Page 1

SERVICE & PARTS MANUAL

ELECTRIC STEAM-IT STEAM COOKER, STYLE C

MODEL:

ST-E

35 Garvey Street

Everett, MA 02149

Form Number 5143B 12/85 Printed in U.S.A. Tel. (617) 387-4100, Telex 94-9414, Cable MAFORCO

Page 2

HOW TO USE THIS MANUAL

This manual contains maintenance and service instructions for the Style C, ST-E Electric Steam-It. Only ST-E

Steam-Its which have serial numbers prefixed with the letter "C" may be serviced according to the instructions

in this manual.

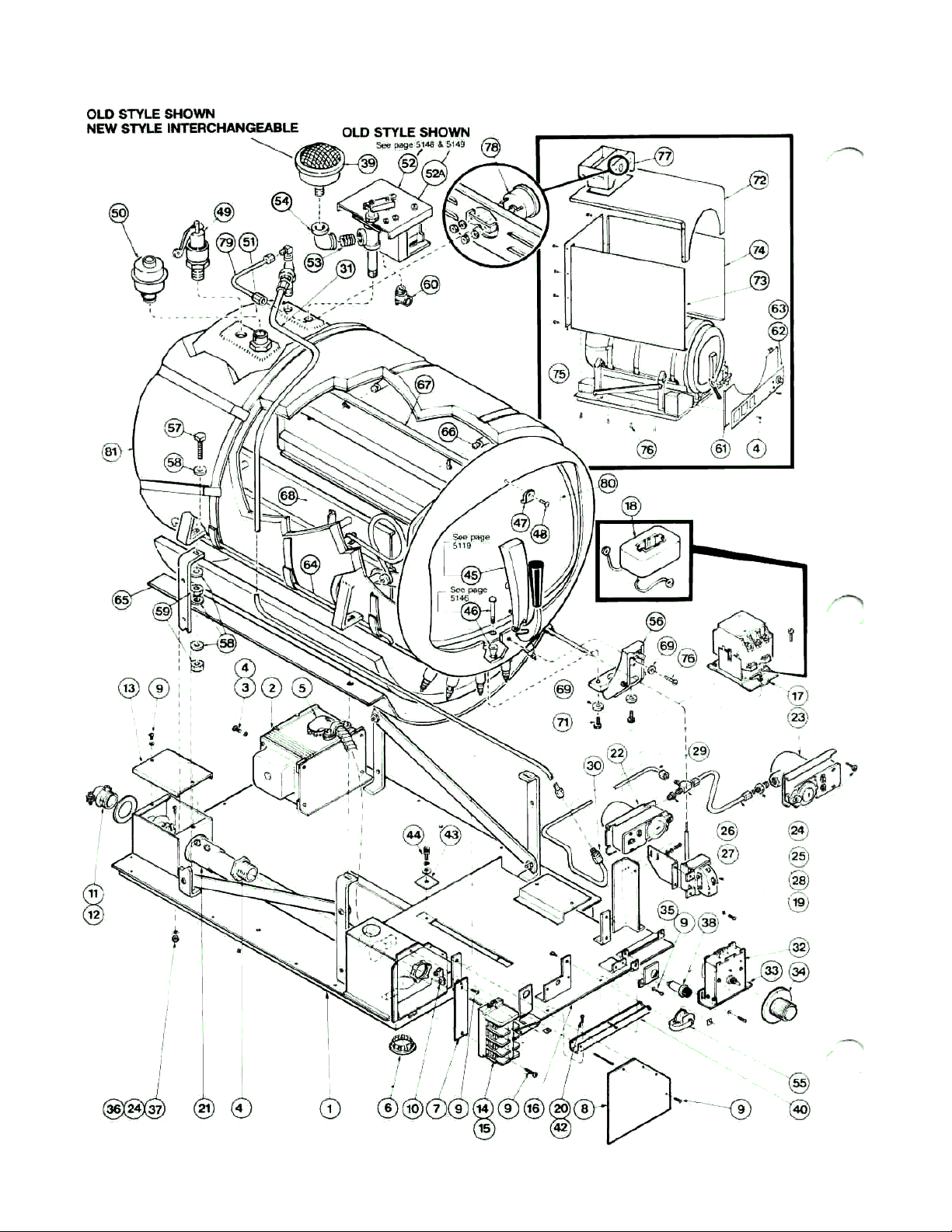

The exploded view drawing of components are aids to the identification, dis-assembly and assembly of parts.

The parts listings provide information necessary for the ordering of replacement parts (proper part names and

part numbers). When requesting parts or service, always furnish the model and serial number of your unit

These numbers are located on the name plate affixed to the top surface of the Steam-It.

TABLE OF CONTENTS

Master Illustration & Parts list 5145

Buzzer, Door Assembly & Gasket 5136

Door Adjustment & Removal 5067

Door Handle Assembly 5119

Fulcrum, Drain Assembly 5146

Safety Valve, Flue, Pressure Gauge & Steam Trap 5147

Exhaust Valve (Old Style) 5148

Exhaust Valve (New Style) 5149

Timer, Low Water Cut -Off & Timer Control Switch 5152

Element Control Switch 5153

Steam-It Stand & Pilot Light 5154

24 Inch Cabinet Base 5011A

Trouble Shooting Guide 5155

Wiring Diagram 5156

Wiring Diagram 5157

Wiring Diagram

Wiring Diagram

Wiring Diagram

Page 3

Page 4

ST-E STEAM-IT STYLE C MASTER

ILLUSTRATION PARTS LIST

Item No. Description Part No.

1 Baseplate Ass'y —Fixed 95-3301

2 Transformer (440/480 V Units 10-5234

3 No 10 Lockwasher (stainless steel) *

4 No 10-32 x 1/2" Binding Hd Screw (st'n st'l) *

5 Lead Ass'y, Transformer 95-3394

6 Plug Button 10-3095

7 Plate-Term Strip Support 95-3289

8 Cover-Term Box 95-3484

9 No 8-32 x 3/8" Rd Hd Screw (st'n st'l) *

10 Ground Lug 10-6969

11 Connector 95-3500

12 Reducing Washer 10-6967

13 Junction Box Cover 95-3489

14 Terminal Strip Section 10-6962

15 Term Strip, End Section 10-6963

16 Baseplate sub-Ass'y —Movable 95-3302

17 Contactor-208V, 50/60 Cycle, Complete 10-5466

Contactor-230/240V, 50/60 Cycle, Complete 10-5467

18 Coil-208V, 50/60 Cycle 10-5470

Coil-230V, 50/60 Cycle 10-5471

19 Low Water Cut-Off 10-5990

20 No 6-32 x 1/4" Truss Hd Screw (st'n st'l) *

21 Connector 10-6966

22 Pressure Control-Open on Rise 95-0998

23 Pressure Control-Closed on Rise 95-0999

24 No 10-32x 1/2";Rd Screw (st'n st'l) *

25 Adapter-Straight 1/4 O.D -1/4 I P.S.M 10-2904

26 Adapter-Tee 1/8 I.P.S-1/4 O.D-1/4 0.D.M 10-3426

27 Reducing Bushing 1/4-1/8 I P S 10-3652

28 Tube 95-3305

29 Tube-Pressure Control 95-3304

30 Union-Compr Fitting 1/4 O.D 10-1154

31 Tubing-Steam Press Line 95-3387

32 Timer, 60-Minute 95-3404

33 Bracket, Timer 95-3277

34 Knob Dial 10-6307

35 Bracket-Pilot Light 95-3403

36 Lock Washer 10-2509

37 Hex Nut 10-32 10-2340

38 Pilot Light 10-6669

39 Exhaust Silencer 10-4963

40 Cage, Electric Wires 95-0483

41 Conduit-Nipple 10-6964

42 Speednut, #6-32 10-4110

43 Washer 95-0463

44 No 10-32 x 3/8 Hex Socket Hd Cap Screw (st'n

st'l) *

45 Door Handle Ass'y Complete 95-0144

46 Drain Plug Ass'y Complete 95-0154

Item No. Description Part No.

47 Handle Bumper 10-0226

48 No 8-32 x 3/8 Binding Hd Screw Ty "Z" (st'n st'l) *

49 Safety Valve 10-4636

50 Steam Trap 10-6156

51 Adapter 10-6158

52 Old Style Exhaust Valve *

Exhaust Valve-208V, 60 Cycle, Complete 95-0944

Exhaust Valve-230-480V, 60 Cycle, Complete 95-0945

Exhaust Valve-230V, 50 Cycle, Complete 95-0946

Exhaust Valve-208 & 230V, 50 Cycle 95-0946

52A New Style Exhaust Valve (Not Shown)

Exhaust Valve-220/240V, 50/60 Hz 09-6545

Exhaust Valve-208V, 50/60 Hz 09-6536

53 Nipple, 3/8 IPS 10-3852

54 Elbow 3/8 I P S st'd 90° 10-3851

55 Buzzer (Complete) 10-6665

56 Fulcrum & Drain Ass'y 95-0115

57 5/16-18 x 11/2" sq Hd Screw (st'l Cad PI) *

58 5/16 Flat Washer, 3/8 I D x #16 Ga St'd (st'l Cad PI) *

59 Hex Nut, 5/16-18 (st'l Cad PI) *

60 Connector, 3/8-90° 10-5036

61 Front Lower Panel Ass'y 95-3 388

62 Nameplate Panel (60 Cycle) 10-6595

63 Nameplate Panel (50 Ccyle) 10-7096

64 Rod 95-0466

65 Pan-Insulation 95-0465

66 Stud 10-1937

67 Pan Rack Ass'y-Right Side 95-2545

68 Pan Rack Ass'y -Left Side 95-2546

69 1/4 Shakeproof Int Tooth Lockwasher (st'n st'l) *

70 1/4-20 x 3/4" Rd Hd Screw (st'n st'l) *

71 1/4-20 x 78" Hex Hd Screw (st'n st'l) *

72 Case-Top Front Upper 95-3131

73 Case-Left Side 95-3140

74 Case-Right Side 95-3141

75 Case-Back 95-3490

76 No 8 x 3/8" Phil Truss Hd Screw Ty "A" (st'l, Ni PI) *

77 Flue Ass'y 95-3135

78 Pressure Gauge 10-0883

79 Tubing-Press Gauge 95-3270

80 Door Assembly, Complete 95-0124

81 Body Assembly (208V and 236V) 95-0478

Body Assembly (470V) 95-0479

*These parts are available at local hardware, plumbing and electrical outlets If not obtainable, special prices will be quoted by Market Forge

on request

Page 5

THE BUZZER

THE DOOR GASKET

The function of the Buzzer is to signify to the operator that the

cycle of cooking has been terminated

The Buzzer is mounted on a bracket which is positioned at the

front of the unit just under the front removable panel.

HOW THE BUZZER WORKS

The Buzzer electrical circuit is controlled by the timer When

the timer reaches "ZERO" (at the end of the cooking cycle),

the circuit will be completed and the Buzzer will continue to

sound until the timer knob is turned to the "OFF" position

THE COOKER DOOR ASSEMBLY

The door of the Cooker has been engineered to establish a

positive method of sealing the steam pressure within the

cooking cylinder As steam pressure builds up within the

cylinder, the door seal will tend to become more positive

However, the door should be adjusted to make a good initial

seal between the door gasket and the door opening without

the added assistance of internal cylinder steam pressures.

With the simple action of securing the door handle down in a

locked position, the door gasket should be sufficiently

compressed against the door opening, all the way around, to

prevent any steam leakage from occurring.

Keep the gasket clean. With normal closing and locking of

the door assembly, a steam-tight seal should be made

between the door gasket and the door opening. This seal

cannot be maintained if particles of foreign matter are

allowed to accumulate upon either of the contacting

surfaces

If leakage should occur by the door gasket before the

additional pressure of a steam build up within the cooking

chamber causes it to stop, the door assembly must be

regarded as improperly adjusted and a readjustment must

be made of the adjustment screw.

To change the door gasket, remove the entire door

assembly as a unit, remove and discard the old gasket,

replace it with a new one (no cement is required), and

reinstall the door assembly. Make an operational check

for leakage and adjust the door if necessary.

DOOR ASSEMBLY - Parts List

Item Description Part No.

1 Pivot Spring Bearing .....……….... 10-6765

2 Door Lift Springs (pair) . ..………... 10-2785

3 10 - 32 Machine Screw 1/2" long …10 1776

4 Door Gasket ....... ..………………. . 10-2666

5 Door & Door Spring Assy. .………. 95-3204

6 Door Spring ...... ……………… . 95-0127

— Complete Door Assembly

(Items 1 thru 6) .....………. 95-0124

5136

Page 6

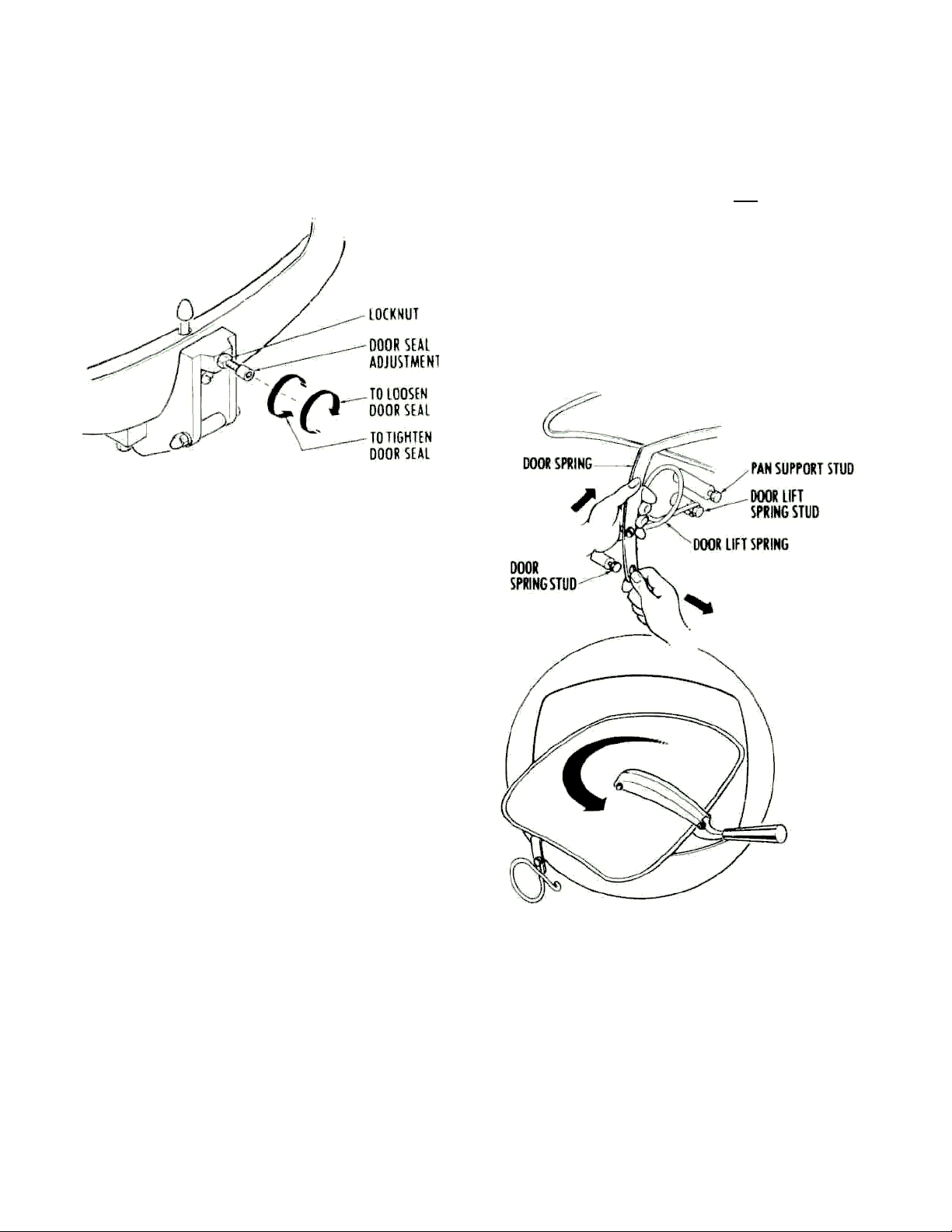

DOOR ADJUSTMENT

The door adjustment is located in the fulcrum casting at the base

of the door opening. This adjustment employes the use of a

screw and locknut. To adjust the Cooker door to a tighter closed

position (to prevent steam from leaking by the door gasket as

pressure builds up), it is necessary to loosen the locknut and

back off the screw at least one-quarter of a turn and retighten the

locknut.

5. To replace the door assembly, reverse the step by step

procedure described above.

DOOR LIFT SPRING REPLACEMENTS

Market Forge Company supplies replacement Door Lift

Springs in sets only. This policy has been found to be in the

best interest of the customer. Through continuous use, some

of the original qualities of the springs are lost and it becomes

advantageous to make replacements to both the left and right

Door Lift Springs in the event one becomes damaged or

broken.

Replacement Door Lift Springs are marked with tabs at the

factory prior to shipping to identify a right from a left spring.

These must be installed with the right Door Lift Spring on the

right and the left Door Lift Spring on the left of the door as

viewed from the front of the Cooker.

TO REMOVE THE DOOR ASSEMBLY

The Door Assembly can be removed from the inner cooking

chamber as a unit without the use of any special tools or

equipment. However, a systematic approach to this is warranted

as the clearances through the portal are close and much

confusion can result if not removed in the sequence described

below.

1. First, lift off and remove the two pan supports to expose the

door linkages on either side of the inner cooking chamber.

2. Raise the door to a fully opened position and disengage the

door spring from each of the door spring studs. Accomplish

this by counter-acting the force of the door lift spring with one

hand while working the end of the door spring of the door

assembly.

3. When the ends of the door spring have been completely freed

from their respective door spring studs, the door lift springs on

either side of the door assembly can easily be slipped off their

studs.

4. Rotate the entire door assembly out through the door opening,

passing the door handle through the opening first, and then

one end of the door spring as shown in the illustration The

remainder of the door assembly will then pass through the

door opening quite easily.

5067

Page 7

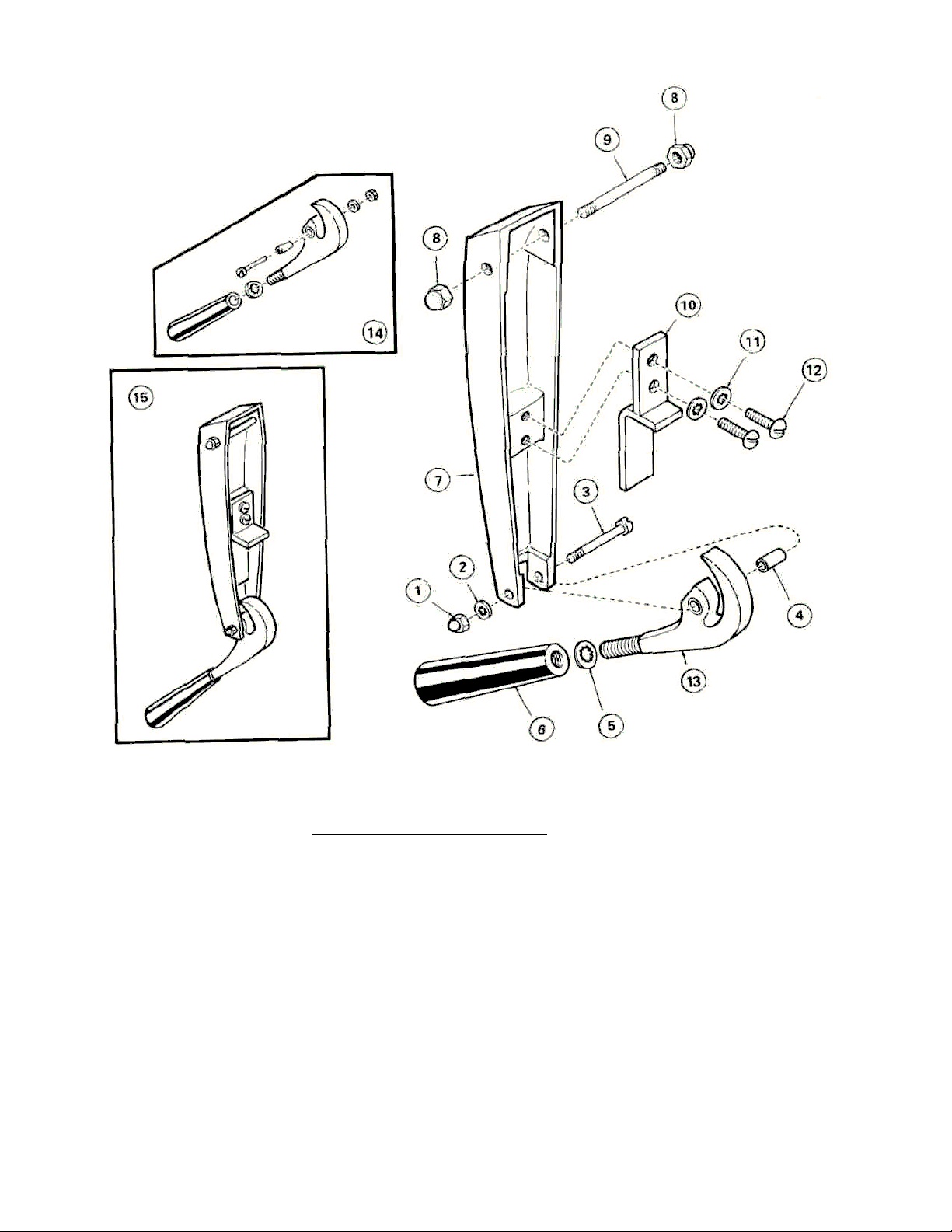

DOOR HANDLE ASSEMBLY - PARTS LIST

2 #10

Shakeproof Lockwasher

. . . 10-2514

4 Bearing Spacer

..............

95-

0120 5 3/8"

Shakeproof Lockwasher

. . 10-2517 6 Door Lock Knob

............

10-

0050

7 Door Handle Casting

.........

95-

0134

8 1/4" - 20

Acorn Nut

.........

10-

2359

*0btain

at local hardware store

11 1/4"

Shakeproof Lockwasher

.. 10-2513 12 1/4"- 20 x 5/8"

Rd. Hd. Screw

... 10-1731*

13

Door Lock Ass'y.

.....

.........

95-

3223

Door Lock Knob Ass'y.

(Items

1

thru

13) .........

Item Description Part No.

1 No. 10 - 32 Acorn Nut...... 10-2318

3 Locking Screw .............. 10-1999

Item Description Part No.

10 Door Handle Bearing Bracket ...... 95-0659

14

95-0145

9 Door Handle Bearing Stud .... 95-0658

15 Complete Door Handle Ass'y.

5119

95-0144

Page 8

FULCRUM & DRAIN ASSEMBLY

The Fulcrum and Drain Assembly is located at the lower

front of the cooking cylinder and furnishes a sturdy

anchorage for the door locking system of the door handle

Also provided in this assembly is a means of adjustment for

the door seal The drain port and drain plug provide a means

of discharging accumulations of water from the cooking

cylinder

ROLLER ASSEMBLY

Built Prior to 10/85 (Items 5, 6, 7, 8 & 9) Built after 10/85

(Items 2, 8, 9, 13 & 14) The Roller Assembly mu st be kept

free-rolling at all times Should this assembly be allowed to

become frozen due to lack of lubrication, undue strain will be

put on the door handle and the fulcrum casting while the

door is being locked Use only a dry lubricant such as

graphite, as oil or grease will tend to attract dirt to this area

5146

Page 9

SAFETY VALVE

D Old Style Shown

The Safety Valve is set to automatically relieve the cooking

compartment of excessive pressure build-ups by opening at a point

between 15 1/2 Ibs and 16 Ibs

CHECKING SAFETY VALVE

If the Safety Valve should leak continually with a pressure build-up,

or should it cause an interruption of the cooking cycle prematurely

(less than 15'/2 Ibs on the steam gauge), it must be determined to

be defective and be replaced However, the steam gauge should first

be checked for accuracy before making this determination The

steam gauge should register absolute zero with no pressure in the

cooking cylinder If the normal zero setting has advanced somewhat

through usage (a characteristic of steam gauges), the amount of

advancement from absolute zero must be subtracted from its

registered reading to determine the true steam pressure

THE FLUE

The Flue serves as a protection shield for the Steam Trap (B) Safety

Valve (A) Exhaust Valve (D) as well as a front-facing mount for the

Steam Gauge (E) As servicing of these parts may at times require

the removal of the flue, an exploded view drawing is provided to

show their proper relative positions within the flue and the method of

their assembly to the cooking cylinder

TO REMOVE THE FLUE

1 Unscrew and remove the exhaust silencer (F)

2 Detach the 3/16" copper tube connector (C) from the Steam

Gauge (E) at the ferrule nearest the steam gauge Then, remove

the copper tube entirely by freeing it at the other ferrule

3 Apply inward pressure at either sides of the Flue at points (1) and

(2) with a screwdriver This will collapse the side walls slightly to

allow the small fluted sections of sheet metal to clear the edges

of the flue opening provided in the outer shell of the Steam-It

With the restrictions of the flutes removed, the Flue may then be

lifted up over the parts it houses

4 To replace the Flue reverse the above steps

STEAM GAUGE

Located at the top rear of the Steam-It and mounted into the

forward face of the flue for visibility, the Steam Gauge registers the

pressure within the Steam-It cooking chamber To replace this unit it

is necessary to disconnect the 3/16" copper tube connector and

remove the two nuts holding the gauge framework in place

STEAM TRAP

The Steam Trap is located within the flue at the top rear of the

Steam -It It has the very important automatic, dual function of

exhausting all cold air from the cooking compartment and of making

a suitable seal to allow a pressure build-up of live steam during the

cooking cycle Failure of this unit to operate properly will result in

uneven cooking

HOW IT WORKS

With the introduction of steam into the cooking compartment, the

cold air escapes through the Steam Trap When sufficient generated

steam dispalces the cold air it passes through the Steam Trap and

the thermostatic element becomes heated and expands to ' make a

seal against the seat This action encloses the live steam within the

cooking compartment and allows a steam pressure build-up to

occur

TROUBLE TESTS AND REMEDIES

the first indication of defective Steam Trap operation will usually be

evidenced by uneven cooking If working properly, the steam

temperature will be even and cooking will be uniform through the

cooking compartment Trouble may occur either through premature

closing of the Steam Trap before all the cold air has been

exhausted or by its failure to close sufficiently to enable a proper

steam pressure build-up Either case warrants the replacement of

the Steam Trap

5147

Page 10

ST-E EXHAUST VALVE-Parts List

Page 11

5149

Page 12

CLEANING EXHAUST SILENCER

The Exhaust Silencer should be removed and cleaned periodically

As the cooking chamber is exhausted of steam through the silencer,

impurities can build up from food particles Cleanings should be

frequent enough to prevent clogging to occur For this reason, the

Exhaust Silencer is made easily accessible and simple to remove To

Clean

1 Remove the one-piece Exhaust Silencer from the unit by

unscrewing it in a counter-clockwise direction

2 Clean the Silencer by sloshing it in hot soapy water and rinse it in

clear water If dirt has clogged the Silencer, presoak it in an

alkaline cleaning solution

3 After cleaning stand the silencer on edge to allow it to drain

4 Screw it back into the elbow of the Exhaust Valve (Clockwise)

LOW WATER CUT-OFF

the Low Water Cut-Off is mounted above the timer assembly under

the front lower panel with its thermostat bulb extending and inserting

into a channel provided for it at the outer edge of the cast-in heating

elements It functions as a safety feature to shut off the complete unit

in event the water runs dry

HOW IT WORKS

If the Steam-It operated with no water or the water has evaporated

away, the temperature of the cooking cylinder will rise and by heat

induction effect the thermostat bulb of the Low Water Cut-Off

Electric current flow will be broken at the Low Water Cut-Off and the

unit will shut down With the replacement of water into the cooking

cylinder, the thermostat bulb will be cooled and the unit will then

again be operative after the reset button has been pressed If the unit

does not start after pressing the reset button, more time will have to

be allowed for further cooling

NOTE:

Should a cooking cycle be started with insufficient water, and

interrupted due to safety action of the Low Water Cut-Off, the food in

the process of cooking will be affected Proper compensation will

have to be made for the cooking performed and, with proper amount

of water in the cooking cylinder, a new cycle determined and set to

complete the process

TIMER

The Timer, located at the lower right front of the Steam-It, provides a

means of manual control The Steam-It is put into an automatic cycle

of cooking with the setting of the Timer to any of its calibrated

periods of cooking Its timing cycle, however, is automatically

delayed by the Timer Control Switch until free-venting has occurred

and a cylinder pressure build-up to 10 PSI has been reached

TROUBLE TESTS AND REMEDIES

If the Timer should fail to operate the Steam-It and a check shows

all wiring to be in good order, and should the Timer Control Switch

be found in good order as ascertained by a continuity check, the

Timer must be regarded as defective and must be replaced The

Timer is replaceable only as a complete unit

TIMER CONTROL SWITCH

The Timer Control Switch, located under the removable front lower

panel Just right of center, automatically delays the timer count-down

at the beginning of the cycle until the Steam-It has fully free-vented

out all cold air from within the cooking cylinder and pressure has

reached 10 PSI This delay insures the timer to count only that

portion of the cycle when cylinder steam pressure is actually acting

on the foods This, of course, is important when processing foods

which only require very short periods of cooking time

HOW IT WORKS

The copper tube which extends from the top of the cylinder to the

rear portion of the Timer Control Switch constantly reflects internal

cylinder steam pressures upon the Timer Control Switch's built-in

bellows While cylinder free-venting is occurring, the switch keeps

the timer circuit open After free-venting has terminated and when

the cylinder pressure has built-up to approximately 10 PSI, the

contacts will be forced closed by back-pressures working on the

bellows, the timer circuit will be completed, and the timer will then

start its countdown

DIAL ADJUSTMENTS (Refer to Fig 11) The cut-in point of the

Timer Control Switch has been factory set at its maximum setting of

10 Ibs and should not be altered unless it is found that the timer

does not start until well after 10 Ibs of steam pressure has been

realized on the pressure gauge In this case, insert a screwdriver into

the center slot (H) of the larger dial (G) and rotate slightly counterclockwise to adjust timer to start at 10 PSI

RECALIBRATING TIMER CONTROL SWITCH

Should the Timer Control Switch vary through usage from its original

factory setting, it may be restored to proper working order by

recalibration

A visual check of the Timer Control Switch during a trial cycle will

quickly determine the need of recalibration With the Timer Control

Switch dial set at 10 Ibs (fully clockwise), the timer motor should cutin when 10 Ibs of steam pressure is registered on the steam

pressure gauge By watching the smaller dial (F) of the timer Control

Switch, the cut-in of the switch may be observed and heard to click

forward at the moment the circuit is made to the timer motor At that

precise moment the pressure gauge should measure 10 Ibs

RECALIBRATION PROCEDURE

1 Set the larger dial (G) of the Timer Control Switch to 10 Ibs (fully

clockwise)

2 Loosen the two screws (I) and (J) located on either side of the dial

slot (H)

3 First, note the position of the slot (H) in relation to the dial (G)

Then, while holding the dial stationary, insert a screwdriver into

the slot and rotate slightly to adjust (Clockwise rotation will set the

Timer Control Switch to cut the timer in at an increased amount of

steam pressure-counterclockwise will allow it to cut-in at a

decreased amount of steam pressure) Tighten the two screws (I)

and (J) to hold this adjustment

4 Check the unit through a trial cycle and note the pressure gauge

reading when the Timer Control Switch is observed and heard to

click forward Pressure reading should then be at 10 Ibs (Check

also may be made by continuity) Re-adjust necessary

5152

Page 13

ELEMENT CONTROL SWITCH TIMER CONTROL SWITCH

ELEMENT CONTROL SWITCH

The Element Control Switch, located under the removable front

lower panel, just left of center, governs the flow of current to the

heating elements to maintain cylinder pressures at a near—constant

14 PSI

HOW IT WORKS

A copper tube extending from the top of the cylinder to the rear

portion of the Element Control Switch constantly reflects internal

cylinder steam pressures upon the built-in bellows of the Element

Control Switch to cause it to open or close an electrical circuit to the

contactor coil With little or no pressure applied to the bellows, the

circuit to the contactor will be closed, and providing the timer is set

to cycle, the contactor will click in and current will flow to the heating

elements When the pressure rises to 14 PSI (ongional factory

setting), the bellows will be sufficiently compressed by the steam

back-pressure to break the circuit to the contactor coil, the contactor

will click out, and current flow to the heating elements will cease

When cooling allows the pressure to drop below 13 Ibs, the bellows

will again complete the contactor coil circuit, activate the contactor to

click in, and allow the heating elements to energize Thus, by

working intermittently to open and close the contactor coil circuit, the

Element Control Switch, in effect, regulates current flow to the

heating elements

DIAL ADJUSTMENT

Two dial settings determine the operational range of the Element

Control Switch The larger dial (D) determines the maximum build-up

of cylinder steam pressure while the smaller dial (E) governs the

range of differential between the switch's cut-in and cut-off points

Should a lower cylinder cooking pressure be desired, adjust the

larger dial (D) by inserting a screwdriver into the slot (B) found at its

center and turning it slightly counterclockwise to lower the pressure

Clockwise rotation will increase the pressure. Pressure must not be

adjusted to exceed 14 Ibs as the safety valve is set to automatically

open just above this point

The cut-in and cut-off points of the Element Control Switch may be

adjusted by rotating the small screw at the center of the smaller dial

(E) Normal factory setting is for a one pound differential between

cut-in and cut-off To increase the range of differential, rotate screw

clockwise, to decrease the range of differential, rotate the screw

counterclockwise Check adjustments through a trial cycle by

observing pressure gauge reading when contactor clicks out at

maximum cylinder pressure and again when it clicks in after cylinder

cooling The difference in pressures as read on the pressure gauge

should, at these points, be approximately one pound

RECALIBRATING ELEMENT CONTROL SWITCH

The Element Control Switch may be recalibrated should it vary

somewhat, through usage from its original factory setting

At the precise moment of contactor "click-out", the dial setting of the

Element Control Switch and the steam pressure gauge reading

should both be 14 Ibs A slight override of steam pressure build-up

will normally occur and indicate itself on the pressure gauge after

the contactor has "clicked-out" This is normal and is not to be

interpreted as an Element Control Switch out of calibration

PRESSURE CONTROL SWITCH (BARKSDALE)

Models built after September 1980 use 2 Barksdale Pressure

Switches in place of the White-Rodgers Element Control

Switch and the Timer Control Switch

OPERATING PRESSURE ADJUSTMENT (BARKSDALE)

The operating pressure is determined by setting the right

switch (A) at approximately 10 PSI and the left switch (B) at

approximately 14 PSI Both switches were set at the factory

These settings can be verified by looking through the slot (in

the Red Rectangle) and observing the alignment of the black

line inside with the white scales on either side of the slot

To readjust turn the white knurled knob in appropriate

direction to raise or lower pressure

WARNING Because power must be on to adjust pressure

switches, be sure to protect against electrical shock

Check adjustments through a trial cycle and observe

pressure readings on pressure gauge when switch (B) clicks

off at maximum cylinder pressure and when switch (A) clicks

on after cylinder cooling Making adjustments as needed

being careful not to let switch (B) pressure be set to exceed

14 Ibs Since the safety valve is set to automatically open just

above this point

RECALIBRATING PRESSURE CONTROL SWITCH

The actuation valve (differential) is factory set and cannot be

recalibrated

5153

Page 14

RECALIBRATION PROCEDURE

1 Set the larger dial (D) of the Element Control Switch at

14 Ibs. pressure (dial (D) fully clockwise).

2. Loosen the two small screws (A) and (C) located on

either side of the dial slot (B)

4 Check this new sotting by operating the Steam It

through a trial cycle and note the pressure gauge

reading at the precise moment when the contactor

"clicks out" This should be at 14 Ibs. (Check may also

be made by continuity) Repeat the process of

adjustment until the Steam It test operates to

satisfaction

3. First, note the position of the slot (B) in

relation to the dial (D). Then, while holding the dial

stationary, insert a screwdriver in the slot to adjust.

(Clockwise to increase steam pressure —

counterclockwise to decrease pressure). Tighten

screws to hold this adjustment.

OPTIONAL STEAM-IT STAND

Market Forge Steam-Its can be supplemented with an optional stand

for utility where maximum compact ness is desired. The sturdy

stainless steel stand unit is equipped with adjustable leg extensions

which allow the unit to be installed and leveled over existing contours

in the floor.

The open under-shelf of the stand gives added utility, providing a

handy tabouret for cooking utensils- The open design lends itself to

maximum sanitary conditions because of the ease in which periodic

cleanings can be made.

Though simple in design and appearance, the Steam-It Stand is the

ideal arrangement for mounting in that it elevates the unit to the most

efficient working height, can be leveled easily, and may easily be

maintained in a state of cleanliness.

THE PILOT LIGHT

The Pilot Light is located at the lower right front of the

front panel. This unit is wired to operate when the heating

elements are on. The circuit will be broken when the timer

returns to the "ZERO" position. Thus, when the pilot light

is on and off it signifies that the heating elements are

cycling on and off to maintain cooking pressure in the

cooking chamber

5154

Page 15

ITEM NO. PART NO. DESCRIPTION

1

2

3

4

5

6

7

90-2657 Rear Panel St. Steel

Kit 90-3013 Rear Panel St. Steel Kit

90-2661 Side Panels R & L St. Steel

Kit 90-9039 Side Panels R & L St. Steel Kit

10-0631 Leg

90-8974 Ass'y. 24" x 33" Modular Frame

90-2993 Door Ass'y. L Hand St. Steel

Kit 90-9098 Door Ass'y. L Hand St. Steel Kit

90-3154 Door Ass'y. R Hand St. Steel

90-2663 Panel MTG Bracket

10-0493 Feature Strip

ITEM NO. PART NO. DESCRIPTION

8 90-3210 Bracket Magnetic Catch

9 10-5561 Magnetic Catch

10 10-1869 No. 10-32 x 1/2" Flat Head Screw

11 10-0454 Cabinet Hinge Right Bottom

10-0453 Cabinet Hinge Left Bottom

12 10-2365 Lock Nut

13 10-2511 Washer

14 10-2307 Hex Nut

5011A

Page 16

TROUBLE POSSIBLE CAUSE CORRECTION

Check timer for continuity of primary circuit thru

Unit releases pressure before cooking

Steam -It fails to operate at all. (No

pressure build-up).

TROUBLE SHOOTING GUIDE

1. Blown fuse.

2. Wiring is defective.

3. Not installed correctly.

4. Element control switch or contactor coil

not in circuit.

5. Current not passing through timer to

start unit.

1. Replace fuse. If it blows again, check that

source of electric supply is 60 Amp.

2. Check all wiring. Repair or replace.

3. Check wiring diagram for correct hookup.

4. Check both element control switch and

contactor coil for continuity. Repair or replace

either if found defective.

5.

timer control switch.

Steam -It operates but fails to build-up

to 14 Ibs. pressure

cycle has terminated on timer.

Timer does not function at 10 PSI of

cylinder pressure to start countdown.

Uneven cooking. 1. Steam trap closing prematurely-preventing

1. Steam trap fails to properly close.

2. Exhaust valve fails to hold pressure

at 14 Ibs.

3. Steam leaks around door.

4. Safety valve blows off below 15 Ibs.

pressure.

5. Element control switch not properly

adjusted.

1. Power loss.

2. Low water cut-off has functioned

prematurely.

1. Loose or broken electrical leads to

the timer or timer control switch.

2. Timer motor defective.

3. Timer control switch defective or

out of adjustment.

removal of air from the cooking chamber.

1. Replace the steam trap.

2. Check for correct adjustment — or strip

down, clean and repair.

3. Clean seating surfaces and gasket to make

sure they are free of food particles. Check for

worn gasket, or make door adjustment.

4. Replace safety valve. 5. Readjust.

1. Check for disruption at source of electric

supply.

2. Adjust or replace low water cut-off.

1. Repair or replace defective wiring.

2. Check timer motor for continuity. Replace

complete timer if found defective.

3. Make continuity check, adjust, replace if

necessary.

1. Replace the steam trap.

Heating elements cutting out before

13 Ib. pressure is reached.

1. Pressure cutting off electric at the element

control switch too soon.

1. Make adjustments on the dial of the element

control switch to remedy.

5155

Page 17

5156

Page 18

UNITS BUILT PRIOR TO

6/79

Page 19

FOR 3 PHASE

-4 WIRE. CONNECTION:

380/22O OR 4l5/240V

CONNECT Ll L2 L3 TO THE. 3 lNCOMING PHASES

POWER

REQUIREMENTS

V

CONTROL CIRCUIT

CONNECT N TO THE INCOMING NEUTRAL

CONNECT E TO THE INCOMING EARTH (GROUND WIRE)

CONNECT CONTROL CIRCUIT WIRE C1 TO L3

CONNECT CONTROL CIRCUIT WIRE C2 TO N

FOR 3 PHASE -3 WIRE CONNECTION : (380V OR. 415V,')

CONNECT L1 L2 L3 TO THE 3 INCOMING PHASES

CONNECT E TO THE INCOMING EARTH (GROUND WIRE)

DO NOT CONNECT ANY INCOMING WIRES TO N

REMOVE CONTROL CIRCUIT WIRE C1 FROM L3

REMOVE- CONTROL CIRCUIT WIRE C2_ FROM N

CONNECT SEPARATE 22O/240 VOLT SUPPLY ONLY TO C1 C2

FOR SINGLE PHASE CONNECTION: (220V OR 240V)

BRIDGE L1 L2 L3 AND CONNECT TO INCOMING

PHASE CONNECT N TO INCOMING NEUTRAL

CONNECT CONTROL CIRCUIT WIRE C1 TO L3

CONNECT CONTROL CIRCUIT WIRE C2 TO N

NOTE: FOR. Norway

230 V, 3PH,, 5OHz., 3 WIRE

ELECTRICAL SERVICE USE

WIRING DIA B95-3775

NOMINAL AMPS. PER WIRE

3 PHASE 1 PHASE

380 V. 415

220 V. 240V.

16 17 48 51

12.0 KW 12.0 KW

MODEL ST-F For Operation On

380/415 Volt-3 Phase

Supply

OR

220/2401 VOLT- Single Phase Supply

50 50 Cycles

All Heating Elements Rated 236 Volts 1

Page 20

Page 21

Loading...

Loading...