Page 1

SERVICE &

PARTS MANUAL

STEAM·IT, STYLE F

GAS OPERATED COOKER

MODELST·AG

Form Number S2127 Printed in U.S.A. Copyright 1977

An

Employee Owned Company

35 Garvey Street, Everett, MA 02149-4403

Page 2

TABLE OF CONTENTS

!'!'.l.;·.1

SECTION 1 INTRODUCTION

1.1 Description .

1.2 Basic Functioning .

1.3 Service.

SECTION 2 INSTALLATION

2.1 Unpacking and Assembly .

2.2 Setting in Place .

2.3 Gas Connection .

2.3.1 Pressure Regulator Setting .

2.3.2 Canadian Gas Connections .

2.4 Electrical Connection .

2.5 Water and Drain Connections .

2.6 Installation Checkout .

2.6.1 Initial Control Setting .

2.6.2 Cooker Checkout .

2.6.3 Shutdown Procedure .

SECTION 3 OPERATION

3.1 Operating Controls and

Indicators .

3.2 Operating Procedures .

3.2.1 Preliminary Procedures .

3.2.2 Preheating .

3.2.3 Cooking Procedures ...

3.2.4 Low Water Cut-Off Operation .

3.2.5 Shut-Down Procedure .

3.3 Cleaning .

3.3.1 Exhaust Silencer .

SECTION 4 PRINCIPLES OF OPERATION

4.1 General .

4.2 Detailed Operation .

4.3 Steam Circuit. . .. . .

4.3.1 Steam Trap .

4.3.2 Pressure Switches .

4.3.3 Steam Pressure Gauge and

Safety Relief Valve .

4.3.4 Steam Exhaust Valve and

Silencer .

4.4 Electrical Circuits .

4.4.1 Control Circuit Components .

1·1

1·1

1.,

2·1

2·1

2·'

2·1

2-1

2·2

2-2

2·2

2-2

2·3

2-3

3-1

3·'

3-1

3·,

3-1

3-3

3-4

3-4

3-4

4-1

4-1

4-1

4·1

4·1

4-1

4-1

4-2

4-2

I .• ".

SECTION 5 TROUBLE-SHOOTING

5.1 General. . . . . . 5·1

5.2 Trouble-Shooting Guides. . . . . .. 5·'

5.3 Electrical Fault Isolation. . . 5·1

54 Electrical Trouble-Shooting

Procedures. . . . . . . . . . . . 5·3

5.4.1 Incoming Power. . . . . . . . . . . . . .. 5·3

5.4.2 Electrical Inspection . . . . . . . 5-5

5.4.3 Direct Spark Ignition Control

System . . . . . . . . . . . . . . 5·5

5.4.4 50-Minute Timer. . . . . . . . . . . . . 5-7

54.5 Solenoid Gas Valve. . . . . . . . . 5-7

5.4.6 Buzzer. . . . . . . . . . . . . . . . . . . . . .. 5-7

5.4.7 Indicator Light.. . ... . .. .... . 5-7

5.4.8 Wiring . . . . . . . . . . 5-8

SECTION 5 MAINTENANCE

6.1 General... . . . . . . . .. 6-1

6.2 Preventive Maintenance. . . . . . .. 6-1

62.1 Door Disassembly and Cleaning. 6-1

6.2.2 Safety Valve Check. . . 6-2

62.3 Door Fulcrum and Drain Cleaning

and Lubrication. . . . . . . . . . . . . .. 6-2

6.2.4 Cooki ng Compartment. . . . . . . .. 6-2

6.2.5 General Inspection . . . . . . . . . . .. 6-2

6.3 Repair and Replacement. . . . . . .. 6-3

6.3.1 Door Assembly. . . . . . . . . . . . . . .. 6-3

6.3.2 Exterior Panel Removal. . . . . . . .. 6-4

6.3.3 Steam Exhaust Valve and Trap

Replacement. . . . . . . . . . . . . . . .. 6-4

6.3.4 Direct Spark Ignition System. . .. 6-4

6.4 Adjustments and Operational

Checks. . . . . . . . . . . . . . . . . . . . .. 6-5

6.4.1 Gas Burners and Pressure

Regulator. . . . . . . . . . . . . . . . . . .. 6-5

6.4.2 Electrode Assembly. . . . . . . . . . .. 6-5

6.4.3 Solenoid Gas Valve. . . . . . . . . . .. 6-5

6.4.4 Timer and Gas Control Switches. 6-5

SECTION 7 ILLUSTRATED PARTS LIST

7.1 General...................... 7-1

7.2 Ordering Information.. 7-1

7.3 Index of Illustrated Parts List - 7-1

III

S2127

Page 3

LIST OF ILLUSTRATIONS

Paoe

SECTION 1 INTRODUCTION

1-1 Model ST-AG Steam-It Cooker ... 1-2

SECTION 2 INSTALLATION

2-1 Installation of Gas Shutoff Valve. 2-2

SECTION 3 OPERATION

3-1 Steam-It Controls and Indicators. 3-2

3-2 Drain Plug. . . . . . . . . . . . . . . . . . .. 3-4

3-3 Pan Support Removal. . . . . . . . .. 3-4

SECTION 4 PRINCIPLES OF OPERATION

4-1 Steam and Gas Circuits. . . . . . .. 4-2

4-2 Pictorial Diagram, Electric

Circuits, 120V 4-3

SECTION 5 TROUBLE-SHOOTING

5-1 Wiring Diagram, Steam-It, 120V,

60 Hz 5-4

5-2 Schematic Diagram, Steam-It,

120V 5-5

5-3 Placement of Flame Current

Meter. . . . . . . . . . . . . . . . . . . . . . .. 5-6

SECTION 6 MAINTENANCE

6-1 Door Spring Disengagement. . .. 6-1

6-2 Door Removal. . . . . . . . . . . . . . . .. 6-2

6-3 Gasket Removal. . . . . . . . . . . . . .. 6-2

6-4 Door Seal Tension Adjustment. .. 6-3

6-5 Air Shutter Adjustment _. 6-5

6-6 Gas Regulator Adjustment. . . . .. 6-5

SECTION 7 ILLUSTRATED PARTS LIST

7-1 Cabinet and Frame Assembly ... 7-2

7-2 Steam Exhaust Valve Assembly .. 7-5

7-3 Burner Chassis Subassembly. " 7-6

7-4 Door Assembly. . . . . . . . . . . . . . .. 7-8

7-5 Door Latch Assembly. . . . . . . . .. 7-9

7-6 Fulcrum and Drain Assembly. . .. 7-10

LIST OF TABLES

Table

SECTION 3 OPERATION

3-1 Controls and Indicators. . . . . . .. 3-3

SECTION 5TROUBLE-SHOOTING

S2127

Page

Table

5-1 Operator's Trouble-Shooting

Guide 5-1

5-2 General Trouble-Shooting Guide. 5·2

5-3 Electrical Fault Isolation Guide.. 5·3

iv

Page

Page 4

SECTION 1 INTRODUCTION

.-~~-- ...-~~.~-.-=-:::-::~=-=-=~-=-=-:~-::::-:::-=-=-=-::-::-:'-~;-::-:-:--;-:---:---;--;-;----;-:------:-7-~--'----'

This service and parts manual contains general information, installation, operation, principles

of operation, trouble-shooting, and maintenance information for the Market Forge Steam-It,

Style F,Gas

IS Identified and shown in an accompanying exploded view.

Operated,

Model ST-AG. Also included is a parts list in which each replaceable part

1.1 DESCRIPTION

The Market Forge Model ST-AG Steam-It

Cooker is a gas fired pilotless, direct spark

ignition system cooker. The unit is designed

to operate from a natural, propane, butane or

manufactured gas supply. It consists of a

cooking compartment fitted with electrically

controlled steam circuits for application of

steam for the duration selected by the

operator. The cooking compartment and all

control components are enclosed within

stainless steel cover panels with operator

controls displayed on a front mounted panel.

(See Figure 1-1)

The major assemblies of the Model ST-AG

steam cooker are, the stainless steel cabinet

enclosure, a cooking compartment with pan

supports for cooking trays, the gas burner

and ignition control assembly for the direct

spark electrode, and a steam exhaust valve

assembly. Located on the lower front panel is

a 50-minute timer with a pilot light (red) "on"

indicator and a reset switch marked RESET.

The RESET switch is used to re-cycle the unit

in the event of shut off during a cooking

period.

The unit is designed to be mounted on a

stand which is offered and highly recommended as an optional unit. However, the

Steam-It unit may be mounted on any heat-

resistant table, counter top etc. as long as

certain clearance from combustible

materials are maintained (refer to Section 2

for complete installation instructions) and

the unit is perfectly level.

As the pressure builds up, cold air is

forced out of the cylinder through the thermostatic steam trap. The air will continue to

escape as pressure builds up and the steam

trap will close after all the air has been forc-

ed out of the cooking compartment. When

the pressure reaches approximately 9-10

psi,the contact on the pressure switch will

close, thereby closing the circuit to the clock

motor and starting the actual cooking time

period. When the pressure in the cooking

compartment reaches 15 psi, the contacts on

the pressure switch will open. These contacts will shut off gas to the main burner

when they are open, causing the pressure to

stop rising. When the cooking compartment

cools and the pressure drops to 13 psi, the

contacts on the pressure switch will close

gas will flow to the main burner and be re- ig:

nited by the electrodes. Any number of such

"OFF" and "ON" cycles might occur during

the selected cooking time.

1.3

SERVICE

Required service, both preventive and corrective, is explained in Section 5. Should

repairs be required, a network of authorized

agencies is available to assist with prompt

service. A current Directory of Authorized

Service Agencies may be obtained by

contacting:

Product Service Department

Market Forge

35 Garvey Street

Everett, Massachusetts 02149

Telephone: (617) 387·4100

1.2 BASIC FUNCTIONING

The Model ST-AG steam cooker becomes

operational when water is loaded into the

cooking compartment and the 60-minute

timer is set to the desired cooking time. With

the time set, the electric ignition comes on,

the exhaust valve closes automatically and

the burner ignitor is energized. The gas is ig-

nited by the electrodes to heat the water in

the cooking cylinder.

The Model and serial numbers must be

referenced when corresponding with Market

Forge. The data plate containing the serial

number pertaining to the equipment is

located on the front top of the cabinet.

1·1

S2127

Page 5

SECTION 2 INSTALLATION

2.1 UNPACKING AND ASSEMBLY

The Stearn-It cooker is shipped in a carton

with protective padding and mounted on a

wooden pallet. Carefully remove the carton,

padding and the bolts securing the unit to

the wooden pallet. Inspect assemblies as

follows:

1. Inspect unit overall for dents or

deformations in stainless steel

cabinet enclosures.

2. Make sure visible attaching hardware

for all assemblies are not missing or

damaged.

3. Inspect timer, indicator light, RESET

switch and pressure gauge to see they

are not damaged.

4. Remove caplug from door handle and

install handle.

5. Install pan supports so that the

horizontal keyhole is at the rear of the

cooking chamber and so that the

flange and embossments face the

middle of the chamber.

NOTE

The cooker is carefully inspected and

packaged before leaving the factory. If

there are missing components or unit

is damaged, notify the carrier or dealer

immediately.

2.2 SETTING IN PLACE

If possible, a location should be selected

under an exhaust hood which will remove

small amounts of water vapor emitted when

the cooker door is opened. Level the unit in

final location, using the cabinet top as a

reference to obtain level adjustment left-toright and tront-to-back.

NOTE

If the Steam-It cooker is installed

without the optional stand, it may be

set on a heat-resistive table, counter

or back bar. The minimum clearance

from combustible construction must

be 2 inches from left side, 12 inches

from right side and 2 inches from

back.

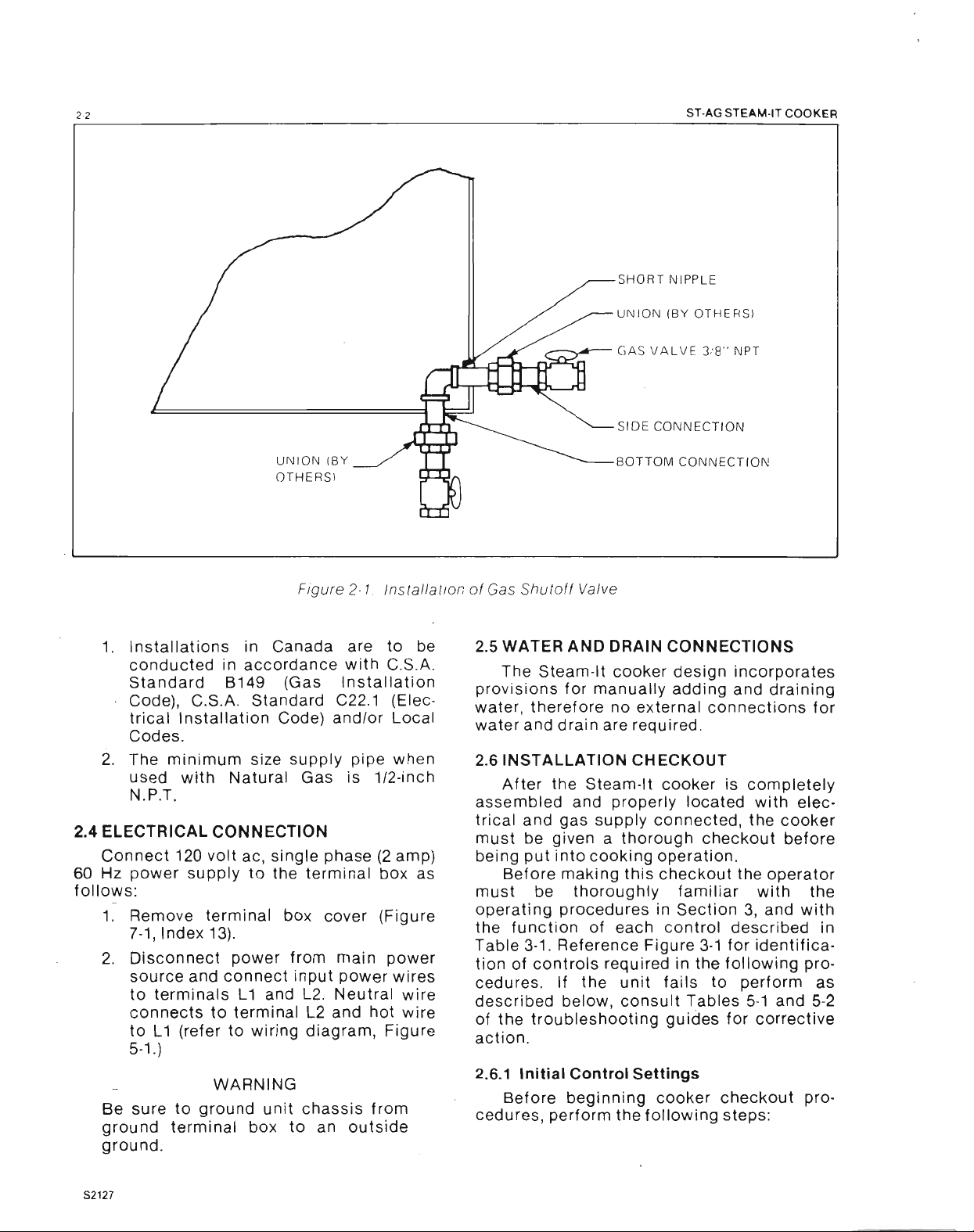

2.3 GAS CONNECTION

The gas connection is made by removing

the lower front panel to gain access to the

gas supply line elbow (Figure 7-3, Index 37).

WARNING

Gas lines should be thoroughly blown

out and cleaned before connection to

the Steam-It is made. This will prevent

dirt, dust or pipe compound from

reaching the sensitive gas solenoid

valve.

Installation must conform with the

National Fuel Gas Code, ANSI Z223.1-1974.

The gas line should not be smaller than 3/8inch pipe. A gas shutoff valve is supplied

with the unit and must be installed as close

as possible to the gas connection of the

Steam-It, adjacent to the outside of the unit.

(Refer to Figure 2-1.)

2.3.1

Pressure Regulator Setting

The pressure regulator must be set to the

proper flow, depending upon the type of gas

used. Setting is as follows:

1. Remove pressure regulator access

cover (Figure 7-1, Index 29) and remove

cap from pressure regulator (Figure

7-3 Index 39).

2. For natural or manufactured gas

supply, set regulator at 4.0·inch W.C.

(See Subsection 6.4.1.)

3. For propane or butane gas supply set

regulator at 10.0-inch W.C. (See

Subsection 6.4.1.)

4. Reinstall protective cap.

5. Check to see that proper burner

orifices are installed. Use a #47 OMS

(yellow) for natural gas; a #55 OMS

(purple) for propane or butane gases; a

#31 OMS (brown) for manufactured

gas. Refer to Figure 7-3, Index 43,44

and 45 for proper part numbers.

2.3.2 Canadian Gas Connections

Special instructions are required for in-

stalling the Steam-It cooker in Canada. Instructions are as follows:

2·'

SZ127

Page 6

2·2

SHORT NIPPLE

UNION (BY OTHERS)

----- GAS VALVE 3/8" NPT

SIDE CONNECTION

ST·AG STEAM·IT COOKER

UNION (BY

OTHERS)

Figure 2·1

tnstetteuon

1. Installations in Canada are to be

conducted in accordance with C.S.A.

Standard B149 (Gas Installation

Code), C.S.A. Standard C22.1 (Electrical Installation Code) and/or Local

Codes.

2. The minimum size supply pipe when

used with Natural Gas is 1/2-inch

N.P.T.

2.4 ELECTRICAL CONNECTION

Connect 120 volt aCt single phase (2 amp)

60 Hz power supply to the terminal box as

follows:

1. Remove terminal box cover (Figure

7-1, Index 13).

2. Disconnect power from main power

source and connect input power wires

to terminals L1 and L2. Neutral wire

connects to terminal L2 and hot wire

to L1 (refer to wiring diagram, Figure

5-1.)

WARNING

Be sure to ground unit chassis from

ground terminal box to an outside

ground.

BOTTOM CONNECTION

of Gas Shutoff Valve

2.5 WATER AND DRAIN CONNECTIONS

The Stearn-lt cooker design incorporates

provisions for manually adding and draining

water, therefore no external connections for

water and drain are required.

2.6 INSTALLATION CHECKOUT

After the Steam-It cooker is completely

assembled and properly located with electrical and gas supply connected, the cooker

must be given a thorough checkout before

being put into cooking operation.

Before making this checkout the operator

must be thoroughly familiar with the

operating procedures in Section 3, and with

the function of each control described in

Table 3-1. Reference Figure 3-1 for identifica-

tion of controls required in the following procedures. If the unit fails to perform as

described below, consult Tables 5-1 and 5-2

of the troubleshooting guides for corrective

action.

2.6.1

Initial Control Settings

Before beginning cooker checkout procedures, perform the following steps:

S2127

Page 7

INTRODUCTION

1.

Check to see that

120

volt ac. single

phase 60 Hz power is available from

power source and properly connected

to unit terminal box.

2. Check to see that the gas supply line

shutoff valve is closed.

3. Check to see that the timer is off

4 Visually check interior of cooking

compartment and remove any

materials, papers, etc. Check to see

that pan supports are properly install-

2.1

ed (refer to par aqraph

step 5) and

secured.

5 Check pressure gauge to see that it

registers zero pounds.

2.6.2

Cooker Checkout

The cooker checkout procedures are as

follows:

1. Secure drain plug (Figure 7-6, Index

18), then pour 6 quarts of water into

Steam-It cooking compartment

through the door opening.

2. Close the door and lock in position by

placing the tongue of the door lock

under the roller on the drain casting

and pressing downward until door

lock comes to a firm stop. This lock

makes the initial seal. (When steam

pressure builds up in the compartment it will force the door to a tighter

closed position.)

3. Open gas shut-off valve.

4. Turn the Steam-It on by setting the

timer to the desired cooking time.

Observe pressure increase indicated

by pressure gauge.

5. At the close of the preset cooking

period, the timer pointer will stop at

the "0" position on the dial. This will

shut down the Steam-It and

automatically open the exhaust valve.

The Buzzer will continue to sound un-

til the dial pointer is manually turned

to the "OFF" position.

6. Observe that the indicator light

(Figure 3·1, Item 2) goes out when

timer is at the "O·minute" position.

7. Check the pressure gauge to see that

the pressure reads zero.

8. The door will not open while there is

steam pressure working against it

from within the cooking compartment.

The door must be kept locked until the

cooking cycle has completely finished, then the door opened to allow

vapor to clear.

9. Shut off gas supply by closing the gas

shutoff valve.

2.6.3

Shutdown Procedure

No special shutdown procedures are

required with the exception that the door is

left open, timer must be in the OFF position

and the gas supply valve closed, (consult

local codes for daily shut-off requirement.)

NOTE

Before using the Steam-It for cooking,

it is recommended that checkout

operations be performed 2 or 3 times

in order to determine that it is working

properly and to insure cleanliness of

the cooking compartment.

23

S2127

Page 8

SECTION 3 OPERATION

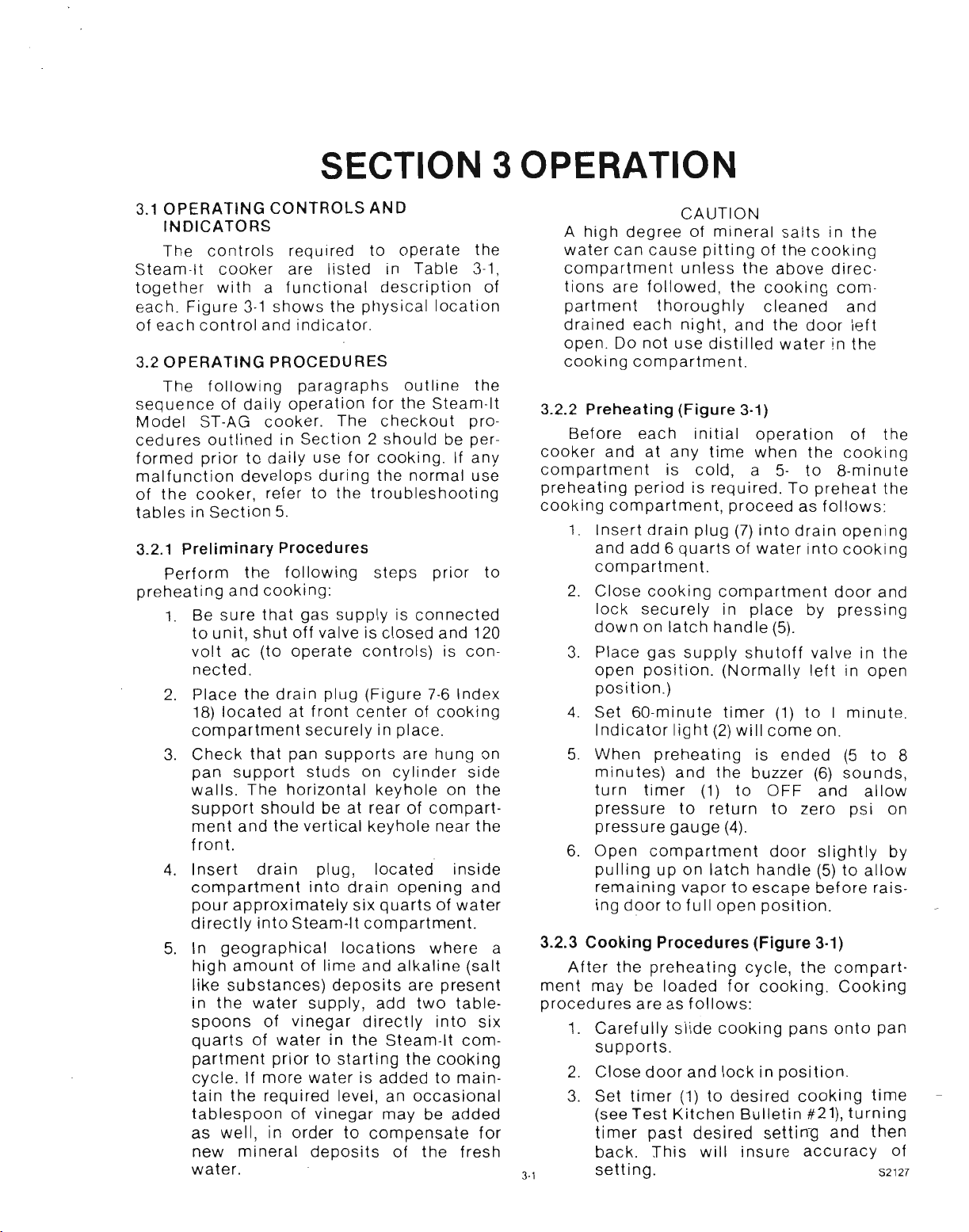

3.1

OPERATING CONTROLS AND

INDICATORS

The controls required to operate the

Steam-It cooker are listed in Table 3-1,

together with a functional description of

each. Figure 3-1 shows the physical location

of each control and indicator.

3.2

OPERATING PROCEDURES

The following paragraphs outline the

sequence of daily operation for the Steam-It

Model ST-AG cooker. The checkout procedures outlined in Section 2 should be performed prior to daily use for cooking. If any

malfunction develops during the normal use

of the cooker, refer to the troubleshooting

tables in Section 5.

3.2.1

Preliminary Procedures

Perform the following steps prior to

preheating and cooking:

1. Be sure that gas supply is connected

to unit, shut off valve is closed and 120

volt ac (to operate controls) is connected.

2. Place the drain plug (Figure 7-6 Index

18) located at front center of cooking

compartment securely in place.

3. Check that pan supports are hung on

pan support studs on cylinder side

walls. The horizontal keyhole on the

support should be at rear of compart-

ment and the vertical keyhole near the

front.

4. Insert drain plug, located inside

compartment into drain opening and

pour approximately six quarts of water

directly into Steam-It compartment.

5. In geographical locations where a

high amount of lime and alkaline (salt

like substances) deposits are present

in the water supply, add two table-

spoons of vinegar directly into six

quarts of water in the Steam-It com-

partment prior to starting the cooking

cycle. If more water is added to main-

tain the required level, an occasional

tablespoon of vinegar may be added

as well, in order to compensate for

new mineral deposits of the fresh

water.

CAUTION

A high degree of mineral salts in the

water can cause pitting of the cooking

compartment unless the above directions are followed, the cooking compartment thoroughly cleaned and

drained each night, and the door left

open. Do not use distilled water in the

cooking compartment.

3.2.2

Preheating (Figure

Before each initial operation of the

cooker and at any time when the cooking

compartment is cold, a 5- to 8-minute

preheating period is required. To preheat the

cooking compartment, proceed as follows:

1. Insert drain plug (7) into drain opening

and add 6 quarts of water into cooking

compartment.

2. Close cooking compartment door and

lock securely in place by pressing

down on latch handle (5).

3. Place gas supply shutoff valve in the

open position. (Normally left in open

position.)

4. Set 60-minute timer (1) to I minute.

Indicator light (2) will come on.

5. When preheating is ended (5 to 8

minutes) and the buzzer (6) sounds,

turn timer (1) to OFF and allow

pressure to return to zero psi on

pressure gauge (4).

6. Open compartment door slightly by

pulling up on latch handle (5) to allow

remaining vapor to escape before raising door to full open position.

3-1)

3.2.3 Cooking Procedures (Figure 3-1)

After the preheating cycle, the compartment may be loaded for cooking. Cooking

procedures are as follows:

1. Carefully slide cooking pans onto pan

supports.

2. Close door and lock in position.

3, Set timer (1) to desired cooking time

(see Test Kitchen Bulletin #21), turning

timer past desired settin-g and then

back. This will insure accuracy of

3-1

setting.

S2127

Page 9

OPERATION

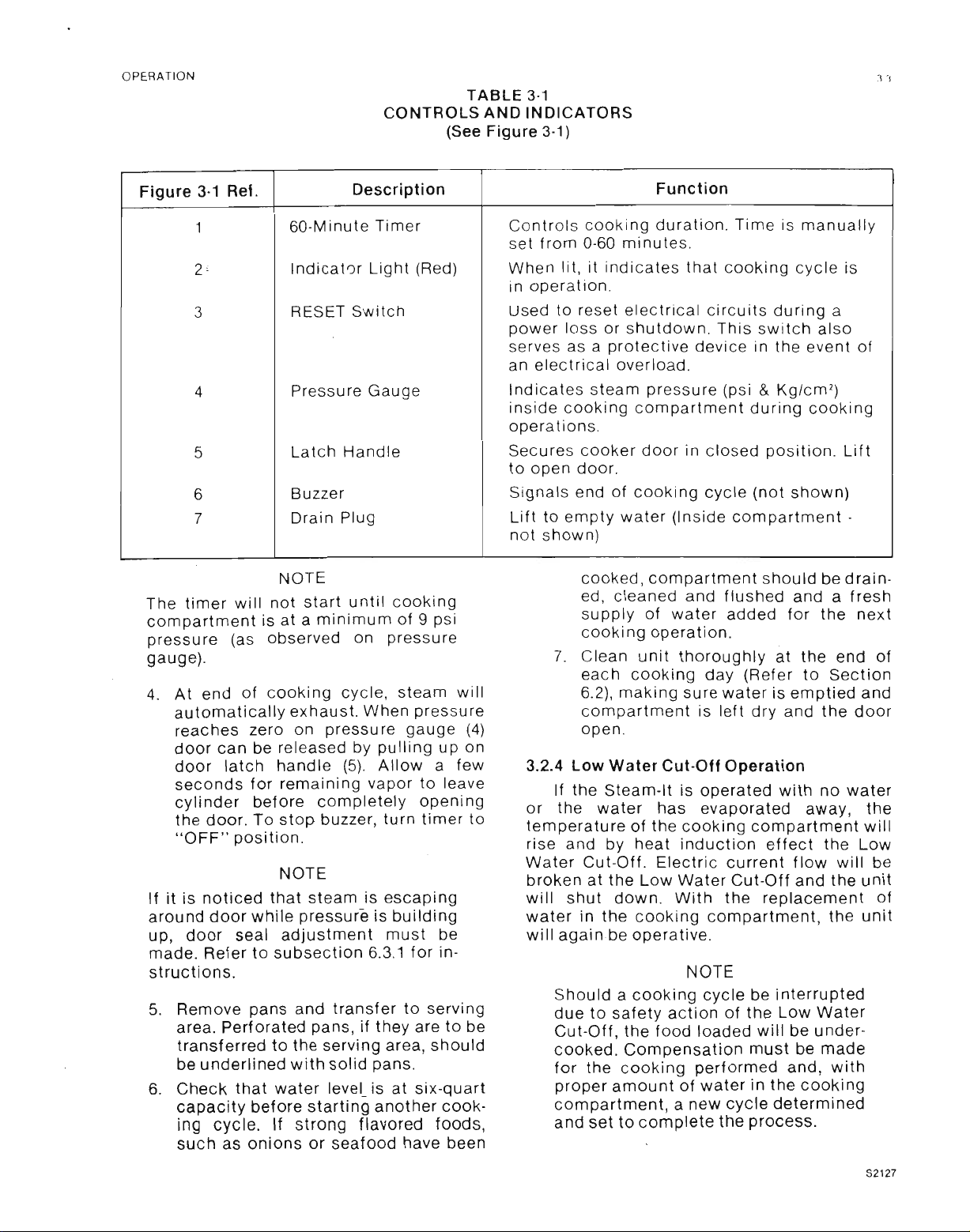

TABLE 3-1

CONTROLS AND INDICATORS

(See Figure 3-1)

Figure 3-1

1

2'

3

4

5

6

7

Ref.

60-Minute Timer

indicator Light (Red) When lit, it indicates that cooking cycle is

RESET Switch Used to reset electrical circuits during a

Pressure Gauge

Latch Handle Secures cooker door in closed position. Lift

Buzzer

Drain Plug

Description

NOTE

The timer will not start until cooking

compartment is at a minimum of 9 psi

pressure (as observed on pressure

gauge).

4. At end of cooking cycle, steam will

automatically exhaust. When pressure

reaches zero on pressure gauge (4)

door can be released by pulling up on

door latch handle (5). Allow a few

seconds for remaining vapor to leave

cylinder before completely opening

the door. To stop buzzer, turn timer to

"OFF" position.

NOTE

If it is noticed that steam is escaping

around door while pressure is building

up, door seal adjustment must be

made. Refer to subsection 6.3.1 for in-

structions.

5. Remove pans and transfer to serving

area. Perforated pans, if they are to be

transferred to the serving area, should

be underlined with solid pans.

6. Check that water leveL is at six-quart

capacity before starting another cooking cycle. If strong flavored foods,

such as onions or seafood have been

Function

Controls cooking duration. Time is manually

set from 0-60 minutes.

in operation.

power loss or shutdown. This switch also

serves as a protective device in the event of

an electrical overload.

Indicates steam pressure (psi&Kg/cm

2

)

inside cooking compartment during cooking

operations.

to open door.

Signals end of cooking cycle (not shown)

Lift to empty water (Inside compartment -

not shown)

cooked, compartment should be drain-

ed, cleaned and flushed and a fresh

supply of water added for the next

cooking operation.

7. Clean unit thoroughly at the end of

each cooking day (Refer to Section

6.2), making sure water is emptied and

compartment is left dry and the door

open.

3.2.4 Low Water Cut-Off Operation

If the Steam-It is operated with no water

or the water has evaporated away, the

temperature of the cooking compartment will

rise and by heat induction effect the Low

Water Cut-Off. Electric current flow will be

broken at the Low Water Cut-Off and the unit

will shut down. With the replacement of

water in the cooking compartment, the unit

will againbe operative.

NOTE

Should a cooking cycle be interrupted

due to safety action of the Low Water

Cut-Off, the food loaded will be undercooked. Compensation must be made

for the cooking performed and, with

proper amount of water in the cooking

compartment, a new cycle determined

and set to complete the process.

S2127

Page 10

3·4

3.2.5 shut- Down Procedure

No shut-down procedure is required for

the Stearn-It cooker except that the timer is

in the OFF position, the compartment door is

open, the compartment drained of water, and

the gas supply shutoff valve is closed (only if

required by local code).

3.3 CLEANING

After each period of daily operation (more

frequently as required to maintain

cleanliness), the Steam-It cooker should be

thoroughly cleaned by completing the following steps:

1. Drain water from compartment by

opening drain plug (Figure 3-2) into

suitable container (to hold at least 6

quarts).

ST·AG STEAM·IT COOKER

Figure 3-3. Pan Support Removal

3. Wash cooking compartment interior

using mild non-abraslve solution.

Rinse and dry thoroughly.

Figure

3-2.

Drain Plug

2.. Remove left and right side pan supports (Figure 3·3) by lifting front

up and forward to disengage from

mounting studs. Wash with detergent,

rinse, and set aside for reassembly.

52127

CAUTION

Failure to wash compartment may

result in pitting of the aluminum

surfaces. Use only mild detergent

suitable for use with aluminum.

4. Replace pan supports in compartment •

and leave door open.

3.3.1 Exhaust Silencer

The exhaust silencer (Figure 7-1, Index 51)

should be removed and cleaned periodically.

As the cooking compartment is exhausted of

steam through the silencer, impurities can

build up from food particles. Cleanings

should be frequent enough to prevent clogging. For this reason, the exhaust silencer is

made easily accessible and simple to

remove. To Clean silencer proceed as

follows:

1. Remove the one-piece exhaust

silencer from the unit by unscrewing it

in a counter-clockwise direction from

exhaust valve elbow.

2. Clean the silencer by sloshing it in hot

soapy water and rinse it in clear water.

If

dirt has clogged the silencer,

presoak it in an alkaline cleaning solution.

3. After cleaning, stand the silencer on

edge to allow it to drain.

4. Screw it back into the elbow of the

exhaust valve (clockwise).

Page 11

SECTION 4 PRINCIPLES OF OPERATION

4.1 GENERAL

The Stearn-ltcooker consists of a cooking

compartment into which pans of food are

loaded through an inward opening door. The

compartment is filled with water (for steam

generation) which is heated by gas burners

located under the cooking compartment. The

gas burners are ignited by a pilotless, direct

spark (electrode) ignition system which is

electrically controlled by the ignition control

board. Internal compartment pressure is

regulated by the exhaust system which is

mounted at the top rear of the cabinet. The

pressure may be monitored (by the operator)

by viewi ng the pressure gauge which is connected in the steam pressure line. Cooking

cycles are controlled by a 60-minute electric

timer which is mounted on the lower front

panel.

4.2 DETAILED OPERATION

With electrical power applied, gas supply

valve open and the timer set to the desired

cooking time, the electrical control circuits

are activated. The exhaust valve closes

automatically and the burner electrodes are

energized. Gas passes through the gas

regulator and valve body to the burners

where the gas is ignited by the direct spark

ignition electrodes. The gas flame on the

main burner heats the water in the cooking

compartment and within a few minutes,

steam pressure begins to build up.

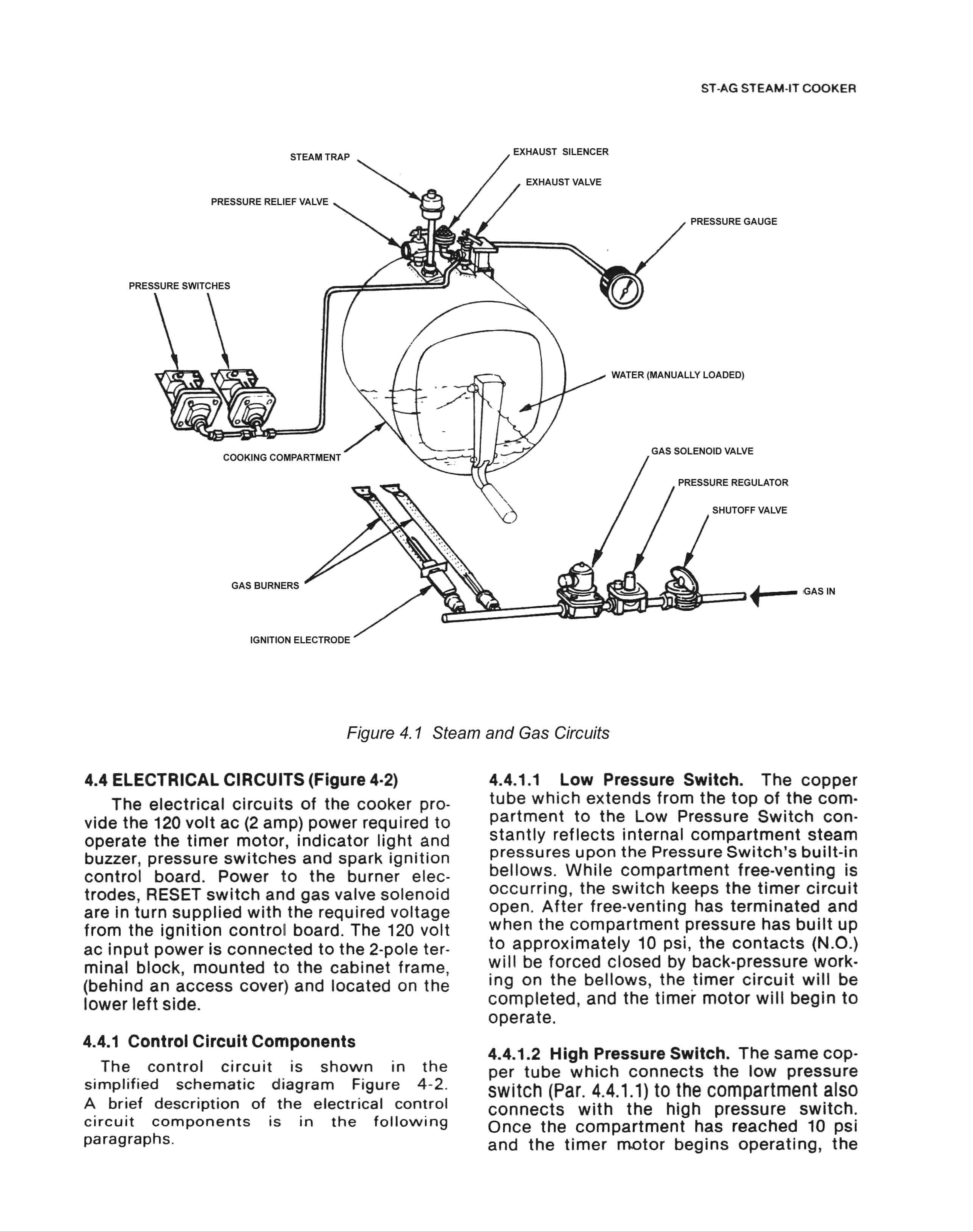

4.3 STEAM CIRCUIT (Figure 4·1)

The steam circuit consists of the steam

pressure gauge, steam trap assembly,

pressure switch, steam exhaust valve

assembly (including an exhaust valve

silencer), a 15 psi pressure relief valve and

associated steam circuit fittings. These are

shown in Figure 4·1.

4.3.1 Steam Trap

As the pressure builds up in the cooking

compartment, cold air is forced out of the

compartment through the thermostatic

steam trap located in the collar at the top

rear of the Steam·lt. The air will continue to

escape as pressure builds up and the steam

trap will close after all the air has been forced out of the cooking compartment

4.3.2 Pressure Switch

When the pressure reaches 9 to 10 psi

(the Steam-It is set to operate at 15 psi) of

pressure the contact on low pressure switch

(Close on Rise) will close, thereby closing the

circuit to the clock motor and starting the actual cooking time period. When the pressure

in the cooking compartment reaches 15 psi,

the contacts on high pressure switch will

open These contacts being wired in series

with the cycling coil of the gas valve (through

the ignition control board), will shut off gas

to the main burner when they are open, causing the pressure to stop rising.

When the cooking compartment cools

and the pressure drops to 13 psi, the contacts on the high pressure switch (Open on

Rise) will close, gas will flow to the main

burner and be reignited by the electrodes.

Any number of such "OFF" and "ON" cycles

might occur during the selected cooking

time.

4.3.3 Steam Pressure Gauge and Safety

Relief Valve

Located at the top rear of the Steam-It

and mounted into the forward face of the flue

for visibility, the Steam Gauge registers the

pressu re within the Steam-It cooking

compartment.

The Safety Valve is set to automatically

relieve the cooking compartment of ex·

cessive pressure buildups by opening at a

point between 151/2 psi and 16 psi.

4.3.4 Steam Exhaust Valve and Silencer

The steam exhaust valve is located in the

collar at the top rear of the Steam-lt and it

lets the pressure escape from the cornpartment when the timer is shut off. When the

timer is turned on this valve is closed permitting the pressure to build up.

To overcome objectionable noises, the

exhaust valve is equipped with an exhaust

silencer which will permit the exhaust valve _

to release steam at the end of the cooking

cv-

cle without any objectionable noises.

4·1

S2127

Page 12

Page 13

PRINCIPLES OF OPERATION

4-3

120V.60Hl

INPUT

LOW WATER

CUTOFF SWITCH

NC

TIMER

INDICATOR

LIGHT

EXHAUST

VALVE

NO

r-----,

I I

I

I

I

COIL

L

-----

J

I

IGNITION

ELECTRODE

I

I

I

I

I

I

I

L _

LOW PRESSURE

SWITCH NO

r-------,

I

I

I

I

I I

L

r------------,

I

I

I

I

J

MOTOR

____ ...J

4

I

I

I

I

I

I

I

I

HIGH PRESSURE

SWITCH NC

r------l

I I

I I

I I

I I

I

I I

L_ J

BUZZER

I

~ ~ I

,-----,

I

I

I ~~--~--.

I

COIL I SPARK IGNITION CONTROL

L .J

GAS SOLENOID VALVE NC

NOTE: ALL CONTROLS SHOWN IN THE OPERATING POSITION_

Figure

4-2.

:

I:

I

I L ~

Pictoral Diagram, Electric Circuits,

~~

~I--_

RESETNe

I _

I

120V

52127

Page 14

44

pressure will continue to rise until the con-

tacts of the high pressure switch (N.C.) are

forced open (at approx 13 psi) by pressure

working on the bellows. When contacts are

opened the gas solenoid valve is closed by

the ignition control board. As the cornpartment cools the pressure drops until the con-

tacts return to the closed position, activating

the spark ignition control board in the firing

sequence.

4.4.1.3 60·Minute Timer. The timer contains

a 120 volt ac synchronous motor which drives

a timing dial through a gear reduction and

clutch mechanism. The timer dial is manually

set for any interval of operation from O· to

minutes as read on the calibrated dial face.

The manual rotation of the dial moves the

common element (1) of the timer switch from

the neutral position to contact (3) which connects with pressure controls and gas firing

system. The Steam-It is put into an automatic

cycle of cooking with the setting of the Timer

to any of its calibrated periods of cooking. Its

timing cycle, however, is automatically

delayed by the Low Pressure Switch until

free-ventinp has occurred and a cornpartment pressure buildup to 10 psi has been

reached. When the timer motor has operated

for the preset duration, the common element

is transferred to contact (4), ending gas firing

cycle, returning exhaust valve to open position and energizing the buzzer. Contact to the

buzzer circuit remains closed until the dial is

manually turned to the OFF position, returning the common element (1) of the timer

switch to the neutral position.

4.4.1.4

which operates by oscillation of a striker

against the core of an electromagnet. When

the timer dial reaches "O-minutes" the buzzer

coil is energized to sound the buzzer. Move-

ment of the timer dial to the OFF position

opens the contact to the buzzer coil to shut it

off.

Buzzer. The buzzer is an alarm device

60·

ST·AG STEAM·IT COOKER

4.4.1.5 Indicator light. The Indicator Light is

located at the lower right front of the front

panel adjacent to the timer knob. It is

to operate only when the timer is set to

cooking cycle. The circuit will be broken

when the timer returns to the "ZERO" posttion. Thus, when lit, it signifies that the

Steam-It is in the process of cooking.

4.4.1.6 RESET Switch. The RESET switch is

located on the left side of the lower front

panel. The switch is used to reset the

trical circuits of the ignition control board in

the event of an ignition failure

4.4.1.7 Direct Spark Ignition System. The

direct spark ignition system consists of the

electrodes, ignition control board and

associated wiring. On a call for heat, input

power is applied to the control board,

sparking is then initiated and the gas valve

is energized. Sparking continues with the

gas valve powered for a "trial for ignition"

period of 3.3 seconds. If flame has not been

established by the end of the trial

the system will lock out, the gas valve will

close, and the reset function will then trip

out. Reset action is manually accomplish.

by pressing RESET switch. In normal oper ,

tion, as soon as flame is established and

proven by the flame sensing circuitry,

sparking will cease immediately and the

system will remain "on", monitoring the

flame until the end of the duty cycle.

Should flame-out occur during the duty

cle, the system will reactivate the spark to

provide for reignition.

The flame will either be reestablished or

the system will lock out in the normal manner. Should lock out occur, the system is

reactivated with the RESET switch for

recycling. Control for operation of the

solenoid gas valve, gas pressure switch and

RESET switch is provided from the circuits

contained on the ignition control board.

wirr

etec-

period,

cv-

S2127

Page 15

SECTION 5 TROUBLE-SHOOTING

5.1

GENERAL

The information cin this section is in-

tended to assist both the operator and service personnel in locating the general source

of problems which

Steam-It cooker. Before following any of the

procedures given in this section, the operator

should be thoroughly familiar with the

operating instructions and the function of all

controls which are described in Section 3. If

the problem cannot be readily corrected, the

operator should contact the nearest authorized Market Forge service agency for

assistance.

may

occur with the

TABLE 5-1

OPERATOR'S TROUBLE-SHOOTING GUIDE

5.2

TROUBLE-SHOOTING GUIDES

An operator's trouble-shooting guide for

use by the Steam-It operator is given in Table

5-1. Table 5-2 gives additional, more extensive information for use by service personnel.

5.3

ELECTRICAL FAULT ISOLATION

Correction of an electrical failure first

requires isolation of the fault to a single circuit or component. In most cases the

nature of the failure and its effect upon the

operation of the Steam-It will be sufficient

to isolate it to one or more circuit elements.

Table 5-3 is provided as a guide for

isolating electrical faults.

PROBLEM

Probable

INDICATOR LIGHT FAILS TO LIGHT.

1.

Cause

a. Power to Steam-It off.

b.60-Minute timer not set.

c. RESET switch not pressed.

GAS BURNERS FAIL TO IGNITE

2.

a. External gas supply shutott

-

closed.

STEAM FAILS TO BUILD UP IN COMPARTMENT

3.

a. Compartment does not latch

securely.

b. Low water in compartment.

Remedy

Locate external circuit breaker for

incoming power and place in ON

position.

Set 60-Minute timer.

Due to power interruption. The RESET

switch must be pressed to reset control

functions of control board.

Open gas supply shutoff valve.

Close door and engage handle in latch.

Add water, as required, to bring up to 6

quarts.

5-1

52127

Page 16

5-2

ST-AG STEAM-IT COOKER

TABLE 5-2

GENERAL TROUBLESHOOTING GUIDE

CONDITION

1) INDICATOR LIGHT FAILS TO LIGHT WITH TIMER SET

a) Power to STAG off

b) Indicator light burned out

c) Faulty wiring

d) Timer contacts faulty Replace Timer

e) Unit will not stay on Reverse Polarity (reverse black

2) GAS BURNERS FAIL TO IGNITE

a) Extemal gas supply

b) Gas solenoid valve fails in closed position Clean or replace valve

c) Faulty ignition control board

d) Electrode unit malfunctioning Clean carbon off electrode or replace

e) Damaged or loose wiring

f) Gas pressure not per specification

(Water Column 3

3) STEAM FAILS TO BUILD UP IN COMPARTMENT

a) Compartment door not latched securely Close door and engage handle in latch. If steam

1/2"

Nat, 10" L.P.)

I

Make sure external circuit breaker for incoming

power is in ON position

Replace light

Inspect condition of wiring and tightness of all

connections

Open gas supply shut-off valve

Replace ignition control board

Trace all wiring from control board to controls.

Check to see that all wiring is secure, and that

high and low voltage leads to electrode are

properly connected

Adjust or replace pressure regulator

fails to build up after door is secured, the problem

may be that the door seal requires adjustment or

replacement

IIUN

&

white wire)

PIN

N/A

10-6683

N/A

10-6291

N/A

N/A

10-7694

10-7696

10-7697

N/A

09-7018 NAT.

09-7019 L.P.

10-2666

b) Steam trap not sealing properly Clean steam trap wI hot soapy water or replace

c) Gas burners not igniting Refer to Problem

d) Safety valve fails to close

e) Safety valve opens intermittently

4) EXCESSIVE STEAM PRESSURE IN COMPARTMENT (ABOVE 15 LBS.)

a) Safety valve fails in closed position

b) Pressure switch setting too high

5) BUZZER FAILS TO SOUND AT END OF COOKING CYCLE

a) Faulty wiring

b) Faulty buzzer Replace buzzer

c) Faulty timer Replace timer

52127

Replace safety valve

Open and close valve to clear blockage

Replace safety valve

Adjust or replace pressure switch

Check wiring from buzzer to terminal block and

timer

#

2 N/A

10-6156

10-7955

10-7955

95-3720

10-6682

10-6291

-

N/A

N/A

Page 17

TROUBLESHOOTING

-·-----·

Failure

1. Wili not operate when GO-Minute

,

f

urner'Sset

I

i

~

...

2. Intermittent operation

3. Exhaust valve fails to close

.

.

,

--

-

TABLE 5-3

ELECTRICAL FAULT ISOLATION GUIDE

Fault Location

--------_._--

a lncorninq power

Faulty timer

D.

c Wiring

(J.

Ignition system control board

e.

Low

water cutot

3.

Damaged

to paragraph 5.43

-

Exhaust solenoid valve coil

d.

Wiring

b

c. Faulty timer

control

t

system

-··-1

-l

Refer

4. Indicator light off (system operating)

5. Buzzer fails to sound at end of cycle

6. Will not stop operating

7. System fails to operate upon

pressing RESET switch.

5.4 ELECTRICAL TROUBLE-SHOOTING

PROCEDURES

Before performing the trouble-shooting

procedures in this section the serviceman

must be familiar with the function of all

controls as described in Section 3 and with

the Principles of Operation described in

Section 4.

Electrical trouble-shooting procedures

which follow require access to components

and terminals of the operating controls and

ignition control board. Electrical controls

are reached by removing the lower front

panel as described in paragraph 6.3.2. Wiring and terminal locations are shown in

Figure 5-1. Figure 5-2 shows the circuit

schematically.

a. Indicator light

Wiring

b.

a. GO-Minute timer contacts

b. Buzzer

c. Wiring

a. 60-Minute timer motor

a. RESET switch

Wiring

b.

c. Ignition control board

5.4_1

Incoming Power

Before trouble-shooting any of the electrical parts or assemblies, verify that power

is being supplied to the Steam-It input

power terminals. Incoming power is connected at the terminal block (Figure 7-1,

items 15, 16). With power connected to the

Steam-It, an ac volt-meter is used to

measure 120 volts across terminals to lines

coded L1 (hot lead to wire number 5) and L2

(neutral lead to wire number 4). If power is

not present, the connection to the Steam-It

is faulty. If 120 volts is present, and the

cooker will not operate, the fault lies within

the electrical circuits of the Steam-It.

S2127

Page 18

5·4

HOT LEG IL 1) OF

LINE SIDE MUST BE

CONNECTED TO LE

NO 5

AD

IMPORTANT

CHASSIS MUST

BE GROUNDED

TERM

BOX

GRD

L2

r--

'--

1

,II

LlIHOT)

LINE

~

~

~

'--

'--- GAS VALVE

4

5

SPARK IGNITION

CONTROL BOARD

12

6

7

10-

SOLENOID

NC

1

B El

A

V2

•

L2

'--

RESET

SWITCH

ST-AG STEAM-IT COOKER

HV

r-

(

LV!

ELECTRODE

•......

",C

1-1

I--

t--

t>--

t--

22

2d

x

20

191

}SEE NOTE 2

I EXHAUST

VALVE NO

ILOWWATER

CUT·OF F

E2

(,:f[yj

PRESSURE

SWITCHES

c!:!J

BUZZER

NOTES:

1. ALL WIRING NO. 16 AWG. 26 STRAND GE CLR 125X·

LINK. 600V (WHITE) EXCEPT AS NOTED. UL AND

CSA APPROVED

2. SRG·5600 NO. 167/0.0192. 600V·200 C IRED)

(CONTINENTAL). UL AND CSA APPROVED

FigureS-1. Wiring Diagram, Steam-It, 120V,60Hz

r--:

'"

-~

N

N

'"

0

N

;:;,

INDICATOR

LIGHT

~

)24

TERM

BLOCK

5

16

2

11

4

1"

17

16

1

14 •••

~4 3.

11

c::

TIMER

~ 13

3

-

M

~

S2127

Page 19

TROUBLE-SHOOTING

5-5

Ll

TIMER

SWI TCH

...--

"'-4~-..J"'-""''''-- I (OFF) POSITION ON DIAL

LOW WATER I 31TIMER SET

CUTOFF

r-

o

I

RESET

(CIRCUIT ~

BREAKER) ~

L__J

r-------------..a

-,

4 : (0) POSITION ON DIAL

PRESSURE

SWITCH NC

SPARK IGNITION

PR ESSU RECONTROL BOAR D

SWITCH NC ,-- ---,

4~ ...•

~_~1

.A

I:

I -

INDICATOR

LIGHT

EXHAUST

VALVE

III

L- ~~

TIMER

MOTOR

L2.~I~--------~

B•••

I

T

-----.

L2

--.J

<t:

a:

r-

z

r---L V__ ~ J-Efl _ V2

ELECTRODE : HV _

'-------- L

Figure 5-2 SchemaUc Diagram Steamtt. 120V

5.4.2 Electrical Inspection

The first step in any electrical trouble-

shooting procedure is a thorough physical

inspection of all wiring connections. To access electrical components remove the

lower front panel (Figure 7-1, 11), -and the

chassis assembly (Figure 7-3) as explained

in paragraph 6.3.4.

WARNING

Before removing panels or checking

connections and wiring be sure that

the main circuit breaker for incoming

power to the

power is supplied all exposed terminals of the control panel

volts.

Stearn-lt

is OFF. When

carrv

tzn

..J

SOLENOID

GAS VALVE

Check all wiring connections by hand to

assure that both ends of all connection

points are tightly secured. Use a screwdriver

to tighten connection points if necessary.

Visually inspect all quick-disconnect ter-

minals for evidence of corrosion. Terminals

in this condition should be separated, cleaned with sandpaper until shiny and tightly

reconnected. If excessive corrosion is

ed, the terminals must be replaced. Check all

wiring for signs of cracked insulation.

Replace any damaged wiring.

5.4.3 Direct Spark Ignition Control System

The ignition control board and associated

components are the main electrical control

for operation of the Steam-It cooker. If it is

determined that the electrical controls

torrn-

52127

Page 20

5-6

(solenoid valve, RESET switch, electrode,

etc.) are not damaged and the interconnecting wiring is complete and not damaged, the

trouble is due to a malfunction of the cornponents on the ignition control board. Cornponents on the control board are not

replaceable and a damaged control board

must be replaced with a functional unit. The

following paragraphs outline possible problems and symptoms that may be encountered during the normal use of the

Stearn-lt.

CAUTION

If a control board is replaced, be sure

that the high voltage lead of the

etectrode is connected to terminal E1 and

the low voltage lead is connected to

terminal E2 of the control board.

5.4.3.1

Improper Polarity. If a spark is present

and the gas valve opens, but the system

shuts down after the trial period, check the

120 volt ac input voltage at terminals A (L1),

and L2 of the control board, for proper polarity. Terminal A should be the hot side of the

line and L2 neutral.

5.4.3.2

Damaged Grounding. If a spark is present and gas valve opens, but the system

shuts down after the trial period, check to

make sure the system is properly grounded

to the burner and that the burner is properly

grounded. Proper grounding is essential for

the proof of flame safety device. If the

system is not grounded to the burner, it can·

not determine the presence of flame and will

lock out. A restart will initiate the trial for ig·

nition period, but the system will continue to

go into "lock out" if it is not properly ground·

ed, and the thermal reset timer will trip. Wait

one minute before pushing the RESET button

in. Check all power and ground terminals to

make sure good contact is made. Clean any

corrosion that might interfere with good elec·

trical contact.

5.4.3.3

Malfunction Due to High Voltage.

During the trial for ignition, if the spark is intermittent and the valve may (or may not)

open, check the spark gap on the electrodes

and system wiring as follows:

1. Remove the electrode from burner and

check to see that the gap is 1/8 inch

±

1/32 inch. If it is not, replace elec·

trode.

2. Visually check the ceramic housing

and lead wires for cracks or breaks.

52127

ST·AG STEAM·IT COOKER

3. Check terminals E1 and E2 for

inadvertent grounding. They should be

no closer than

1/2

inch from metal objects, which can cause arcing to

ground.

If

the electrode or electrode

lead wires are faulty, replace with new

electrode and wiring.

5.4.3.4

Malfunction of Gas Valve. If the board

is receiving proper power and there is a spark

during the trial for ignition period, but the

valve will not open, check the valve for an

open coil or other malfunction. Be sure

voltage rating of the valve is 120 volts ac. Use

a voltage tester or volt-meter at terminals B

and V2 of the ignition control board. The

voltage shou Id be the same as the valve.

5.4.3.5

Erratic Operation. If the system

operates properly for a while but randomly

shuts down during the duty cycle, or won't

operate during "cold" starts, check the flame

proving circuit with a dc microamp meter.

Refer to Figure 5-3 and proceed as follows:

1. Locate ignition control board, Figure

7·3, Item 5.

2. Remove low voltage wire from

terminal E2 and connect one lead of

microamp meter to push-on connector

attached to lead wire.

3. Connect second lead of meter to

terminal E2 on ignition control board.

4. Energize control board and read

current on microamp meter. Typical

flame current is 2 to 20 microamperes.

=

o

TO

SO

MICROAMP

METER'

51

ELECT RODE

Figure

5-3.

Placement of Flame Current Meter

Page 21

TROUBLE·SHOOTING

If you have low or marginal flame current,

it is tripping the thermal reset switch. If this

is the case, you should relocate the electrodes or flame sensor into the flame to increase the flame current. If the ignitor is switched off and on several times in succession,

the thermal reset switch will trip, and it will

have to be reset. If ignition is not achieved

after the first two or three attempts, check to

insure that the other components in the

system are functioning correctly.

5.4.4 GO·Minute Timer

5.4.4.1 Timer Contacts. Defective timer contacts will result in failure of the Steam-It to

operate properly. If the cooker fails to

operate when timer is set to desired time the

fau It is with the 60·m inu te ti mer contacts or

its wiring. When this occurs, remove the control panel (paragraph 6.3.2), and proceed as

follows:

1. Turn off power to the Stearn-lt at

external (main) circuit breaker.

2. Disconnect all wires (13,14 and 16)

from timer terminals. (See Figure 5·1.)

3. Connect an ohmmeter between

terminal 1 and terminal 3 of timer.

4. Rotate timer dial beyond the

O·MINUTE point (any setting) to obtain

a reading of zero ohms on the ohmmeter. If zero reading cannot be obtained, timer contacts are defective

and the timer must be replaced.

5. Move ohmmeter leads to terminals 1

and 4.

6. Rotate timer dial to a-MINUTE

position. (An audible click indicates

correct position.) If zero ohm reading

cannot be obtained, the timer is defective and must be replaced.

7. Remove ohmmeter and replace all

leads on timer terminals as shown in

Figure 5-1.

5.4.4.2 Timer Motor. A defective timer motor

will cause continuous operation with the

timer dial failing to return to the a-MINUTE

position. If the timer motor fails to turn pro-

ceed as follows:

1. Turn off power and carefully check

motor wire leads and tighten connections if found loose.

5·7

WARNING

Use care while working with control

wiring. Terminals carry 120 volts.

2. Turn on power to the Steam-It.

3. Set 60-minute timer dial (any setting

beyond "a-minute"). If operation is

correct the motor will turn the dial dart

through an arc toward "a-minute". If

the motor fails to operate, it is defective and the entire timer must be

replaced.

4. Shut off power to the Steam-It.

5.4.5 Solenoid Gas Valve

When the solenoid gas valve fails to

operate, the fault may be a defective valve or

control board. An ac volt-meter is used to

check the voltage at the coil wire terminals

with the Steam-It operating. If voltage of 120

volts IS present the valve is defective and

must be replaced as a unit. If 120 volts is not

pres~nt ~nd all wiring connections are tight,

the Ignition control board is defective and

must be replaced.

5.4.6 Buzzer

If the buzzer does not sound at the ter-

mination of cooking time (timer dial returned

to "a-minute" position), the fault may be a

defective buzzer. Buzzer operation is verified

using an ac volt-meter at buzzer coil connec-

tions (permanently SOldered), with input

power on, and the 60-minute timer dial at the

"O-minute" position. If voltage is 120 volts,

the fault is in the buzzer which must be

replaced. If 120 volts is not present, the fault

is in the wiring.

5.4.7 Indicator Light

If the Steam-It functions correctly with

the single exception that the indicator light

falls to light during operation, the fault is a

defective indicator light or wiring. A "burned-

out" or defective light is verified by using an

ac volt-meter at the leads on terminal block

with input power on, and the 60·minute timer

dial set (any setting beyond "a-minute"). If

120 volts is present the fault is in the in-

dicator light and requires replacement. If 120

volts is not present the fault is in the wiring.

52127

Page 22

5-8

5.4.8

Wiring

All of the electrical components of the

Steam-It (60-minute timer, pressure switches,

gas solenoid valve, RESET switch, exhaust

valve, low water cutoff switch and ignition

control board, buzzer and indicator light) are

connected to each other by wiring shown in

Figure 5-1. If all of the electrical components

are operating correctly (and the incoming

power has been checked), but the cooker

fails to operate the fault lies in the wiring.

Figure 5-1 is a wiring diagram which

shows all terminals and interconnections

within the electrical circuits. All numbered

terminals are identified and all leads number

TROUBLE-SHOOTING

coded as shown. Connections can be easily

removed. Figure 5-2 shows the same information schematically and is an aid in isolating

circuits for testing.

Using an ohmmeter, wiring continuity

between the connections shown on the wiring diagram (Figure 5-1) are readily verified.

This is best done in stages, removing only

those wires required for each continuity

check. As each lead is replaced it should be

checked for evidence of corrosion and cleaned if necessary. All leads must be tightly attached so as to provide a good electrical connection.

52127

Page 23

SECTION 6 MAINTENANCE

6.1

GENERAL

This section contains both preventive and

corrective maintenance information. Preventive maintenance may be performed by

maintenance personnel at the establishment

in which the cooker is installed. It is recommended that user personnel never attempt to

make repairs or replacements to the equipment without the assistance of authorized

service. Assistance in service methods or a

current Director of Authorized Service Agen·

cies may be obtained from Market Forge.

(See paragraph

6.2

PREVENTIVE MAINTENANCE

A good preventive maintenance program

begins with the daily cleaning procedure

described in paragraph 3.3 in Section 3. Additional preventive maintenance operations are

presented in this section. In establishments

which employ full-time maintenance person-

nel, the tasks described can be assigned to

them. For other installations, tasks requiring

mechanical or electrical experience should

be performed by an authorized service

agency.

The following paragraphs set forth

minimum preventive maintenance pro-

cedures which must be completed

periodically to assure continued trouble-tree

operation of the Steam-It cooker.

1.3

in Section 1).

1. With cooking compartment door open,

lift pan supports up and forward to

disengage from mounting studs.

Remove from compartment as shown

in Figure 3-3.

2. Disengage left and right ends of door

seal spring by counter-acting the force

of the door lift spring with one hand

while disengaging studs with the

other hand (Figure 6·1).

DOOR SEAL

SPRING

PAN SUPPORT

CAUTION

Under no circumstances shall hardware (or parts) be replaced with a different length, size or type other than

specified in the parts list. The hardware used in THE STEAM-IT COOKER

has been selected or designed

specifically for their applications and

the use of hardware other than those

specified may damage the equipment

and will void any warranty.

6.2.1 Disassembly and Cleaning

The door assembly must be removed from

the cooker compartment for weekly cleaning.

Though no tools are needed, care in follow-

ing procedure is necessary to insure that the

door will pass through the compartment

opening.

Figure 6-1 Door Spring Disengagement

3. Push door lift springs to the rear and

off studs.

4. Rotate the door assembly out through

the door opening, door handle first, as

shown in Figure 6-2.

5. Inspect door gasket for cleanliness

and wear. If food soil has become

lodged behind the gasket or the

gasket is torn, push it off perimeter of

door and clean with mild detergentwater solution, or replace as needed

(Figure 6-3). A gasket which is stuck to

the door is easily removed by first

soaking the entire door in hot soapy

water.

6·1

52127

Page 24

6·2

ST-AG STEAM-IT COOKER

Figure 6-2. Door Removal

NOTE

To assure a pressure seal, the gasket

must be cleaned of soil and scale, and

be free of breaks.

6. Replace gasket on door and

reassemble door assembly in compartment. Open and close door

several times to check for correct

operation and tight seal of door in

closed position. See paragraph 6.3.1.2

to adjust door seal tension.

6.2.2 Safety Valve Check

The safety valve is a protective device

which automatically relieves excessive

pressure between

unlikely event of equipment malfunction. If

the safety valve should leak continually with

a pressure build-up, or should it cause an interruption of the cooking cycle prematurely

(less than

15-1/2

must be assumed that the safety valve is

defective and be replaced. However, the

steam gauge should first be checked for accuracy before making this determination.

The steam gauge should register zero with no

pressure in the cooking compartment. If the

normal zero setting has advanced somewhat

through usage (a characteristic of steam

gauges), the steam gauge should be replac-

ed.

6.2.3 Door Fulcrum and Drain Cleaning and

Lubrication

The door fulcrum and drain assemblies,

located under the door opening, include the

door latch anchor, drain components and the

15-1/2

and 16 psi, in the

psi on the steam gauge), it

Figure

6-3.

Gasket Removal

fulcrum adjustment screw. These parts are

shown in Figure 7-6.

Periodic unscheduled cleaning of the

drain and plug assembly with detergentwater solution will ensure trouble-free opera-

tion. The drain plug handle and drain hole

must be free of food particles, with motion

easy and unrestricted.

The anchor is equipped with a bronze

roller bearing (11) which engages the hooked

door latch. The entire roller assembly is

shown as item (13) in Figure 7-6. The roller

must be cleaned periodically to insure free-

moving operation. Should accumulated dirt

or food interrupt normal rolling, detergentwater solution should be used to free it.

Cleaning should be followed by lubrication

using graphite or other dry lubricant.

6.2.4 Cooking Compartment

A

daily cleaning of the cooking compartment is required. Remove pan supports and

thoroughly wash and rinse cooker compartment interior with mild soap or aluminum

cleaner. Leave door open when cooker is not

in use. See paragraph 3.3 in Section 3.

CAUTION

Do not use strong detergent or

abrasive cleaners. Pitting of aluminum

interior will result.

6_2.5 General Inspection

Prior to daily use the operator should

visually inspect the unit to see that there is

no missing or detective hardware, cracked

glass on pressure gauge, cracked timer knob,

and that pan supports are properly installed.

52127

Page 25

MAINTENANCE

During operation the operator should

observe that the timer is indicating proper

cooking time, pressure gauge is reading correctly and steam trap and exhaust valve are

operating properly The first indication of

defective steam trap operation will usually be

evidenced by uneven cooking. If working pro-

perly, the steam temperature will be even and

cooking will be uniform through the cooking

compartment. Trouble may occur either

through premature closing of the steam trap

before all the cold air has been exhausted or

by its failure to close sufficiently to enable a

proper steam pressure build-up. Either case

warrar.ts the replacement of the steam trap.

6.3 REPAIR AND REPLACEMENT

NOTE

The critical function of the door seal

makes it imperative that the gasket be

in good condition. For this reason it is

recommended that at least one spare

gasket be kept at all times.

6.3.1.2 Door Seal Tension Adju~tment. An

adjustment screw is built into the door anchor and fulcrum assembly to allow compensation for normal variation in gasket

thickness caused by wear. The adjustment

screw is shown in Figure

6-4.

If steam

escapes from around the door, sealing tension against the door opening can be increased by loosening the

1/4-20

jam nut and

6·3

WARNING

Be sure to disconnect

120

volt input

power and shut off gas supply before

disassembling components and making repairs and replacements.

Section 7 of this manual contains a listing

of all replaceable parts and associated ex-

ploded views of the Steam-It. In most cases

disassembly procedures will be obvious from

the exploded views. Illustrated disassembly

and assembly instructions follow for procedures which are not readily apparent.

NOTE

Complete disassembly of cabinet and

panels are not required. Remove only

the panels or components required to

make repairs and replacements.

6.3.1 Door Assembly

The door assembly consists of the door

latch and the latch fulcrum assembly. All

parts are replaceable as shown in Figure 7-4,

Door Assembly; Figure 7-5, Door Latch; and

Figure 7-6, Door Fulcrum and Drain.

6.3.1.1 Gasket Replacement. The door

gasket (Figure 7-4 index 6) is readily replaced

by first removing the door assembly from the

cooking compartment as explained in

paragraph

6.2.1.

The worn gasket is removed

in the same manner as described for cleaning and a replacement substituted. A new

gasket which is difficult to stretch onto the

door can be made pliable by first soaking it in

hot soapy water. Remounting the door in the

compartment completes the replacement.

Adjustment

Jam

Nil!

" /screw

! ) .'

~~:I- . ....

.)'

~

,

_"" ;.1 /

~

To Trqhten

Door Se~J

To Loosen /

Door S"al

Figure

6-4.

Door Seal Tension Admustment

turning the socket head adjustment screw

counterclockwise with an allen wrench. Installation of a replacement door gasket may

result in excessive door latching tension and

require clockwise adjustment of the screw.

Trial and error will achieve the screw adjust-

ment which both seals the door against the

compartment opening yet allows door lat-

ching with only moderate force applied to the

handle. The final position is set by holding

the cap screw with an allen wrench while

tightening the

1/4-20

6.3.1.3 Door Lift Spring Replacement.

Should either spring become damaged, it is

necessary to replace both left and right

springs as a set (Figure 7-4). The door

assembly is removed from the cooking com-

.

/

jam nut.

/

./

/

52127

Page 26

6·4

partment as explained in paragraph 6.2.1.

Springs are installed by removing spring

bearings (2), screws (1), and worn springs (3

and 4) and mounting replacements. Springs

are marked with tabs indicating the left and

right side replacement springs for installation on the appropriate side as viewed from

the front of the compartment.

6.3.2

Exterior Panel Removal

Access to all internal pJumbing

assemblies is from the top and front of the

Steam-It cabinet. Whenevec internal repairs

or replacements are required, the applicable

panels must first be removed. These parts

are shown in Figure 7-1. The following procedure is required for removal of exterior

panels.

1. Raise the cooking compartment door.

2. Remove screws (7) in lower front panel

(11) and timer knob (Figure 7-3,23).

3. Slide lower front panel (11) down from

cylinder and lift off.

4. To gain access to terminal block (for

primary power), remove screws (1)

securing terminal box cover (13) to

side panel.

5.

To gain access to the gas pressure

regulator, remove screws (28) securing

access cover (29) to side panel.

6.3.3

Steam Exhaust Valve and Trap Replace·

ment

The components of the steam exhaust

valve assembly, trap, safety valve, silencer,

pressure guage and associated plumbing

and hardware are replaced by first removing

flue assembly (Figure 7-1, index 32) and

pressure gauge (33). To remove flue

assembly proceed as follows:

1. Unscrew and remove exhaust silencer

(Figure 7-1 index 51).

2. Detach the

3/16"

copper tube

connector from the pressure gauge at

the ferrule nearest the pressure

gauge. Then, remove the copper tube

entirely by freeing it at the other ferrule.

3. Apply inward pressure at either side of

the flue with a screwdriver. This will

collapse the side walls slightly to

allow the small fluted sections of

sheet metal to clear the edges of the

ST-AG STEAM·IT COOKER

flue opening provided in the outer

shell of the Steam-It. With the restrictions of the flutes removed, the flue

may then be lifted up over the components.

4. Replacement of safety valve, trap

plumbing and exhaust valve assembly

(as required) may now be made. The

. components of the steam exhaust

valve assembly are shown in Figure

7-2.

6.3.4

Direct Spark Ignition System

The ignition system components may be

replaced by removing the burner chassis

assembly (Figure 7-3). To remove complete

burner chassis assembly proceed as follows:

WARNING

Be sure that electrical power and gas

supply are shut off before removing

burner chassis.

1. Complete exterior panel removal. (See

paragraph 6.3.2)

2. Disconnect the lead wires NO.4 and 5

in the terminal box on left side of the

Steam-It. (See Figure 5-1) These wires

must follow the chassis as it is pulled

forward.

3. Disconnect the gas connection at the

right side (or bottom). The piping must

be unscrewed from the gas elbow inside.

4. Disconnect the steam pressure line

from pressure switch assembly

(Figure 7-3, index 17).

5. Disconnect red low-water cut-off wires

19 and 20 and exhaust valve wires 21

and 22 from the terminal block.

6. Remove centering screw, nut and

washer from front center bottom of

chassis. The chassis assembly may

now be pulled forward and completely

removed from the Steam-It.

6.3.4.1

Gas Burners. The gas burners may be

removed by first disconnecting wires to electrode (Figure 7-3, index 30). Remove stud,

receiver (55) and carefully lift the back end of

burners (32) until clear of holding pins in bracket

then pull backwards. To replace burners, slide

the front end over orifice holder then drop the

back end into position and replace receiver (55).

Reconnect wires to the electrode (See Fig.5-1 ).

S2127

Page 27

MAINTENANCE

6.3.4.2 Ignition Control Board. (See Figure

7·3.) To remove ignition control board (5),

first disconnect wires at electrode (30), reset

switch (20), gas valve (42), pressure switch

assembly (17)and terminal strip (27). Remove

screws (1) nuts (2) lockwashers (3) and

spacers

(4)

and remove control board

(5).

NOTE

Ignition control board components are

not replaceable. A damaged board

must be replaced with a new

assembly.

In addition, regulator (39) must be set to proper setting of4,0" W.C. for natural and

manufactured gas and 10"

w.e.

for propane

and butane gases. (Regulator is set at 4"

W.C. pressure at the factory and must be

changed to 10" W.C. pressure as required.)

Regulator is adjusted by removing slotted

cap and positioning marked spring guide as

shown in Figure

~.-.S(Alll\f>

6-6.

0---

lOP

v"w--@

6-5

6.4 ADJUSTMENTS AND OPERATIONAL

CHECKS

During normal use or when parts are

replaced certain adjustments must be made.

Components requiring adjustments or operational checks are outlined in the following

paragraphs.

6.4.1 Gas Burners and Pressure Regulator

The burners and fixed orifices are sized

at the factory for natural gas operation. The

burner air shutters should be adjusted at the

proper opening to produce a blue flame

without yellow tipping. To adjust air shutters

see Figure 6-5. Special size orifices are required for the gas burners. Refer to Figure 7-3

indexes 43, 44 and 45 for correct orifices to

be used with certain gases.

~---GAS BURNERS

~SHUTTERS

BURNER

CHASSI~

TYPE OF GAS DIM A

NATURAL&MANF'D. 5.132"

PROPANE & BUTANE

Figure

6-5.

Air Shutter Adjustment

7/32"

=tl=~

NAIUqAl GAS,

POSITION

Figure

6-6.

Gas Regulator Adjustment

6.4.2 Electrode Assembly

Electrode assemblies (Figure 7-3 index

30) are preset to a gap spacing of 0,125 inch

±

0.032 inch and should be checked

periodically. If spacing is not correct adjustment is not to be made, The complete

assembly must be replaced with a new unit.

Electrodes are not field adjustable.

6.4.3 Solenoid Gas Valve

The solenoid gas valve (Figure 7-3 index

42) is used to control the flow of gas to the

main burner which is under control of the

pressure switch. To check valve operation

proceed as follows:

1. Make certain the power disconnect for

the unit is on,

2. Turn on gas supply and turn timer

knob to 15 minutes. Electrodes will be

energized.

3. Turn timer to zero. Listen carefully for

the slight sound indicating the valve

has closed.

4. If burner flame has not gone out, cycle

the valve several times. The cycling

should jar loose any dirt or impurities

that may settle on the valve seat.

5. After check ..is made return timer to

OFF and shut off gas supply.

6.4.4 Timer and Gas Control Switches

The timer control switch automatically

delays the timer count-down at the beginning

of the cooking cycle until the

fully vented out all cold air from inside the

cooking compartment and pressure has

ll' GAS POSITrON

Steam-It

has

52127

Page 28

6-6

reached 10 psi. The gas control switch

governs the flow of heat to the cooking compartment to maintain compartment pressure

at a near constant 14 psi. To adjust each

ST-AG STEAM-IT COOKER

switch for proper activation, turn adjustment

nut (as applicable) clockwise to raise and

cou nterclockwise to lower actuation

pressure point.

52127

Page 29

SECTION 7 ILLUSTRATED PARTS LIST

7.1 GENERAL

This section contains a complete listing

of all replaceable parts of the Model ST-AG,

Steam-It Style F, Gas Operated cooker. For

the purpose of parts identification, the unit is

broken down into functional assemblies, and

each assembly is shown in an exploded view

which is keyed to the accompanying parts

list. Each parts list contains the figure index

number, the Market Forge part number and

an abbreviated description.

7.2 ORDERING INFORMATION

Orders for repair parts should be directed

to the nearest authorized parts distributor.

For a current Market Forge Authorized Parts

Distributor List contact:

Product Service Department

Market Forge

35 Garvey Street

Everett, Massachusetts 02149

Telephone: (617) 387-4100

Product Service Department

Market Forge Canada, Ltd.

1375Aimco Blvd., Unit 5

Mississauga, Ontario, Canada

Telephone: (416) 621-9252

All orders should contain the Market Forge

part number(s), the part description(s), and

the model and serial numbers of the cooker

for which the part(s) is ordered.