Market Forge STM-ED Installation Manual

STERILMATIC

DIGITAL ELECTRIC STERILIZER

INSTALLATION - OPERATION - MAINTENANCE

MODELS

STM-ED

STM-EDX

44 Lakeside Avenue, Burlington, Vermont 05401 USA

Telephone: (802) 658-6600 Fax: (802) 864-0183

www.mi.com PN 14-0413 Rev C (10/15)

© 2015 - Market Forge Industries Inc.

Your Service Agency’s Address:

Model

Serial number

Sterilizer installed by

Installation checked by

IMPORTANT

TABLE OF CONTENTS

WARNING: Improper installation, adjustment, alternation,

service or maintenance can

cause property damage, injury or death. Read the installation, operation and maintenance instructions thoroughly

before installing or servicing

this equipment.

FOR YOUR SAFETY

Do not store or use gasoline or

other ammable vapors or liquids in the vicinity of this or any

other appliance.

The information contained in this

manual is important for the proper installation, use, and maintenance of this sterilizer. Adherence to these procedures and

instructions will result in satisfactory baking results and long,

trouble free service. Please

read this manual carefully and

retain it for future reference.

INSTALLATION

Introduction .............................................................. 2

Service Connections ..................................................... 4

Installation Instructions ................................................... 5

Optional Cold Water Condenser ........................................... 6

Pan Supports and Bafes ................................................. 7

Optional Stands .......................................................... 9

OPERATION

General Operating Instructions ........................................... 10

Minimum Sterilization Times ............................................. 11

Digital Control Panel .................................................... 12

Detailed Operating Instructions ........................................... 13

MAINTENANCE

Cleaning ............................................................... 18

Warranty ............................................................... 19

ERRORS: Descriptive, typographic or pictorial errors are

subject to correction. Specications are subject to change

without notice.

Introduction

PRODUCT DESCRIPTION

The Market Forge Sterilmatic Sterilizer with Digital Controller (model STM-ED) is a compact, automatic, low cost

steam pressure sterilizer (autoclave).

The sterilizing cylinder is a 3/16” (4.8mm) thick wall, welded aluminum. The exterior is made of polished stainless

steel. Interior dimensions of 16” (406mm) diameter and

26” (660mm) long with a cubic content of 5,220 cubic

inches (0.085 cubic meters) and has a door opening of

13-1/2” (343mm) wide and 11” (279mm) high. The sterilizing compartment has a pan capacity of:

• (3) 12” x 20” x 2 ½” (305mm x 508mm x 64mm) or,

• (2) 12” x 20” x 4” (305mm x 508mm x 102mm) or,

• (1) 12” x 20” x 6” (305mm x 508mm x 152mm)

The sterilizer door is a self-sealing type that cannot be

opened until the steam pressure is completely exhausted

from the chamber. The door is 12 gauge stainless steel

and removable for cleaning without tools. The door gasket is one-piece molded, also replaceable without tools

or cement.

The sterilizing cycle is fully automatic with the time, temperature and venting controlled by the microprocessor

based, digital controller.

The sterilizing temperature can be set anywhere in a

range from 225°F (107°C) and 250°F (121°C). There is

an on-board data logger/printer. The data logger records

the time, temperature and pressure for each sterilization

cycle. This data can be stored for future printing or printed

out following each cycle.

OPERATING ENVIRONMENTAL CONDITIONS

This unit is designed for commercial use and to be safe at

least under the following conditions:

• For indoor use only.

• For use at altitudes up to 6500ft (2000m)

• For use at temperatures from 41°F (5°C) to 104°F

(40°C).

• Maximum relative humidity 80% for temperatures up

to 88°F (31°C) decreasing linearly to 50% relative

humidity at 104°F (40°C).

• Main supply voltage uctuations not to exceed ±

10% of nominal voltage.

• Transient overvoltages according to Installation Categories II (in accordance with IEC 664).

• Pollution Degree 2 (in accordance with IEC 664).

SERVICE & TECHNICAL INFORMATION CONTACT

WARNING

This unit should be serviced by qualied service personnel only.

Your Sterilmatic Sterilizer has been developed to answer

the need for a compact, automatic, low-cost steam pressure sterilizer. The following instructions cover installa-

tion. Should service be required, it is readily available by

contacting our authorized service agency located nearest

to you. The name of your local service company can be

obtained on our website, www.mi.com.

INTENDED USE - STERILIZATION CYCLE

This unit is intended to be operated intermittently. After

a pre-heat cycle, the longest period of sterilization (heating) should be a maximum of 60 minutes. The digital timer allows up to 99 minutes, but it should be kept at no

more than 60 minutes. After each use the unit should be

opened for removal and reloading of product. The water

level should be checked after each use and relled when

necessary.

WATER CONDITIONS

When sterilizing culture mediums that generate sul-

de gas or chlorine gas, the inside of the chamber

must be cleaned and rinsed thoroughly without fail

Market Forge from time to time is asked the question

about using distilled or deionized water for use with our

Sterilizer models STM-ED and STM-EDX. We are always

asked why these water choices are not allowed for use

with our units and what would be recommended. To address this situation, we have complied the following as a

means of satisfying these questions:

1. We have found that the use of distilled or deionized

water will aggressively attack the pure coat of Aluminum Alclad, which protects the bottom surface from

oxidizing and then eventually pitting (reference: Operating and Maintenance Instructions).

2. In addition pitting can also be caused by several other

external environmental factors. Few examples are as

follows. These conditions have been highlighted in

our documentation.

• Grains of hardness in the water supply should

be as follows (.25 to 2).

• A pH imbalance in the water supply can greatly

affect the life to the aluminum cylinder. The pH

range that would be recommended is between

7.0-8.5.

INSTALLATION

2

Introduction

• The lack of a positive electrical ground can

cause an electrolytic reaction that will accelerate

pitting.

• Another contribution to accelerate pitting is the

type of cleaning solutions used or the abrasive

scrubbing pads. If a low pH is present with the

detergents being used or an abrasive pad, the

protective Alclad coating will be removed during

the cleaning process.

• Spillage of media being sterilized can also contribute to the accelerated pitting if it is corrosive.

• CHLORINE LEVEL ≤ 1 PPM.

IMPORTANT

Market Forge will not be responsible for damage resulting from the use of hard or corrosive

water, from failure to drain the unit daily, or

from inadequate cleaning procedures.

3

INSTALLATION

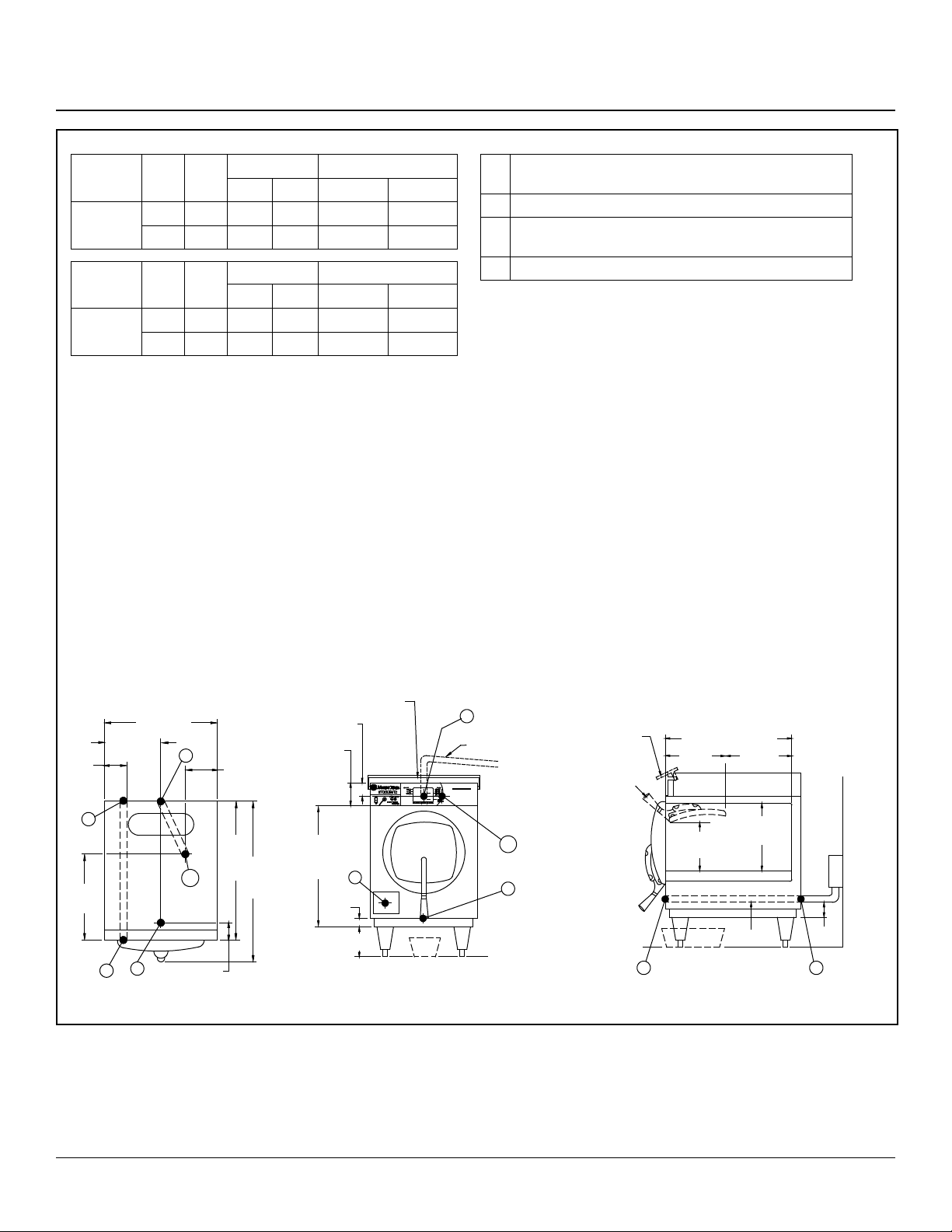

Service Connections

ELECTRICAL SPECIFICATIONS

Domestic

Model

STM-ED

Export

Model

STM-EDX

kW Hz

9.3 60 45A - 26A -

12.4 60 - 52A - 30A

kW Hz

10.4 50 48A - 16A -

12.4 50 - 52A - 18A

1 Phase

208V 240V 208V 240V

1 Phase

220V 240V 220/380V 240/415V

Unit must be grounded. Main supply voltage fluctuations are not to

exceel ± 10% nominal supply voltage.

3 Phase

3 Phase

WATER SUPPLY

Good quality water feed is the responsibility of the owner. Water quality must be within the following general guidelines.

TDS: 40-125 ppm Hardness: 35-100 ppm Chlorine: <0.2 ppm

Silica: <13 ppm Chlorides: <25 ppm

Chloramine: <0.2 ppm pH: 7.0 - 8.5

The best defense against poor water quality is a water treatment

system designed to meet your water quality conditions.

Appliance to be installed with backflow protection according to federal, state or local codes.

SERVICE CONNECTIONS

A Drain - 1/2” (13mm) N.P.T. of 3/8” (10mm) OD copper

(see note 1)

B Steam Exhaust Connection - 5/8” (16mm) (see note 2)

C Electrical Connection - (*see electrical specifications

table)

D Power Supply

NOTES:

1. An air break must be provided if a unit drain line is run.

2. Vent exhaust to atmosphere. B1 is actual connection, but

must exit casing at B.

IMPORTANT: Exhaust line must be vented to the outside to eliminate the exhaust steam and the accompanying noise from entering the room. Use 1/2” (13mm) copper tubing or suitable alternate.

The overall height and length of the line should not rise more then

4’ (1.2 meters) above the unit and exceed 15’ (4.5 meters) with a

minimum of bends. The line should slope downward after leaving

the sterilizer in order to ensure condensate drainage.

IMPORTANT: Failure to comply with this outline will affect the

sterilization process.

When an exhaust condenser is supplied; the following services

must be provided: 1/2” (13mm) cold water: 1” (25mm) waste: 115V

electrical line.

DIMENSIONS ARE IN INCHES [MM]

18.69 [475]

3.5

[89]

15.5

[394]

D

9.34 [237]

C

A

CONDUIT

B

B1

SEE

NOTE 2

1.5 [38]

4.75

[121]

25 [635]

30 [762]

STEAM SHIELD

3 [76]

5.63

[143]

23 [584]

C

1 [25]

6 [152]

Customer provided Drain Catch Pan

Approx. 4-6 quarts (3.8-5.7 liters)

Figure 1

B

SEE NOTE 2

B1

A

4 [102]

ADJ. LEGS

STEAM SHIELD

DOOR IN

OPEN POSITION

21 [533] CHAMBER

9 [230]

CLEARANCE

9 [228]

CLEARANCE

CONDUIT

Locate electric box as close to

C

sterilizer as possible and per

local electrical codes

12 [305]

11 [280]

3 [76]

D

INSTALLATION

4

Installation Instructions

INSTALLATION

Set sterilizer on counter, using the 6” (152mm) legs provided or assemble the optional stainless steel stand with

under-shelf. If your Sterilmatic includes a water-cooled

exhaust condenser, we recommend the use of the Sterilmatic stand, part number 95-6060. First, level unit in

place, then adjust rear legs to pitch the unit forward 1/4”

(6mm) to insure positive drainage of the cylinder.

ELECTRICAL

Connect to proper electrical supply box and disconnect

switch as shown on one of the following schematic diagrams - 208 or 240 volts, single or three phase. Connection is made from the rear of the unit, through the conduit

to the terminal box located at the front of the unit.

Electric supply connection for STM-ED

Connect to proper electrical supply as indicated on nameplate on top of unit. The power supply cord is brought in

from the rear of the unit, through the conduit and the connection is made at the terminal box located at the front of

the unit.

Electric supply connection for STM-EDX (export models)

Connect to proper electrical supply as indicated on nameplate on top of unit. Connection is made from the rear of

the unit, through the conduit to the terminal box located at

the front of the unit. All control circuits are 220 volts.

In order to accomplish this, a current-carrying grounded

neutral must be provided.

Thus, a three phase system must be 4-wires. Most elec-

trical codes require, and we recommend, that a separate

switch be located within sight of the sterilizer.

OUTSIDE VENTING

Connect 1/2” (13mm) nominal tubing exhaust to outside

vent connection located on top of unit, within the control

housing.

IMPORTANT: Exhaust line must be vented to the outside to eliminate the exhausted steam and the accompanying noise from entering the room.

Use 1/2” (13mm) copper tubing or suitable alternate. The

overall height and length of the line should not rise more

then 4 feet (1.2 meters) above the unit and exceed 15 feet

(4.5 meters) with a minimum of bends. The line should

slope downward after leaving the sterilizer in order to insure condensate drainage.

WATER-COOLED EXHAUST CONDENSER

If outside venting is not possible, an optional water-cooled

condenser is available for connection to an open drain. If

required order part no. 95-0436 kit.

TRAY SUPPORTS

Install side tray supports. Tray supports are attached by

means of key-hole clearance slots which are slipped over

studs located on the sides of the Sterilmatic chamber.

BAFFLE INSTALLATION

To insure maximum drying of packs, a bafe is supplied

with your Sterilmatic. Place perforated splash bafe in

bottom of the sterilizing chamber. Install small bafe with

no perforation at the rear of the upper tray support channel.

NOTE: The perforated bafe is not to be used as a shelf

to place media or other items. It is intended to

eliminate splashing.

OPERATION CHECK

To check for proper operation of unit:

1. Close drain valve by turning handle clockwise.

WARNING

DO NOT OPEN DRAIN VALVE WHILE UNIT

IS OPERATING. PREMATURE OPENING MAY

RESULT IN SCALDING OF OPERATOR.

2. Fill chamber with 4 to 5 quarts (3.8 to 4.7 liters) of

ordinary tap water. DO NOT USE DISTILLED OR DEIONIZED WATER.

3. Close chamber door.

4. Set exhaust selector to INSTRUMENTS AND PACKS

(fast exhaust) or LIQUIDS (slow exhaust).

5. Set timer to 15 minutes. Cycle will go to completion

automatically.

5

INSTALLATION

Loading...

Loading...