1 Start-up and Preheating

The Steam Tech Plus pressureless steam cooker

requires no start-up procedure. Simply press the

POWER switch into the ON position. The ignitor will

attempt to ignite the burner for up to 90 seconds, If

after 90 seconds, the burner hasn't ignited, the gas

ignition control will go into lockout. The system will

then need to be manually reset by pressing the

POWER switch into the OFF position for 5 minutes.

Wait 5 minutes before turning the unit on again.

The tempering tank and selected cooking

compartment's steam generator will fill with water.

Once full, the burner will automatically preheat the

water in the generator to 193°F. This will take

approximately 7 minutes. When the generator is ready

to create steam, the green READY light will come on.

4.2.2 Cooking

NOTE : The green READY light must be on

before any controls become operational.

5. At the end of a timed cook cycle (when the timer

has timed out to zero), return the TIMER knob to

the OFF position to:

a. Silence the buzzer (when using the

STEAM Mode).

b. Exit the HOLD function (when using the

STEAM & HOLD Mode).

6. For untimed cooking, press the CONSTANT

STEAM button to override the TIMER and create

continuous untimed steam.

7. When using the untimed cooking cycle, and you

have determined that the food in the cooking

compartment is done, press the CONSTANT

STEAM button again to exit the CONSTANT

STEAM Mode.

8. In any cooking cycle or mode, the Steam

DEMAND light will cycle on and off. This indicates

the automatic creation of steam as it is called for

by the food being cooked.

CONDENSATE WARNING:

Normal steam cooking conditions will create

some condensate due to temperature differences

between the steam and the objects/surfaces it

contacts. When an excessive volume of

condensate appears in the cooking compartment,

the steam generator water level control should be

checked for possible malfunction and the need for

maintenance. Continued use of the equipment,

without maintenance, will create a potential for

scalding.

MARKET FORGE INDUSTRIES, INC,

35 GARVEY STREET EVERETT, MA 02149 4.1

TEL-6173874100 TELEX: 94-94 1 4

FAX: 617 387 4456 OUTSIDE MA 800 227 2659

Page 15

4. Operation

Figure 4. 1

Control Panel

4.2.3 Shut-down

No Shut Down procedure is required for the

Steam Tech Plus. Simply press the POWER Switch

into the OFF position. When shut down, all indicator

lights on the control panel for that cooking compartment will go out, and the generator for that compartment will automatically drain. The tempering tank

will not drain until both POWER switches ore in the

OFF position.

MARKET FORGE INDUSTRIES, INC.

35 GARVEY STREET EVERETT, MA 02149

TEL: 617 387 4100 TELEX: 94-9414 4.2

FAX: 6 I 7 387 4456 OUTSIDE MA 800 227 2659

When a cooking compartment Is not in use, be

sure to leave its door slightly ajar to extend the life of

the cooking compartment door gasket. When the unit is

completely shut down, both cooking compartment

doors should be left ajar.

NOTE : To avoid the unintentional creation of

steam upon startup, return both timer knobs to the OFF

position and be sure that both CONSTANT STEAM

switches are disengaged.

Page 16

4. Operation

supply power to unit and activate the corresponding system. Pressing this switch into the

Located in the center of the control panel, just above the ready light. Turn the switch to the

Located above the Steam On indicator. Lights up red as the product you are cooking calls

Located at the bottom of the control panel. Pressing this switch into the ON position will

Power Switch

OFF position will cut off power to the corresponding system and shut down the unit.

Power Indicator

Ready Light

Mode Selector Switch

Timer Knob

Steam On Indicator

Steam Demand Indicator

Hold Indicator

Temperature Gauge

Located in the body of the POWER SWITCH. Lights up red when the POWER SWITCH Is

pressed into the ON position.

Located above the POWER SWITCH. Lights up green when the corresponding generator

has warmed up, indicating that it is ready to create steam.

right to select the STEAM mode. Turn the switch to the left to select the STEAM & HOLD

mode.

Located near the top of the control panel. Turn the timer knob clockwise to set the cook

time.

Located near the top of the control panel. Lights up green when any cooking mode is

active.

for steam. It will cycle on and off at varying rates depending on the quantity and product

being cooked.

Located near the center of the control panel, on the left side. Lights up amber when the

unit is in the HOLD mode.

Located on the right side of each of the steam hoods, above the control panel. They are

used to monitor the internal temperature of the cooking compartments during the HOLD

mode.

Located near the center of the control panel, on the right side. Press the button once to

Constant Steam Switch

Constant Steam Indicator

Clean Generator Warning

Indicator

engage it and enter the CONSTANT STEAM mode. Press it again to disengage it and exit

the CONSTANT STEAM mode.

Located next to the Constant Steam button. Lights up green whenever the unit Is in the

CONSTANT STEAM mode.

Located in the lower right side of the control panel. This will light up red when the

generator needs to be de-limed.

Table 4.1

Controls and Indicators

MARKET FORGE INDUSTRIES, INC.

35 GARVEY STREET EVERETT, MA 02149 4.3

TEL: 6 17 387 4100 TELEX: 94-94 I 4

FAX: 6 I 7 387 4456 OUTSIDE MA 800 227 2659

Page 17

4 1 Left Pan Slide

E91-5700

4. Operation

Table 4.2 - Daily Cleaning Parts List, (single cooking compartment shown*)

ITEM QTY.* DESCRIPTION PART NO.

1 1 A-la-carte Tray E91-5782

2 1 Cooking Compartment Drain Screen E91-5718

3 1 Drip / Spill Trough Screen E91-5769

5 1 Right Pan Slide E91-5698

*NOTE The components and quantities shown on this page are for a single cooking compartment only. These

components and quantities are identical for both the upper and lower cooking compartments.

MARKET FORGE INDUSTRIES, INC.

35 GARVEY STREET EVERETT, MA 02149 4.4

TEL: 617 387 4100 TELEX: 94-94 I 4

FAX. 6 1 7 387 4456 OUTSIDE MA 800 227 2659

Page 18

4. Operation

4.3 DAILY CLEANING

After each period of daily operation (more frequently as

required to maintain cleanliness) the cooker should be

thoroughly cleaned by completing the following steps:

1. Remove the left and right side pan support racks by

lifting them up off their mounting brackets.

2. Remove the a-la-carte tray from the floor of the

cooking compartment by lifting the front of the tray

off the mounting pins and sliding it forward.

3. Remove the drain screen from the rear wall of the

cooking cavity by sliding it up off its mounting tabs.

4. Wash cooking compartment interior using detergent

and water. Rinse and dry thoroughly.

5. Remove upper and lower Drip/Spill Trough screens.

Lift the left side of the screen up and swing it out

away from the face of the unit until it Is free to slide

out from under the control panel housing.

6. Wash all removed pieces with a detergent, using a

brush, and rinse. These pieces can also be sent

through a commercial automatic dishwashing

machine. Set these pieces aside for reassembly.

9. Replace a-la-carte tray by sliding it back until it drops

down onto its mounting pins.

10. Replace pan supports into cooking cavity by

hanging them on their mounting brackets. 8e sure

to hang the support with the metal baffling on it on

the right (steam inlet opening) side of the cooking

cavity.

4.4 PROLONGED SHUT-DOWN AND CLEANING

1. Press the both POWER switches into the OFF position. The

steam generators and tempering tank will automatically

drain.

2. Clean the cooking compartment, as described in Section

4.3 of this manual.

3. The Steam Generator must be Rinsed & Drained. Refer to

Section 6.4, Cleaning the Generator, for complete

instructions.

4. Turn gas valve to the OFF position.

CAUTION:

7. Replace the Drip/Spill Trough screens by sliding the

right hand side of the screens under the control

panel housing. Then swing the left hand side of the

screen in towards the face of the unit until the

screen is free to drop down into position.

8. Replace drain screen onto rear wall of cooking

compartment by sliding it down onto its mounting

tabs.

• Disconnect the power supply to the steam generators

before servicing.

• Keep appliance area free & clear from combustibles.

• Don't obstruct the flow of combustion & ventilation air.

• Contact the factory, the factory representative, or a factory

authorized service company to preform maintenence and

repairs.

• In the event of a power failure, no attempt should be made

to operate this appliance. Be sure both power switches are

in the OFF position.

• Keep this manual for daily reference.

MARKET FORGE INDUSTR IES, INC.

35 GARVEY STREET EVERETT, MA 02149 4.5

TEL: 617 387 4100 TELEX: 94-9414

FAX: 017 387 4456 OUTSIDE MA 800 227 2659

Page 19

Water enters the steam generator

5. Troubleshooting

5.1 GENERAL

The information in this section is intended to assist the

operator, maintenance and the service personnel in locating

the source of problems which may occur with the cooker.

Before following any of the procedures given in this section,

the operator/maintenance person should be thoroughly

familiar with the "Operation" Section of this manual.

TROUBLE POSSIBLE CAUSE REMEDY

POWER Light does not come on

when the POWER Switch is

pressed into the ON position.

1. No 120v power to unit.

2. Fuse blown.

3. Faulty POWER Switch.

If the problem cannot be readily corrected without the

use of tools, the operator/maintenance person should contact

the nearest Market Forge service agency for assistance.

1. Be sure 120v power supply is on.

2. Replace fuse.

3. Check/replace POWER Switch.

1. Dirty strainer screen in the water fill solenoid

and/or tempering tank very slowly.

Steam generator will not fill.

Tempering tank will not fill. 1. Fuse blown.

valve.

2. Dirt or lime accumulation on seat of water fill

solenoid valve.

1. Faulty generator fill solenoid valve. 2. Faulty

generator drain solenoid valve.

2. Faulty tempering tank fill/cool solenoid valve.

3. Faulty tempering tank drain solenoid valve.

1. Clean/replace strainer screen.

2. Clean valve seat.

1. If 120 Volt is verified at the solenoid

coil, but the valve fails to open, replace

solenoid.

2. If 120 Volt is verified at the solenoid

coil, but the valve fails to close, replace

solenoid.

1. Replace fuse.

2. If 120 Volt is verified at the solenoid

coil, but the valve fails to open, replace

solenoid.

3. If 120 Volt is verified at the solenoid

coil, but the valve fails to close, replace

solenoid.

MARKET FORCE INDUSTRIES, INC.

35 GARVEY STREET EVERETT, MA 02149 5.1

TEL: 617 387 4100 TELEX: 94-94 1 4

FAX: 6 17 387 4456 OUTSIDE MA 800 227 2659

Page 20

5. Troubleshooting

Make sure that the manual safety gas

lator gas

Be sure ignitor is seated properly in its

TROUBLE POSSIBLE CAUSE REMEDY

Warm-Up Burner will not ignite. 1. No gas supply to unit. 1. Make sure that gas service is

connected and turned on.

2. No gas supply to gas regulator valve. 2.

valve is turned on.

3. No gas supply beyond gas regulator valve. 3. Make sure that the main regu

valve is turned on.

4. Faulty Warm-up burner solenoid valve in gas

regulator.

4. If 24 volts is verified at the solenoid

coil, but valve fails to open, replace gas

regulator.

5. Faulty ignition/flame sensor control module. 5. See Ignition/Flame Sensor Control

Diagnostic section.

6. Faulty ignitor. 6. Check electrical connections.

* Be sure ignitor gap is 1/8".

* Check ignitor alignment.

* Be sure ignitor is seated properly in

its mounting.

Warm-Up Burner will not stay lit. 1. Faulty ignition/flame sensor control module. 1. See Ignition/Flame Sensor Control

Diagnostic section.

2. Faulty ignitor/flame sensor. 2. * Check etectrical connections.

*Be sure ignitor gap is 1/8".

*Check ignitor alignment.

*

mounting.

3. Sediment trap may be full. 3. Empty sediment trap. Be sure to turn

off main gas supply!

READY light will not come on. 1. Faulty 190°F generator thermostat. 1. Check/replace 190°F generator

thermostat.

MARKET FORGE INDUSTRIES, INC.

35 GARVEY STREET EVERETT, MA 02149 5.2

TEL: 6 17 387 4100 TELEX: 94-94 1 4

FAX: 617 387 4456 OUTSIDE MA 800 227 2659

2. Faulty READY light. 2. Check/replace READY light.

Page 21

5. Troubleshooting

(Main Burner will not ignite, STEAM

* Be sure ignitor is seated properly in its

coil, but valve fails to open, replace gas

TROUBLE POSSIBLE CAUSE REMEDY

Generator will not create steam

ON light does not come on).

1. Cooking compartment door is ajar.

2. Cooking compartment door out of

alignment.

1. Check to be sure that the cooking

compartment door is closed and

latched.

2. Check to be sure cooking

compartment door is properly aligned.

3. Faulty door magnet or magnetic reed switch. 3. Check magnet and reed switch.

Replace if necessary.

4. Faulty ignition/flame sensor control module, 4. See Ignition/Flame Sensor Control

Diagnostic section.

5. Faulty ignitor. 5. * Check electrical connections.

* Be sure ignitor gap is 1/8".

* Check ignitor allignment.

mounting.

6. Faulty Main burner solenoid on gas regulator

valve relay.

7. Faulty Main burner solenoid on gas regulator

valve.

6. Check Main burner solenoid relay.

Replace if necessary.

7. If 24 volts is verified at the solenoid

regulator.

8. Faulty pressure switch. 8. Check/replace pressure switch if

necessary.

9. Faulty control panel TIMER 9. Check/replace control panel TIMER if

necessary.

10. Faulty MODE SELECT Switch. 10.Check/replace MODE SELECT

11. Faulty CONSTANT STEAM Button. 11 .Check/replace CONSTANT

MARKET FORGE INDUSTR IES, INC.

35 GARVEY STREET EVERETT, MA 02149 5.3

TEL: 6 17 387 4100 TELEX: 94-94 1 4

FAX: 6 1 7 387 4456 OUTSIDE MA 800 227 2659

switch if necessary.

STEAM button if necessary.

Page 22

TROUBLE POSSIBLE CAUSE REMEDY

Loss of water seal due to low water or no water

r

Generator continuously creates

steam (Steam DEMAND light is

always on).

1. Cooking compartment door out of

alignment.

2. Cooking compartment door gasket leaky.

1. Check alignment of door.

Realign if necessary.

2. Check/replace door gasket.

Steam Suppression not

functioning. ( Excess steam

comes out of the cooking

compartment when the door is

opened.)

3. Pressure switch disconnected. 3. Check to be sure all pressure switch

connections are made.

4. Faulty pressure switch (contacts failed closed). 4. Check/replace pressure switch.

5. Leaky cooking compartment drain line. 5. Check to be sure cooking

compartment drain line is sealed.

Replace if necessary.

6. Steam trap failed open.* 6. Check/replace steam trap.

7.

in tempering tank.*

1. Dirty strainer screen in the spray nozzle

solenoid valve.

2. Dirt or lime accumulation in the generator

spray nozzle.

3. Faulty timer which controls spray nozzle wate

solenoid valve.

7. See "Tempering tank will not fill"

section, on page 5.1 of this manual.

1. Clean or replace strainer

screen.

2. Clean generator spray nozzle.

3. Check to be sure that timer is set

properly, and works. If it doesn't work,

replace it.

4. Misaligned ventilation ductwork. 4. Check ductwork and realign where

5. Blower not running. 5. Check/replace fuse. Be sure that the

6. Faulty wiring. 6. Check wiring.

• If this is the problem, you will also notice excess amounts of steam coming out the vent tube at the top of the unit.

MARKET FORGE INDUSTRIES, INC.

35 GARVEY STREET EVERETT, MA 02149 5.4

TEL! 6 1 7 387 4 1 00 TELEX: 94-94 1 4

FAX: 617 387 4456 OUTSIDE MA 800 227 2659

necessary.

blower motor works.

If not, replace blower.

Page 23

TROUBLE POSSIBLE CAUSE REMEDY

Generator doesn't drain when the

to the

Tempering tank doesn't drain when

ter it has been cleaned (delimed)

Check to be sure timer is set correctly.

Generator continues to create

steam when the cooking

compartment door is opened.

Tempering tank drain water

temperature too high.

POWER Switch is pressed in

OFF position.

1. Faulty magnet reed switch (contacts failed

closed).

2. Faulty wiring.

1. Faulty 130°F thermostat in the tempering

tank.

2. Faulty tempering tank fill/cool solenoid valve.

3. Faulty wiring.

1. Clogged or kinked generator drain line.

2. Clogged generator drain hole. 3. Faulty

generator solenoid drain valve.

1. Check magnetic reed switch.

Replace if necessary.

2. Check wiring.

1. Check 130°F thermostat.

Replace if necessary.

2. If 120 Volt is verified at the solenoid

coil, but the valve fails to open, replace

solenoid.

3. Check wiring.

1. Check to be sure that the generator

drain line is not kinked and is free of

debris.

2. Check to be sure the generator drain

hole is free of debris.

3. Rebuild or replace generator

solenoid drain valve.

1. Clogged tempering tank drain line.

both POWER Switches are in the

OFF position.

2. Clogged tempering tank drain hole.

3. Faulty tempering tank solenoid drain

valve.

CLEAN GENERATOR light stays on

af

and rinsed.

1. Faulty or incorrectly set CLEAN

GENERATOR timer.

2. Faulty CLEAN GENERATOR relay.

3. Faulty wiring.

MARKET FORGE INDUSTRIES, INC.

35 GARVEY STREET EVERETT, MA 02149 5.5

TEL; 0 1 7 387 4 1 00 TELEX. 94-94 1 4

FAX: 617 387 4456 OUTSIDE MA 800 227 2659

1. Clean or replace tempering tank

drain line.

2. Check to be sure that the

tempering tank drain hole is free of

debris.

3. Rebuild or replace tempering tank

solenoid drain valve.

1.

Replace if necessary.

2. Check/replace if necessary.

3. Check wiring.

Page 24

5. Troubleshooting

5.2 WATER LEVEL CONTROL BOARD

The Dual Function Water Level Controller is two

controls on one board. One controller maintains correct

water level in the boiler, the other a low water safety

cutoff.

The following troubleshooting procedure will only

determine if the Water Level Control Board is working

properly, it will not determine why the board has failed.

This procedure exposes you to a shock hazard and

must be performed only by qualified service personnel.

NOTE: Improperly connected or malfunctioning water

level controller may cause damage to the steam

generator due to low water, or create a scalding hazard

to the operator due to a hot water overflow condition.

Tools Required:

A digital or analog volt meter capable of reading 120

volts A.C. and a jumper wire with alligator clips.

MARKET FORGE INDUSTRIES, INC

35 GARVEY STREET EVERETT, MA 02149 5.6

TEL 6173874100 TELEX 94-9414

FAX 6173874456 OUTSIDE MA 800 227 2659

Procedure:

1. Turn off all power to the unit.

2. Select the controller to be tested. Inside the electrical

panel, the water level control for the top cooking cavity

is at the top of the electrical panel and wires to the

controller will have an "A" after the wire number. The

controller for the bottom cooking cavity is at the bottom

of the electrical panel and its wires will have a "B" suf fix. In this test procedure, reference to the wires' "A" or

"B" suffix will be omitted.

3. Remove the wires #40,41, and 42 from the terminal

connectors "G", "H", and "LLOC".

WARNING: When you turn the power on, there are

terminals that carry 120 volts. Protect the ends of these

disconnected wires to prevent snorting to hot /eads.

4. Turn power ON. Using the voltmeter, check that

power being supplied to terminals L I & L2 is 120 volts,

plus 10%, minus 15%.

Page 25

6. Maintenance

6.1 GENERAL

This section contains both preventive and

corrective maintenance information. Preventive

maintenance may be performed by maintenance

personnel at the establishment In which the cooker is

installed. It is recommended that user personnel never

attempt to make repairs or replacements to the

equipment. Assistance in service methods or a current

directory of authorized agencies may be obtained from

Market Forge Industries.

6.2 DAILY CLEANING

After each period of daily operation (more

frequently as required to maintain cleanliness) the

cooker should be thoroughly cleaned by completing the

following steps:

Procedure:

1. Remove the left and right side pan support

racks by lifting them up off their mounting

brackets.

2. Remove the a-la-carte tray from the floor of the

cooking compartment by lifting the front of the

tray off the mounting pins and sliding it

forward.

4. Wash cooking compartment interior using

detergent and water. Rinse and dry thoroughly.

5. Remove upper and lower Drip/ Spill Trough

screens. Lift the left side of the screen up and

swing it out away from the face of the unit

until it is free to slide out from under the

control panel housing.

6. Wash all removed pieces with a detergent,

using a brush, and rinse. These pieces can

also be sent through a commercial automatic

dishwashing machine. Set these pieces aside

for reassembly.

7. Replace the Drip/Spill Trough screens by

sliding the right hand side of the screens

MARKET FORGE INDUSTRIES, INC.

35 GARVEY STREET EVERETT, MA 02149 6.1

TEL: 6 17 387 4100 TELEX: 94-94 1 4

FAX: 6 17 387 4456 OUTSIDE MA BOO 227 2659

under the control panel housing.

Then swing the left hand side of the screen in

towards the face of the unit until the screen is

free to drop down into position.

8. Replace drain screen onto rear wall of cooking

compartment by sliding it down onto its

mounting tabs.

9. Replace a-la-carte tray by sliding it back until it

drops down onto its mounting pins.

10. Replace pan supports into cooking cavity by

hanging them on their mounting brackets. Be

sure to hang the support with the metal

baffling on it on the right (steam inlet

opening) side of the cooking cavity .

6.3 PREVENTIVE MAINTENANCE

A good preventive maintenance program begins

with the daily cleaning procedure described above,

along with examinations of the flue and ventilation

systems to be sure they are free of any obstructions.

NOTE: Your unit may be equipped with a blower

motor which requires lubrication. Check the information

plate located on the side of the blower motor for

lubrication instructions. The blower assembly is located

inside the unit, mounted to the rear center of the floor

pan.

Additional preventive maintenance operations are

presented in this section. In establishments which

employ full-time maintenance personnel, the tasks

described can be assigned to them. For other

installations, tasks requiring mechanical or electrical

experience mu st be performed by an authorized service

agency.

CAUTION: Under no circumstances should

hardware (or parts) be replaced with a different size

or type other than as specified in the parts list. The

hardware used in the cooker has been selected or

designed specifically for its application and the use

of other hardware may damage the equipment,

present a safety hazard and will void any warranty.

Page 26

6. Maintenance

Table 6. 1 - Exterior Sheetmetal Cover Panels and Fasteners Ports List

ITEM QTY. DESCRIPTION PART NO.

1 4 Leg, black, adjustable El 0-0631

2 1 Front Cover Panel Assembly E91-5767

3 1 Rear Cover Panel Assembly E91-5789

4 1 Removable Vent Hatch E91-5777

5 2 Side Cover Panel Assembly E9I -5778

Fasteners 22 8-32 slotted truss head machine screw, 3/8" long, stainless steel E08-3492

MARKET FORGE INDUSTRIES, INC

35 GARVEYSTREET EVERETT, MA 02149

TEL 617 387 A 100 TELEX: 94-94 I 4 6.2

FAX 61 7 387 4456 OUTSIDE MA 800 227 2659

Page 27

The following sections set forth minimum

preventive maintenance procedures which must be

completed periodically to assure continued trouble free

operation.

6.4 CLEANING THE GENERATOR

The Steam Tech Plus Pressureless Steam

Cooker has an automatic indicator light which tells you

when the steam generator needs to be cleaned. When

the CLEAN GENERATOR light comes on, the

generator remains fully functional until it is shut down.

This will allow you to continue to use the unit for the

remainder of the day, until you shut it down. The next

time the unit is turned on, the generator will fill and

preheat to 190°F, but it will not create steam. The

CLEAN GENERATOR light will remain illuminated. The

steam generator must be cleaned before it will create

steam again.

6. Maintenance

protective hand covering. DO NOT TRY TO

REACH INTO THE OPEN SIDE WALL PORTS

This opening is directly connected to the

steam generator.

3. Pour 1/2 gallon of Market Forge's TOTAL CONCEPT™ de-liming solution directly into the open

side wall port. This will immerse the generator

interior and water level probes in the solution.

CAUTION: Read directions and information on

TOTAL CONCEPT™ de-liming solution before using.

4. Wait two hours for TOTAL CONCEPT™ de-liming

solution to work. (Other de-liming solutions may

take much longer.)

5. Make sure the cooking compartment door is

unlatched and slightly ajar, then press the

RINSE & DRAIN button for the generator being

cleaned. (The RINSE & DRAIN buttons are

located on the front of the electrical box, inside

the unit. See Figure 6.1 on page 6.2)

6.4.1 Cleaning Instructions

These cleaning instructions can also be found

printed on the sticker, on the top of the electrical box

inside the unit.

In order to perform this procedure, you will need

TOTAL CONCEPT™ de-liming solution. (Market Forge

Pan Number 20-0307.)

Procedure:

1. Leave the POWER switch on, and wait for the

green READY light.

2. Remove the right pan support rack from inside the

cooking compartment to reveal the side wall

opening

CAUTION: The steam generator and pipe

fittings reach 190°F during the preheat cycle.

Use caution and wear

MARKET FORGE INDUSTRIES, Inc.

35 GARVEY STREET EVERETT, MA 02149

TEL: 017 387 4100 TELEX: 94-94 1 4 6.3

FAX: 61 7 387 4456 OUTSIDE MA 800 227 2659

This will start the draining and spray rinsing of the

steam generator. The RINSE & DRAIN cycle will run for

approximately 3 minutes. At the end of the RINSE &

DRAIN cycle, the steam generator will automatically

refill and warm up.

IT IS NOT NECESSARY TO RINSE & DRAIN

MORE THAN ONCE. The rinsing spray inside the

steam generator will remove all traces of the de-liming

solution.

NOTE: When the steam generator is clean, the

CLEAN GENERATOR light will go off as soon as the

green READY light comes on.

CAUTION: If, after cleaning the steam generator, the

CLEAN GENERATOR light is still on after warm-up

(when the READY light comes on), there may be an

electrical problem. See page 5.5 of the Troubleshooting

section of this manual. Consult with qualified service

personnel for test and repair.

Page 28

6. Maintenance

6.5 CLEANING THE STEAM

VENTILATION DUCTWORK

The Steam Tech Plus steam ventilation ductwork

system is made up of a series of horizontal and vertical

ducts. This series of ductwork must be cleaned

periodically, in order to maintain cleanliness.

Frequency will vary according to use. The recommended procedure for cleaning of the steam ventilation

ductwork is contained in this section.

NOTE: In order to perform this procedure, you

must gain access to the rear of the unit.

Procedure:

1. Turn off the Main gas supply and disconnect the

gas service connection.

2. Disconnect the 120v power supply.

3. Slide the unit out, away from the wall. (You may

need to disconnect the water inlet line.)

7. Using detergent and a damp cloth, wipe clean

the inside of the vent access hatch.

8. Reinstall vent access hatch onto rear of unit.

9. Using detergent and a damp cloth, wipe clean the

inside of the upper and lower steam vent hoods,

located on the front of the unit, just above each

of the cooking compartments.

10. Reconnect 120v power supply.

11. Reconnect the gas service connection and turn

the Main gas supply back on.

12. Slide the unit back into place.

NOTE: You may need to relevel the unit, as

described in step 5 of Section 2.1.

13. If you hav e disconnected the water inlet line,

reconnect it now.

4. Remove the 11 screws which hold the louvered

vent access hatch onto the rear panel of the

unit. (Refer to Figure 6.1 on page 6.2.)

5. Using detergent and a damp cloth, wipe clean the

inside of both the upper and lower horizontal

intake ducts, located just above the cooking

compartments. The very front of these ducts

may be accessed more easily from the front of

the unit.

6. Using detergent and a damp cloth, wipe clean the

inside of both the vertical intake and exhaust

ducts. These ducts are mounted onto the Inside

of the rear panel of the unit.

CAUTION: When cleaning the vertical

exhaust duct, be very careful not to damage

the blower, which is located at the bottom of

this duct. Looking at the unit from the rear,

the vertical exhaust duct is the one on the

right..

6.6 ELECTRICAL BOX SERVICE ACCESS

The Steam Tech Plus electrical box is located

behind the lower front panel of the unit. Most major

electrical componentry is mounted onto the inside of

the electrical box.

CAUTION: Be sure to disconnect BOTH power

supplies from the unit before servicing any

electrical componentry.

To gain access to the electrical box, the lower

cover panel must be removed from the front of the unit.

Prior to removing this panel, the lower drip/spill trough

screen must be removed. Gripping the round handle,

slide the panel upwards until it stops, and pull it out

away from the unit. This will reveal the hinged

electrical box. Unscrew the captive screw latch, which

is located on the left si de of the electrical box and

swing the electrical box open to access the electrical

componentry for service.

MARKET FORGE INDUSTRIES, INC.

35 GARVEY STREET EVERETT, MA 02149 6.4

TEL: 617 387 4100 TELEX: 94-94 1 4

FAX: 6 17 387 4456 OUTSIDE MA 800 227 2659

Page 29

6. Maintenance

5 2 Control Board

08-6536 1

1 2 Terminal Block

08-6518

Figure 6.2 - Electrical Panel Assembly

Table 6.2 - Electrical Panel Assembly Parts List

ITEM

QTY.

1

2 1 Fuse Block 08-6520 8 2 Signal Transformer 08-6450

3 2 Gas Ignition Control 08-6542 9 2 Push Button Switch 08-6517

4 1 Grounding Lug 10-5220 10 1 Terminal Block Assembly 08-6519

6 4 DIN Rail Retainer Clips 08-6516 12 4 Relay, SPDT 10-9174

DESCRIPTION

2

Relay Mounting Rail

PART NO.

08-6515

ITEM

7

QTY

4

DESCRIPTION

Relay Socket

PART NO.

10-9175

MARKET FORGE INDUSTR IES, INC

35 GARVEY STREET EVERETT, MA 02149 6.5

TEL 617 387 4100 TELEX 94-9414

FAX 6173874456 OUTSIDE MA 800 227 2659

Page 30

6. Maintenance

Principles of Operation Schematic

MARKET FORGE INDUSTRIES. INC

35 GARVEY STREET EVERETT.MA 02149

TEL: 6 I 7 387 4 100 TELEX: 94-94 I 4

FAX: 617 387 4456 OUTSIDE MA 800 227 2659

Page 31

6. Maintenance

MARKET FORGE INDUSTRIES. INC.

35 GARVEY STREET EVERETT.MA 02149

TEL.: 61 7 387 4100 TELEX: 94-94 1 4

FAX! 0 I 7 387 800 OUTSIDE MA 800 227 2659

Single Compartment System Wiring Diagram

Page 32

6. Maintenance

Single Compartment System Wiring Diagram

MARKET FORGE INDUSTRIES. 1NC-

35 GARVEY STREET EVERETT. MA 02149

TEL: 617 387 4100 TELEX: •94-9414 6.9

FAX: 617 387 4456 OUTSIDE MA 800 227 2659

Page 33

6.7 CONTROL PANEL

3 1 "Constant Steam" Button

E08-6526

11 1 Power Switch

E08-6524

16 1 Terminal Block

E08-6518

ELECTRICAL SERVICE ACCESS

The control panel assembly is mounted onto the front

of the unit. It houses all of the controls and indicators which

are used to operate the Steam Tech Plus. In order to service

any of the control panel electrical componentry, the control

panel assembly must be removed from the front of the unit.

CAUTION: Be sure to disconnect 120 volt power supply from

the unit and turn off the main gas supply before servicing any

electrical componentry.

Procedure:

1. Remove the 4 screws that fasten the control panel

assembly onto the front of the unit.

2. Gently move the control panel assembly out

away from the unit.

NOTE: Only move the control panel assembly out as far as

is necessary to access the rear of the assembly. PULLING

THE CONTROL PANEL OUT TOO FAR CAN CAUSE

DAMAGE BY PUTTING UNNECESSARY STRAIN ON

WIRES AND CONNECTIONS!

3. Separate the control panel housing and indicator light

mounting bracket by removing the 4 nuts which hold them

together. Be careful not to lose the 1/4-20 nuts which are

used as spacers, (I -per stud). This will allow total access

to all controls and indicators for service, repair, or

replacement. See Figure 6.3 on page 6.11.

6.8 DOOR ADJUSTMENT

Table 6.3 - Control Panel Assembly Parts List

ITEM QTY. DESCRIPTION PART NO.

I 1 Buzzer El 0-6682

2 1 "Clean Generator" Indicator Light (round neon, red) E08-6530

4 1 "Constant Steam" Indicator Light (round neon, green) E08-6529

5 1 Control Panel Housing Assembly E91-5743

6 1 Control Panel Light Mounting Bracket E91-5688

7 1 "Hold" Indicator Light (round neon, amber) E08-6531

8 1 "Mode Select" Switch Assembly E08-6525

9 1 "Power On" Indicator Light E08-6523

10 1 "Power On" Indicator Light Tinnerman Retainer Clip E08-6523

12 1 "Ready* Indicator Light (rectangular neon, green) E08-6527

13 3 Round Indicator Light Retainer Clip E08-6527

14 1 "Steam Demand" Indicator Light (rectangular neon, red) E08-6528

15 1 "Steam On" Indicator Light (rectangular neon, green) E08-6527

17 1 Timer El 0-6291

18 1 Timer Knob E08-3826

19 1 Timer Mounting Nut El 0-6291

20 4 1/4-20 Hex Nut, zinc plated E08-3844

21 2 6-32 Nut with nylon insert, zinc plated E08-3838

22 2 6-32 Slotted Pan Head Machine Screw, zinc plated, 1/2" long E08-3484

23 4 8-32 Nut with nylon insert, zinc plated E08-3839

MARKET FORGE INDUSTR IES, INC.

35 GARVEY STREET EVERETT, MA 02140 6.10

TEL-: 617 387 4100 TELEX: 34-9414

FAX: 617 387 4456 OUTSIDE MA 800 227 2659

Page 34

6. Maintenance

Figure 6.3 - Control Panel Assembly

MARKET FORGE INDUSTRIES, INC

35 GARVEY STREET EVERETT, MA 02149

TEL 6173874100 TELEX 94-9414 6.11

FAX 6173874456 OUTSIDE MA 800 227 2659

Page 35

6. Maintenance

The cooking compartment door alignment, door

handle tension and latch tension are pre-adjusted at

the factory during assembly. During normal usage,

these should not need any attention.

Note that when the cooking compartment doors

are rev ersed, as described in Section 2.5, the doors

will need to be aligned and the door latch tension will

need to be adjusted (the door handle will not need

adjustment when the door is reversed).

6.8.1 Door Alignment

The cooking compartment doors are pre-aligned

at the factory during assembly, and should not need

adjusting unless they are reversed. Should the doors

need realignment, the procedure is as follows:

Procedure:

1. Open the cooking compartment door.

2. Loosen all 4 bolts (2 per hinge) which mount the

upper and lower hinge brackets to the face of

the unit using a 5/16" wrench. DO NOT

REMOVE THE BOLTS.

3. Begin to retighten all 4 bolts so that they are snug

against the face of the unit. DO NOT

COMPLETELY TIGHTEN THE BOLTS.

4. Slowly, ease the cooking compartment door

dosed until it is latched.

5. The cooking compartment door can now be

raised, lowered, and/or rotated into position by

bumping it with the palm of your hand or by

using a small rubber mallet.

6. First, check the alignment at the front of the door

by making sure that the striker in the door is

centered, with the latch mechanism on the front

of the unit.

7. Square the door to the unit by raising or

MARKET FORGE INDUSTRIES, INC.

35 GARVEY STREET EVERETT, MA 02149 6.12

TEL: 617 387 4100 TELEX: 94-94 1 4

FAX: 6 17 387 4450 OUTSIDE MA 800 227 2859

lowering the hinge side of the door, keeping the latch

centered with the striker.

8. Visually inspect the door. Be sure that the door is square

to the unit, the striker is centered with the latch, and

the gasket is in contact with the entire lip of the

cooking compartment.

9. Gently open the cooking compartment door, taking care

not to move it out of position.

10. Tighten all 4 door hinge bracket mounting bolts, using

a 5/16" wrench.

11. Close and visually inspect the door again, as described

in step 8.

6.8.2 Door Latch Tension Adjustment

The cooking compartment door latch tension is

preset at the factory, and should not need adjusting

unless the doors are reversed. Should the latch need

adjustment, the procedure is as follows:

Procedure:

1. Open the cooking compartment door.

2. If latch is mounted on the right side of the cooking

compartment, remov e the corresponding control

panel. If latch is mounted on the left side of the

cooking compartment, remove left side panel.

3. Tighten both nuts down until the springs are fully

compressed.

4. Back each nut off 1/2 turn.

5. Remount the control panel or left side panel.

Page 36

6. Maintenance

1 1 Door Latch

E91-

5746

Table 6.4 - Door Latch and Magnet Sensor Assemblies Parts List

ITEM QTY. DESCRIPTION PART NO.

2 1 Door Sensor (Magnetic Reed Switch) E08-6308

3 1 Door Sensor Mounting Bracket E91-5697

4 2 Door Sensor Spacer ( 6-32 hex nut, zinc plated) El 0-2331

5 2 Spring E08-4600

6 4 Washer, Nylon E10-0100

7 2 4-40 Hex Nut, with Nylon insert, zinc plated E08-3845