Market Forge STP-6E Specifications

JOB NAME: __________________________

ITEM NO.: ___________________________

NO. REQUIRED: ______________________

STP-6E AGA and NSF Listed

Operation: Each compartment utilizes a powerful closecoupled 9 kW steam generator that supplies steam to the

cook-ing compartments. Generators are held in the “ready”

mode for quick response to heavy-demand situations. An

automatic generator blowdown feature with spray and rinse

and clean generator light are provided as standard

equipment. Each generator is rated at 9kW. Generator

chambers are mounted on the right side of the steamer and

close-coupled to the steam compartment. Generators

include as standard a pilotless ignition system, automatic

water level control, low-water cutoff, water strainer, safety

relief valve, and preheat thermostat (190°F) and high limit.

Generator includes an access port for Total Concept

delimer/descaler and PM Plus (a corrosion inhibitor).

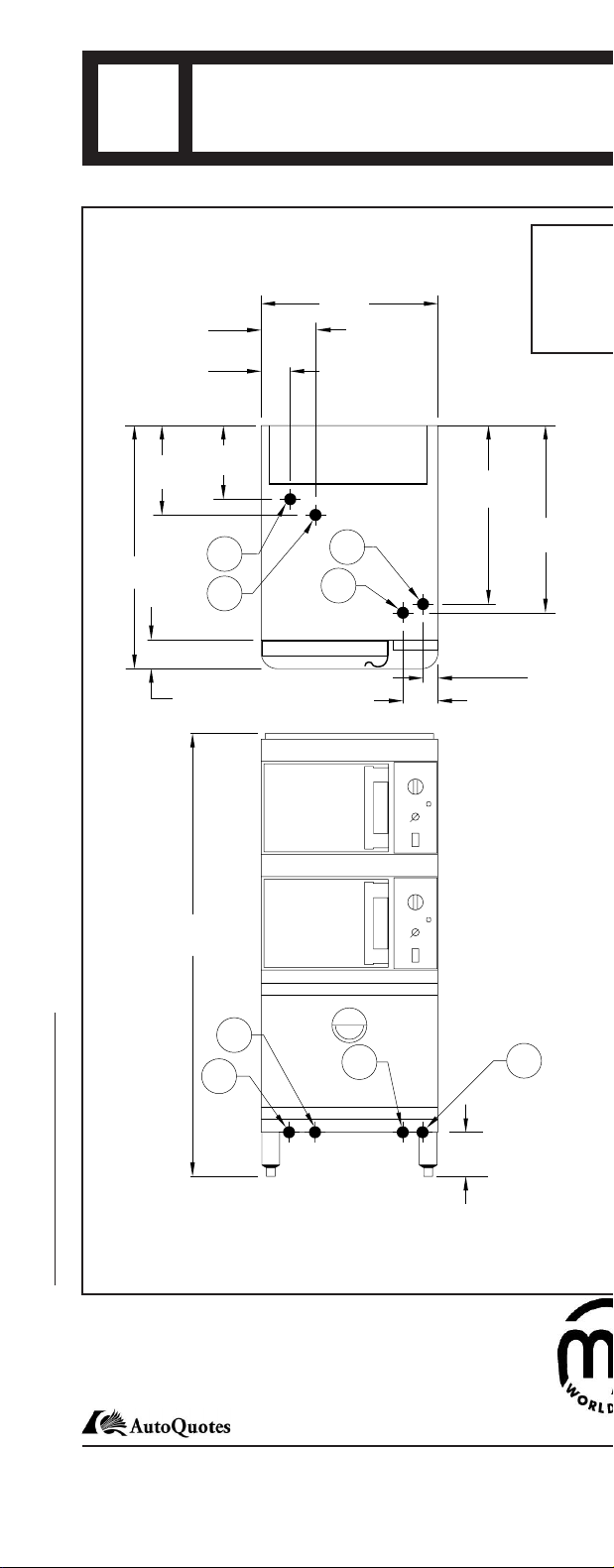

DIMENSIONS AND CAPACITY:

Internal Dimensions of cooking compartments:

14.5” Wide x 10.75” High x 23” Front-To-Back.

(368 mm Wide x 273 mm High x 584 mm Front-To-Back)

Allow 6” 152 mm of space on the right side if height of

adjoining wall or equipment exceeds 29” 737 mm.

External Dimensions:

24” Wide x 60.2" High x 33" Front-To-Back.

(610 mm Wide x 1529 High x 838mm Front-To-Back)

Capacity:

Each cooking compartment will accommodate

(6) 12” x 20” x 1” deep pans; (6) 1/1 Gastronorm pans, 35 mm.

(3) 12” x 20” x 21/2” deep pans; (3) 1/1 Gastronorm pans, 65 mm.

(2) 12” x 20” x 4” deep pans; (2) 1/1 gastronorm pans, 100 mm.

Spec No. S-2439B

05/04

Spec No. S-2439B

05/04

FOOD SERVICE EQUIPMENT

Convection Steamer

Convection Steamer

*It is our policy to build equipment which is design certified by A.S.A., U.L., A.S.M.E., N.S.F., C.G.A. and C.S.A. However, a continuing program of product improvement makes it

FOOD SERVICE EQUIPMENT

STP-6E STEAM TECH PLUS

E

7.8"

198mm

4.3"

109mm

12.3"

312mm

33"

259838

259mm

4"

102mm

60"

1529mm

necessary to submit new models to the agencies as they are developed and consequently not all models bear the appropriate agency labels at all times.

CONVECTION STEAMER

24"

610mm

10.3"

CW

D

D

CW

EP

EC

122mm

EC

152mm

24.8"

617mm

4.8"

6"

All service connections are

made at the bottom of the unit,

in the 6” high space between the

floor and the bottom of the

ELECTRICAL AND GAS CHARACTERISTICS:

Electrical Connection: 120 VAC, 60 Hz, 1/2” conduit or

equivalent. Current draw for 120V control circuitry is

6.5 amps. Use wire suitable for at least 90°C.

NOTE: If the equipment is to be installed where the

25.5"

648mm

elevation exceeds 2,000 ft. (609.6 meters) above sea level,

specify installation altitudes so that the proper gas orifices

can be provided.Rated Input: 45,000 BTU per compartment.

WATER CONNECTIONS:

Cold Water: 1/2” NPT male to cold water supply manifold.

Cold water supply line to have a maximum of 50 PSI

2"

59mm

(3.5 kg/cm

pressure.

Drain: 1 1/2” O.D. pipe coupled to 1 1/2” O.D. tempering

tank drain. Do not make solid connection to floor drain. PVC

and CPVC pipe are not acceptable materials for drains.

Before connecting water to this unit, have water supply

analyzed to make sure that hardness is no greater than

2.0 grains per gallon and a pH level is within the range of

7.0–8.5. Water that fails to meet these standards should be

treated by the installation of a water conditioner. Equipment

failure caused by inadequate water quality is not covered

under warranty.

OPTIONAL:

m 12” X 20” X 1” perforated stainless steel pans.

m 12” X 20” X 2 1/2” perforated stainless steel pans.

m 12” X 20” 2 1/2” solid stainless steel pans.

m 12” X 20” X 4” perforated stainless steel pans.

m 12” X 20” X 4” solid stainless steel pans.

EP

m Total Concept Discaler (case of 4 gallons).

m PM Plus Corrosion Inhibitor (case og 4 gallons).

m A-LA-Carte Shelf.

m Model# STP-6E, SE Steam exhaust, no steam & hold

feature .

m Model# STP-6E, VE No steam & hold, no steam exhaust.

An Employee Owned Company

35 Garvey Street l Everett l MA l 02149

l

(617) 387-4456 (MA and Overseas)

E-Mail: CUSTSERV@mfii.com l Website: www.mfii.com

Printed in U.S.A.

Tel: (617) 387-4100 l Fax: 1-800-227-2659 (Ex. MA)

E-Mail: CUSTSERV@mfii.com

E

7.8"

198mm

4.3"

109mm

12.3"

312mm

33"

259838

4"

102mm

Spec No. S-2439B

05/04

60"

1529mm

STP-6E STEAM TECH PLUS

CONVECTION STEAMER

24"

610mm

10.3"

259mm

CW

D

D

CW

EP

EC

EC

24.8"

617mm

4.8"

122mm

6"

152mm

All service connections are

made at the bottom of the unit,

in the 6” high space between the

floor and the bottom of the

ELECTRICAL AND GAS CHARACTERISTICS:

Electrical Connection: 120 VAC, 60 Hz, 1/2” conduit or

equivalent. Current draw for 120V control circuitry is

6.5 amps. Use wire suitable for at least 90°C.

NOTE: If the equipment is to be installed where the

25.5"

648mm

elevation exceeds 2,000 ft. (609.6 meters) above sea level,

specify installation altitudes so that the proper gas orifices

can be provided.Rated Input: 45,000 BTU per compartment.

WATER CONNECTIONS:

Cold Water: 1/2” NPT male to cold water supply manifold.

Cold water supply line to have a maximum of 50 PSI

2"

59mm

(3.5 kg/cm

pressure.

Drain: 1 1/2” O.D. pipe coupled to 1 1/2” O.D. tempering

tank drain. Do not make solid connection to floor drain. PVC

and CPVC pipe are not acceptable materials for drains.

Before connecting water to this unit, have water supply

analyzed to make sure that hardness is no greater than

2.0 grains per gallon and a pH level is within the range of

7.0–8.5. Water that fails to meet these standards should be

treated by the installation of a water conditioner. Equipment

failure caused by inadequate water quality is not covered

under warranty.

OPTIONAL:

m 12” X 20” X 1” perforated stainless steel pans.

m 12” X 20” X 2 1/2” perforated stainless steel pans.

m 12” X 20” 2 1/2” solid stainless steel pans.

m 12” X 20” X 4” perforated stainless steel pans.

m 12” X 20” X 4” solid stainless steel pans.

EP

m Total Concept Discaler (case of 4 gallons).

m PM Plus Corrosion Inhibitor (case og 4 gallons).

m A-LA-Carte Shelf.

m Model# STP-6E, SE Steam exhaust, no steam & hold

feature .

m Model# STP-6E, VE No steam & hold, no steam exhaust.

Convection Steamer

*It is our policy to build equipment which is design certified by A.S.A., U.L., A.S.M.E., N.S.F., C.G.A. and C.S.A. However, a continuing program of product improvement makes it

FOOD SERVICE EQUIPMENT

necessary to submit new models to the agencies as they are developed and consequently not all models bear the appropriate agency labels at all times.

Printed in U.S.A.

Tel: (617) 387-4100 l Fax: 1-800-227-2659 (Ex. MA)

E-Mail: CUSTSERV@mfii.com

Loading...

Loading...