Page 1

PLUS-TWELVETM

PRESSURELESS STEAM COOKER

Warning

Improper Installation, adjustment,

alteration, service, or maintenance can

cause property damage, injury, or death.

Read the installation, operating, and

maintenance instructions thoroughly

before installing or servicing this

equipment.

For Your Safety

Do not store or use gasoline or other

flammable vapors or liquids in the vicinity

of this or any other appliance.

MODEL: m ST-12 COVERING:

m Installation

m Operation

m Service & Parts

INSTALLATION, OPERATION & MAINTENANCE MANUAL

35 Garvey Street l Everett l MA l 02149

Tel: (617) 387-4100

E-Mail: custserv@mfii.com

Form Number: S-4475 Rev: A 06/03 Printed in U.S.A.

l Fax: (617) 387-4456 l Fax: (Outside MA) 1-800-227-2659

l Website: http://www.mfii.com

Page 2

Page 3

TABLE OF CONTENTS

PARAGRAPH

SECTION 1 INTRODUCTION

1.1Description ............................................

1.2Basic Functioning .................................

1.3Service ..................................................

SECTION 2 INSTALLATION

2.1Assembly ..............................................

2.2Setting in Place .....................................

2.3Mechanical Connections ......................

2.4W ater Connections ...............................

2.5Installation Check-Out ..........................

2.5.1Initial Control Settings ...........................

2.5.2Cooker Check-Out ................................

2.5.3Shut-Down Procedure ..........................

2.6Reversing the Doors .............................

SECTION 3 OPERATION

3.1Operating Controls & Indicators ...........

3.2Operating Procedures ..........................

3.2.1Steam Source Operation ......................

3.2.2Preheating ............................................

3.2.3Cooking ................................................

3.2.4Shut-Down Procedure ..........................

3.3Cleaning ...............................................

3.4Drainage ...............................................

3.4.1Cooking Compartment Drainage ..........

3.4.2Drip/Spill Trough Drainage ...................

3.5T est Kitchen Bulletin .............................

PAGE

1-1

1-1

1-1

2-1

2-1

2-1

2-1

2-1

2-2

2-2

2-2

2-2

3-1

3-1

3-1

3-1

3-1

3-1

3-2

3-2

3-2

3-2

3-2

PARAGRAPH

5.4.8Buzzer ..................................................

5.4.9Cold W ater Condener Circuit ................

5.4.10Wiring ...................................................

SECTION 6 MAINTENANCE

6.1General .................................................

6.2Preventive Maintenance .......................

6.2.1Cooking Compartment Cleaning ..........

6.3Repair & Replacement .........................

6.3.1Door Latch Tension Adjustment ............

6.3.2Door Handle Tension Adjustment .........

6.3.3Door Gasket Replacement ...................

6.3.4Exterior Panel Removal ........................

6.3.5Steam & W ater Solenoid Valve

Replacement ........................................

SECTION 7 ILLUSTRATED PARTS LIST

7.1General .................................................

7.2Ordering Information .............................

7.3Index of Illustrated Parts List ................

7.4Illustrated Parts List ..............................

LIST OF TABLES

TABLE

SECTION 3 OPERATION

3-1Controls & Indicators ............................

PAGE

5-6

5-7

5-7

6-1

6-1

6-1

6-1

6-1

6-2

6-2

6-2

6-2

7-1

7-1

7-1

7-2/7-6

3-3

SECTION 4 PRINCIPLES OF OPERATION

4.1General .................................................

4.2Plumbing Circuits ..................................

4.2.1Steam Inlet Line ....................................

4.2.2Steam Exhaust & Drain Lines ...............

4.2.3Steam Exhaust Condensing System ....

4.3Electrica Circuits ...................................

4.3.1Control Circuit Components .................

4.3.1.160 Minute Timer ....................................

4.3.1.2Indicator Lights .....................................

4.3.1.3Buzzer ..................................................

4.3.1.4Door Interlock Switch ............................

4.3.1.5Thermostatic Switch .............................

SECTION 5 TROUBLE-SHOOTING

5.1General .................................................

5.2T rouble-Shooting ..................................

5.3Electrical Fault Isolation ........................

5.4Elec Trouble-Shooting Procedures .......

5.4.1Incoming Power ....................................

5.4.2Electrical Inspection ..............................

5.4.360 Minute Timer ....................................

5.4.3.1Timer Contacts .....................................

5.4.3.2Timer Motor ..........................................

5.4.4Door Interlock Switch ............................

5.4.5Steam Solenoid V alves .........................

5.4.6Indicator Lights .....................................

5.4.7Cooking Compartment Thermostat

Switch ...................................................

4-1

4-1

4-1

4-1

4-1

4-2

4-3

4-3

4-3

4-3

4-3

4-3

5-1

5-1

5-1

5-1

5-2

5-2

5-3

5-3

5-3

5-6

5-6

5-6

5-6

SECTION 5 TROUBLE-SHOOTING

5-1General Trouble-Shooting Guide ..........

5-2Electrically Fault Isolation Guide ..........

LIST OF ILLUSTRATIONS

FIGURE

SECTION 2 INSTALLATION

2-1T ypical Door Layout ..............................

SECTION 3 OPERATION

3-1Controls & Indicators ............................

SECTION 4 PRINCIPLES OF OPERATION

4-1Pictorial Diagram -

Steam & W ater Circuits ........................

SECTION 5 TROUBLE-SHOOTING

5-1Wiring Diagram, ST -12 .........................

5-2Schematic Diagram, ST -12 ...................

SECTION 7 ILLUSTRATED PARTS LIST

7-1Cabinet Assembly .................................

7-2Door Assembly .....................................

7-3Control Panel Assembly .......................

7-4Condenser Assembly ............................

5-1

5-2

2-3

3-2

4-2

5-4

5-7

7-3

7-4

7-5

7-6

i

Page 4

SECTION 1 INTRODUCTION

This service and parts manual contains general information, installation instructions, principles of operation, trouble-shooting,

and maintenance information for Market Forge ST-12 Pressureless Steam Cooker. Also included is a part list in which each

replaceable part is identified and shown in an accompanying exploded view.

1.1 Description

The ST-12 is a pressureless steam cooker consisting of a

controlled compartment enclosed in a single cabinet. The

compartment is equipped with a separate three-piece door

with inner gasket plate isolated from the exterior surface.

The door latch design ensures positive sealing of the inner

door. Steam delivery and steam-condensing circuits are

both electrically controlled. The operating controls are

displayed on a single front-mounted panel that includes a

timer with an indicator light for the selection of constant

steam or 60-minute-long duration cooking.

A separate steam source is required for operation of the

Pressureless Cooker and is normally purchased with it,

please refer to the respective manual for guidance.

1.2 Basic Functioning

The Model ST-12 compartment is equipped with controls,

allowing selection of constant steam or 60-minute timer

operation. The cooker becomes operational when it is set

to constant steam, or the timer is set at the desired

cooking time and the compartment door is closed. The

indicator light comes on and the steam solenoid valve

opens, allowing steam to flow into the compartment.

1.3 Service

Required service, both preventive and corrective, is

explained in Section 6. Should repairs be required, a

network of authorized service agencies is available to

assist with prompt service. A current Directory of

Authorized Service Agencies may be obtained by

contacting:

Product Service Department

Market Forge Industries Inc.

35 Garvey Street l Everett l MA l 02149

Tel: (617) 387-4100 l Fax: (617) 387-4456

Fax: (Outside MA) 1-800-227-2659

E-Mail: custserv@mfii.com l Website: http://www.mfii.com

The model and serial number must be referenced when

corresponding with Market Forge service personnel. The

data plate containing the serial number pertaining to the

equipment is located on the top front trim of the cabinet

base and also on the top panel of the steamer.

When steam flowing inside the compartment has raised

the interior temperature to 195°F, the contacts of a

thermostatic switch automatically close, completing the

circuit to the timer motor and starting the selected cooking

time period. At the end of the set interval, timer contacts

switch to shut off the cooking operation and sound a signal

buzzer. The buzzer is silenced by returning the timer dial

to the OFF position.

In the constant steam mode, operation will be continuous.

When steam and condensate is emitted from the

compartment it is directed through a drain screen inside

the compartment into the cooker drain line. A cold water

solenoid valve connected into the compartment drain line

is automatically actuated by a thermostatic switch in the

cooking compartment drain line to condense the steam to

water prior to discharge into the drain.

1-1

Page 5

SECTION 2 INSTALLATION

2.1 Assembly

The Pressureless Cooker is factory-mounted on a cabinet

base containing either a steam boiler or direct steam

connection controls for the cooker. The assembled unit is

shipped bolted to a skid, with cabinet feet in a separate

container. Steps required for assembly are as follows:

1. Remove the four bolts that fasten the equipment frame

to the skid.

2. Install feet in threaded mounting locations of the cabinet

frame.

3. Mount the two pan support racks in brackets and studs

inside cooking compartment.

4. Attach panels to lower cabinet. Detailed instructions are

enclosed with the panels.

5. Attach the drip trough on studs located on the face of

the unit.

2.2 Setting in Place

Level the unit in final location by turning the adjustable

feet. Using the cabinet top as a reference, obtain level

adjustment left-to-right and front-to-back.

2.3 Mechanical Connections

Since the Pressureless Cooker is interconnected at the

factory to the steam boiler or direct steam plumbing, no

field connections to the cooker are required. All electrical

and plumbing connections are routed to the steam boiler

cabinet through the 6-inch-high space between the floor

and the bottom edge of the cabinet frame. Connection

locations for the cooker mounted on steam boilers of

electric, gas, and steam coil utility and direct-connected

steam are shown in separate installation instructions for

each.

2.4 Water Connections

2.5 Installation Check-Out

Check-out procedures for the cooker mounted on steam

boilers of electric, gas, and steam coil or direct-connected

steam are given in separate installation instructions for

each. Procedures for the cooker only are included in

Subsection 2.5.2.

If the cooker fails to perform as described, consult Table 51 of the Trouble-Shooting Guide for corrective action. If

difficulty arises with the boiler, reference the separate

service and parts manual for that equipment.

Before making this check-out, the operator must be

thoroughly familiar with the operating procedures in

Section 3 and with the function of each control described

in Table 3-1. Reference Figure 3-1 for identification of

controls required in the following procedures.

2.5.1 Initial Control Settings

Before beginning the start-up procedures for the cooker,

the instruction plate and service manual for the steam

boiler must be consulted and all start-up procedures

completed to supply 15 PSI steam to the steam inlet line

for the cooker.

1. All steam boiler controls are in the operating mode and

15 PSI steam is applied to the cooker inlet plumbing.

2. Cooker timer for the compartment (Figure 3-1) is in the

OFF position.

3. Cooker compartment is empty of all information

materials, pan supports are mounted in place, and door

is open.

2.5.2 Cooker Check-Out

The cooker check-out procedures are as follows:

1. With the door open set timer to about the “4-minute”

position. Observe that indicator light is off and steam

does not enter compartment.

Before connecting water to this unit, have water supply

analyzed to make sure that hardness is no grater than

2.0 grains per gallon and pH level is within the range of

7.0–8.5. Water that fails to meet these standards should

be treated by the installation of a water conditioner.

EQUIPMENT FAILURE CAUSED BY INADEQUATE

WATER QUALITY IS NOT COVERED UNDER

WARRANTY!

CAUTION

PVC or CPVC are not acceptable materials for drains.

2. Close cooker compartment door. Observe that indicator

light turns on, and steam can be heard rushing into the

compartment simultaneously with the door closing.

3. Observe the boiler drain line for passage of steam into

the open floor drain. Correct steam condenser operation

is evidenced by presence of water flowing from the

drain line.

4. Observe cooker operation for several minutes. Operation is correct if timer dials begin to rotate after a short

delay period required for preheating. After the delay

period plus the “4-minute” initial setting, the timer dials

will return to the “0-Minute” position, at which a buzzer

sounds. The buzzer is silenced by turning the dial to the

OFF position.

2-1

Page 6

SECTION 2 INSTALLATION

2.5.3 Shut-Down Procedure

No shut-down procedure is required for the Pressureless

Cooker except to check that the timer dial is in the OFF

position and the compartment door are open. Consult the

steam boiler instruction plate and complete the shut-down

procedures for the boiler.

2.6 Reversing the Doors

The Pressureless Steam Cooker has a reversible cooking

compartment door. This section contains instructions for

reversing this door.

1. Turn off power to the unit.

2. Open the cooking compartment door

3. Remove the two screws that attach the top hinge to the

front of the unit.

4. Slide the door upwards, off the bottom hinge.

5. Remove the two screws that attach the bottom hinge to

the front of the units.

6. Remove the right and left side panels by unscrewing the

1 screw on each panel and sliding the panel down.

7. Remove the door interlock assembly by unscrewing the

two nuts that hold it in place (assembly is attached to

the screws in the top right hinge mounting holes, see

fig. 2-1).

8. Remove the four screws in the right side hinge

mounting holes and install them in the left side hinge

mounting holes (where the hinges were originally

mounted).

12. Remove the two white hole plugs from the left door

latch mounting holes, and insert them into the right

door latch mounting holes (where the door latch

assembly was originally mounted).

13. Rotate the door latch assembly 180°, and install into

the left door latch mounting holes.

NOTE:

Each stud on the latch assembly should have a plastic

washer, a spring, a plastic washer and a Nyloc type nut.

14. To adjust the tension of the door latch, tighten both

nuts down until the springs are fully compressed, then

back each nut off 1 1/2 turn.

15. Rotate the door 180° for mounting.

16. Slide the remaining hinge into the top door bearing.

17. Slide the door and hinge assembly down onto the

hinge which you have already mounted to the front of

the unit. Use the two screws to mount the top hinge

into the right upper hinge mounting holes. DO NOT

COMPLETELY TIGHTEN THE HINGE MOUNTING

SCREWS YET.

18. Slowly push the cooking compartment door closed

until it is latched.

19. The cooking compartment door can now be raised,

lowered, and/or rotated into position by bumping it with

the palm of your hand or by using a small rubber

mallet.

20. First, check the alignment at the front of the door by

making sure that the striker in the door is centered with

the latch mechanism on the front of the unit.

9. Using the nuts removed in step #6, reinstall the door

interlock assembly onto the 2 screws in the lower left

hinge mounting holes (see fig. 2-1) with by moving the

assembly over the cooking cavity to the other side of the

unit. Rotate the door interlock assembly 180° for

installation, so that the switch is now facing up.

10. Reinstall the top hinge and screws into the right lower

hinge mounting holes. Rotate the hinge 180° for

installa- tion, so that the pin which the door rides on is

now facing up. The hinge must be rotated because it

will now function as the bottom hinge. DO NOT

COMPLETELY TIGHTEN THE HINGE MOUNTING

SCREWS YET. These will be used later for adjusting

the door.

11. Remove the door latch assembly from the face of the

unit. The 2 nuts mounting the door latch are located

behind the face of the unit and must be accessed

where the right side panel was removed.

21. Square the door to the unit by raising or lowering the

hinge side of the door, keeping the latch centered with

the striker.

22. Visually inspect the door. Be sure that the door is

square to the unit, the striker is centered with the latch,

and the gasket is in contact with the entire lip of the

cooking compartment.

23. Gently open the cooking compartment door, taking

care not to move it out of position.

24. Tighten all 4 door hinge bracket mounting screws.

25. Close and visually inspect the door again, as

described in step 22.

26. Reinstall the left and right side panels, using the

screws for each panel.

2-2

Page 7

SECTION 2 INSTALLATION

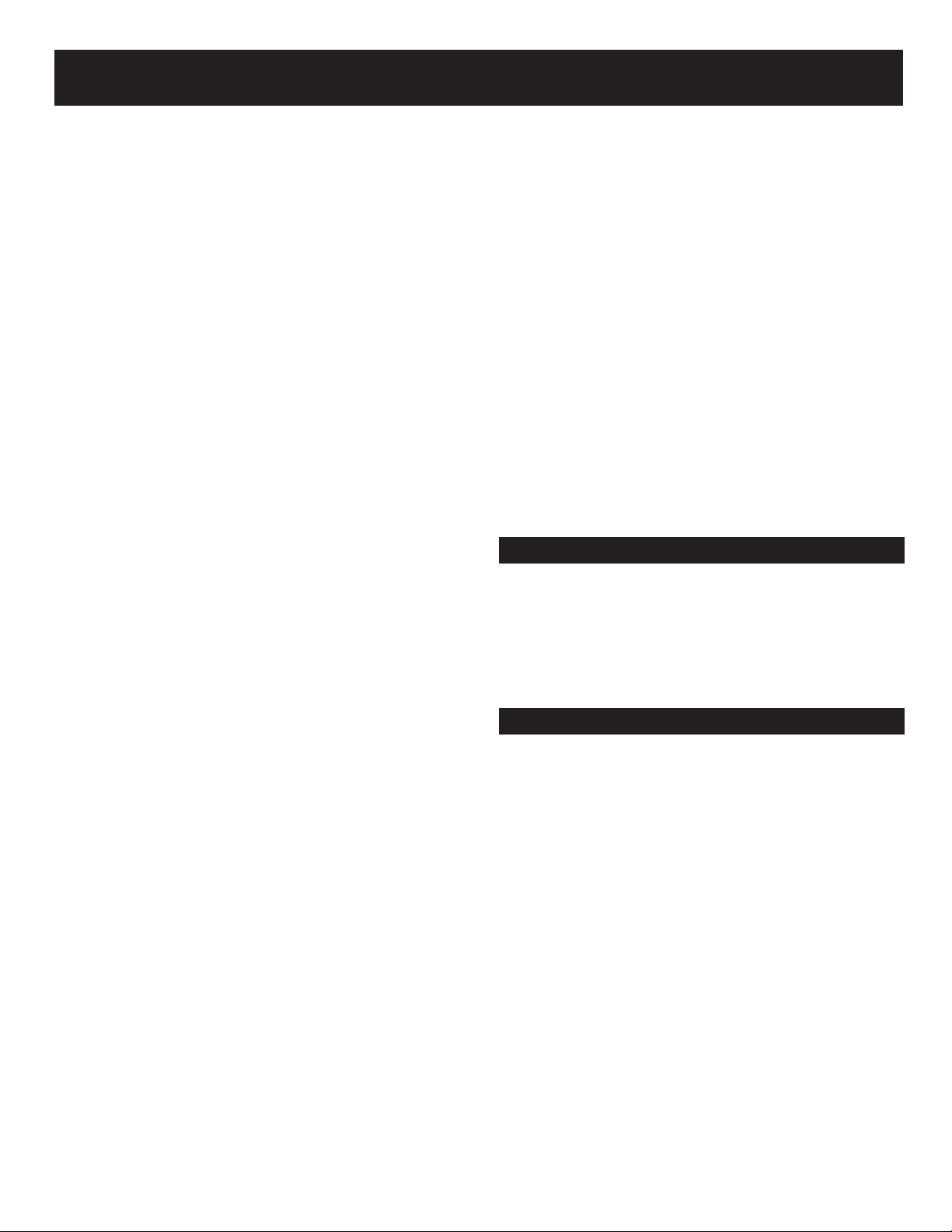

INTERLOCK ASSEMBLY

ORIGINAL POSITION

DOOR LATCH ASSEMBLY

ORIGINAL POSITION

TOP RIGHT HINGE

MOUNTING HOLES

LOWER RIGHT HINGE

MOUNTING HOLES

TOP LEFT HINGE

MOUNTING HOLES

LEFT DOOR LATCH

MOUNTING HOLES

LOWER LEFT HINGE

INTERLOCK ASSEMBLY

POSITION WHEN DOOR IS

REVERSED

2-3

Figure 2-1 Typical Door Layout

MOUNTING HOLES

Page 8

SECTION 3 OPERATION

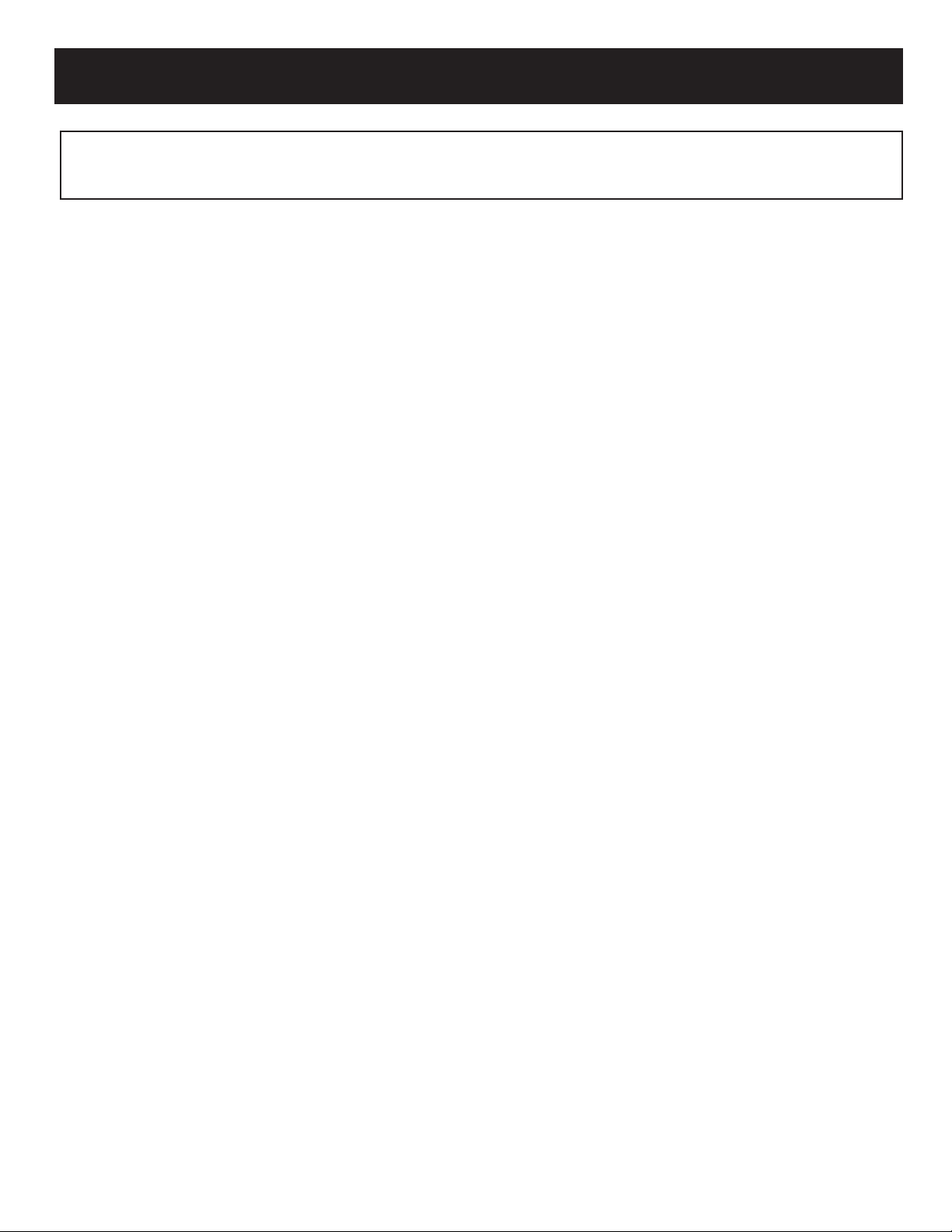

3.1 Operating Controls and Indicators

The controls and indicators required to operate the

Pressureless Steam Cooker are listed in Table 3-1,

together with a short functional description of each.

Figure 3-1 shows the physical location of each control and

indicator.

3.2 Operating Procedures

The ST-12 Pressureless Steam Cooker defrosts frozen

foods and cooks fresh and defrosted foods. The cooking

compartment permits selection of continuous (constant

steam) cooking or timed (0–60 minutes) cooking.

Instructions for operation are included in this section.

Consult Test Kitchen Bulletin for detailed cooking

information.

3.2.1 Steam Source Operation

The Pressureless Cooker is supplied mounted on a

cabinet containing either a steam boiler or controls for

direct-connected steam. Manual controls are accessed by

opening the cabinet door. The start-up procedure for the

steam source is completed once before each daily

operating period of the cooker. (For steam boilers, see

instruction plate.)

3.2.2 Preheating

3. Set timer cooking time:

a. constant steam—for continuous cooking

b. 60-minute timer—for timed cooking.

4. Set appropriate timer to the required cooking time (see

pages 3.3 to 3.6).

5. Turn off buzzer, which sounds to indicate cooking is

complete, by setting timer dial (1) to the OFF position.

6. Open door sightly at first letting most of the steam out of

the compartment and then fully open the door.

7. Unload by sliding pans of food from pan supports,

taking care to avoid hitting compartment opening.

3.2.4 Shut-Down Procedure

No shut-down procedure is required for the cooker except

to check the timer dial (1) are in the OFF position and that

the compartment door is open. When all cooking has been

completed for the day, the steam source must be shut off.

(For steam boilers, see instruction plate.)

CAUTION

When the unit is not in use, leave the cooking

compartment door slightly ajar to prolong the life of

the door gasket.

Before each initial operation of the cooker, and at any

other time when the cooking compartment is cold, a 1minute preheating period is required. To preheat the

cooker, put steam source into operation and proceed as

follows:

1. Close cooking compartment door.

2. Set 60-Minute Timer Dial (1) to “4-minute” setting.

NOTE:

Total elapsed preheating time equals the timer

setting plus a short delay period needed to active a

thermostatic switch included in the controls.

3. Turn off buzzer, which sounds to indicate cooking is

complete, by setting the Timer Dial (1) to OFF position.

3.2.3 Cooking

Before loading the cooker, be sure compartment is hot.

See Subsection 3.2.2 for preheating instructions.

1. Slide pans of food into cooking compartment pan

supports.

2. Close cooking compartment door.

3.3 Cleaning

After each period of daily operation (more frequently as

required to maintain cleanliness), the cooker should be

thoroughly cleaned by completing the following steps:

1. Remove left, right & center pan supports, and drain

screen by lifting up and off mounting studs. Wash with a

mild detergent. Rinse and set aside for reassembly.

2. Wash cooking compartment interior using a mild

detergent and water. Rinse and dry thoroughly.

3. Replace pan supports, and drain screen in compartment

and leave door slightly ajar.

3.4 Drainage

3.4.1 Cooking Compartment Drainage

The bottom of the cooking compartment is angled slightly

toward the rear of the unit. This assures that any

condensate build-up or spills will be directed toward the

drain hole, which is located at the rear bottom center of the

cooking compartment. Any liquid exiting the cooking

compartment runs down the cooking compartment drain

tube and into the drain line.

3-1

Page 9

SECTION 3 OPERATION

PLUS - 12

TIMER

2

1

3

6

4

TIMED

STEAM

5

9

8

7

START

CLEAR

0

STOP

4

O

OFF

3.4.2 Drip/Spill Trough Drainage

The ST-12 Pressureless Steam Cooker has a drip/spill

trough below the cooking compartment door. It will catch

CONSTANT

STEAM

any condensate gathering on the front of the unit when the

door is opened.

3

5

5

MANUAL OPTION

1

STEAM

UPPER COMPARTMENT

&

LOWER COMPARTMENT

o

OFF

STEAM

LOWER COMPARTMENT

&

KETTLE

STEAM

UPPER COMPARTMENT

&

LOWER COMPARTMENT

o

OFF

STEAM

LOWER COMPARTMENT

&

KETTLE

C

O

N

S

F

T

F

O

A

N

S

T

T

E

A

M

0

60

5

10

15

20

40

25

35

30

55

50

45

DIGITAL OPTION

2

REF. NUMBER

1

2

3

4

TABLE 3-1

CONTROLS & INDICATORS

(See Figure 3-1)

DESCRIPTION

Timer/Constant Steam

Indicator Light

Digital Timer

Mode Switch

FUNCTION

Controls cooking up to

60 Minutes or uses

constant operation.

Indicates cooker is in

operation.

Control cooking up to

99 minutes or constant.

Constant Steam/Timer

O

OFF

CONVECTION

STEAM

COOKER

Figure 3-1 Controls & Indicators

3-2

Page 10

SECTION 3 OPERATION

TEST KITCHEN BULLETIN

Model ST-12 Pressureless Cooker

Facts On Parade

3.5 TEST KITCHEN BULLETIN

1. Frozen vegetables should always be cooked in perforated 12” x 20” x 2 1/2” (1/1 65mm) pans.

2. Frozen entrees should be underlined with a perforated pan for best results. If they are defrosted first, the heating

time will be decreased.

3. Fresh foods may also be cooked in this unit. Vegetables and other foods where the stock is not to be retained

should be cooked in perforated 12” x 20” x 2 1/2” (1/1 65mm) pans for the most nutritious results.

4. There is a thermostatic time delay built into this unit which adapts the unit to the proper cooking time. This means

that the total time will usually be longer than the time setting.

5. There is a safety interlock switch on the door which shuts off the steam each time the door is opened if the unit is in

the cooking cycle.

6. Compartments may be filled and timer set simultaneously.

7. Sheet pans will fit in compartment with the center rack removed.

8. All foods, except cakes and pastry, can be cooked in a steam cooking unit.

9. Steam cooked meals have greater nutritional value since they retain most of their vitamins and minerals.

10. Because foods are cooked faster by the higher temperatures of steam cooking, they can be prepared closer to

serving time, insuring maximum freshness.

11. Steam cooked foods have a higher percent yield more portions per dollar spent.

12. Food may be served from the same pan in which it is steam cooked, thus reducing food breakage since there is no

extra handling or transferring of food from cooking pans to serving pans. It also reduces pot washing tasks.

13. Some important advantages of steam cooking are labor saving, reduced operating costs, space saving, and the

lifting of heavy stock pots is eliminated.

14. Rice and spaghetti products, if thoroughly wet at the start of the cooking process, are very easily prepared.

15. Food such as potatoes, poultry, seafood, and some meats may be blanched in the steam cooker, thus reducing the

total cooking time and grease absorption.

16. Fuel is used only when the steam cooking unit is in operation.

17. The steam cooker will loosen foods burned on pans making washing easier.

18. Solid pans are recommended when liquid is to be retained and perforated pans when the liquid is not to be retained.

19. Eggs may be cooked out of the shell if they are to be chopped which eliminates peeling after steaming.

20. The steam cooker can be opened during the cooking period to add or remove items. If any time is lost, an

adjustment may be made on the timer.

21. Steam cooking information, including recommended pan size and type, weight per pan, cooking times and pan

yields are given on the following pages of this manual.

3-3

Page 11

SECTION 3 OPERATION

The ST-12 Pressureless Cooker is a one compartment unit. The compartment holds twelve 12” x 20” x 2 1/2” or six 12” x

20” x 4” pans. This unit enables the cook to prepare foods close to the time of service. The cooking times given are timer

settings and should be set in a preheated compartment. There is a thermostatic time delay in the compartment that

adjusts the total time depending on the temperature and amount of the food. Therefore the total time will be greater than

the timer setting. At the end of the timer cooking cycle the buzzer will sound, steam will stop flowing and the food can be

removed.

FROZEN VEGETABLES

ITEM

Asparagus Spears

Beans, Green Regular

Beans, Green French Cut

Beans, Lima

Broccoli

Brussel Sprouts

Carrots

Cauliflower

Corn-Cut

Mixed Vegetables

Peas (Loose)

Spinach

Squash

Approx. Frozen

Weight

Per Pan

7 1/2 lbs. (3.4 kg)

6 lbs. (2.7 kg)

6 lbs. (2.7 kg)

7 1/2 lbs. (3.4 kg)

6 lbs. (2.7 kg)

7 1/2 lbs. (2.7 kg)

6 lbs. (2.7 kg)

6 lbs. (2.7 kg)

7 1/2 lbs. (3.4 kg)

7 1/2 lbs. (3.4 kg)

7 1/2 lbs. (3.4kg)

9 lbs. (4kg)

12 lbs. (5.4 kg)

Recommended

12” x 20” (1/1)

Perforated Pan

2 1/2” (65mm)

2 1/2” (65mm)

2 1/2” (65mm)

2 1/2” (65mm)

2 1/2” (65mm)

2 1/2” (65mm)

2 1/2” (65mm)

2 1/2” (65mm)

2 1/2” (65mm)

2 1/2” (65mm)

2 1/2” (65mm)

2 1/2” (65mm)

2 1/2” (65mm)

Number

of Pans

12

12

12

12

12

12

12

12

12

12

12

12

12

Timer

Settings in

Minutes

12-15

10-15

5-7

12-15

4-6

10-15

10-15

7-12

8-12

8-12

3-5

Must be defrosted

Must be defrosted

Approx. Number

Cooked Servings

Per Pan

30 3 oz. (85 g)

25 3 oz. (85g)

25 3 oz. (85 g)

30 3 oz. (85 g)

25 3 oz. (85 g)

30 3 oz. (85 g)

25 3 oz. (85 g)

25 3 oz. (85 g)

30 3 oz. (85 g)

30 3 oz. (85 g)

30 3 oz. (85 g)

30 4 oz. (115 g)

50 3 oz. (85 g)

ITEM

Lobster Tails

6-8 oz. (170-255 g)

Shrimp, C.D.P.

Shrimp Green

Bulk Pack Frozen

Bulk Pack Defrosted

ITEM

Canned Vegetables

FROZEN PREPARED ENTREES

Weight Per Pan

7-8 lbs. (3.2-3.6 kg)

16-20 lbs. (7-9 kg)

16-20 lbs. (7-9 kg)

3 1/2-4 lbs. (1.6-1.8 kg)

3 1/2-4 lbs. (1.6-1.8 kg)

VEGETABLES (CANNED)

Weight Per Pan

7 lbs. (3.2 kg)

Recommended

12” x 20” (1/1)

Perforated Pan

2 1/2” (65mm)

2 1/2” (65mm)

2 1/2” (65mm)

2 1/2” (65mm)

2 1/2” (65mm)

Recommended

12” x 20” (1/1)

Perforated Pan

2 1/2” (65mm)

3-4

Number

of Pans

12

12

12

12

12

Number

of Pans

12

Timer

Settings in

Minutes

15-25

8-11

11-15

35-45

25-35

Timer

Settings in

Minutes

5-10

Approx. Number

Cooked Servings

Per Pan

15 6 oz. (170 g)

75 3 oz. (85g)

50 3 oz. (85 g)

10 6 oz. (170 g)

10 6 oz. (170 g)

Approx. Number

Cooked Servings

Per Pan

25-30 3oz. (85 g)

Page 12

SECTION 3 OPERATION

PRESSURELESS STEAM COOKING TIMER SETTINGS & PORTIONS

VEGETABLES

ITEM

Beans, Snap Green

or Waxed

Beets (50mm) 2” E

Broccoli 1/2-3/4”

(12-20mm) Stalks

Carrots Sliced

Cauliflower, Trimmed

1 1/2-2” (38-50 mm)

Corn on Cob Husked

Cabbage Head 1/4-1/6

Cored

Onions (50 mm) 2" E

Peas, Shelled

Potatoes, French Fry Cut

Potatoes, Regular

Cut, 3” (75 mm)

Approx. Frozen

Weight

Per Pan

6 lbs. (2.7 kg)

7 1/2 lbs. (3.4 kg)

6 lbs. (2.7 kg)

9 lbs. (4 kg)

6 lbs. (2.7 kg)

1 doz.

5 lbs. (2.25 kg)

6 lbs. (2.7 kg)

5 lbs. (2.25 kg)

10 lbs. (4.5 kg)

10 lbs. (4.5 kg)

Recommended

12” x 20” (1/1)

Perforated Pan

2 1/2” (65mm)

2 1/2” (65mm)

2 1/2” (65mm)

2 1/2” (65mm)

2 1/2” (65mm)

2 1/2” (65mm)

2 1/2” (65mm)

2 1/2” (65mm)

2 1/2” (65mm)

2 1/2” (65mm)

2 1/2” (65mm)

Number

of Pans

12

12

12

12

12

12

12

12

12

12

12

Timer

Settings in

Minutes

18-22

40-50

14-18

18-21

12-16

10-15

14-18

20-25

5-6

18-21

35-40

Approx. Number

Cooked Servings

Per Pan

25-30 3 oz. (85 g)

30-35 3 oz. (85g)

25-30 3 oz. (85 g)

35-40 3 oz. (85 g)

30-35 3 oz. (85 g)

12

15-20 4 oz. (115 g)

25-30 4 oz. (115 g)

25-30 3 oz. (85 g)

50 3 oz. (85 g)

50 3 oz. (85 g)

Spinach, Cleaned Cut

Squash, Summer, Sliced

1” thick (25 mm)

Squash, Winter Peeled

Diced Turnip

ITEM

Chicken Cut-up

Chicken, 4 lbs. Whole

Fowl, 5lbs. or more Whole

Fish, Fillets

Frankforts

Hamburgers3 oz. (85 g)

Meatballs 1 oz. (30 g)*

3 lbs. (1.4 kg)

7 lbs. (3.2 kg)

9 lbs. (4 kg)

5 lbs. (2.25 kg)

Weight Per Pan

8 lbs (3.6 kg)

3 each

2 each

3 lbs (1.4 kg)

5 lbs (2.3 kg)

5 lbs (2.3 kg)

6 lbs (2.7 kg)

2 1/2” (65mm)

2 1/2” (65mm)

2 1/2” (65mm)

2 1/2” (65mm)

MEAT, POULTRY & FISH

Recommended

12” x 20” (1/1)

Perforated Pan

2 1/2” (65mm)

4” (100 mm)

4” (100 mm)

2 1/2” (65mm)

2 1/2” (65mm)

2 1/2” (65mm)

2 1/2” (65mm)

Number

of Pans

12

12

12

12

2

6

6

12

12

12

12

3-5

7-10

10-15

28-32

Timer

Settings in

Minutes

20-30

45-50

50-60

10-15

3-5

18-22

20-25

10-12 3 3/4 oz. (105 g)

30-35 3 oz. (85 g)

25-30 3 oz. (85 g)

20-25 4 oz. (115 g)

Approx. Number

Cooked Servings

Per Pan

15-20 2 oz. Protein (55 g)

25-30 2 oz. Protein (55 g)

20-25 2 oz. Protein (55 g)

12-15 2 oz. (55 g)

35-40 2 oz. (55 g)

20-25 2 oz. Protein (55 g)

20-25 2 oz Protein (55 g)

3-5

Page 13

SECTION 3 OPERATION

PRESSURELESS STEAM COOKING TIMER SETTINGS & PORTIONS

MEAT, POULTRY & FISH CONTINUED

ITEM

Meatloaf*

Pork Chops, 4 oz.

Loin Bone (115 g)

Sausage 1 1/2 oz. (45 g)

Turkey On Carcass

TurkeyOff Carcass

ITEM

Eggs In Shell

Eggs Out of Shell

Rice — Bulletin 16

gives direction

Spaghetti — Bulletin 13

gives direction

Approx. Frozen

Weight

Per Pan

15 lbs (6.8 kg)

6 lbs (2.7 kg)

6 lbs (2.7 kg)

20-22 lbs (9-10 kg)

10-12 lbs (4.5-5 kg)

Weight

Per Pan

3 dozen

4 dozen

4 lbs. (1.8 kg)

3 lbs. (1.4 kg)

Recommended

12” x 20” (1/1)

Perforated Pan

2 1/2” (65mm)

2 1/2” (65mm)

2 1/2” (65mm)

2 1/2” (65mm)

2 1/2” (65mm)

MISCELLANEOUS

Recommended

12” x 20” (1/1)

Perforated Pan

2 1/2” (65mm)

2 1/2” (65mm)

2 1/2” (65mm)

4” (100mm)

Number

of Pans

12

12

12

2

12

Number

of Pans

12

12

12

6

Timer

Settings in

Minutes

40-50

25-30

18-21

2-2 1/2 hrs.

1-1 1/4hrs.

Timer

Settings in

Minutes

9-11

6-8

18-22

18-22

Approx. Number

Cooked Servings

Per Pan

50-60 2 oz. Protein (55 g)

24 2 oz. Protein (55 g)

18-20 2oz. (55 g)

50-60 2 oz. Protein (55 g)

55-65 2 oz. Protein (55 g)

Approx. Number

Cooked Servings

Per Pan

36 -1 egg each

48 - 1 egg each

60-65 3oz. (85 g)

40-45 4oz. (115 g)

3-6

Page 14

SECTION 4 PRINCIPLES OF OPERATION

4.1 General

The ST-12 Pressureless Steam Cooker consists of one

cooking compartment in a single cabinet assembly. The

compartment is fitted with an independent electrically

controlled steam circuit and spring-loaded, self-sealing

door with a slam action latch. The compartment can be

used for either constant steam or 60-minute timing. The

principles of operation in this section include an

explanation of steam, steam condensing, and electrical

circuits and their functioning.

4.2 Plumbing Circuits

The plumbing circuit consists of the piping, steam solenoid

valve, steam jet-pipe, drain, and cold water condenser

required to provide controlled steam application to the

cooking compartments. A simplified diagram of this circuit

is shown in Figure 4-1.

NOTE:

Figure 4-1 is strictly a pictorial schematic diagram and is

not intended to show the actual configuration of the

plumbing. All components are shown in correct

relationship with each other. However, the diagram does

not show their actual locations or position within the

cooker.

As shown in the diagram, steam inlet and exhaust

connections are connected at the factory directly into a

steam boiler or direct-connected steam plumbing enclosed

within the base cabinet on which the cooker is mounted.

The boiler (or direct-connected steam control system) is

equipped to supply constant, regulated steam at

14–15 PSI. Steam exhaust, having been reduced to water

by the cold water condenser, is directed into the boiler (or

direct-connected steam control) drain system.

Steam inlet lines for the compartment are equipped with a

normally closed solenoid valve operated by the electrical

control circuit. The inlet valve is opened whenever the

compartment control circuit is activated by use of the 60minute timer.

4.2.1 Steam Inlet Line

A steam supply line is plumbed from the boiler output (or

direct-connected steam control) to a 1/2-inch barb fitting

connected to the input sides of the steam inlet solenoid

valve. When a cooking compartment is not in use, the

valve for the compartment remains closed to prevent

steam from entering. During operation, the appropriate

inlet solenoid valve is opened by activation of the control

circuit.

Steam is projected onto the surface of pans of food loaded

into the compartment by an orifice located inside the

compartment. Steam continues to flow through the

compartment in this manner until the control circuit closes

the solenoid valve.

4-1

4.2.2 Steam Exhaust and Drain Lines

Perforated strainers at the drain line opening inside the

compartment allow only steam, condensation, and liquid

cooking drainage to enter. Prior to discharge into the boiler

drain system, steam is converted to water by the cold

water condensing system for the compartment.

4.2.3 Steam Exhaust Condensing System

The steam condensing system consists of a, two-position,

normally closed cold water solenoid valve, with outlet

sides connected into the exhaust plumbing for each

cooking compartment. A spray nozzle directs cold water

about the inside of the drain lines to increase cold water

contact with exhausted steam. Valve inlet side is

connected remote from the supply line of the steam boiler

(or direct-connected steam plumbing). The valve responds

to a thermostatic switch located inside the compartment.

When the timer starts the cold water solenoids will

energize.

4.3 Electrical Circuits

The electrical circuits of the cooker control the power to

activate timer motors and energize solenoid-operated

valves and circuits, which in turn control application of

steam to the cooking compartment and condensation of

steam from the exhaust line. The cooker operates on

120V, 2 amp, 60Hz electrical service connected to all

circuits from the circuits of the steam boiler (or directconnected steam controls) contained within the cabinet on

which the cooker is mounted. Power is supplied to the

control circuit at all times when the shut-off device (Circuit

Breaker) for the unit (installed by an certified Electrician) is

in the ON position.

4.3.1 Control Circuit Components

A brief description of the electrical circuit elements follows.

4.3.1.1 60 Minute Timer/Constant Steam

The timer contains a 120-volt AC synchronous motor that

drives a timing dial through a gear reduction and clutch

mechanism. The timer dial is manually set for any interval

of operation from 0 to 60 minutes or constant steam as

read on the calibrated dial face. The manual rotation of the

dial moves the common element (1) of the timer switch

from the neutral (OFF) position to contact (3), which

connects with the steam inlet solenoid valve operating

circuit.

The cooker is placed into automatic operation with the

setting of the timer dial. Its timing cycle, however, is

automatically delayed by a thermostatic switch, which

assures operating temperature is achieved before the

timer motor begins to “time out.”

Page 15

SECTION 4 PRINCIPLES OF OPERATION

WATER INLET TO

TOP CAVITY

STEAM JET PIPE

(2 PER COMPARTMENT)

STEAM LINE

TO CAVITY

WATER INLET

FROM BOILER

Figure 4-1 Pictorial Diagram, Steam & Water Circuits (Model ST-20 Shown Here)

When the timer motor has operated for the preset

duration, the common element is transferred to contact (4),

returning the inlet solenoid valve to the closed position and

energizing the buzzer. Contact to the buzzer circuit

remains closed until the dial is manually turned to the OFF

position, returning the common element (1) of the timer

switch to the neutral position.

4.3.1.2 Indicator Lights

WATER TO

DRAIN LINE

STEAM LINE

TO CAVITY

STEAM LINE

FROM BOILER

mally open contacts. The switch is operated by the

proximity of a magnet within the door. When the door is

open, the switch contacts remain in the open position.

When the door is closed and securely latched in place, the

magnet is near the switch to close the contacts.

Connected between the operating contact (3) of the timers

and the steam inlet solenoid valve, the door switch acts as

a protective device to interrupt valve operation unless the

door is closed.

An indicator light is included for the compartment. The light

remains on (red) at all times when the coinciding timer dial

is set and the door interlock switch is closed. The light

turns off at the end of the timed cooking duration or when

the set time has elapsed.

4.3.1.3 Buzzer

The buzzer is an alarm device that operates by oscillation

of a striker against the core of an electromagnet. When the

60-minute timer dials reach the “0-Minute” position, the

buzzer coil is energized to sound the buzzer. Movement of

the timer dial to the OFF position opens the contact to the

buzzer coil to shut it off.

4.3.1.4 Door Interlock Switch

The interlock switch is a single-pole proximity switch with

normally open contacts. The switch is operated by the nor-

4.3.1.5 Thermostatic Switch

The thermostatically operated switch is a two-position,

normally open switch mounted on the cooking

compartment. The switch functions to activate the cold

water solenoid valves of the steam condensing system

and to delay timer motor operation until the compartment

temperature reaches 195°F, thus assuring that cooking

temperature exists throughout the timed duration.

4.3.1.6 Digital Timers (Optional)

The timer controls the steam to the cavity by either a

constnat steam setting or a used defined timer that will be

programmed by the user into the timer

4-2

Page 16

SECTION 5 TROUBLE-SHOOTING

5.1 General

The information in this section is intended to assist both

the operator and service personnel in locating the general

source of problems that may occur with the cooker. Before

following any of the procedures given in this section, the

operator should be thoroughly familiar with the operating

instructions and the function of all controls that are

described in Section 3. If the problem cannot be readily

corrected, the operator should contact the nearest Market

Forge service agency for assistance.

5.2 Trouble-Shooting Guides

A trouble-shooting guide for use by service personnel is

given in Table 5-1.

TABLE 5-1 GENERAL TROUBLE-SHOOTING GUIDE

PROBLEM

1. INDICATOR LIGHT FAILS TO

LIGHT WITH TIMER SET.

PROBABLE CAUSE

a. Power to Cooker OFF.

b. Door Interlock Switch contacts

not closed.

c. Door Interlock Switch faulty.

5.3 Electrical Fault Isolation

Correction of an electrical failure first requires isolation of

the fault to a single circuit or component. In most cases,

the nature of the failure and its effect upon the operation of

the cooker will be sufficient to narrow it down to one or

more circuit elements. Table 5-2 is provided as a guide for

isolating electrical faults.

5.4 Electrical Trouble-Shooting Procedures

Before performing the trouble-shooting procedures in this

section, the serviceman must be familiar with the function

of all controls as described in Section 3 as well as with the

Principles of Operation described in Section 4.

REMEDY

a. Locate External Circuit Breaker for

incoming power & place in ON position.

b. Shut cooker door to close switch contacts,

Check alignment of door with switch.

c. Replace Switch (see subsection 5.4.4).

2. STEAM FAILS TO ENTER

COOKING COMPARTMENT WITH

INDICATOR LIGHT ON.

3. STEAM ENTERS COMPARTMENT

CONTINUOUSLY. TIMER DIAL NOT

TURNING.

4. STEAM CONTINUES TO FLOW

INTO COMPARTMENT AND/OR

BUZZER FAILS OT SOUND AT

END OF TIMER SETTING.

5. STEAM FLOWS CONTINUSLY

FROM BOILER (

ECTED STEAM CONTROL

WITH COOKER IN OPERATION.

OR DIRECT CONN-

) DRAIN LINE

d. Indicator Light burned out.

e. Faulty Timer contacts.

f. Faulty Wiring.

a. Faulty Steam Solenoid Valve.

b. Faulty Wiring.

a. Constant Steam Position.

b. Faulty Thermostatic Switch.

c. Faulty Timer Motor.

d. Faulty Steam Solenoid Valve.

e. Faulty Wiring.

a. Timer Contacts Faulty.

b. Buzzer Faulty.

c. Faulty Wiring.

a. Cold water not connected.

b. Faulty Thermostat.

c. Faulty Cold water.

d. Replace Light.

e. Replace Timer (see subsection 5.4.3).

f. Inspect condition od wire & tightness of all

connections, Correct as needed.

a. Replace Valve (see subsection 5.4.5).

b. Inspect condition od wire & tightness of all

connections, Correct as needed.

a. Move knob to timing location.

b. Replace Switc (see subsection 5.4.7).

c. Replace Timer (see subsection 5.4.3).

d. Replace Valve (see subsection 5.4.5).

e. Inspect condition od wire & tightness of all

connections, Correct as needed.

a. Replace Timer (see subsection 5.4.3).

b. Replace Buzzer (see subsection 5.4.8).

c. Inspect condition od wire & tightness of all

connections, Correct as needed.

a. Turn on external shut-off valve.

b. Replace Thermostat (see subsection 5.4.7).

c. Replace Valve.

d. Faulty Wiring.

d. Inspect condition od wire & tightness of all

connections, Correct as needed.

5-1

Page 17

SECTION 5 TROUBLE-SHOOTING

The electrical trouble-shooting procedures that follow

require access to components and terminals of the

electrical control panel shown in Figure 7-3. Electrical

controls are reached by removing screws that fasten the

control panel to the frame. The panel may be pulled

forward for testing while interconnected to the cooker

circuits or disconnected at the pin connection for complete

removal and repair.

5.4.1 Incoming Power

Before trouble-shooting any of the electrical parts or

assemblies, verify that power is being supplied to the

cooker. Incoming power is connected at the boiler (or

direct-connected steam) control box located in the base

cabinet. With power connected to the cooker, an AC voltmeter is used to measure 120 volts across L1 and L2. If

120 volts is present, and the cooker will not operate, the

fault lies within the electrical circuits of the cooker.

5.4.2 Electrical Inspection

The first step in any electrical trouble-shooting procedure

is a thorough physical inspection of all wiring connections.

To access electrical components, remove the control panel

as explained in Subsection 6.3.4.

Warning

Before removing control panel or checking connections

and wiring, be sure that the circuit breaker for incoming

power is OFF. When power is supplied, all exposed

terminals of the control panel carry 120 volts.

Check all wiring connections by hand to assure that both

ends of all connection points are tightly secured. Use a

screwdriver to tighten connection points. If necessary,

visually inspect all quick-disconnect terminals for evidence

of corrosion. Terminals in this condition should be

separated, cleaned with emery cloth until shiny, and tightly

reconnected.

5.4.3 60-Minute Timer

5.4.3.1 Timer Contacts

Defective timer contacts will result in failure of either

cooker compartment to operate. When this occurs, remove

the control panel (see Subsection 6.3.4), and proceed as

follows:

1. Turn off power to the cooker at external circuit breaker.

timer contacts are defective and the timer must be

replaced.

5. Move ohmmeter leads to terminals 1 and 4.

6. Rotate timer dial to “0-Minute” position (an audible click

indicates correct position). If zero ohm reading cannot

be obtained, the timer is defective and must be

replaced.

7. Remove ohmmeter and replace all five leads on timer

terminals as shown in Figure 5-1.

5.4.3.2 Timer Motor

A defective timer motor will cause continuous operation in

the Time mode, with the timer dial failing to return to the

“0-Minute” position. Since thermostatic switch failure can

cause the same symptom, fault must first be isolated to

the timer by testing the thermostat (see Subsection 5.4.8).

To confirm timer motor condition, proceed as follows:

1. Carefully check motor wire leads and tighten loose

connections.

WARNING

Use care while working with control panel. Terminals carry

120 volts.

2. Turn on power to the cooker.

3. Set timer dial (any setting beyond “0-minute”). If

operation is correct, the motor fails to operate, it is

defective and the entire timer must be replaced.

4. Shut off power to the cooker.

5.4.4 Door Interlock Switch

Malfunction of the cooker door interlock switch prevents

timer indicator lights from turning on and steam solenoid

from opening when the timer dial is set. If steam does not

enter the compartment and the indicator light fails to turn

on with the door latch securely engaged, the fault may be

in the door interlock switch. Proceed as follows:

1. Turn off power to the cooker.

2. Disconnect wires to the door switch terminals

(see Figure 5-1).

2. Disconnect all five wires from timer terminals

(see Figure 5-1).

3. Connect an ohmmeter between terminals 1 and 3.

4. Rotate timer dial beyond the “0-Minute” point (any

setting) to obtain a reading of zero ohms on the

ohmmeter. If zero ohm reading cannot be obtained,

3. Connect an ohmmeter between the terminals of the

switch.

4. Actuate the switch by closing the cooking compartment

door. If a zero reading cannot be obtained, the switch is

defective and must be replaced.

5. Remove the ohmmeter and replace the leads on switch

terminals (see Figure 5-1).

5-2

Page 18

SECTION 5 TROUBLE-SHOOTING

TO FRONT

FRAME GRD

STUD

14

5

47

B

A

A

THERMOSTAT

SWITCH S3

B

13

9

59

COLD WATER

CONDENSER

V1

33

B

60

60

50

A

BUZZER

B1

(UPPER)

5

7

105

1 2 3 7 8

B

9

PILOT-LIGHT

LT1 GRN

A B

2 1

TB1

6

TIMER

24

DONE RUN

ON

21

11

A

TIMER

60 MIN. TIMER

TMR1 (UPPER)

CONNECTOR

1111

1212

11

BLK

109654

4

106

22

55

12

B

53

3

8

10

11

2

2

9

9

3

3

5655

27

101

29

BLK

34

51

30

BLK

WHT

WHT

REED SWITCH

S1

A

RELAY R1

14

5

B

13

9

56

51

BLK

102

WHT

28

WHT

31

59

36

WHT

A

STEAM SOL.

VALVE V3

50

4 4

32

49

TO 120/240V

SUPPLY BOX

185

184

5 5

6 6

7 7

10 10

8 8

P1 J1

TO FRONT

FRAME GRD

STUD

NOTES:

1. ALL WIRES 18 AWG AND YELLOW EXCEPT WHERE INDICATED OTHERWISE.

2. FOR WIRE LEAD SCHEDULE REFER TO DRAWING C 91-6472.

Figure 5-1 Wiring Diagram Mechanical Controls, Model ST-12

L1

N (L2)

BLK

EXISTING

WIRES

TO 120/240V

SUPPLY BOX

48

11 3

L1

BOILER CONTROL BOX

(AUTOMATIC BOILERS)

(OPTIONAL)

47

186

N

TO 120/240V

SUPPLY BOX

5-3

Page 19

SECTION 5 TROUBLE-SHOOTING

NOT AVAILIABLE AT THIS TIME

Figure 5-1 Wiring Diagram Digital Controls, Model ST-12 (NOT AVAILIABLE AT THIS TIME)

5-4

Page 20

SECTION 5 TROUBLE-SHOOTING

5.4.5 Steam Solenoid Valve

When either inlet solenoid valve fails to operate, the fault

may be a defective coil. A defective coil is found using an

AC volt-meter to check the voltage at the coil wire

terminals, with the cooker compartment operating in either

constant steam or 60-minute timer mode. If voltage of

120 volts is present and the coil fails to open the valves,

the fault is in the valve coil. Defective valve coils are not

separately replaceable, requiring complete valve

replacement.

5.4.6 Indicator Lights

If the cooker compartment functions correctly, with the

single exception that the indicator light fails to light during

operation, the fault is a defective indicator light. A “burned

out” or defective light is verified by using an AC volt-meter

at the leads, with input power on the selector switch in the

correct position for that timer, the timer set, and the door

latches closed. If 120 volts is present, the fault is in the

indicator light and requires replacement. If 120 volts is not

present, the fault is in the wiring or control components

(selector switch, timer, or door switch).

5.4.7 Cooking Compartment

Thermostatic Switch

A thermostatic switch included in the circuit for the timer

motor delays timer operation until steam flowing into the

compartment satisfies the temperature-actuated switch

device. If a timer motor fails to operate within about one

minute after the indicator light comes on (with cooker

compartment empty), the cause may be a defective

thermostatic switch. To test the switch, proceed as follows:

buzzer coil connections with input power on and selector

switch and coinciding timer dial set at the “0-Minute”

position. If voltage is 120 volts, the fault is in the buzzer,

which must be replaced. If 120 volts is not present, the

fault is in the wiring or control components (timer or

selector switch).

5.4.9 Cold Water Condenser Circuit

If during cooker operation steam exits from the drain line

opening (located in lower boiler compartment) and the

condensing system fails to operate, as evidenced by

repeated discharge of water from the drain line, the

condensing circuit is malfunctioning. The failure can be

caused by a defective condenser thermostat or cold water

solenoid coil, or by wiring failure. To test condenser

thermostat, refer to Subsection 5.4.8.

If the condenser thermostat functions correctly, but either

of the cold water solenoid valves fails to operate, the

cause might be a faulty valve coil. A defective coil is found

using an AC volt-meter to check the voltage at the coil wire

terminals with the cooker compartment in operation. If

voltage of 120 volts is present and the valve fails to open,

the fault is in the valve coil. Defective valve coils are

separately replaceable.

5.4.10 Wiring

All of the electrical components of the cooker (timers,

indicator lights, etc.) are connected to each other by wiring

shown in Figure 5-1. If all of the electrical components are

operating correctly (and the incoming power has been

checked), but the cooker fails to operate, the fault lies in

the wiring.

1. Disconnect the two wires connected to the thermostatic

switch terminals.

2. Connect an ohmmeter between the two terminals of the

switch.

3. Place the cooker into operation and observe ohmmeter

dial. Within one minute of operation, the switch contacts

close automatically to register a zero ohm reading on

the dial. If a zero ohm reading is not obtained, the

switch is defective.

4. Shut off cooker, disconnect ohmmeter leads, and

replace wires on switch terminals.

5.4.8 Buzzer

If the buzzer does not sound at the termination of the

operator-selected timer setting (timer dial returned to “0Minute” position), the fault may be a defective buzzer.

Buzzer operation is verified using an AC volt-meter at the

Figure 5-1 is a diagram that shows all terminals and

interconnections within the electrical circuits. All numbered

terminals are identified and all leads number-coded as

shown. Connections can be easily removed. Figure 5-2

shows the same information schematically and is an aid in

isolating circuits for testing.

Using an ohmmeter, wiring continuity between the

connections shown on the wiring diagram (Figure 5-1) is

readily verified. This is best done in stages, removing only

those wires required for each continuity check. As each

lead is replaced, it should be checked for evidence of

corrosion, and cleaned if necessary. All leads must be

tightly attached so as to provide a good electrical

connection.

5-5

Page 21

SECTION 5 TROUBLE-SHOOTING

Figure 5-3 Ladder Diagram, Plus 12 (1) Compartment

5-6

Page 22

SECTION 6 MAINTENANCE

6.1 General

This section contains both preventive and corrective

maintenance information. Preventive maintenance may be

performed by maintenance personnel at the establishment

in which the cooker is installed. It is recommended that

user personnel never attempt to make repairs or

replacements to the equipment without the assistance of

authorized service. Assistance in service methods or a

current Directory of Authorized Agencies may be obtained

from Market Forge (see Subsection 1.3).

6.2 Preventive Maintenance

A good preventive maintenance program begins with the

daily cleaning procedure described in Subsection 3.3.

Additional preventive maintenance operations are

presented in this section. In establishments that employ

full-time maintenance personnel, the tasks described can

be assigned to them. For other installations, tasks

requiring mechanical or electrical experience should be

performed by an authorized service agency.

The following paragraphs set forth minimum preventive

maintenance procedures that must be completed

periodically to assure continued trouble-free operation of

the cooker.

2. Remove the control panel by removing the eight

mounting screws and disconnecting the wire plug and

restraining wire.

3. Tighten both nuts down until the springs are fully

compressed.

4. Back each nut off 1/2 turn.

5. Remount the control panel, reconnecting wire plug and

restraining wire.

6.3.2 Door Handle Tension Adjustment

Procedure:

1. Open the cooking compartment door.

2. Remove the six screws and washers from the top edge

and bottom edge of the door.

3. Remove the inner door gasket mounting plate assembly

from the outer door. Do not disassemble these three

components—remove them as an assembly.

4. Tighten both nuts down until the springs on the outer

door are fully compressed.

CAUTION

Under no circumstances should hardware (or parts) be

replaced with a different length, size, or type other than as

specified in the parts list. The hardware used in the cooker

has been selected or designed specifically for its

application, and the use of other hardware may damage

the equipment and will void any warranty.

6.2.1 Cooking Compartment Cleaning

A daily cleaning of the cooking compartment and pan

supports is required. See Subsection 3.3 for details.

6.3 Repair & Replacement

Section 7 of this manual contains a listing of all

replaceable parts and associated exploded views of the

ST-12 Cooker. In most cases, disassembly procedures will

be obvious from the exploded views. Instructions follow for

procedures that are not readily apparent.

6.3.1 Door Latch Tension Adjustment

CAUTION

Shut off main electrical power to unit.

Procedure:

1. Open the cooking compartment door.

5. Back each nut off 1/2 turn.

6. Remount the inner door gasket mounting plate

assembly by assembling the six screws and washers.

6.3.3 Door Gasket Replacement

The cooking compartment door gaskets are made of a

silicone-type rubber material that is very durable but

subject to wear during normal operation. Should the

gasket leak, readjust the door gasket to the unit or replace

it.

Procedure—Replace Gasket:

1. Open the cooking compartment door.

2. Remove the six screws on the outside of the door, and

remove the inner door assembly.

3. Remove the eight nuts from the door gasket mounting

plate on the inside of the inner door assembly.

4. Remove the door gasket mounting plate and the door

gasket.

5. Install the new door gasket (see Figure 7-2 for part

number) to the mounting plate.

6. Reassemble the mounting plate with gasket to the

inside of the inner door assembly using the eight nuts.

6-1

Page 23

SECTION 6 MAINTENANCE

7. Reassemble the inner door assembly using the six

screws on the outside of the door.

NOTE:

Remember that the lip on the door gasket mounting plate

must fit into the channel on the inside edge of the gasket

to insure a proper seal.

Procedure—To Adjust Gasket to Unit:

To prevent steam leaks around the door, adjust the gasket

tension to cavity. Adjust the gasket by loosening the six

screws on top and bottom of door, move inner door plate

in or out, left side or right side, and tighten the six screws.

6.3.4 Exterior Panel Removal

WARNING

To prevent hazard in servicing the cooker, be certain that

the steam supply boiler is shut down, the cold water shutoff valve is closed, and the electrical disconnect circuit

breaker for the cooker/boiler unit is off before removing

side panels.

Access to all internal plumbing and electrical assemblies is

from the right side and right front. The left-side panel is

removed by removing the bottom screw and pushing up on

the panel until the lower lip disengages the frame. The

panel is shown as item #25 in Figure 7-1. The electric

control panel, shown in Figure 7-3, may also be removed

as a unit by removing screws and pulling the panel

forward. Removal of the control panel is completed by

unplugging interconnecting wiring at the pin housing.

6.3.5 Steam & Water Solenoid Valve

Replacement

Replacements for the 1/2-inch steam solenoid valves and

the 1/4-inch water valves are available as complete units

from Market Forge Authorized Service Agencies. It is

necessary to replace an entire steam valve when the coil

is faulty or the diaphragm ruptures. Replacement coils are

available for the water valves. The valves are accessed as

explained in Subsection 6.3.4.

6-2

Page 24

7.1 General

SECTION 7 ILLUSTRATED PARTS LIST

This section contains a complete listing of all replaceable

parts of the ST-12. For the purpose of parts identification,

the unit is broken down into functional assemblies, and

each assembly is shown in an exploded view that is keyed

to the accompanying parts list. Each parts list contains the

figure index number, the Market Forge part number, and

an abbreviated description.

7.2 Ordering Information

Orders for repair parts should be directed to the nearest

authorized parts distributor. For a current Market Forge

Authorized Parts Distributor List, contact:

Product Service Department

Market Forge Industries Inc.

35 Garvey Street

Everett, Massachusetts 02149

Telephone: (617) 387-4100

All orders should contain the Market forge part number(s),

the part description(s), and the model and serial number of

the cooker for which the part or parts are ordered.

7.3 Index of Illustrated Parts List

Figure Part Page

7-1 Cabinet Assembly ...................................................7-2

7-2 Door Assembly ........................................................7-3

7-3 Control Panel Assembly ..........................................7-4

7-4 Condensor Assembly ..............................................7-5

7-1

Page 25

SECTION 7 ILLUSTRATED PARTS LIST

ITEM PART

NO. NO. DESCRIPTION QTY.

1 08-6308 REED SWITCH 1

2 98-1691 ASSY, PLUMBING DRAIN 1

3 98-1709 POST, REAR 2

4 08-4912 COUPLER, 1/2"NPT X 5/8"ID BARB 2

5 10-2793 ELBOW, 90, 1/2" IPS 2

6 08-6538 CHECK VALVE 3/8 OD BLACK 1

7 91-6491 GROMMET, SILICONE, RED 1

8 91-7318 WELD ASSY, TOP 1

9 10-9174 RELAY, TUBE 2

10 10-9175 RELAY, BASE 2

11 91-6940 BRACKET, RELAY 1

12 91-6475 HINGE, ASSY TOP 1

13 91-6476 HINGE, ASSY BOTTOM 1

14 91-7334 TROUGH, DRIP, ST-12/ST-24 1

15 91-7385 ASSY, DOOR, ST-12/ST-24 1

16 91-5621 ASSY, JET PIPE 2

17 91-6492 LATCH, DOOR 1

18 08-4600 SPRING, COMPRESSION 2

19 91-7684 STRAINER, CAVITY 1

20 98-1605 WELD ASSY, MIDDLE RACK 1

21 91-7699 RACK SIDE 2

22 10-4586 NUT, 1/2" IPS, S.S. W/TEFLON 3

23 10-8105 THERMOSTAT, SNAP DISC, PROBE TYPE 1

24 10-3343 NUT, BRASS, 1/2" IPS 1

25 10-1956 SCREW, TAPTIGHT, 8-32 X 3/8" 20

26 10-2571 NUT, LOCK, 8-32 17

27 08-1204 PLUG, HOLE WHITE 2

28 10-2184 SCREW, HEX HEAD, 10-32, 3/4" LG 4

29 98-1705 PANEL, SIDE 2

30 98-1708 PANEL, REAR 1

31 98-1632 INSULATION, FRONT 1

32

98-1631 INSULATION, REAR 1

33

08-7959 TUBING, NORPRENE 3/8" I.D. AS

MEASURED

34

08-7960 TUBING, NORPRENE 5/8" I.D. AS

MEASURED

35

98-1712

MECHANICAL CNTRL PANEL

1

36

~NPN~

DIGITIAL CNTRL PANEL

1

37

08-2702

BUSHING, DOOR, WHITE

2

38

91-7690

BRACKET, REED SWITCH

1

7-2

Page 26

SECTION 7 ILLUSTRATED PARTS LIST

Figure 7-1 Cabinet Assembly

7-3

Page 27

SECTION 7 ILLUSTRATED PARTS LIST

ITEM PART

NO. NO. DESCRIPTION QTY.

1 91-7386 OUTER DOOR 1

2 91-7387 INNER DOOR 1

3 91-7388 GASKET RETAINING PLATE 1

4 91-7389 DOOR GASKET 1

5 91-5745 DOOR HANDLE 1

6 09-1608 STRIKER 1

7 08-5027 MAGNET 1

8 91-5901 MAGNET BRACKET 1

9 08-4600 COMPRESSION SPRING 2

Figure 7-2 Door Assembly

7-4

Page 28

SECTION 7 ILLUSTRATED PARTS LIST

ITEM PART

NO. NO. DESCRIPTION QTY.

1 98-1706 CONTROL PANEL 1

2 98-1698 ARTWORK, CONTROL PANEL 1

3 08-6464 60 MIN. TIMER 2

4 08-6541 TERMINAL STRIP 2

5 91-6471 BRACKET, TERMINAL STRIP 2

6 10-7395 BUZZER 2

7 08-3826 KNOB, TIMER 2

8 10-5052 LIGHT, RED 2

Figure 7-3 Control Panel Assembly

7-5

Page 29

SECTION 7 ILLUSTRATED PARTS LIST

ITEM PART

NO. NO. DESCRIPTION QTY.

1 10-5859 VALVE, STEAM SOLENOID 1

2 08-4892 COUPLER, BRS 3/8ODX1/2THRD NPT 2

3 10-2885 UNION, FEMALE 1/2 IPS 1

4 10-2849 NIPPLE, CLOSE 1/2" NPT BRS 2

5 98-1477 COUPLERBRS,BARB 3/8"X3/8" NPT 1

6 08-6581 TEE, MALE 1/2" NPTX FEML 1/2" BRANCH 1

7 10-3739 1/2"X 3/8 REDUCING BUSHING 1

8 98-1630 WELDMENT, COLDH20/STEAM VALVE 1

9 10-1055 TEE, 3/8" ALL AROUND 1

10 10-3644 PLUG, SQ HEAD 3/8"IPS BRASS 1

11 08-7525 NIPPLE, CLOSE 3/8" NPT BRASS 2

12 08-6498 VALVE, 3/8" NPT, COLDW COND 1

13 08-4912 COUPLER, BARB 5/8"ODX1/2" IPS 1

14 08-7962 COUPLER, BARB 5/8"ODX3/8"THD 1

15 98-1477 COUPLER, BRS BRARB,3/8"X3/8" THD NPT 1

Figure 7-4 Condenser Assembly

7-6

Loading...

Loading...