Page 1

TABLE OF CONTENTS

ST-AS STEAM COOKER

Subject Code No. Page

SEQUENCE OF OPERATION 5133 3

SUGGESTED STEAM CONNECTIONS 5133 3

BALL FLOAT TRAP 5134 4

ILLUSTRATION AND PARTS LIST 5135 5

DOOR ASSEMBLY AND GASKET 5136 6

DOOR ADJUSTMENT AND REMOVAL 5067 7

DOOR HANDLE ASSEMBLY 5119 8

FULCRUM & ROLLER ASSEMBLY 5120 9

FLUE, PRESSURE GAUGE & STEAM TRAP 5137 10

PILOT LIGHT & TIMER 5138 11

TROUBLE SHOOTING GUIDE 5139 12

WIRING DIAGRAM 5140 13

OPTIONAL STEAM-IT STAND 5141 14

24 INCH CABINET BASE 5142 15

WATTS PRESSURE REDUCING VALVE 5129 16

Page 2

HOW TO USE THIS MANUAL

This manual contains maintenance and service instructions for

the Automatic, Direct-Connected Steam-It, Style H Model ST-AS.

The exploded view drawings of components are aids to the

identification, disassembly and assembly of parts. The parts

listings provide information necessary for the ordering of

replacement parts (proper part names and part numbers). When

requesting parts or service, always furnish the model and serial

number of your unit. These numbers are located on the name

plate affixed to the top surface of the Steam-It.

STEP 5. The steam trap closes from the intense heat

generated by steam acting upon its thermostatic

element and free-venting will cease.

STEP 6. A full steam pressure build-up to approximately 14

P.S.I, will occur within the cooking chamber. The

Steam -It door must be kept locked until the cooking •

period has completely finished.

STEP 7. The timer will return to "zero" position and cooki ng

wilt be terminated. The inlet valve will close, the

exhaust valve will open, the buzzer will again sound,

and the pilot light will go out. The buzzer will continue

to sound until the timer is turned to the "off" position.

OPERATION SEQUENCE

STEP 1. Put the food in a proper pan for the cooking to be

performed and place it in the Steam-It in keeping

with proper loading techniques.

STEP 2. Close and lock the door into position by placing the

tongue of the door lock under the roller of the fulcrum

casting and press downward until the handle comes to

a firm stop. This lock makes the initial seal and when

steam pressure builds up within the cooking chamber

the door will be forced to a tighter closed position.

STEP 3. Turn the Steam-It on by setting the timer clock past

and then back to the desired cooking period. The pilot

light will go on to signify that cooking is in progress.

STEP 4. The steam exhaust valve will automatically close, the

steam inlet valve will open, and a period of freeventing through the open steam trap will occur. During

this period of free-venting, trapped cold air is

exhausted from the cooking chamber and replaced

with live steam.

STEAM REQUISITES

The ST-AS Steam-It is designed for operation with a piped-in

steam supply not in excess of 14 Ibs per square inch. Should it

be used with a system of steam generation that exceeds 14 Ibs

per square inch, a pressure regulator must be used on the

steam input line to reduce and regulate the steam pressures

within the operational range of the Steam-It.

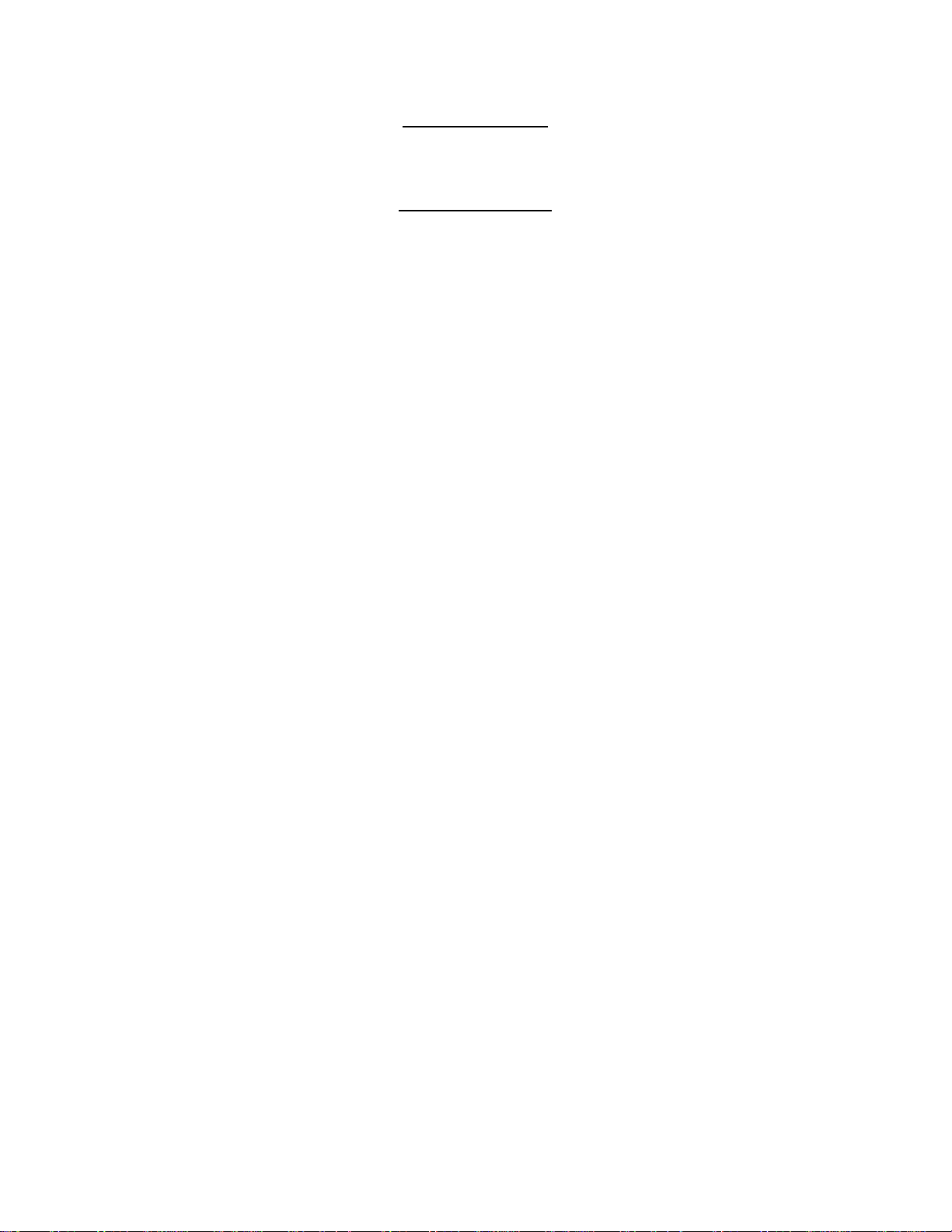

SUGGESTED STEAM CONNECTIONS

The illustration shows a recommended system of installation

which provides a regulating valve for delivery of 14 Ibs of steam

pressure, a globe valve for emergency shut off, a pressure

gauge to measure the pressure input from the source of supply,

and a ball-float trap to prevent dirt and water from entering the

unit. The globe valve, regulating valve, and ball-float trap and

pressure gauge are not furnished with this equipment. The

pres-gauge must be selected to operate within the range of the

pressures experienced at the place of installation. With the

introduction of a pressure reducing valve, the Steam-It will then

require input steam pressures in excess of 14 Ibs from its

source of supply.

NOTE: With pressure constant and between 11 and 14 PSI,

use the same system of installation with the pressure

reducing valve omitted.

Page 3

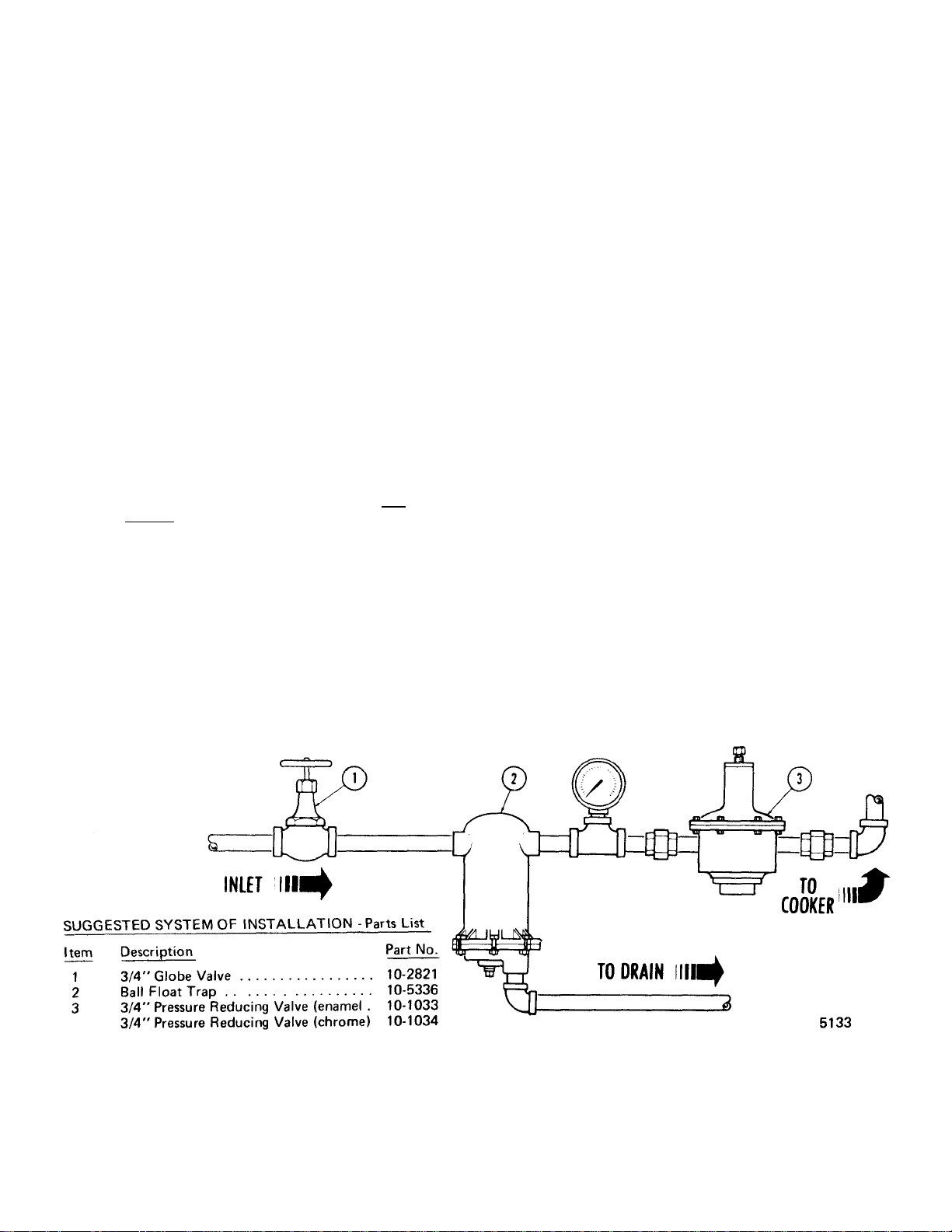

BALL FLOAT TRAP PART NUMBER 10-5336

2 Cover Gasket

10-5639

3 Valve and Sea

10-5640

4 Bracket and Screw

10-5642

5 Lever Assembly

10-5641

6 Ball Float

10-5643

PART NUMBER 10-5473, CHROME

Item Description Part No.

1 Cover Bolt and Nut 10-5644

5134

Page 4

Page 5

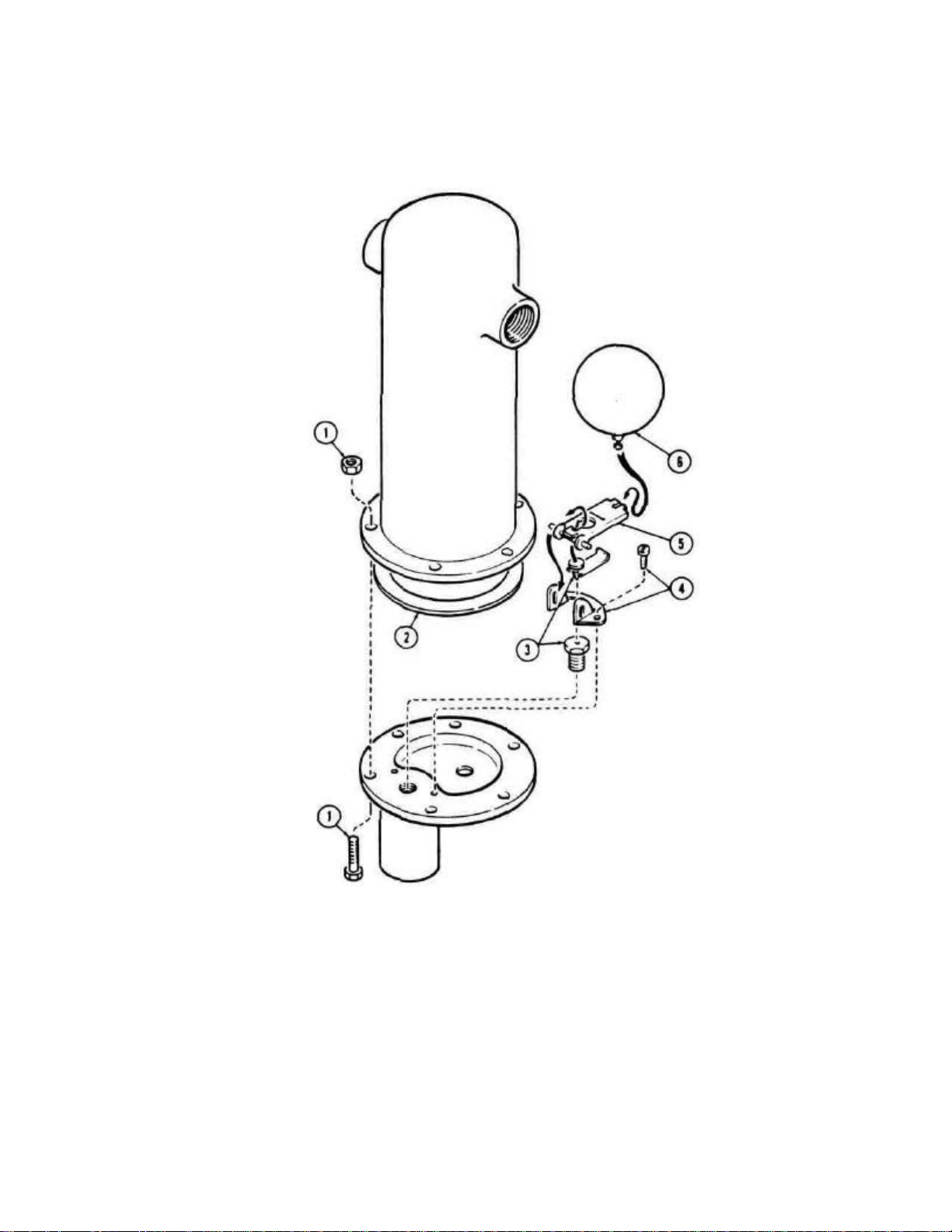

ST-AS STEAM-IT

2 Safety Valve

10-4636 3 Strainer Ass'y

95-0516 4 Handle Bumper

10-0226 5 No.

8 - 32 x 3/8"

Binding Hd. Screw

10-1774 6 Fulcrum

95-0116 7 1

/4" Sha

keproof Washer

10-2513 8 1/4" - 20 x 3/4"

Rd. Hd. Screw

10-1763 9 1/4" - 20 x 7/8"

Hex. Hd. Screw

10-1790 10 Street Elbow,

90° 10-2811 11 Solenoid Valve (Inlet)

10-5859 12 Grommet

10-0280 13 Elbow

1/2"

I.P.S. x

5/8 0.

D. 10-

2837

15 1/2"

I.P.S. x

5/8 0.

D. Straight Connector

10-2867 16 Nipple

1/2"

I.P.S. 10-

1107 17 Bracket

95-0065 18 Elbow

&

Bracket Ass'y.

95-

0064 19 1/4"

Lockwasher

10-2500 20 1/4" - 20 x 1/2

Hex. Hd. Screw

10-2073 21 Solenoid Valve (Outlet)

10-

5787 22

Tubing

95-3154 23 Nut, Grip

1/4" - 20 10-2312 24 Elbow

1/2"

I.P.S. St'd.

90° 10-2853 25 Nipple

1/2"

I.P.S. 10-

2864 26 Support Bracket, Buzzer

95-2007 27 Buzzer

10-4563 28 No.

8 - 32 x 3/8"

Rd. Hd. Screw

10-1717 29 No.8 Lockwasher

10-

2518 30

Hex. Nut,

#8-

32 10-2378 31 Handy Box

– Raco

10-

5163 32 Ground Lug

10-5492 33 No.

10 - 32 x 3/8"

Rd. Hd. Screw

10-1759 34 Cover, Handy Box

- Raco

10-5164 35 5/16"- 18

x 1"Hex. Hd. Screw

10-2105 36 5/16"

Flat Washer

10-2405 37 Hex. Nut

5/

16"- 18 10-2307 38 Pan Support

- Left Side

95-0097 39 Pan Support

- Right Side

95-

0096 40 Steam Trap

10-

6156 41 Bracket, Pilot Light

95-3408 42 Pilot Light

10-5052 43 Front Lower Panel Ass'y.

95-3185 44 Case -

Top Front Upper

95-3131 45 Case -

Left Side

95-3140 46 Case -

Right Side

95-

3141 47 Case -

Back

95-3126 48 No. 8 x

3/8"

Phil. Truss Hd. Screw Ty. "A"

10-1956 49 Nameplate Panel

(60

Cy.) 10-

6587 50 Decal, Dial Overlay

(50

Cy.) 10-

6577 51 No.

10 - 32 x 1/2"

Binding Hd. Screw

10-1776 52 Flue Ass'y.

95-3135 53 Pressure Gauge

10-5399 54 Tubing

- Press. Gauge

95-3285 55 Timer,

60

Minute

95-3393 56 Knob, Dial

10-

6381 57 Comp. Conn.,

1/8"

I.P.S. F'male x

3/16" 0.

D. 10-

3361

MASTER ILLUSTRATION PARTS LIST

Item Description Part No.

1 Body Assembly 95-2156

14 Tubing 95-2997

58 Comp. El. 900, 1/8" I.P.S. Male x 3/16" 0. D. 10-3360

Page 6

THE BUZZER

2 Door Lift Springs (pair)

10-2785

3

4

10 - 32

Machine Screw

1/2"

long

.

Door Gasket

101776

10-2666

5 Door & Door Spring Assy.

95-3204

6 Door Spring

95-0127

6)

The function of the Buzzer is to signify to the operator that the

cycle of cooking has been terminated.

The Buzzer is mounted on a bracket which is positioned at the

front of the unit just under the front removable panel.

THE DOOR GASKET

Keep the gasket clean. With normal closing and locking

of the door assembly, a steam-tight seal should be made

between the door gasket and the door opening. This seal

cannot be maintained if particles of foreign matter are

allowed to accumulate upon either of the contacting

surfaces.

HOW THE BUZZER WORKS

The Buzzer electrical circuit is controlled by the timer. When

the timer reaches "ZERO" (at the end of the cooking cycle),

the circuit will be completed and the Buzzer will continue to

sound until the timer knob is turned to the "OFF" position.

THE COOKER DOOR ASSEMBLY

The door of the Cooker has been engineered to establish a

positive method of sealing the steam pressure within the

cooking cylinder. As steam pressure builds up within the

cylinder, the door seal will tend to become more positive.

However, the door should be adjusted to make a good initial

seal between the door gasket and the door opening without

the added assistance of internal cylinder steam pressures.

With the simple action of securing the door handle down in a

locked position, the door gasket should be sufficiently

compressed against the door opening, all the way around, to

prevent any steam leakage from occurring.

DOOR ASSEMBLY - Parts List

Item Description Part No.

1 Pivot Spring Bearing 10-6765

If leakage should occur by the door gasket before the

additional pressure of a steam build up within the cooking

chamber causes it to stop, the door assembly must be

regarded as improperly adjusted and a readjustment

m ust be made of the adjustment screw.

To change the door gasket, remove the entire door

assembly as a unit, remove and discard the old gasket,

replace it with a new one (no cement is required), and

reinstall the door assembly. Make an operational check

for leakage and adjust the door if necessary.

Complete Door Assembly (Items 1 thru

95-0124

5136

Page 7

DOOR ADJUSTMENT

The door adjustment is located in the fulcrum casting at the

base of the door opening. This adjustment employs the use of

a screw and locknut. To adjust the Cooker door to a tighter

closed position (to prevent steam from leaking by the door

gasket as pressure builds up), it is necessary to loosen the

locknut and back off the screw at least one-quarter of a turn

and retighten the locknut.

5. To replace the door assembly, reverse the step by step

procedure described above.

DOOR LIFT SPRING REPLACEMENTS

Market Forge Company supplies replacement Door Lift

Springs in sets only. This policy has been found to be in the

best interest of the customer. Through continuous use, some

of the original qualities of the springs are lost and it becomes

advantageous to make replacements to both the left and right

Door Lift Springs in the event one becomes damaged or

broken.

Replacement Door Lift Springs are marked with tabs at the

factory prior to shipping to identify a right from a left spring.

These must be installed with the right Door Lift Spring on the

right and the left Door Lift Spring on the left of the door as

viewed from the front of the Cooker.

TO REMOVE THE DOOR ASSEMBLY

The Door Assembly can be removed from the inner cooking

chamber as a unit without the use of any special tools or

equipment. However, a systematic approach to this is warranted

as the clearances through the portal are close and much

confusion can result if not removed in the sequence described

below.

1. First, lift off and remove the two pan supports to expose the

door linkages on either side of the inner cooking chamber.

2. Raise the door to a fully opened position and disengage the

door spring from each of the door spring studs. Accomplish

this by counter-acting the force of the door lift spring with

one hand while working the end of the door spring of the

door assembly.

3. When the ends of the door spring have been completely

freed from their respective door spring studs, the door lift

springs on either side of the door assembly can easily be

slipped off their studs.

4. Rotate the entire door assembly out through the door

opening, passing the door handle through the opening first,

and then one end of the door spring as shown in the

illustration. The remainder of the door assembly will then pass

through the door opening quite easily.

5067

Page 8

1/4"

Shakeproof Lockwasher

Item Description Part No. Item Description Part No.

1 No. 10 - 32 Acorn Nut 10-2318 10 Door Handle Bearing Bracket 95-0659

2 # 10 Shakeproof Lockwasher 10-2514 11

3 Locking Screw 95-0563 12 1/4"-20 x 5/8" Rd. Hd. Screw 10-1731

4 Bearing Spacer 95-0120 13 Door Lock Ass'y. 95-3223

5 3/8" Shakeproof Lockwasher 10-2517

7 Door Handle Casting 95-0134 15 Complete Door Handle Ass'y.

8 1/4"- 20 Acorn Nut 10-2359

9 Door Handle Bearing Stud 95-0658

DOOR HANDLE ASSEMBLY - PARTS LIST

14 Door Lock Knob Ass'y. (Items 1

(Items 1 thru 13) 95.0144

10-2513

95-0145

Page 9

THE FULCRUM ASSEMBLY

Item Description

Part No.

7

Bron

ze Bearing

12

14 1/4-20x 5/8

Helicoil

10-3116

The Fulcrum Assembly is located at the lower front of the

cooking cylinder and furnishes a sturdy anchorage for the door

locking system of the door handle. Also provided in this

assembly is a means of adjustment for the door seal.

FULCRUM ASSEMBLY - Parts List

1 Fulcrum Casting 95-2176

2 1/4 -20x 3/8 Helicoil 10-3111

3 1 /4" Shakeproof Washer 10-2513

4 5 1/4-20 Cap Screw, 7/8" long

10-32 Hex Nut

6

# 10 Shakeproof Lockwasher

8 Bearing Spacer 95-0120

9

10 - 32 Machine Screw, 1 1/2"long

Roller Assembly (Items 5 thru 9)

10

1/4-20 Machine Screw, 3/4"long

11

1/4-20 Allen Set Screw

13 1/4-20 Famine Nut 10-2358

Complete Fulcrum Assy.

(Items 1-14 less item 2A)

10-1790

10-2339

10-2514

10-1578

95-0563

95-0149

10-1763

10-2087

95-2003

ROLLER ASSEMBLY CLEANING

The Roller Assembly provides a sturdy, free-rolling anchor

for the hooked arm of the door handle. Note that items 5, 6,

7, 8, and 9 in the illustration above makes up the complete

Roller Assembly, item 10.

The Roller Assembly must be kept free-rolling at all times.

Should this assembly become "frozen" due to

accumulations of dirt or food matter, strain will be put upon

the door handle and the fulcrum casting when the door is

being locked. Use only a dry lubricant such as graphite, as

oil or grease will tend to attract dirt to this area.

THE SAFETY VALVE

The Safety Valve is set to automatically relieve the cooking

compartment of excessive pressure buildups by opening at

a point between 151/2 Ibs. and 16 Ibs.

CHECKING THE SAFETY VALVE

If the Safety Valve should leak continually with a pressure buildup, or should it cause an interruption of the cooking cycle

prematurely (less than 151/2 Ibs. on the steam gauge), it must be

determined to be defective and be replaced. However, the steam

gauge should first be checked for accuracy before making this

determination. The steam gauge should register absolute zero

with no pressure in the cooking cylinder. If the normal zero setting

has advanced somewhat through usage (a characteristic of steam

gauges), the amount of advancement from absolute zero must be

subtracted from its registered reading to determine the true steam

pressure.

5120

Page 10

THE FLUE

B

1/2"

Steam Trap

..........

10-

6156 C Pressure Gauge Tubing

....... 10-3285

The Flue serves as a protective shield for the steam trap (B)

and the safety valve (A) as well as, a front facing mount for

the steam gauge (D). As servicing of these parts may at

times require the removal of the Flue, an exploded view

drawing is provided to show their proper relative positions

within the Flue and the method of their assembly to the

cooking cylinder.

TO REMOVE THE FLUE

1. Detach the 3/16" copper tube connector or (C) from the

steam gauge (D) at the ferrule nearest the steam gauge.

Then, remove the copper tube entirely by freeing it at the

other ferrule.

2. Apply inward pressure at either side of the Flue at points

(1) and (2) with a screwdriver. This will collapse the side

walls slightly to allow the small fluted sections of sheet

metal to clear the edges of the flue opening in the outer

shell of the Steam-It. With the restrictions of the flutes

removed, the Flue may then be lifted over the parts it

houses.

3. To replace the Flue, reverse steps above.

FLUE -Parts List

Item Description Part No.

A 1/2"- 15 Ib Safety Valve ...... 10-4636

D 0 - 30 Ib Pressure Gauge ..... 10-5399

THE STEAM PRESSURE GAUGE

Located at the top rear of the Steam-It and mounted into the

forward face of the flue for visibility, the Steam Pressure

Gauge registers the pressure within the Steam-It cooking

chamber. To replace this unit it is necessary to disconnect

the 3/16" copper tube connector and remove the two nuts

holding the gauge framework in place. Normal pressure

reading during a cycle of cooking will be:

1. Immediately after the Steam-It is set into operation; a

gradual rise to approximately 5 P.S.I.

2. After full free-venting has exhausted all cold air from

the cylinder; an increase in pressure to approximately

1 4 P.S.I.

3. During the remainder of the cooking period; a relatively

constant pressure reading of about 14 P.S.I.

4. After the timer has returned to the "ZERO" position and

complete exhaust venting has occurred; a pressure

reading of zero.

THE STEAM TRAP

The Steam Trap is located within the flue at the top rear of

the Steam-It. It has the very important automatic, dual

function of exhausting all cold air from the cooking

compartment and of making a suitable seal to allow a

pressure build-up of live steam during the cooking cycle.

Failure of this unit to operate properly will result in uneven

cooking.

HOW IT WORKS

With the introduction of steam into the cooking

compartment, the cold air escapes through the Steam

Trap. When sufficient generated steam displaces the cold

air, it passes through the Steam Trap, and the thermostatic

element becomes heated and expands to "make" a seal

against the seal against the seat. This action encloses the

live steam within the cooking compartment and allows a

steam pressure build-up to occur.

5137

Page 11

TROUBLE SHOOTING

THE TIMER

The first indication of defective Steam Trap

operation will usually be evidenced by uneven

cooking. If working properly, the steam temperature will be even and cooking will be uniform

through the cooking compartment. Trouble may

occur either through premature closing of the

Steam Trap before all the cold air has been

exhausted or by its failure to close sufficiently to

enable a proper steam pressure build-up. Either

case warrants the replacement of the Steam

Trap.

NOTE: The Steam Trap cannot exhaust cold air

properly if the thermostatic element is already

heated to its closed position prior to the start of a

new cycle. Therefore, a short interval is

recommended between cook ing cycles to allow it

to sufficiently cool. Usually the normal unloading

and reloading time is sufficient.

THE PILOT LIGHT

The Pilot Light is located at the lower right front of

the front panel. This unit is wired to operate only

when the timer is set to a cooking cycle. The

circuit will be broken when the timer returns to the

"ZERO" position. Thus, when lit, it signifies that

the Steam-It is in the act of cooking.

The Timer, located at the lower right front of the

Steam-It, provides a means of manual control. The

Steam-It is put into an automatic cycle of cooking with

the setting of the Timer to any of its calibrated periods

of cooking.

TROUBLE SHOOTING

If setting the Timer fails to operate the Steam-It and

the pilot light also fails to light, look first for a break in

the electric supply line (main switch off, burned out

fuse, defective wiring, etc.). Then look for poor

connections or defective wiring within the Steam-It

itself. With these initial checks accomplished

satisfactorily and the unit still inoperative:

1. If the pilot light comes on but timer fails to operate

then check terminals 11 and 12 to see if 115V is

present. If not, replace the timer.

2. Apply 115 volts across the solenoid coil terminals

of the steam inlet valve and the steam exhaust valve,

in turn, to determine if their solenoids or valves are in

proper working order.

The Timer is replaceable only as a complete unit as

factory repairs of it are not practical in the economic

interest of the customer

Page 12

TROUBLE POSSIBLE CAUSE CORRECTION

TROUBLE SHOOTING GUIDE

Setting the timer tails to light the pilot light. 1. Power not reaching unit.

2. Pilot light burned out; connections loose;

defective wiring.

3. Timer circuit not completed; loose

connections; defective wiring; defective

timer.

Steam fails to enter cooking chamber. 1. Operating circuit broken; inlet valve defective; timer

defective.

Steam-It fails to build up to approx. 14 Ibs pressure. 1. Induced steam to unit has in-

sufficient pressure.

2. Steam leaks around door.

3. Steam trap fails to properly close.

4. Safety valve blows off below 14 Ibs

pressure.

5. Exhaust valve fails to close.

1. Check for interruption in your

electrical input line.

2. Replace pilot light assembly; tighten

connections; replace defective

wiring.

3. Check connections; replace defective

wiring; If pilot light lights and unit is

inoperative -check for defective

timer. Replace if defective.

1. Check for faulty connections or defective

wiring - tighten or replace. Make continuity

check of solenoid coil. Replace any defective

components. If okay -replace timer.

1. Provide suitable pressurized steam to

unit.

2. Check for worn gasket. Adjust door or

replace gasket.

3. Replace the steam trap. 4.

Replace safety valve.

5. Check ex haust valve solenoid coil

continuity. Check for binding valve.

Replace defective components.

Steam-It does not shut down when timer reaches

zero.

Uneven cooking. 1. Steam trap closing prematurely. 1. Replace the steam trap.

Buzzer fails to stop buzzing when timer dial reaches

"O".

1. If unit fails to exhaust all steam: Circuit to

exhaust valve solenoid is broken or exhaust

valve is binding in a closed position.

2. If neither the exhaust valve or the inlet

valve operates to shut -down position, timer

is defective.

3. Check to see if cirucit to inlet valve

solenoid is broken or inlet valve is

binding in an open position.

1. Short. 1. Check connections or replace wire where

1. Make continuity checks of ex haust valve

solenoid coil. Re-establish circuit if

found broken. Repair or replace valve if

found binding.

2. Replace timer.

3. Make continuity checks to inlet valve

solenoid coil. Reestablish circuit if

found broken. Repair or replace valve if

found binding.

needed.

Page 13

Page 14

OPTIONAL STEAM-IT STAND

1

Corner Bracket with set screw

. .

27"

Leg

... ................

Leg Top

... ................

Flat Washer

1/16"

th'k

...... .

Cap Bracket

............. .

Complete Stand Ass'y

...... .

Market Forge Steam-Its can be supplemented with an optional stand for

utility where maximum compactness is desired. The-sturdy stainless steel

stand unit is equipped with adjustable leg extensions which allow the unit

to be installed and leveled over existing contours in the floor.

The open under-shelf of the stand gives added utility, providing a handy

tabouret for cooking utensils. The open design lends itself to maximum

sanitary conditions because of the ease in which periodic cleanings can be

made.

Though simple in design and appearance, the Steam-It Stand is the ideal

arrangement for mounting in that it elevates the unit to the most efficient

working height, can be leveled easily, and may easily be maintained in a

state of cleanliness.

STEAM-IT STAND ASSEMBLY - Parts List

Item Description Part No.

Shelf ......................

2

3

4

Rd. Hd. Screw 1/4" - 20 x 5/8" .

5

6

Lockwasher1/4" .......... .

7

8

9

95-1680

25-1507

10-0634

10-0635

10-1804

10-2520

10-2400

95-3211

95-0300

Page 15

24 INCH CABINET BASE - Parts List

90-3020 Rear Panel Enamel

9 10-

5561 Magnetic Catch

909039

Side Panels R & L St. Steel

10 90-9057 Door Handle

2 90-9041 Side Panels R & L Enamel

11 10-

2422 Special Washer

3 10-

0631 Leg 12 10-1869 No. 10

-

32 x 1/2" Flat Head Screw

4 90-

8974 Ass'y. 24" x 33" Modular Frame

13 10-

0454 Cabinet Hinge Right Bottom

90-

9098 DoorAss'y. St. Steel

14 90-

3185 Double Washer

5 90-9099 Door Ass'y

-

Enamel

15 10-

2511 Washer

6 90-

2663 Panel MTG Bracket

16 10-

2147 Hex. Nut

10-

0493 Feature Strip

17 10-

1982 Self Tapping Screw

7 18 10-2514 #

10 Lockwasher

ITEM NO. PART NO. DESCRIPTION ITEM NO. PART NO. DESCRIPTION

90-3013 Rear Panel St. Steel 8 90-3210 Bracket — Magnetic Catch 1

5142

Page 16

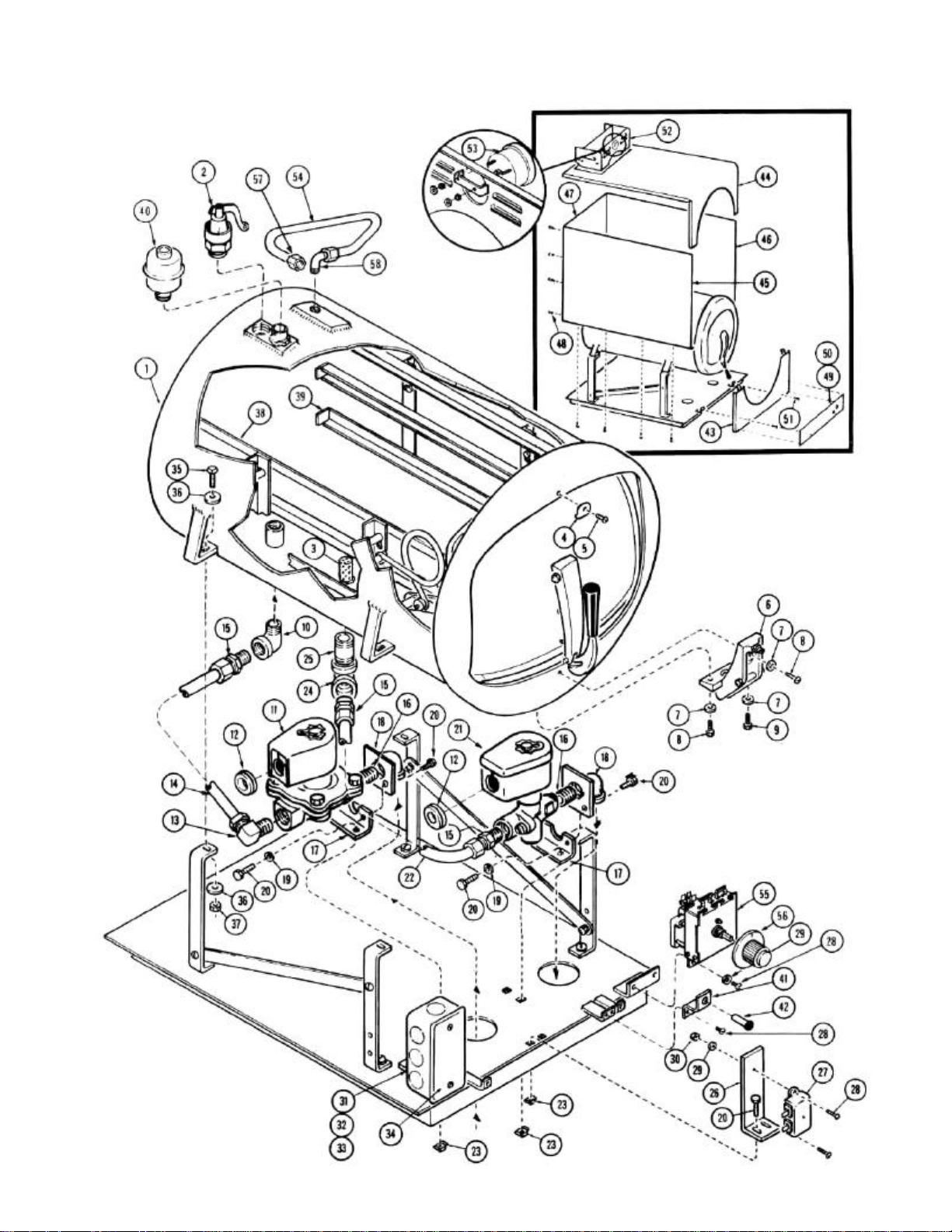

WATTS PRESSURE REDUCING VALVE

OPERATION OF WATTS 3/4 REDUCING VALVE

Steam enters the valve at the inlet port and passes upward

through the seat (8) into the discharge side

of the valve. As pressure in the discharge side increases, it forces

the diaphragm (2) upward, overcoming the tension of the adjusting

spring (1) and closing valve. As the pressure drops, the adjusting

spring forces the dia phragm down, reopening the valve. Where

demand and initial pressures are fairly constant, the valve opens to

the proper position and maintains the desired reduced pressure.

ADJUSTING WATTS 3/4 REDUCING VALVE

1. Release the adjusting screw lock nut and loosen the adjusting

screw enough to release all tension on adjusting spring (1).

2. Turn steam on slowly. Then turn adjusting screw clockwise just

enough to allow the valve to open slightly. Allow cooker to

operate in this manor several minutes.

3 Turn adjusting screw down slowly, at intervals, until reduced

pressure reaches the desired Point. (5 P.S.I.)

ITEM 1 PART NO. 10

1083

2 10 1082 Diaphragm

3 10 1075 Diaphragm Gasket

4 10-1076 Diaphragm Button Stem Assy.

5 10 1077 Strainer

6 10-1078 Bottom Plug

7 10 1079 Bottom Spring

8 10-1080 Seat

9 10-1081 Disc Assy.

10 10-1033 3/4" Complete valve-Enameled

10-1034 3/4" Complete valve-Chrome

WATTS PRESSURE REDUCING VALVE - % INCH

To provide adequate steam pressure regulation

steam cookers are equipped with a steam pressure

reducing valve. The 3/4" Watts pressure reducing valve is

designed to operate from a 7 to 50 P.S.I, source of steam

pressure and reduce this to 5 P.S.I, for delivery to your cooker.

Installation must be made from your source of steam supply,

through the pressure reducing valve, and into the manifold input

port of the steam cooker.

WARNING: Before final connection is made, blow down

your steam line to remove all dirt, scale, packing and

compound which may have accumulated during the

installation of piping to the cooker.

DESCRIPTION Adjusting Spring

4. Tighten adjusting screw lock nut.

5. If chattering noise should occur turn adjusting screw located in

bottom half of valve body, clockwise or counterclockwise,

until chattering stops.

INSPECTION - MAINTENANCE - REPAIRS

Reports of unsatisfactory regulation of the pressure reducing valve

is usually due to dirt, pipe compound, etc., blocking the internal

strainer, or gumming up the seat and disc assembly. To clean the

strainer, seat, and disc assembly remove the bottom plug (6) and

remove strainer screen (5), bottom spring (7) and disc assy. (9)

Clean the lower part of the valve. This can be accomplished

without removing the valve from the line or unbolting the cover. If

cleaning the strainer and disc assy. does not correct fault, the disc

assy. and seat should be replaced. Also the top cover should be

removed and the diaphragm button stem assembly should be

removed and cleaned.

5129

Loading...

Loading...