Market Forge ST-AS Installation Manual

OWNER’S MANUAL

DIRECT CONNECTED STEAM-IT WITH

GAS BOILER BASE, STYLE G

MODEL ST-AS

An Employee Owned Company

35 Garvey Street ● Everett ● MA ● 02149-4403 Form No. S-21B

Tel: (617) 387-4100 ● Fax: (617) 387-4456 (MA)

Toll Free: (866) 698-3188 ● Outside MA Fax: (800) 227-2659

Customer Service: custserv@mi.com ● Visit Us At: www.mi.com

●

06/07

TABLE OF CONTENTS

INTRODUCTION .............................................................................ii

INSTALLATION ...............................................................................1-2

OPERATION ...................................................................................

TROUBLE-SHOOTING ................................................................... 6-7

MAINTENANCE ..............................................................................8-15

ILLUSTRATED PARTS LIST ...........................................................16-23

3-5

i

INTRODUCTION

STEAM REQUIREMENTS:

The ST-AS is designed for operation with a piped-in steam supply not in excess of 15 lbs. per square inch, a

pressure regulator must be used on the steam input line to reduce and regulate the steam pressures within the

operational range of the steam-it.

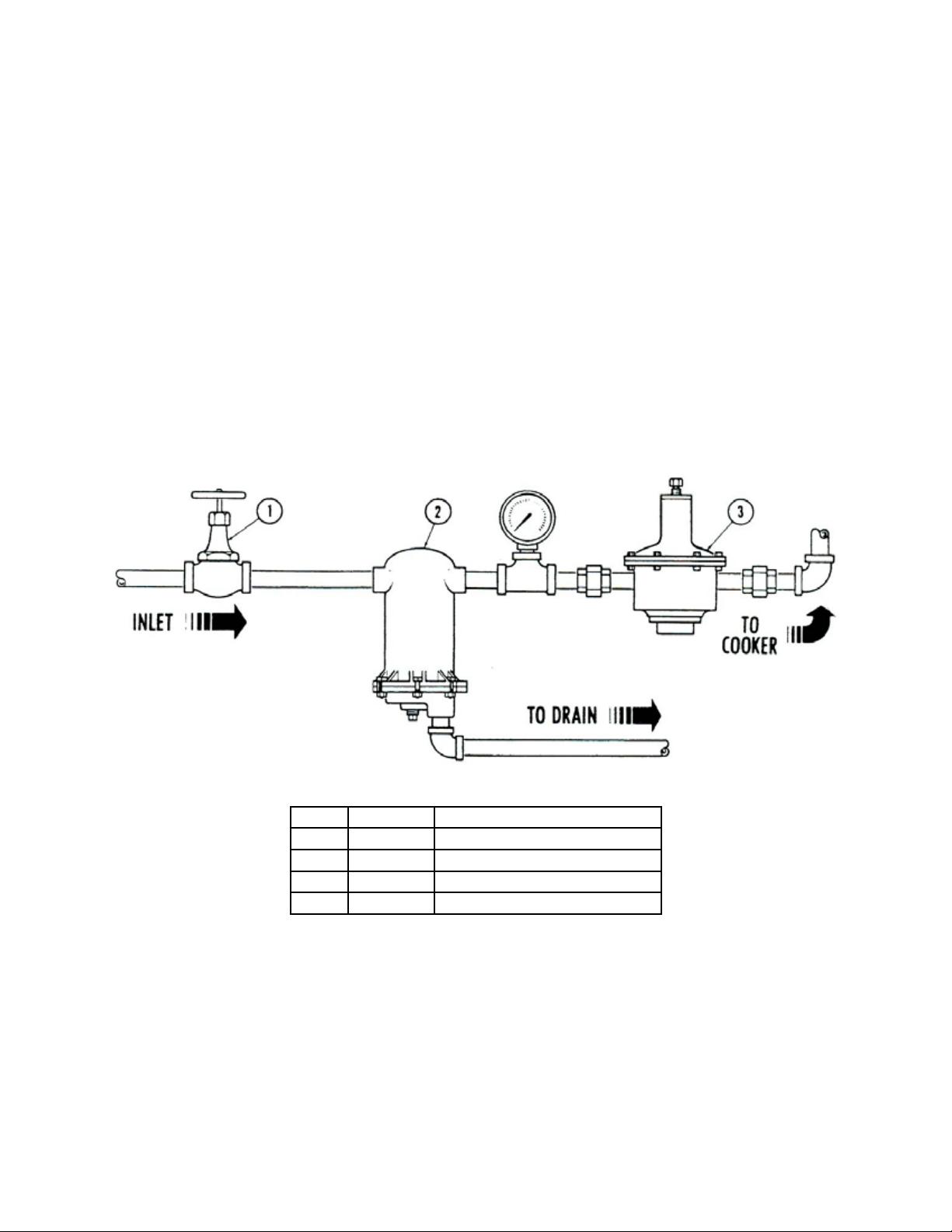

SUGGESTED STEAM CONNECTIONS:

The illustration shows a recommended system of illustration which provides a regulating valve for delivery of

15 lbs. of steam pressure, a globe valve for emergency cut-off, a pressure gauge measures the pressure input

from the source of supply, and a ball oat trap to prevent dirt and water from entering the unit. The globe valve,

regulating valve, and ball oat trap and pressure gauge are not furnished with this equipment. The pressure

gauge must be selected to operate within the range of the pressure experienced at the place of installation. With

the introduction of a pressure reducing valve, the steam-it will then require input steam pressure in excess of 15

lbs. from its source of supply.

NOTE: With pressure constant and between 11 and 14 PSI use the same system of installation with the pressure

reducing valve omitted.

Figure 1.

ITEM PART NO. DESCRIPTION

1 10-2821 3/4” globe valve

2 10-5336 Ball oat trap

3 10-1033 3/4” pressure reducing valve - enamel

- 10-1034 3/4” pressure reducing valve - chrome

STRONG PRESSURE REDUCING VALVE TYPE “K”:

The 3/4” pressure reducing valve is designed to operate from a 20 to 100 PSI source of steam and to reduce this

to 15 PSI for delivery to your steam-it. Before nal connection is made, blow down your steam line to remove all

dirt, scale, packing and compound accumulated during the installation of the piping.

Steam enters inlet port and passes upward through seat into discharge side of valve. As pressure in discharge

side increases, diaphragm is forced upward overcoming tension of adjusting spring and closing valve. As pressure drops, adjusting spring forces diaphragm down reopening valve.

ii

INSTALLATION

Locate the steam-it where it will be level and if possible, under an exhaust hood.

NOTE: Steam-it without stand may be set on a table,

counter, or cabinet base, but drain and steam connections must be made through supporting unit.

PAN SUPPORTS:

The pans are an optional accessory and will be found

inside the steam-it cooking chamber. The pan supports

should be installed so that the horizontal keyhole is at

the rear of the cooking chamber, and so that the ange

and embossments face the middle of the chamber.

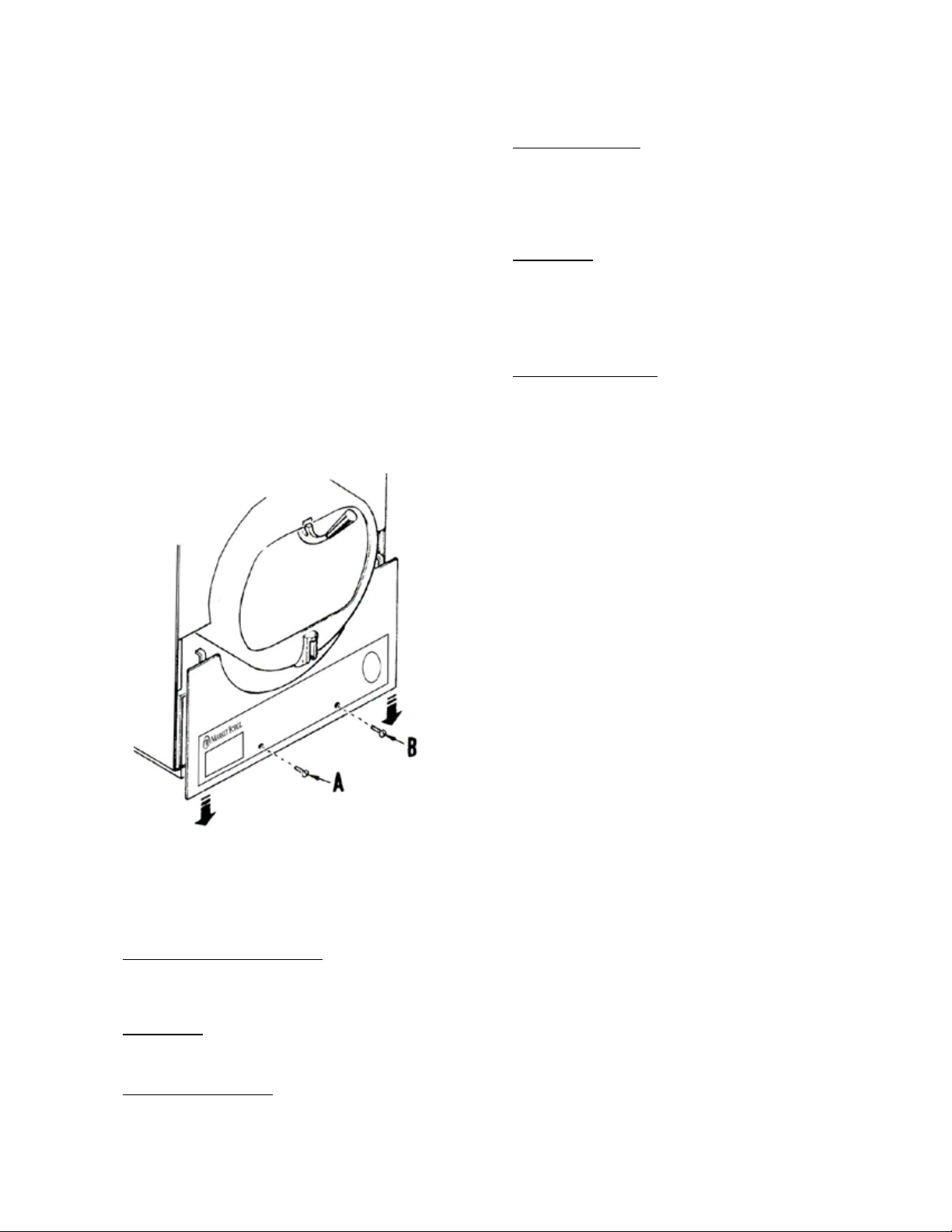

STEAM SUPPLY & EXHAUST CONNECTION:

In order to make the steam supply and steam exhaust

connection, it is necessary to remove the lower from

service panel.

Figure 2.

Remove screws A and B.

1.

Slide service panel down, gradually pulling service

2.

panel forward.

Steam Connection - This connection can be made

3.

on the bottom left side as you stand facing the

steam-it. Steam supply line should be at least 1/2”

in size. If pressure is over 15 PSI a pressure reducing valve must be installed in the line to reduce

the pressure going to the steam-it to 15 PSI.

WARNING: NEVER connect a steam-it to a feed

line supplying other steam consuming units,

unless the pipe size and pressure has been

carefully veried as to capacity. Whenever possible install a separate feed line for the steam

direct from the boiler main.

Steam Consumption - This Market Forge direct

4.

connect steam-it requires 1 BHP or 34.5#’s of

steam per hour at 15 PSI to operate efciently.

BUILDING UP PRESSURE

Steam pressure must be built up in the steam cooker

to properly adjust this valve. The following sequence of

operation should be used to build up steam pressure

in the cooker.

Turn on steam supply valve to unit.

1.

Close the door and lock ion position by placing

2.

the tongue of the door lock under the roller on the

drain castings and press downward until door lock

comes to a rm stop. This lock makes the initial

seal (when steam pressure builds up in the compartment, it will force the door to a tighter closed

position).

Set timer to desired cooking time. As the pres-

3.

sure builds up, cold air is forces out of the cylinder through the thermostatic steam trap located in

the collar at the top rear of the steam-it. The air

will continue to escape as pressure builds up and

the steam trap will close after all the air has been

forces out of the cooking compartment.

At the close of the timing period a buzzer will ring

4.

advising that the cycle is complete. The supply

valve will close and the exhaust valve will open letting the pressure out of the cooking compartment.

CONNECTIONS REQUIRED:

Open Drain for Exhaust Line - Provide a 1/2” IPS

1.

drain line from exhaust valve to an open oor

drain. Exhaust connection is located at the bottom

center of the steam-it.

WARNING: DO NOT UNDER ANY CIRCUMSTANCES connect the exhaust drain line directly to a sewer line.

Electrical Connection - One 115 volt AC single

2.

phase, two amp supply. Connection is for 1/2” conduit. This activates the timer.

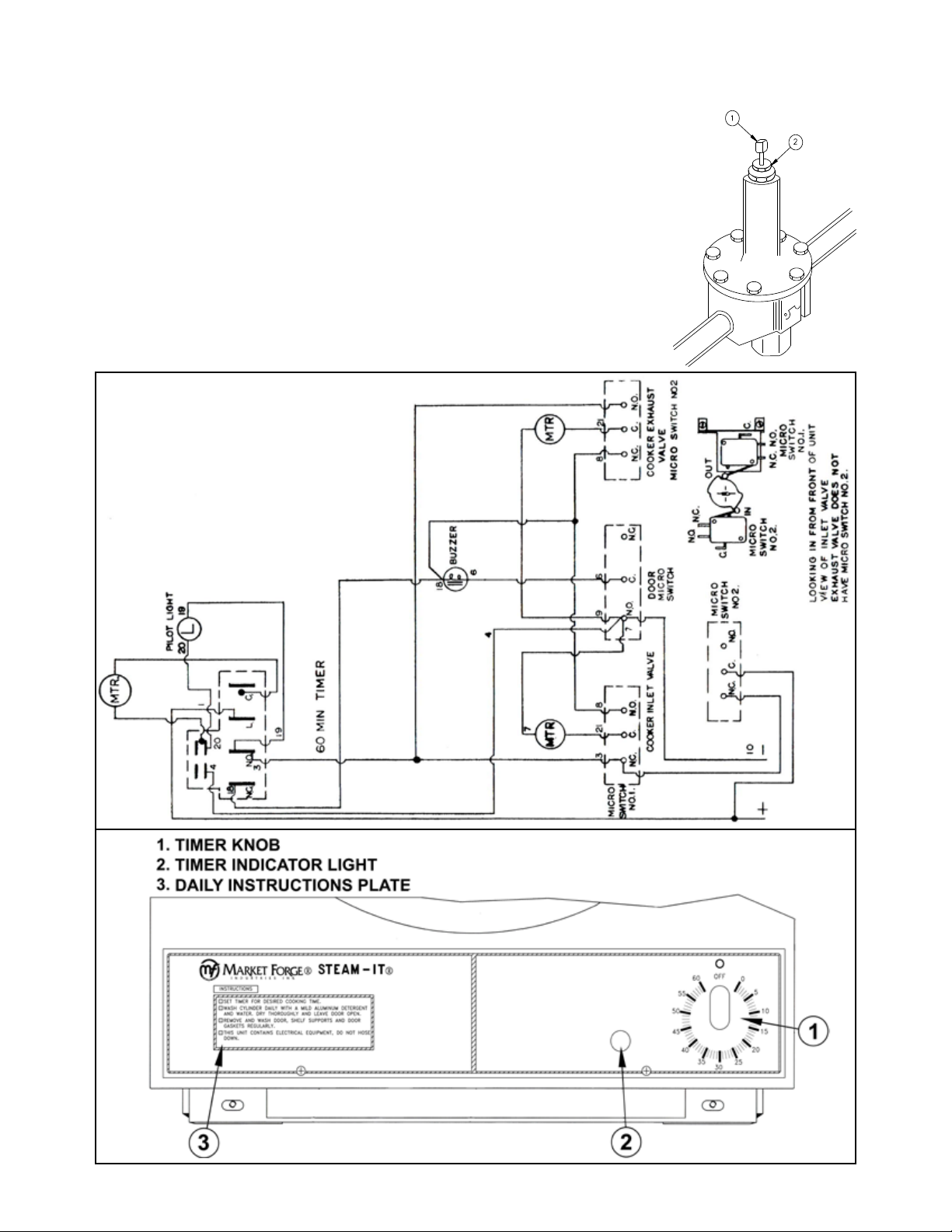

ADJUSTING PRESSURE REDUCING VALVE:

Release the adjusting screw locknut (Figure 3, #2)

1.

and run the steam-it through a trial cycle by turning

the steam-it timer on. Turn on steam supply valve

to unit. Set timer to desired cooking time. As the

pressure builds up in the cooking compartment,

cold air is forces out of the cylinder through the

thermostatic steam trap located in the collar at the

top rear of the steam-it. The sir will continue to escape as pressure build up and the steam trap will

close after all the sir has been forced out of the

cooking compartment.

1

INSTALLATION

Turn adjusting screw (Figure3, #1) down or up un-

2.

til the proper operating steam pressure of 15 lbs. is

reached on the ST-AS steam-it pressure gauge.

Turn back the timer to the “OFF” position. The

3.

steam-it will free-vent. When the pressure gauge

has reached to approximately 8 lbs., turn the timer

on again to a short period of cooking.

The steam-it should build up to 15 lbs. maximum

4.

and hold until the cycle is complete. Should it fail

to reach 15 lbs. or exceed it and blow off the safety

Figure 4. Wiring Diagram

valve, repeat the adjustment

procedure and retest.

Tighten the adjusting screw

5.

locknut (Figure3, #2) when

satisfactorily set and tested.

Figure 3.

CONTROL PANEL

2

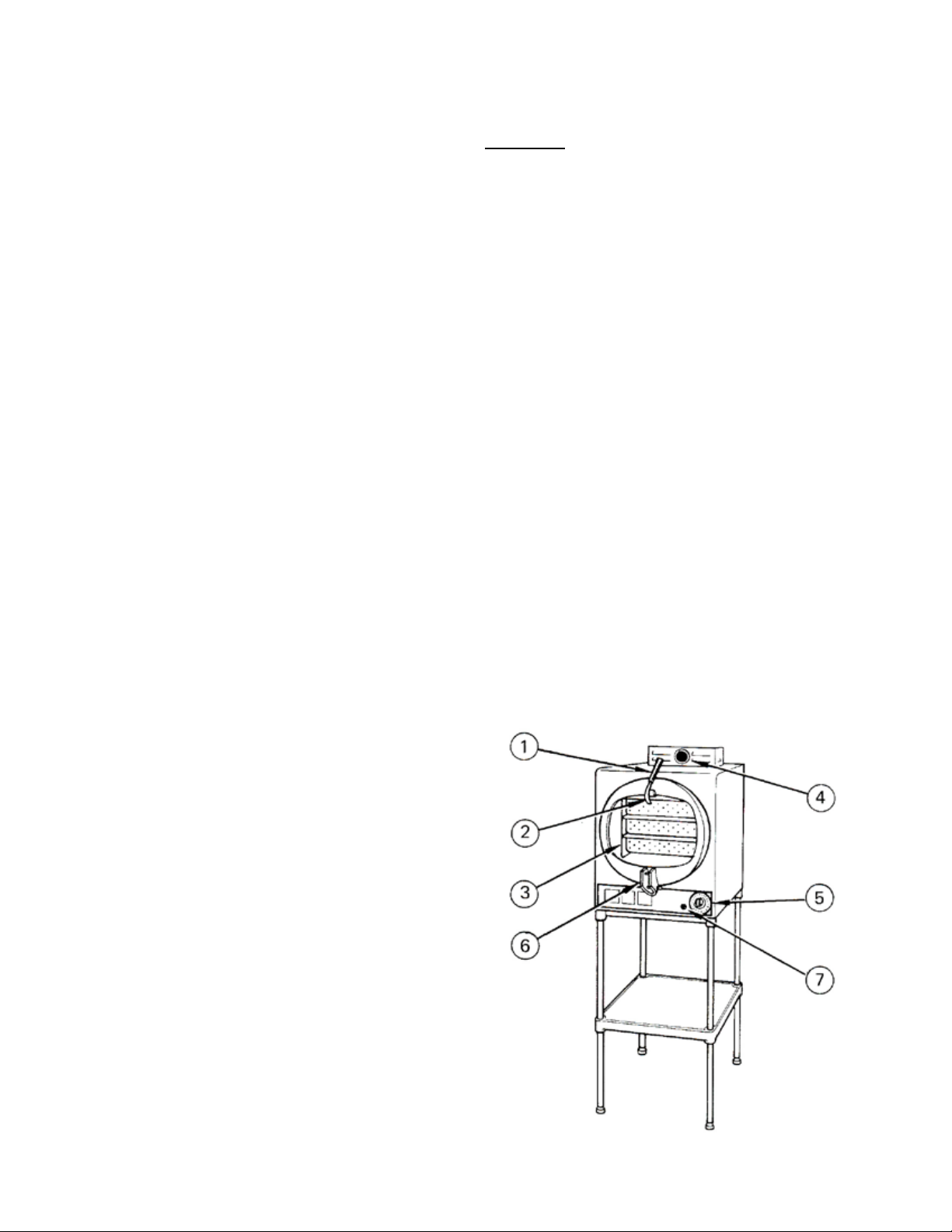

OPERATION

Be sure that steam supply is connected to unit and

1.

120 VAC (to operate controls) is connected.

Pan supports (3) should be hung on pan support

2.

studs on cylinder side walls. The horizontal keyhole on the support should be at the rear of cylinder and the vertical keyhole near the front.

Preheat unit. Follow steps 5 through 7 for preheat-

3.

ing, setting timer for one minute. Preheating is

necessary only when unit is cold and will take 2 to

3 minutes.

Slide pans of food to be cooked onto pan supports

4.

(3).

Close door and lock in position by placing tongue

5.

of door lock casting (2) under roller on drain casting (6). Press downward on door lock knob (1) until

door is secured.

Set timer (5) to desired cooking time (refer to cook-

6.

ing guide on page 4), turning it past the proper setting and then back. This will insure accuracy of setting. The pilot light is wired to operate only when

the timer is set to a cooking cycle. The circuit will

be broken when the timer returns to the “0” posi-

tion. Thus, when lit, it signies that the steam-it is

in the act of cooking.

At end of cooking cycle, steam will automatically

7.

exhaust. When pressure reaches “0” on pressure

gauge (4), door can be released by pulling up on

door lock knob (1). Allow a few seconds for remaining vapor to leave cylinder before completely

opening the door. To stop buzzer, turn timer to

“OFF” position.

Remove cooked food, add desires seasoning, and

8.

transferred to serving area. Perforated pans, if they

are to be transferred to the serving area, should be

underlined with a sold pan.

Clean unit thoroughly at the end of each cook-

9.

ing day, making sure cylinder is left dry and the

door open (refer to the maintenance section of this

manual).

WARNING: A HIGH DEGREE OF MINERAL SALTS

IN THE WATER CAN CAUSE PITTING OF THE

COOKING CYLINDER UNLESS THE CLEANING DIRECTIONS ARE FOLLOWED. THE COOKING CYLINDER MUST BE THOROUGHLY CLEANED AND

THE DOOR LEFT OPEN EVERY DAY.

NOTE: If steam escapes around the steam-it door

edges while pressure is building up, door seal adjustments can usually be made (refer to page 10 for door

adjustments).

THE BUZZER:

The function of the buzzer is to signify to the operator that the cycle of cooking has been terminated. The

buzzer is mounted on a bracket which is positioned

at the front of the unit just under the front removable

panel. The buzzer electrical circuit is controlled by the

timer. When the timer reaches zero the circuit will be

completed and the buzzer will continue to sound until

the timer knob is turned to the off position.

PILOT LIGHT:

The pilot light is located at the lower right front of the

panel. This unit is wired to operate when the heating

elements are on. The circuit will be broken when the

timer returns to the “0” position. Thus, when the pilot

light is on and off it signals that the heating elements

are cycling on and off to maintain cooking pressure in

the cooking chamber.

Figure 5.

Door Lock Knob

1.

Door Lock Casting

2.

Pan Supports

3.

Pressure Gauge

4.

Timer

5.

Drain Casting

6.

Pilot Light

7.

3

OPERATION

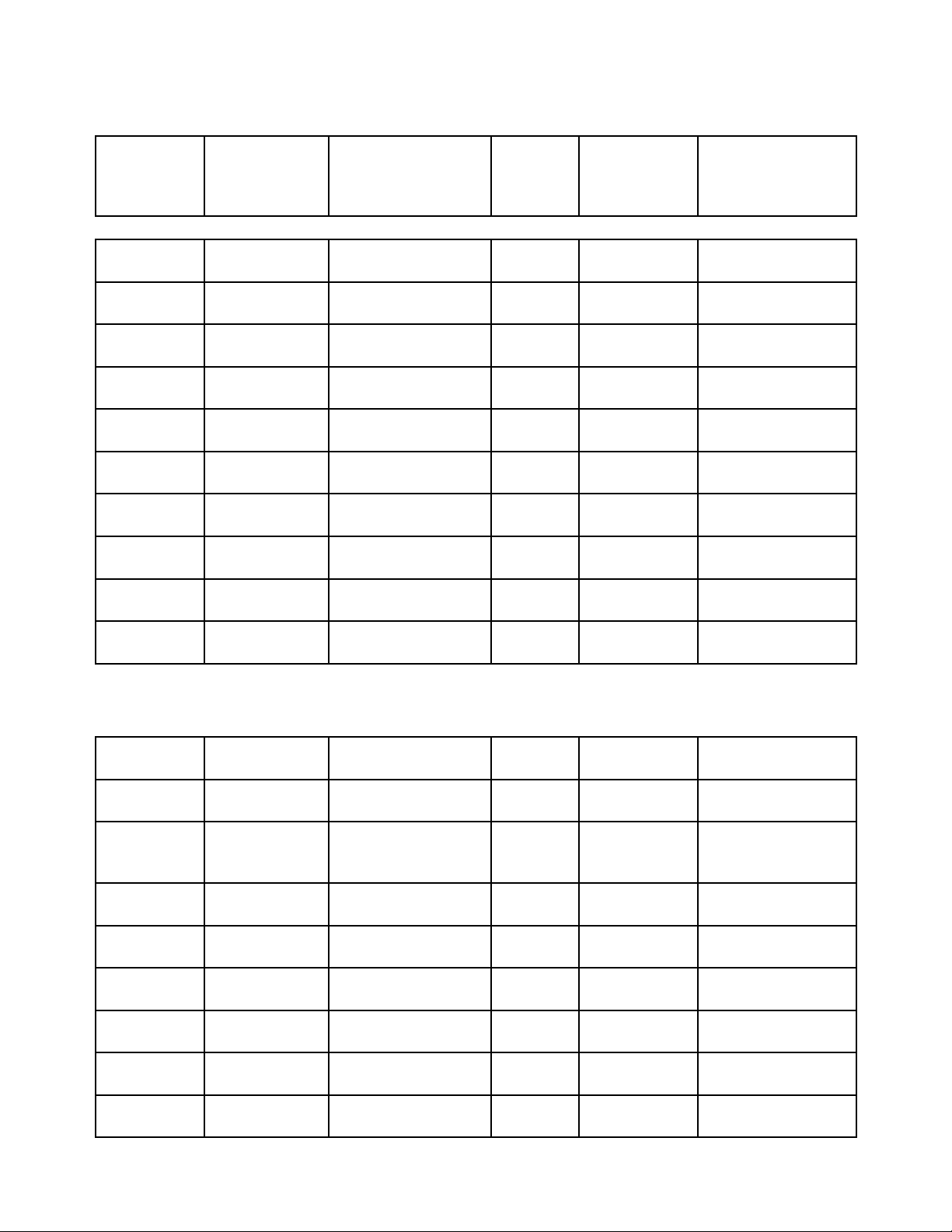

RECOMMENDED

APPROX.

ITEM

VEGETABLES, FROZEN - DEFROSTED

Asparagus

Spears

Beans, Green

Regular

Beans, Green

French Cut

Beans,

Lima

Broccoli

Brussel,

Sprouts

Carrots

Cauliower

Corn

Peas

* All portions are equivalent to approximately 1/2 cup cooked.

WT. PER PAN

#5

(2.3 kg)

#5

(2.3 kg)

#5

(2.3 kg)

#5

(2.3 kg)

#4

(1.8 kg)

#5

(2.3 kg)

#5

(2.3 kg)

#5

(2.3 kg)

#5

(2.3 kg)

#5

(2.3 kg)

PAN SIZE, 12” x 20”

PERFORATED

2 1/2”

(65mm)

2 1/2”

(65mm)

2 1/2”

(65mm)

2 1/2”

(65mm)

2 1/2”

(65mm)

2 1/2”

(65mm)

2 1/2”

(65mm)

2 1/2”

(65mm)

2 1/2”

(65mm)

2 1/2”

(65mm)

NUMBER

OF PANS

1

2-3

1

2-3

1

2-3

1

2-3

1

2-3

1

2-3

1

2-3

1

2-3

1

2-3

1

2-3

TIMER

SETTINGS IN

MINUTES

10-11

11-13 23-25

10-11

11-13 23-25

10-12

12-14 23-25

9-10

10-11 23-25

8-9

9-10 18-20

9-10

11-13 23-25

8-9

10-12 23-25

10-11

11-13 23-25

8-9

10-11 23-25

5-6

7-8 23-25

COOKED 2 Oz.

(55g) SERVINGS

APPROX/ NO.

PER PAN*

VEGETABLES, FRESH

Beans, Wax

Green

Broccoli,

1/2-3/4” Stalk

Cabbage,

Cored - 1/4

1/6 of head

Carrots,

Sliced

Cauliower

Corn on Cob,

Husked

Potatoes,

French Fry

Potatoes,

Regular Cut

Spinach, Cut

and Cleaned

(2.7 kg)

(2.7 kg)

(2.3 kg)

(4.1 kg)

(2.7 kg)

1 Dozen 2 1/2”

#10

(4.5 kg)

#10

(4.5 kg)

(1.4 kg)

#6

#6

#5

#9

#6

#3

2 1/2”

(65mm)

2 1/2”

(65mm)

2 1/2”

(65mm)

2 1/2”

(65mm)

2 1/2”

(65mm)

(65mm)

2 1/2”

(65mm)

2 1/2”

(65mm)

4”

(100mm)

1

2-3

1

2-3

1

2-3

1

2-3

1

2-3

1

2-3

1

2-3

1

2-3

1

2

4

8-10

12-15 30-35

6-8

8-10 25-30

10-14

15-20 12-20

12-15

15-18 35-40

8-10

10-12 30-35

8-10

10-12 12

11-13

14-16 50

20-25

25-30 50

2-3

3-4

4 oz (110g)

10-12

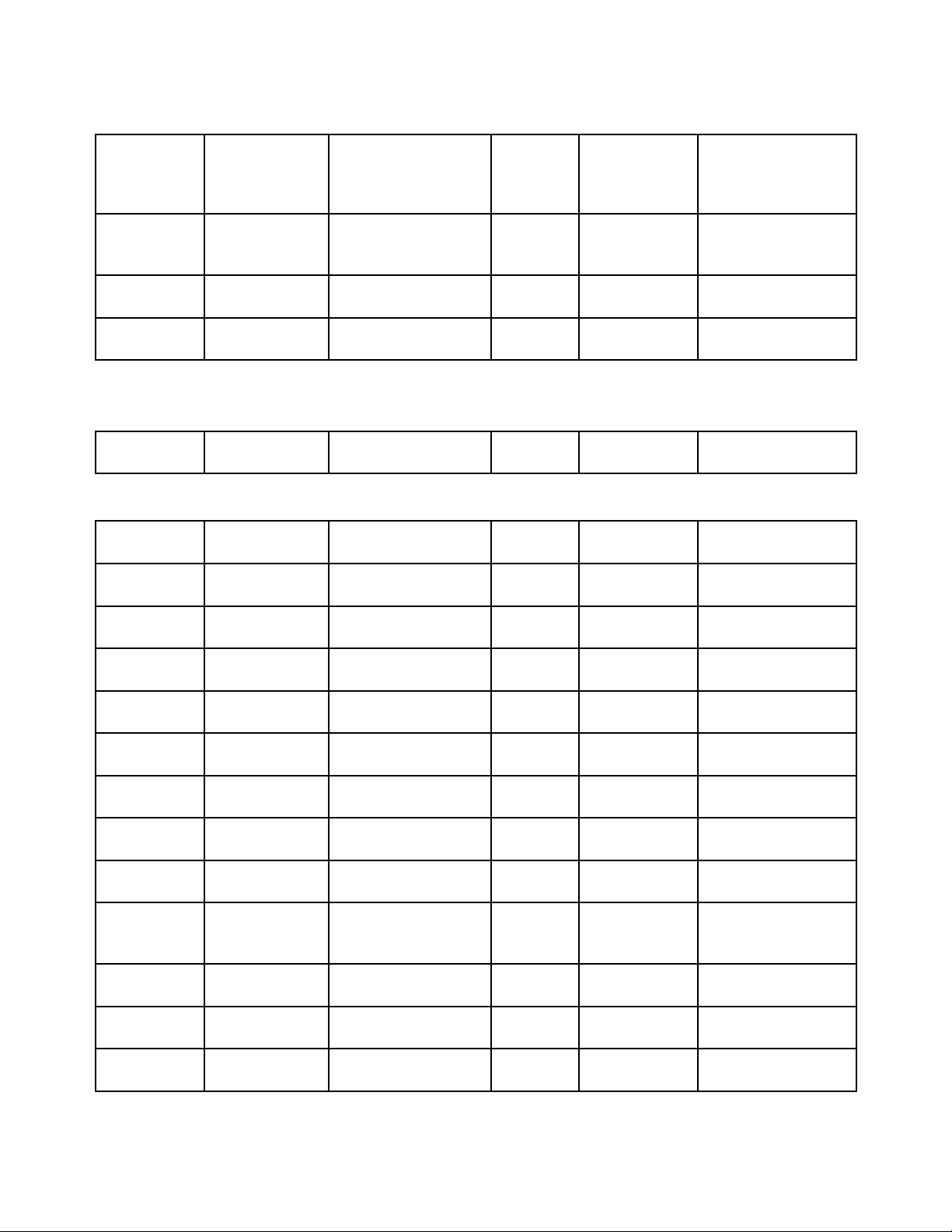

OPERATION

APPROX/ NO.

RECOMMENDED

APPROX.

ITEM

Squash,

Summer, 1”

Slices

Squash,

Winter, diced

Turnip, diced #5

* All portions are equivalent to approximately 1/2 cup cooked.

VEGETABLES, CANNED

Canned,

Vegetables

MEAT - POULTRY - FISH

Chicken, cutup, breaded

Chicken,

Whole

Fish,

Fillets

Fowl,

Whole

Frankforts

Hamburgers,

3 oz (85g)

Lobster 1#

size (450g)

Meatballs **

1 oz. (28g)

Meatloaf **

Pork Chops

4 oz. (114g)

with bone

Sausages, 10

per lb. (45g)

Turkey, on

Carcass

Turkey, off

Carcass

** Raw weight for meatballs and meatloaf includes hamburg and extenders and yields 2 oz. (55g) protein

plus extenders for 3 oz. (85g) total portion.

WT. PER PAN

#7

(3.2 kg)

#9

(4.1 kg)

(2.3 kg)

#7.5

(3.4 kg)

#8

(3.6 kg)

3 - #4

(1.8 kg)

#3

(1.4 kg)

2 - #5

(2.3 kg)

#5

(2.3 kg)

#5

(2.3 kg)

#10

(4.5 kg)

#6

(2.7 kg)

#15

(6.8 kg)

#6

(2.7 kg)

#6

(2.7 kg)

20 - 22#

(9-10 kg)

10 - 12#

(4.5-5.4 kg)

PAN SIZE, 12” x 20”

PERFORATED

2 1/2”

(65mm)

2 1/2”

(65mm)

2 1/2”

(65mm)

2 1/2”

(65mm)

2 1/2”

(65mm)

4”

(100mm)

2 1/2”

(65mm)

4”

(100mm)

2 1/2”

(65mm)

2 1/2”

(65mm)

2 1/2”

(65mm)

2 1/2”

(65mm)

2 1/2”

(65mm)

2 1/2”

(65mm)

2 1/2”

(65mm)

4”

(100mm) 1 90-100

2 1/2”

(65mm)

NUMBER

OF PANS

1

2-3

1

2-3

1

2-3

1

2-3

1

2-3

1

2-3

1

2-3

1

2-3

1

2-3

1

2-3

1

2-3

1

2-3

1

2-3

1

2-3

1

2-3

1

2

TIMER

SETTINGS IN

MINUTES

6-8

8-10 30-35

10-12

13-15 30-35

15-20

20-25

6-7

7-9 26-30

15-20

20-25

40-45

50-60

8-12

10-13

45-60

50-65

2-3

3-4

10-12

13-16

4-7

6-10

17-19

20-22

30-35

35-40

20-25

25-30

16-18

18-20

50-55

55-60

COOKED 2 Oz.

(55g) SERVINGS

PER PAN*

4 oz (110g)

20-25

15-20

Protein

25-30

Protein

12-15

Protein

20-25

Protein

35-40

Protein

20-25

Protein

10-1#

(150mm)

20-25

Protein

50-60

Protein

24

Protein

18-20

Protein

50-60

Protein

55-65

Protein

5

Loading...

Loading...