Page 1

ST-5G

GAS COUNTERTOP CONVECTION STEAMER

PARTS AND SERVICE MANUAL

EFFECTIVE JUNE 12, 2015

The Company reserves the right to make substitution in the event that items specied are not available.

ERRORS: Descriptive and/or typographic errors are subject to correction.

44 Lakeside Avenue, Burlington, Vermont 05401 USA Telephone: (802) 658-6600 Fax: (802) 860-3732

Superseding All Previous Parts Lists.

MARKET FORGE INDUSTRIES

www.mi.com

P/N 14-0287 Rev C

Page 2

TABLE OF CONTENTS

GENERAL TROUBLESHOOTING GUIDE ................................................3

TROUBLESHOOTING ..................................................................5

ELECTRICAL FAULT ISOLATION GUIDE ................................................6

WIRING DIAGRAMS ...................................................................7

ILLUSTRATED PARTS LIST

MAIN ASSEMBLY ......................................................................9

DOOR ASSEMBLY ................................................................... 12

BURNER, PROPANE AND NATURAL GAS ASSEMBLY ................................. 13

GAS PLUMBING AND VALVE ASSEMBLY ............................................. 14

JUNE 12, 2015 2 ST-5G

Page 3

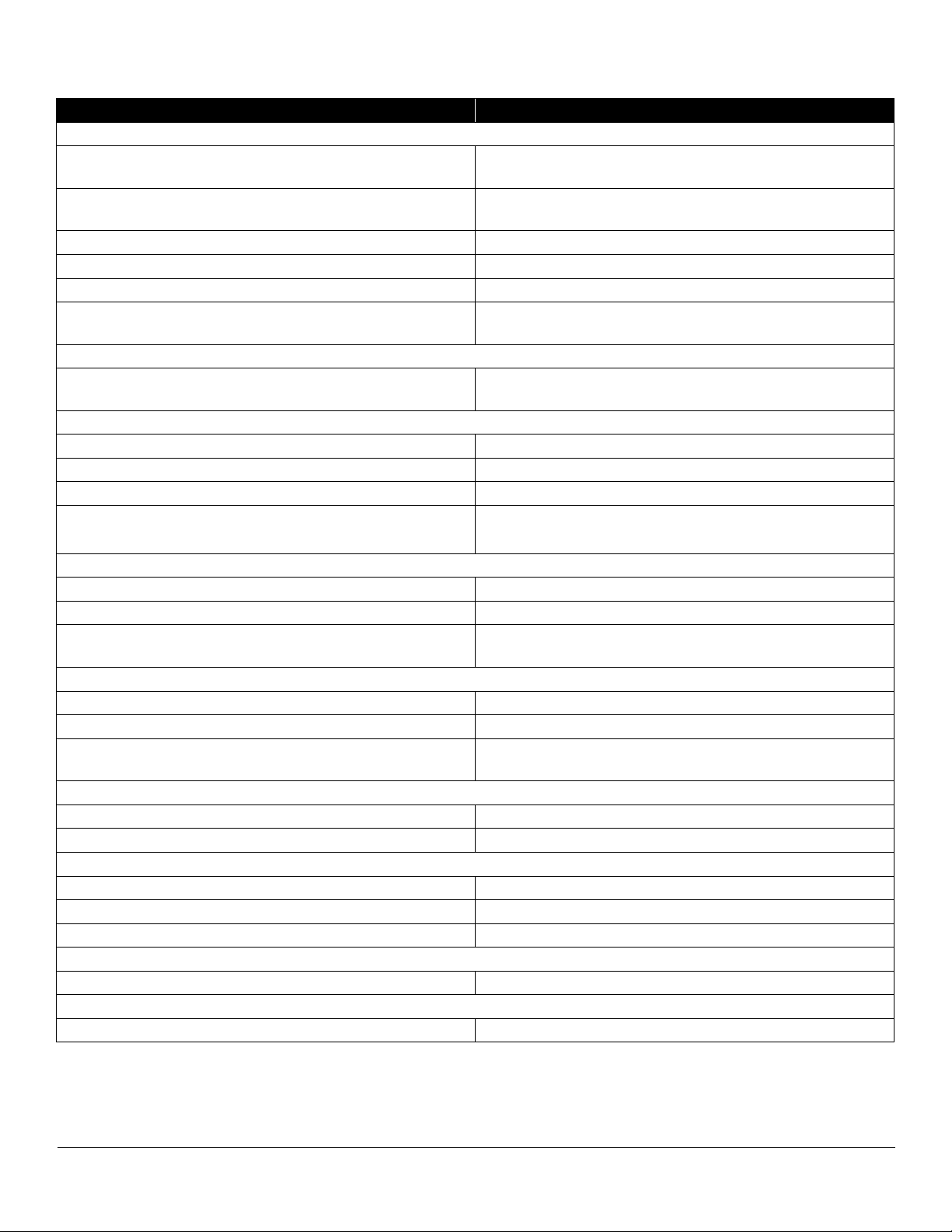

GENERAL TROUBLESHOOTING GUIDE

PROBLEM / PROBABLE CAUSE REMEDY

1. 1. Cooking Indicator Light Fails to Light with Timer Set.

a. Main power circuit breaker tripped. Located external circuit breaker for incoming power and

place in ON position.

b. Door interlock switch contacts not closed. Shut cooker door to close switch contacts. Check alignment

of door with switch.

c. Door interlock switch faulty. Replace switch.

d. Indicator light burned out. Replace light.

e. Faulty timer contacts. Replace timer.

f. Faulty wiring. Inspect condition of wire and tightness of all connections.

Correct as needed.

2. Steam Fails to Enter Cooking Compartment with Cooking Indicator Light On.

a. Faulty wiring.

3. Steam Enters Compartment Continuously. Timer Dial Not Turning.

a. Constant steam position. Move knob to timing location.

b. Faulty thermostatic switch. Replace switch.

c. Faulty timer motor. Replace timer.

d. Faulty wiring. Inspect condition of wire and tightness of all connections.

4. Steam Continues to Flow into Compartment and/or Buzzer Fails to Sound at End of Timer Setting.

a. Faulty timer contacts. Replace timer.

b. Faulty buzzer. Replace buzzer.

c. Faulty wiring. Inspect condition of wire and tightness of all connections.

5. Steam Flows Continuously from Boiler Drain Line with Cooker in Operation.

a. Cold water not connected. Turn on external shut-off valve.

b. Faulty cooling valve. Replace cooling valve.

c. Faulty wiring. Inspect condition of wire and tightness of all connections.

6. Door Leaks.

a. Damaged door gasket. Check gasket for cuts and replace as needed.

b. Clogged compartment drain or plumbing. Remove screen and clean drain line or plumbing.

7. Water Flows into Cooking Compartment.

a. Level probe short circuited. Check and correct.

b. Scale build-up on probe. Clean all probes.

c. Water ll solenoid valve. Plugged, defective, clean or replace.

8. Water Accumulates in Compartment.

a. Plugged compartment drain. Remove screen and clean drain line.

9. Water Flows into Drain During Shut-Down.

a. Cooling valve does not close. Check valve for foreign material or damage.

Inspect condition of wire and tightness of all connections. Correct

as needed.

Correct as needed.

Correct as needed.

Correct as needed.

JUNE 12, 2015 3 ST-5G

Page 4

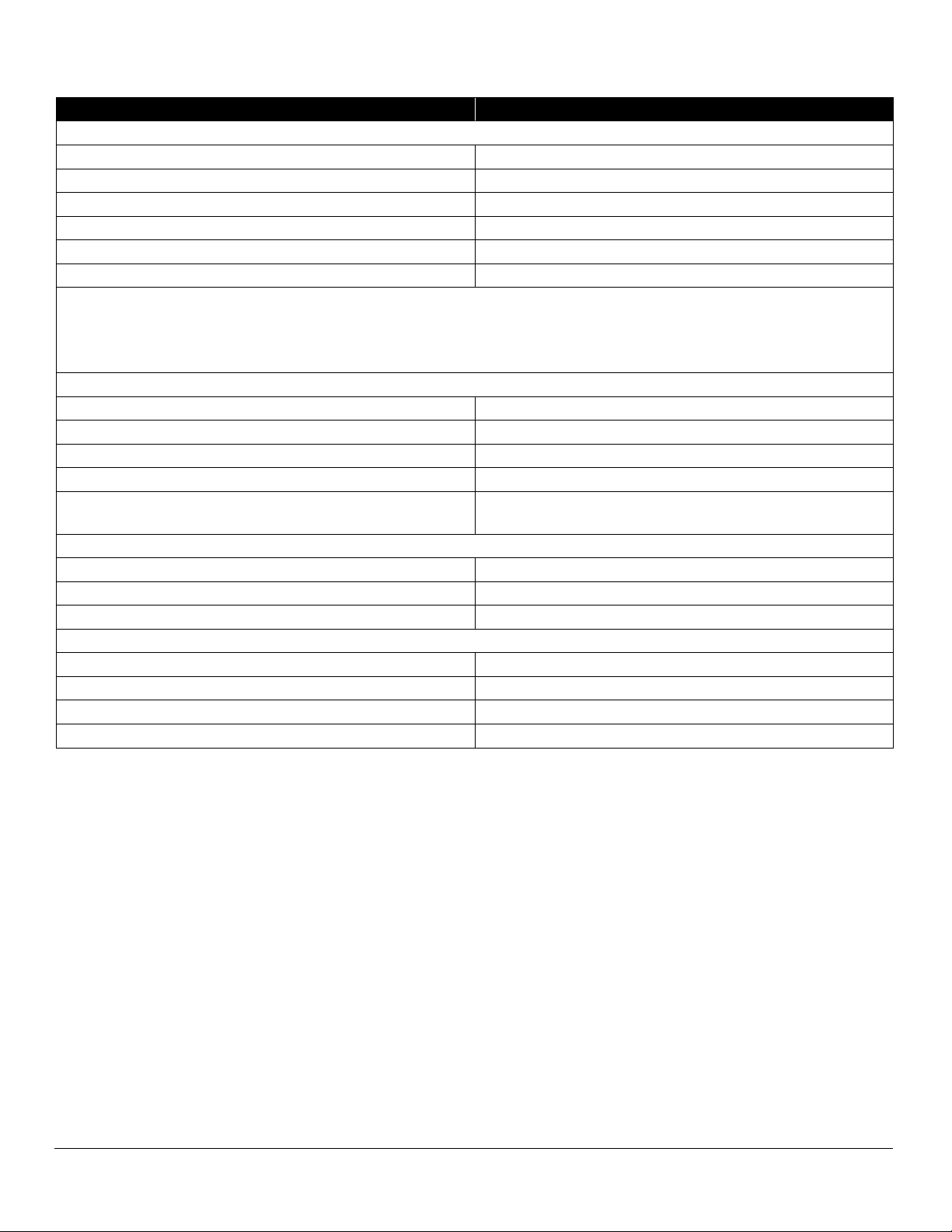

GENERAL TROUBLESHOOTING GUIDE

PROBLEM / PROBABLE CAUSE REMEDY

10. Water not Being Supplied to Generator.

a. Water supply off. Check incoming water valve is on.

b. Supply water pressure too low. Call supply agency.

c. Defective water solenoid valve. Replace or clean.

d. Level probe shorted. Check and correct.

e. Defective water level control. Replace.

f. Drain valve is open. Check valve, clean or replace.

IMPORTANT NOTE: These problems are an indication of severe water conditions which should be corrected immediately

to avoid damage to the components and performance of the steamer. Call your Service Agency for Assistance.

ADJUSTMENTS: All units are adjusted at the factory. in case of operation problems at initial installation, check type of gas

supply and manifold pressure and compare it with information on the rating plate.

11. Burners Do Not Come On.

a. Gas supply is off. Locate supply line and turn on.

b. Power switch is off. Located switch in cabinet and turn on.

c. Probe not sensing water level. Clean probes, check wiring.

d. Ignitor not functioning. Check ignition module relay.

e. Combination gas valve not opening. Check that control knob is in the ON position, check that

120 volts is at the gas valve.

12. Burners Produce Carbon Deposits.

a. Incorrect orice size. Check size and correct.

b. Incorrect gas supply. Check size and correct.

c. Incorrect gas pressure. Check gas pressure at manifold. Correct if necessary.

13. Flash Back.

a. Burning inside mixer tube. Reduce primary air.

b. Incomplete combustion. Increase burner input.

c. Sooting of burner. Increase primary air.

d. Miss-located ignitor. Adjust ignitor.

IMPORTANT NOTICE: AT LEAST TWICE A YEAR, HAVE AN AUTHORIZED SERVICE PERSON CLEAN AND ADJUST

THE UNIT FOR MAXIMUM PERFORMANCE.

ADJUSTMENTS AND SERVICE WORK MAY BE PERFORMED ONLY BY A QUALIFIED TECHNICIAN WHO IS EXPERIENCED IN AND KNOWLEDGEABLE WITH THE OPERATION OF COMMERCIAL GAS COOKING EQUIPMENT.

HOWEVER, TO ASSURE YOUR CONFIDENCE, CONTACT YOUR AUTHORIZED SERVICE AGENCY FOR RELIABLE

SERVICE, DEPENDABLE ADVICE OR OTHER ASSISTANCE AND FOR GENUINE FACTORY PARTS.

JUNE 12, 2015 4 ST-5G

Page 5

TROUBLESHOOTING

FINDING, UNDERSTANDING AND FIXING THE PROBLEM

Timer Contacts (60 Minute Timer)

Defective timer contacts will result in failure of cooker

compartment to operate. When this occurs, remove the

control pan and proceed as follows:

1. Turn off power to the cooker at external circuit breaker.

2. Disconnect all ve wires from timer terminals.

3. Connect an ohmmeter terminals 1 and 3.

4. Rotate timer dial beyond the “0 minute” point (any

setting) to obtain a reading of zero ohms on the

ohmmeter. If zero ohm reading cannot be obtained,

timer contacts are defective and the timer must be

replaced.

5. Move ohmmeter leads to terminals 1 and 4.

6. Rotate timer dial to “0 minute” position (an audible

click indicates correct position). If zero ohm reading

cannot be obtained, timer contacts are defective and

the timer must be replaced.

7. Remove ohmmeter and replace all ve leads on timer

terminals.

Timer Motor (60 Minute Timer)

A defective timer motor will cause continuous operation

in the TIME mode, with the timer dial failing to return to

the “0 minute” position. Carefully check motor condition,

proceed as follows:

1. Carefully check motor wire leads and tighten lose

connections. !! WARNING: !! USE CARE WHILE

WORKING WITH CONTROL PANEL. TERMINALS

CARRY 120 VOLTS.

2. Turn on power to the steamer.’

3. Set timer dial (any setting beyond “0 minute”). If operation s correct, the motor will turn the dial toward “0

minute”. If the motor fails to operate, it is defective

and the entire timer must be replaced.

4. Shut off power to the cooker.

Door Interlock Switch

Malfunction of the cooker door interlock switch prevents

timer indicator light from turning on and steam solenoid

from opening when the timer dial is set. If steam does not

enter the compartment and the cooking indicator light fails

to turn on with the door latch securely engaged, the fault

may be in the door interlock switch. Proceed as follows:

1. Turn off power to the cooker.

2. Disconnect wire to the door switch terminals.

3. Connect an ohmmeter between the terminals of the

switch.

4. Actuate the switch by closing the cooking compartment door. If zero ohm reading cannot be obtained,

timer contacts are defective and the timer must be

replaced.

5. Remove the ohmmeter and replace the leads on

switch terminals.

Indicator Lights

If the cooker compartment functions correctly, with the

single exception that the indicator light fails to light during

operation, the fault is a defective indicator light. A “burned

out” or defective light is veried by using a AC volt-meter

at the leads, with input power on the selector switch in

correct position for that timer, the timer set, and the door

latches closed. If 120 volts is present, the fault is in the

indicator light and requires replacement. If 120 volts is

not present, the fault is in the wiring control components

(selector switch, timer or door switch).

Buzzer

If the buzzer does not sound at the termination of the operator-selected timer setting (timer dial returned to “0 minute” position), the fault may be a defective buzzer. Buzzer

operation os veried using an AC volt-meter at buzzer coil

connections with input power on a selector switch and coinciding timer dial set at the “0 minute” position. If voltage

is 120 volts, the fault is in the buzzer, which must be replaced. If 120 volts is not present, the fault is in the wiring

control components (selector switch or timer).

Wiring

Using an ohmmeter, wiring continuity between the con-

nections shown on the wiring diagram is readily veried.

This is best done in stages, removing only those wires

required for each continuity check. As each lead is replaced, it should be checked for evidence of corrosion and

cleaned if necessary. All leads must be tightly attached so

as to provide a good electrical connection.

JUNE 12, 2015 5 ST-5G

Page 6

TROUBLESHOOTING

Door Gasket Replacement

The cooking compartment door gaskets are made of silicone-type rubber material that is very durable, but subject

to wear during normal operation. Should the gasket leak

replace it as follows:

1. Open the cooking compartment door.

2. Remove the four screw on the outside of the door

frame and remove the door panel assembly.

3. Remove the six screw from the gasket plate in the

door panel assembly.

4. Remove the gasket plate and the door gasket from

the door panel.

5. Install the new door gasket to the door panel. Replace

the gasket plate and six screws.

6. Reassembly the door panel assembly in the door

frame using the four screws.

7. Gasket replacement is now complete.

Door may be difcult to close until the gasket has compressed to conform to the door opening. Leaving door

closed overnight will compress gasket.

Exterior Panel Removal

WARNING

TO PREVENT HAZARD IN SERVICING THE

COOKER, BE CERTAIN THAT THE STEAM

SUPPLY BOILER IS SHUT DOWN, THE COLD

WATER SHUT-OFF VALVE IS CLOSED, AND

THE ELECTRICAL DISCONNECT CIRCUIT

BREAKER FOR THE COOKER/BOILER UNIT IF

OFF BEFORE REMOVING SIDE PANELS.

Access to all internal plumbing and electrical assemblies

is from the right side. The right side panel is removed by

removing the bottom screws and pushing up on the panel

until the lower lip disengages from the frame. Gas control

is located on the right side behind the bottom panel. Remove the four screws.

ELECTRICAL FAULT ISOLATION GUIDE

FAILURE FAULT LOCATION

Will not operate in either CONSTANT STEAM or 60 MINUTE TIMER

positions.

Operating in CONSTANT STEAM position, but not in 60 MINUTE TIMER position.

Operates in 60 MINUTE TIMER position, but not in CONSTANT

STEAM position.

With indicator light on and steam solenoid valve open, timer dial fails

to turn.

BUZZER fails to sound at the end of 60 MINUTE TIMER mode. a. 60 minute timer.

Steam ows continuously from boiler drain line. a. Cooling valve needs replacing.

a. Incoming power.

b. Timer.

c. Door interlock switch.

d. Wiring.

a. 60 minute timer.

b. Wiring.

a. Timer.

b. Wiring.

a. Constant steam position.

b. Timer motor.

c. Wiring.

b. Buzzer.

c. Wiring.

b. Wiring.

JUNE 12, 2015 6 ST-5G

Page 7

WIRING DIAGRAMS

JUNE 12, 2015 7 ST-5G

Page 8

WIRING DIAGRAMS

JUNE 12, 2015 8 ST-5G

Page 9

MAIN ASSEMBLY

JUNE 12, 2015 9 ST-5G

Page 10

MAIN ASSEMBLY

ITEM

1 97-6364 HINGE ROD 1

2 97-6173 DOOR ASSEMBLY 1

3 97-6175 PAN RACK 2

4 97-6183 LEFT HAND SIDE AND BACK PANEL 1

5 97-6340 RACK PIN ASSEMBLY 4

6 97-6300 STEAM DIVERTER 2

7 ~NPN~ HEX NUT 1

8 ~NPN~ LOCK WASHER 1

9 97-6302 WASHER 1

10 97-6178 STRIKER 1

11 97-6184 CONTROL LEXAN 1

12 97-6170 PILOT LIGHT - GREEN 2

13 97-6171 PILOT LIGHT - RED 1

14 98-6046 DIAL 1

15 97-6365 COMPARTMENT STRAINER 1

16 97-6177 PERFORATED DOOR TROUGH 1

17 97-6185 OPERATION INSTRUCTION DECAL 1

18* 97-6186 FUSE, 2A, 250V (120V UNIT) 1

18* 98-6134 FUSE, 1A, 250V (220V UNIT) 1

19 97-5864 FUSE HOLDER 1

20 97-6179 DIAL 1

21 97-5048 OPERATING THERMOSTAT 1

22 97-6366 COMPONENT MOUNTING BOARD 1

23 97-6172 RELAY 2

24 97-6367 POWER SWITCH 1

25 97-6190 BUZZER 1

26 10-6962 END SECTION 1

26 10-6963 TERMINAL BLOCK SECTION 2

27 97-5052 GROUND LUG 1

28* 97-6194 LEVEL CONTROL, 10K, OHM, 120V 1

28* 97-6200 LEVEL CONTROL, 1 M, OHM (OPTIONAL) 2

29 97-6913 IGNITION MODULE, INTERMITTENT PILOT 1

30 97-6193 RELAY, DPDT 1

31 ~NPN~ SCREW, 10-32 x 1/2 17

32 97-6201 RIGHT PANEL 1

33 97-6188 ELBOW, 3/8 C x 1/8 MPT 2

33A 98-6089 ELBOW, 1/4 C x 1/8 MPT 1

34 98-6123 CONNECTOR, 1/4 C x 1/8 MPT 1

35 97-6282 SOLENOID VALVE 2

36 97-5702 CORD SET, 120V 1

37 97-6191 DOOR SWITCH 1

37 97-6301 SWITCH ACTUATOR C/W CLIP 1

PART NUMBER DESCRIPTION

QTY.

JUNE 12, 2015 10 ST-5G

Page 11

MAIN ASSEMBLY

ITEM

38 08-6464 TIMER 2

39 97-6331 HOSE BARB ELBOW, 1/2 C x 1/4 MPT 1

40* 97-7100 STEAM HOSE 1/2 x 13” 1

41A 97-6262 GENERATOR TANK 1

41B 97-6436 ELBOW 5/8C x 3/8 MPT 1

41C 97-7102 DRAIN TUBE

42 97-6196 HIGH LIMIT SENSOR 1

43 97-6208 ELBOW, 1/2 C x 3/4 MPT 1

44 97-6210 BLOWDOWN SOLENOID 1

45 97-6209 CONNECTOR, 5/8 C x 3/4 MPT 1

46 97-6368 DOWN TUBE 1

47 97-6202 ELBOW, 3/4 1

48 97-6369 NIPPLE, 3/4 x 2 1/2 1

49 97-6219 RELIEF VALE, 5 PSI 1

50 97-6217 TOP COVER 1

51 97-6370 CAP, 3/4 1

52 97-6371 NIPPLE, 3/4 X 3 1/2 1

53 97-6203 TEE, 3/4 1

54 97-6204 CLOSE NIPPLE, 3/4 1

55 97-6212 PROBE- LOW LEVEL CUT OFF 1

56 97-6372 PROBE-HIGH LEVEL 1

57 976213 PROBE-LOW LEVEL 1

58 97-6215 FLUE ASSEMBLY 1

59 97-6216 FLUE COVER ASSEMBLY 1

60 ~NPN~ SCREW, 1/4-20 x 1/2 6

61 98-6047 ROTARY SHAFT SEAL 1

62** 97-6223 RIGHT HAND SIDE RISER 1

* 97-6222 LEFT HAND SIDE RISER 1

63 97-6220 FRONT RISER 1

* 97-6221 REAR RISER 1

64 97-6211 APPLIANCE LEG 4

65* 97-7103 HOSE CLAMP 4

66* 97-7104 HOSE BARB, 1/2 x 1/4 MPT 1

67* 97-6207 ELBOW, 1/2C x 1/4 MPT 1

68* 97-5701 TRANSFORMER, 115-24 1

69 97-6225 WIRE HARNESS 1

70* 97-5619 THERMOSTAT BULB FITTING 1

71* 97-6226 WATER SUPPLY CONNECTOR 2

72* 98-6138 TRANSFORMER, 100VA, 200-240/120V, (220V UNITS) 1

* Not Shown.

** Select as Required.

PART NUMBER DESCRIPTION

QTY.

JUNE 12, 2015 11 ST-5G

Page 12

DOOR ASSEMBLY

ITEM PART NUMBER DESCRIPTION QTY.

1 97-6227 DOOR FRAME 1

2 97-6231 DOOR HANDLE ASSEMBLY 1

-- 97-6235 DOOR HANDLE DECAL 1

3 97-6232 LATCH ASSEMBLY 1

4 97-6261 BUSHING SPACER 4

5 97-6236 UPPER & LOWER SPACER 1 ea.

6 97-6230 DOOR PANEL 1

7 97-6228 DOOR GASKET 1

8 97-6229 GASKET PLATE 1

9 97-6233 GASKET PANEL SCREWS 8

10 97-6173 DOOR ASSEMBLY 1

JUNE 12, 2015 12 ST-5G

Page 13

BURNER, PROPANE AND NATURAL GAS ASSEMBLY

ITEM PART NUMBER DESCRIPTION QTY.

1 ~NPN~ HEX SHELF TAPPING SCREW, 8-32 x 1/4 4

2** 97-6244 PILOT BURNER, LIQUID PROPANE 1

97-6465 PILOT BURNER, NATURAL GAS 1

3 97-6245 BURNER MOUNTING BRACKET 1

4 ~NPN~ MACHINE SCREW, 10-32 x 3/8 2

5 ~NPN~ MACHINE SCREW, 10-32 x 1/4 2

6 97-6237 SPARK ELECTRODE 1

7 97-6533 PILOT TUBE 1

8 98-6124 PIPE PLUG, 1/8 MPT 1

9** 97-6239 GAS MANIFOLD ASSY, NATURAL GAS 1

97-6247 GAS MANIFOLD ASSY, L.P. 1

10 ~NPN~ HEX CAP SCREW, 1/4-20 x 1/2 2

11** 97-6535 JET ORIFICE, #64, L.P. 4

97-6498 JET ORIFICE, #53, NATURAL GAS 4

12** 97-6238 TWIN BURNERS, NATURAL GAS 2

97-6246 TWIN BURNERS, L.P. 2

13 ~NPN~ SHEET METAL SCREW 4

* Not Shown.

** Select as Required.

JUNE 12, 2015 13 ST-5G

Page 14

GAS PLUMBING AND VALVE ASSEMBLY

ITEM PART NUMBER DESCRIPTION QTY.

1 97-6249 BALL VALVE, 3/4 1

2 ~NPN~ SCREW, #10-32 x 1/2 2

3 97-6250 GAS SUPPLY PIPE ASSEMBLY 1

4 98-6112 REDUCING COUPLING 1

5 97-6251 90O STREET ELBOW 1

6 98-6109 CLOSE NIPPLE, 1/2 1

7 98-6122 UNION ELBOW, 1/2 1

8** 97-5808 COMBINATION GAS CONTROL - NATURAL 1

8** 97-5809 COMBINATION GAS CONTROL - PROPANE 1

9 97-6252 FLEX TUBE, 1/2 x 18 1

** Select as Required.

JUNE 12, 2015 14 ST-5G

Loading...

Loading...