Market Forge ST-3E Installation Manual

Steam Tech™

ST-3E

E-MAIL

CUSTSERV@MFII.COM

ELECTRIC STEAM COOKER

MODELS:

ST-4E

ST-5E

INSTALLATION AND OPERATION MANUAL

MARKET FORGE

INDUSTRIES INC

An Employee-Owned Company

35 Garvey Street • Everett, MA 02149-4422 USA Tel:

(617) 3 87-4100-Fax: (617)387-4456

Outside MA FAX: 1 -800-227-2659 Form No. S-2470

REV. B 1/98 Printed In U.S.A

COVERING

• INSTALLATION

• OPERATION

• SERVICE & PARTS

1.0 INTRODUCTION 1

i

TABLE OF CONTENTS

1.1 Description 1

1.2 Basi c Functioning 1

1.3 Service 2

2.0 INSTALLATION 3

2.1 Assembly 3

2.2 Setting in Place 3

2.3 Service Connections 3

2.3.1 Water Connections 3

2.3.2 Electrical Connections 3

Electrical Characteristics 3

Water Connections 4

Dimensions 4

Capacity 4

2.4 Reversing the Doors 5

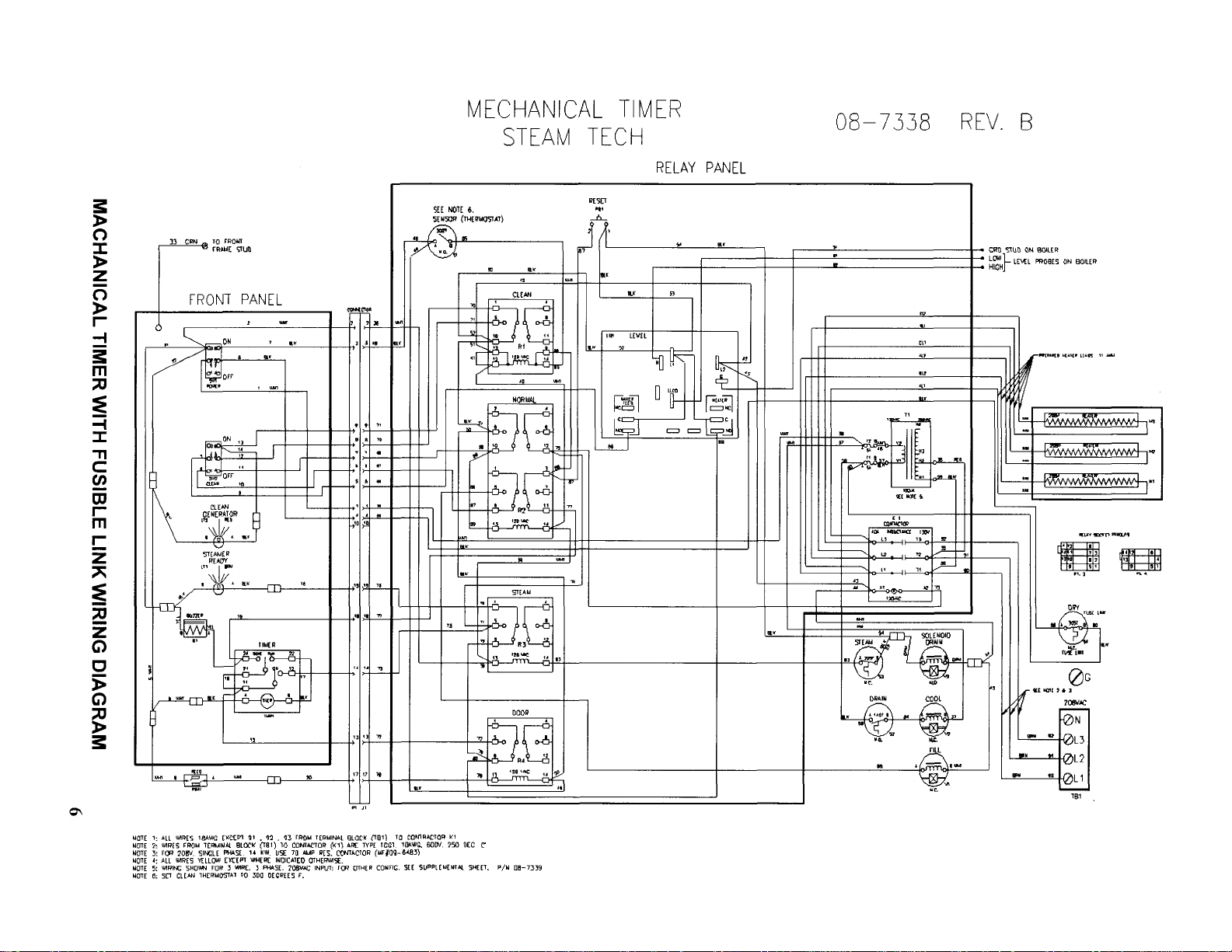

Wiring Diagram Mechanical Timer, Fusible Link 6

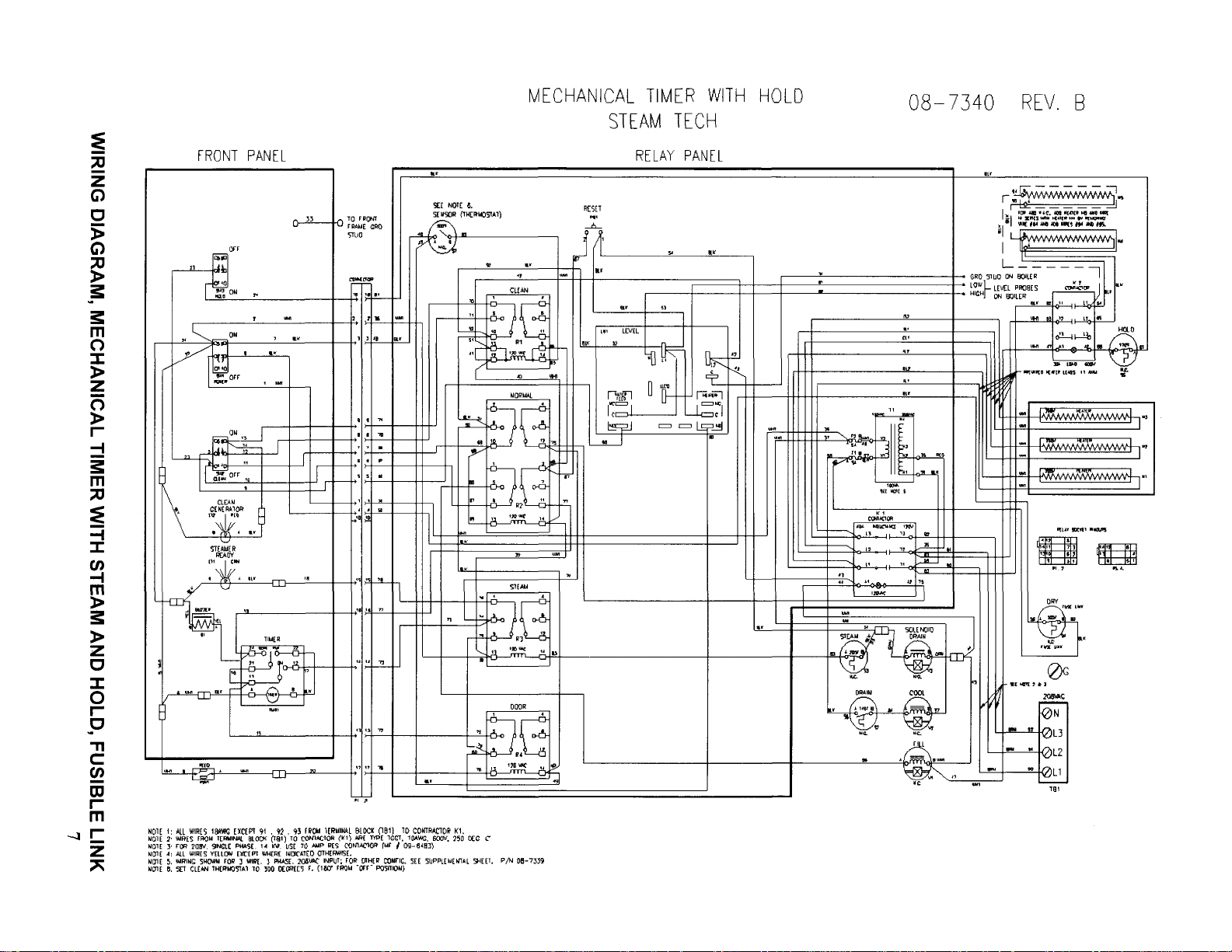

Wiring Diagram Mechanical Timer with Hold, Fusible Link 7

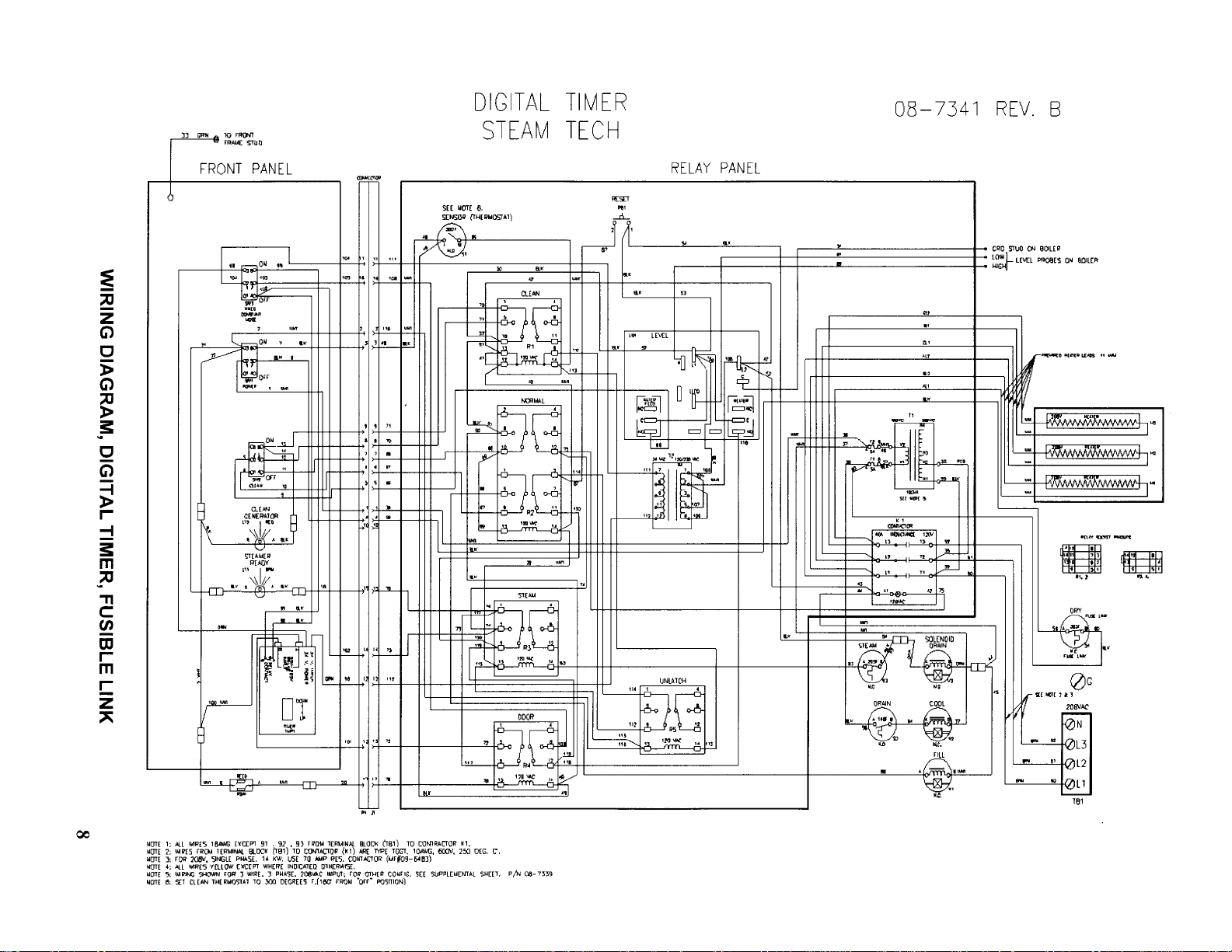

Wiring Diagram, Digital Timer, Fusible Link 8

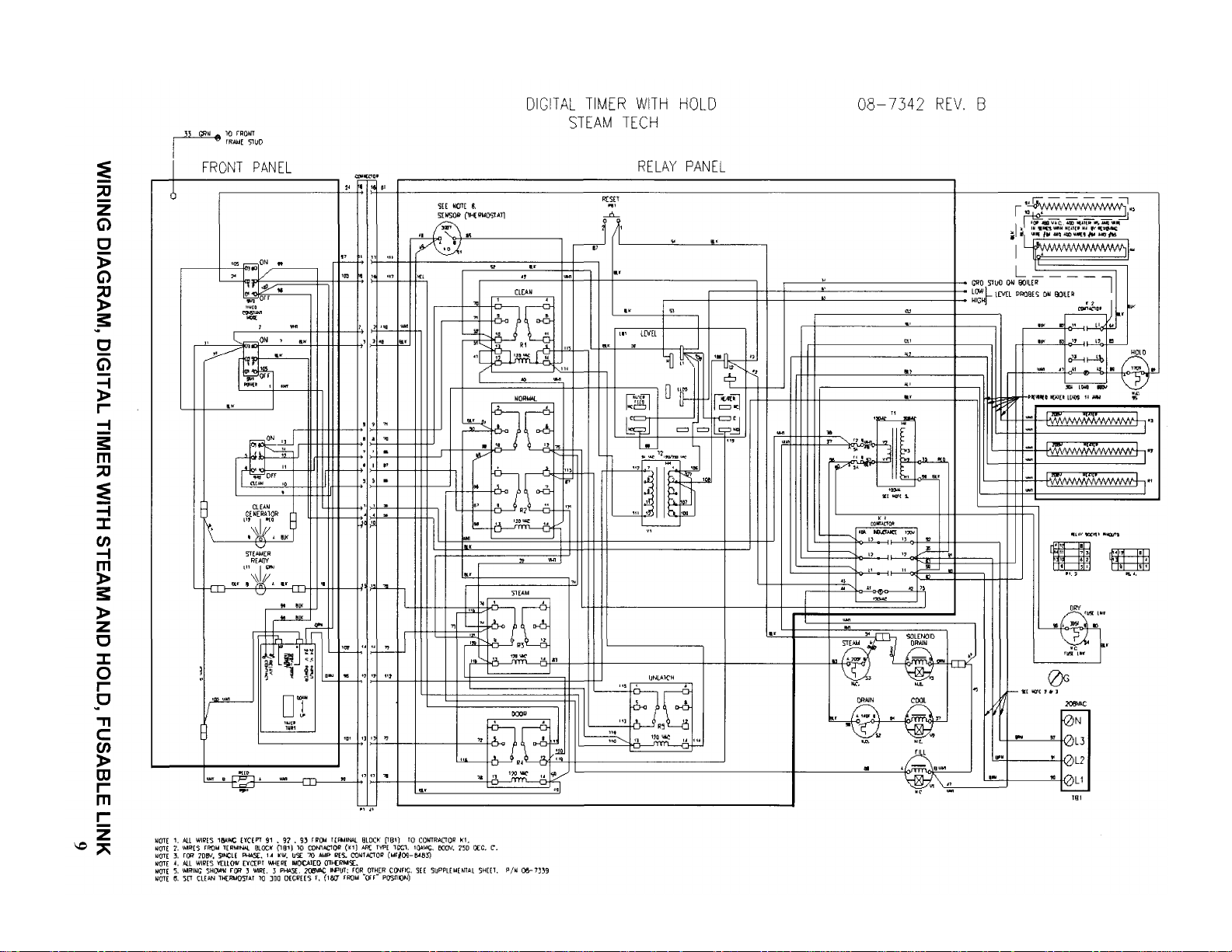

Wiring Diagram, Digital Timer with Hold, Fusible Link 9

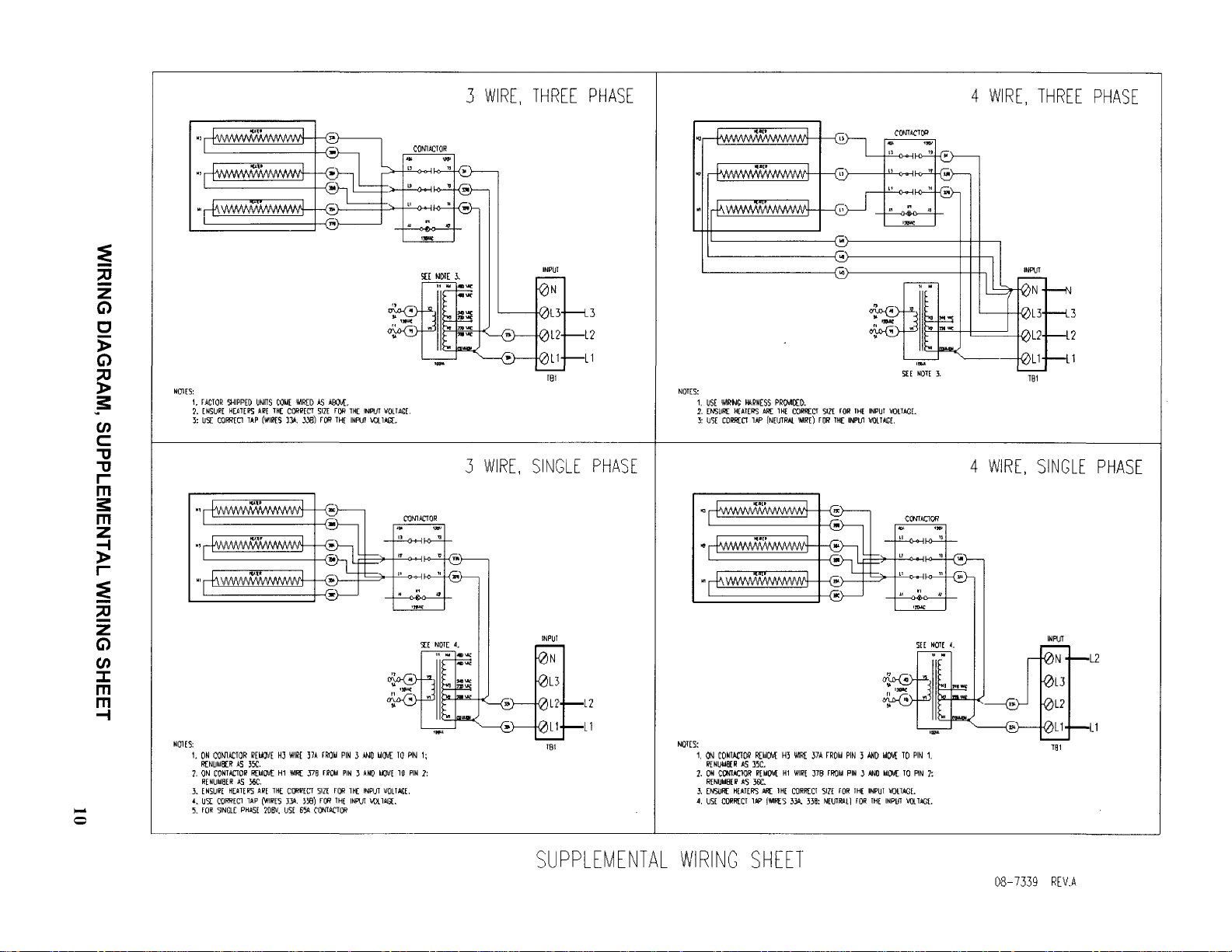

Wiring Diagram, Supplamental Wiring Sheet 1

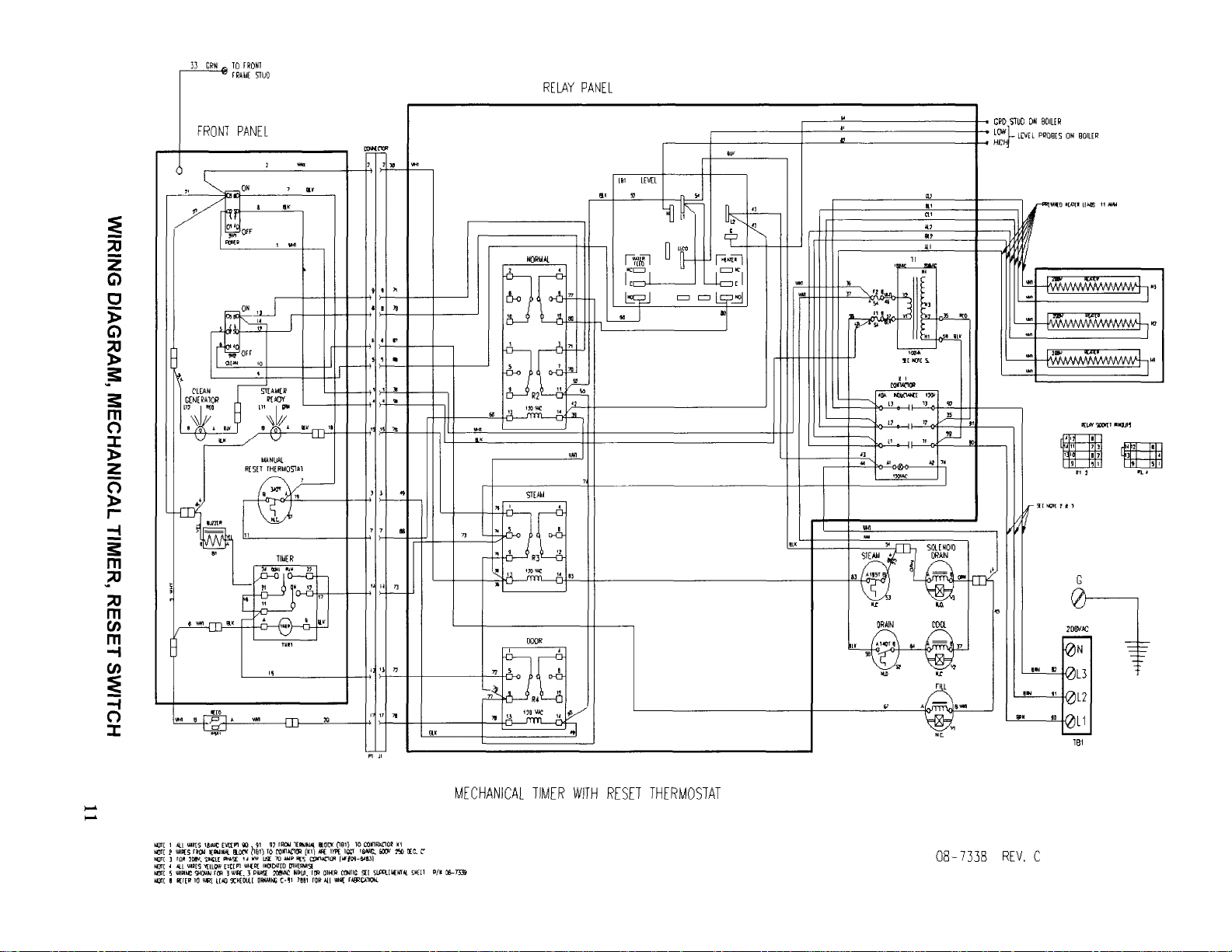

Wiring Diagram, Mechanical Timer, Reset Switch 1

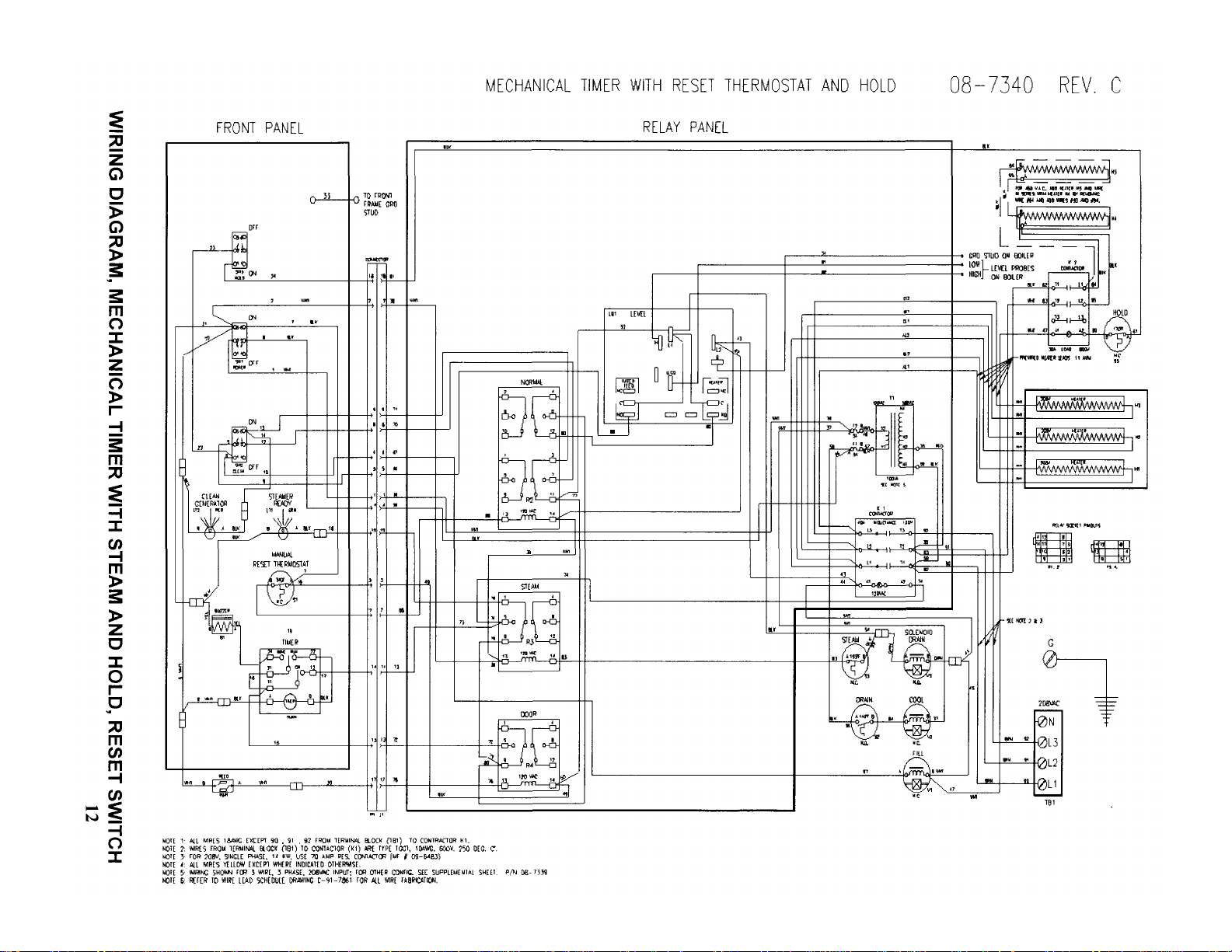

Wiring Diagram, Mechanical Timer with Hold, Reset Switch 1

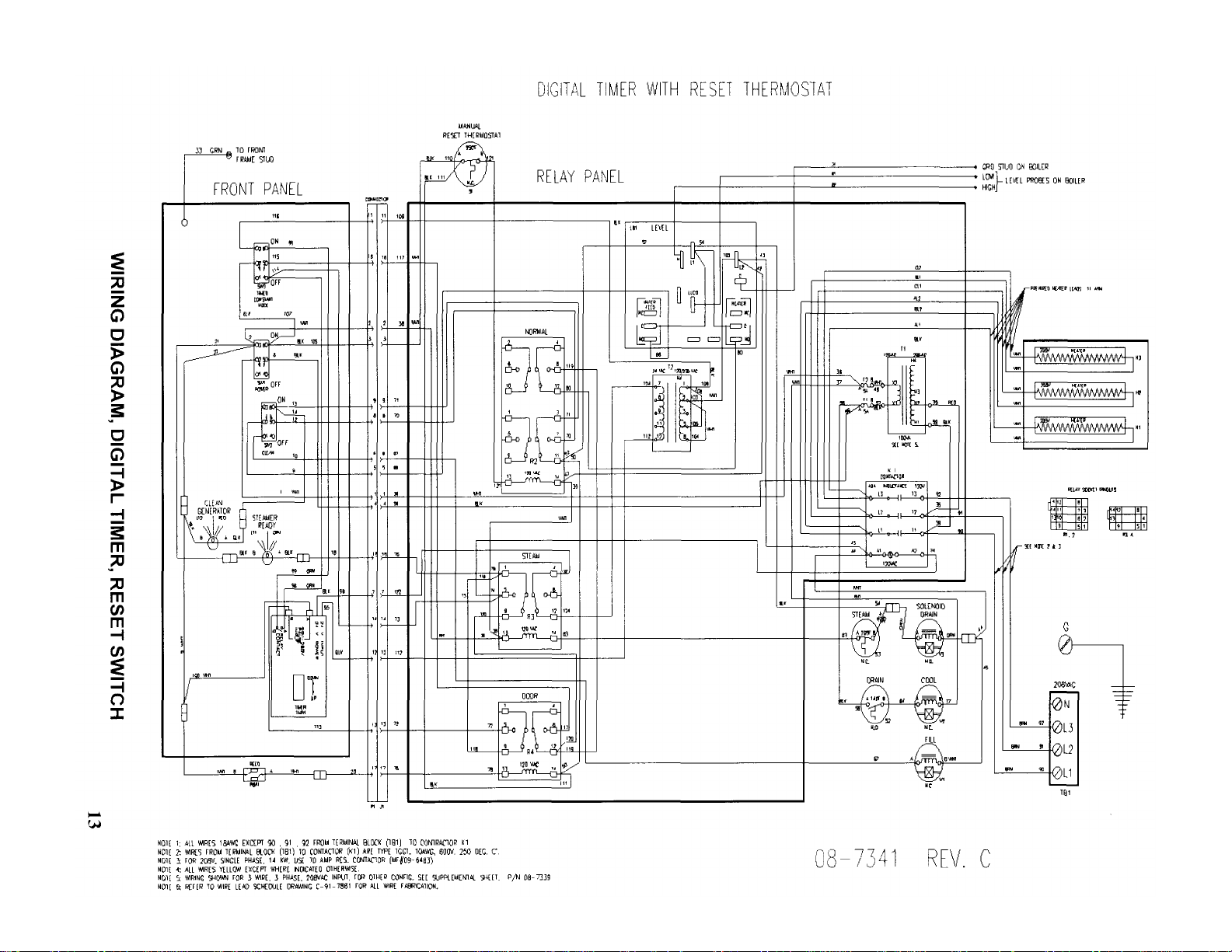

Wiring Diagram, Digital Timer, Reset Switch 1

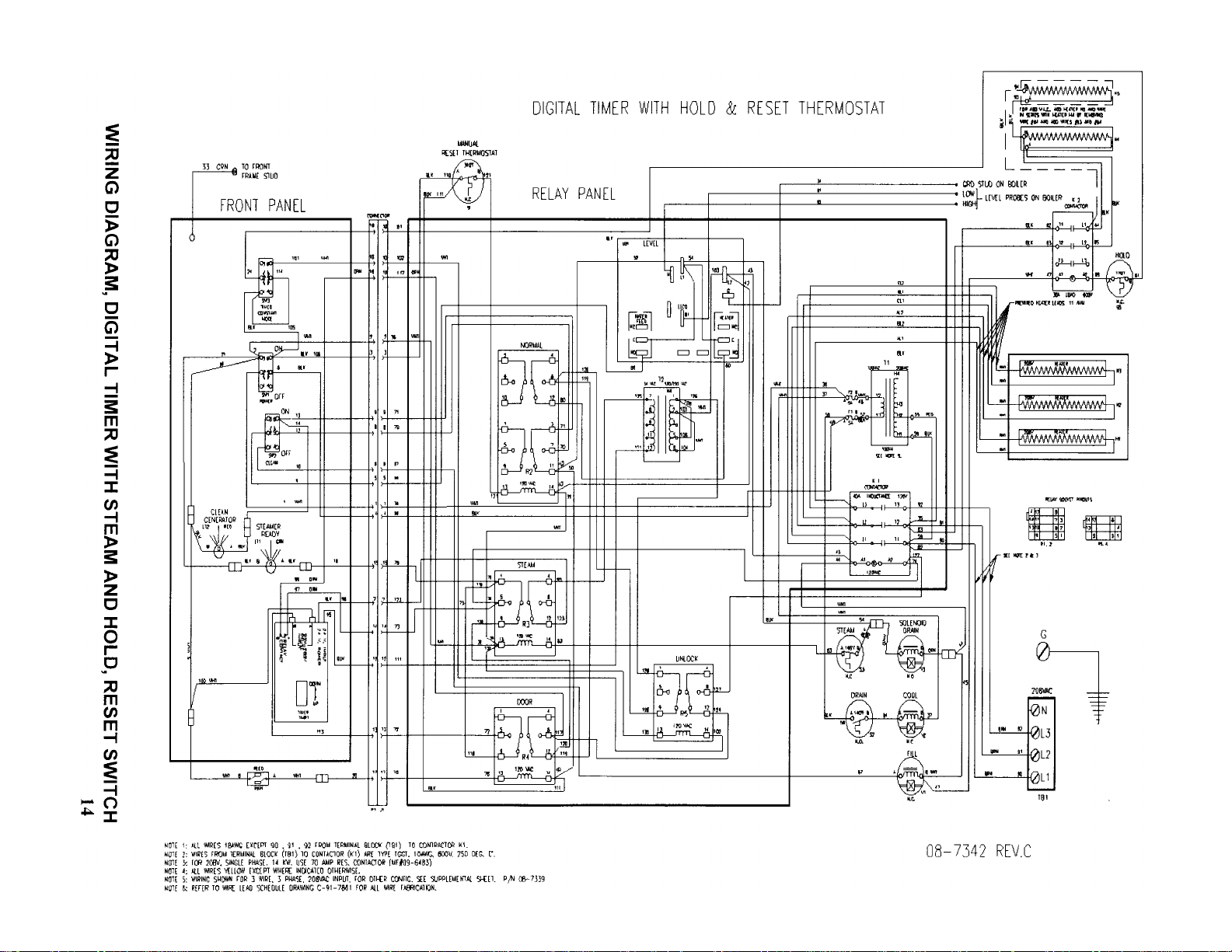

Wiring Diagram Digital Timer with Hold Reset Switch 1

3.0 INITIAL SYSTEM INSPECTION 1

3.1 General 1

3.2 Warm-up 1

3.3 Timed Steam Mode 1

3.4 Constant Steam Mode 1

3.5 Optional Steam and Hold Mode 1

3.6 Optional Digital Control Timer 1

3.7 Shut Down 1

4.0 OPERATION 1

4.1 Controls and Indicators 1

4.2 Operating Procedures 1

4.2.1 Start-up and Preheating 7

4.2.2 Cooking - Mechanical Controls 7

4.2.3 Cooking - Use of the Digital Timer 1

4.2.4 Shut -down 1

4.3 Daily Cleaning 1

4.4 Prolonged Shutdown and Cleaning 1

4.5 Generator Cleaning 1

Control Panel Mechanical Timer 2

Control Panel Mechanical Timer With Hold 2

Control Panel Digital Timer 2

Control Panel Digital Timer With Hold 2

5.0 PRINCIPLES OF OPERATION 24

5.1 General 24

5.2 Fill/Cold Water Inlet 24

5.3 Preheating and Standby 24

5.4 Steam Generation 24

5.5 Hold Feature (Option) 25

5.6 Drainage 25

5.6 1 Cooking Compartment Drainage 25

5.6.2 Drip/Spill Trough Drainage 26

5.6.3 Steam Generator Drainage 26

6.0 TROUBLESHOOTING 27

6.1 General 27

6.2 Water Level Control Board 27

6.2.1 Testing the Water Fill Relay 29

6.2.2 Testing the Low Water Relay 30

7.0 MAINTENANCE 31

7.1 General 31

7.2 Daily Cleaning 31

7.3 Preventive Maintenance 31

7.4 Cleaning the Generator 31

7.4.1 Cleaning Instructions 32

7.5 Control Panel Electrical Service Access 32

7.7 Door Adjustment 33

7.7.7 Door Alignment 33

7.7.2 Door Latch Tension Adjustment 34

7.7.3 Door Handle Tension Adjustment 34

7.8 Door Gasket Replacement 34

7.9 Solenoid Fill Valve Strainer Screen Cleaning 34

STE Top Assembly Part List 35

STE Top Assembly 36

Boiler Assembly Part List 37

Boiler Assembly 38

Door Assembly Part List 39

Door Assembly 40

Electric Plate Assembly Part List 41

Electric Plate Assembly 42

Mechanical Control Panel Assembly Part List 43

Mechanical Control Panel Assembly 44

Mechanical Control Panel With Hold Assembly Part List 45

Mechanical Control Panel With Hold Assembly 46

Digital Control Panel Assembly Part List 47

Digital Control Panel Assembly 48

Plumbing Assembly Part List 49

Plumbing Assembly 50

ii

1.1 Description

The Steam Tech™ represents the latest in

counter top steam technology, designed to

apply the benefits of steam cooking to

today's health-conscious menus. Ideal for

batch cooking, a-la-carte and

rethermalization of individual entrees, the

Steam Tech™ puts the power of steam on

your countertop. The Steam Tech™ is a

pressureless steam cooker consisting of:

• 3-, 4-, or 5-pan cavity

• Electric pressureless generator (9,10,or

14kW inputs)

• Controls - mechanical or electronic

• Cleaning indicator

• Optional hold feature

These features and functions will be

discussed in greater detail in Sections 3.

A "clean generator" light indicates when it's

time to de-lime. Generators can be easily

cleaned from the outside of the cooking

compartment, through a port on top (Some

models may have an inside port).

A "close-coupled" steam generator system

gives quick start -ups and efficient steam

transfer to the cooking compartment,

without the use of fans or expensive blower

motors. In tests for energy efficiency and

cooking times performed in accordance with

ASTM standards, the Steam Tech™ yielded

impressive results over other similar counter

top steamers.

With an optional "hold" feature, your Steam

Tech™ will keep cooked foods at 160°F

until you are ready to serve, giving you

more time between cooking and serving -

it's a Market Forge exclusive.

As your operation grows, so does your

Steam Tech™. By stacking multiple

Steam Tech™ models, you can accommodate

up to 10 pans, creating a complete high-output

steam cooking system.

1.2 Basic Functioning

To begin operation, the power switch is

pressed into the on position, illuminating the

power light. This opens the water feed

solenoid valves to the steam generator. Once

the appropriate water levels have been

reached, the heating element is energized.

When the water in the steam generator has

reached 195°F, the green ready light, is

illuminated, indicating that the unit is now

ready to make steam and all controls are

functional.

A steaming mode is selected, with the timer/

selector switch.

For continuous steam, set the selector timer

knob to the "constant steam" position (the

green area of the selector/timer switch). The

cooker will continue to steam until the switch is

moved to the "off' position.

If you desire a timed steam cooking cycle, just

set the timer knob to the cook time (up to 60

minutes).

In the timed steam mode, the cooker will

create steam for the duration of time you have

set. Once the timer reaches the end of its cycle

(0 minutes) the buzzer will sound. The buzzer

is silenced by returning the timer knob to the

"off' position, which ceases the steaming

function. The generator will continue to idle at .

For units equipped with the optional

digital timer, please refer to section 3.6 for

basic explanation.

1

For units equipped with the optional steam

and hold feature, an additional mode

selector switch is used to place the cooker

into the hold mode. At the completion of

the cooking cycle, place the timer knob to

the "off position and then place the hold

switch to the "on" position. When in the

"hold" mode, the auxiliary thermostatically

controlled electric strip heater is activated.

The strip heater is mounted onto the

outside back wall of the cooking

compartment and will maintain safe

internal holding temperature (minimum of

160°F). The hold feature is controlled by a

separate thermostat with an additional

temperature gauge mounted just above

the control panel. The unit will now act as

a holding cabinet until you call for steam

again. During this time, the generator will

continue to idle at 195 °F.

Your new cooker is equipped with a clean

generator light which automatically

illuminates when the steam generator has

accumulated mineral build-up). When the

red light is "on", indicating that the heating

element has reached a point where it is

not safe to operate the steamer without

cleaning the generator and electric

heaters. To prevent heater burn-out, the

steam generator must be cleaned. The

red light tells the operator that he/she can

continue to cook until the power switch is

turned off at the end of the day. On the

next start, the unit must be cleaned (see

Section 4.5) or it will not operate.

Steam or hot water leaving the unit is drained out

the rear of the cooking cavity. Your unit is equipped

with a drain wa ter cooling system which adds cold

water to this discharge. The cold water cools the

hot discharge below 140°F which is suitable for

standard drain lines. (Note: Do not use PVC or

CPVC for drain piping.)

1.3 Service

Required service, both preventative and corrective,

is explained in Section 6. Should repairs be

required, a network of Authorized Agencies is

available to assist with prompt service. A current

Directory of Authorized Service Agencies may be

obtained by contacting:

Product Service Department Market Forge

Industries, Inc. 35 Garvey Street

Everett, Massachusetts 02149 Telephone:

(617)387-4100

The Model and Serial Numbers must be referenced

when corresponding with Market Forge. The data

plate containing the serial number is located on the

top front of the steamer (body panel).

2

2.1 Assembly

Volts AC

ST-3E ST-4E ST-5E

1- 3

- 1- 3

- 1- 3

-

PH

PH PH

PH PH

PH

The assembled Steam Tech™ Pressureless

Steam Cooker is shipped in a carton on a

skid. Steps required for assembly are as

follows:

1. Remove the carton and the unit off the

skid.

2. Install the feet into the threaded mount ing

locations on the bottom of the unit.

3. Mount the left and right pan support racks

on the mounting brackets located inside

each of the cooking compart ments.

2.2 Setting in Place

If possible, a location should be selected

under an exhaust hood which will remove

small amounts of vapor emitted from the

cooker during normal operation. Next, level

the unit after it is placed in its final location.

This is accomplished by turning the bottom

part of the adjustable feet. Using the cabinet

top as a reference, obtain level adjus tment

left-to-right and front -to-back.

2.3 Service Connections

Service connections that are made at the back

of the cooker, include cold water inlet, drain,

and electrical. Please see the illustrations and

table located in Table 2.1 for service

connections, details and dimensions.

2.3.1 Water Connections

Before connecting water to this unit, have

water supply analyzed to make sure that

hardness is no greater than 2.0 grains per

gallon and pH level is within the range of 7.0-

8.5. Water which fails to meet these standards

should be treated by the installation of a water

conditioner.

EQUIPMENT FAILURE CAUSED BY INADEQUATE

WATER QUALITY IS NOT COVERED UNDER WAR-

RANTY.

Caution: Do not use PVC or CPVC piping for inlet

water service connections.

Please refer to Table 2.1 for details and locations of

water and drain connections.

2.3.2 Electrical Connections

Caution: Use copper wire only for power supply

connections.

Please refer to Table 2.1 for details of electrical service

connections.

Electrical Characteristics

Electrical connection power supply should utilize wire

suitable for 90°C.

(9kW)

208 (197- 41A 24A 46A 26A 64A 37A

219) 46A 26A 51A 29A 71A 41A

240 (220- 34A 20A 38A 22A 53A 31A

240) 38A 22A 42A 24A 58A 34A

480 (360- 19A 11A 21A 12A 29A 17A

500)

220/380

3-phase

4 wire

240/415

3-phase

4 wire

11A

13A

(10kW)

13A

14A

(14kW)

18A

19A

3

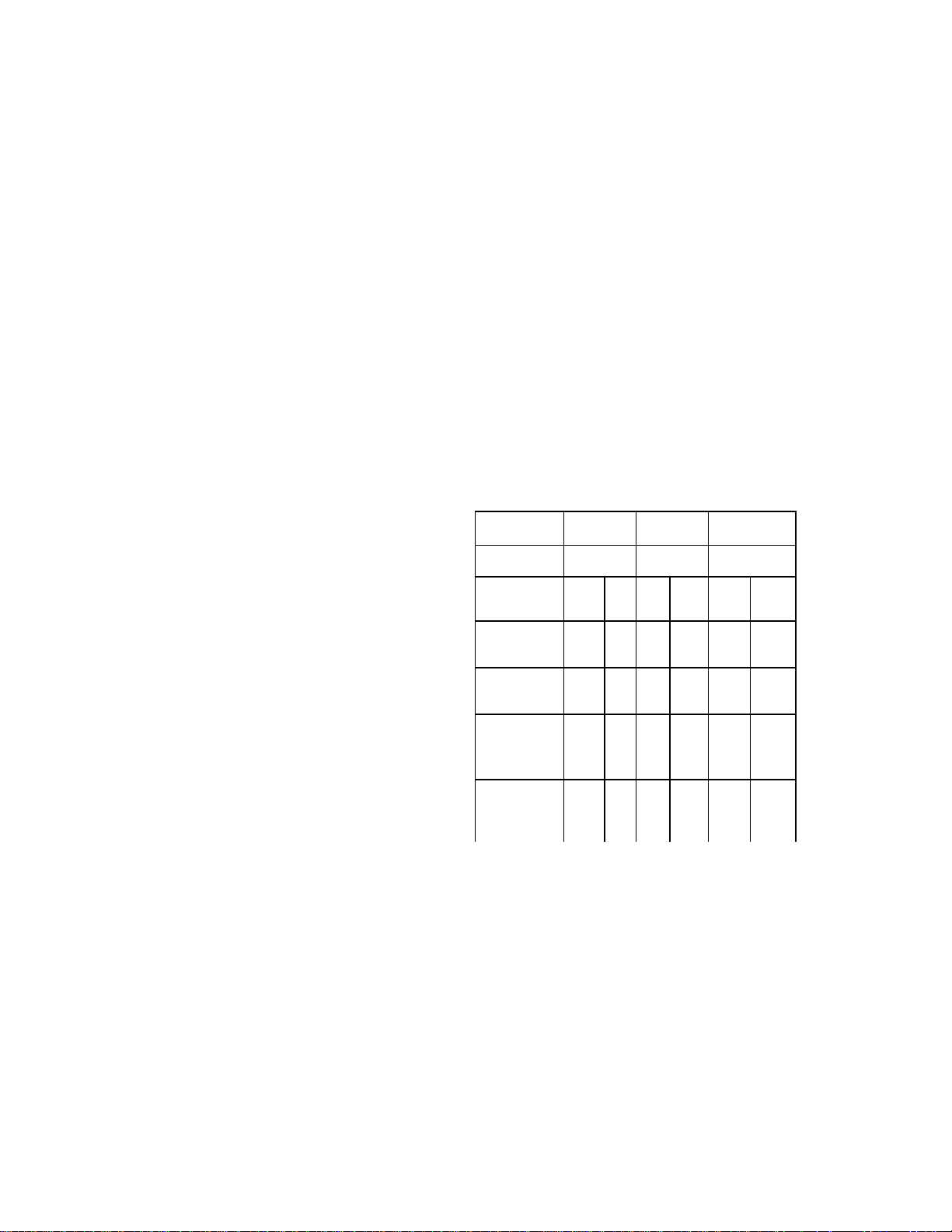

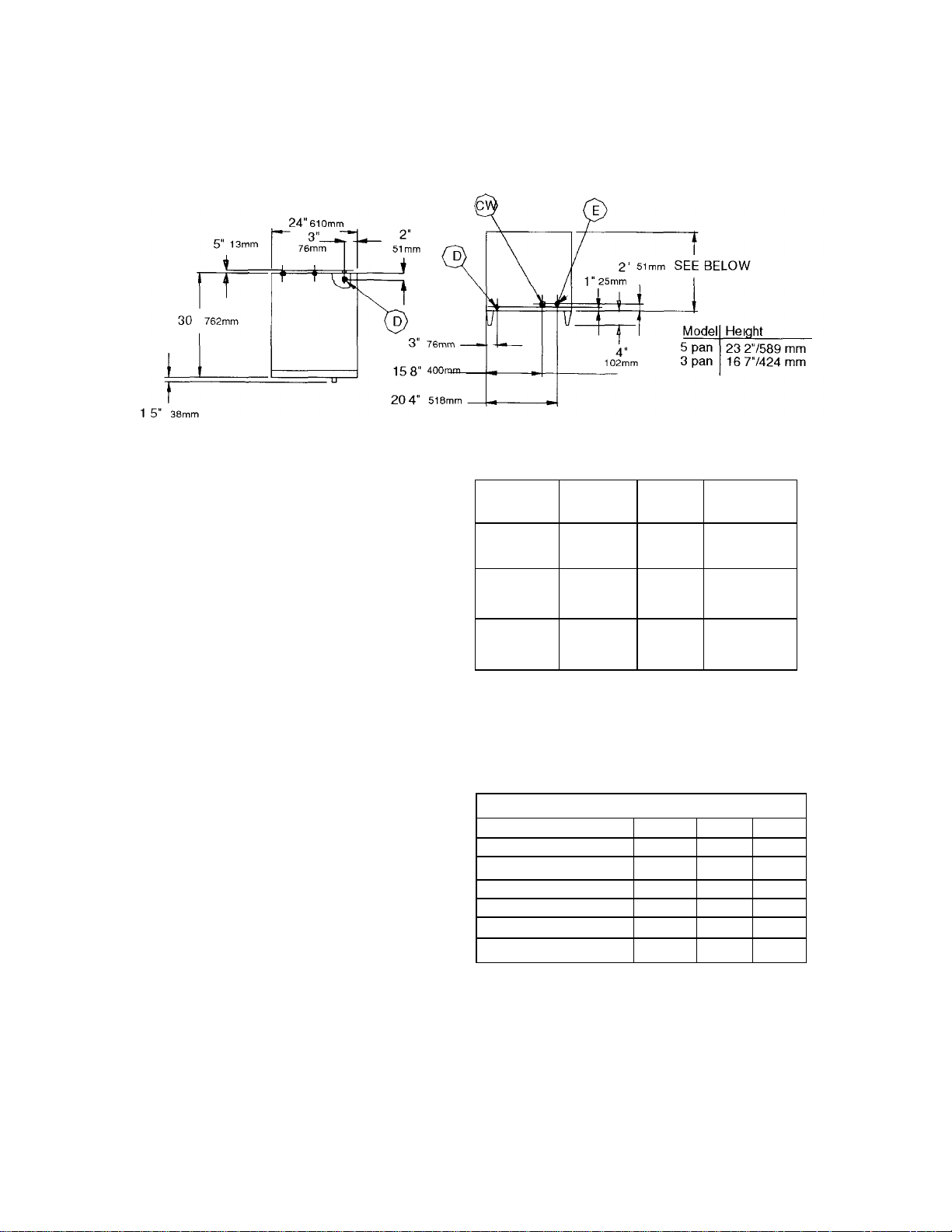

Table 2.1: Service Connections

E -Electncal Connection

CW- Cold Water Inlet

D- Drain Connection

Water Connections

Cold water 1/2" female compression fitting

water line will have maximum of 50 psi

and minimum of 25 psi of water pressure.

Drain pipe full 1" female NPT to open floor

drain with air break. Do not exceed 8' in

length and no more than 2 elbows. Before

connecting water to this unit, water supply

should be analyzed to make sure

hardness is no greater than 2.0 grains per

gallon and pH level is within the range of

7.0-8.5. Water which fails to meet these

standards should be treated by

installation of a water conditioner.

Equipment failure caused by

inadequate water quality is not covered

under warranty.

Internal Dimensions

Model Height Width Depth

ST-3E

ST-4E

ST-5E

107" 271

mm

1395" 354

mm

172" 436

mm

14" 356

mm

14" 356

mm

14" 356

mm

225" 571 mm

225" 571 mm

225" 571 mm

Capacity

Pan Size Number of Pans

ST-3E ST-4E ST-5E

12"X20"X1" 6 7 8

12"x20"x2 1/2" 3 4 5

12"X20"X4" 2 3 4

GN 1/1 25mm deep 6 7 8

GN 1/1 65mm deep 3 4 5

GN 1/1 100mm deep 2 3 4

4

2.4 Reversing the Doors

The Steam Tech™ Pressureless Steam

Cooker has a reversible cooking compart ment door for your convenience. This section

contains instructions for reversing this door.

1. Opening the cooking compartment door

2. Remove the two screws that attach the

top hinge to the front of the unit.

3. Slide the door upwards, off the bottom

hinge.

4. Remove the two screws that attach the

bottom hinge to the front of the units.

5. Remove the plastic hole plugs from the

front of the unit. Push the black hole

plugs into the left upper and lower hinge

mounting holes.

6. Reinstall the top hinge with spacers and

screws into the right lower hinge mount ing holes. Rotate the hinge 180° for

installation, so that the pin which the

door rides on is now facing up. The hinge

must be rotated because it will now

function as the bottom hinge. DO NOT

COMPLETELY TIGHTEN THE HINGE

MOUNTING SCREWS YET. These will

be used later for adjusting the door.

7. Remove the door latch assembly from the

face of the unit. The 2 nuts mounting the

door latch are located behind the face of

the unit and must be accessed by

removing the control panel. Remove the

control panel by unscrewing the six

mounting screws and pulling the panel

away from the front frame.

8. Remove the two white hole plugs from

the left door latch mounting holes, and

insert them into the right door latch

mounting holes (where the door latch

assembly was originally mounted).

9. Rotate the door latch assembly 180°,

and install into the left door lat ch mounting

holes.

NOTE: Each stud on the latch assembly

should have a plastic washer, a spring, a

plastic washer and a Nyloc type nut,

10. To adjust the tension of the door latch,

tighten both nuts down until the springs are

fully compressed, then back each nut off

1/2 turn.

11. Replace the control panel.

12. Remove the inner door panel by removing the six screws and spacers on the top

and bottom of the door.

13. Move the magnet and magnet clip to

the opposite side of the inner door panel

(REF Fig.7.3).

14. Put the door back together, making sure

the magnet is located at the top of the door,

and refasten it together with the six screws

and spacers, into the top and bottom of the

door.

15. Rotate the door 180° for mounting.

16. Slide the remaining hinge into the top

door bearing.

17. Slide the door and hinge assembly

down onto the hinge which you have

already mounted to the front of the unit.

Use the two to mount the top hinge into the

right upper hinge mounting holes. DO NOT

COMPLETELY TIGHTEN THE HINGE

MOUNTING SCREWS YET. These will be

used later for adjusting the door.

NOTE: Be sure to include spacer washers

behind hinges.

18. Door adjustment is covered in Section

7.7 of this manual.

5

Loading...

Loading...