Page 1

STERILMATIC

ANALOG ELECTRIC STERILIZER

PARTS AND SERVICE MANUAL

EFFECTIVE APRIL 15, 2016

The Company reserves the right to make substitution in the event that items specied are not available.

ERRORS: Descriptive and/or typographic errors are subject to correction.

44 Lakeside Avenue, Burlington, Vermont 05401 USA Telephone: (802) 658-6600 Fax: (802) 860-3732

Superseding All Previous Parts Lists.

MARKET FORGE INDUSTRIES

www.mi.com

P/N 14-0412 Rev D

Page 2

TABLE OF CONTENTS

DOOR ASSEMBLY & ADJUSTMENT ....................................................3

FULCRUM AND DRAIN ASSEMBLY .....................................................5

PRESSURE ACTUATED TEMPERATURE CONTROL .....................................6

MISCELLANEOUS COMPONENTS .....................................................8

TROUBLESHOOTING ................................................................ 10

ILLUSTRATED PARTS LIST ...........................................................11

APRIL 15, 2016 2 STM-E, STM-EL, STM-EX & STM-ELX STERILIZERS

Page 3

DOOR ASSEMBLY & ADJUSTMENT

STERILMATIC DOOR ASSEMBLY

The Door of the Sterilmatic has been engineered to establish a positive method of sealing the steam pressure

within the sterilizing cylinder. As steam pressure builds

up within the cylinder, the door seal will tend to become

more positive.

However, the door should be adjusted to make a good

initial seal between the door gasket and the door opening

without the added assistance of internal cylinder steam

pressure with the simple action of securing the door handle down in a locked position, the door gasket should be

sufciently compressed against the door opening, all the

way around to prevent any steam leakage from occurring.

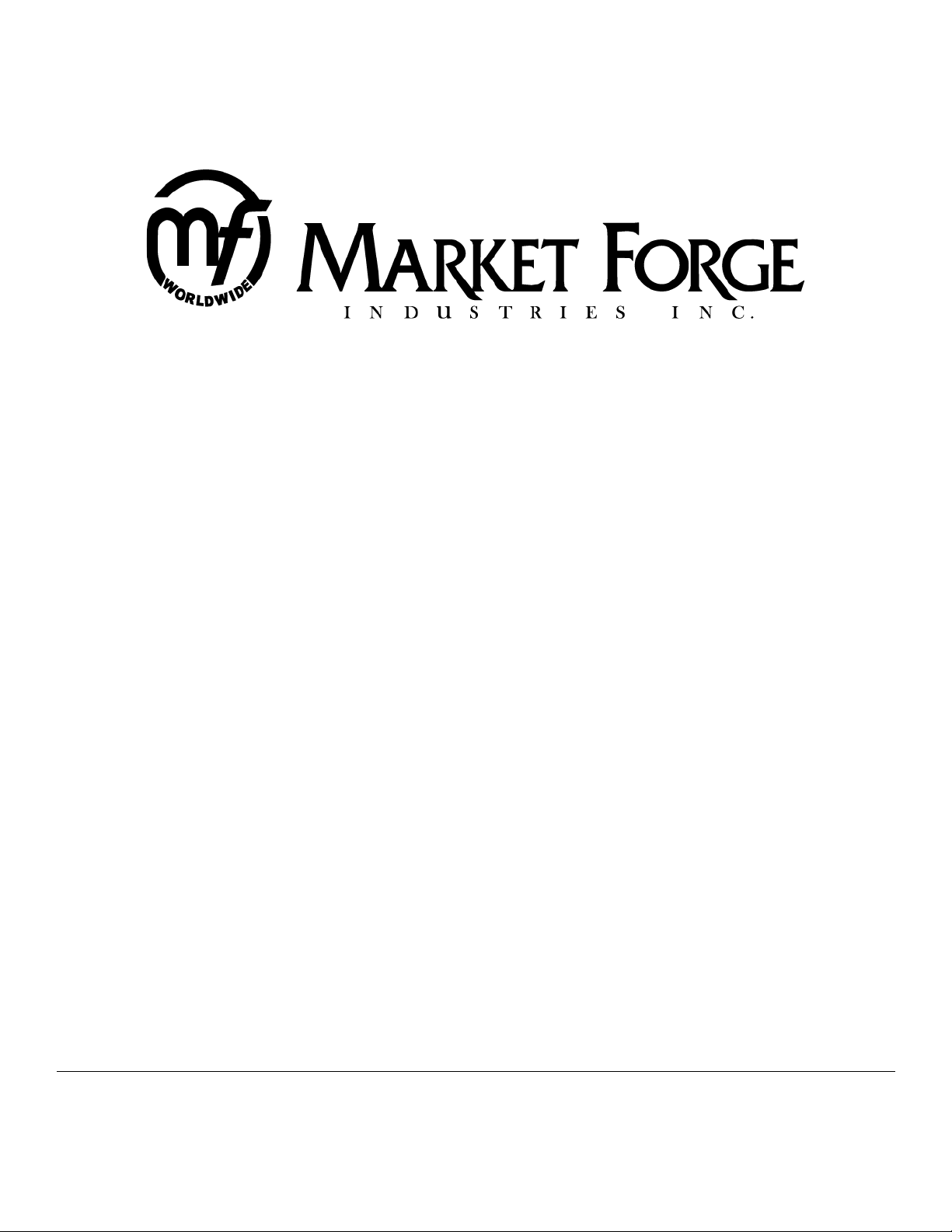

DOOR ADJUSTMENT

The Door Adjustment is Located in the Fulcrum Casting

at the base of the door opening. This adjustment employs

the use of a screw and locknut in order to adjust the Sterilmatic Door to a tighter closed position (to prevent steam

from leaking by the door gasket as pressure builds up), it

is necessary to loosen the locknut and back off the screw

at least one-quarter of a turn and re-tighten the locknut.

Figure 1

Figure 2

THE DOOR GASKET

Keep the gasket clean. With normal closing and locking

of the door assembly, a steam-tight seal should be made

between the door gasket and the door opening. This seal

cannot be maintained if particles of foreign matter are allowed to accumulate upon either of the contacting surfaces.

If there is leakage by the door gasket before a steam

build-up within the steam chamber and leakage does not

stop when the sterilizer reaches sterilizing temperature

and pressure than regard the door assembly as improperly adjusted. A re-adjustment must then be made of the

seal adjustment door screw.

To change the door gasket, remove the entire door assembly as a unit. Discard the old gasket, replace it with

a new one (no cement is required), and reinstall the door

assembly. Make an operational check for leakage and adjust the door, if necessary.

APRIL 15, 2016 3 STM-E, STM-EL, STM-EX & STM-ELX STERILIZERS

Page 4

DOOR ASSEMBLY & ADJUSTMENT

DOOR LIFT SPRING

Market Forge supplies door lift springs in sets only. This

policy has been found to be in the best interest of the

customer. Through continuous use, some of the original

qualities of the springs are lost and it becomes advantageous to make replacements to both the left and right

door lift springs in the event that one becomes damaged

or broken.

Replacement door lift springs are marked with tabs at

the factory prior to shipment to identify a right from a left

spring. These springs must be installed with the right

door lift spring on the right of the door and the left door lift

spring on the left of the door as viewed from the front of

the sterilizer.

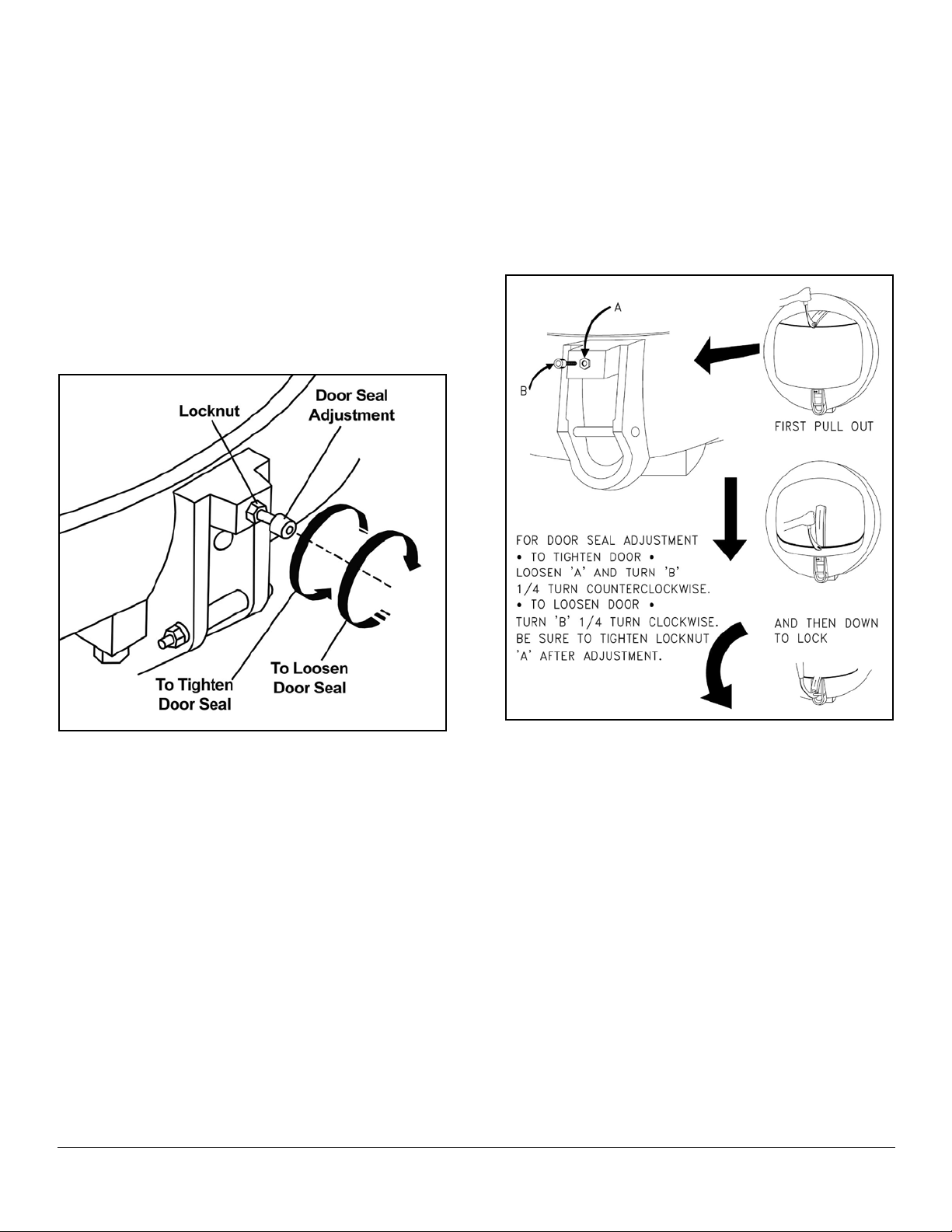

TO REMOVE THE DOOR ASSEMBLY

The Door Assembly can be removed from the inner sterilizing chamber as a unit without the use of any special

tools or equipment. However, a systematic approach to

this is warranted as the clearances through the portal are

close, and much confusion can result if not removed in

the sequence described below:

1. First, lift off and remove the two pan supports to expose the door linkage on either side of the inner sterilizing chamber .

2. Raise the door to a fully opened position, and disengage the door spring from each of the door spring

studs. Accomplish this by counteracting the force of

the door lift spring with one hand while working the

end of the door spring off the spring stud with the free

hand. Do this on both sides of the door assembly.

3. When the end of the door springs have been completely freed from their respective door spring studs,

the door springs on either side of the door assembly

can easily be slipped off their studs.

4. Rotate the entire door assembly out through the

door opening, passing the door handle through the

opening rst, and then one end of the door spring as

shown in the illustration. The remainder of the door

assembly will then pass through the door opening

quite easily.

5. To replace the door assembly, reverse the step-bystep procedure described above.

Figure 3

ITEM PART NO. DESCRIPTION

1 10-6765 Pivot Spring Bearing

2 91-2718 Right and Left Door Spring (sold as a pair)

3 10-1776 10-32 Machine Screw 1/2” Long

4 10-2666 Door Gasket

5 95-3204 Door & Door Spring Assembly

- 95-0124 Items 1 through 5

APRIL 15, 2016 4 STM-E, STM-EL, STM-EX & STM-ELX STERILIZERS

Page 5

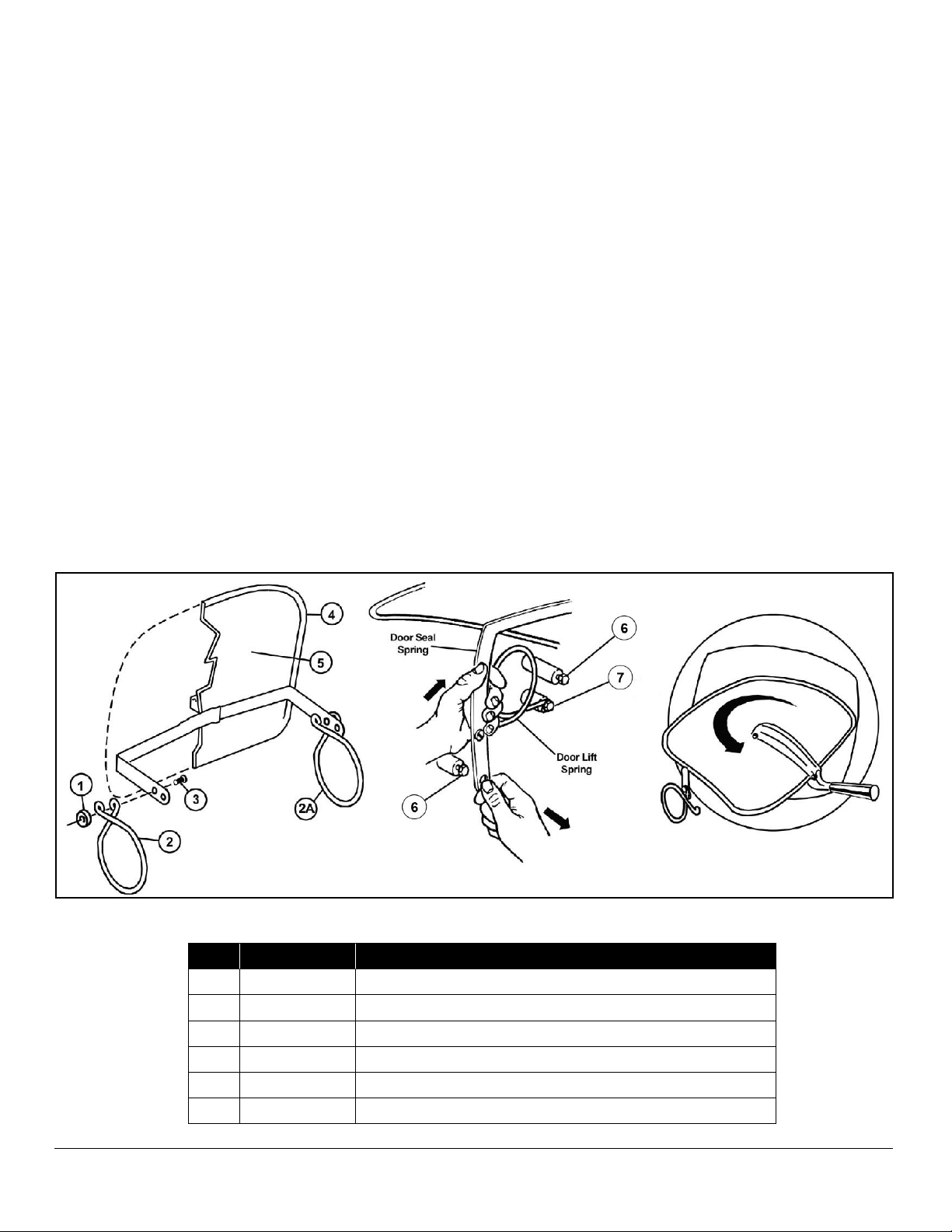

FULCRUM AND DRAIN ASSEMBLY

THE FULCRUM & DRAIN

ASSEMBLY

The fulcrum and drain assembly is located at the lower front

of the sterilizing chamber and

furnishes a sturdy anchorage

for the door locking system of

the door handle. Also provided

in this assembly is a means for

adjustment of the door seal. The

drain port and drain valve provide a means of discharging accumulations of water from within

the sterilizing chamber.

ROLLER ASSEMBLY

(ITEMS 8 & 9)

The Roller Assembly must be

kept free-rolling at all times.

Should this assembly be allowed

to become frozen due to lack of

lubrication, undue strain will be

put on the door handle and the

fulcrum casting while the door

is being locked. Use only a dry

lubricant such as graphite; as oil

or grease will tend to attract dirt

to this area.

Figure 4

ITEM PART NO. DESCRIPTION

1 10-3116 1/4” - 20 X 5/8 helicoil

2 10-1999 10-32 Machine screw, 1 5/8” long

3 10-2358 1/4” - 20 fulcrum nut

4 10-2087 1/4” - 20 allen set screw

5 10-3111 1/4” - 20x 3/8 helicoil

6 10-2513 1/4” Shakeproof washer

7 10-1763 1/4” - 20 Machine screw 3/4” long

8 95-0120 Bearing spacer

9 95-0198 Bronze Bearing

10 10-3111 1/4” - 20 x 3/8 helicoil

11 10-2513 1/4” Shakeproof washer

12 10-1790 1/4” - 20 Cap screw 7/8” long

ITEM PART NO. DESCRIPTION

13 10-4485 Drain valve knob

14 10-2514 #10 Shakeproof lockwasher

15 10-2318 10-32 acorn nut

16 95-2643 Adapter - steinball valve

17 10-1950 6-32 Round head screw 1 5/8” long

18 95-2616 Front outer case lower

19 95-0116 Fulcrum and drain casting

20 10-1049

21 10-1041 Ball valve stein

- 95-0115

Nipple 1/2” IPS 2 1/4” long stainless

steel

Fulcrum and drain assembly, Items 1

through 12, 14, 15, and 19

APRIL 15, 2016 5 STM-E, STM-EL, STM-EX & STM-ELX STERILIZERS

Page 6

PRESSURE ACTUATED TEMPERATURE CONTROL

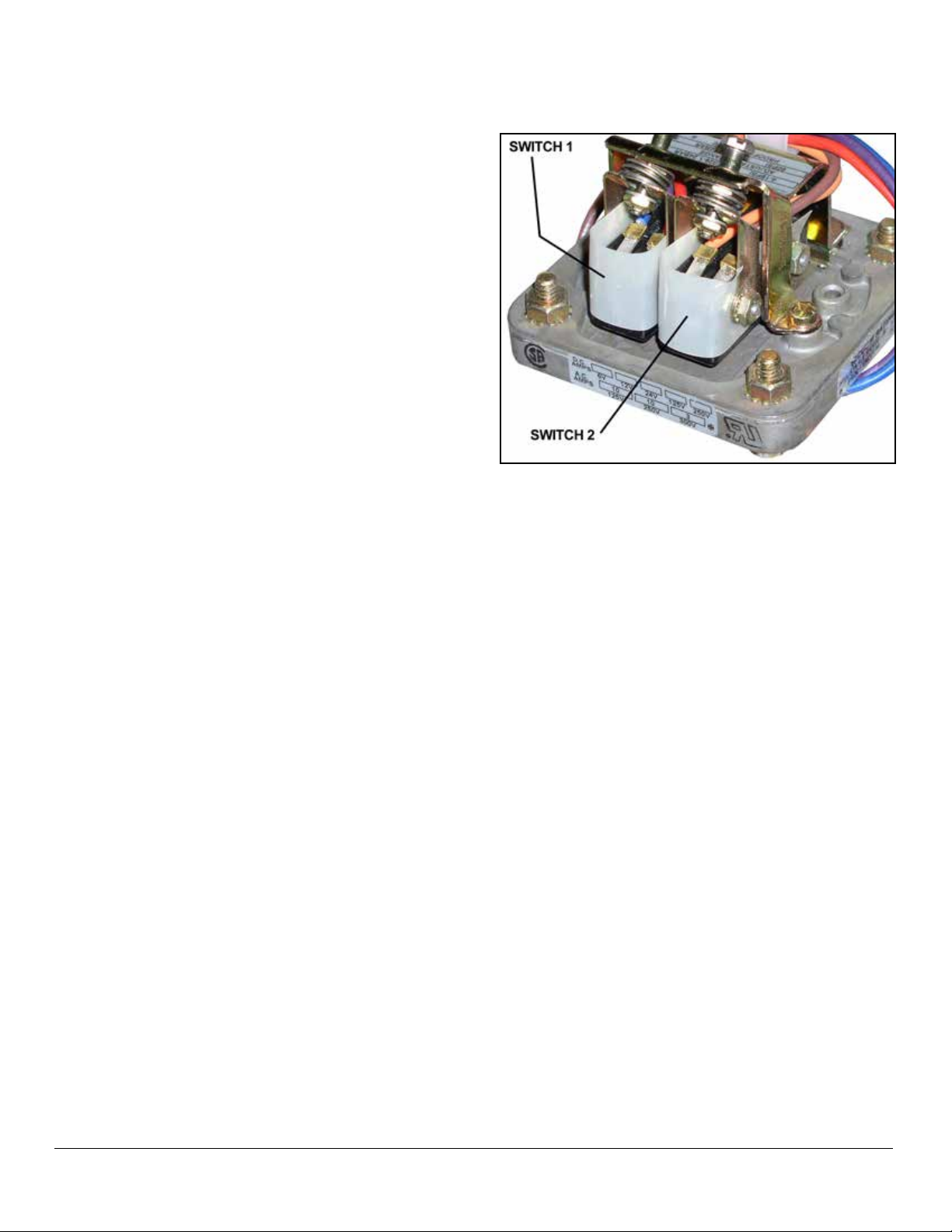

STM-E AND STM-EL

The pressure actuated temperature control, located behind the control panel assembly, governs the manufacture of steam by controlling the input of electric current to

the heating elements.

HOW IT WORKS

When the Timer is set, rear and front contactors will become energized allowing input of current to the temperature control, thus closing the contacts completing the

current to the heating elements. Steam will then be generated within the sterilizing chamber.

The steam pressure within the sterilizing chamber is

transmitted by means of a tube to the bellows of the temperature control; as the steam pressure increases, its

compression action on the bellows is set to cause the

Switch #1 on the control to cut out on rising pressure at

13.5 PSI and to cut in on falling pressure at 13 PSI (controlling the two outer banks of heating elements). Switch

#2 is set to cut out on rising pressure at 15.5 PSI and cut

in on falling pressure at approximately 15 PSI (controlling

center heater element only).

Thus, a balancing effect of steam pressure build-up and

heater element current is constantly maintained during

the sterilizing cycle. When the Timer signies the end of

the cycle, the electric current to the contactors will automatically be broken; the temperature control contacts will

be broken; and steam generation will stop.

ADJUSTING THE RANGE OF OPERATION, STM-E

NOTE: These instructions should be performed by

qualied service personnel only.

The operational range of the temperature control is factory set as follows: Outer bank of elements OFF at 13.0-

13.5 PSI; Center bank of elements OFF at 15.5- 15.0 PSI;

minor compensating adjustments can be made by turning

the adjusting screws counter-clockwise to increase pressure and clockwise to decrease pressure. Both screws

should be turned the same amount when making an adjustment.

NOTE: When resetting this control for elevations above

sea level a correction of 6/10 Ib. per thousand

feet is necessary.

1. Before making adjustments, shut all electrical current

to the sterilizer OFF to eliminate shock hazard.

Figure 5

CHECKING THE 230° SETTING, STM-EL

The Unit should be completely evacuated then temperature selector dial should be turned on 230° Fahrenheit.

Observe the current until it takes a sharp drop to approximately one-third of the full load; at this instant, there

should be a corresponding chamber pressure of 2 PSI

Observing the current further will show another sharp

drop to approximately 2 Amps; at this instant, there should

be a corresponding chamber pressure of 6.1 PSI and a

temperature reading of 228° to 232° Fahrenheit, on the

temperature gauge.

ADJUSTING THE RANGE OF OPERATION

STM-EL

The range of operation of Model STM-EL is adjusted by

simply turning the adjusting knob on the outside of the

Control Panel. A counter-clockwise turn decreases the

pressure while a clockwise turn increases the pressure.

Observe pressure and temperature gauges and adjust

knob as required.

NOTE: When resetting this control for elevations above

sea level, a correction of 6/10 Ibs. per thousand

feet is necessary.

2. Remove the Flue Cover.

3. Make sure that all exposed wires are not in a hazardous position, and then turn on electrical power.

4. Run unit through cycle, observing pressure and temperature gauges, turn adjusting screws as required.

APRIL 15, 2016 6 STM-E, STM-EL, STM-EX & STM-ELX STERILIZERS

Page 7

PRESSURE ACTUATED TEMPERATURE CONTROL

STM-EX AND STM-ELX

The pressure actuated temperature control, located behind the control panel assembly, governs the manufacture of steam by controlling the input of electric current to

the heating elements.

HOW IT WORKS

When the timer is set, rear and front contactors will become energized allowing input of current to the temperature control, thus closing the contacts completing the

current to the heating elements. Steam will then be generated within the sterilizing chamber.

The steam pressure within the sterilizing chamber is

transmitted by means of a tube to the bellows of the temperature control; as the steam pressure increases, its

compression action on the bellows causes the contacts

to make or break according to the condition of the pressure at that time (rising or falling).

Switch #1 on the control is set to cut out on rising pressure at 0.95 kg/cm2 and to cut in on falling pressure at

0.91 kg/cm2 (controlling the two outer banks of heating

elements). Switch #2 is set to cut out on rising pressure

at 1.09 kg/cm2 and cut in on falling pressure at approximately 1.05 kg/cm2 (controlling center heater element

only).

Thus, a balancing effect of steam pressure build-up and

heater element current is constantly maintained during

the sterilizing cycle. When the Timer signies the end of

the cycle, the electric current to the contactors will automatically be broken.

CHECKING THE 110°C. SETTING, STM-ELX

The Unit should be completely evacuated then temperature selector dial turned to 110oC Centigrade. Observe

the current until it takes a sharp drop to approximately

one-third of the full load; at this instant, there should be a

corresponding chamber pressure of 0.14 kg/cm2.

Observing the current further will show another sharp

drop to approximately 1 Amp; at this instant, there should

be corresponding chamber pressure of 0.43 kg/cm2 and

a temperature reading of 110°C Centigrade, on the temperature gauge.

ADJUSTING THE RANGE OF OPERATION, STM-ELX

The range of operation of Model STM-ELX is adjusted by

simply turning the adjusting knob on the outside of the

Control Panel. A counter-clockwise turn decreases the

pressure while a clockwise turn increases the pressure.

Observe pressure and temperature gauges and adjust

knob as required.

NOTE: When resetting this control for elevations above

sea level, a correction of 0.13 kg/cm2 per kilometer elevation is necessary.

Figure 6

APRIL 15, 2016 7 STM-E, STM-EL, STM-EX & STM-ELX STERILIZERS

Page 8

MISCELLANEOUS COMPONENTS

CAST-IN HEATING ELEMENTS

Located under the sterilizing cylinder is a bank of (3) Ushaped heating elements. These elements are welded in

place in a protective aluminum shield. The elements cannot be removed, and in the unlikely event that one or all

fail, the complete cylinder must be replaced.

THE LOW WATER CUT-OFF (MANUAL RESET)

Fastened to a special mounting brace behind the front

panel, the Low Water Cut-Off acts to shut off the complete

unit, should the water run dry. The Low Water Cut Off is

factory set, to shut the unit off when the cylinder temperature rises between 380

When the Sterilmatic is turned on without water or the

water has been evaporated away, the temperature of

the aluminum sterilizing cylinder will rise and by heat induction effect the Low Water Cut-Off. Its inner electrical

contacts will be forced open from heat expansion, thus

cutting off the ow of electric current to the heating elements. With the replacement of water into the cylinder

the cylinder temperature will drop and the contacts of the

Low Water Cut-Off can be again closed. The unit will only

restart after the manual button has been re-set.

o

and 440° Fahrenheit.

THE ELECTRIC CONTACTORS

The Electric Contactors are located on the top of the unit,

underneath the top ue cover. These important components receive an electrical impulse when the Timer is

turned on. When the unit reaches a pre-set pressure of

13-13.5 PSI the #1 switch will cut out causing the front

contactor to become de-energized. This, in turn, will disconnect the left and right bank of heaters and the timer

motor will start.

THE STEAM PRESSURE GAUGE

The Steam Pressure Gauge registers the pressure of

steam, which is within the sterilmatic sterilizing chamber.

To replace this unit, it is necessary to disconnect the copper tubing and to remove the two nuts holding the gauge

framework in place.

THE SAFETY VALVE

The Safety Valve is factory set to automatically open and

exhaust excess steam from within the sterilizing cylinder,

thereby assuring that operating pressures remain within

safe limits. The lever action of the safety valve must be

free to operate unrestricted at all times. If the Safety Valve

should leak continually with a pressure build-up or should

it cause an interruption on a sterilizing cycle prematurely (below 124° Centigrade on the temperature gauge),

it must be replaced. However, the temperature gauge

should rst be checked for accuracy.

THE FLUE

The Flue serves as a protective shield for the steam trap

safety valve, exhaust valve, and electrical components as

well as a mounting base for the control panel. The pressure gauge, dial thermometer, exhaust valve switch and

timer, protrude through the control panel. The Flue cover

may be removed to allow more room for servicing the

control components. The control panel face may then be

removed by unscrewing the sheet metal screws, which

mount it to the Flue.

THE EXHAUST SOLENOID VALVE

The exhaust solenoid is normally closed and only opens

at the end of the cycle when it is energized.

THE TIMER

The Sterilmatic is put into operation with the manual setting of the timer. With the setting of the timer, an electrical

current is directed to the pressure control. The current energizes the pressure control, which activates the contac-

tor coils to cause a current ow to the heating elements.

When the cylinder pressure reaches 13 to 13.5 PSI, the

timer motor and pilot light are energized. At the end of

the cycle the timer will cut off the ow of electricity to all

the components except the exhaust, the exhaust solenoid

and the timer motor. They will revert back to their original

deactivated state. The timer motor and pilot light will continue to be energized after the timed sterilizer cycle has

been completed and for two additional minutes. Only after

this will the timer and white pilot light be de-energized. If

the timer fails to operate the Sterilmatic, replace it. The

timer is replaceable only as a complete unit as factory

repairs to it would not be practical in the economical interests of the customer.

APRIL 15, 2016 8 STM-E, STM-EL, STM-EX & STM-ELX STERILIZERS

Figure 7

Page 9

MISCELLANEOUS COMPONENTS

TO REPLACE A THERMOSTATIC ELEMENT:

1. Remove the cap of the steam trap (turn it counterclockwise).

2. Unscrew the diaphragm and seat and discard.

3. Wipe all dirt and scale from the inside of the steam

trap.

4. Place a new diaphragm and seat securely into the

steam trap and replace the cap (New Style - Part No.

98-1719).

Figure 8

THE STEAM TRAP

The Steam Trap has the very important automatic, dual

function of exhausting all air from the sterilizing compartment, and of making a suitable seal to allow a pressure

build-up of live steam during a cycle of sterilization. Also,

a slot is milled at an angle through the seat to allow a

constant bleed-off of a slight amount of steam during the

cycle to completely eliminate any air pockets in the cylinder. Failure of the trap to operate properly will result in an

uneven distribution of live steam within the compartment.

How it works

With the introduction of steam into the sterilizing com-

partment, cold air will escape. When sufcient generated

steam displaces the cold air, it will then start to exhaust

through the steam trap to heat the thermostatic element.

The expansion of the thermostatic element will make a

seal against the seat to enclose the live steam within the

sterilizing compartment and a steam pressure build-up

will occur.

Figure 9

APRIL 15, 2016 9 STM-E, STM-EL, STM-EX & STM-ELX STERILIZERS

Page 10

TROUBLESHOOTING

STEAM TRAP TROUBLE-SHOOTING

Trouble can only occur either through the premature closing of the steam trap before all the cold air has been exhausted,

or by its failure to close sufciently to enable a proper steam pressure build-up. Either case warrants a replacement of the

thermostatic element.

TROUBLE POSSIBLE CAUSE CORRECTION

Sterilizer fails to operate at all (no pressure build up).

Sterilizer operates, but fails to build up

15.5 PSI pressure.

1. Not installed correctly.

2. Blown fuse.

3. Contactor burned out.

4. Wiring is defective.

1. Current not heating all of the elements.

2. Steam trap fails to close.

3. Exhaust valve fails to hold pressure at 15.5 PSI.

4. Steam leaks around door.

5. Safety valve blows-off prematurely.

1. Check wire diagram for correct

hook up.

2. Replace fuse. If it blows, check

that source of electric supply is 60

amps.

3. Replace.

4. Check all wiring. Repair or replace.

1. Remove lower front panel and

see if the heating elements are

working.

2. Replace the thermometer within

the steam trap.

3. Check for incorrect adjustment on

temperature control. Readjust.

4. Check for worn gasket or make

door adjustment.

5. Replace safety valve.

Unit releases pressure before cycle

has terminated on timer.

Timer is erratic, or fails to return to zero. 1. Loose or broken electrical leads

Unable to obtain set temperature at

peak of cycle.

One or both sides of the cast-in heating

elements remain on when the timer is

in an OFF position.

Heating element cutting out before 15

lbs. of pressure is reached.

1. Low water cut-off has functioned

prematurely.

on timer.

1. Steam trap closing prematurely,

preventing removal of air from the

chamber.

1. Contactors of the temperature

control switch remains closed.

2. Temperature control not properly

calibrated.

1. Pressure cutting off at the temperature control too soon.

1. Replace low water cut-off.

1. Repair defective wiring.

1. Replace the thermostatic element

in the steam trap.

1. Replace switches.

2. Recalibrate.

1. See adjusting the range of operation and calibration of the temperature control. Readjust.

APRIL 15, 2016 10 STM-E, STM-EL, STM-EX & STM-ELX STERILIZERS

Page 11

ILLUSTRATED PARTS LIST

ITEM QTY. STM-EL (120V) STM-ELX (240V) DESCRIPTION

1 1 95-0438 95-0438 Nipple, 1/2" NPT x 1.5"

2 1 98-1718 98-1718 Steam Trap

3 1 10-1048 10-1048 Compression Fitting, 1/2" OD Tube x 1/2" NPT

4 1 95-2667 95-2667 Tube, Copper, 1/2" OD

5 2 10-1055 10-1055 Tee, Brass, 3/8" x 3/8" x 3/8"

6 3 08-7525 08-7525 Nipple, 3/8" NPT, Close

7 1 10-1058 10-0938 Valve, Solenoid

8 3 10-1054 10-1054 Elbow, Street, 3/8 NPT

9 1 10-1017 10-1017 Adapter, 5/8" OD Tube x 3/8"MNPT

10 1 10-1057 10-1057 Union, 3/8" NPT

11 1 10-7988 10-7988 Bushing, Hex, Reducing 1/4" MNPT

12 1 10-3741 10-3741 Bushing, Hex, Reducing 3/8"NPTx1/4"NPT

13 1 10-3918 10-3918 Fitting, 1/4" Comp. X 1/4" MNPT

14 1 10-7942 10-7942 Valve, Safety, 17PSIG

15 2 10-3352 10-3352 Tee, 1/2" NPT, Brass

16 1 10-3327 10-3327 1/2" NPT Square Plug

17 1 Temp. Probe, Available with Control Module Only

18 2 95-3730 95-3730 Elbow, 1/2" NPT, 90, Street, Modied

19 1 08-4980 08-4980 Nipple, Pipe, Male, 1/2 Npt x 3"

20 1 10-3684 10-3684 Adapter, 1/2" OD Tube to 3/8" NPT

APRIL 15, 2016 11 STM-E, STM-EL, STM-EX & STM-ELX STERILIZERS

Page 12

ILLUSTRATED PARTS LIST

ITEM

1 1 95-3434 1 95-3434 Barksdale Pressure Switch

2 1 95-2907 1 95-2907 Pressure Switch Gear Assy.

3 2 10-5944 - N/A Contactor, 120V Coil

3 - N/A 2 10-5943 Contactor, 240V Coil

4 1 10-6290 - N/A Timer, 120V

4 - N/A 1 10-6873 Timer, 240V

5 1 10-9268 1 10-9268 Temperature Gauge

6 1 10-6515 - N/A Relay, 120V

6 - N/A 1 10-6874 Relay, 208/240V

7 1 10-6005 1 10-6005 Terminal Block

8 1 10-9267 1 10-9267 Pressure Gauge

9 1 08-6469 1 08-6469 Fuse Holder

10 1 10-5990 1 10-5990 Low Water Cut-off

11 1 09-6483 - N/A Contactor, 75 Amps, 120V

11 - N/A 1 09-6484 Contactor, 75 Amps, 240V

12 1 10-7355 1 10-7355 Transformer, 100 KVA, 60Hz

STM-EL STM-ELX (EXPORT)

QTY. PART NO. QTY. PART NO.

DESCRIPTION

APRIL 15, 2016 12 STM-E, STM-EL, STM-EX & STM-ELX STERILIZERS

Page 13

ILLUSTRATED PARTS LIST

ITEM

1 1 95-3442 1 95-3442 Barksdale Pressure Switch

2 2 10-5944 - N/A Contactor 120V Coil

3 - N/A 2 10-5943 Contactor 240V Coil

3 1 10-6290 - N/A Timer 120V

4 - N/A 1 10-6873 Timer 240V

4 1 10-9268 1 10-9268 Temperature Gauge

5 1 10-6515 - N/A Relay, 120V

6 - N/A 1 10-6874 Relay, 208/240V

6 1 10-6005 1 10-6005 Terminal Block

7 1 10-9267 1 10-9267 Pressure Gauge

8 1 08-6469 1 08-6469 Fuse Holder

9 1 10-5990 1 10-5990 Low Water Cutt-Off

10 1 09-6483 - N/A Contactor, 75 Amps, 120V

10 - N/A 1 09-6484 Contactor, 75 Amps, 240V

11 1 10-7355 1 10-7355 Transformer, 100KVA, 60HZ

STM-E STM-EX (EXPORT)

QTY. PART NO. QTY. PART NO.

DESCRIPTION

APRIL 15, 2016 13 STM-E, STM-EL, STM-EX & STM-ELX STERILIZERS

Page 14

ILLUSTRATED PARTS LIST

ITEM

1 1 95-2558 Flue Cover Assy.

2 1 95-2652 Flue Outer Case Wrap

3 1 95-2650 Upper Case, Front

4 1 98-4371 Lower Case, Front w/cutout

5 1 10-6363 Insulation, Body

6 1 10-6365 Insulation, Back

7 1 10-6364 Insulation, Bottom

8 1 95-0465 Bottom Cover for Elements

9 1 98-4217 Cylinder, 208V - 240V (Shown with Door Assy.)

ALL MODELS

QTY. PART NO.

1 95-2616 Lower Case, Front (old style w/o cutout)

DESCRIPTION

APRIL 15, 2016 14 STM-E, STM-EL, STM-EX & STM-ELX STERILIZERS

Page 15

ILLUSTRATED PARTS LIST

ITEM

1 1 95-3196 Outside Case, Left Side

2 1 95-3195 Outside Case, Right Side

3 1 95-3194 Outside Case, Back

4 1 10-0226 Handle Bumper

5 1 95-3484 Terminal Box Cover

6 2 95-2545 Pan Rack, 1 Left & 1 Right

7 1 95-2637 Condensate Bafe, Upper

8 1 95-3207 Perforated Water (Splash) Bafe

9 4 95-3284 Wear Strip

ALL MODELS

QTY. PART NO.

DESCRIPTION

APRIL 15, 2016 15 STM-E, STM-EL, STM-EX & STM-ELX STERILIZERS

Page 16

ILLUSTRATED PARTS LIST

ITEM

1 10-0489 - 10-0489 - Bezel

2 10-1722 - 10-1722 - Round Head Machine Screw, 6-32

3 10-9280 - 10-9279 - Control Panel

4 10-5052 10-6669 10-5052 10-6669 Pilot Light, Red

5 10-9267 10-9271 10-9267 10-9271 Pressure Gauge

6 10-5999 - 10-5999 - Switch

7 10-9268 - 10-9268 - Temperature Gauge

8 10-0189 - 10-0189 - Timer Knob

9 10-5940 10-6876 10-5940 10-6876 Pilot Light, White

10 10-5990 - 10-5990 - Low Water Cut-Off

11 - - 10-0051 - Knob

STM-E

PART NO.

STM-EX

PART NO.

STM-EL

PART NO.

STM-ELX

PART NO.

DESCRIPTION

APRIL 15, 2016 16 STM-E, STM-EL, STM-EX & STM-ELX STERILIZERS

Page 17

ILLUSTRATED PARTS LIST

14

10

9

11

12

13

3

8

4

15

2

1

6

7

Door Handle Assembly

APRIL 15, 2016 17 STM-E, STM-EL, STM-EX & STM-ELX STERILIZERS

5

16

Page 18

ILLUSTRATED PARTS LIST

DOOR HANDLE ASSEMBLY

ITEM PART NO. DESCRIPTION

1 10-2318 10-32 Acorn Nut

2 10-2514 #10 Shakeproof Lockwasher

3 10-1999 10-32 Machine Screw 1 3/8” Lg.

4 95-0120 Bearing Spacer

5 95-0136 Door Lock Casting

6 10-2517 3/8” Shakeproof Lockwasher

7 10-0050 Door Lock Knob

8 95-0134 Door Handle Casting

9 10-2359 1/4”-20 Acorn Nut

10 95-0658 Door Handle Bearing Stud

11 95-0659 Door Handle Bearing Plate

12 10-2513 1/4” Shakeproof Lockwasher

13 10-1731 1/4”-20 Machine Screw 5/8” Lg.

14 95-0190 Door Lock Casting Assy. (Items 1 through 6)

15 95-0145 Door Lock Knob Assy. (Items 1 through 7)

16 95-0144 Complete Door Handle Assy. (Items 1 through 13)

17 95-0198 Handle Bushing (Not Shown)

MISCELLANEOUS PARTS NOT SHOWN

STM-E(L) STM-E(L)X

QTY. PART NO. QTY. PART NO.

1 95-2606 Temperature Recorder, 120 V (Optional)

1 10-5343 Temperature Recorder, 240 V (Optional)

1 20-0316 - - Replacement Probe (For Recorder)

1 95-2653 - - Upper Mounting Plate

1 10-5788 - - 120v, 50/60 Hz Cycle Coil

1 95-3552 - - Wire Harness, Flue Assy.

1 95-3553 - - Wire Harness, Contactors

DESCRIPTION

APRIL 15, 2016 18 STM-E, STM-EL, STM-EX & STM-ELX STERILIZERS

Loading...

Loading...